torque DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 409 of 537

ST202

Fig

ST

6

Withdrawing

gear

ann

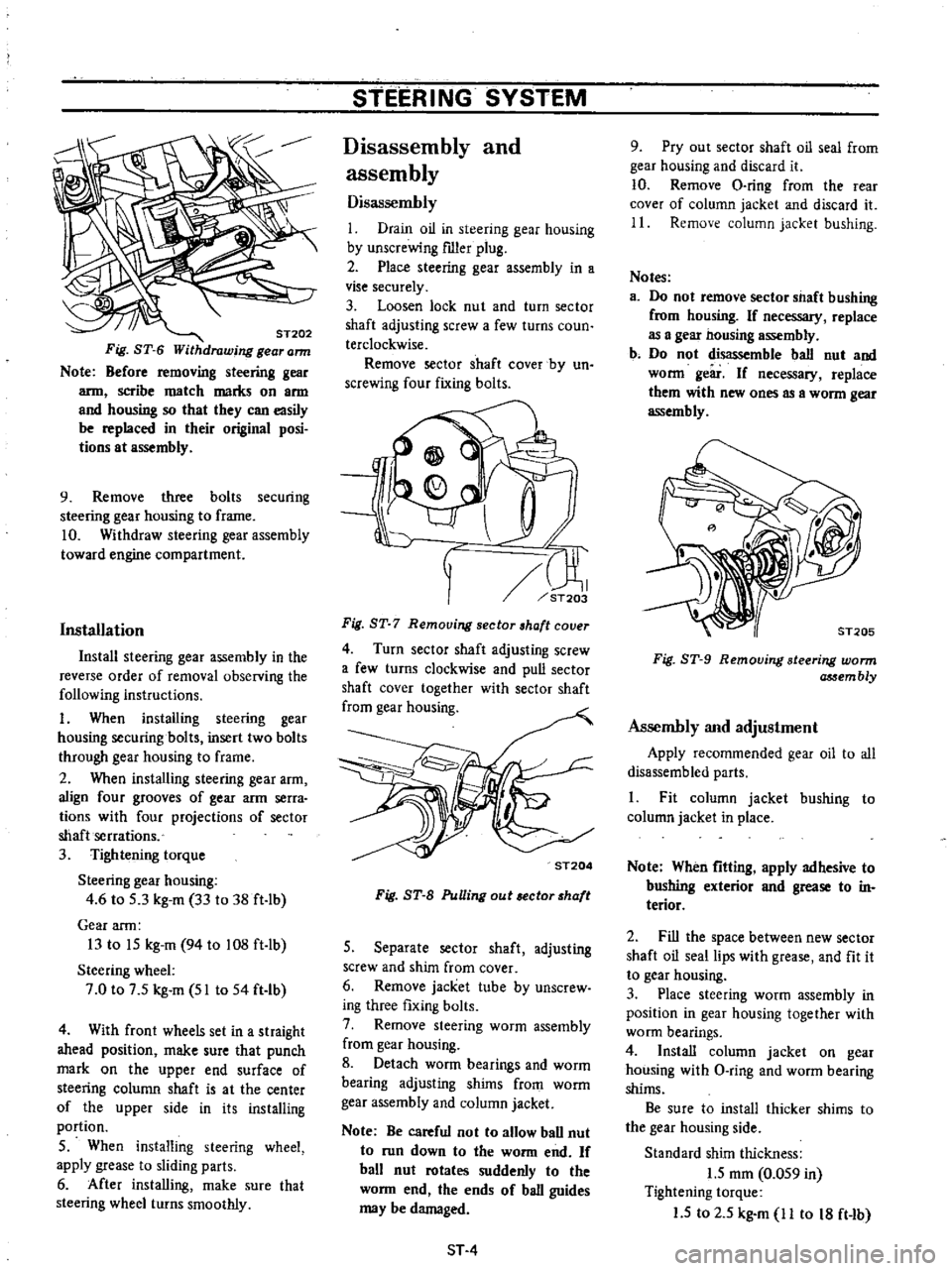

Note

Before

removing

steering

gear

arm

scribe

match

marks

on

arm

and

housing

so

that

they

can

easily

be

replaced

in

their

original

posi

tions

at

assembly

9

Remove

three

bolts

securing

steering

gear

housing

to

frame

10

Withdraw

steering

gear

assembly

toward

engine

compartment

Installation

Install

steering

gear

assembly

in

the

reverse

order

of

removal

observing

the

following

instructions

I

When

installing

steering

gear

housing

securing

bolts

insert

two

bolts

through

gear

housing

to

frame

2

When

installing

steering

gear

arm

align

four

grooves

of

gear

arm

serra

tions

with

four

projections

of

sector

shaft

serrations

3

Tightening

torque

Steering

gear

housing

4

6

to

S

3

kg

m

33

to

38

ft

lb

Gear

arm

13

to

IS

kg

m

94

to

108

ft

lb

Steering

wheel

7

0

to

7

S

kg

m

51

to

54

ft

Ib

4

With

front

wheels

set

in

a

straight

ahead

position

make

sure

that

punch

mark

on

the

upper

end

surface

of

steering

column

shaft

is

at

the

center

of

the

upper

side

in

its

installing

portion

S

When

installing

steering

wheel

apply

grease

to

sliding

parts

6

After

installing

make

sure

that

steering

wheel

turns

smoothly

STEERING

SYSTEM

Disassembly

and

assembly

Disassembly

I

Drain

oil

in

steering

gear

housing

by

unscrewing

fIller

plug

2

Place

steering

gear

assembly

in

a

vise

securely

3

Loosen

lock

nut

and

turn

sector

shaft

adjusting

screw

a

few

turns

coun

terclockwise

Remove

sector

shaft

cover

by

un

screwing

four

fixing

bolts

rn

ST203

Fig

ST

7

Remouing

sector

haft

couer

4

Turn

sector

shaft

adjusting

screw

a

few

turns

clockwise

and

pull

sector

shaft

cover

together

with

sector

shaft

from

gear

housing

ST204

Fig

ST

B

PuUing

out

ector

haft

S

Separate

sector

shaft

adjusting

screw

and

shim

from

cover

6

Remove

jacket

tube

by

unscrew

ing

three

fixing

bolts

7

Remove

steering

worm

assembly

from

gear

housing

8

Detach

worm

bearings

and

worm

bearing

adjusting

shims

from

worm

gear

assembly

and

column

jacket

Note

Be

careful

not

to

allow

ball

nut

to

run

down

to

the

worm

end

If

ball

nut

rotates

suddenly

to

the

worm

end

the

ends

of

ball

guides

may

be

damaged

ST

4

9

Pry

out

sector

shaft

oil

seal

from

gear

housing

and

discard

it

10

Remove

O

ring

from

the

rear

cover

of

column

jacket

and

discard

it

11

Remove

column

jacket

bushing

Notes

a

Do

not

remove

sector

shaft

bushing

from

housing

If

necessary

replace

as

a

gea2

nousing

assembly

b

Do

not

disassemble

ball

nut

and

worm

geir

If

necessary

replace

them

with

new

ones

as

a

worm

gear

assembly

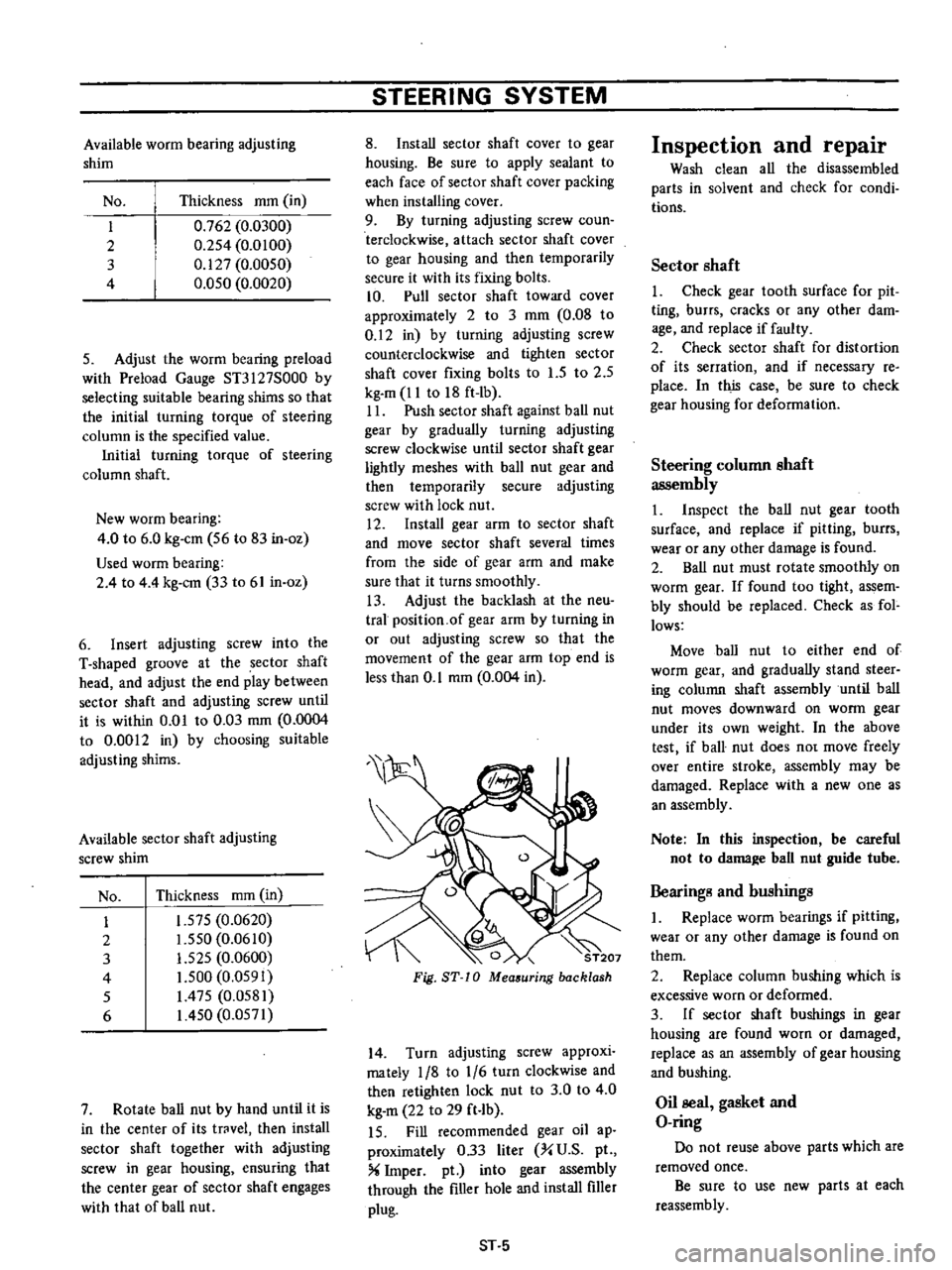

Fig

ST

9

Removing

steering

worm

assem

bly

Assembly

and

adjustment

Apply

recommended

gear

oil

to

all

disassembled

parts

1

Fit

column

jacket

bushing

to

column

jacket

in

place

Note

When

fitting

apply

adhesive

to

bushing

exterior

and

grease

to

in

terior

2

Fill

the

space

between

new

sector

shaft

oil

seal

lips

with

grease

and

fit

it

to

gear

housing

3

Place

steering

worm

assembly

in

position

in

gear

housing

together

with

worm

bearings

4

Install

column

jacket

on

gear

housing

with

O

ring

and

worm

bearing

shims

Be

sure

to

install

thicker

shims

to

the

gear

housing

side

Standard

shim

thickness

1

5

mOl

0

OS9

in

Tightening

torque

1

5

to

2

S

kg

m

11

to

18

ft

Ib

Page 410 of 537

Available

worm

bearing

adjusting

shim

No

Thickness

mOl

in

I

0

762

0

0300

2

0

2S4

0

0100

3

0

127

0

0050

4

O

OSO

0

0020

5

Adjust

the

worm

bearing

preload

with

Preload

Gauge

ST3127S000

by

selecting

suitable

bearing

shims

so

that

the

initial

turning

torque

of

steering

column

is

the

specified

value

Initial

turning

torque

of

steering

column

shaft

New

worm

bearing

4

0

to

6

0

kg

em

S6

to

83

in

oz

Used

worm

bearing

2

4

to

4

4

kg

em

33

to

61

in

oz

6

Insert

adjusting

screw

into

the

T

shaped

groove

at

the

sector

shaft

head

and

adjust

the

end

play

between

sector

shaft

and

adjusting

screw

until

it

is

within

0

01

to

0

03

mm

0

0004

to

0

0012

in

by

choosing

suitable

adjusting

shims

Available

sector

shaft

adjusting

screw

shim

No

Thickness

mOl

in

I

1

57S

0

0620

2

1

550

0

0610

3

1

525

0

0600

4

I

S00

0

OS91

S

1

475

0

0581

6

I

4S0

0

0571

7

Rotate

ball

nut

by

hand

until

it

is

in

the

center

of

its

trovel

then

install

sector

shaft

together

with

adjusting

screw

in

gear

housing

ensuring

that

the

center

gear

of

sector

shaft

engages

with

that

of

ball

nut

STEERING

SYSTEM

8

Install

sector

shaft

cover

to

gear

housing

Be

sure

to

apply

sealant

to

each

face

of

sector

shaft

cover

packing

when

installing

cover

9

By

turning

adjusting

screw

coun

terclockwise

attach

sector

shaft

cover

to

gear

housing

and

then

temporarily

secure

it

with

its

fixing

bolts

10

Pull

sector

shaft

toward

cover

approximately

2

to

3

mOl

0

08

to

0

12

in

by

turning

adjusting

screw

counterclockwise

and

tighten

sector

shaft

cover

fixing

bolts

to

l

S

to

2

5

kg

m

11

to

18

ft

Ib

II

Push

sector

shaft

against

ball

nut

gear

by

gradually

turning

adjusting

screw

clockwise

until

sector

shaft

gear

lightly

meshes

with

ball

nut

gear

and

then

temporarily

secure

adjusting

screw

with

lock

nut

12

Install

gear

arm

to

sector

shaft

and

move

sector

shaft

several

times

from

the

side

of

gear

arm

and

make

sure

that

it

turns

smoothly

13

Adjust

the

backlash

at

the

neu

tral

position

of

gear

arm

by

turning

in

or

out

adjusting

screw

so

that

the

movement

of

the

gear

arm

top

end

is

less

than

0

1

mOl

0

004

in

0

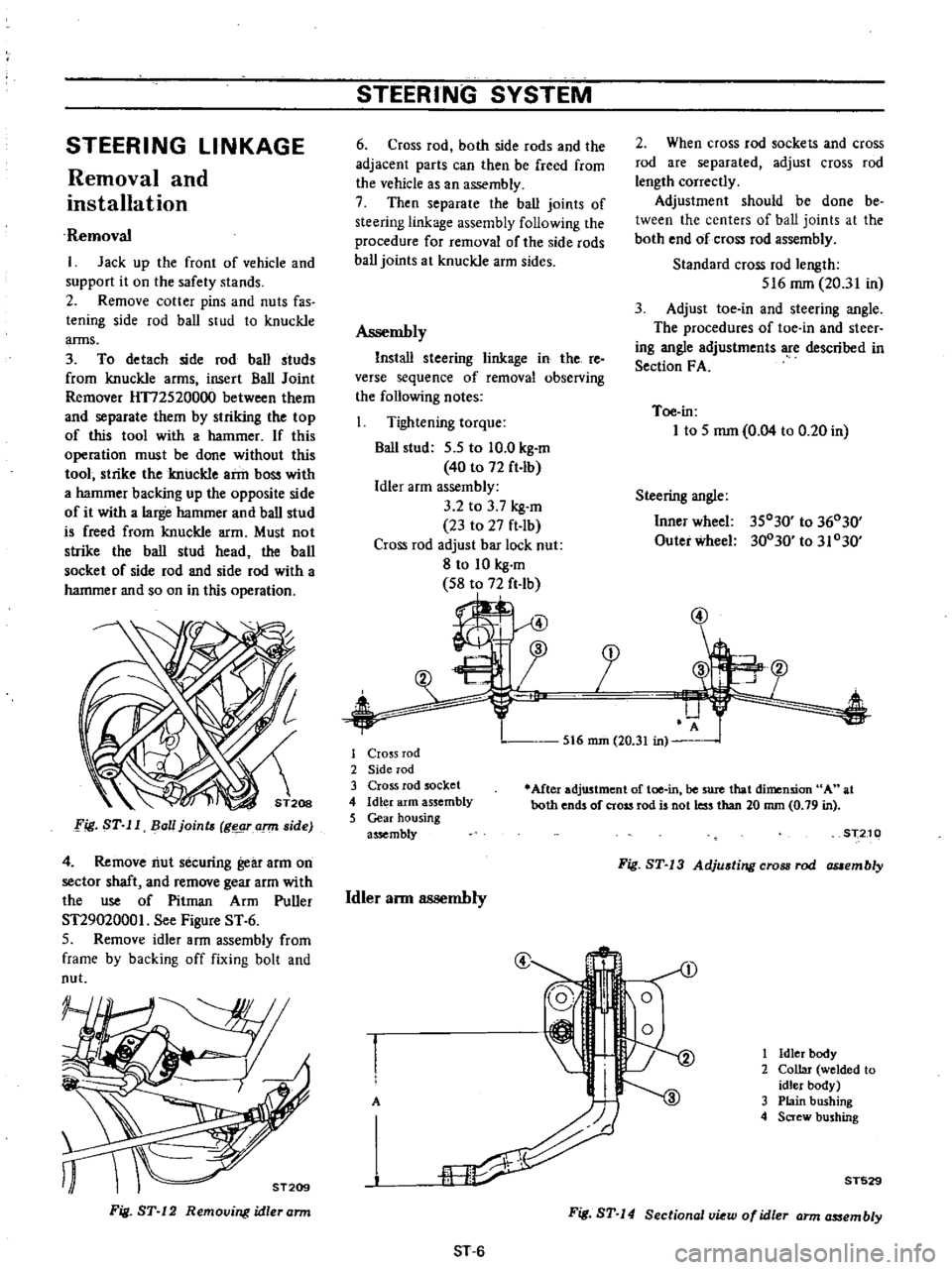

ST207

Fig

ST

10

Mea

uring

backlash

14

Turn

adjusting

screw

approxi

mately

1

8

to

1

6

turn

clockwise

and

then

retighten

lock

nut

to

3

0

to

4

0

kg

m

22

to

29

ft

Ib

IS

Fill

recommended

gear

oil

ap

proximately

0

33

liter

X

U

S

pI

X

Imper

pt

into

gear

assembly

through

the

filler

hole

and

install

filler

plug

ST

5

Inspection

and

repair

Wash

clean

all

the

disassembled

parts

in

solvent

and

check

for

condi

tions

Sector

shaft

1

Check

gear

tooth

surface

for

pit

ting

burrs

cracks

or

any

other

dam

age

and

replace

if

faulty

2

Check

sector

shaft

for

distortion

of

its

serration

and

if

necessary

re

place

In

this

case

be

sure

to

check

gear

housing

for

deformation

Steering

column

shaft

assembly

1

Inspect

the

ball

nut

gear

tooth

surface

and

replace

if

pitting

burrs

wear

or

any

other

damage

is

found

2

Ball

nut

must

rotate

smootWy

on

worm

gear

If

found

too

tight

assem

bly

should

be

replaced

Check

as

fol

lows

Move

ball

nut

to

either

end

of

worm

gear

and

gradually

stand

steer

ing

column

shaft

assembly

until

ball

nut

moves

downward

on

worm

gear

under

its

own

weight

In

the

above

test

if

ball

nut

does

no

move

freely

over

entire

stroke

assembly

may

be

damaged

Replace

with

a

new

one

as

an

assembly

Note

In

this

inspection

be

careful

not

to

dama

e

ball

nut

guide

tube

Bearings

and

bushings

I

Replace

worm

bearings

if

pitting

wear

or

any

other

damage

is

found

on

them

2

Repiace

column

bushing

which

is

excessive

worn

or

deformed

3

If

sector

shaft

bushings

in

gear

housing

are

found

worn

or

damaged

replace

as

an

assembly

of

gear

housing

and

bushing

Oil

seal

gasket

and

O

ring

Do

not

reuse

above

parts

which

are

removed

once

Be

sure

to

use

new

parts

at

each

reassembly

Page 411 of 537

STEERING

LINKAGE

Removal

and

installation

Removal

I

Jack

up

the

front

of

vehicle

and

support

it

on

the

safety

stands

2

Remove

cotter

pins

and

nuts

fas

tening

side

rod

ball

stud

to

knuckle

arms

3

To

detach

side

rod

ball

studs

from

knuckle

arms

insert

Ball

Joint

Remover

HT72520000

between

them

and

separate

them

by

striking

the

top

of

this

tool

with

a

hammer

If

this

operation

must

be

done

without

this

tool

strike

the

knuckle

arm

boss

with

a

hammer

backing

up

the

opposite

side

of

it

with

a

large

hammer

and

bail

stud

is

freed

from

knuckle

arm

Must

not

strike

the

baIl

stud

head

the

ball

socket

of

side

rod

and

side

rod

with

a

hammer

and

so

on

in

this

operation

Fig

ST

11

Ball

joints

Ic

ann

side

4

Remove

riut

securing

gear

armOD

sector

shaft

and

remove

gear

arm

with

the

use

of

Pitman

Arm

Puller

ST29020001

See

Figure

ST

6

S

Remove

idler

arm

assembly

from

frame

by

backing

off

fixing

bolt

and

nut

Ffa

ST

12

Removing

idler

ann

STEERING

SYSTEM

6

Cross

rod

both

side

rods

and

the

adjacent

parts

can

then

be

freed

from

the

vehicle

as

an

assembly

7

Then

separate

the

ball

joints

of

steering

linkage

assembly

following

the

procedure

for

removal

of

the

side

rods

ball

joints

at

knuckle

arm

sides

Assembly

Install

steering

linkage

in

the

reo

verse

sequence

of

removal

observing

the

following

notes

Tightening

torque

Ball

stud

S

S

to

10

0

kg

m

40

to

72

ft

lb

Idler

arm

assembly

3

2

to

3

7

kg

m

23

to

27

ft

lb

Cross

rod

adjust

bar

lock

nut

8

to

10

kg

m

72

fL

2

f

2

When

cross

rod

sockets

and

cross

rod

are

separated

adjust

cross

rod

length

correctly

Adjustment

should

be

done

be

tween

the

centers

of

ball

joints

at

the

both

end

of

cross

rod

assembly

Standard

cross

rod

length

516

rom

20

31

in

3

Adjust

toe

in

and

steering

angle

The

procedures

of

toe

in

and

steer

ing

angle

adjustments

Ie

described

in

Section

F

A

Toe

in

1

to

5

mm

0

04

to

0

20

in

Steering

angle

Inner

wheel

3S030

to

36030

Outer

wheel

30030

to

31030

5t6

mm

20

31

in

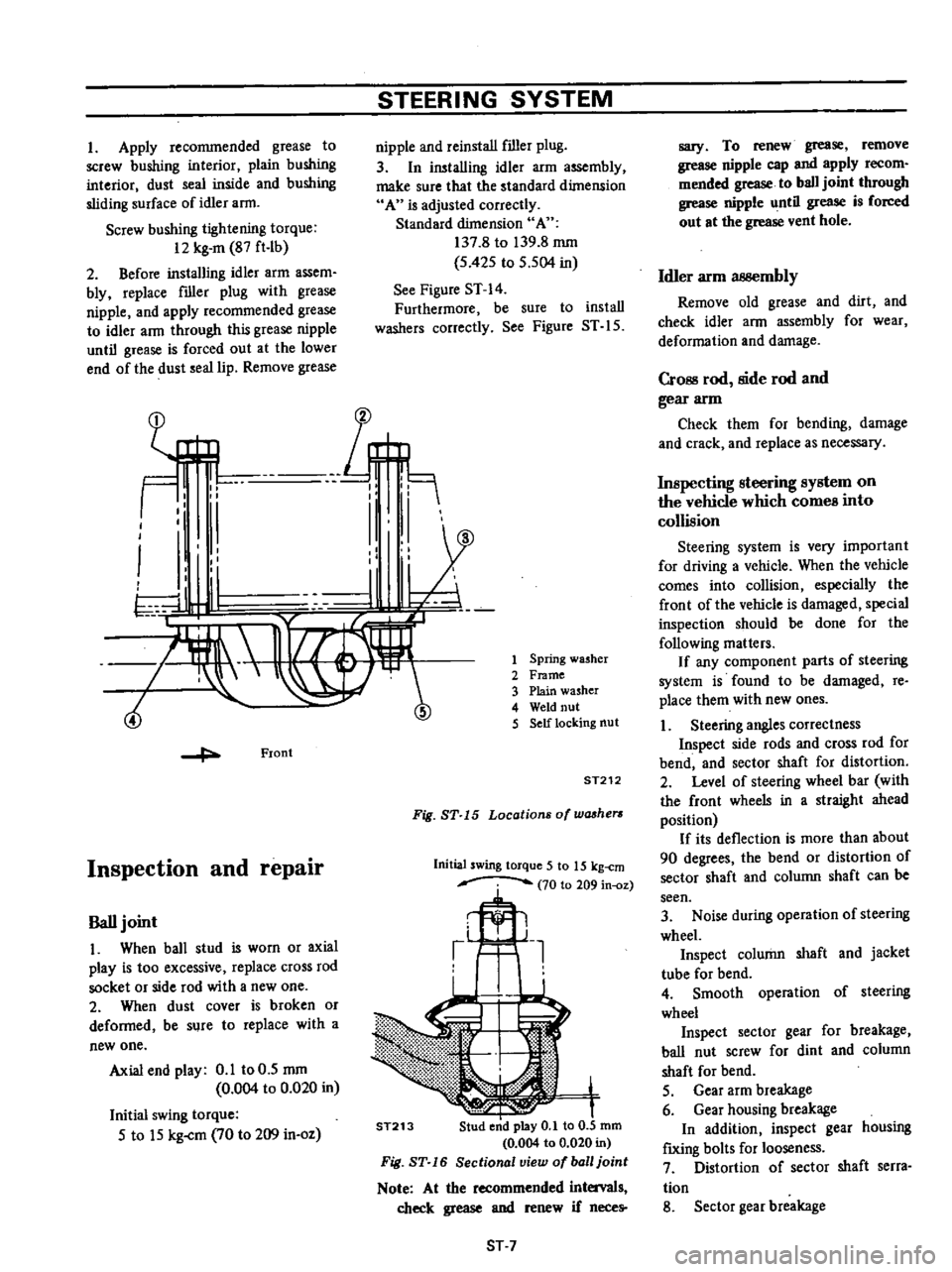

1

Cro

s

rod

2

Side

rod

3

Cross

rod

socket

4

Idler

arm

assembly

5

Gear

housing

assembly

Mter

adjustment

of

toe

in

be

sure

that

dimension

A

at

both

ends

of

cross

rod

is

not

less

than

20

nun

0

79

in

Idler

ann

assembly

ST210

Fig

ST

13

Adjusting

cross

rod

assembly

@

1

Idler

body

2

Collar

welded

to

idler

body

A

3

Plain

bushing

4

Screw

bushing

T529

ST

6

Fig

ST

14

Sectional

W

of

idler

arm

as

sembly

Page 412 of 537

I

J

L6

3

4

5

1

Apply

recommended

grease

to

screw

bushing

interior

plain

bushing

interior

dust

seal

inside

and

bushing

sliding

surface

of

idler

ann

Screw

bushing

tightening

torque

12

kg

m

87

ft

lb

2

Before

installing

idler

arm

assem

bly

replace

f

iller

plug

with

grease

nipple

and

apply

recommended

grease

to

idler

ann

through

this

grease

nipple

until

grease

is

forced

out

at

the

lower

end

of

the

dust

seal

lip

Remove

grease

I

8

I

II

I

I

FIODt

Inspection

and

repair

Ball

joint

1

When

ball

stud

is

worn

or

axial

play

is

too

excessive

replace

cross

rod

socket

or

side

rod

with

a

new

one

2

When

dust

cover

is

broken

or

defonned

be

sure

to

replace

with

a

new

one

Axial

end

play

0

1

to

0

5

mm

0

004

to

0

020

in

Initial

swing

torque

S

to

15

kg

cm

70

to

209

in

oz

STEERING

SYSTEM

nipple

and

reinstall

filler

plug

3

In

installing

idler

arm

assembly

make

sure

that

the

standard

dimension

A

is

adjusted

correctly

Standard

dimension

A

137

8

to

139

8

mm

S

42S

to

S

504

in

See

Figure

ST

14

Furthermore

be

sure

to

install

washers

correctly

See

Figure

ST

IS

Spring

washer

Frame

Plain

washer

Weld

nut

Self

locking

nut

ST212

Fig

ST

15

Locations

of

washers

Initial

swing

torque

5

to

15

kg

cm

70

to

209

in

oz

ST213

ST

7

sary

To

renew

grease

remove

grease

nipple

cap

and

apply

recom

mended

grease

to

ball

joint

through

grease

nipple

until

grease

is

forced

out

at

the

grease

vent

hole

Idler

arm

3B8embly

Remove

old

grease

and

dirt

and

check

idler

ann

assembly

for

wear

deformation

and

damage

CrOBS

rod

side

rod

and

gear

arm

Check

them

for

bending

damage

and

crack

and

replace

as

necessary

Inspecting

steering

system

on

the

vehicle

which

comes

into

collision

Steering

system

is

very

important

for

driving

a

vehicle

When

the

vehicle

comes

into

collision

especially

the

front

of

the

vehicle

is

damaged

special

inspection

should

be

done

for

the

following

matters

If

any

component

parts

of

steering

system

is

found

to

be

damaged

re

place

them

with

new

ones

1

Steering

angles

correctness

Inspect

side

rods

and

cross

rod

for

bend

and

sector

shaft

for

distortion

2

Level

of

steering

wheel

bar

with

the

front

wheels

in

a

straight

ahead

position

If

its

deflection

is

more

than

about

90

degrees

the

bend

or

distortion

of

sector

shaft

and

column

shaft

can

be

seen

3

Noise

during

operation

of

steering

wheel

Inspect

column

shaft

and

jacket

tube

for

bend

4

Smooth

operation

of

steering

wheel

Inspect

sector

gear

for

breakage

ball

nut

screw

for

dint

and

column

shaft

for

bend

S

Gear

arm

breakage

6

Gear

housing

breakage

In

addition

inspect

gear

housing

f

IXing

bolts

for

looseness

7

Distortion

of

sector

shaft

serra

tion

8

Sector

gear

breakage

Page 413 of 537

STEERING

SYSTEM

9

Column

shaft

breakage

on

the

welded

section

In

addition

inspect

column

shaft

for

scratch

10

Deformation

of

body

construc

tion

and

frame

Inspect

the

installation

portion

of

steering

system

on

the

body

construe

tion

and

frame

for

deformation

or

any

other

faulty

conditions

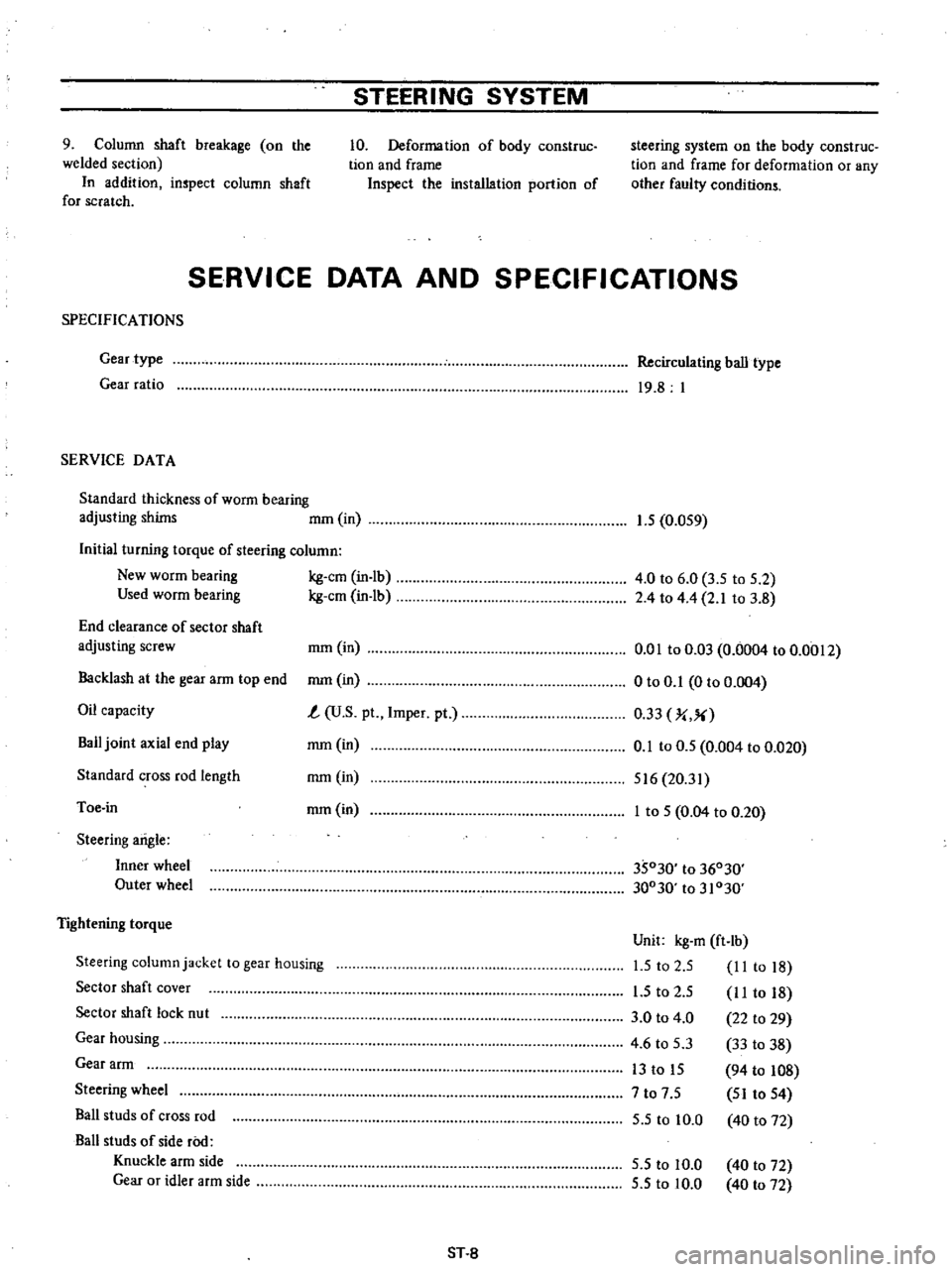

SERVICE

DATA

AND

SPECIFICATIONS

SPECIFICA

nONS

Gear

type

Gear

ratio

SERVICE

DATA

Standard

thickness

of

worm

bearing

adjusting

shims

mOl

in

Initial

turning

torque

of

steering

column

New

worm

bearing

kg

em

in

lb

Used

worm

bearing

kg

em

in

lb

End

clearance

of

sector

shaft

adjusting

screw

rom

in

Backlash

at

the

gear

arm

top

end

rom

in

Oil

capacity

t

U

S

pt

Impel

pt

Bail

joint

axial

end

play

rom

in

Standard

cross

rod

length

rom

in

Toe

in

rom

in

Steering

arigle

Inner

wheel

Outer

wheel

Tightening

torque

Steering

column

jacket

to

gear

housing

Sector

shaft

cover

Sector

shaft

lock

nut

Gear

housing

Gear

arm

Steering

wheel

Bail

studs

of

cross

rod

Ball

studs

of

side

roo

Knuckle

arm

side

Gear

or

idler

arm

side

ST

8

Recirculating

ball

type

19

8

I

1

5

0

OS9

4

0

to

6

0

3

5

to

S

2

2

4

to

4

4

2

1

to

3

8

om

to

0

03

0

0004

to

0

0012

o

to

0

1

0

to

0

004

0

33

J

X

0

1

to

0

5

0

004

to

0

020

516

20

31

I

to

S

0

04

to

0

20

35030

to

36030

30030

to

31030

Unit

kg

m

ft

lb

1

5

to

2

S

II

to

18

I

S

to

2

S

I

I

to

18

3

0

to

4

0

22

to

29

4

6

to

5

3

33

to

38

13

to

IS

94

to

108

7

to

7

S

SI

to

S4

S

S

to

10

0

40

to

72

S

S

to

10

0

S

5

to

10

0

40

to

72

40

to

72

Page 415 of 537

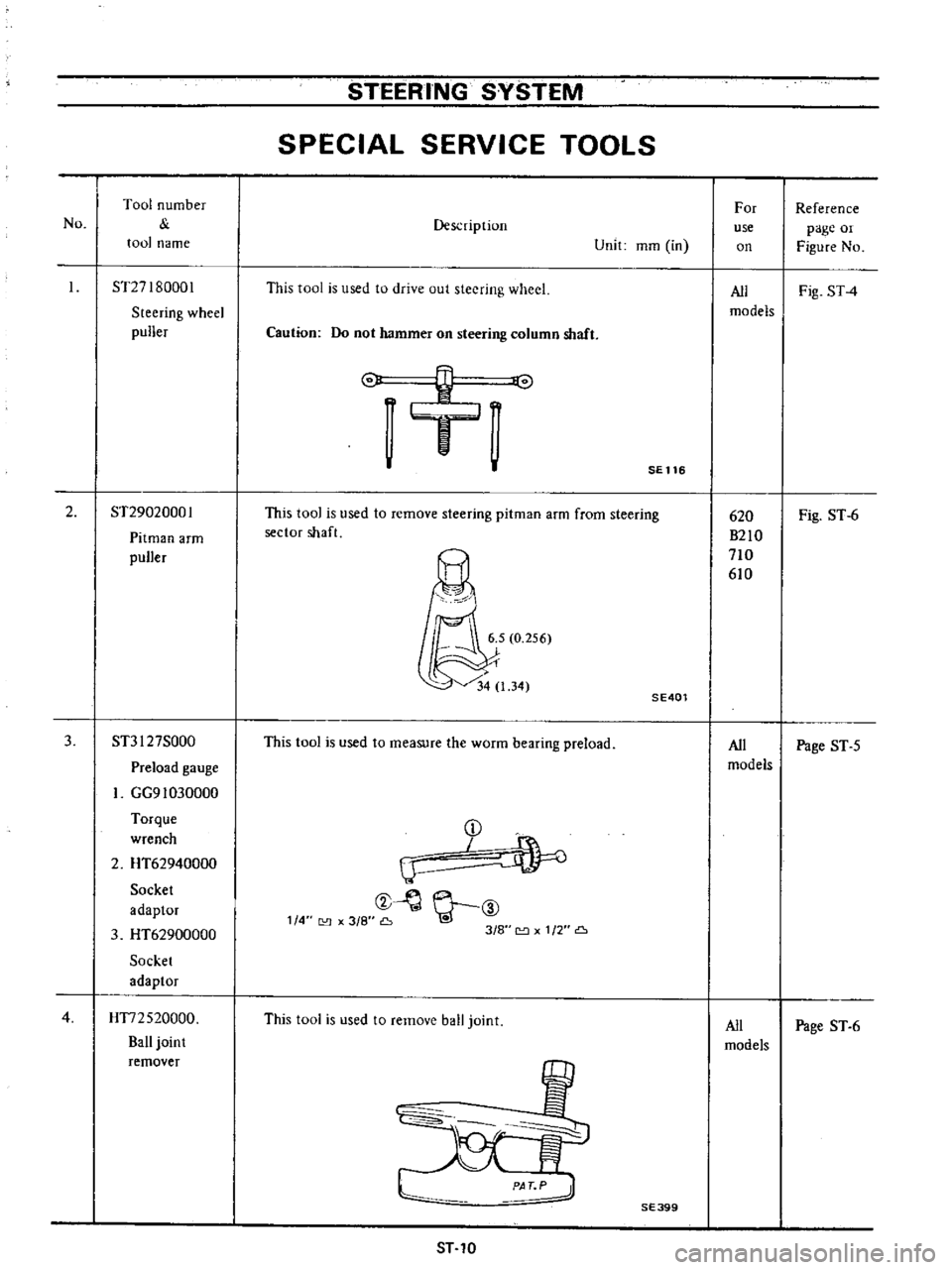

STEERING

SYSTEM

SPECIAL

SERVICE

TOOLS

No

Tool

number

tool

name

Description

Unit

mOl

in

For

use

on

Reference

page

or

Figure

No

ST27I80001

Steering

wheel

puller

This

tool

is

used

to

drive

out

steering

wheel

All

Fig

ST4

models

Caution

Do

not

hammer

on

steering

column

shaft

o

v

J

SE

116

2

ST29020001

Pitman

arm

puller

This

tool

is

used

to

remove

steering

pitman

arm

from

steering

sector

shaft

Fig

ST

6

SE401

3

ST3I

27S000

This

tool

is

used

to

measure

the

worm

bearing

preload

All

Page

ST

5

Preload

gauge

models

GG91030000

Torque

D

wrench

I

2

HT62940000

IJ

Socket

t

Y

ID

adaptor

114

3

8

Go

3

HT62900000

318

1

2

Socket

adaptor

4

HT72520000

This

tool

is

used

to

remove

ball

joint

All

Page

ST

6

Ball

joint

models

remover

620

B210

710

610

SE399

ST

10

Page 418 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

AND

INSTALLATION

Accelerator

wire

I

Remove

air

cleaner

assembly

2

Disconnect

accelerator

wire

from

carburetor

3

Loosen

lock

nut

and

disconnect

accelerator

wire

outer

case

from

wire

holder

See

Figure

FE

I

4

Remove

spring

clamp

and

discon

nect

accelerator

wire

from

accelerator

pedal

arm

S

Remove

two

screws

securing

ac

celerator

wire

outer

case

to

body

and

detach

accelerator

wire

6

To

install

reverse

the

order

of

removal

Apply

recommended

multi

purpose

grease

slightly

to

portion

MG

shown

in

Figure

FE

I

Accelerator

pedal

assembly

I

Remove

spring

clamp

then

dis

connect

accelerator

wire

from

tip

of

pedal

ann

2

Remove

two

screws

securing

ac

celerator

pedal

bracket

to

body

3

Remove

accelerator

pedal

from

dash

panel

See

Figure

FE

I

4

To

install

reverse

the

order

of

removal

INSPECTION

I

Check

accelerator

pedal

return

spring

for

rust

fatigue

or

damage

Replace

if

necessary

2

Check

accelerator

wire

cases

and

fastening

locations

for

rust

damage

or

looseness

Repair

or

replace

if

necessary

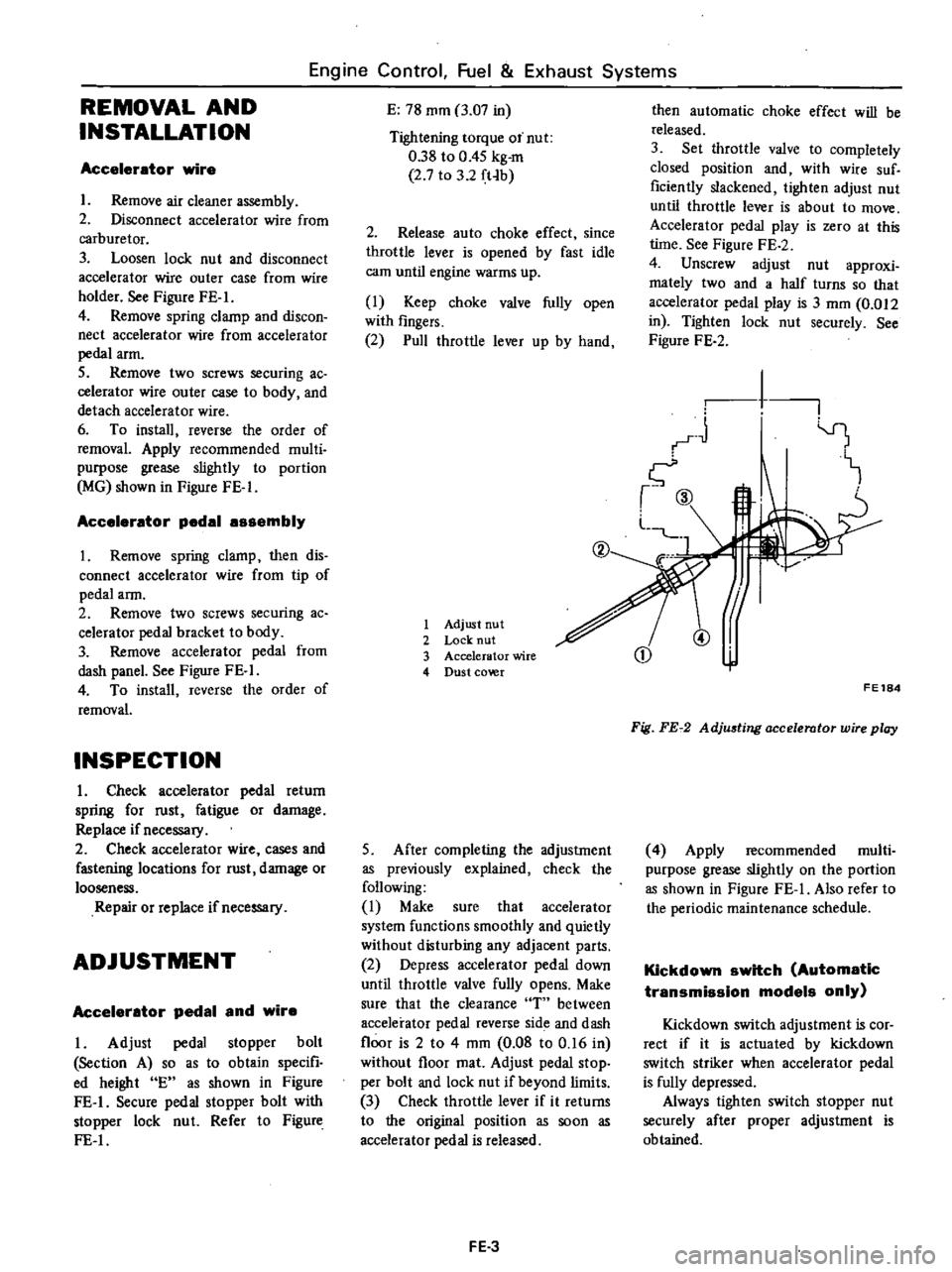

ADJUSTMENT

Accelerstor

pedal

and

wire

Adjust

pedal

stopper

bolt

Section

A

so

as

to

obtain

specifi

ed

height

E

as

shown

in

Figure

FE

I

Secure

pedal

stopper

bolt

with

stopper

lock

nut

Refer

to

Figure

FE

I

E

78

mOl

3

07

in

Tightening

torque

01

nut

0

38

to

0

4S

kg

m

2

7

to

3

2

ft

b

2

Release

auto

choke

effect

since

throttle

lever

is

opened

by

fast

idle

earn

until

engine

warms

up

I

Keep

choke

valve

fully

open

with

fingers

2

Pull

throttle

lever

up

by

hand

1

Adjust

nut

2

Lock

nut

3

Accelerator

wire

4

Dust

co

r

5

After

completing

the

adjustment

as

previously

explained

check

the

following

I

Make

sure

that

accelerator

system

functions

smoothly

and

quietly

without

disturbing

any

adjacent

parts

2

Depress

accelerator

pedal

down

until

throttle

valve

fully

opens

Make

sure

that

the

clearance

T

between

accelerator

pedal

reverse

side

and

dash

floor

is

2

to

4

mm

0

08

to

0

16

in

without

floor

mat

Adjust

pedal

stop

per

bolt

and

lock

nut

if

beyond

limits

3

Check

throttle

lever

if

it

returns

to

the

original

position

as

soon

as

accelerator

pedal

is

released

FE

3

then

automatic

choke

effect

will

be

released

3

Set

throttle

valve

to

completely

closed

position

and

with

wire

suf

ficiently

slackened

lighten

adjust

nut

until

throttle

lever

is

about

to

move

Accelerator

pedal

play

is

zero

at

this

lime

See

Figure

FE

2

4

Unscrew

adjust

nut

approxi

mately

two

and

a

half

turns

so

that

accelerator

pedal

play

is

3

mOl

0

012

in

Tighten

lock

nut

securely

See

Figure

FE

2

1

I

1

CD

@

FE184

Fig

FE72

AdjU6ting

accelerator

wire

play

4

Apply

recommended

multi

purpose

grease

slightly

on

the

portion

as

shown

in

Figure

FE

I

Also

refer

to

the

periodic

maintenance

schedule

Kickdown

switch

Automatic

transmission

models

only

Kickdown

switch

adjustment

is

cor

rect

if

it

is

actuated

by

kickdown

switch

striker

when

accelerator

pedal

is

fully

depressed

Always

tighten

switch

stopper

nut

securely

after

proper

adjustment

is

obtained

Page 421 of 537

Engine

Control

Fuel

Exhaust

Systems

2

Remove

fuel

filter

INSPECTION

Fuel

tanle

Check

fuel

tank

for

cracks

or

deformation

If

necessary

replace

2

Fuel

hose

Inspect

all

hoses

for

cracks

fatigue

sweating

or

deterioration

Replace

any

hose

that

is

damaged

3

Fuel

tube

Replace

any

fuel

tube

that

is

crack

ed

rusted

collapsed

or

deformed

Note

Inspect

hoses

and

tubes

ac

cording

to

the

periodic

mainte

nance

schedule

4

Fuel

filter

Replace

fuel

filter

according

to

the

periodic

maintenance

schedule

or

when

it

is

clogged

or

restricted

DESCRIPTION

REMOVAL

DESCRIPTION

The

exhaust

systems

installed

on

the

non

California

models

differ

in

specifications

from

those

installed

on

the

California

models

Fuel

filter

is

of

a

cartridge

type

and

cannot

be

cleaned

Always

replace

with

a

new

one

5

Fuel

tank

gauge

unit

Check

gauge

unit

for

rust

deforma

tion

or

deterioration

If

necessary

replace

INSTALLATION

To

install

reverse

the

order

of

removal

Observe

the

following

I

Install

hose

clamps

securely

Do

not

tighten

excessively

to

avoid

damaging

hoses

2

Fasten

clips

holding

fuel

tube

on

under

body

securely

Failure

to

follow

this

caution

could

result

in

damage

to

the

surface

of

fuel

tube

3

Do

not

kink

or

twist

hose

and

tube

when

they

are

routed

EXHAUST

SYSTEM

CONTENTS

FE

6

FE

8

INSPECTION

INSTAllATION

Non

California

models

The

exhaust

system

consists

of

a

front

exhaust

tube

a

main

muffler

assembly

with

rear

tube

mounting

hangers

brackets

and

a

heat

insulator

FE

6

4

Install

fIller

hose

after

fuel

tank

has

been

mounted

in

place

Failure

to

follow

this

caution

could

result

in

leakage

from

around

hose

connections

5

When

installing

fuel

tank

gauge

unit

align

the

projection

of

tank

gauge

unit

with

the

notch

in

fuel

tank

and

tighten

it

securely

Be

sure

to

install

gauge

unit

with

O

ring

in

place

6

Run

engine

and

check

for

leaks

at

connections

Tightening

torque

Drain

plug

5

0

to

6

0

kg

m

36

to

43

ft

Ib

Fuel

tank

securing

bolt

0

8

to

1

I

kg

m

6

to

8

ft

Ib

Reservoir

tank

securing

bolt

032

to

0

44

kg

m

2

to

3

ft

Ib

FE

8

FE

8

California

models

The

exhaust

system

cOllsists

of

a

front

exhaust

tube

a

catalytic

conver

ter

assembly

a

center

tube

a

main

muffler

assembly

with

rear

tube

mounting

hangers

brackets

and

heat

insulators

The

catalytic

converter

is

COD

nected

to

the

front

tube

and

the

center

tube

with

bolts

and

nuts

Page 423 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

Non

California

models

I

Remove

exhaust

tube

U

bolt

clamp

2

Break

sealant

off

at

front

tube

to

main

muffler

connectio

n

3

Remove

rear

tube

mounting

bolt

and

remove

muffler

assembly

with

rear

tube

4

Remove

front

tube

heat

insulator

5

Remove

nuts

securing

front

tube

to

exhaust

manifold

and

remove

front

tube

mounting

bolts

Then

detach

front

tube

When

disconnecting

the

exhaust

tube

connections

pay

attention

to

the

following

point

I

Break

old

se

lant

off

at

t

1e

connection

by

lightly

tapping

around

the

tube

witlJ

a

hammer

and

twisting

muffler

See

Figures

FE

7

and

FE

8

2

Using

a

rubber

hammer

tap

on

the

front

end

of

muffler

while

pushing

it

toward

rear

The

mumer

assembly

can

then

be

taken

out

See

Figure

FE

9

FE187

Fig

FE

7

Breaking

Bealant

FEl88

Fig

FE

8

Twisting

muffler

ijl

4

FE189

Fig

FE

9

Tapping

muffler

with

Q

rubber

hammer

California

models

I

Remove

all

heat

insulators

2

Remove

exhaust

tube

U

bolt

clamp

3

Break

sealant

off

at

center

tube

to

main

muffler

connection

4

Remove

rear

tube

mounting

bolt

and

remove

muffler

assembly

with

rear

tube

5

Remove

bolts

securing

catalytic

converter

to

center

tube

and

remove

center

tube

mounting

bolts

Then

detach

center

tube

6

Remove

bolts

and

nuts

securing

catalytic

converter

to

front

tube

and

detach

catalytic

converter

7

Remove

nuts

securing

front

tube

to

exhaust

manifold

and

remove

front

tube

mounting

bolts

Then

detach

front

tube

INSPECTION

I

Check

muffler

and

tubes

for

cracks

Qr

damage

Replace

any

part

that

is

damaged

beyond

limits

2

Replace

bracket

and

mounting

insulator

that

are

cracked

fatigued

or

sweated

FE

8

INSTALLATION

Install

the

exhaust

system

assembly

in

reverse

order

of

removal

Observe

the

following

Notes

a

Insert

front

tube

until

it

touches

emboss

b

When

there

is

110

clearance

between

front

tube

and

floor

or

propeUer

shaft

turn

tube

along

center

line

of

tube

in

the

manifold

connecting

unit

and

obtain

proper

clearance

c

Check

all

tube

connections

for

ex

haust

gas

leaks

and

entire

system

for

unusual

noises

with

engine

running

d

After

installation

check

that

mounting

brackets

and

mounting

rubbers

are

free

from

undue

stress

If

any

of

the

above

parts

is

not

installed

properly

excessive

noises

or

vibrations

may

be

transmitted

to

the

vehicle

body

e

Tightening

torque

Exhaust

manifold

to

front

tube

nut

1

9

to

2

5

kg

m

14

to

18

ft

lb

U

bolt

securing

nut

1

9

to

2

1

kg

m

14

to

15

ft

lb

Mounting

bracket

bolt

1

0

to

1

2

kg

m

710

9

ft

lb

Front

tube

mounting

bracket

bolt

california

models

1

9

to

2

1

kg

m

14

to

15

ft

lb

Catalytic

converter

to

front

and

center

tube

bolt

California

models

3

2

to

4

3

kg

m

23

to

31

ft

Ib

If

exhaust

tubes

are

separated

at

connection

t

renew

muffler

assembly

etc

use

the

Genuine

Nissan

Sealant

Exhaust

Sealant

Kit

20720

N2225

or

equivalent

See

Figure

FE

IO

to

eliminate

gas

leakage

at

the

joint

Be

sure

to

observe

the

following

Page 424 of 537

Engine

Control

Fuel

Exhaust

Systems

I

Wipe

clean

all

the

contact

por

tions

of

tube

joints

allow

them

to

dry

thoroughly

2

Temporarily

mount

in

place

muffler

assembly

as

an

assembled

unit

on

the

vehicle

3

Insert

front

tube

until

it

touches

emboss

m

b

nlfrnnjj

mm

lJ

Ij

@L

J

FE263

Fig

FE

ll

Exhawt

tube

connection

4

Torque

nut

securing

the

male

and

female

tubes

at

the

connection

Tightening

torque

is

1

6

to

2

0

kg

m

12

to

14

ft

lb

5

Squeeze

approximately

5

CC

0

31

cu

in

of

sealant

into

injection

from

sealant

tube

See

Figure

FE

12

Sealant

tube

polyethylene

Injector

Fig

FE

IO

Exhaust

sealant

kit

Be

sure

to

place

cap

back

to

sealant

tube

since

sealant

will

dry

Approximately

5

cc

0

31

Cll

in

FE1l1

Fig

FE

12

Squeezing

sealant

to

injec

tor

6

Position

nozzle

of

injector

to

the

guide

and

press

it

there

firmly

Inject

sealant

slowly

until

sealant

begins

to

flow

out

of

the

slit

of

tube

This

indicates

that

the

bead

requires

no

further

sealant

Excessive

sealant

can

cause

a

clogged

tube

See

Figure

FE

13

After

injecting

wash

injector

thoroughly

in

clean

water

to

remove

all

traces

of

sealant

FE191

Fig

FE

13

Injecting

sealant

FE

9

7

Start

engine

and

let

it

idle

slowly

for

ten

minutes

minimum

to

hilfden

sealant

with

the

heat

of

exhaust

gas

8

Check

the

condition

of

sealant

before

driving

the

vehicle

It

is

also

essential

that

the

vehicle

should

not

be

accelerated

sharply

for

20

to

30

minutes

subsequent

to

this

operation

Noles

a

The

sealant

should

be

used

within

guaranty

term

indicated

on

the

kit

case

b

Exposure

of

sealant

to

the

skin

may

cause

a

rash

Wash

sealant

off

the

skin

with

water

c

Do

not

keep

the

sealant

tube

in

a

place

where

the

ambient

tempera

ture

is

above

400C

I040F

A

sealant

hardened

above

4QoC

I040F

cannot

be

used

The

most

suitable

storage

temperature

is

from

15

to

350C

59

to

950F

If

sealant

becomes

hardened

because

of

low

temperatures

wann

the

sealant

tube

with

lukewarm

water

until

the

sealant

is

softened

Do

not

warm

tube

at

a

temperature

over

400C

1040F

for

a

long

time

d

Thoroughly

read

the

instruction

sheet

furnished

with

the

kit

before

using

the

sealant

i