ECO mode DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 6 of 537

General

Information

L

GENERAL

INFORMATION

CONTENTS

MOOEL

VARIATION

GI

3

APPROXIMATE

REFILL

CAPACITIES

GI

B

IDENTIFICATION

NUMBERS

GI

5

RECOMMENDED

FUEL

GI

B

LIFTING

POINTS

AND

TOWING

GI

B

RECOMMENDED

LUBRICANTS

GI

8

LIFTING

POINTS

GI

B

RECOMMENDED

SAE

VISCOSITY

SUPPORTABLE

POINTS

GI

7

NUMBER

GI

8

TOWING

GI

7

LUBRICANT

SPECIFICATIONS

GI

g

TIE

DOWN

GI

7

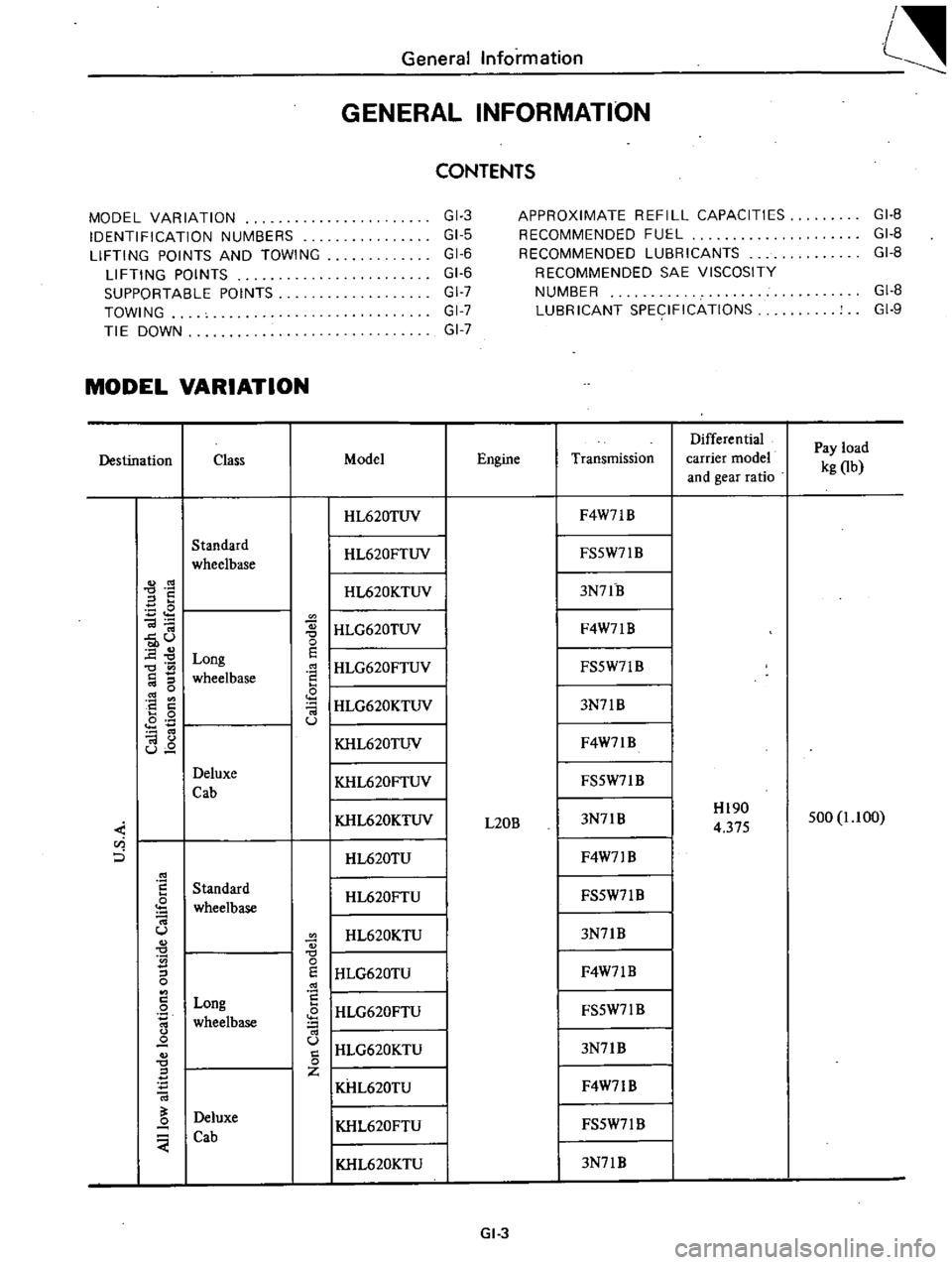

MODEL

VARIATION

Differential

Pay

load

Destination

Class

Model

Engine

Transmission

carrier

model

kg

Ob

and

gear

ratio

I

HL620TUV

F4W7lB

Standard

I

HL620FTUV

FS5W71

B

wheelbase

S

I

HL620KTUV

3N7lB

E

I

HLG620TUV

Ol

F4W7lB

u

0

0

E

Long

E

I

HLG620FTUV

0

FS5W71B

wheelbase

0

I

HLG620KTUV

8

a

3N7lB

0

Ol

0

u

I

KHL620TUV

Ol

F4W7lB

u

Deluxe

I

KHL620FTUV

FS5W7lB

Cab

KHL620KTUV

3N7lB

Hl90

500

1

1

00

L20B

4

375

u

i

0

HL620TU

F4W71

B

Standard

HL620FTU

FS5W7l

B

wheelbase

U

HL620KTU

3N7lB

S

0

I

HLG620TU

0

E

F4W7lB

0

8

Long

I

HLG620FTU

0

FS5W7lB

wheelbase

IHLG620KTU

Q

u

3N7lB

0

0

Z

KHL620TU

F4W71B

Deluxe

Q

KHL620FTU

FS5W7l

B

Cab

I

KHL620KTU

3N7lB

GI

3

Page 11 of 537

General

Information

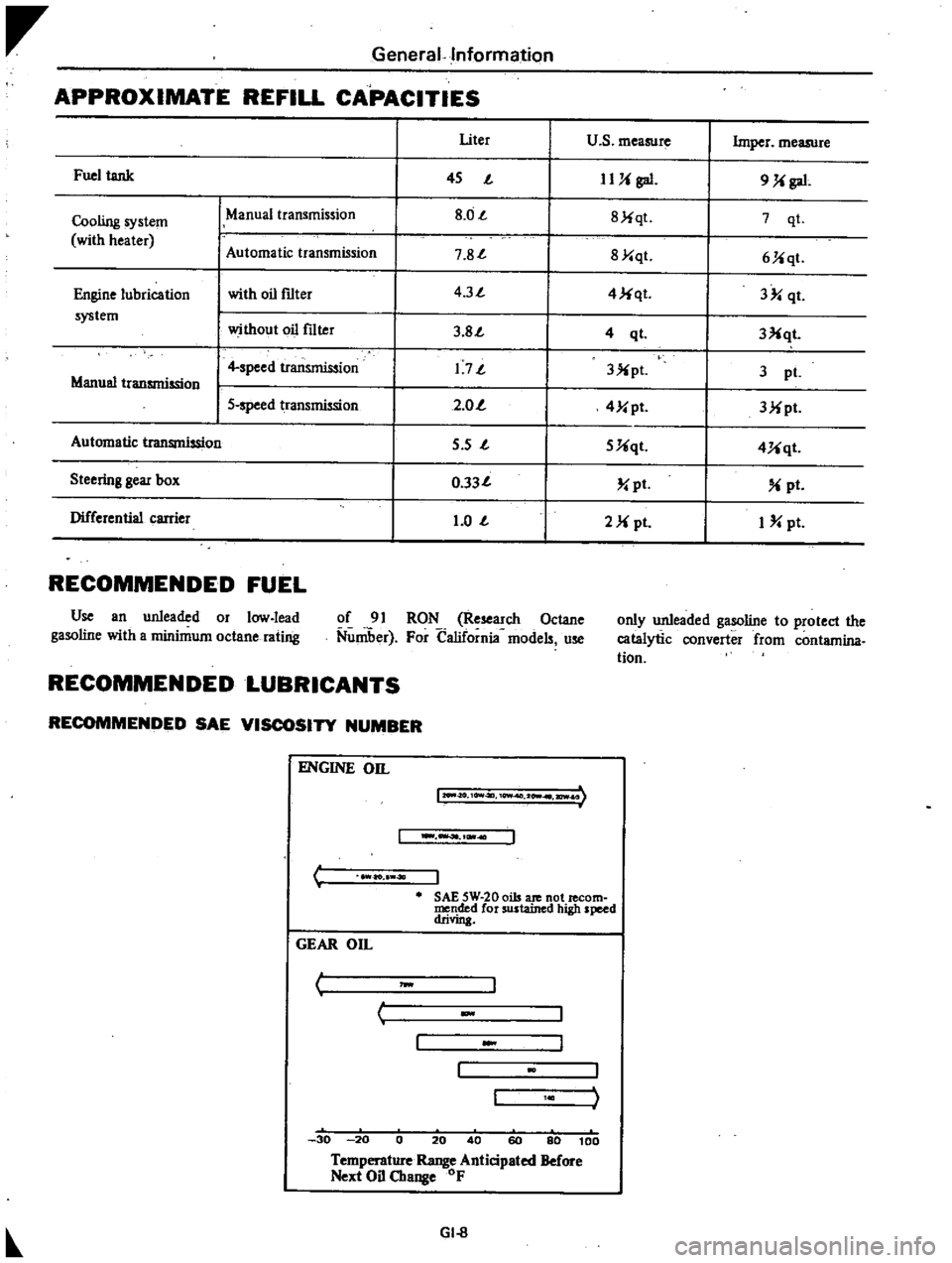

APPROXIMATE

REFILL

CAPACITIES

I

Uter

u

s

measure

Imper

measure

Fuel

tank

I

45

J

IUi

gal

9

Ji

gal

Cooling

system

ManUal

transmission

I

8

0J

I

8Jiqt

7

qt

with

heater

Automatic

tr

smission

I

7

8J

I

8Y

qt

6Jiqt

Engine

lubrication

with

oil

f1lter

I

4

3J

I

4

Ji

qt

3

qt

system

without

oil

f1lter

I

3

8J

I

3Xqt

4

ql

I

4

speed

transmission

I

1

7J

I

3X

pl

3

pI

Manual

transmission

I

5

speed

transmission

I

2

0

I

4Y

pt

3Mpt

Automatic

transmission

I

5

s

J

I

5Uqt

4Uqt

Steering

gear

box

I

0

33J

I

pt

pt

Differential

carrier

I

1

0

J

I

2M

pI

I

pt

RECOMMENDED

FUEL

Use

an

unleaded

or

low

lead

gasoline

with

a

minimum

octane

rating

of

91

RON

Research

Octane

Nuniber

For

California

models

use

only

unleaded

gasoline

to

protect

the

catalytic

converter

from

contamina

tion

RECOMMENDED

LUBRICANTS

RECOMMENDED

SAE

VISCOSITY

NUMBER

C

ENGINE

on

12O

II

O

10Vt4ll

10Wf

2

I

ICWI

I

ao

40

J

SAE

5W

20

oils

ate

not

lecom

mended

for

sustained

high

speed

drivin

GEAR

On

I

J

w

c

30

20

0

20

40

60

80

100

Temperature

Range

Anticipated

Before

Next

Oil

Change

OF

GI

8

Page 23 of 537

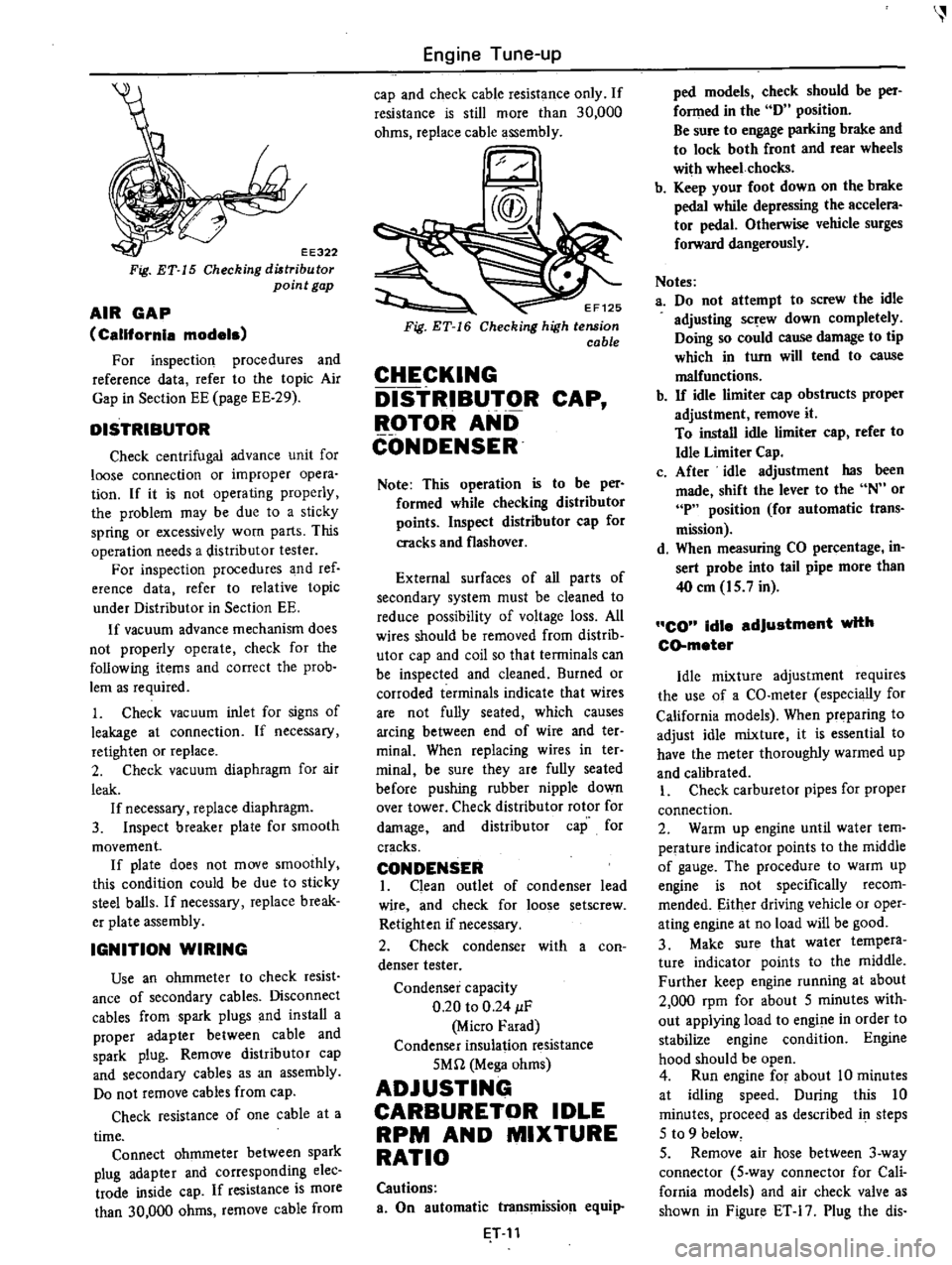

EE322

Fig

ET

15

Checking

diltribu

tor

point

gap

AIR

GAP

California

models

For

inspection

procedures

and

reference

data

refer

to

the

topic

Air

Gap

in

Section

EE

page

EE

29

DISTRIBUTOR

Check

centrifugal

advance

unit

for

loose

connection

or

improper

opera

tion

If

it

is

not

operating

properly

the

problem

may

be

due

to

a

sticky

spring

or

excessively

worn

parts

This

operation

needs

a

distributor

tester

For

inspection

procedures

and

ref

erence

data

refer

to

relative

topic

under

Distributor

in

Section

EE

If

vacuum

advance

mechanism

does

not

properly

operate

check

for

the

following

items

and

correct

the

prob

lem

as

required

1

Check

vacuum

inlet

for

signs

of

leakage

at

connection

If

necessary

retighten

or

replace

2

Check

vacuum

diaphragm

for

air

leak

If

necessary

replace

diaphragm

3

Inspect

breaker

plate

for

smooth

movement

If

plate

does

not

move

smoothly

this

condition

could

be

due

to

sticky

steel

balls

If

necessary

replace

break

er

plate

assembly

IGNITION

WIRING

Use

an

ohmmeter

to

check

resist

ance

of

secondary

cables

Disconnect

cables

from

spark

plugs

and

install

a

proper

adapter

between

cable

and

spark

plug

Remove

distributor

cap

and

secondary

cables

as

an

assembly

Do

not

remove

cables

from

cap

Check

resistance

of

one

cable

at

a

time

Connect

ohmmeter

between

spark

plug

adapter

and

corresponding

elec

trade

inside

cap

If

resistance

is

more

than

30

000

ohms

remove

cable

from

Engine

Tune

up

cap

and

check

cable

resistance

only

If

resistance

is

still

more

than

30

000

ohms

replace

cable

assembly

EF125

Checking

high

tension

cable

CHECKING

DISTRIBUTOR

CAP

ROTOR

AND

CONDENSER

Note

This

operation

is

to

be

per

formed

while

checking

distributor

points

Inspect

distributor

cap

for

cracks

and

flashover

External

surfaces

of

all

parts

of

secondary

system

must

be

cleaned

to

reduce

possibility

of

voltage

loss

All

wires

should

be

removed

from

distrib

utor

cap

and

coil

so

that

terminals

can

be

inspected

and

cleaned

Burned

or

corroded

terminals

indicate

that

wires

are

not

fully

seated

which

causes

arcing

between

end

of

wire

and

ter

minal

When

replacing

wires

in

ter

minai

be

sure

they

are

fully

seated

before

pushing

rubber

nipple

down

over

tower

Check

distributor

rotor

for

damage

and

distributor

cap

for

cracks

CONDENSER

I

Clean

outlet

of

condenser

lead

wire

and

check

for

loose

setscrew

Retighten

if

necessary

2

Check

condenser

with

a

con

denser

tester

Condenser

capacity

0

20

to

0

24

IF

Micro

Farad

Condenser

insulation

resistance

5Mn

Mega

ohms

ADJUSTING

CARBURETOR

IDLE

RPM

AND

MIXTURE

RATIO

Cautions

a

On

automatic

transmission

equip

T

11

ped

models

check

should

be

per

fonned

in

the

D

position

Be

sure

to

engage

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Keep

your

foot

down

on

the

brake

pedal

while

depressing

the

accelera

tor

pedal

Otherwise

vehicle

surges

forward

dangerously

Notes

a

Do

not

attempt

to

screw

the

idle

adjusting

sc

ew

down

completely

Doing

so

could

cause

damage

to

tip

which

in

turn

will

tend

to

cause

malfunctions

b

If

idle

limiter

cap

obstructs

proper

adjustment

remove

it

To

install

idle

limiter

cap

refer

to

Idle

Limiter

Cap

c

After

idle

adjustment

has

been

made

shift

the

lever

to

the

N

or

P

position

for

automatic

trans

mission

d

When

measuring

CO

percentage

in

sert

probe

into

tail

pipe

more

than

40

em

15

7

in

CO

idle

adjustment

with

CD

meter

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

especially

for

California

models

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

up

and

calibrated

I

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tem

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

tempera

ture

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

with

out

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceeq

as

described

i

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

models

and

air

check

valve

as

shown

in

Figure

ET

17

Plug

the

dis

Page 24 of 537

r

connected

hose

to

prevent

dust

from

entering

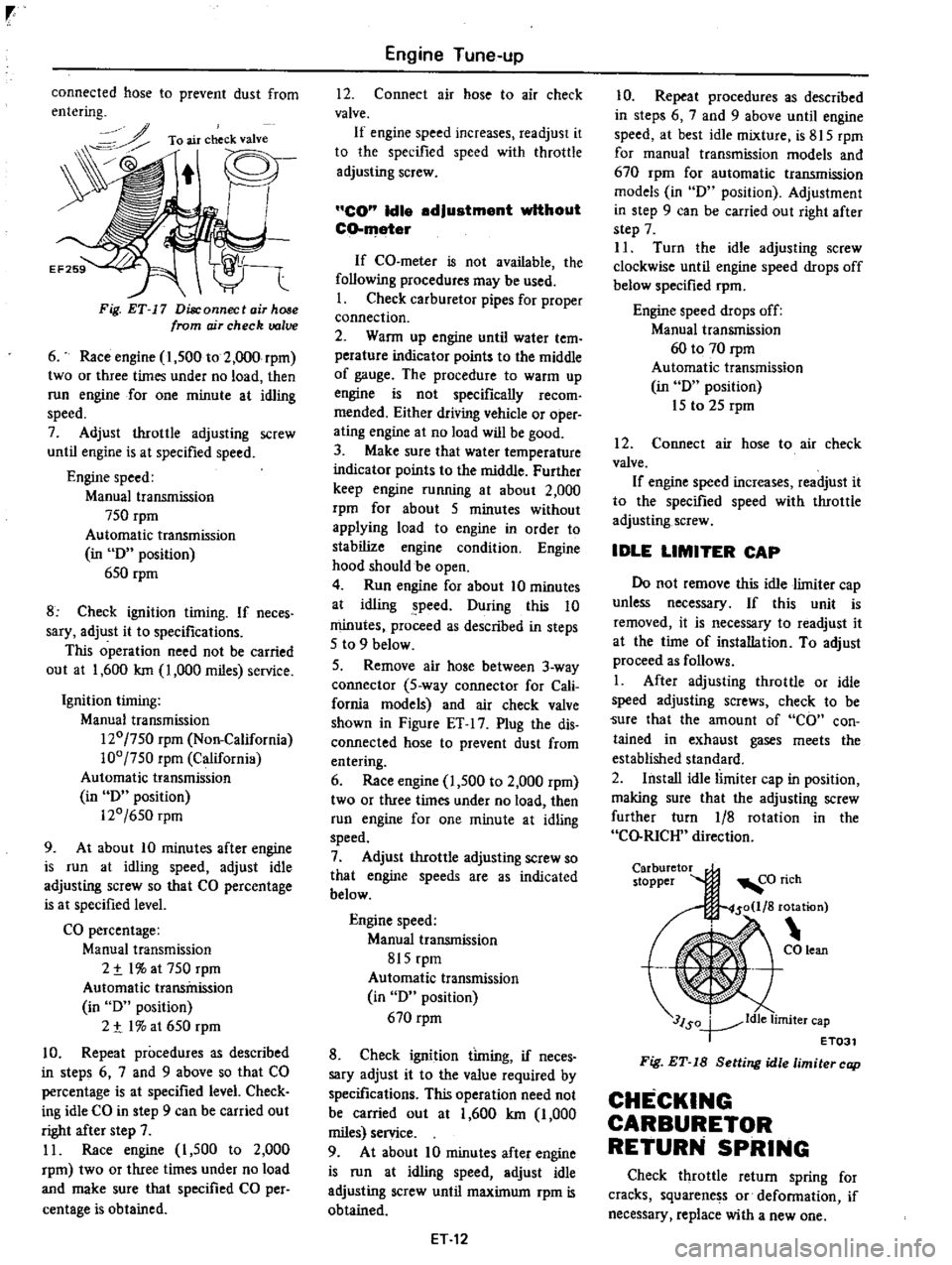

To

air

check

valve

Fig

ET

17

Disconnect

air

hose

from

ojr

check

valve

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

until

engine

is

at

specified

speed

Engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

D

position

650

rpm

8

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

Ignition

timing

Manual

transmission

120

750

rpm

Non

California

100

750

rpm

California

Automatic

transmission

in

D

position

120

650

rpm

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

I

at

750

rpm

Automatic

transmission

in

D

position

2

t

I

at

650

rpm

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

9

can

be

carried

out

right

after

step

7

11

Race

engine

I

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

Engine

Tune

up

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

CO

Idle

adjustment

without

CO

meter

If

CO

meter

is

not

available

the

following

procedures

may

be

used

I

Check

carburetor

pipes

for

proper

connection

2

Wann

up

engine

until

water

tern

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

peed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

modeis

and

air

check

valve

shown

in

Figure

ET

17

Plug

the

dis

connected

hose

to

prevent

dust

from

entering

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

so

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

transmission

815

rpm

Automatic

transmission

in

D

position

670

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

ET

12

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

until

engine

speed

at

best

idle

mixture

is

815

rpm

for

manual

transmission

models

and

670

rpm

for

automatic

transmission

models

in

D

position

Adjustment

in

step

9

can

be

carried

out

right

after

step

7

II

Turn

the

idle

adjusting

screw

clockwise

until

engine

speed

drops

off

below

specified

rpm

Engine

speed

drops

off

Manual

transmission

60

to

70

rpm

Automatic

transmission

in

D

position

15

to

25

rpm

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

IDLE

LIMITER

CAP

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

removed

it

is

necessary

to

readjust

it

at

the

time

of

installation

To

adjust

proceed

as

follows

1

After

adjusting

throttle

or

idle

speed

adjusting

screws

check

to

be

Sure

that

the

amount

of

CO

con

tained

in

exhaust

gases

meets

the

established

standard

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

further

turn

1

8

rotation

in

the

CO

RICH

direction

Carburetor

stopper

3lSo

ldle

limiter

cap

T

ET031

Fig

ET

18

Setting

idle

limiter

cap

CHECKING

CARBURETOR

RETURN

SPRING

Check

throttle

return

spring

for

cracks

squarene

s

or

defonnation

if

necessary

replace

with

a

new

one

Page 30 of 537

r

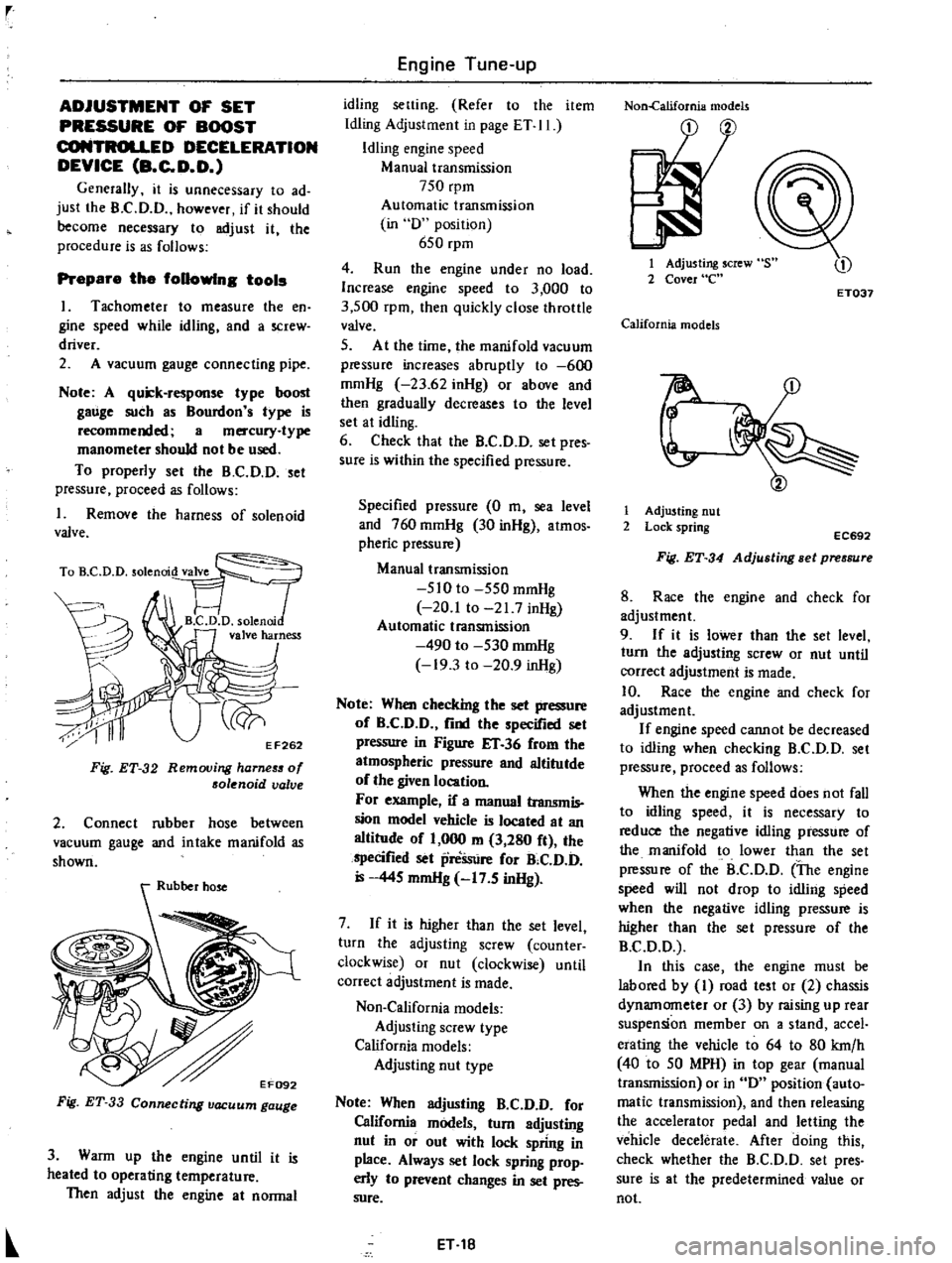

ADJUSTMENT

OF

SET

PRESSURE

OF

BOOST

CONTROLLED

DECELERATION

DEVICE

B

C

D

D

Generally

it

is

unnecessary

to

ad

just

the

B

C

D

D

however

if

it

should

become

necessary

to

adjust

it

the

procedure

is

as

follows

Prepare

the

foUowlnB

tools

I

Tachometer

to

measure

the

en

gine

speed

while

idling

and

a

screw

driver

2

A

vacuum

gauge

connecting

pipe

Note

A

qui

k

response

type

boost

gauge

such

as

Bourdon

s

type

is

recommended

a

mercury

type

manometer

should

not

be

used

To

properly

set

the

B

C

D

D

set

pressure

proceed

as

follows

I

Remove

the

harness

of

solenoid

valve

TO

D

D

solenrod

VT

FJ

1

B

C

D

D

solenni

valve

harness

J

ri

y

EF262

F

g

ET

32

Removing

harneS5

of

solenoid

valve

2

Connect

rubber

hose

between

vacuum

gauge

and

intake

manifold

as

shown

Fig

ET

33

Connecting

vacuum

gauge

3

Warm

up

the

engine

until

it

is

heated

to

operating

temperature

Then

adjust

the

engine

at

normal

Engine

Tune

up

idling

setting

Refer

to

the

item

Idling

Adjustment

in

page

ET

II

Idling

engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

D

position

650

rpm

4

Run

the

engine

under

no

load

Increase

engine

speed

to

3

000

to

3

500

rpm

then

quickly

close

throttle

valve

5

At

the

time

the

manifold

vacuum

pressure

increases

abruptly

to

600

mmHg

23

62

inHg

or

above

and

then

gradually

decreases

to

the

level

set

at

idling

6

Check

that

the

B

C

D

D

set

pres

sure

is

within

the

specified

pressure

Specified

pressure

0

m

sea

level

and

760

mmHg

30

inHg

atmos

pheric

pressure

Manual

transmission

510

to

550

mmHg

20

1

to

21

7

inHg

Automatic

transmission

490

to

530

mmHg

19

3

to

20

9

inHg

Note

When

checking

the

set

pressure

of

B

C

D

D

find

the

specified

set

pressure

in

Figure

IT

36

from

the

atmospheric

pressure

and

altitutde

of

the

given

location

For

example

if

a

manual

transmis

sion

model

vehicle

is

located

at

an

altitude

of

1

000

m

3

280

ft

the

specified

set

preSsure

for

B

C

D

D

445

mmHg

17

5

inHg

7

If

it

is

higher

than

the

set

level

turn

the

adjusting

screw

counter

clockwise

or

nut

clockwise

until

correct

adjustment

is

made

Non

California

models

Adjusting

screw

type

California

models

Adjusting

nut

type

Note

When

adjusting

B

C

D

D

for

California

models

turn

adjusting

nut

in

or

out

with

lock

spring

in

place

Always

set

lock

spring

prop

erly

to

prevent

changes

in

set

pres

sure

ET

18

Non

california

models

1

Adjusting

screw

2

Cover

e

ET037

California

models

r

1

Adjusting

nut

2

Lock

spring

EC692

Fig

ET

34

Adjusting

Bet

pressure

8

Race

the

engine

and

check

for

adjustment

9

If

it

is

lower

than

the

set

level

turn

the

adjusting

screw

or

nut

until

correct

adjustment

is

made

10

Race

the

engine

and

check

for

adjustment

If

engine

speed

cannot

be

decreased

to

idling

when

checking

B

C

D

D

set

pressure

proceed

as

follows

When

the

engine

speed

does

not

fall

to

idling

speed

it

is

necessary

to

reduce

the

negative

idling

pressure

of

the

manifold

to

lower

than

the

set

pressure

of

the

B

C

D

D

The

engine

speed

will

not

drop

to

idling

speed

when

the

negative

idling

pressure

is

higher

than

the

set

pressure

of

the

B

C

D

D

In

this

case

the

engine

must

be

labored

by

I

road

test

or

2

chassis

dynamometer

or

3

by

raising

up

rear

suspension

member

on

a

stand

accel

erating

the

vehicle

to

64

to

80

krn

h

40

to

50

MPH

in

top

gear

manual

transmission

or

in

D

position

auto

matic

transmission

and

then

releasing

the

accelerator

pedal

and

letting

the

vehicle

decelerate

After

doing

this

check

whether

the

B

C

D

D

set

pres

sure

is

at

the

predetermined

value

or

not

Page 33 of 537

Ignition

Switch

Position

START

Detector

Drive

Counter

E

G

R

Warning

Lamp

ON

a

After

completing

inspection

of

E

G

R

control

system

be

sure

to

reset

odometer

of

detector

drive

counter

to

zero

b

This

item

applies

to

620

models

except

those

bound

for

California

and

Canada

3

With

engine

stopped

inspect

E

G

R

control

valve

for

any

indication

of

binding

or

sticking

by

movirig

dia

phragm

of

control

valve

upwards

with

fmgers

Engine

Tune

up

ON

Below

50

000

counts

Above

50

000

counts

OFF

ON

4

With

engine

running

inspect

E

G

R

control

valve

and

thermal

vacu

um

valve

for

normal

operation

I

When

engine

coolant

tempera

ture

is

low

Make

sure

that

E

G

R

control

valve

does

not

operate

when

engine

speed

is

increased

from

idling

to

3

000

to

3

500

rpm

Place

fingers

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

When

engine

coolant

tempera

ture

is

high

I

Make

sure

that

E

G

R

control

valve

operates

when

engine

speed

is

in

creased

from

idling

to

3

000

to

3

500

rpm

Place

fingers

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

If

E

G

R

control

valve

does

not

operate

check

as

follows

Disconnect

one

end

E

G

R

control

valve

side

ofvacuum

hose

connect

ing

thermal

vacuum

valve

to

E

G

R

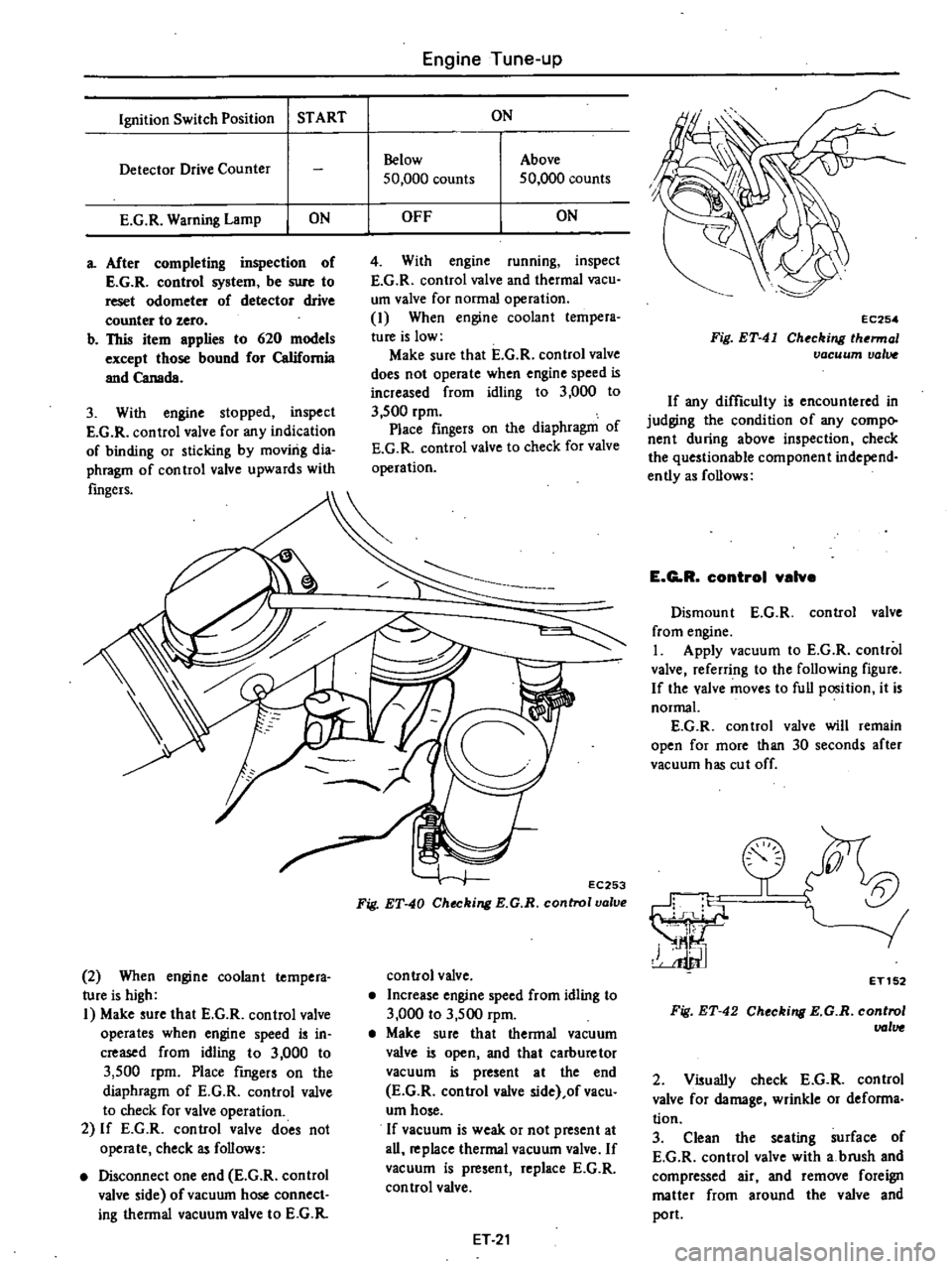

EC253

Fig

ET

40

Checking

E

G

R

control

valve

control

valve

Increase

engine

speed

from

idling

to

3

000

to

3

500

rpm

Make

sure

that

thermal

vacuum

valve

is

open

and

that

carburetor

vacuum

is

present

at

the

end

E

G

R

control

valve

side

ofvacu

urn

hose

If

vacuum

is

weak

or

not

present

at

all

replace

thermal

vacuum

valve

If

vacuum

is

present

replace

E

G

R

con

trol

valve

ET

21

EC254

Fig

ET

41

Checking

thermal

vacuum

valw

If

any

difficulty

is

encountered

in

judging

the

condition

of

any

compo

nent

during

above

inspection

check

the

questionable

component

independ

ently

as

follows

E

G

R

control

valve

Dismount

E

G

R

control

valve

from

engine

I

Apply

vacuum

to

E

G

R

control

valve

referring

to

the

following

figure

If

the

valve

moves

to

full

position

it

is

normal

E

G

R

control

valve

will

remain

open

for

more

than

30

seconds

after

vacuum

has

cut

off

0

r11

hC

J

ET152

Fig

ET

42

Checking

E

G

R

control

VGlve

2

Visually

check

E

G

R

control

valve

for

damage

wrinkle

or

deforma

tion

3

Clean

the

seating

surface

of

E

G

R

control

valve

with

a

brush

and

compressed

air

and

remove

foreign

matter

from

around

the

valve

and

port

Page 71 of 537

30

Install

heatshieid

plate

on

mani

fold

assembly

31

Install

air

gallery

pipe

on

ex

haust

manifold

32

Install

manifold

gasket

and

manifold

assembly

on

cylinder

head

Tightening

torque

1

2to

1

6kg

m

8

7

to

11

6

ft

lb

33

Install

blow

by

gas

pipe

on

cyl

inder

block

and

tighten

with

rear

engine

slinger

34

Install

thermostat

housing

gas

ket

thermostat

housing

and

thermo

stat

35

Install

thermal

vacuum

valve

on

thermostat

housing

Before

installing

apply

a

liquid

packing

slightly

to

the

threads

36

Install

FJ

C

D

bracket

on

cylin

der

head

37

Install

E

G

R

passage

and

E

G

R

valve

on

intake

manifold

38

Connect

E

G

R

tube

to

E

G

R

tube

and

exhaust

manifold

39

Install

check

valve

on

air

gallery

pipe

40

Install

air

cleaner

bracket

on

intake

manifold

41

Install

air

control

valve

on

air

cleaner

bracket

California

models

42

Install

vacuum

and

fuel

tubes

combined

on

cylinder

head

43

Install

distributor

assembly

44

Install

heatshield

plate

joint

seat

and

carburetor

Carbure10r

tightening

torque

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lb

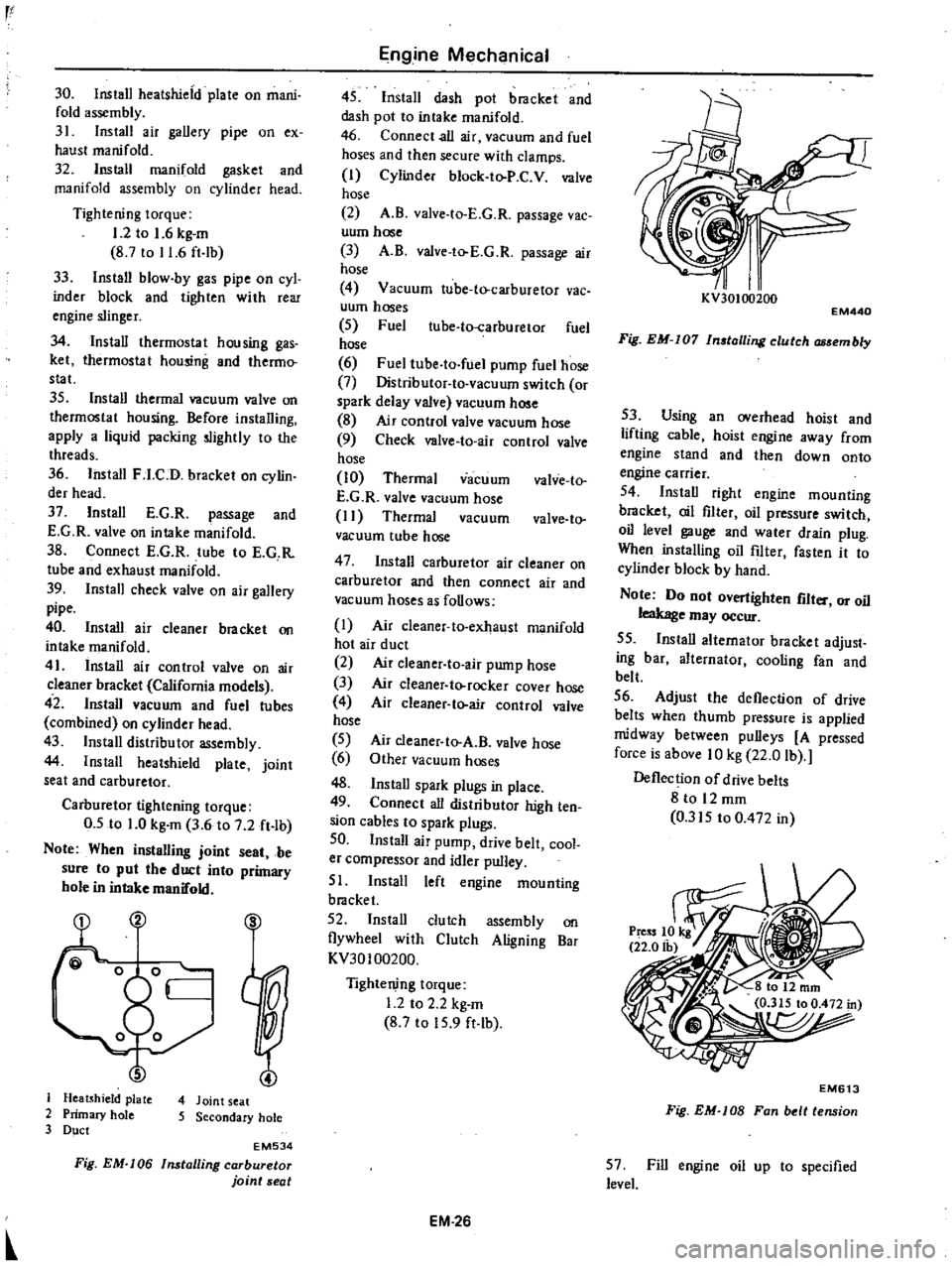

Note

When

instalUng

joint

seat

be

sure

to

put

the

duct

into

primary

hole

in

intake

manifold

S

J

Heatshield

plate

4

Joint

seat

2

Primary

hole

5

Secondary

hole

3

Duct

EM534

Fig

EM

I06

Installing

carburetor

joint

seat

Engine

Mechanical

45

Install

dash

pot

bracket

and

dash

pot

to

intake

manifold

46

Connect

all

air

vacuum

and

fuel

hoses

and

then

secure

with

clamps

I

Cylinder

block

to

P

C

V

valve

hose

2

A

B

valve

to

E

G

R

passage

vac

uum

hose

3

A

B

valve

to

E

G

R

passage

air

hose

4

Vacuum

tube

to

carburetor

vac

uum

hoses

5

Fuel

ube

to

carburetor

fuel

hose

6

Fuel

tube

to

fuel

pump

fuelhose

7

Distributor

to

vacuum

switch

or

spark

delay

valve

vacuum

hose

8

Air

control

valve

vacuum

hose

9

Check

valve

to

air

control

valve

hose

10

Thermal

vacuum

valve

to

E

G

R

valve

vacuum

hose

I

I

Thermal

vacuum

valve

to

vacuum

tube

hose

47

Install

carburetor

air

cleaner

on

carburetor

and

then

connect

air

and

vacuum

hoses

as

follows

I

Air

cleaner

to

exhaust

manifold

hot

air

duct

2

Air

c1eaner

to

air

pump

hose

3

Air

cleaner

to

rocker

cover

hose

4

Air

cleaner

to

air

control

valve

hose

5

6

48

Install

spark

plugs

in

place

49

Connect

all

distributor

high

ten

sion

cables

to

spark

plugs

50

Install

air

pump

drive

belt

cool

er

compressor

and

idler

pulley

51

Install

left

engine

mounting

bracket

52

Install

clutch

assembly

on

flywheel

with

Clutch

Aligning

Bar

KV30100200

Air

cleaner

to

A

B

valve

hose

Other

vacuum

hoses

Tightening

torque

1

2

to

2

2

kg

m

8

7

to

15

9

ft

lb

EM

26

I

I

KV30100200

EM440

Fig

EM

I07

In

talling

clutch

embly

53

Using

an

overhead

hoist

and

lifting

cable

hoist

engine

away

from

engine

stand

and

then

down

onto

engine

carrier

54

Install

right

engine

mounting

bracket

oil

filter

oil

pressure

switch

oil

level

gauge

and

water

drain

plug

When

installing

oil

filter

fasten

it

to

cylinder

block

by

hand

Note

Do

not

overtighten

flit

or

oil

leakage

may

occur

55

Install

alternator

bracket

adjust

ing

bar

alternator

cooling

fan

and

belt

56

Adjust

the

deflection

of

drive

belts

when

thumb

pressure

is

applied

midway

between

pulleys

A

pressed

force

is

above

10

kg

22

0

lb

Deflection

of

drive

belts

8

to

12

mm

0

315

to

0

472

in

EM613

Fig

EM

lOB

Fan

belt

tension

57

Fill

engine

oil

up

to

specified

level

Page 102 of 537

r

AIR

CLEANER

1

Loosen

bolts

securing

air

cleaner

to

air

cleaner

bracket

2

Loosen

air

cleaner

lock

bolt

and

remove

air

cleaner

from

carburetor

Disconnect

the

following

hoses

when

dismounting

air

cleaner

Under

hood

air

inlet

hose

Hot

air

inlet

hose

Vacuum

hose

Sensor

to

intake

manifold

Vacuum

hose

Sensor

to

vacuum

motor

Vacuum

hose

Idle

compensator

to

intake

manifold

Hose

Air

pump

to

air

cleaner

Hose

AB

valve

to

air

cleaner

Hose

Carburetor

to

air

cleaner

Blow

by

hose

Air

cleaner

to

rocker

cover

Hose

Air

control

vaive

to

air

cleaner

California

models

only

3

To

install

reverse

the

removal

procedure

INSPECTION

1

AIR

CLEANER

ELEMENT

Viscous

paper

type

air

cleaner

ele

ment

does

not

require

any

cleaning

operation

until

it

is

replaced

periodi

cally

Brushing

or

blasting

operation

will

cause

clogging

and

result

in

enrich

ment

of

carburetor

mixture

and

should

never

be

conducted

For

reo

placement

interval

of

air

cleaner

ele

ment

refer

to

Maintenance

Sched

ule

2

HOT

AIR

CONTROL

SYSTEM

In

warm

weather

it

is

difficult

to

find

out

malfunction

of

hot

air

control

system

In

cold

wea

thee

however

malfunction

of

air

control

valve

due

to

disconnection

or

deterioration

of

vacu

um

hose

between

intake

manifold

and

vacuum

motor

and

insufficient

dura

bility

of

air

control

valve

will

cause

insufficient

automatic

control

opera

tion

for

intake

air

and

result

in

engine

disorder

including

I

Stall

or

hesitation

of

engine

oper

ation

2

Increase

in

fuel

consumption

3

uck

of

power

Engine

Fuel

These

phenomena

reveal

malfunc

tion

of

hot

air

control

system

If

these

phenomena

should

occur

check

hot

air

control

system

as

described

in

the

following

before

carrying

out

inspec

tion

of

carburetor

2

1

Vacuum

hose

Intake

manifold

to

3

way

connec

tor

3

way

connector

to

temperature

sensor

3

way

connector

to

idle

com

pensator

temperature

sensor

to

vacu

um

motor

I

Check

that

vacuum

hoses

are

se

curely

connected

in

correct

postion

2

Check

each

hose

for

cracks

or

distortion

hose

clip

for

condition

Note

Vacuum

hose

position

R

H

side

of

Nissan

mark

on

the

top

of

sensor

is

for

intake

manifold

L

U

side

of

the

mark

is

for

vacuum

motor

2

2

Vacuum

motor

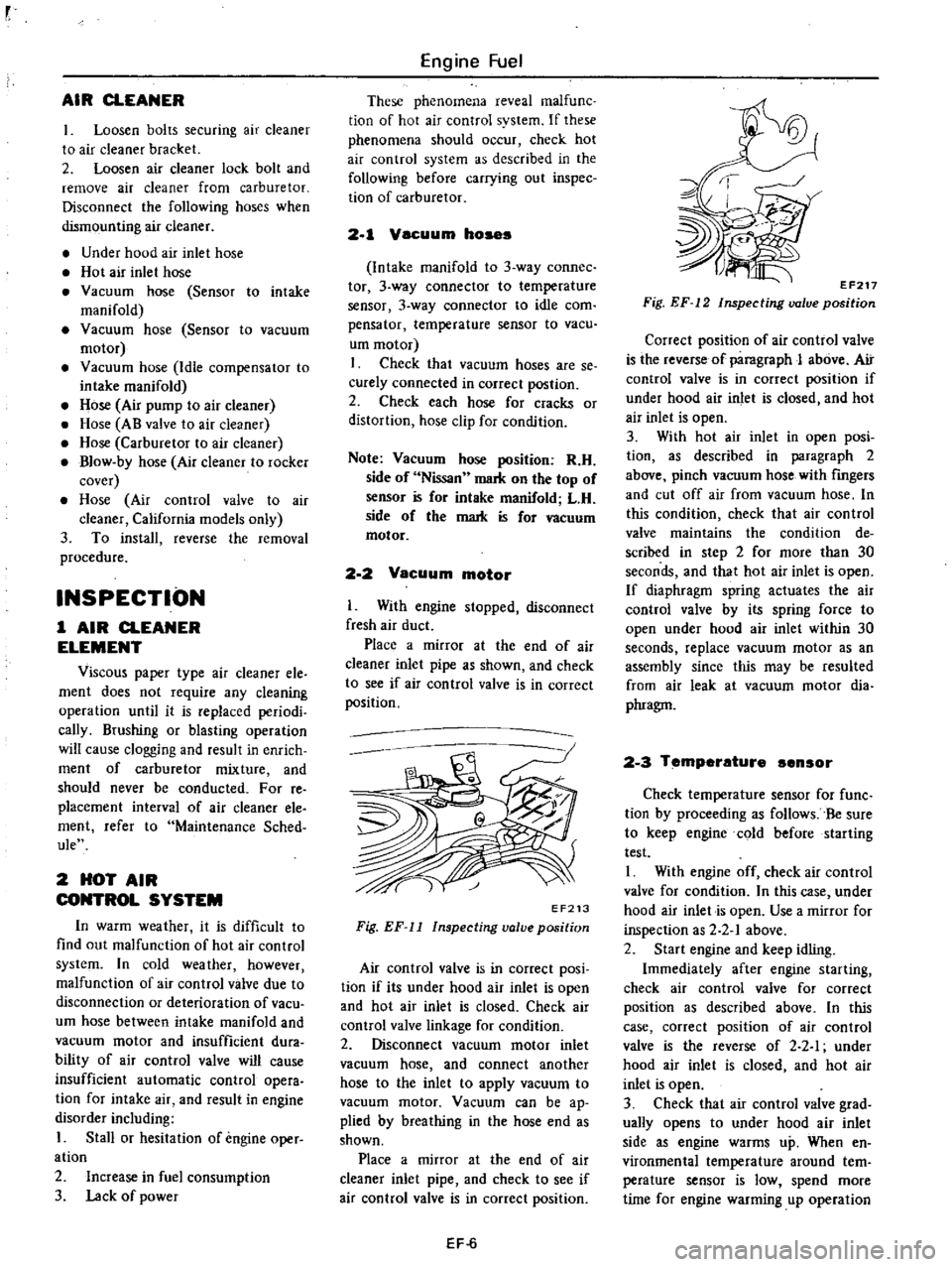

I

With

engine

stopped

disconnect

fresh

air

duct

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

as

shown

and

check

to

see

if

air

con

trol

valve

is

in

correct

position

EF213

Fig

EF

11

Inspecting

valve

position

Air

control

valve

is

in

correct

posi

tion

if

its

under

hood

air

inlet

is

open

and

hot

air

inlet

is

closed

Check

air

control

valve

linkage

for

condition

2

Disconnect

vacuum

motor

inlet

vacuum

hose

and

connect

another

hose

to

the

inlet

to

apply

vacuum

to

vacuum

motor

Vacuum

can

be

ap

plied

by

breathing

in

the

hose

end

as

shown

Place

a

mirror

at

the

end

of

air

cleaner

inlet

pipe

and

check

to

see

if

air

control

valve

is

in

correct

position

EF

6

EF217

Fig

EF

12

Inspecting

valve

position

Correct

position

of

air

control

valve

is

the

reverse

of

paragraph

J

above

Air

control

valve

is

in

correct

position

if

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

With

hot

air

inlet

in

open

posi

tion

as

described

in

paragraph

2

above

pinch

vacuum

hose

with

fingers

and

cut

off

air

from

vacuum

hose

In

this

condition

check

that

air

control

valve

maintains

the

condition

de

scribed

in

step

2

for

more

than

30

seconds

and

that

hot

air

inlet

is

open

If

diaphragm

spring

actuates

the

air

control

valve

by

its

spring

force

to

open

under

hood

air

inlet

within

30

seconds

replace

vacuum

motor

as

an

assembly

since

this

may

be

resulted

from

air

leak

at

vacuum

motor

dia

phragm

2

3

Temperature

ensor

Check

temperature

sensor

for

func

tion

by

proceeding

as

follows

Be

sure

to

keep

engine

cold

before

starting

test

I

With

engine

off

check

air

control

valve

for

condition

In

this

case

under

hood

air

inlet

is

open

Use

a

mirror

for

inspection

as

2

2

1

above

2

Start

engine

and

keep

idling

Immediately

after

engine

starting

check

air

control

valve

for

correct

position

as

described

above

In

this

case

correct

position

of

air

control

valve

is

the

reverse

of

2

2

I

under

hood

air

inlet

is

closed

and

hot

air

inlet

is

open

3

Check

that

air

control

valve

grad

ually

opens

to

under

hood

air

inlet

side

as

engine

warms

up

When

en

vironmental

temperature

around

tern

perature

sensor

is

low

spend

more

time

for

engine

warming

up

operation

Page 107 of 537

3

Check

diaphragm

for

small

holes

carcks

or

wear

4

Check

rocker

arm

for

wear

at

the

mating

portion

with

camshaft

5

Check

rocker

arm

pin

for

wear

A

worn

pin

may

cause

oil

leakage

6

Check

all

other

components

for

any

abnormalities

and

replace

if

neces

sary

DESCRIPTION

INSPECTION

REMOVAL

AND

INSTALLATION

DESCRIPTION

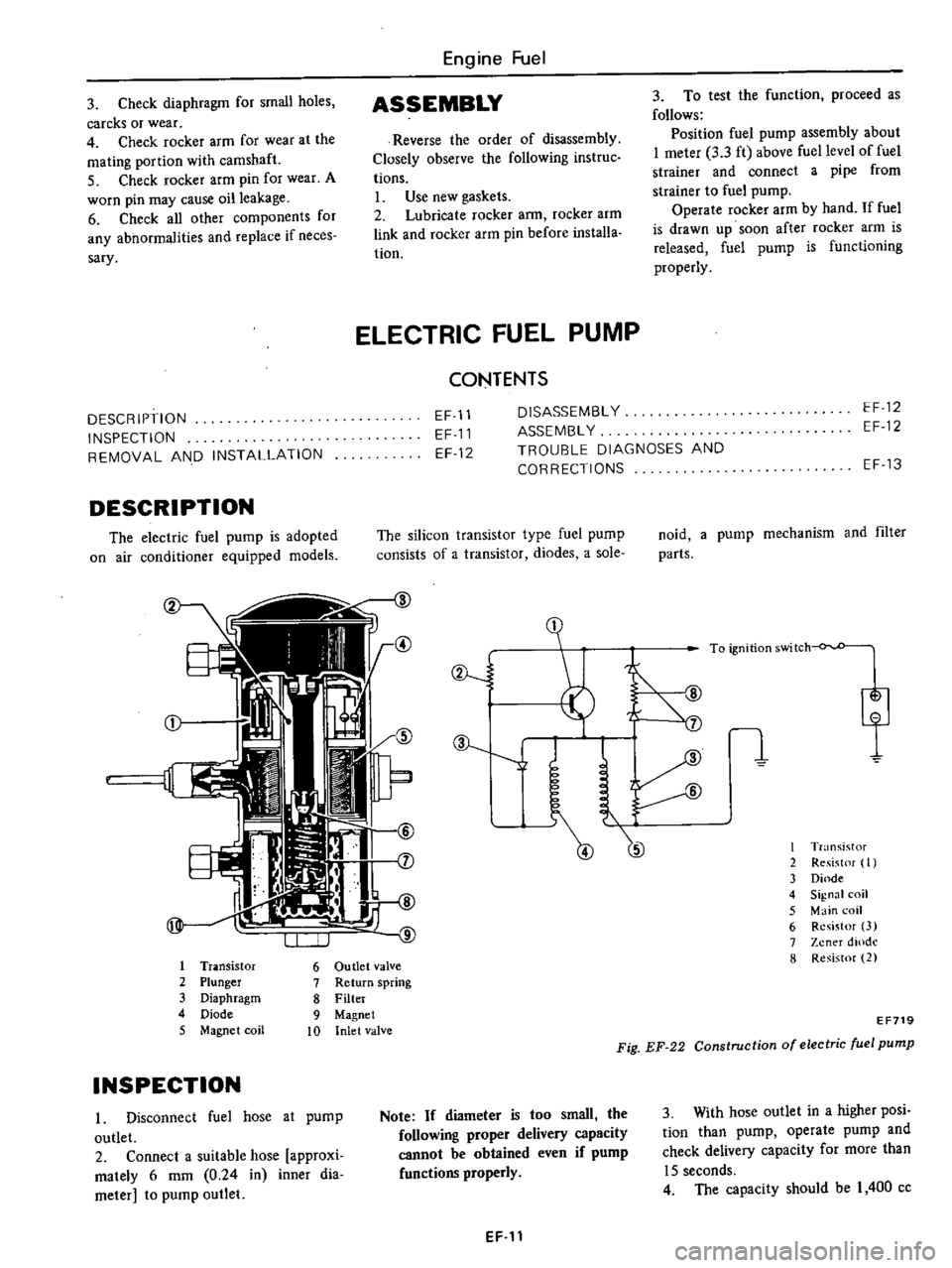

The

electric

fuel

pump

is

adopted

on

air

conditioner

equipped

models

Engine

Fuel

ASSEMBLY

Reverse

the

order

of

disassembly

Closely

observe

the

following

instruc

tions

L

Use

new

gaskets

2

Lubricate

rocker

ann

rocker

arm

link

and

rocker

arm

pin

before

installa

tion

3

To

test

the

function

proceed

as

follows

Position

fuel

pump

assembly

about

I

meter

3

3

ft

above

fuel

level

of

fuel

strainer

and

connect

a

pipe

from

strainer

to

fuel

pump

Operate

rocker

arm

by

hand

If

fuel

is

drawn

up

soon

after

rocker

arm

is

released

fuel

pump

is

functioning

properly

ELECTRIC

FUEL

PUMP

CONTENTS

EF

11

EF

11

EF

12

DISASSEMBL

Y

ASSEMBL

Y

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EF

12

EF

12

The

silicon

transistor

type

fuel

pump

consists

of

a

transistor

diodes

a

sole

I

Tr

lOsistor

6

Ou

tIet

valve

2

Plunger

7

Return

spring

3

Diaphragm

8

Filter

4

Diode

9

Magnet

5

Magnet

coil

10

Inlet

valve

INSPECTION

I

Disconnect

fuel

hose

at

pump

outlet

2

Connect

a

suitable

hose

approxi

mately

6

mm

0

24

in

inner

dia

meter

to

pump

outlet

ev

J

J

Note

If

diameter

is

too

small

the

following

proper

delivery

capacity

cannot

be

obtained

even

if

pump

functions

properly

EF

11

EF

13

noid

a

pump

mechanism

and

filter

parts

I

T

nsistor

2

Re

ist

f

I

3

Dinde

4

Signal

coil

5

Main

coil

6

Resistor

3

7

Zener

dlOdl

8

Resistor

2

EF719

Fig

EF

22

Construction

of

electric

fuel

pump

3

With

hose

outlet

in

a

higher

posi

tion

than

pump

operate

pump

and

check

delivery

capacity

for

more

than

15

seconds

4

The

capacity

should

be

I

400

cc

Page 110 of 537

Engine

Fuel

CARBURETOR

CONTENTS

DESCRIPTION

EF

14

CHOKE

UNLOADER

EF

23

STRUCTURE

AND

OPERATION

EF

14

ELECTRIC

AUTOMATIC

CHOKE

EF

24

PRIMARY

SYSTEM

EF

15

INTERLOCK

OPENING

OF

PRIMARY

AND

SECONDARY

SYSTEM

EF

16

SECONDARY

THROTTLE

VALVE

EF

24

ANTI

DIESELING

SYSTEM

EF

17

DASH

POT

EF

25

FLOAT

SYSTEM

EF

18

ACCELERATING

PUMP

EF

25

BOOST

CONTROLLED

DECELERATION

ANTI

DIESELING

SOLENOID

VALVE

EF

25

DEVICE

B

C

D

D

EF

1B

B

C

D

D

CIRCUIT

WITH

FUNCTION

ELECTRIC

AUTOMATIC

CHOKE

EF

20

TEST

CONNECTOR

EF

25

DASH

POT

SYSTEM

EF

20

ALTITUDE

COMPENSATOR

ALTITUDE

COMPENSATOR

California

modelsl

EF

29

California

models

EF

20

MAJOR

SERVICE

OPERATION

EF

29

ADJUSTMENT

AND

INSPECTION

EF

21

REMOVAL

EF

29

CARBURETOR

IDLE

RPM

AND

DISASSEMBLY

AND

ASSEMBLY

EF

30

MIXTURE

RATIO

EF

21

CLEANING

AND

INSPECTION

EF

34

FUEL

LEVEL

EF

22

SERVICE

DATA

AND

SPECIFICATIONS

EF

35

FAST

IDLE

EF

22

TROU8LE

DIAGNOSES

AND

VACUUM

BREAK

EF

23

CORRECTIONS

EF

36

DESCRIPTION

The

carburetors

are

of

down

draft

two

barrel

types

which

produce

the

optimum

air

fuel

mixture

under

all

operating

conditions

They

present

several

distinct

features

of

importance

to

the

vehicle

owners

A

summary

of

the

features

is

as

follows

1

A

slow

economizer

to

make

a

smooth

connection

with

acceleration

or

deceleration

during

light

load

run

ning

It

also

assures

stable

low

speed

performance

2

An

idle

limiter

to

reduce

harmful

exhaust

emissions

to

a

minimum

3

A

B

C

D

D

device

for

reducing

hydrocarbon

H

C

emissions

4

An

electric

automatic

choke

to

facilitate

cold

starting

and

to

reduce

exhaust

emissions

5

An

anti

dieseling

solenoid

to

eliminate

dieseling

run

on

6

A

power

valve

or

vacuum

actu

ated

booster

to

ensure

smooth

high

speed

operation

7

The

carburetor

comes

equipped

with

dash

pot

which

ensures

smooth

deceleration

without

engine

stall

under

all

operating

conditions

8

The

hand

operated

altitude

com

pensator

is

installed

in

the

California

models

EF

14

STRUCTURE

AND

OPERATION

These

carburetors

consist

of

a

primary

system

for

normal

running

and

a

secondary

system

for

full

load

running

A

float

system

common

to

both

primary

and

secondary

systems

a

se

condary

switch

over

mechanism

an

accelerating

mechanism

etc

are

also

attached

An

anti

dieseling

solenoid

valve

and

a

power

valve

mechanism

are

also

installed

The

hand

operated

altitude

com

pensator

corrects

air

fuel

mixture

to

an

optimum

ratio