torque DATSUN B110 1973 Service Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 80 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

C

DMark

Unit

mm

in

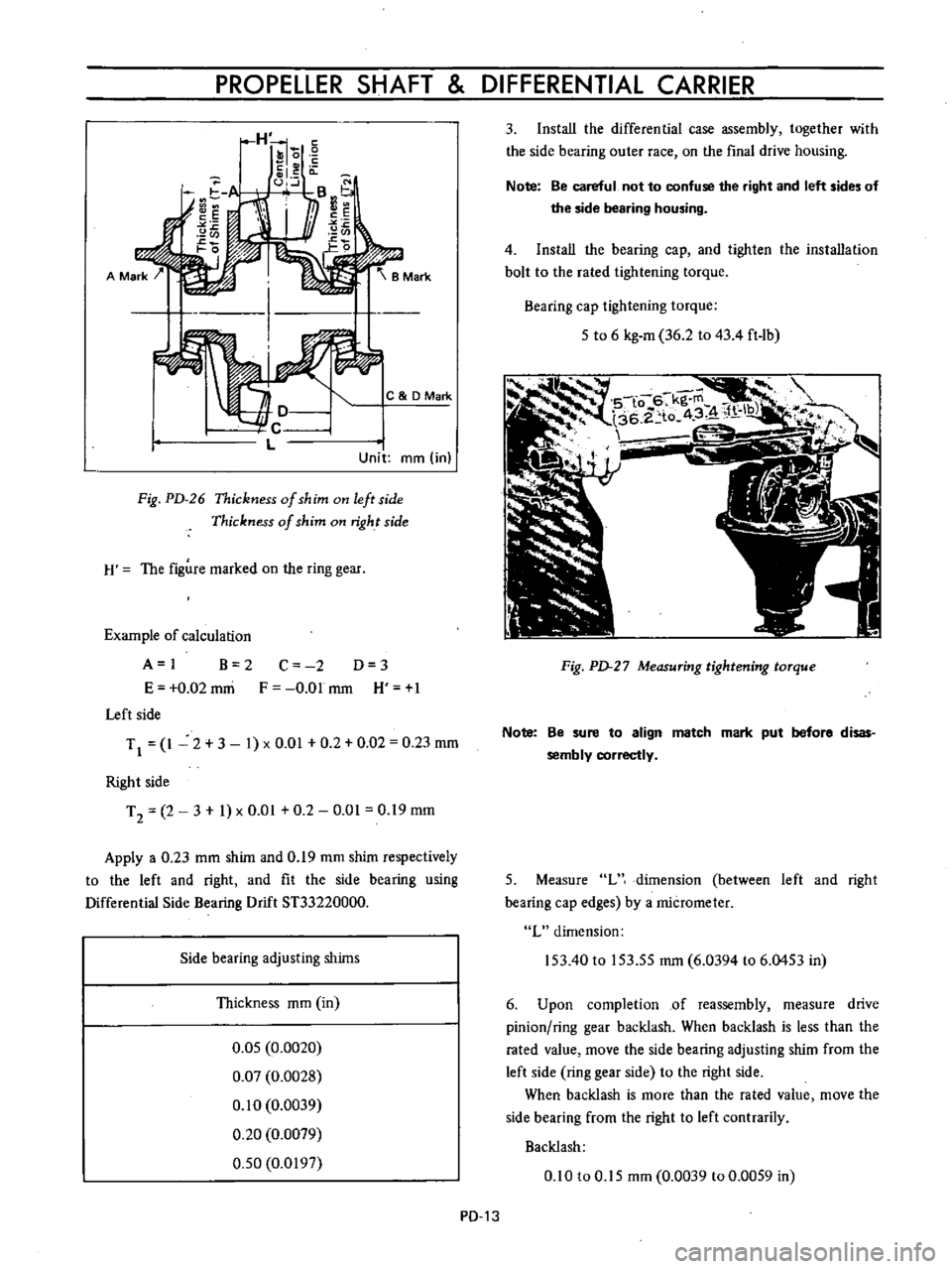

Fig

PD

26

Thickness

of

shim

on

left

side

Thickness

of

shim

on

right

side

H

The

figure

marked

on

the

ring

gear

Example

of

calculation

A

I

B

2

E

0

02

mni

Left

side

C

2

D

3

F

O

Olmm

H

1

TJ

1

2

3

1

xO

01

0

2

0

02

0

23

mm

Right

side

T

2

2

3

1

x

0

01

0

2

0

01

0

19

mm

Apply

a

0

23

mm

shim

and

0

19

mm

shim

respectively

to

the

left

and

right

and

fit

the

side

bearing

using

Differential

Side

Bearing

Drift

ST33220000

Side

bearing

adjusting

shims

Thickness

mm

in

0

05

0

0020

0

07

0

0028

0

10

0

0039

0

20

0

0079

0

50

0

0197

PD

13

3

Install

the

differential

case

assembly

together

with

the

side

bearing

outer

race

on

the

final

drive

housing

Note

Be

careful

not

to

confuse

the

right

and

left

sides

of

the

side

bearing

housing

4

Install

the

bearing

cap

and

tighten

the

installation

bolt

to

the

rated

tightening

torque

Bearing

cap

tightening

torque

5

to

6

kg

m

36

2

to

43

4

ft

1b

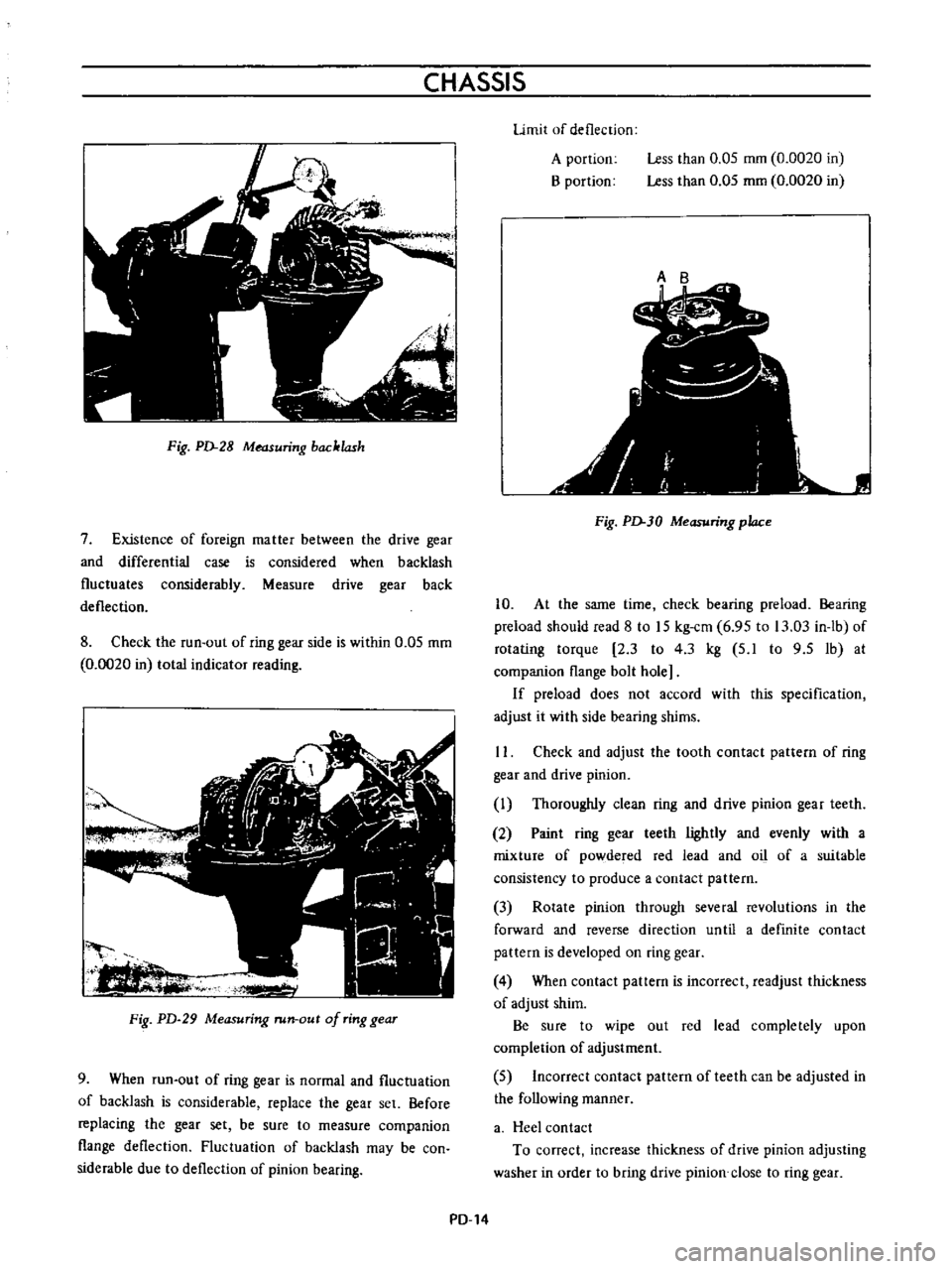

Fig

PD

27

Measuring

tightening

torque

Note

Be

sure

to

align

match

mark

put

before

disas

sembly

correctly

5

Measure

L

dimension

between

left

and

right

bearing

cap

edges

by

a

micrometer

L

dimension

153

40

to

153

55

mm

6

0394

to

6

0453

in

6

Upon

completion

of

reassembly

measure

drive

pinion

ring

gear

backlash

When

backlash

is

less

than

the

rated

value

move

the

side

bearing

adjusting

shim

from

the

left

side

ring

gear

side

to

the

right

side

When

backlash

is

more

than

the

rated

value

move

the

side

bearing

from

the

right

to

left

contrarily

Backlash

0

10

to

0

15

mm

0

0039

to

0

0059

in

Page 81 of 513

CHASSIS

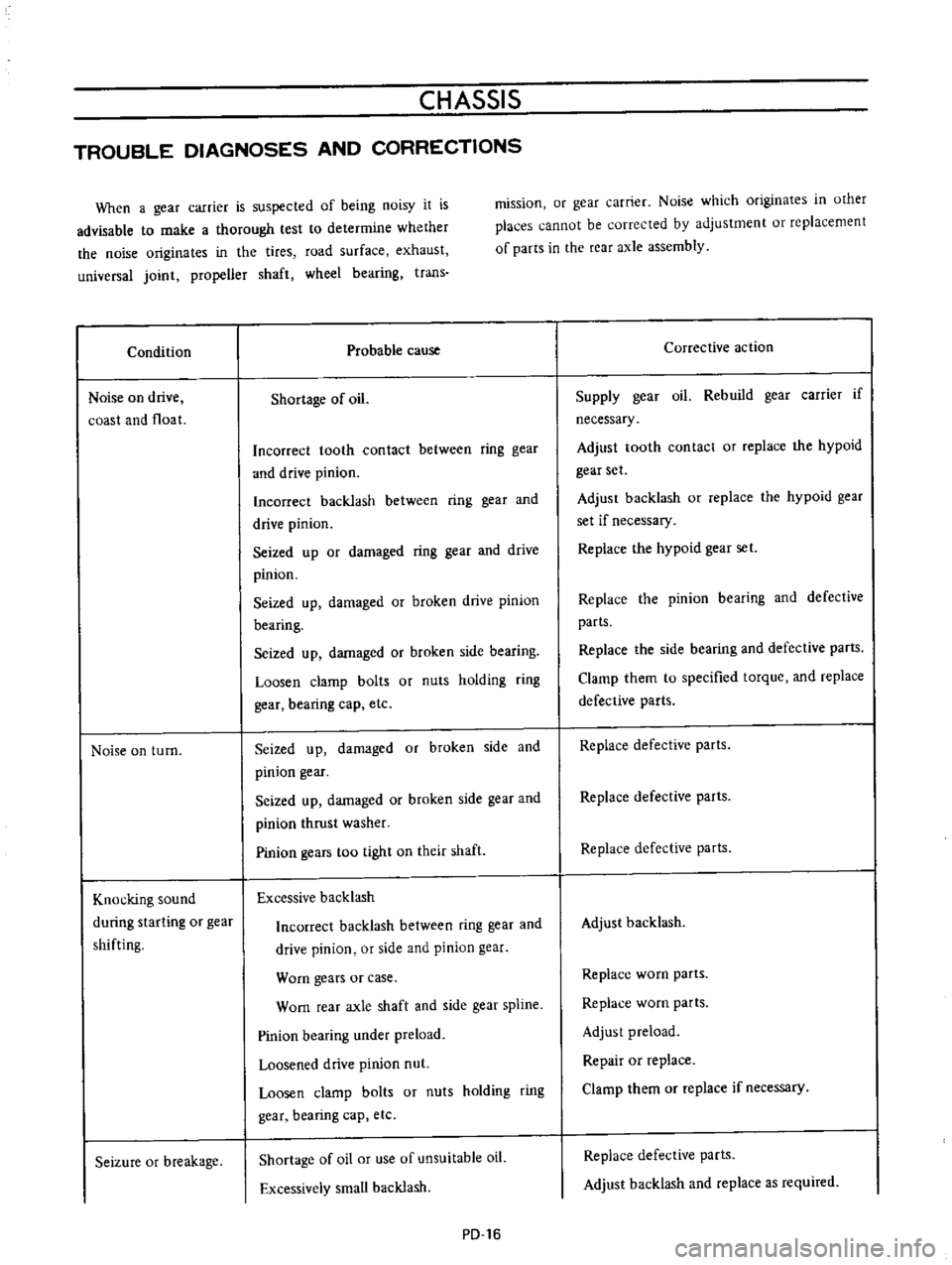

Fig

PD

28

Measuring

backlash

7

Existence

of

foreign

matter

between

the

drive

gear

and

differential

case

is

considered

when

backlash

fluctuates

considerably

Measure

drive

gear

back

deflection

8

Check

the

run

out

of

ring

gear

side

is

within

0

05

mm

0

0020

in

total

indicator

reading

ot

Fig

PD

29

Measuring

run

out

of

ring

gear

9

When

run

out

of

ring

gear

is

normal

and

fluctuation

of

backlash

is

considerable

replace

the

gear

set

Before

replacing

the

gear

set

be

sure

to

measure

companion

flange

deflection

Fluctuation

of

backlash

may

be

con

siderable

due

to

deflection

of

pinion

bearing

Limit

of

deflection

A

portioo

B

portion

Less

than

0

05

mm

0

0020

in

Less

than

0

05

mm

0

0020

in

Ct

r

r

f

1

I

f

i

r

I

oj

j

12

r

Fig

PD

30

Measuring

place

10

At

the

same

time

check

bearing

preload

Bearing

preload

should

read

8

to

15

kg

cm

6

95

to

13

03

in

lb

of

rotating

torque

2

3

to

4

3

kg

5

1

to

9

5

1b

at

companion

flange

bolt

hole

If

preload

does

not

accord

with

this

specification

adjust

it

with

side

bearing

shims

II

Check

and

adjust

the

tooth

contact

pattern

of

ring

gear

and

drive

pinion

I

Thoroughly

clean

ring

and

drive

pinion

gear

teeth

2

Paint

ring

gear

teeth

lightly

and

evenly

with

a

mixture

of

powdered

red

lead

and

oil

of

a

suitable

consistency

to

produce

a

contact

pattern

3

Rorate

pinion

through

several

revolutions

in

the

forward

and

reverse

direction

until

a

definite

contact

pattern

is

developed

on

ring

gear

4

When

contact

pattern

is

incorrect

readjust

thickness

of

adjust

shim

Be

sure

to

wipe

out

red

lead

completely

upon

completion

of

adjustment

5

Incorrect

contact

pattern

of

teeth

can

be

adjusted

in

the

following

manner

a

Heel

contact

To

correct

increase

thickness

of

drive

pinion

adjusting

washer

in

order

to

bring

drive

pinion

close

to

ring

gear

PD

14

Page 83 of 513

CHASSIS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

a

gear

carrier

is

suspected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearing

trans

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

Seizure

or

breakage

mission

or

gear

carrier

Noise

which

originates

in

other

places

cannot

be

corrected

by

adjustment

or

replacement

of

parts

in

the

rear

axle

assembly

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

backlash

between

ring

gear

and

drive

pinion

Seized

up

or

damaged

ring

gear

and

drive

pinion

Seized

up

damaged

or

broken

drive

pinion

bearing

Seized

up

damaged

or

broken

side

bearing

Loosen

clamp

bolts

or

nuts

holding

ring

gear

bearing

cap

etc

Seized

up

damaged

or

broken

side

and

pinion

gear

I

Seized

up

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

gears

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

between

ring

gear

and

drive

pinion

or

side

and

pinion

gear

Worn

gears

or

case

Worn

rear

axle

shaft

and

side

gear

spline

Pinion

bearing

under

preload

Loosened

drive

pinion

nut

Loosen

clamp

bolts

or

nuts

holding

ring

gear

bearing

cap

etc

Shortage

of

oil

or

use

of

unsuitable

oil

Excessively

small

backlash

PD

16

Corrective

action

Supply

gear

oil

Rebuild

gear

carrier

if

necessary

Adjust

tooth

contact

or

replace

the

hypoid

gear

set

Adjust

backlash

or

replace

the

hypoid

gear

set

if

necessary

Replace

the

hypoid

gear

set

Replace

the

pinion

bearing

and

defective

parts

Replace

the

side

bearing

and

defective

parts

Clamp

them

to

specified

torque

and

replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

them

or

replace

if

necessary

Replace

defective

parts

Adjust

backlash

and

replace

as

required

Page 84 of 513

PROPELLER

SHAFT

DIFFERENTIAL

CARRIER

Incorrect

adjustment

of

bearings

or

gears

Severe

service

due

to

an

excessive

loading

improper

use

of

clutch

Loosened

bolts

and

nuts

such

as

ring

gear

clamp

bolts

Oil

leakage

Worn

out

damaged

or

improperly

driven

front

oil

seal

or

bruised

dented

or

abnormally

worn

slide

face

of

companion

flange

Loosened

bolts

holding

gear

carrier

Defective

gasket

Loosen

filler

or

drain

plug

Clogged

or

damaged

breather

SERVICE

DATA

AND

SPECIFICATIONS

Type

of

differential

gear

carrier

assembly

Final

gear

type

Final

gear

ratio

number

of

teeth

Sedan

Coupe

Van

Drive

pinion

Preload

with

oil

seal

Preload

without

oil

seal

Thickness

of

drive

pinion

adjusting

shims

kg

cm

in

lb

kg

cm

in

lb

mm

in

Pinion

bearing

adjusting

spacer

Ring

gear

Backlash

between

ring

gear

and

pinion

Run

out

of

rear

side

of

ring

gear

mm

in

mm

in

Side

gear

and

pinion

mate

Thickness

of

side

gear

thrust

washers

mm

in

PD

17

Replace

defective

parts

Replace

defective

parts

Replace

defective

parts

Replace

the

defective

oil

seal

Ammend

the

affected

flange

with

sand

paper

or

replace

if

necessary

Tighten

the

bolts

to

specified

torque

Replace

defective

parts

with

new

ones

Tighten

the

plug

Repair

or

replace

H145A

Hypoid

3

900

39

10

7

to

9

6

1

to

7

8

6

to

8

5

2

to

6

9

From

2

74

to

3

25

0

1079

to

0

1280

Spacing

0

Q3

0

0012

Non

adjustable

collapsible

spacer

0

10

to

0

15

0

0039

to

0

0059

Less

than

0

05

0

0020

0

76

to

0

91

0

0299

to

0

0358

Page 85 of 513

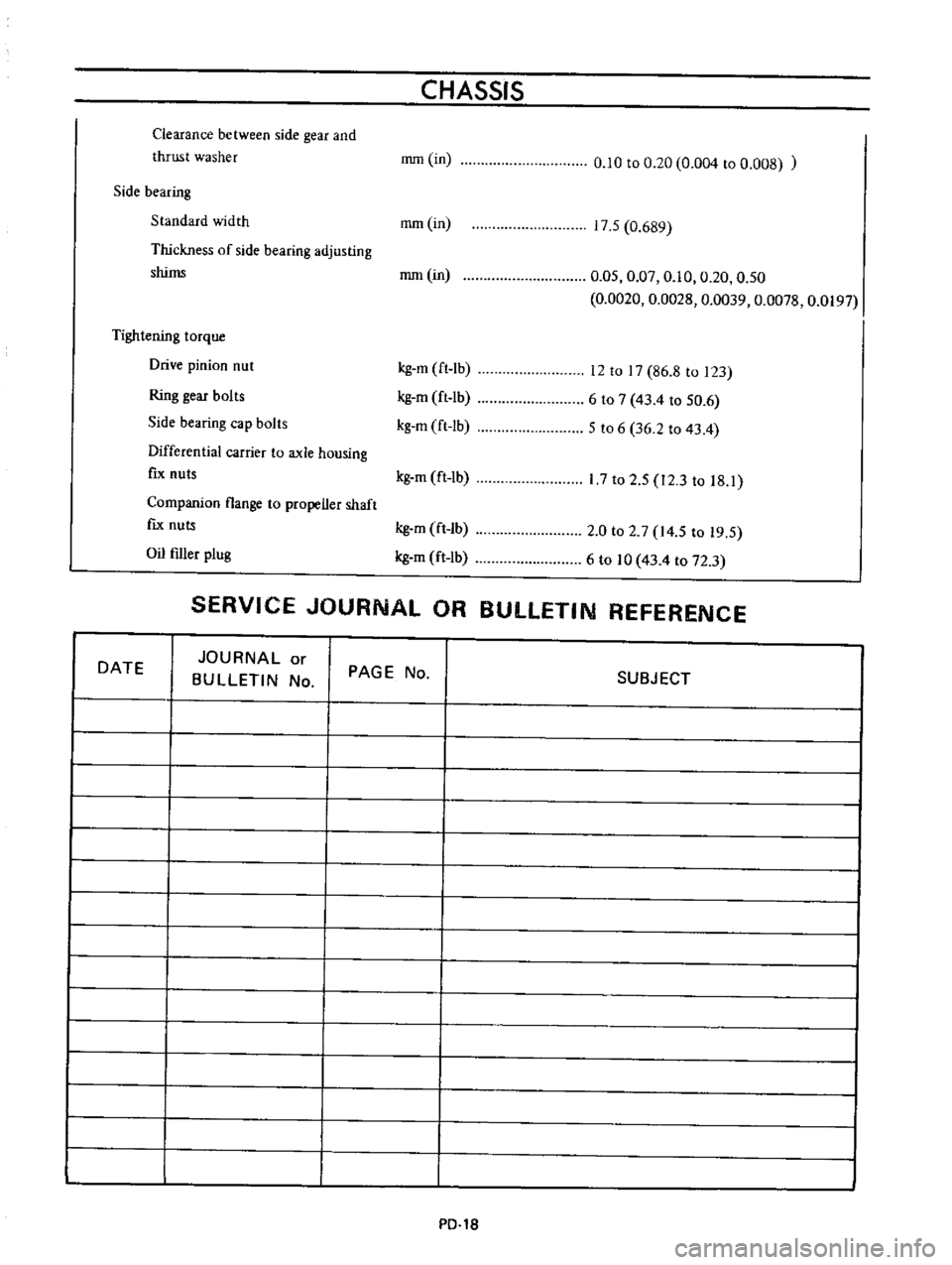

Clearance

between

side

gear

and

thrust

washer

CHASSIS

rrun

in

0

10

to

0

20

0

004

to

0

008

Side

bearing

Standard

width

rom

in

Thickness

of

side

bearing

adjusting

shims

rom

in

Tightening

torque

Drive

pinion

nut

Ring

gear

bolts

Side

bearing

cap

bolts

Differential

carrier

to

axle

housing

fIx

nuts

Companion

flange

to

propeller

shaft

fIx

nuts

Oil

filler

plug

17

5

0

689

0

05

0

07

0

10

0

20

0

50

0

0020

0

0028

0

0039

0

0078

0

0197

kg

m

ft

lb

kg

m

ft

lb

kg

m

ft

lb

12

to

17

86

8

to

123

6

to

7

43

4

to

50

6

5

to

6

36

2

to

43

4

kg

m

ft

1b

17

to

2

5

12

3

to

18

1

kg

m

ft

lb

kg

m

ft

lb

2

0

to

2

7

14

5

to

19

5

6

to

10

43

4

to

72

3

SERVICE

JOURNAL

OR

BULLETIN

REFERENCE

DATE

JOURNAL

or

BULLETIN

No

I

I

I

I

PAGE

No

SUBJECT

PO

1S

Page 91 of 513

FRONT

AXLE

FRONT

SUSPENSION

Reinstalla

tion

First

check

rubber

parts

such

as

tension

rod

mount

ing

bushing

stabilizer

bar

bushing

etc

for

deterioration

crack

and

other

defective

conditions

and

replace

as

required

2

Reinstall

the

front

axle

and

suspension

assembly

in

reverse

sequence

of

removal

noting

the

following

matters

1

Tighten

the

transverse

link

mounting

bolts

and

stabilizer

bar

body

side

installation

bolt

to

the

raled

tightening

torque

under

the

unladen

vehicle

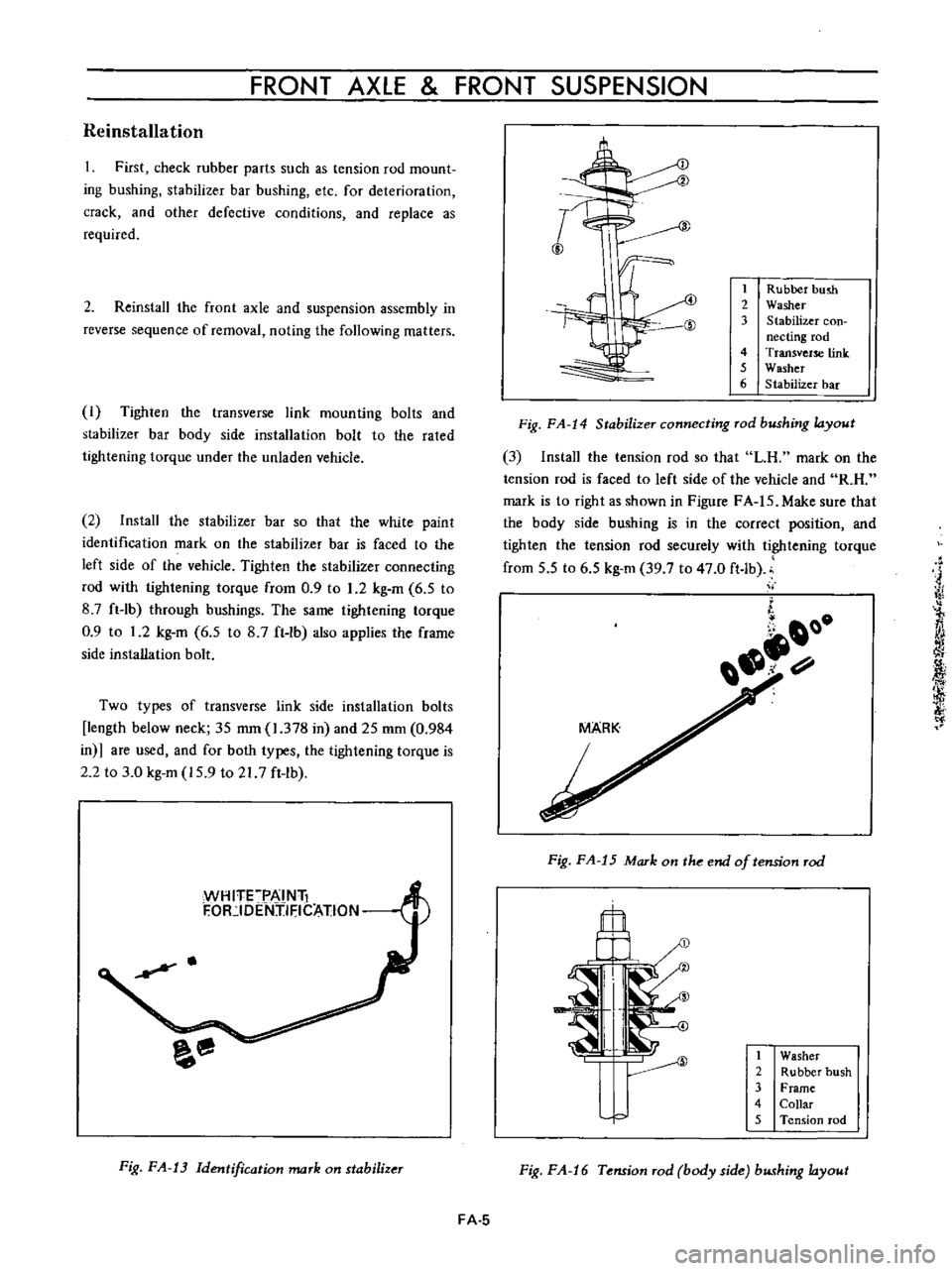

2

Install

the

stabilizer

bar

so

that

the

white

paint

identification

mark

on

the

stabilizer

bar

is

faced

to

the

left

side

of

the

vehicle

Tighten

the

stabilizer

connecting

rod

with

tightening

torque

from

0

9

to

1

2

kg

m

6

5

to

8

7

ft

lb

through

bushings

The

same

tightening

torque

0

9

to

1

2

kg

m

6

5

to

8

7

ft

Ib

also

applies

the

frame

side

installation

bolt

Two

types

of

transverse

link

side

installation

bolts

length

below

neck

35

mm

1

378

in

and

25

mm

0

984

in

are

used

and

for

both

types

the

tightening

torque

is

2

2

to

3

0

kg

m

15

9

to

217

ft

lb

WH

ITFPAI

Nli

F

OR

IDENjIFICATION

H

Fig

FA

13

Identification

mark

on

stabilizer

I

J

1

Rubber

hush

2

Washer

3

Stabilizer

con

necting

rod

4

Transverse

link

5

Washer

6

Stabilizer

bar

Fig

FA

14

Stabilizer

connecting

rod

bushing

layout

3

Install

the

tension

rod

so

that

LH

mark

on

the

tension

rod

is

faced

to

left

side

of

the

vehicle

and

R

H

mark

is

to

right

as

shown

in

Figure

FA

IS

Make

sure

that

the

body

side

bushing

is

in

the

correct

position

and

tighten

the

tension

rod

securely

with

tightening

torque

from

5

5

to

6

5

kg

m

39

7

to

47

0

ft

lb

ii

j

iY

l

fj

i

f

i

Of

1

0

Fig

FA

15

Mark

on

the

end

of

tension

rod

il

1

Washer

2

Rubber

bush

3

Frame

4

Collar

5

Tension

rod

Fig

FA

16

Tension

rod

body

side

bushing

layout

FA

5

Page 92 of 513

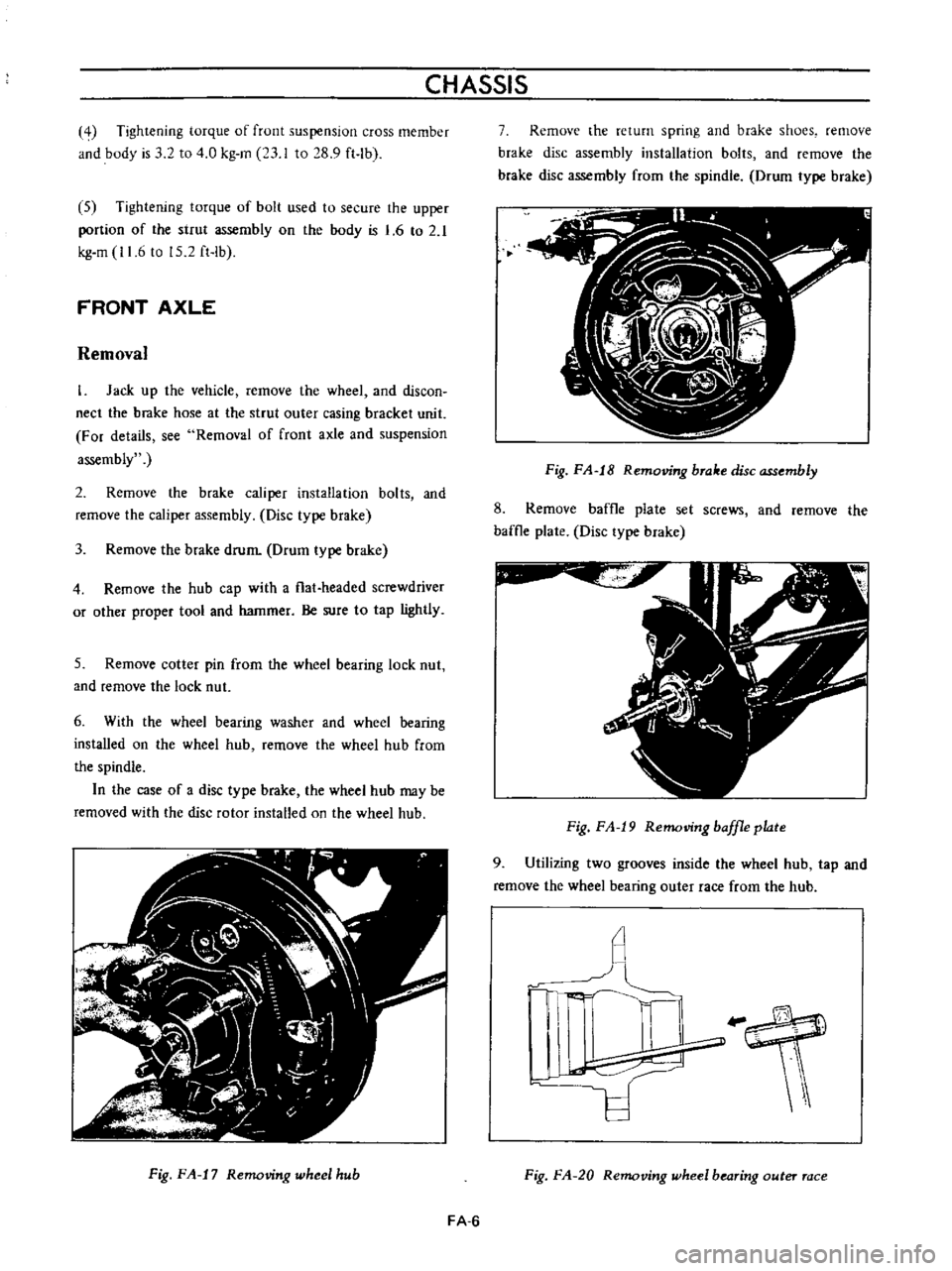

CHASSIS

Tightening

torque

of

front

suspension

cross

member

and

body

is

3

2

to

4

0

kg

m

23

1

to

28

9

ft

Ib

5

Tightening

torque

of

bolt

used

to

secure

the

upper

portion

of

the

strut

assembly

on

the

body

is

1

6

to

2

1

kg

m

11

6

to

15

2ft

lb

FRONT

AXLE

Removal

I

Jack

up

the

vehicle

remove

the

wheel

and

discon

nect

the

brake

hose

at

the

strut

outer

casing

bracket

unit

For

details

see

Removal

of

front

axle

and

suspension

assembly

2

Remove

the

brake

caliper

installation

bolts

and

remove

the

caliper

assembly

Disc

type

brake

3

Remove

the

brake

druOL

Drum

type

brake

4

Remove

the

hub

cap

with

a

flal

headed

screwdriver

or

other

proper

tool

and

hammer

Be

sure

to

tap

lightly

5

Remove

cotter

pin

from

the

wheel

bearing

lock

nut

and

remove

the

lock

nut

6

With

the

wheel

bearing

washer

and

wheel

bearing

installed

on

the

wheel

hub

remove

the

wheel

hub

from

the

spindle

In

the

case

of

a

disc

type

brake

the

wheel

hub

may

be

removed

with

the

disc

rotor

installed

on

the

wheel

hub

Fig

FA

17

Removing

wheel

hub

7

Remove

the

return

spring

and

brake

shoes

remove

brake

disc

assembly

installation

bolts

and

remove

the

brake

disc

assembly

from

the

spindle

Drum

type

brake

Fig

FA

IS

Removing

brake

disc

a

ssembly

8

Remove

baffle

plate

set

screws

and

remove

the

baffle

plate

Disc

type

brake

Fig

FA

19

Removingbaffleplate

9

Utilizing

two

grooves

inside

the

wheel

hub

tap

and

remove

the

wheel

bearing

outer

race

from

the

hub

Fig

FA

20

Removing

wheel

bearing

outer

race

FA

6

Page 96 of 513

CHASSIS

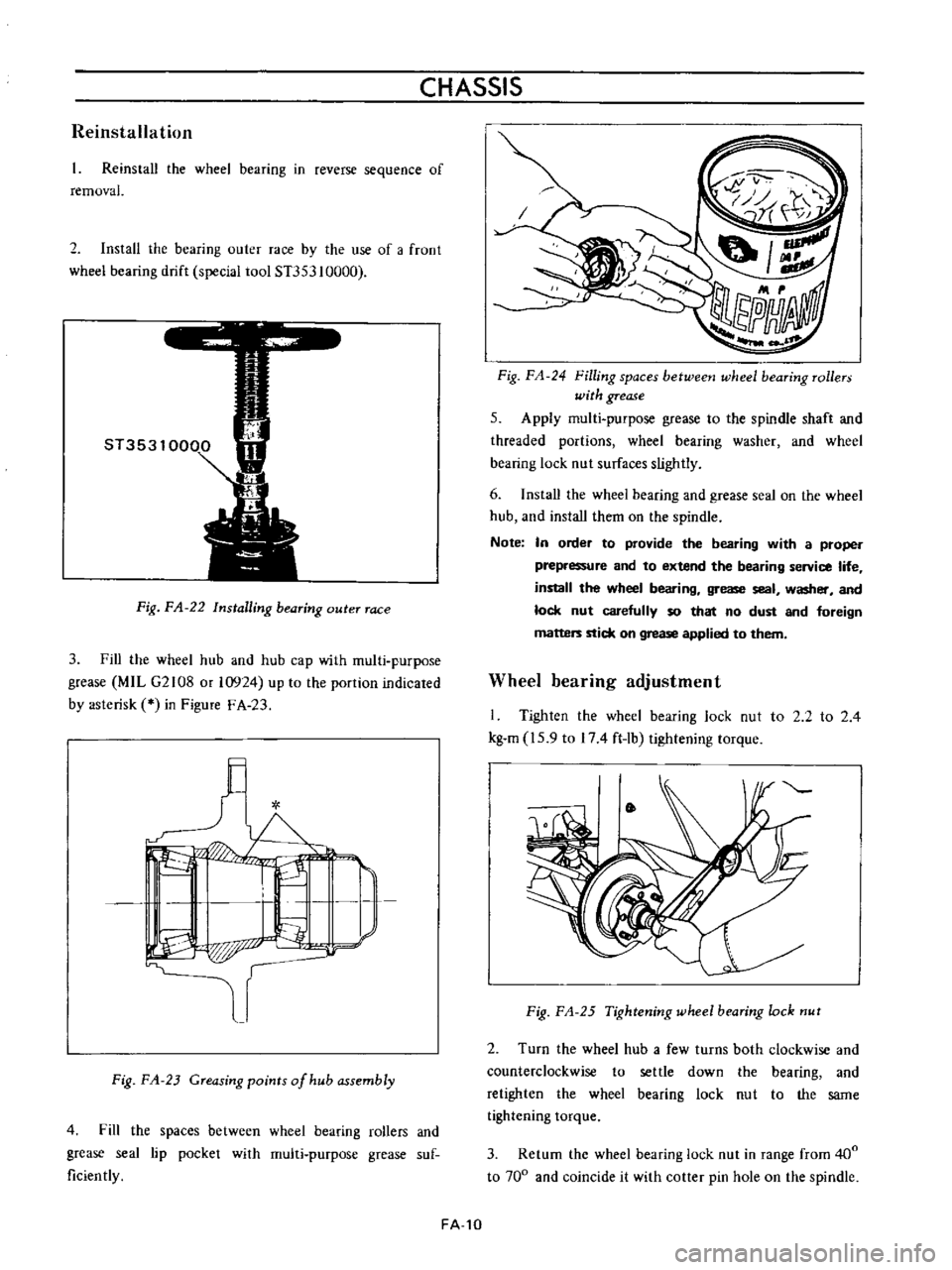

Reinstallation

Reinstall

the

wheel

bearing

in

reverse

sequence

of

removal

2

Install

the

bearing

outer

race

by

the

use

of

a

froot

wheel

bearing

drift

special

tool

ST353

10000

Fig

FA

22

Installing

bearing

outer

race

3

Fill

the

wheel

hub

and

hub

cap

with

multi

purpose

grease

MIL

G2108

or

10924

up

to

the

portion

indicated

by

asterisk

in

Figure

F

A

23

l

I

L

I

I

P

p

r

Fig

FA

23

Greasing

points

of

hub

assembly

4

Fill

the

spaces

between

wheel

bearing

rollers

and

grease

seal

lip

pocket

with

multi

purpose

grease

suf

ficiently

FA

10

Fig

FA

24

Filling

spaces

betweetJ

wheel

bearing

rollers

with

grease

5

Apply

multi

purpose

grease

to

the

spindle

shaft

and

threaded

portions

wheel

bearing

washer

and

wheel

bearing

lock

nut

surfaces

slightly

6

Install

the

wheei

bearing

and

grease

seal

on

the

wheel

hub

and

install

them

on

the

spindle

Note

In

order

to

provide

the

bearing

with

a

proper

prepressure

and

to

extend

the

bearing

service

life

install

the

wheel

bearing

grease

seal

washer

and

lock

nut

carefully

so

that

no

dust

and

foreign

matters

stick

on

grease

applied

to

them

Wheel

bearing

adjustment

I

Tighten

the

wheel

bearing

lock

nut

to

2

2

to

2

4

kg

m

15

9

to

174

ft

lb

tightening

torque

Fig

FA

25

Tightening

wheel

bearing

lock

nut

2

Turn

the

wheel

hub

a

few

turns

both

clockwise

and

counterclockwise

to

settle

down

the

bearing

and

retighten

the

wheel

bearing

lock

nut

to

the

same

tightening

torque

3

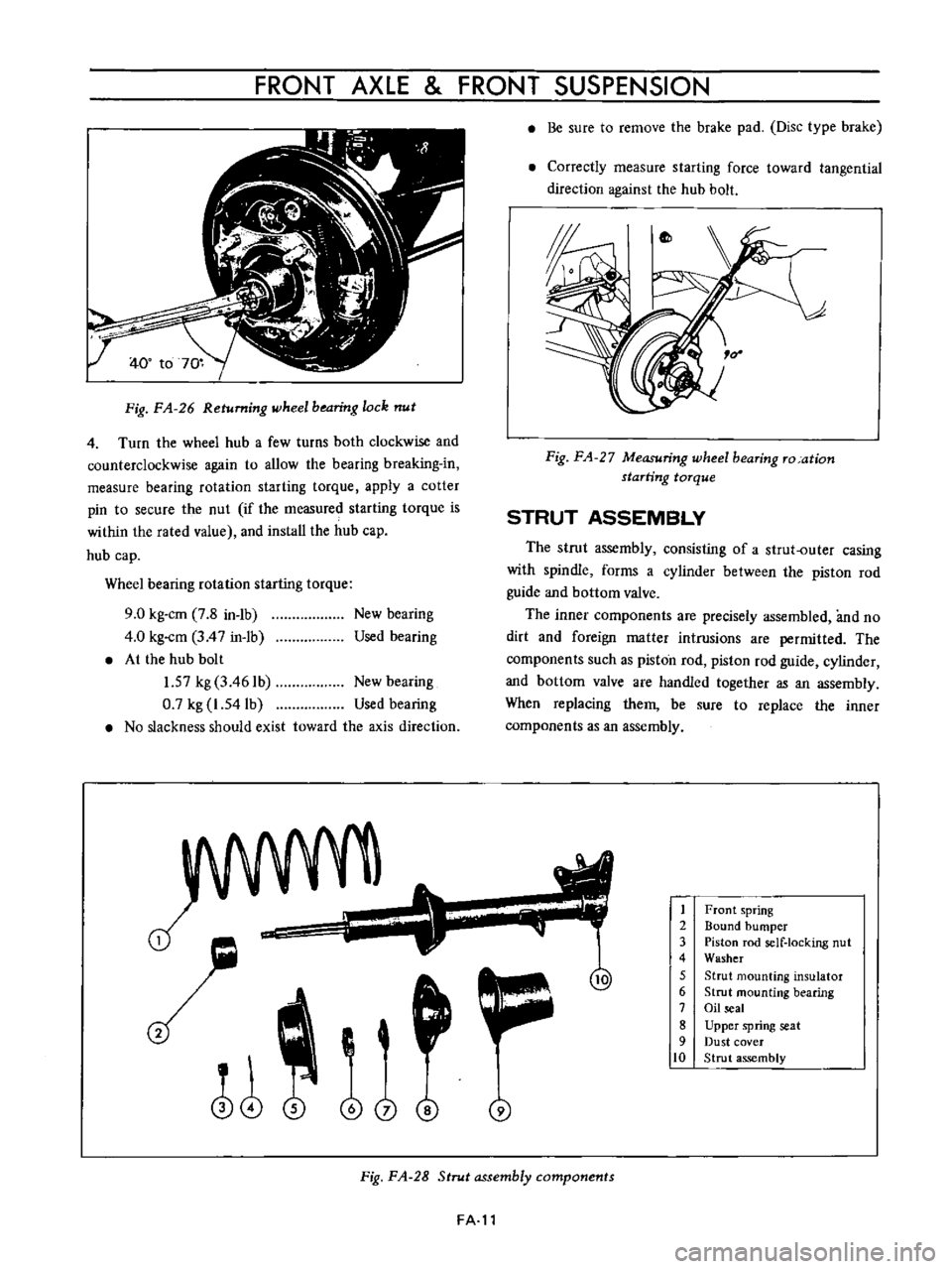

Return

the

wheel

bearing

lock

nut

in

range

from

400

to

700

and

coincide

it

with

cotter

pin

hole

on

the

spindle

Page 97 of 513

FRONT

AXLE

FRONT

SUSPENSION

t

t

Fig

FA

26

Returning

wheel

bearing

lock

nut

4

Turn

the

wheel

hub

a

few

turns

both

clockwise

and

counterclockwise

again

to

allow

the

bearing

breaking

in

measure

bearing

rotation

starting

torque

apply

a

cotter

pin

to

secure

the

nut

if

the

measured

starting

torque

is

within

the

rated

value

and

install

the

hub

cap

hub

cap

Wheel

bearing

rotation

starting

torque

9

0

kg

cm

7

8

in

1b

4

0

kg

cm

3

4

7

in

1b

At

the

hub

bolt

1

57

kg

3

461b

New

bearing

0

7

kg

1

54lb

Used

bearing

No

slackness

should

exist

toward

the

axis

direction

New

bearing

Used

bearing

J

o

i

@

j

Be

sure

to

remove

the

brake

pad

Disc

type

brake

Correctly

measure

starting

force

toward

tangential

direction

against

the

hub

bolt

Fig

FA

27

Measuring

wheel

bearing

ro

ation

starting

torque

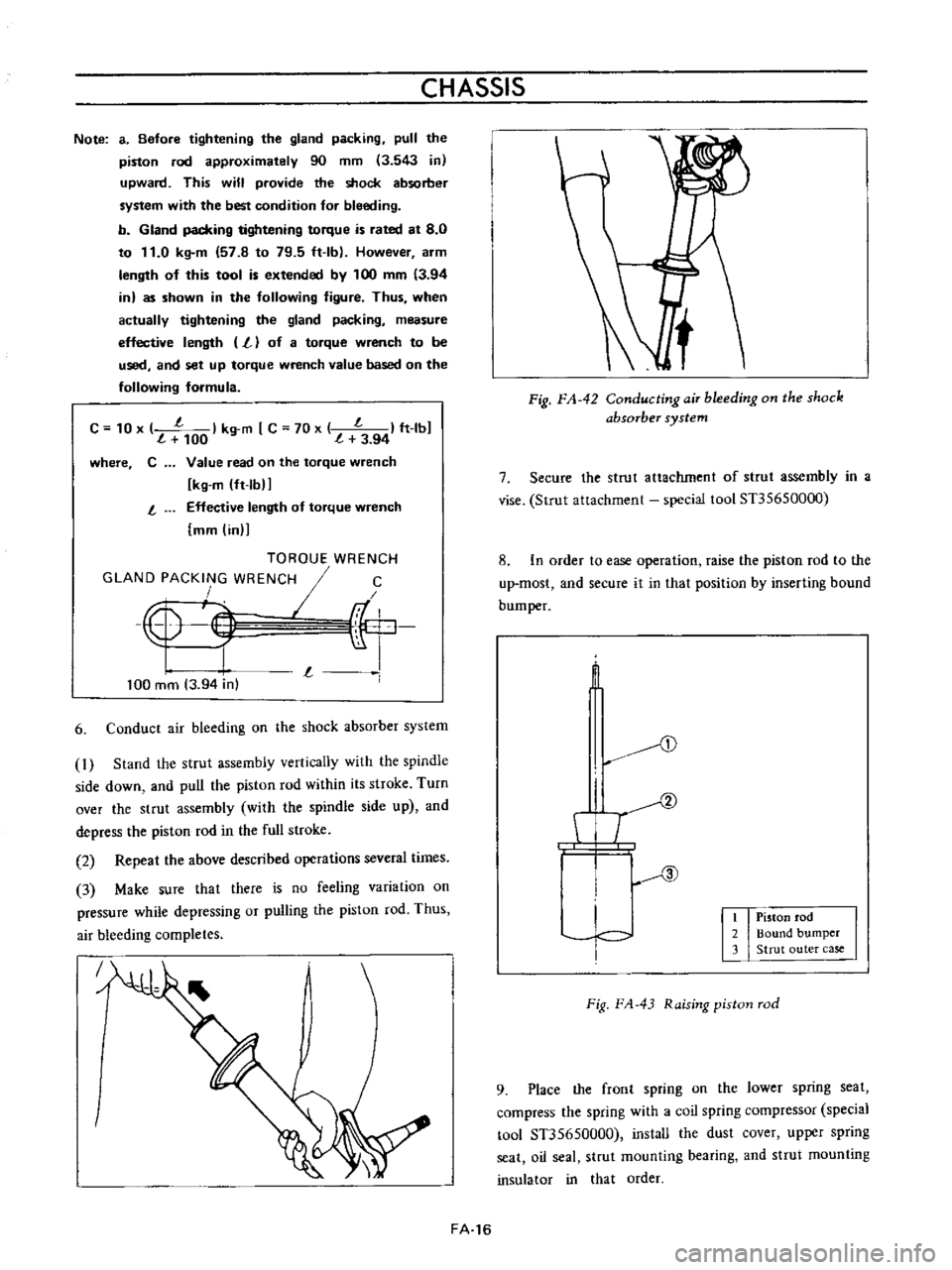

STRUT

ASSEMBLY

The

strut

assembly

consisting

of

a

strut

outer

casing

with

spindle

forms

a

cylinder

between

the

piston

rod

guide

and

bottom

valve

The

inner

components

are

precisely

assembled

and

no

dirt

and

foreign

matter

intrusions

are

permitted

The

components

such

as

piston

rod

piston

rod

guide

cylinder

and

bottom

valve

are

handled

together

as

an

assembly

When

replacing

them

be

sure

to

replace

the

inner

components

as

an

assembly

1

2

3

4

5

6

7

8

9

10

Front

spring

Bound

bumper

Piston

rod

self

locking

nut

Washer

Strut

mounting

insulator

Strut

mounting

bearing

Oil

seal

Upper

spring

seat

Dust

cover

Strut

assembly

Fig

FA

28

Strut

assembly

components

FA

l1

Page 102 of 513

CHASSIS

Note

a

Before

tightening

the

gland

packing

pull

the

piston

rod

approximately

90

mm

3

543

in

upward

This

will

provide

the

shock

absorber

system

with

the

best

condition

for

bleeding

b

Gland

packing

tightening

torque

is

rated

at

8

0

to

11

0

kg

m

57

8

to

79

5

ft

Ib

However

arm

length

of

this

tool

is

extended

by

100

mm

3

94

in

as

shown

in

the

following

figure

Thus

when

actually

tightening

the

gland

packing

measure

effective

length

L

of

a

torque

wrench

to

be

used

and

set

up

torque

wrench

value

based

on

the

following

formula

C

10

x

l

I

kg

m

C

70

x

l

I

ft

lbJ

100

l

3

94

where

C

Value

read

on

the

torque

wrench

kg

m

ft

lbIJ

Effective

length

of

torque

wrench

mm

in

l

TOROUE

WRENCH

GLAND

PACKING

WRENCH

I

C

4

F

r

I

L

I

100

mm

3

94

in

6

Conduct

air

bleeding

on

the

shock

absorber

system

1

Stand

the

strut

assembly

vertically

with

the

spindle

side

down

and

pull

the

piston

rod

within

its

stroke

Turn

over

the

strut

assembly

with

the

spindle

side

up

and

depress

the

piston

rod

in

the

full

stroke

2

Repeat

the

above

described

operations

several

times

3

Make

sure

that

there

is

no

feeling

variation

on

pressure

while

depressing

or

pulling

the

piston

rod

Thus

air

bleeding

completes

J

FA

16

Fig

FA

42

ConductingaiT

bleeding

on

the

shock

absorber

system

7

Secure

the

strut

attachment

of

strut

assembly

in

a

vise

Strut

attachment

special

tool

Sn5650000

8

In

order

to

ease

operation

raise

the

piston

rod

to

the

up

most

and

secure

it

in

that

position

by

inserting

bound

bum

per

t

D

I

T

I

c

I

Piston

rod

2

Bound

bumper

3

Strut

outer

case

Fig

FA

43

Raising

piston

rod

9

Place

the

front

spring

on

the

lower

spring

seat

compress

the

spring

with

a

coil

spring

compressor

special

tool

Sn5650000

install

the

dust

cover

upper

spring

seat

oil

seal

strut

mounting

bearing

and

strut

mounting

insulator

in

that

order