torque DATSUN B110 1973 Service User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1973, Model line: B110, Model: DATSUN B110 1973Pages: 513, PDF Size: 28.74 MB

Page 22 of 513

CHASSIS

rang

e

eutral

In

N

range

all

the

clutches

and

band

are

not

applied

therefore

no

power

is

triJllsmilted

10

the

output

shaft

The

pressure

of

oil

discharged

from

the

oil

pump

is

regulated

by

the

pressure

regulator

valve

D

to

maintain

the

line

pressure

7

and

the

oil

is

led

to

the

manual

valve

r

2

vacuum

throt

tle

valve

@

and

solenoid

downshift

valve

@

The

oil

is

further

introduced

into

the

torque

converter

at

its

operat

ing

pressure

14

and

a

portion

of

this

oil

is

distributed

to

each

part

as

the

front

lubricant

The

oil

which

has

been

discharged

from

the

torque

converter

is

also

distributed

to

each

part

as

the

rear

lubricant

As

the

oil

pump

rotates

at

the

same

speed

as

thal

of

the

engine

the

dis

charge

of

oil

pump

increases

with

the

engine

speed

But

the

surplus

oil

is

returned

to

the

oil

pan

by

the

pressure

regulator

valve

D

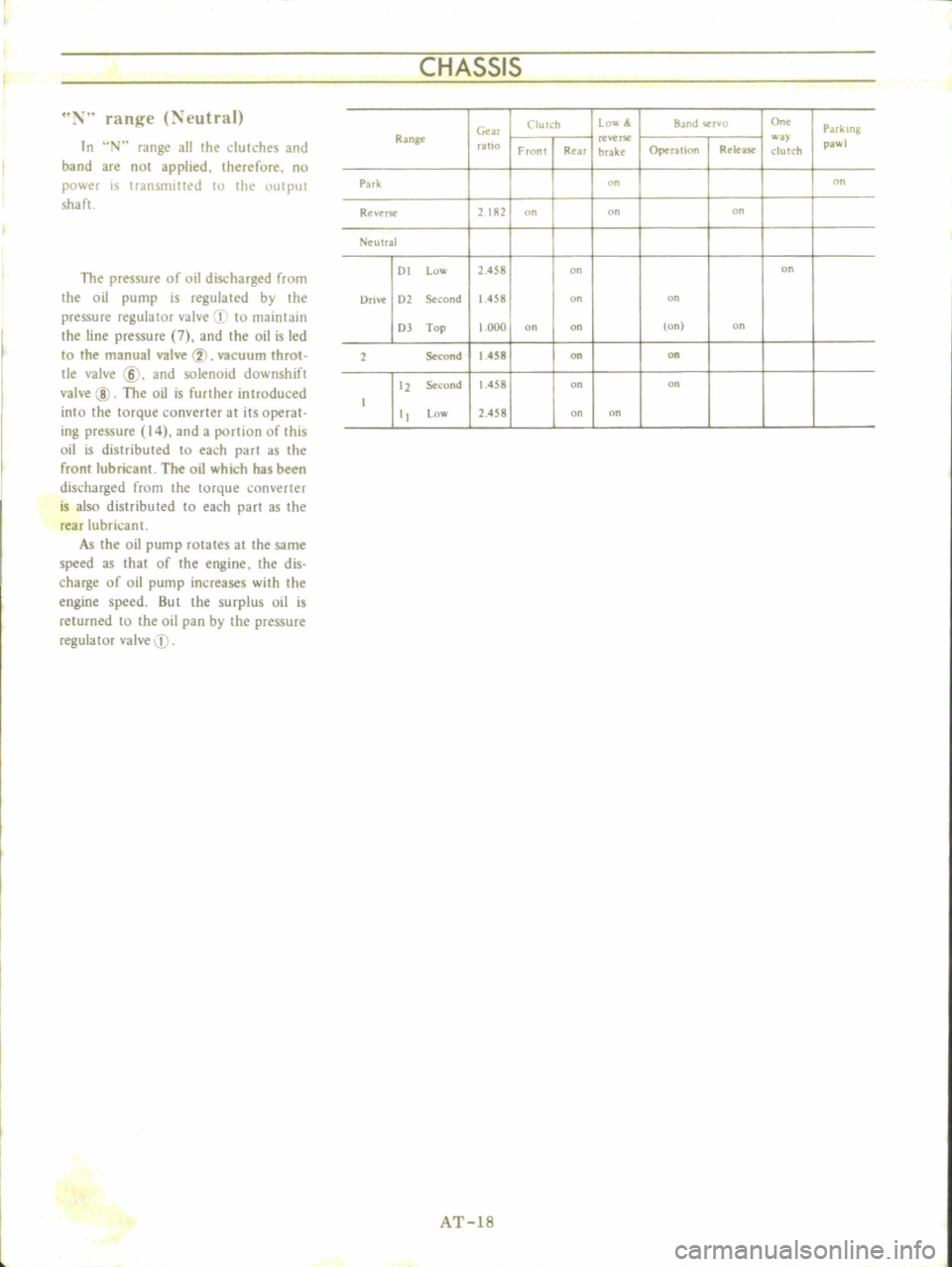

I

l

nUI

h

lo

BJnd

oefVQ

On

Parkin

Gt

ar

Rang

e

rl

tro

e

lA

a

pawl

ratio

Front

RUT

brake

Operation

Rdu

e

clutch

Park

on

on

Revtr

21Rl

on

on

on

Neutral

01

Low

2

458

on

on

Orive

02

Second

1

458

on

on

OJ

Top

1000

on

on

ton

on

2

cond

1

58

on

on

12

Second

1

458

on

on

I

II

low

2

458

on

on

AT

iS

Page 23 of 513

AUTOMATIC

TRANSMISSION

UN

range

Neutral

Low

R

Brek

B

eke

B

x

12

VK

Th

o

I

V

lv

7

G

0

j

Lve

Fro

Lub

lc

l

Otifite

Check

Valve

D

alnValve

j

11

I

3

ThrOUle

OrOlln

Vah

f

11

J

l

8

5018

Back

up

g

Dow

ill

V

lv

V

v

P

Modif

V

lve

15

13

8Jlux

3

j

p

ssu

A

euleto

Velye

6

lL

2

Menuel

V

lv

iiJIN

NOI

M

ked

O

in

Lin

pre

lGovernor

teed

pr

e

Gove

no

pr

s

Torquecon

e

p

e5SU

ThroW

p

S

Ond

y

G

o

V

8

Primary

Goy

no

V

l

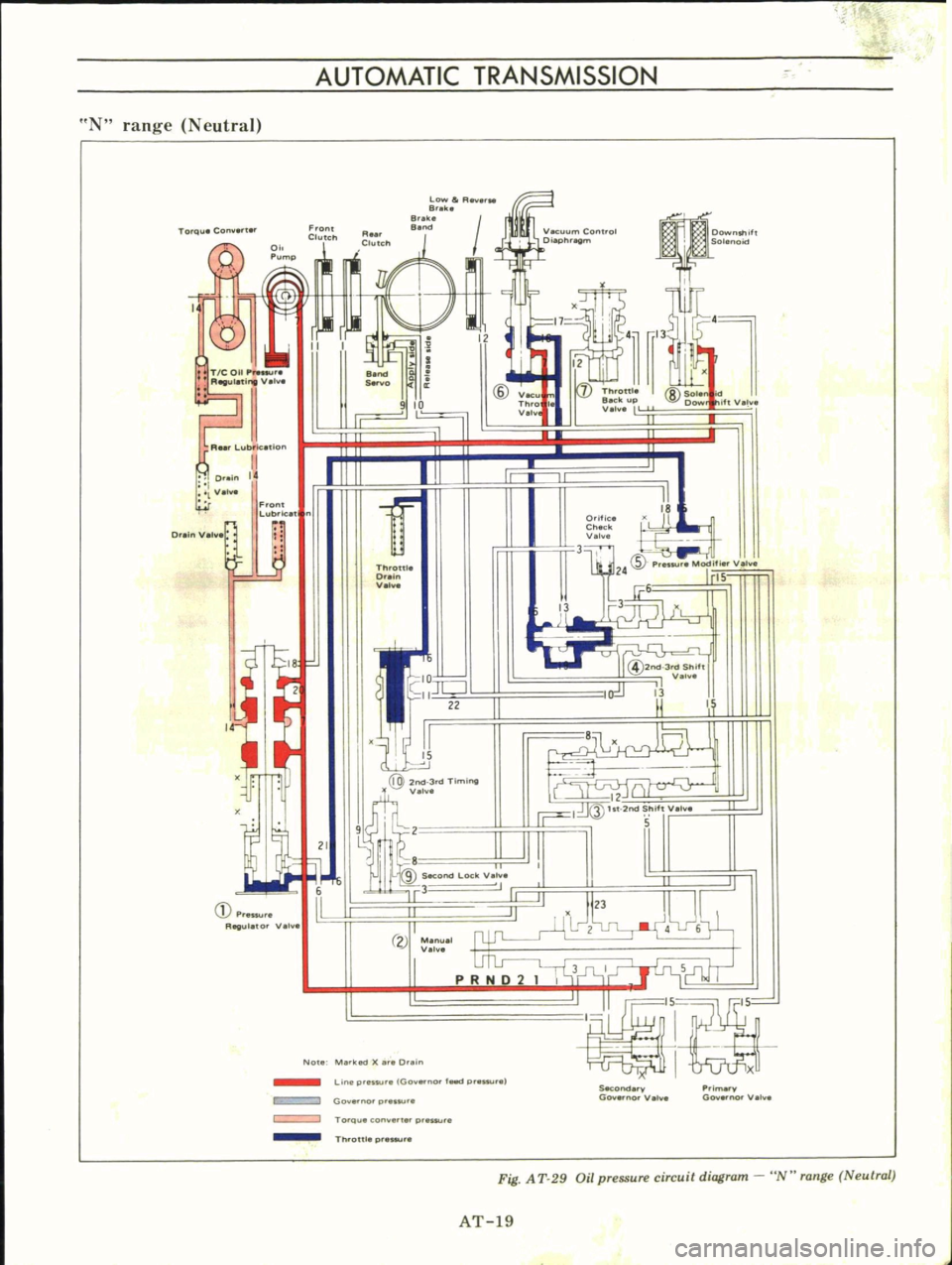

Fig

A

T

29

Oil

pressure

circuit

diagram

N

range

Neutral

AT

19

Page 26 of 513

CHASSIS

D

range

2nd

gl

ar

In

this

case

the

rear

dutch

is

applied

and

the

band

brake

holds

the

front

dUh

h

drum

i

onnel

ting

shell

and

sun

gear

from

rotating

The

power

now

takes

place

through

the

input

shaft

into

the

rear

dutch

and

the

front

internal

gear

WHh

the

sun

gear

held

stationary

the

fronr

plane

lacy

gears

rotate

around

the

sun

gear

carrying

the

front

planet

carrier

with

them

The

front

planet

carrier

being

splined

to

the

output

shaft

causes

clockwise

rotation

of

the

output

shafr

at

a

reduced

speed

compared

with

the

speed

of

the

input

shaft

with

an

increase

in

torque

As

the

low

and

reverse

brake

is

not

applied

the

clock

wise

rotation

of

the

output

shaft

causes

clockwise

rotation

of

rear

inter

nal

gear

and

the

rear

planet

carrier

also

rotates

around

the

sun

gear

in

a

clockwise

direction

The

one

way

clutch

will

act

to

allow

the

clockwise

rotation

of

connecting

drum

When

the

car

speed

increases

while

running

at

D

range

1st

gear

the

st

2nd

shift

valve

4

moves

al

lowing

the

line

pressure

I

to

be

introduced

into

the

line

pressure

8

through

itself

The

line

pressure

8

is

further

led

to

the

line

pressure

9

through

the

second

lock

vaIve@

and

by

locking

the

band

servo

obtains

the

2nd

gear

condition

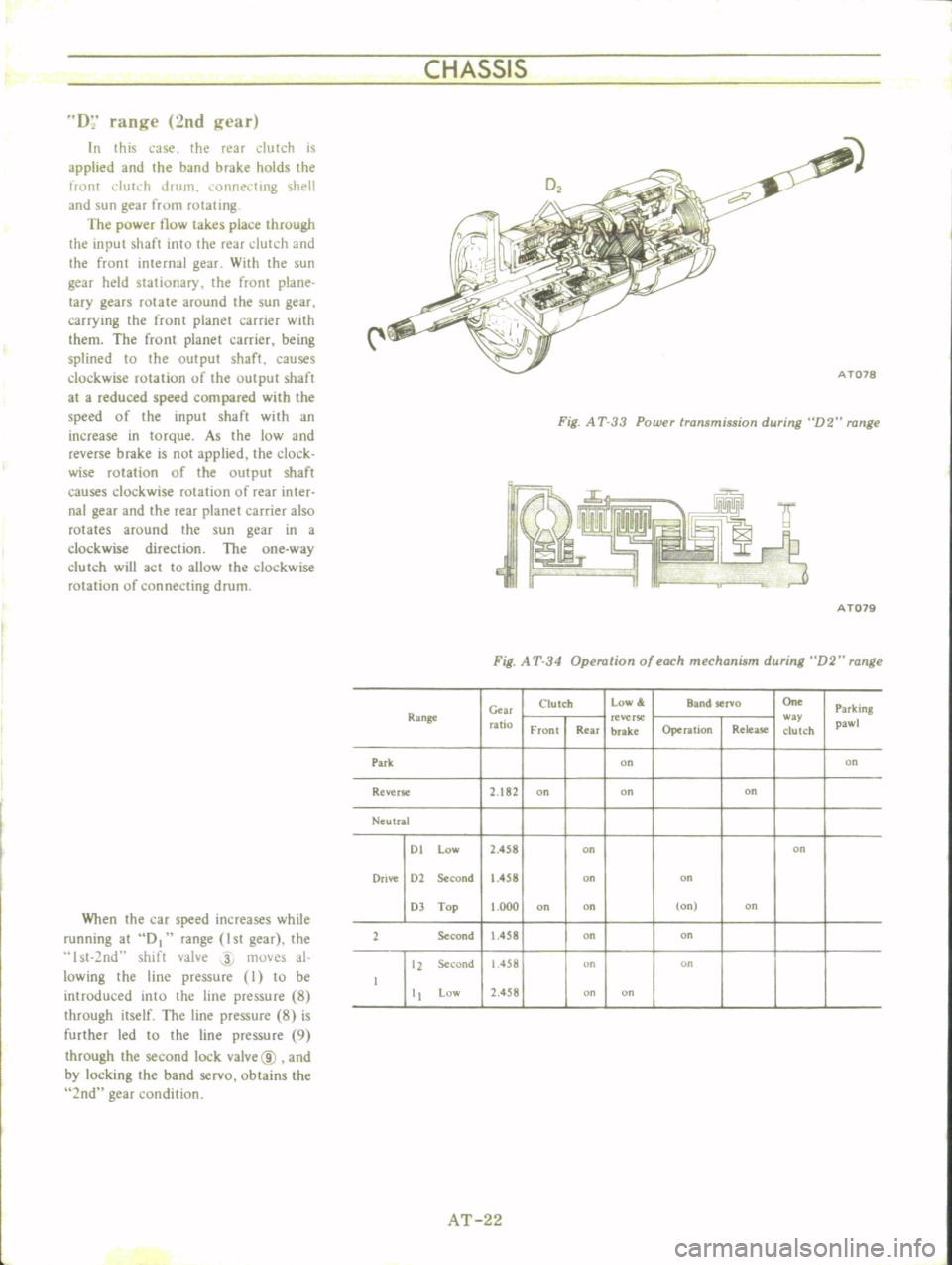

Fig

A

T

33

Power

transmission

during

D2

range

I

r

J

ITMi

A

T079

Fig

A

T

34

Operation

of

each

mechanism

during

D2

range

C

w

Clutch

low

Band

selva

On

Parking

Range

ratio

reverse

w

y

pawl

Front

Rear

brake

Operation

Rdea5e

clutch

Park

on

on

Reverse

2

182

on

on

on

Ne

ulral

01

low

2

458

on

on

Drive

01

Second

1

458

on

on

OJ

Top

000

on

on

on

on

1

Se

cond

458

on

on

11

Second

1

458

on

on

low

1

458

on

on

AT

22

Page 27 of 513

AUTOMATIC

TRANSMISSION

D

range

2nd

gear

Q

FrO

ll

Cluteh

Low

to

R

B

e

8

eke

Torque

Con

ert

14

Throttle

Beck

up

V

l

iftV

I

a

Q

T

COU

P

R

V

A

Lubfkatlon

11

Drain

14

V

I

l

CID

V

Thro

Valli

7

If

SOle

Wo

Front

Lubrlc

at

n

Orific

Check

V

I

OralnValw

Tt

oW

Q

aln

V

l

S

P

Modit

V

2

S

13

j

P

RIGulato

Vel

@2nd

3

dShIH

V

I

13

c

33J

2nd

ShlftV

I

e

s

Manual

V

I

n

NOla

M

ked

X

r

Drein

r

D

I

U

jeeo

v

Primarv

Gov

no

Valva

Goyarno

Val

Li

p

su

aIGo

no

IMod

pr

surel

Gov

nO

pr

sur

TO

Qu

con

pr

Th

on

p

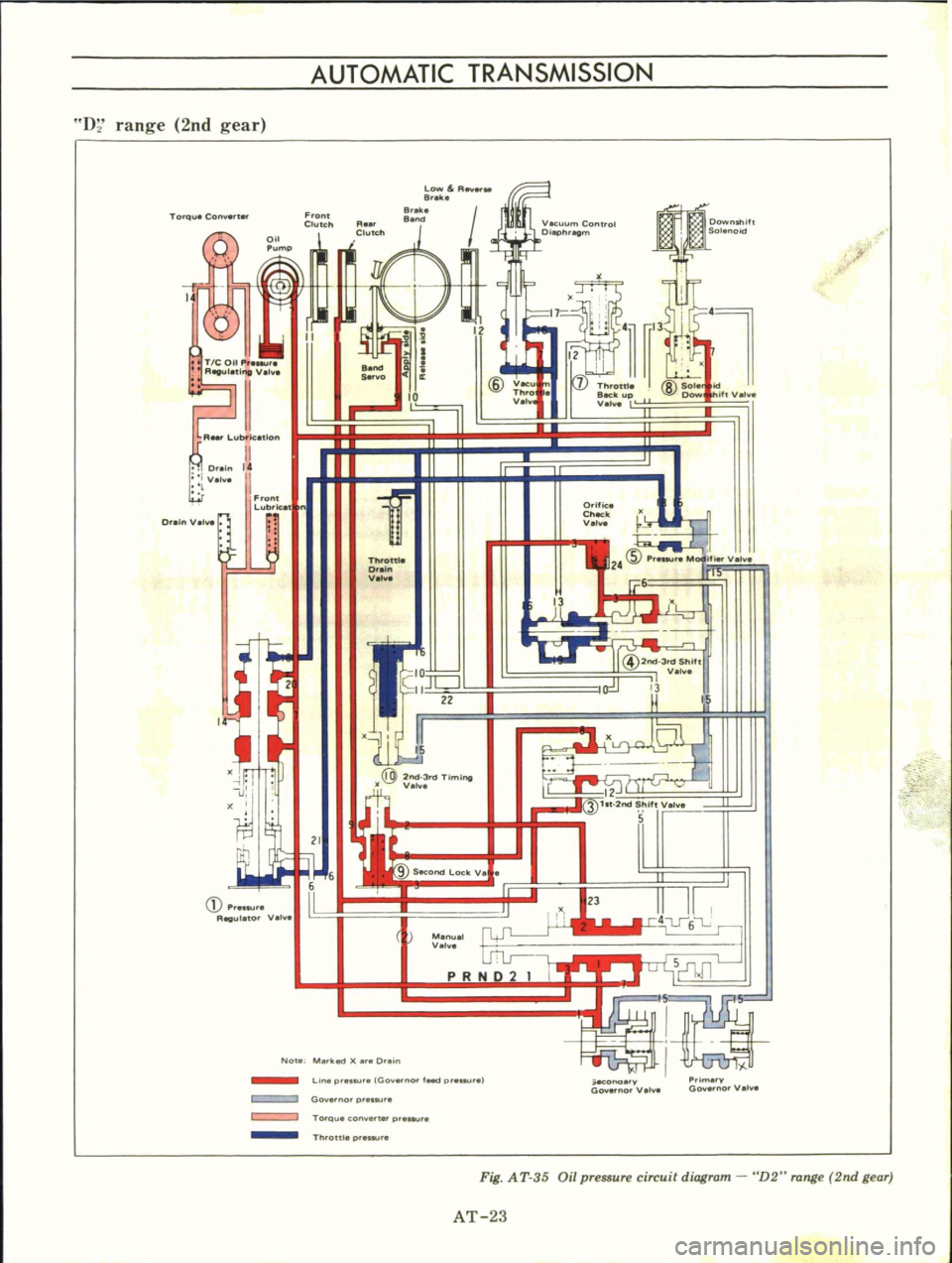

Fig

A

T

35

Oil

pressure

circuit

diagram

D2

range

2nd

gear

AT

23

Page 31 of 513

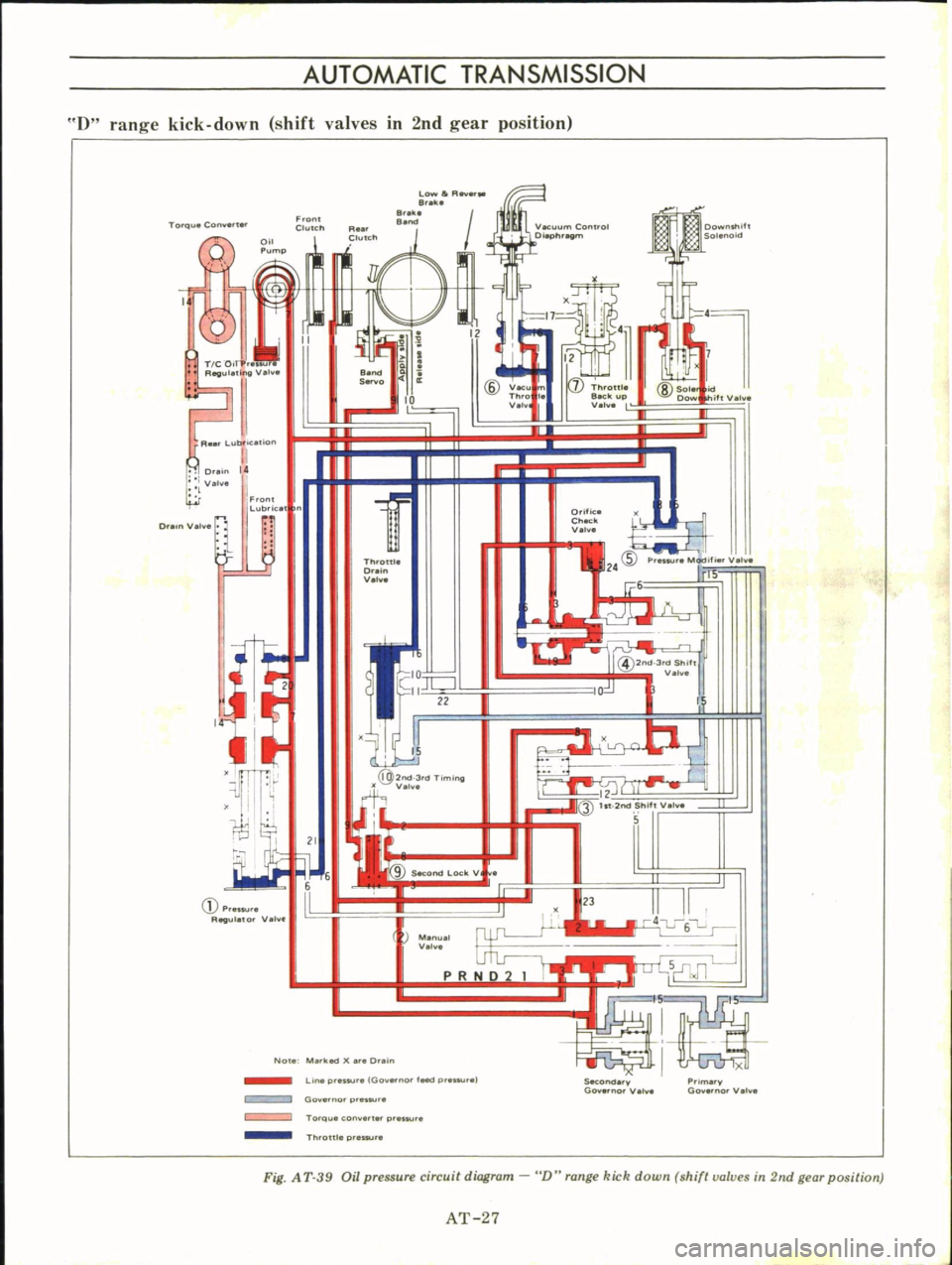

AUTOMATIC

TRANSMISSION

I

ran

e

kick

down

shift

valves

in

2nd

gear

position

iQ

Front

ClutCh

L

llIR

B

ilk

8

e

Downshift

Solenoid

Torqu

Con

t

Q

I

Throttle

Back

up

V

lv

II

iftY

h

TIC

0

A

lV

A

Lubl

tion

e

S

lO

lID

VK

Th

o

I

V

v

8

Sol

Dow

Dr

I

V

I

F

lt

Lubrice

D

Yo

t

Otific

Check

0

Throttle

Dr

n

V

mm

OJ

12

Q

ht

2rod

hif

v

S

C

Ptenu

R

ul

to

Vel

8

Menu

0

PRND2

I

L

J

Jl

No

Me

klld

er

D

in

SKond

Prim

GO

no

0

1

Go

no

V

LIne

pr

s

100

0

l

d

p

1

Goy

rno

p

eslU

s

Torque

con

er

r

pr

Th

oUl

prnsu

Fig

A

T

39

Oil

pressure

circuit

diagram

D

range

kick

down

shift

valves

in

2nd

gear

position

AT

27

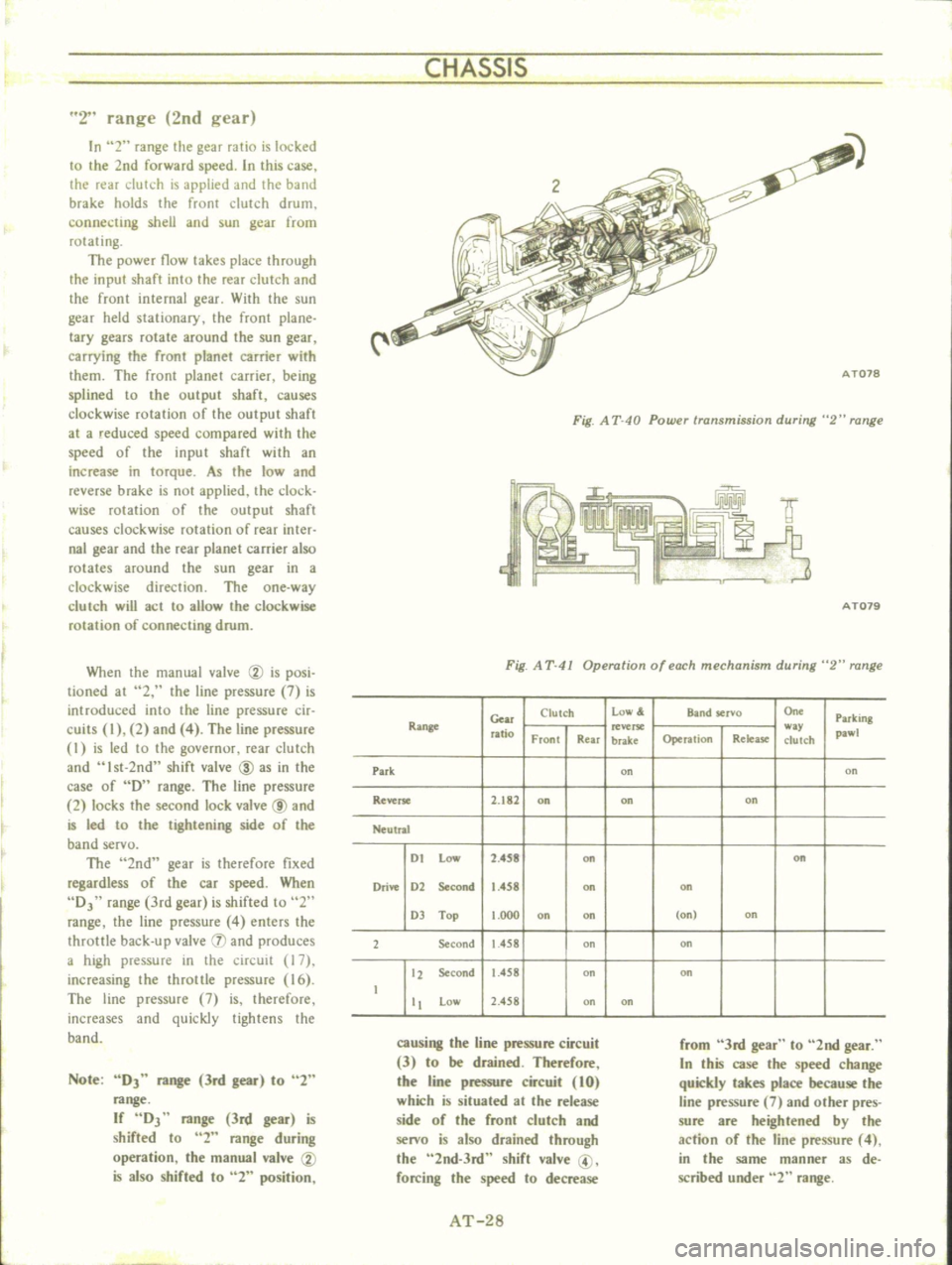

Page 32 of 513

CHASSIS

2

range

2nd

gear

In

2

range

the

gear

ratio

is

locked

to

the

2nd

forward

speed

In

this

case

the

rear

clutch

is

applied

and

the

band

brake

holds

the

front

clutch

drum

connecting

shell

and

sun

gear

from

rotating

The

power

flow

takes

place

through

the

input

shaft

into

the

rear

clutch

and

the

front

internal

gear

With

the

sun

gear

held

stationary

the

front

plane

lacy

gears

rotate

around

the

sun

gear

carrying

the

front

planet

carrier

with

them

The

front

planet

carrier

being

splined

to

the

output

shaft

causes

clockwise

rotation

of

the

output

shaft

at

a

reduced

speed

compared

with

the

speed

of

the

input

shaft

with

an

increase

in

torque

As

the

low

and

reverse

brake

is

not

applied

the

clock

wise

mlation

of

the

output

shaft

causes

clockwise

rotation

of

rear

inter

nal

gear

and

the

rear

planet

carrier

also

rotates

around

the

sun

gear

in

a

clockwise

direction

The

one

way

c1urch

will

act

to

allow

the

clockwise

rotation

of

connecting

drum

When

the

manual

valve

CV

is

posi

tioned

at

2

the

line

pressure

7

is

introduced

into

the

line

pressure

cir

cuits

I

2

and

4

The

line

pressure

I

is

led

to

the

governur

rear

dutch

and

Ist

2nd

shift

valve

ID

as

in

the

case

of

D

range

The

line

pressure

2

locks

the

second

lock

valve

@

and

is

led

to

the

tightening

side

of

the

band

servo

The

2nd

gear

is

therefore

fixed

regardless

of

the

car

speed

When

DJ

range

3rd

gear

is

shifted

to

2

range

the

line

pressure

4

enters

the

throttle

back

up

valve

IJ

and

produces

a

high

pressure

in

the

circuit

17

increasing

the

throttle

pressure

16

The

line

pressure

7

is

therefore

increases

and

quickly

tightens

the

band

Note

DJ

range

3rd

gear

to

2

range

If

DJ

range

3rd

gear

is

shifted

to

2

range

during

operation

the

manual

valve

CV

is

also

shifted

to

2

position

Fig

A

T

40

Powu

transmission

during

2

range

f

IY

9

3

AT079

Fig

A

T

41

Operation

of

each

mechanism

during

2

range

Gear

Clutch

low

Band

servo

On

Parking

Range

ratio

w

pawl

Front

Rear

brake

Operation

Relea

se

clutch

Park

on

on

Reverse

2

182

on

on

on

Neutral

I

t

Low

2

4S8

on

on

Drive

1

2

Second

1

458

on

on

1

Top

t

OOO

on

on

on

on

2

Second

1

458

on

on

12

Second

1

458

on

on

t

tt

Low

2

458

on

on

causing

the

line

pressure

circuit

3

to

be

drained

Therefore

the

line

pressure

circuit

10

which

is

situated

at

the

release

side

of

the

front

clutch

and

senro

is

also

drained

through

the

2nd

3rd

shift

valve

@

forcing

the

speed

to

decrease

from

3rd

gear

to

2nd

gear

In

this

case

the

speed

change

quickly

takes

place

because

the

line

pressure

7

and

other

pres

sure

are

heightened

by

the

action

of

the

line

pressure

4

in

the

same

manner

as

de

scribed

under

2

range

AT

28

Page 37 of 513

AUTOMATIC

TRANSMISSION

REMOVAL

AND

INSTAllATION

TRANSMISSION

ASSEMBLY

Removal

Installation

TRANSMISSION

ASSEMBLY

When

dismounting

the

automatic

transmission

from

a

vehicle

pay

at

tention

to

the

following

points

1

Before

dismounting

the

trans

mission

rigidly

inspect

it

by

aid

of

the

Troubleshooting

Chart

and

dis

mount

it

only

when

considered

to

be

necessary

2

Dismount

the

transmission

with

utmost

care

and

when

mounting

observe

the

tightening

torque

indi

cated

on

another

table

not

to

exert

excessive

force

Removal

In

dismounting

automatic

transmis

sion

from

vehicle

proceed

as

follows

i

Disconnect

battery

ground

cable

from

terminal

2

Jack

up

car

and

support

its

weight

on

safety

stands

Recommend

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

Make

sure

that

safety

is

insured

3

Remove

propeller

shaft

Note

Plug

up

the

opening

in

the

rear

extension

to

prevent

oil

from

flowing

out

4

Disconnect

front

exhaust

tube

5

Disconnect

selector

range

lever

from

manual

shaft

6

Disconnect

wire

connections

at

inhibitor

switch

CONTENTS

AT

33

AT

33

AT

33

TRANSMISSION

CONTROL

LINKAGE

Removal

and

installation

Adjustment

AT

35

AT

36

AT

36

7

Disconnect

vacuum

tube

from

vacuum

diaphragm

and

wire

connec

tions

at

downshift

solenoid

8

Disconnect

speedometer

cable

from

rear

extension

9

Disconnect

oil

charging

pipe

10

Support

engine

by

locating

a

jack

under

oil

pan

with

a

wooden

block

used

between

oil

pan

and

jack

Support

transmission

by

means

of

3

transmission

jack

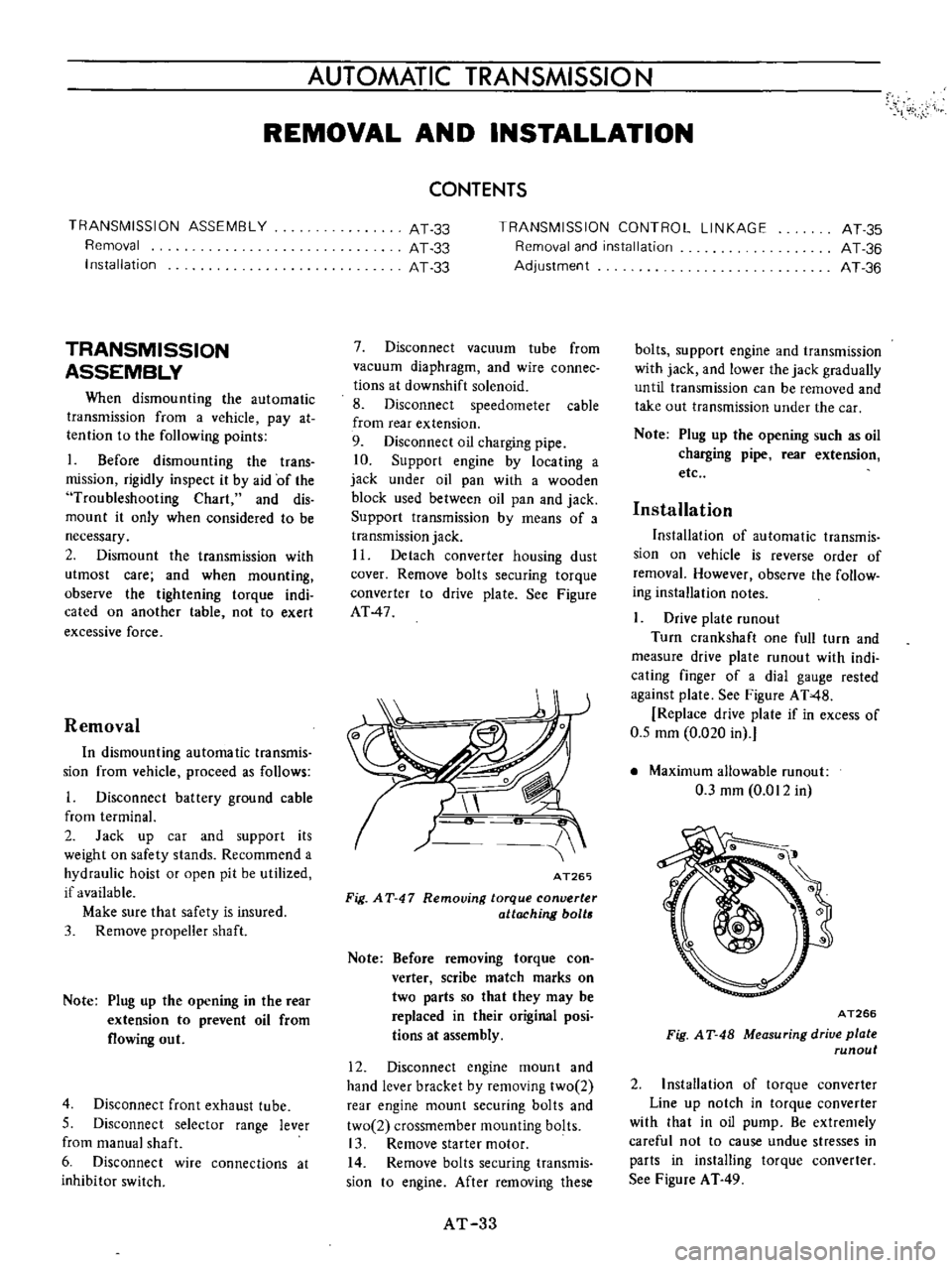

11

Detach

converter

housing

dust

cover

Remove

bolts

securing

torque

converter

to

drive

plate

See

Figure

AT

47

AT265

Fig

AT

47

Removing

torque

converter

attaching

bolt

Note

Before

removing

torque

con

verter

scribe

match

marks

on

two

parts

so

that

they

may

be

replaced

in

their

original

posi

tions

at

assembly

12

Disconnect

engine

moun

t

and

hand

lever

bracket

by

removing

two

2

rear

engine

mount

securing

bolts

and

two

2

crossmember

mounting

bolts

13

Remove

starter

motor

14

Remove

bolts

securing

transmis

sion

to

engine

After

removing

these

AT

33

bolts

support

engine

and

transmission

with

jack

and

lower

the

jack

gradually

until

transmission

can

be

removed

and

take

out

transmission

under

the

car

Note

Plug

up

the

opening

such

as

oil

charging

pipe

rear

extension

etc

Installation

Installation

of

automatic

transmis

sion

on

vehicle

is

reverse

order

of

removal

However

observe

the

follow

ing

installation

notes

Drive

plate

mnout

Turn

crankshaft

one

full

turn

and

measure

drive

plate

mnou

t

with

indi

cating

finger

of

a

dial

gauge

rested

against

plate

See

Figure

AT48

Replace

drive

plate

if

in

excess

of

0

5

mm

0

020

in

Maximum

allowable

mnout

0

3

mm

0

012

in

A

T266

Fig

A

T

48

Measuring

drive

plate

runout

2

Installation

of

torque

converter

Line

up

notch

in

torque

converter

with

that

in

oil

pump

Be

extremely

careful

not

to

cause

undue

stresses

in

parts

in

installing

torque

converter

See

Figure

A

T

49

Page 38 of 513

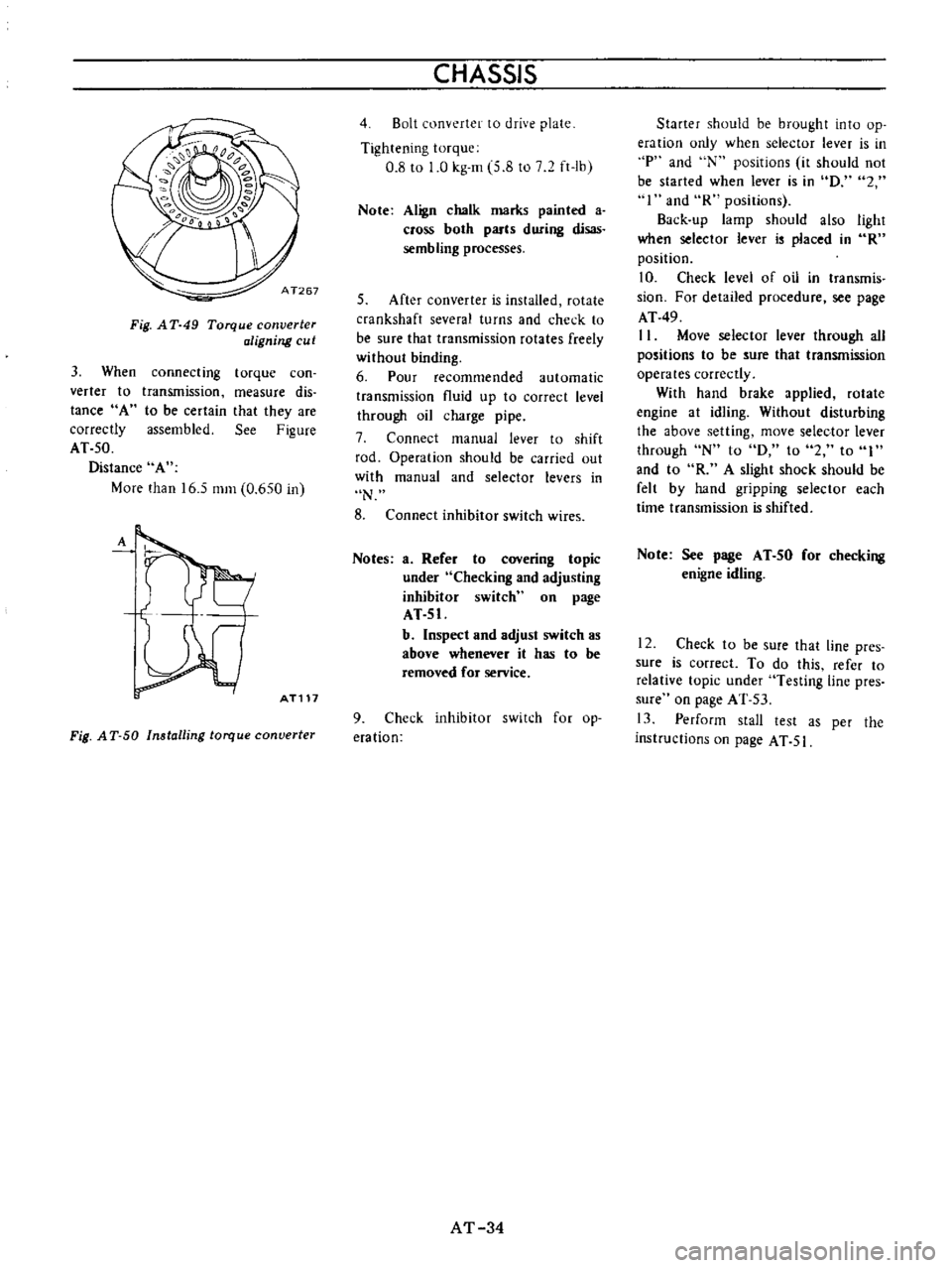

Fig

A

T

49

Torque

converter

aligning

cut

3

When

connecting

torque

con

verter

to

transmission

measure

dis

tance

A

to

be

certain

that

they

are

correctly

assembled

See

Figure

AT

50

Distance

A

More

than

16

5

IllIll

0

650

in

A

AT117

Fig

A

T

50

Installing

torque

converter

CHASSIS

4

Bolt

converter

to

drive

plate

Tightening

torque

0

8

to

1

0

kg

Ill

5

8

to

7

2

ft

Ib

Note

Align

chalk

marks

painted

a

cross

both

parts

during

disas

sembling

processes

5

After

converter

is

installed

rotate

crankshaft

several

turns

and

check

to

be

sure

that

transmission

rotates

freely

without

binding

6

Pour

recommended

automatic

transmission

fluid

up

to

correct

level

through

oil

charge

pipe

7

Connect

manual

lever

to

shift

rod

Operation

should

be

carried

out

with

manual

and

selector

levers

in

N

8

Connect

inhibitor

switch

wires

Notes

a

Refer

to

covering

topic

under

Checking

and

adjusting

inhibitor

switch

on

page

AT

51

b

Inspect

and

adjust

switch

as

above

whenever

it

has

to

be

removed

for

service

9

Check

inhibitor

switch

for

op

eration

AT

34

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

2

1

and

R

positions

Back

up

lamp

should

also

light

when

selector

lever

is

placed

in

R

position

10

Check

level

of

oil

in

transmis

sion

For

detailed

procedure

see

page

AT

49

II

Move

selector

lever

through

all

positions

to

be

sure

that

transmission

operates

correctly

With

hand

brake

applied

rotate

engine

at

idling

Without

disturbing

the

above

setting

move

selector

lever

through

N

to

D

to

2

to

I

and

to

R

A

slight

shock

should

be

felt

by

hand

gripping

selector

each

time

transmission

is

shifted

Note

See

page

AT

50

for

checking

enigne

idling

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

relative

topic

under

Testing

line

pres

sure

on

page

AT

53

13

Perform

stall

test

as

per

the

instructions

on

page

AT

51

Page 41 of 513

AUTOMATIC

TRANSMISSIO

N

i

MAJOR

REPAIR

OPERATION

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

TORQUE

CONVERTER

Inspection

TRANSMISSION

Disassembly

Inspection

Assembly

SERVICE

NOTICE

FOR

DISASSEMBLY

AND

ASSEMBLY

I

It

is

desirable

that

the

repair

operations

are

carried

out

in

the

dust

proof

room

2

Due

to

the

differences

of

the

engine

capacities

the

specifications

of

component

parts

for

each

model

s

transmission

may

be

different

How

ever

they

do

have

common

adJust

ments

and

repair

as

well

as

cleaning

and

inspection

procedures

ou

tlined

hereinafter

3

During

the

repair

operations

refer

to

the

Service

Data

and

Specifi

cations

section

for

the

correct

parts

for

the

applicable

model

transmission

4

Before

removing

any

of

subas

semblies

thoroughly

clean

the

outside

of

the

transmission

to

preven

t

dirt

from

entering

the

mechanical

parts

5

Do

not

use

a

waste

rag

Use

a

nylon

waste

or

paper

waste

6

After

disassembling

wash

all

dis

assembled

parts

clean

and

examine

them

to

see

if

there

are

any

worn

damaged

or

defective

parts

and

how

they

are

affected

Refer

to

Service

Data

for

the

extent

of

damage

that

justifies

replacement

7

Packings

seals

and

similar

parts

once

disassembled

should

be

replaced

with

new

ones

as

a

rule

TORQUE

CONVERTER

CONTENTS

AT

37

AT

37

AT

37

AT

37

AT

37

AT

39

AT

39

COMPONENT

PARTS

F

rant

clutch

Rear

clutch

Low

reverse

brake

Servo

piston

Governor

Oil

pump

Planetary

carrier

Control

valve

The

torque

converter

is

a

welded

construction

and

can

not

be

disas

sembled

Inspection

I

Check

torque

converter

for

any

sign

of

damage

bending

oil

leak

or

deformation

If

necessary

replace

2

Remove

rust

from

pilots

and

bosses

completely

If

torque

converter

oil

is

fouled

or

contaminated

due

to

burnt

clutch

flush

the

torque

converter

as

follows

I

Drain

oil

in

torque

converter

2

Pour

none

Iead

gasoline

or

kero

sene

into

torque

converter

approxi

mately

0

5

liter

I

1

8

V

S

p

7

8

Imper

p

3

Blow

air

into

torque

converter

and

flush

and

drain

out

gasoline

4

Fill

torque

converter

oil

into

torque

converter

approximately

0

5

liter

I

i

8

I

pt

7

8

lmper

pt

5

Again

blow

air

into

torque

con

verter

and

drain

torque

converter

oil

TRANSMISSION

Disassembly

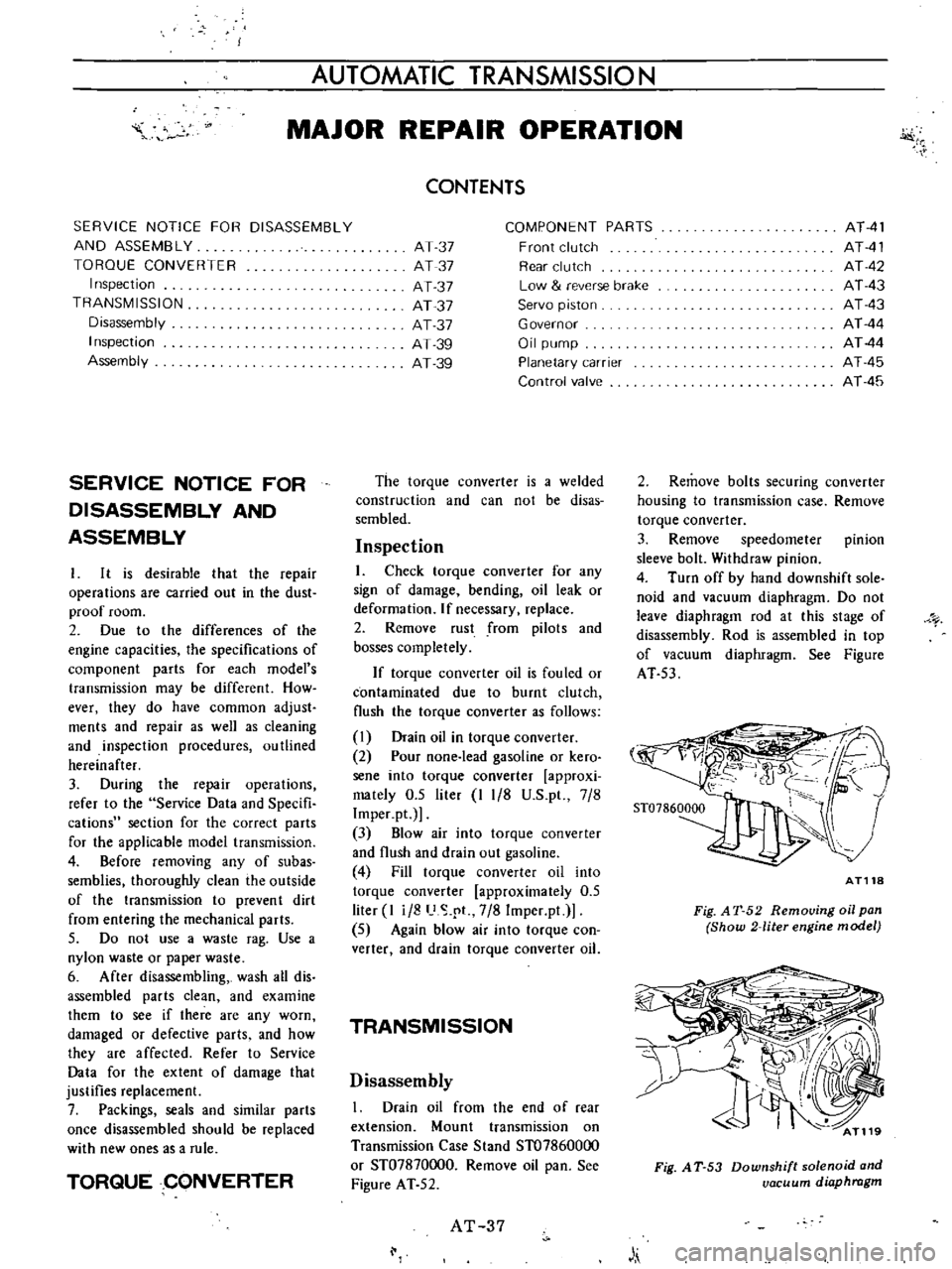

I

Drain

oil

from

the

end

of

rear

extension

Mount

transmission

on

Transmission

Case

Stand

ST07860000

or

ST07870000

Remove

oil

pan

See

Figure

AT

52

AT

37

T

AT

41

AT

41

AT

42

AT

43

AT

43

AT

44

AT

44

AT

45

AT

45

2

Remove

bolts

securing

converter

housing

to

transmission

case

Remove

torque

converter

3

Remove

speedometer

pinion

sleeve

boll

Withdraw

pinion

4

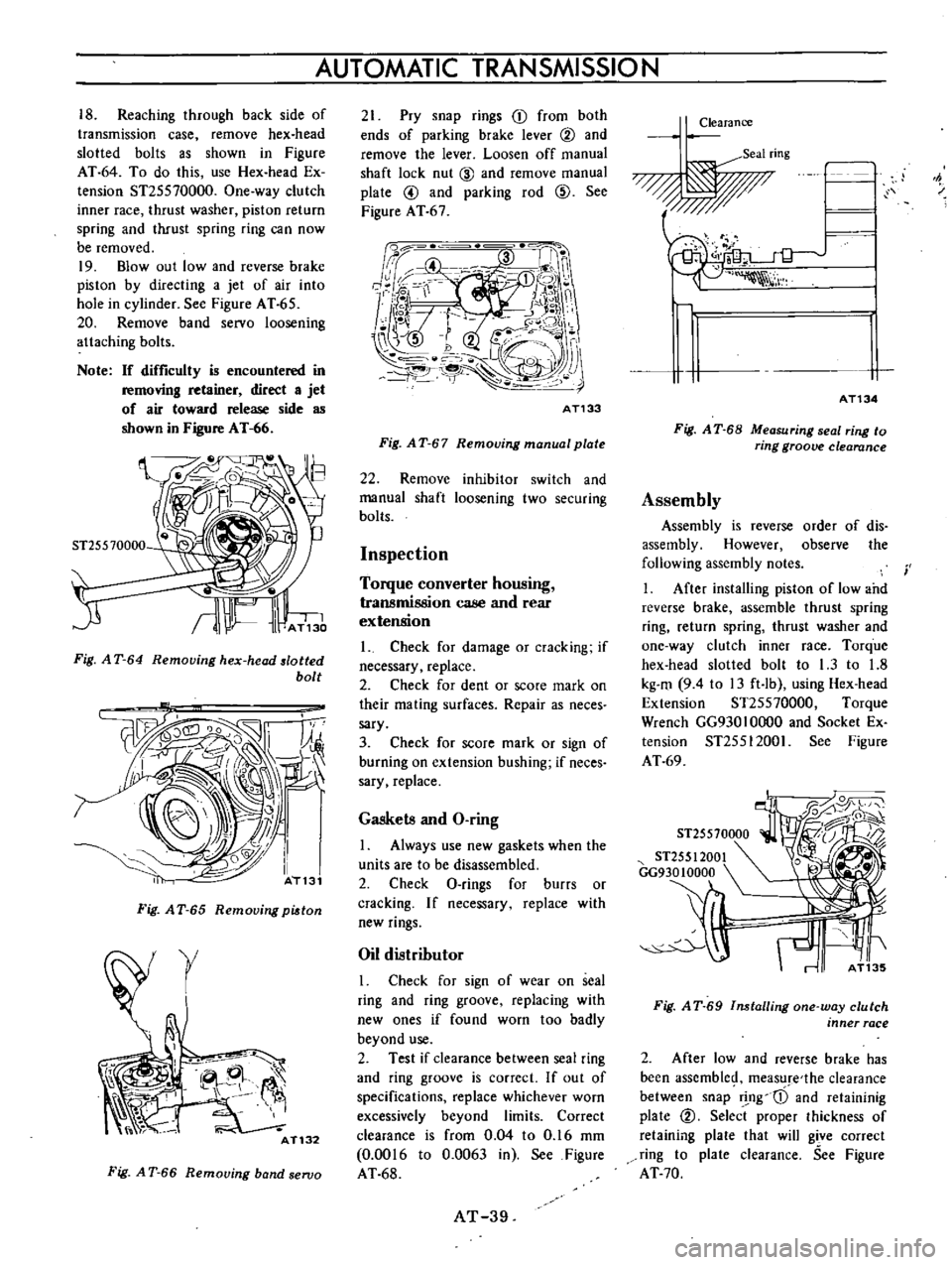

Turn

off

by

hand

downshift

sole

noid

and

vacuum

diaphragm

Do

not

leave

diaphragm

rod

at

this

stage

of

disassembly

Rod

is

assembled

in

top

of

vacuum

diaphragm

See

Figure

AT

53

ST07860000

AT118

Fig

AT

52

Remouing

oil

pan

Show

2

liter

engine

model

Fig

A

T

53

Downshift

solenoid

and

uacuum

diaphragm

Page 43 of 513

18

Reaching

through

back

side

of

transmission

case

remove

hex

head

slotted

bolts

as

shown

in

Figure

AT

64

To

do

this

use

Hex

head

Ex

tension

ST25570000

One

way

clutch

inner

race

thrust

washer

piston

return

spring

and

thrust

spring

ring

can

now

be

removed

19

Blowout

low

and

reverse

brake

piston

by

directing

a

jet

of

air

into

hole

in

cylinder

See

Figure

A

T

65

20

Remove

band

servo

loosening

attaching

bolts

Note

If

difficulty

is

encountered

in

removIng

retainer

direct

a

jet

of

air

toward

release

side

as

shown

in

Figure

AT

66

ST25570000

Fig

A

T

64

Removing

hex

head

lotted

bolt

Fig

A

T

65

Removing

pi

ton

r

AT132

Fig

A

T

66

Removing

band

seroo

AUTOMATIC

TRANSMISSION

21

Pry

snap

rings

CD

from

both

ends

of

parking

brake

lever

@

and

remove

the

lever

Loosen

off

manual

shaft

lock

nut

CID

and

remove

manual

plate

@

and

parking

rod

@

See

Figure

AT

67

Qd

i

f

W

II

4

i

n

n

r

1

K

j

e

0

H

o

i

j

j

I

j

l

m

r

JlII

2

U

r

K

F

J

r

0

f

1

r

AT133

Fig

A

T

67

Removing

manual

plate

22

Remove

inhibitor

switch

and

manual

shaft

loosening

two

securing

bolts

Inspection

Torque

converter

housing

transmission

case

and

rear

extension

1

Check

for

damage

or

cracking

if

necessary

replace

2

Check

for

dent

or

score

mark

on

their

mating

surfaces

Repair

as

neees

sary

3

Check

for

score

mark

or

sign

of

burning

on

extension

bushing

if

neces

sary

replace

Gaskets

and

O

ring

1

Always

use

new

gaskets

when

the

units

are

to

be

disassembled

2

Check

O

rings

for

burrs

or

cracking

If

necessary

replace

with

new

rings

Oil

distributor

I

Check

for

sign

of

wear

on

seal

ring

and

ring

groove

replacing

with

new

ones

if

found

worn

too

badly

beyond

use

2

Test

if

clearance

between

seal

ring

and

ring

groove

is

correct

If

out

of

specifications

replace

whichever

worn

excessively

beyond

limits

Correct

clearance

is

from

0

04

to

0

16

mm

0

0016

to

0

0063

in

See

Figure

AT

68

AT

39

Clearance

Seal

ring

F

1

I

i

h

AT134

Fig

A

T

68

Measuring

seal

ring

to

ring

groove

clearance

Assembly

Assembly

is

reverse

order

of

dis

assembly

However

observe

the

following

assembly

notes

1

After

installing

piston

of

low

and

reverse

brake

assemble

thrust

spring

ring

return

spring

thrust

washer

and

one

way

clutch

inner

race

Torque

hex

head

slotted

bolt

to

1

3

to

1

8

kg

m

94

to

13

ft

Ib

using

Hex

head

Extension

ST25570000

Torque

Wrench

GG930

1

0000

and

Socket

Ex

tension

ST25512001

See

Figure

AT

69

i

ST25570000

ST255

1

2001

GG93010000

0

rr

l

f

r

Fig

A

T

69

Installing

one

way

clutch

inner

race

2

After

low

and

reverse

brake

has

been

assemble

measure

the

clearance

between

snap

r

ng

cD

and

retaininig

plate

@

Select

proper

thickness

of

retaining

plate

that

will

gi

ve

correct

ring

to

plate

clearance

See

Figure

AT

70