engine DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 151 of 537

Air

pump

I

Operate

engine

until

it

reaches

normal

operating

temperature

2

Inspect

all

hose

hose

connec

tions

and

air

gallery

for

leaks

and

correct

if

necessary

before

checking

air

injection

pump

3

Check

air

injection

pump

belt

tension

and

adjust

to

specifications

if

necessary

4

Disconnect

air

supply

hose

at

check

valve

5

Disconnect

vacuum

hose

from

the

air

control

valve

California

type

only

6

Insert

open

pipe

end

of

Air

Pump

Test

Gauge

Adapter

STl9870000

in

air

supply

hose

Clamp

hose

securely

to

adapter

to

prevent

it

from

blowing

out

Position

adapter

and

test

lli

uge

so

that

air

blast

emitted

through

drilled

pipe

plug

will

be

harmlessly

dissipated

7

Install

a

tachometer

on

engine

With

engine

speed

at

2

600

rpm

ob

serve

pressure

produced

at

test

gauge

Air

pressure

should

be

100

mmHg

3

94

inHg

or

more

8

If

air

pressure

does

not

meet

above

specifications

proceed

as

fol

lows

I

Repeat

2

and

3

above

2

Disconnect

air

supply

hose

at

anti

backfire

valve

Plug

air

hose

open

ing

and

screw

with

a

clamp

Repeat

pressure

test

3

With

engine

speed

at

1

500

rpm

close

hole

of

test

gauge

with

finger

If

a

leaking

sound

is

heard

or

leaking

air

is

felt

by

ftnger

at

relief

valve

relief

valve

is

malfunctioning

Relief

valve

should

be

replaced

or

repaired

4

If

air

injection

pump

does

not

meet

minimum

requirement

of

pres

sure

test

it

should

be

replaced

Control

valve

The

following

procedures

are

reo

commended

for

checking

and

or

as

certaining

that

the

various

components

of

the

exhaust

emission

con

Irol

system

are

operating

properly

The

engine

and

all

components

must

be

at

normal

operating

tempera

tures

when

the

tests

are

performed

Prior

to

performing

any

extensive

diag

nosis

of

the

exhaust

control

system

it

Emission

Control

System

must

be

determined

that

the

engine

as

a

unit

is

functioning

properly

Check

valva

Warm

up

engine

thoroughly

2

Disconnect

hose

leading

to

check

valve

from

air

hose

COJUlector

3

Check

hose

opening

for

any

indi

cation

of

exhaust

gas

leaks

Ifleaks

are

detected

replace

check

valve

4

Race

the

engine

lightly

at

about

2

000

cpm

and

then

return

it

to

idling

VisuaDy

check

the

hose

for

any

indication

of

exhaust

gas

leaks

before

the

engine

returns

to

idling

speed

If

leaks

are

detected

replace

check

valve

EC310

Fig

EC

43

Checking

check

valve

Air

pump

raIle

valve

After

completing

inspection

of

air

pump

check

air

pump

relief

valve

in

the

following

steps

J

Disconnect

hoses

leading

to

check

valve

and

air

control

valve

from

air

hose

connector

and

install

blind

cap

to

the

connector

2

With

engine

running

at

about

3

000

rpm

under

no

load

place

your

hand

on

the

air

outlet

of

air

pump

relief

valve

to

check

for

discharged

air

If

no

air

is

felt

replace

the

air

pump

relief

valve

EC311

Fig

EC

44

Checking

air

pump

relief

valve

EC

18

Air

control

valve

C

U

ornla

models

I

Warm

up

engine

thoroughly

2

Before

checking

air

control

valve

check

all

hoses

for

loose

connection

leaks

etc

and

repair

or

correct

if

necessary

3

With

engine

idling

disconnect

the

outlet

side

hose

of

the

air

control

valve

and

place

your

hand

on

the

air

hose

outlet

to

check

for

air

If

no

air

is

felt

replace

the

air

control

valve

4

Pull

vacuum

hose

off

from

air

con

trol

valve

If

discharge

of

air

from

air

hose

stops

the

air

con

trol

valve

is

normaL

If

discharge

is

still

felt

replace

the

valve

Plug

up

the

removed

vacuum

hose

to

stabilize

engine

running

EC312

Fig

EC

45

Checking

air

control

valve

Emarsancy

air

rella

valve

E

A

R

Valve

lCalHornla

models

L

Warm

up

engine

thoroughly

2

Before

checking

air

control

valve

check

all

hoses

for

loose

connection

leaks

etc

and

repair

or

correct

if

necessary

3

Race

engine

approximately

2

000

rpm

under

no

load

Place

your

hand

on

air

outlet

of

E

A

R

valve

to

check

for

presence

of

discharged

air

If

no

air

is

felt

E

A

R

valve

is

normal

4

Disconnect

vacuum

hose

from

B

A

R

valve

as

shown

in

Figure

EC

46

Page 152 of 537

Race

engine

approximately

2

000

rpm

under

no

load

Place

your

hand

on

air

outlet

of

E

A

R

valve

to

check

for

presence

of

discharged

air

If

air

is

felt

E

A

R

valve

is

normaL

5

If

E

A

R

valve

does

not

function

properly

at

above

steps

replace

E

A

R

valve

To

air

pump

I

ET267

Fig

EC

46

Cheeking

E

A

R

volve

Anti

backfire

valve

A

valve

Warm

up

engine

thoroughly

2

Disconnect

hose

from

air

cleaner

and

place

a

finger

near

the

outlet

3

Run

engine

at

about

3

000

rpin

under

no

load

then

quickly

cetum

it

to

idling

If

you

feel

a

pull

or

suction

force

on

your

finger

the

anti

backfire

valve

is

functioning

normally

If

no

suction

is

felt

replace

the

anti

backflre

valve

Fig

EC

47

Checking

anti

backfire

valve

1

t

D

I

Y1

VI

I

ID

4

JO

0

2

E

C

R

control

valve

3

E

C

R

passage

4

Intake

manifold

5

Thermal

vacuum

valve

6

E

C

R

tube

7

Exhaust

manifold

Emission

Control

System

tXHAUST

GAS

RECIRCULATION

CONTROL

SYSTEM

E

G

R

DESCRIPTION

In

the

exhaust

gas

recirculation

system

a

part

of

the

exhaust

gas

is

returned

to

the

combustion

chamber

to

lower

the

spark

flame

temperature

during

combustion

This

results

in

a

reduction

of

the

nitrogen

oxide

con

ten

t

in

the

exhaust

gas

The

exhaust

gas

recirculation

sys

tem

consists

of

an

E

G

R

passage

E

G

R

con

trol

valve

thermal

vacuum

volve

E

G

R

tube

and

hose

A

warn

@

I

ing

system

which

indicates

when

the

E

G

R

control

system

must

be

in

spected

is

also

installed

in

all

620

models

except

those

bound

for

Coli

fornia

and

Canada

When

the

E

G

R

con

trol

valve

is

open

some

of

the

exhaust

gas

is

led

from

the

exhaust

manifold

to

the

E

G

R

chamber

through

the

E

G

R

passage

The

exhaust

gas

is

then

con

trolled

in

quantity

by

the

E

G

R

valve

and

is

introduced

into

the

intake

manifold

Open

c1ose

operation

of

the

E

G

R

control

valve

is

controlled

by

the

thermal

vacuum

valve

which

opera

tes

on

carburetor

vacuum

and

engine

cool

ant

temperature

EC349

Fig

EC

4

Exhaust

Gas

Recirculation

system

E

G

R

E

G

R

system

operating

Thermal

Intake

manifold

E

G

R

Remarks

E

G

R

water

temperature

oC

OF

vacuum

valve

vacuum

control

valve

Below

570C

135OF

Close

Close

Non

california

Above

MfT

models

only

Idling

Not

Above

57

to

630C

Open

70

mmHg

Close

actuated

135

to

145OF

76

inHg

California

models

Below

and

N

on

Fullthrollle

f

alifomia

AfT

Above

57

to

6

oC

models

Actua

ted

Open

Above

50

mmHg

Open

135

to

145OF

1

97

inHg

EC

19

OPERATION

Operation

of

E

G

R

system

is

as

shown

below

Page 153 of 537

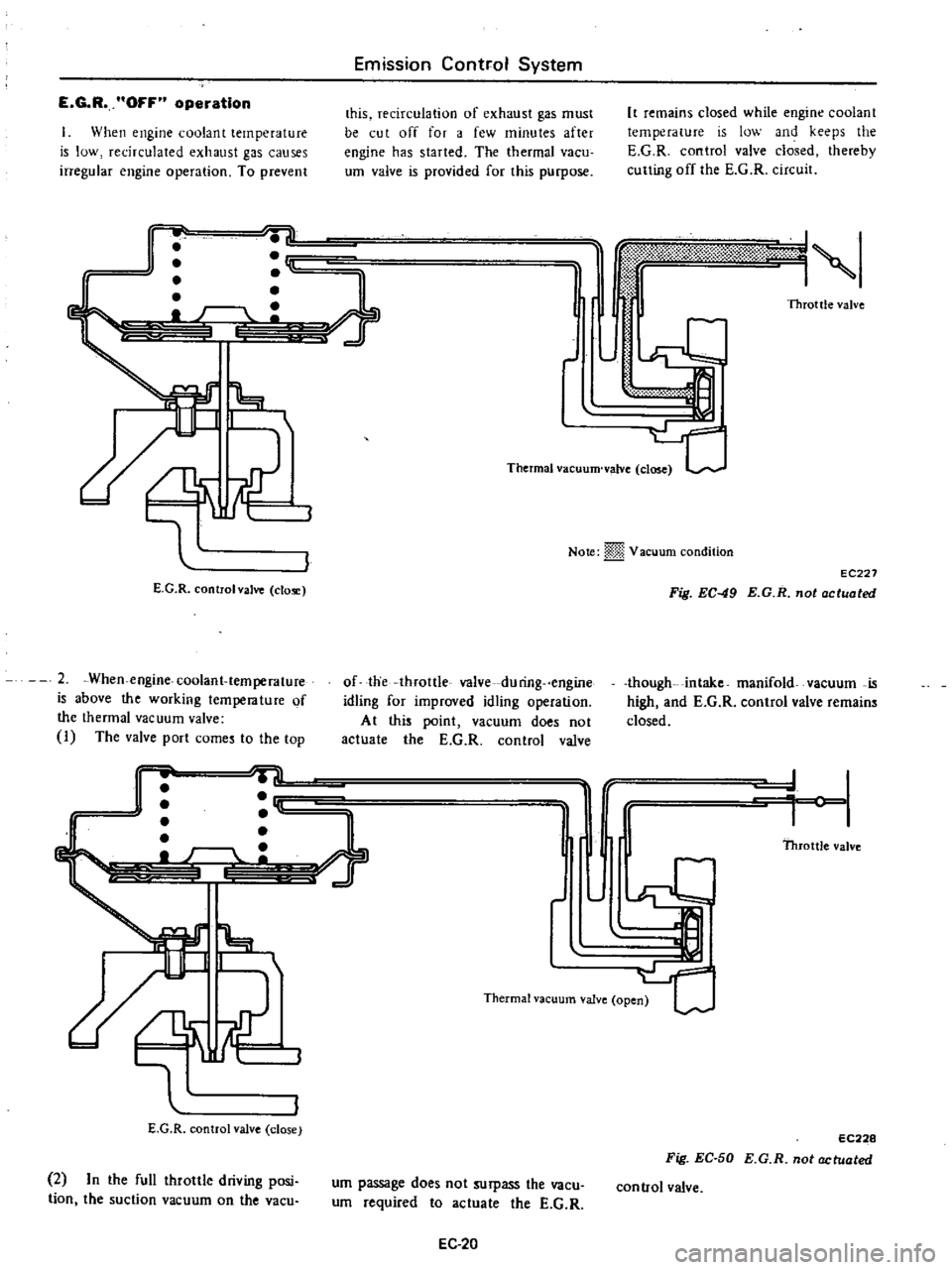

E

G

R

OFF

operation

When

engine

coolant

temperature

is

low

recirculated

exhaust

gas

causes

irregular

engine

operation

To

prevent

Emission

Control

System

this

recirculation

of

exhaust

gas

must

be

cut

off

for

a

few

minutes

after

engine

has

started

The

thermal

vacu

um

valve

is

provided

for

this

purpose

r

rn

11

L

e

7

E

G

R

controlval

le

clo

2

When

engine

coolant

temperature

is

above

the

working

temperature

of

the

thermal

vacuum

valve

I

The

valve

port

come

to

the

top

J

It

remains

closed

while

engine

coolant

temperature

is

low

and

keeps

the

E

G

R

control

valve

closed

thereby

culling

off

the

E

G

R

circuit

I

lW

jS

1

Throttle

valve

Thermal

vacuum

valve

close

j

Note

m

Vacuum

condition

of

the

throttle

valve

du

ring

engine

idling

for

improved

idling

operation

At

this

point

vacuum

does

not

actuate

the

E

G

R

control

valve

r

T

D

L

t

i

q

II

E

G

R

control

valve

close

2

In

the

full

throttle

driving

posi

tion

the

suction

vacuum

on

the

vacu

JllrI

Thermal

vacuum

valve

ope

um

passage

does

not

surpass

the

vacu

um

required

to

actuate

the

E

G

R

EC

20

EC227

Fig

EC

49

E

G

R

not

actuated

though

intake

manifold

vacuum

is

high

and

E

G

R

control

valve

remain

closed

l

Throttle

valve

EC228

Fig

EC

50

E

G

R

nol

actualed

control

valve

Page 154 of 537

6

Thermal

vacuum

valve

Open

E

G

R

control

valve

Close

E

G

R

ON

operation

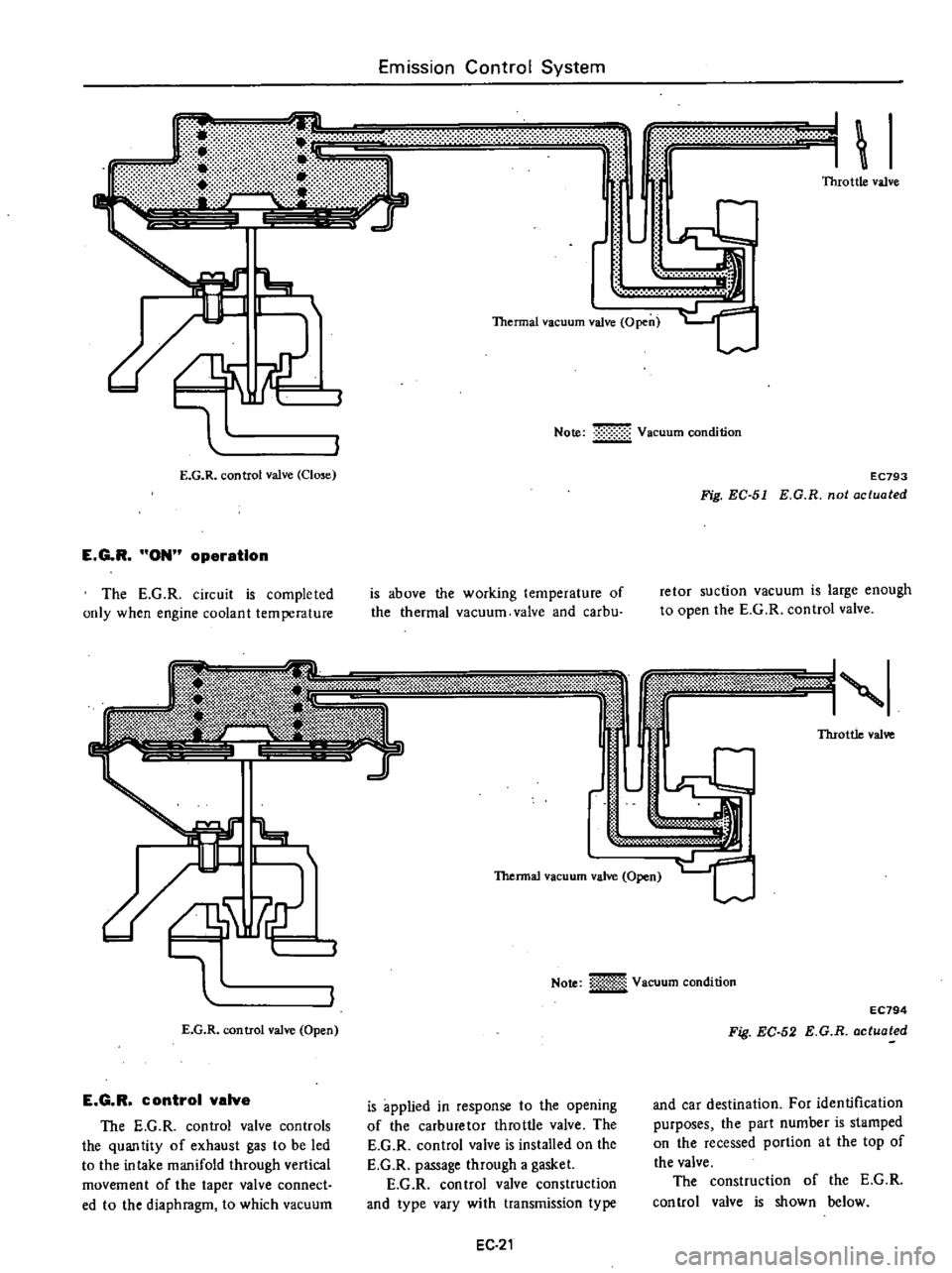

The

E

G

R

circuit

is

completed

only

when

engine

coolant

temperature

Emission

Control

System

I

I

Note

Vacuum

condition

EC793

Fig

EC

51

E

G

R

not

actuated

is

above

the

working

temperature

of

the

thermal

vacuum

valve

and

carbu

retor

suction

vacuum

is

large

enough

to

open

the

E

G

R

control

valve

Y

m

l

fj

t1f

1t

3

0

l

P

@

0

f

Y

f

1

i0

W

g

1

i3

iiA

d

m

E

N

ti

n

k

i

l

i

Throttle

valve

n

L

r

E

G

R

control

valve

Open

E

G

R

control

valva

The

E

G

R

control

valve

controls

the

quantity

of

exhaust

gas

to

be

led

to

the

intake

manifold

through

vertical

movement

of

the

taper

valve

connect

ed

to

the

diaphragm

to

which

vacuum

Thermal

vacuum

valve

Open

Note

iiiI

Vacuum

condition

EC794

Fig

EC

52

E

G

R

actuated

is

applied

in

response

to

the

opening

of

the

carburetor

throttle

valve

The

E

G

R

control

valve

is

installed

on

the

E

G

R

passage

through

a

gasket

E

G

R

con

trol

valve

construction

and

type

vary

with

transmission

type

and

car

destination

For

identification

purposes

the

part

number

is

stamped

on

the

recessed

portion

at

the

top

of

the

valve

The

construction

of

the

E

G

R

control

valve

is

shown

below

EC

21

Page 155 of 537

j

EC231

Thermal

vacuum

valva

o

o

m

Emission

Control

System

0

o

o

o

l

l

@

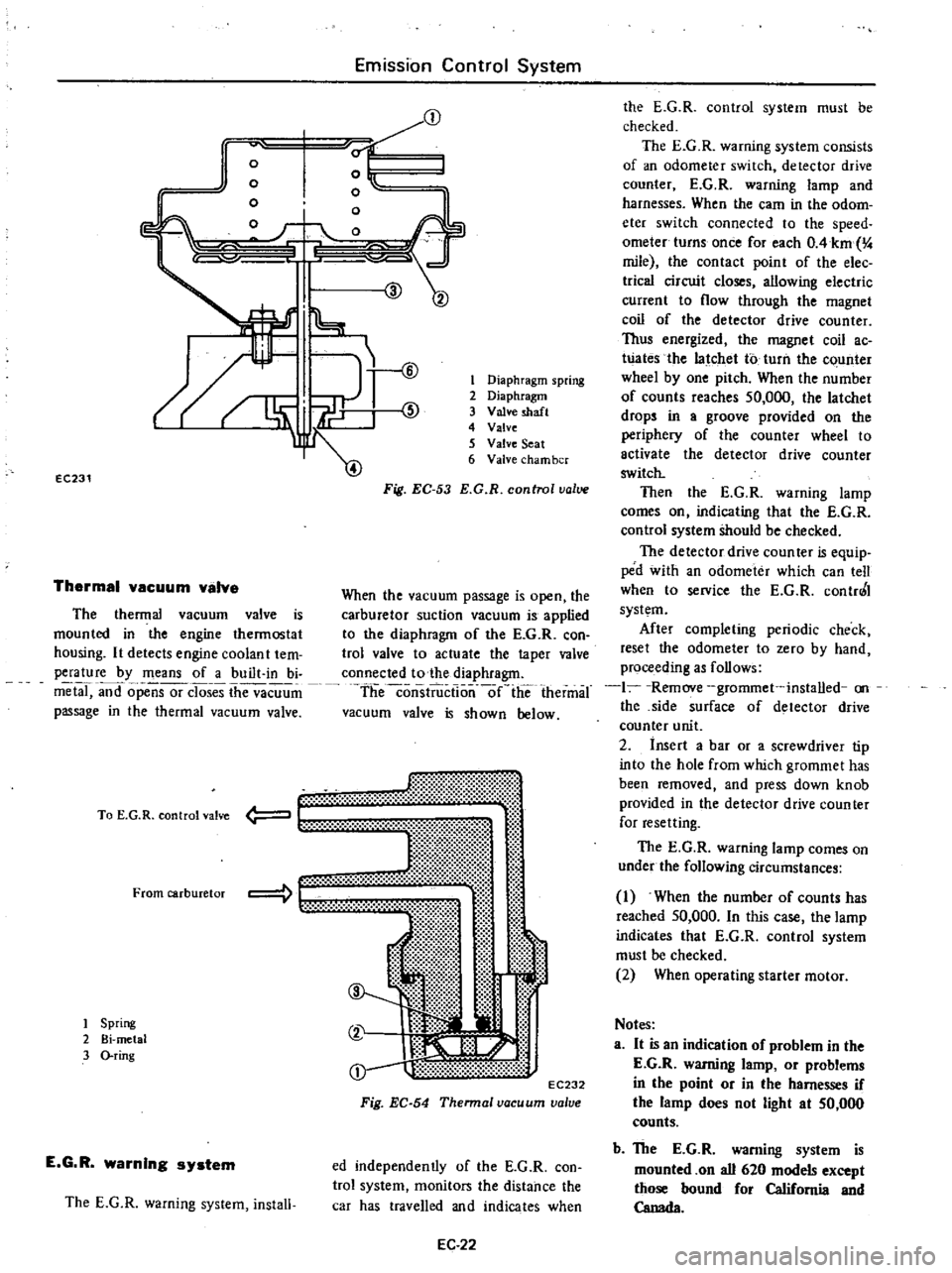

The

thermal

vacuum

valve

is

mounted

in

the

engine

thermostat

housing

It

detects

engine

coolan

t

tem

perature

by

means

of

a

built

in

bi

metal

and

opensor

closes

the

vacuum

passage

in

the

thermal

vacuum

valve

mt

li

t

00

t

EC232

Fig

EC

54

Thennal

vacuum

valve

To

E

G

R

control

valve

From

carburetor

1

Spring

2

Bi

metal

3

O

ring

E

G

R

warning

system

The

E

G

R

warning

system

install

1

Diaphragm

spring

2

Diaphragm

3

Valve

shaft

4

Valve

5

Valve

Seat

6

Valve

cham

ber

Fig

EC

53

E

G

R

control

value

When

the

vacuum

passage

is

open

the

carburetor

suction

vacuum

is

applied

to

the

diaphragm

of

the

E

G

R

con

trol

valve

to

actuate

the

taper

valve

connected

to

the

diaphragm

theconsiiiictlo

nlie

thermal

vacuum

valve

is

shown

below

ed

independently

of

the

E

G

R

con

trol

system

monitors

the

distance

the

car

has

travelled

and

indicates

when

EC

22

the

E

G

R

control

system

must

be

checked

The

E

G

R

warning

system

consists

of

an

odometer

switch

detector

drive

counter

E

G

R

warning

lamp

and

harnesses

When

the

earn

in

the

odom

eter

switch

connected

to

the

speed

ometer

turns

once

for

each

OAkm

4

mile

the

contact

point

of

the

elec

trica

circuit

closes

allowing

electric

current

to

flow

through

the

magnet

coil

of

the

detector

drive

counter

Thus

energized

the

magnet

coil

ac

Wates

the

latchet

to

turn

the

c

unter

wheel

by

one

pitch

When

the

number

of

counts

reaches

50

000

the

latchet

drops

in

a

groove

provided

on

the

periphery

of

the

counter

wheel

to

activate

the

detector

drive

counter

switch

Then

the

E

G

R

warning

lamp

comes

on

indicating

that

the

E

G

R

control

system

Should

be

checked

The

detector

drive

coun

teT

is

equip

ped

with

an

odometer

which

can

tell

when

to

service

the

E

G

R

contr0

I

system

After

completing

periodic

check

reset

the

odometer

to

zero

by

hand

proceeding

as

follows

1

Remove

grommet

installed

on

the

side

surface

of

detector

drive

counter

unit

2

insert

a

bar

or

a

screwdriver

tip

into

the

hole

from

which

grommet

has

been

removed

and

press

down

knob

provided

in

the

detector

drive

counter

for

resetting

The

E

G

R

warning

lamp

comes

on

under

the

following

circumstances

1

When

the

number

of

counts

has

reached

50

000

In

this

case

the

lamp

indicates

that

E

G

R

control

system

must

be

checked

2

When

operating

starter

motor

Notes

a

It

is

an

indication

of

problem

in

the

E

G

R

warning

lamp

or

problems

in

the

point

or

in

the

harnesses

if

the

lamp

does

not

light

at

50

000

counts

b

The

E

G

R

warning

system

is

mounted

on

all

620

models

except

those

bound

for

California

and

Canada

Page 156 of 537

1

1

I

I

I

1

v

v

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

L

0

I

Magnet

coil

Detector

drive

counter

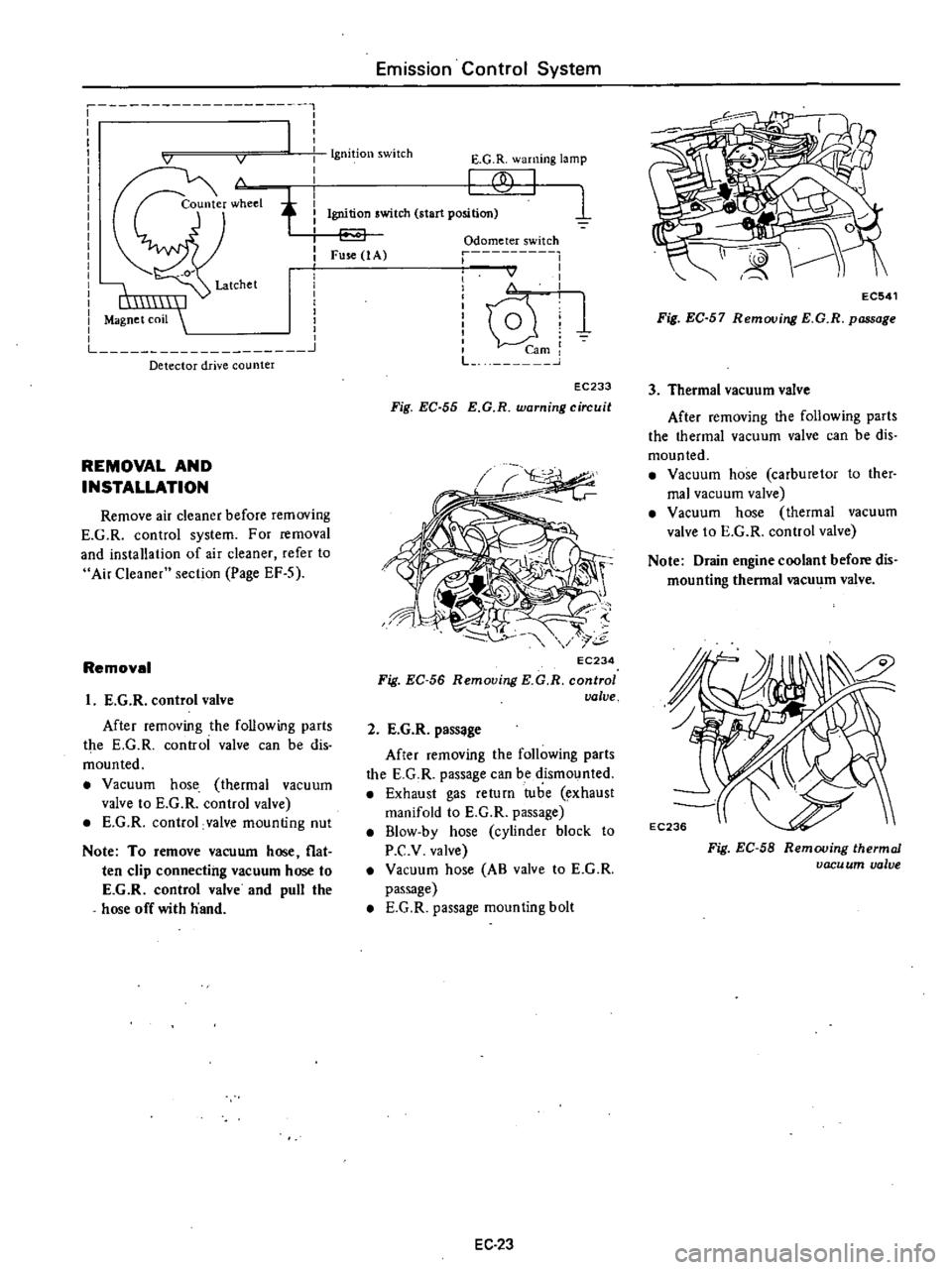

REMOVAL

AND

INSTALLATION

Remove

air

cleaner

before

removing

E

G

R

control

system

For

removal

and

installation

of

air

cleaner

refer

to

Air

Cleaner

section

Page

EF

S

Removal

I

E

G

R

control

valve

After

removing

the

following

parts

the

E

G

R

controi

valve

can

be

dis

mounted

Vacuum

hose

thermal

vacuum

valve

to

E

G

R

control

valve

E

G

R

control

valve

mounting

nut

Note

To

remove

vacuum

hose

flat

ten

clip

connecting

vacuum

hose

to

E

G

R

control

valve

and

pull

the

hose

off

with

hand

Emission

Control

System

Ignition

switch

E

G

R

warning

lamp

f

1

Ignition

switch

start

position

Fuse

1

A

Odometer

switch

r

I

I

I

I

v

I

I

I

i

lQ

U

1

mi

L

J

EC233

Fig

EC

55

E

G

R

warning

circuit

EC234

Fig

EC

56

Removing

KG

R

control

valve

2

E

G

R

pass

ge

After

removing

the

following

parts

the

E

G

R

passage

can

be

dismounted

Exhaust

gas

return

tube

exhaust

manifold

to

E

G

R

passage

B1ow

by

hose

cylinder

block

to

P

C

v

valve

Vacuum

hose

AB

valve

to

E

G

R

passage

E

G

R

passage

mounting

bolt

EC

23

EC541

Fig

EC

57

Removing

E

G

R

passage

3

Thermal

vacuum

valve

After

removing

the

following

parts

the

thermal

vacuum

valve

can

be

dis

mounted

Vacuum

hose

carburetor

to

ther

mal

vacuum

valve

Vacuum

hose

thermal

vacuum

valve

to

E

G

R

control

valve

Note

Drain

engine

coolant

before

dis

mounting

thermal

vacu

m

valve

Fig

EC

58

Removing

thermal

vacu

um

valve

Page 157 of 537

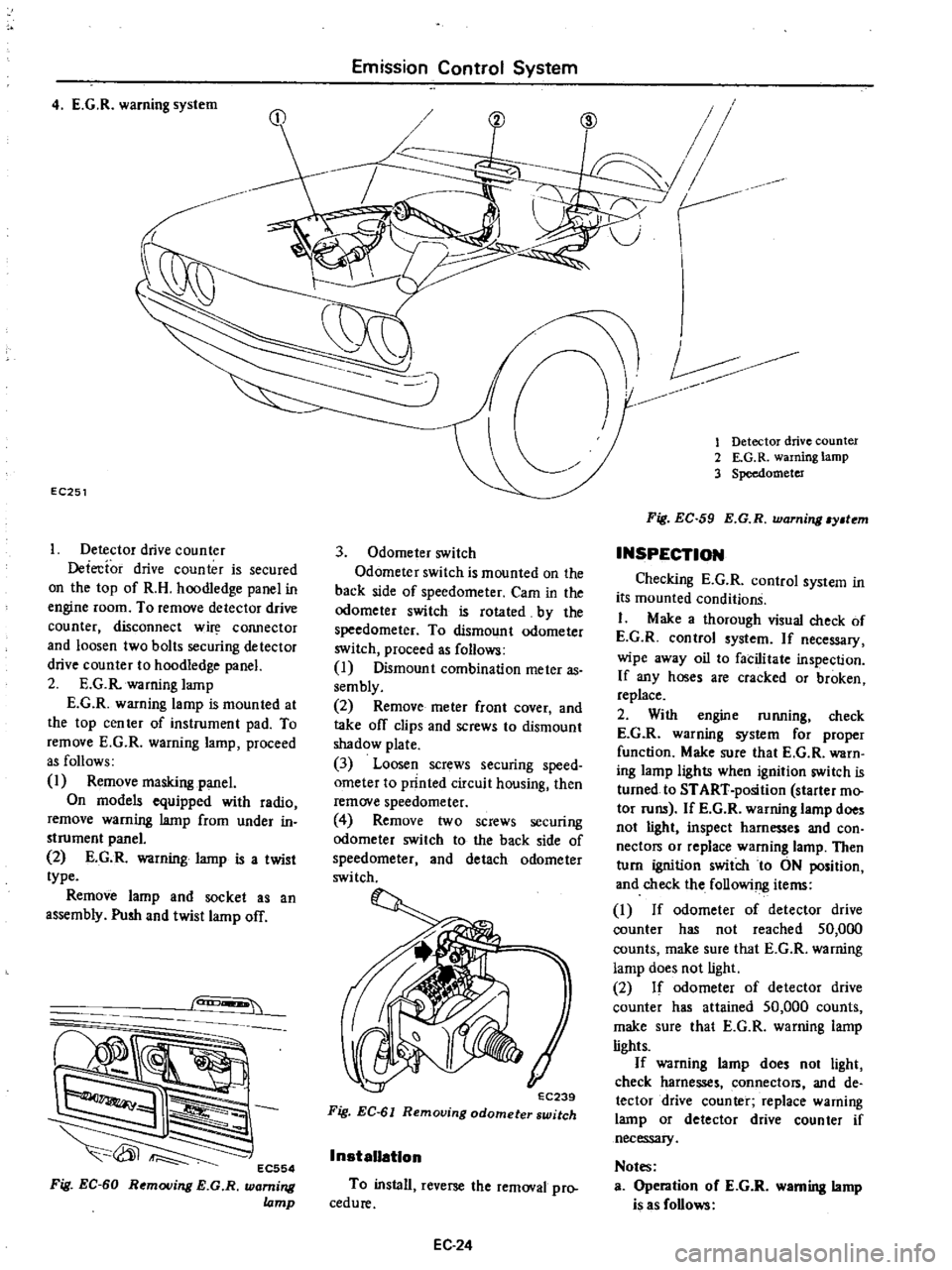

4

E

G

R

warning

system

EC251

Detector

drive

counter

Detecfor

drive

counter

is

secured

on

the

top

of

R

H

hoodledge

panel

in

engine

room

To

remove

detector

drive

counter

disconnect

w

COJUlector

and

loosen

two

bolts

securing

detector

drive

counter

to

hoodledge

panel

2

E

G

R

warning

lamp

E

G

R

warning

lamp

is

mounted

at

the

top

cen

ter

of

instrument

pad

To

remove

E

G

R

warning

lamp

proceed

as

follows

1

Remove

masking

panel

On

models

equipped

with

radio

remove

warning

lamp

from

under

in

strument

panel

2

E

G

R

warning

lamp

is

a

twist

type

Remove

lamp

and

socket

as

an

assembly

Push

and

twist

lamp

off

can

EC554

Fig

EC

60

Removing

E

G

R

warning

lamp

Emission

Control

System

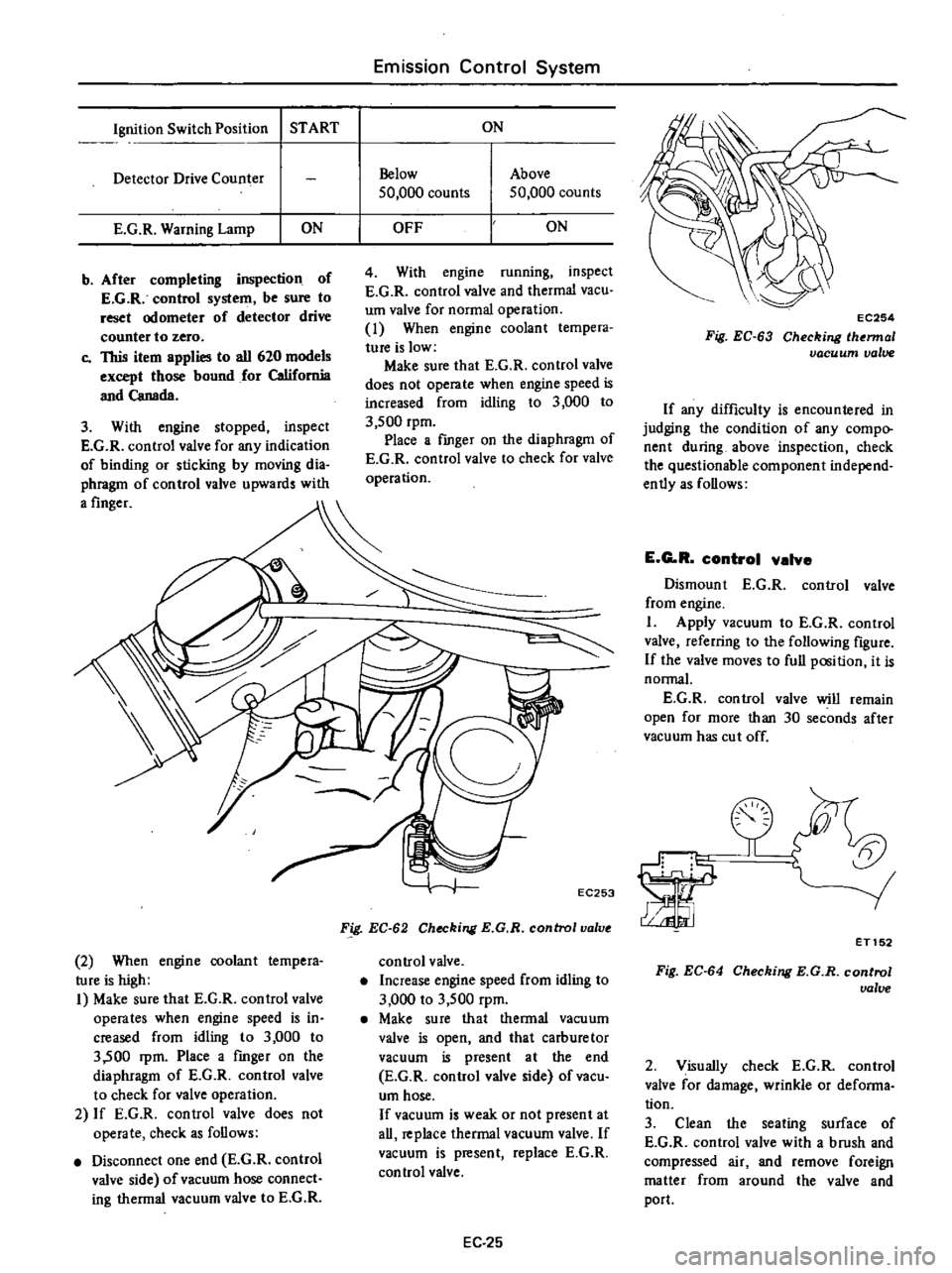

3

Odometer

switch

Odometer

switch

is

mounted

on

the

back

side

of

speedometer

Cam

in

the

odometer

switch

is

rotated

by

the

speedometer

To

dismount

odometer

switch

proceed

as

follows

I

Dismount

combination

meter

as

sembly

2

Remove

meter

front

cover

and

take

off

clips

and

screws

to

dismount

shadow

plate

3

Loosen

screws

securing

speed

ometer

to

printed

circuit

housing

then

remove

speedometer

4

Remove

two

screws

securing

odomete

switch

to

the

back

side

of

speedometer

and

detach

odometer

switch

EC239

Fig

EC

61

Removing

odometer

switch

InstaUatlon

To

install

reverse

the

removal

pro

cedure

EC24

V

r

CID

1

Detector

drive

counter

2

E

G

R

warning

lamp

3

Speedometer

Fig

EC

59

E

G

R

warning

y

tem

INSPECTION

Checking

E

G

R

control

system

in

its

mounted

conditionS

I

Make

a

thorough

visual

check

of

E

G

R

control

system

If

necessary

wipe

away

oil

to

facilitate

inspection

If

any

hoses

are

cracked

or

broken

replace

2

With

engine

running

check

E

G

R

warning

system

for

proper

function

Make

sure

that

E

G

R

warn

ing

lamp

lights

when

ignition

switch

is

turned

to

START

position

starter

mo

tor

runs

If

E

G

R

wanung

lamp

does

not

light

inspect

harnesses

and

con

nectors

or

replace

warning

lamp

Then

turn

ignition

switch

to

ON

position

and

check

the

following

items

I

If

odometer

of

detector

drive

counter

has

not

reached

50

000

counts

make

sure

that

E

G

R

warning

lamp

does

not

light

2

If

odomete

of

detector

drive

counter

has

attained

50

000

counts

make

sure

that

E

G

R

warning

lamp

lights

If

warning

lamp

does

not

light

check

harnesses

connectors

and

de

tector

drive

counter

replace

warning

lamp

or

detector

drive

counter

if

necessary

Notes

Operation

oC

E

G

R

warning

lamp

is

as

Collows

Page 158 of 537

Ignition

Switch

Position

START

Detector

Drive

Counter

E

G

R

Warning

Lamp

ON

b

After

completing

inspection

of

E

G

R

control

system

be

sure

to

reset

odometer

of

detector

drive

counter

to

zero

c

This

item

applies

to

all

620

models

except

those

bound

for

California

and

Canada

3

With

engine

stopped

inspect

E

G

R

control

valve

for

any

indication

of

binding

or

sticking

by

moving

dia

phragm

of

control

valve

upwards

with

a

finger

2

When

engine

coolant

tempera

ture

is

high

I

Make

sure

that

E

G

R

control

valve

operates

when

engine

speed

is

in

creased

from

idling

to

3

000

to

3

500

rpm

Place

a

fmger

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

2

If

E

G

R

control

valve

does

not

operate

check

as

follows

Disconnect

one

end

E

G

R

control

valve

side

of

vacuum

hose

connect

ing

thermal

vacuum

valve

to

E

G

R

Emission

Control

System

ON

Below

50

000

counts

Above

50

000

counts

OFF

ON

4

With

engine

running

inspect

E

G

R

control

valve

and

thermal

vacuo

um

valve

for

normal

operation

1

When

engine

coolant

tempera

ture

is

low

Make

sure

that

E

G

R

control

valve

does

not

operate

when

engine

speed

is

increased

from

idling

to

3

000

to

3

500

rpm

Place

a

fmger

on

the

diaphragm

of

E

G

R

control

valve

to

check

for

valve

operation

EC253

Fig

EC

62

Checking

E

G

R

control

valve

control

valve

Increase

engine

speed

from

idling

to

3

000

to

3

500

rpm

Make

su

re

that

thermal

vacu

um

valve

is

open

and

that

carburetor

vacuum

is

present

at

the

end

E

G

R

control

valve

side

of

vacu

um

hose

If

vacuum

is

weak

or

not

present

at

all

replace

thermal

vacuum

valve

If

vacuum

is

present

replace

E

G

R

control

valve

EC

25

EC254

Fig

EC

63

Checking

lhermal

vacuum

valve

If

any

difficulty

is

encountered

in

judging

the

condition

of

any

compo

nent

during

above

inspection

check

the

questionable

component

independ

ently

as

follows

E

G

R

control

valve

Dismount

E

G

R

control

valve

from

engine

I

Apply

vacuum

to

E

G

R

control

valve

referring

to

the

following

figure

If

the

valve

moves

to

full

position

it

is

normal

E

G

R

control

valve

will

remain

open

for

more

than

30

seconds

after

vacuum

has

cut

off

la

ET152

Fig

EC

64

Checking

E

G

R

control

ualue

2

Visually

check

E

G

R

control

valve

for

damage

wrinkle

or

defonna

tion

3

Clean

the

seating

surface

of

E

G

R

control

valve

with

a

brush

and

compressed

air

and

remove

foreign

matter

from

around

the

valve

and

port

Page 159 of 537

EC350

Fig

EC

65

Cleaning

E

G

R

control

valve

Thermal

vacuum

valve

Dismount

thermal

vacuum

valve

from

engine

Note

Before

dismounting

drain

en

gine

coolant

from

engine

Apply

vacuum

to

thermal

vacuum

valve

and

check

to

be

sure

thaI

ther

mal

vacuum

valve

opens

or

closes

in

response

to

engine

coolant

tempera

ture

as

specified

Thermal

vacuum

valve

should

open

at

a

temperature

of

57

to

630C

135

to

1450F

completing

the

vacuum

passage

Note

Do

not

allow

water

to

get

inside

the

thermal

vacuum

valve

EC242

Fig

EC

66

Checking

hennal

vacuum

valve

Emission

Control

System

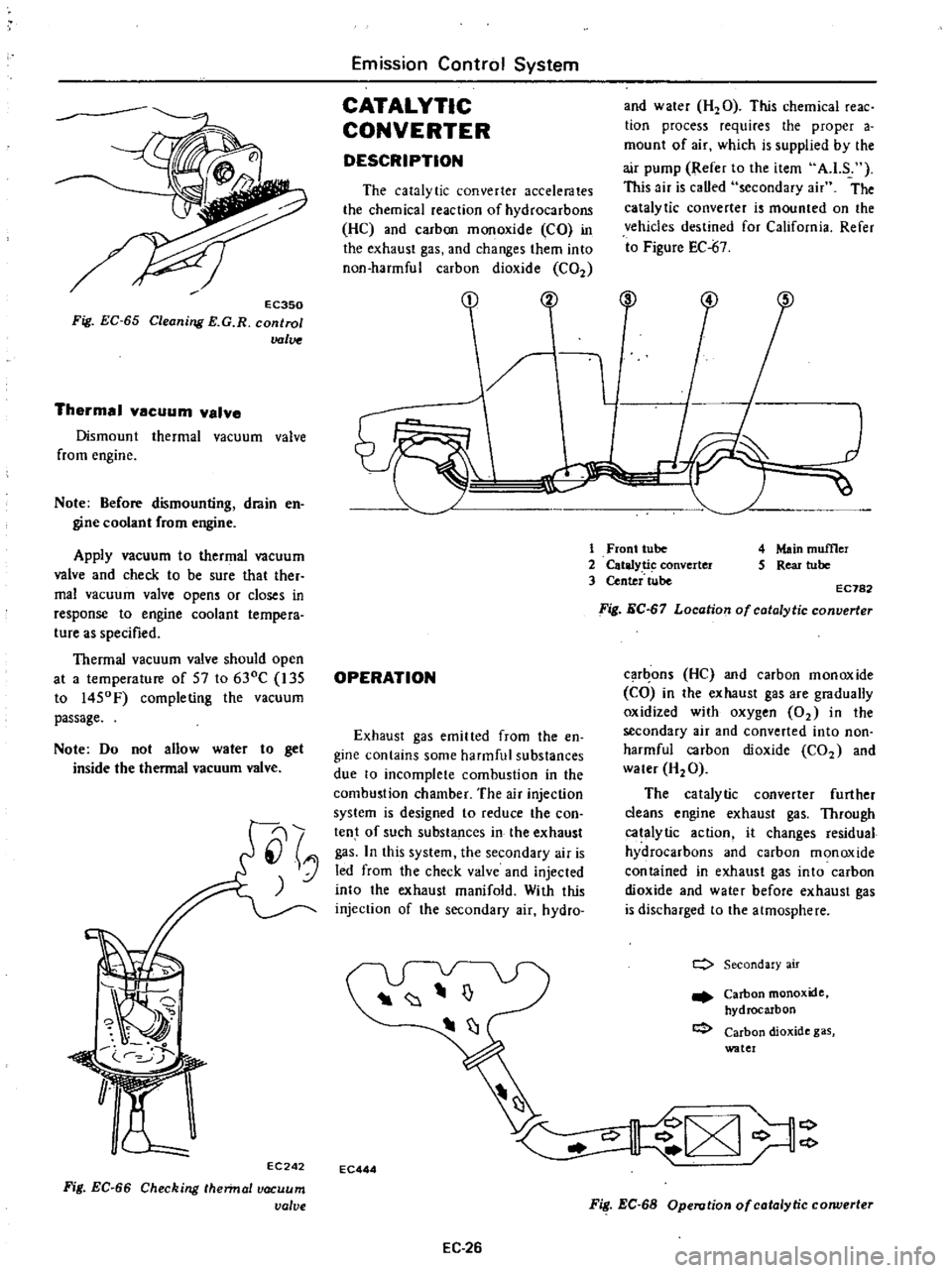

CATALYTIC

CONVERTER

DESCRIPTION

The

catalytic

converter

accelerates

the

chemical

reaction

of

hydrocarbons

HC

and

carbon

monoxide

CO

in

the

exhaust

gas

and

changes

them

into

non

harmful

carbon

dioxide

C02

OPERATION

Exhaust

gas

emitted

from

the

en

gine

contains

some

harmful

substances

due

to

incomplete

combustion

in

the

combustion

chamber

The

air

injection

system

is

designed

to

reduce

the

con

tent

of

such

substances

in

the

exhaust

gas

In

this

system

the

secondary

air

is

led

from

the

check

valve

and

injected

into

the

exhaust

manifold

With

this

injection

of

the

secondary

air

hydro

EC444

EC

26

and

water

H20

This

chemical

reac

tion

process

requires

the

proper

a

mount

of

air

which

is

supplied

by

the

air

pump

Refer

to

the

item

AJ

S

This

air

is

caUed

secondary

air

The

catalytic

converter

is

mounted

on

the

vehicles

destined

for

California

Refer

to

Figure

EC

67

3

4

1

Front

tube

2

Catalyti

converter

3

Center

tube

4

Main

muffler

5

Rear

tube

EC782

Fig

EC

67

Location

of

catalytic

converter

car

ons

He

and

carbon

monoxide

CO

in

the

exhaust

gas

are

gradually

oxidized

with

oxygen

02

in

the

secondary

air

and

converted

into

non

harmful

carbon

dioxide

C02

and

water

H20

The

catalytic

converter

further

cleans

engine

exhaust

gas

Through

catalytic

action

it

changes

residual

hydrocarbons

and

carbon

monoxide

contained

in

exhaust

gas

into

carbon

dioxide

and

water

before

exhaust

gas

is

discharged

to

the

atmosphere

c

Secondary

air

Carbon

monoxide

hydrocarbon

Carbon

dioxide

gas

water

F

EC

68

Operution

of

catalytic

corwerter

Page 160 of 537

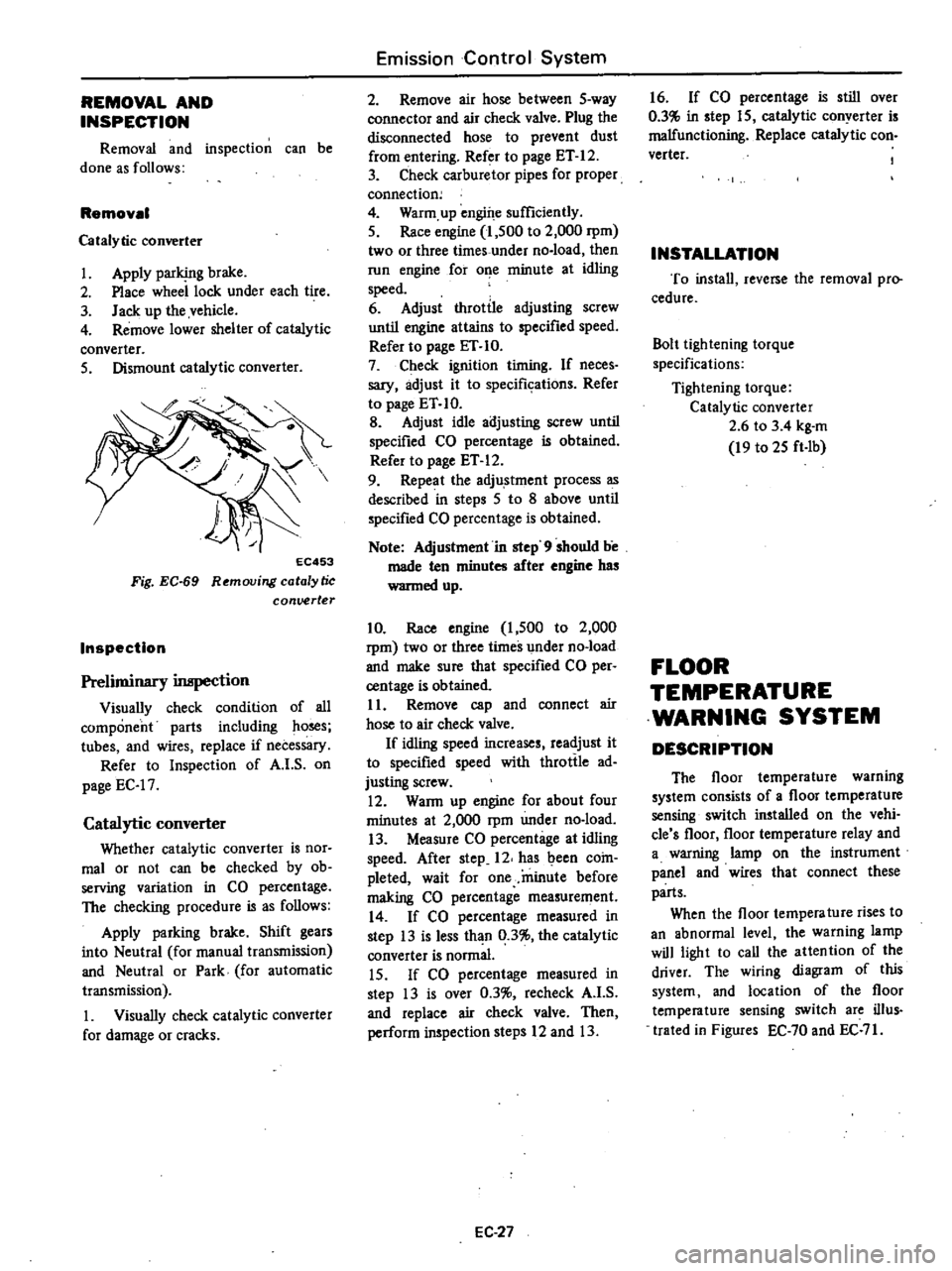

REMOVAL

AND

INSPECTION

Removal

and

inspection

can

be

done

as

follows

Removal

Catalytic

converter

1

Apply

parking

brake

2

Place

wheel

lock

under

each

tire

3

Jack

up

the

vehicle

4

Remove

lower

shelter

of

catalytic

converter

5

Dismount

catalytic

converter

EC453

Fig

EC

69

Removing

catalytic

conuerter

Inspection

Preliminary

inspection

Visually

check

condition

of

all

component

parts

including

ho

s

tubes

and

wires

replace

if

necessary

Refer

to

Inspection

of

A

I

S

on

page

EC

17

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

be

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Visually

check

catalytic

converter

for

damage

or

cracks

Emission

Control

System

2

Remove

air

hose

between

5

way

connector

and

air

check

valve

Plug

the

disconnected

hose

to

prevent

dust

from

entering

Refer

to

page

ET

12

3

Check

carburetor

pipes

for

proper

connection

4

Warm

up

engine

sufficiently

5

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

o

e

minute

at

idling

speed

6

Adjust

throttle

adjusting

screw

until

engine

attains

to

specified

speed

Refer

to

page

ET

10

7

Check

ignition

timing

If

neces

sary

adjust

it

to

specifkations

Refer

to

page

ET

10

B

Adjust

idle

adjusting

screw

until

specified

CO

percentage

is

obtained

Refer

to

page

ET

12

9

Repeat

the

adju

stment

process

as

described

in

steps

5

to

8

above

until

specified

CO

percentage

is

obtained

Note

Adjustment

in

step

9

should

be

made

ten

minutes

after

engine

has

wanned

up

10

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

11

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

ad

justing

screw

12

WaRn

up

engine

for

about

four

minutes

at

2

000

rpm

under

no

load

13

Measure

CO

percentage

at

idling

speed

After

step

12

has

been

coin

pleted

wait

for

one

minute

before

making

CO

percentage

measurement

14

If

CO

percentage

measured

in

step

13

is

less

than

0

3

the

catalytic

converter

is

normal

15

If

CO

percentage

measured

in

step

13

is

over

0

3

recheck

A

I

S

and

replace

air

check

valve

Then

perform

inspection

steps

12

and

13

EC

27

16

If

CO

percentage

is

still

over

0

3

in

step

15

catalytic

conyerter

is

malfunctioning

Replace

catalytic

con

verter

INSTALLATION

To

install

reverse

the

removal

pro

cedure

Bolt

lightening

torque

specifications

Tightening

torque

Catalytic

converter

2

6

to

3

4

kg

m

19

to

25

ft

Ib

FLOOR

TEMPERATURE

WARNING

SYSTEM

DESCRIPTION

The

floor

temperature

warning

system

consists

of

a

floor

temperature

sensing

switch

installed

on

the

vehi

cle

s

floor

floor

temperature

relay

and

a

warning

lamp

on

the

instrument

panel

and

wires

that

connect

these

parts

When

the

floor

tempera

ture

rises

to

an

abnormal

level

the

warning

lamp

will

light

to

call

the

attention

of

the

driver

The

wiring

diagram

of

this

system

and

location

of

the

floor

temperature

sensing

switch

are

ilIus

trated

in

Figures

EC

70

and

EC

71