engine DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 112 of 537

Engine

Fuel

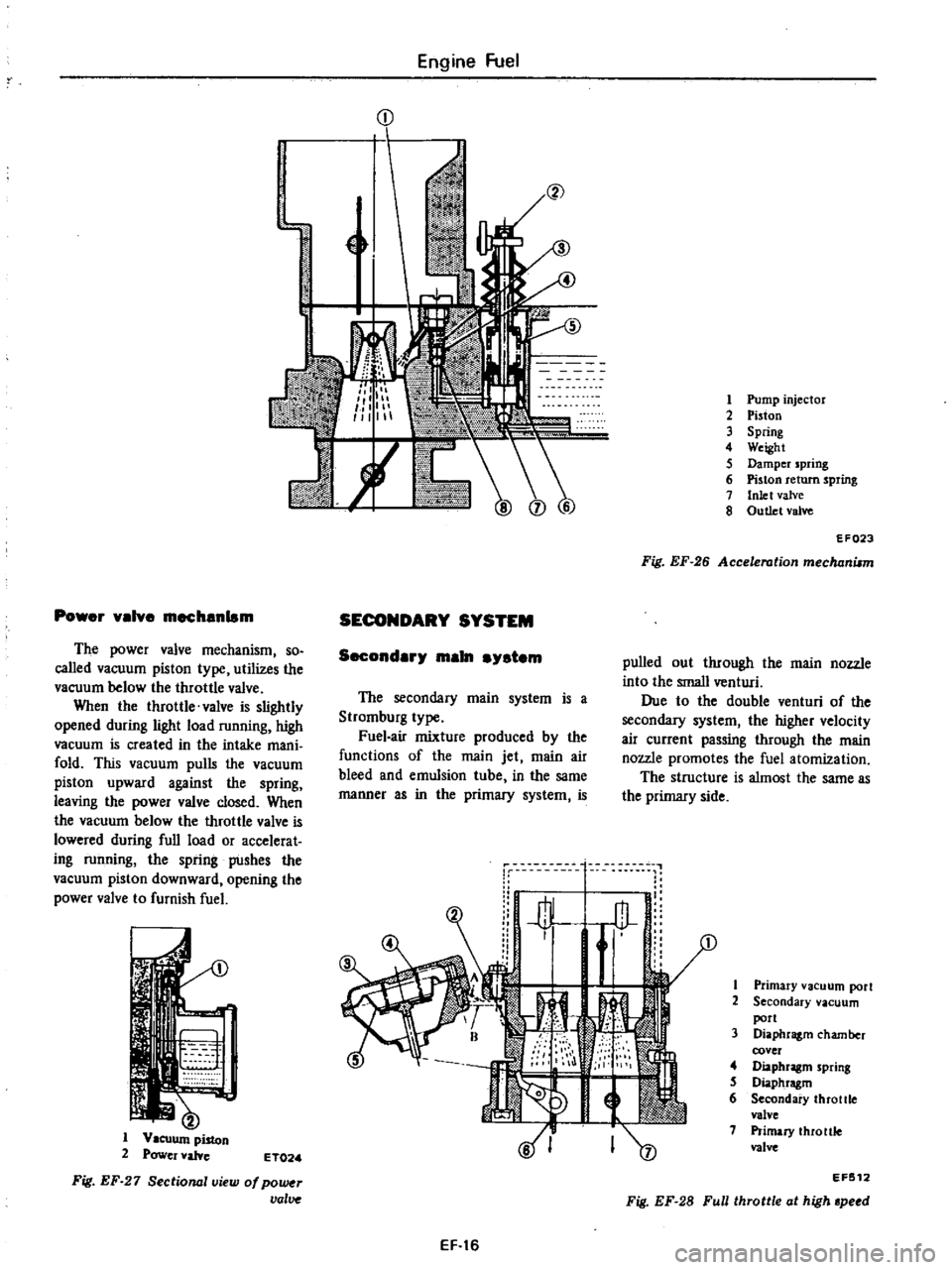

1

L

if

1

Pump

injector

2

Piston

3

Spring

4

Weight

5

Damper

spring

6

Piston

return

spring

7

Inlet

valve

8

Outlet

valve

EF023

Fig

EF

26

Acceleration

mechanism

Power

valve

mechanism

SECONDARY

SYSTEM

The

power

valve

mechanism

so

called

vacuum

piston

type

utilizes

the

vacuum

below

the

throttle

valve

When

the

throttle

valve

is

slightly

opened

during

light

load

running

high

vacuum

is

created

in

the

intake

mani

fold

This

vacuum

pulls

the

vacuum

piston

upward

against

the

spring

leaving

the

power

valve

closed

When

the

vacuum

below

the

throttle

valve

is

lowered

during

full

load

or

accelerat

ing

running

the

spring

pushes

the

vacuum

piston

downward

opening

the

power

valve

to

furnish

fuel

Secondary

main

lIYlltem

pulled

out

through

the

main

nozzle

into

the

small

venturi

Due

to

the

double

venturi

of

the

secondary

system

the

higher

velocity

air

current

passing

through

the

main

nozzle

promotes

the

fuel

atomization

The

structure

is

almost

the

same

as

the

primary

side

The

secondary

main

system

is

a

Stromburg

type

Fuel

air

mixture

produced

by

the

functions

of

the

main

jet

main

air

bleed

and

emulsion

tube

in

the

same

manner

as

in

the

primary

system

is

11

1

I

1

1

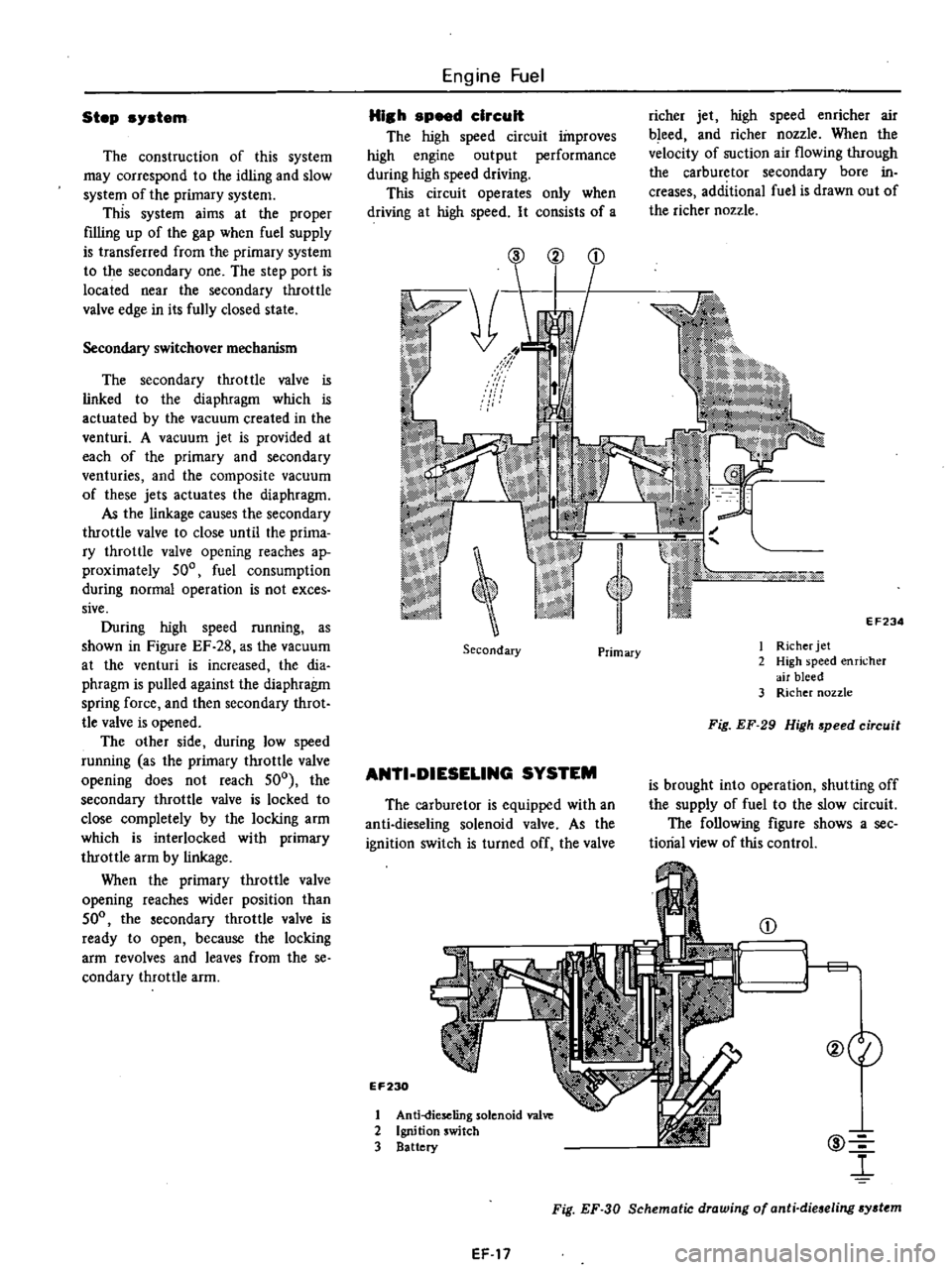

Primary

vacuum

port

2

Secondary

vacuum

port

3

Diaphragm

chamber

cover

of

Diaphragm

spring

S

Diaphragm

6

Secondary

throttle

valve

7

Primary

theo

nle

valve

lWll

I

1

11

l

v

1

Vacuum

piston

2

Power

valve

ET02

a

EF

512

Fig

EF

27

Sectional

view

of

po

r

valve

Fig

EF

28

Full

throttle

al

high

peed

EF

16

Page 113 of 537

Step

system

The

construction

of

this

system

may

correspond

to

the

idling

and

slow

system

of

the

primary

system

Tlris

system

aims

at

the

proper

filling

up

of

the

gap

when

fuel

supply

is

transferred

from

the

primary

system

to

the

secondary

one

The

step

port

is

located

near

the

secondary

throttle

valve

edge

in

its

fully

closed

state

Secondary

switchover

mechanism

The

secondary

throttle

valve

is

linked

to

the

diaphragm

which

is

actuated

by

the

vacuum

created

in

the

venturi

A

vacuum

jet

is

provided

at

each

of

the

primary

and

secondary

venturies

and

the

composite

vacuum

of

these

jets

actuates

the

diaphragm

As

the

linkage

causes

the

secondary

throttle

valve

to

close

until

the

prima

ry

throttle

valve

opening

reaches

ap

proximately

500

fuel

consumption

during

normal

operation

is

not

exces

sive

During

high

speed

running

as

shown

in

Figure

EF

28

as

the

vacuum

at

the

venturi

is

increased

the

dia

phragm

is

pulled

against

the

diaphragm

spring

force

and

then

secondary

throt

tie

valve

is

opened

The

other

side

during

low

speed

running

as

the

primary

throttle

valve

opening

does

not

reach

500

the

secondary

throttle

valve

is

locked

to

close

completely

by

the

locking

arm

which

is

interlocked

with

primary

throttle

arm

by

linkage

When

the

primary

throttle

valve

opening

reaches

wider

position

than

500

the

secondary

throttle

valve

is

ready

to

open

because

the

locking

arm

revolves

and

leaves

from

the

se

condary

throttle

arm

Engine

Fuel

HI

h

speed

circuit

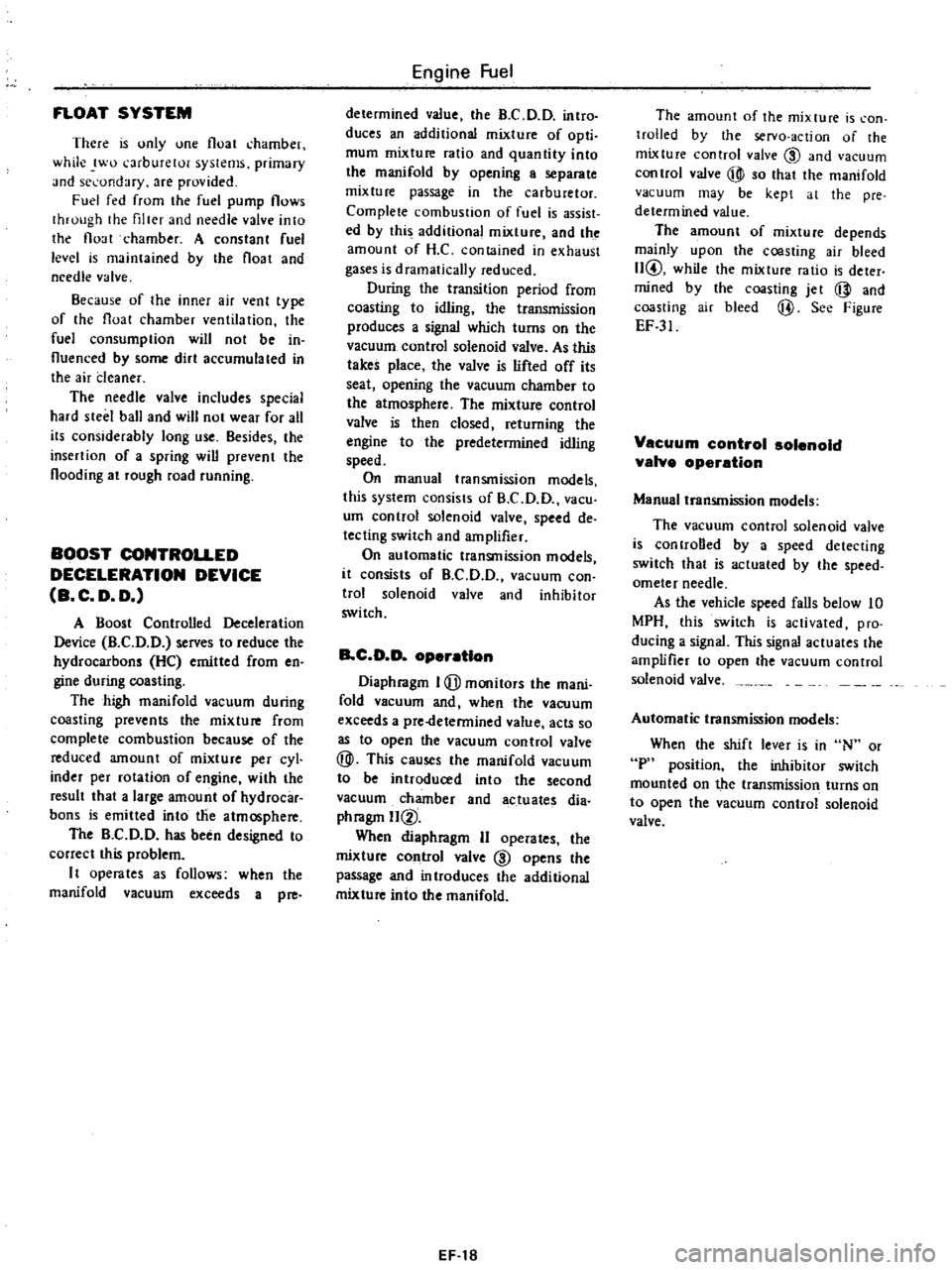

The

high

speed

circuit

improves

high

engine

output

performance

during

high

speed

driving

This

circuit

operates

only

when

driving

at

high

speed

It

consists

of

a

richer

jet

high

speed

enricher

air

bleed

and

richer

nozzle

When

the

velocity

of

suction

air

flowing

through

the

carburetor

secondary

bore

in

creases

additional

fuel

is

drawn

out

of

the

richer

nozzle

@

2

EF234

Secondary

I

Richer

jet

2

High

speed

enricher

air

bleed

3

Richer

nozzle

Primary

Fig

EF

29

High

speed

circuit

ANTI

DIESELlNG

SYSTEM

is

brought

into

operation

shutting

off

the

supply

of

fuel

to

the

slow

circuit

The

following

figure

shows

a

see

tiorial

view

of

this

control

The

carburetor

is

equipped

with

an

anti

dieseling

solenoid

valve

As

the

ignition

switch

is

turned

off

the

valve

EF230

@

l

CD

1

1

g

@eI

1

Anti

dieseling

solenoid

va1

2

Ignition

switch

3

Battery

Fig

EF

30

Schematic

drawing

of

anti

dieseling

sydtm

EF

17

Page 114 of 537

FLOAT

SYSTEM

There

IS

only

one

float

chamber

while

two

l

arburetor

systems

primary

Jnd

st

l

ondary

are

provided

Fuel

fed

from

the

fuel

pump

flows

through

the

filler

and

needle

valve

into

the

flo

t

chamber

A

constant

fuel

level

is

maintained

by

the

float

and

needle

valve

Because

of

the

inner

air

vent

type

of

the

float

chamber

ventilation

the

fuel

consumption

will

not

be

in

fluenced

by

some

dirt

accumulated

in

the

air

deaner

The

needle

valve

includes

special

hard

steel

ball

and

will

not

wear

for

all

its

considerably

long

use

Besides

the

inserrion

of

a

spring

wiU

prevent

the

flooding

at

rough

road

running

BOOST

CONTROLLED

DECELERATION

DEVICE

B

C

D

D

A

Boost

Controlled

Deceleration

Device

B

C

D

D

serves

to

reduce

the

hydrocarbons

He

emitted

from

en

gine

during

coasting

The

high

manifold

vacuum

during

coasting

prevents

the

mixture

from

complete

combustion

because

of

the

reduced

amount

of

mixture

per

cyl

inder

per

rotation

of

engine

with

the

result

that

a

large

amount

of

hydrocar

bons

is

emitted

into

tile

atmosphere

The

B

C

D

D

has

been

designed

to

correct

this

problem

It

opern

tes

as

follows

when

the

manifold

vacuum

exceeds

a

pre

Engine

Fuel

determined

value

the

B

C

D

D

intro

duces

an

additional

mixture

of

opti

mum

mixture

ratio

and

quantity

into

the

manifold

by

opening

a

separate

mixture

passage

in

the

carburetor

Complete

combustion

of

fuel

is

assist

ed

by

this

additional

mixture

and

the

amount

of

H

C

contained

in

exhaust

gases

is

dramatically

reduced

During

the

transition

period

from

coasting

to

idling

the

transmission

produces

a

signal

which

turns

on

the

vacuum

control

solenoid

valve

As

this

takes

place

the

valve

is

lifted

off

its

seat

opening

the

vacuum

chamber

to

the

atmosphere

The

mixture

control

valve

is

then

closed

returning

the

engine

to

the

predetermined

idling

speed

On

manual

transmission

models

this

system

consists

of

B

C

D

D

vacuo

urn

control

solenoid

valve

speed

de

tecting

switch

and

amplifier

On

automatic

transmission

models

it

consists

of

B

C

D

D

vacuum

con

trol

solenoid

valve

and

inhibitor

switch

B

C

D

D

operation

Diaphragm

I

Qj

monitors

the

mani

fold

vacuum

and

when

the

vacuum

exceeds

a

pre

fetermined

value

acts

so

as

to

open

the

vacuum

control

valve

@

This

causes

the

manifold

vacu

urn

to

be

introduced

into

the

second

vacuum

chamber

and

actuates

dia

phragm

ll@

When

diaphrngm

II

operates

the

mixture

control

valve

@

opens

the

passage

and

introduces

the

additional

mixture

into

the

manifold

EF

18

The

amount

of

the

mixture

is

con

trolled

by

the

servo

action

of

the

mixture

control

valve

CID

and

vacuum

control

valve

@

so

that

the

manifold

vacuum

may

be

kept

at

the

pre

determined

value

The

amount

of

mixture

depends

mainly

upon

the

coasting

air

bleed

II@

while

the

mixture

ratio

is

deter

mined

by

the

coasting

jet

@

and

coasting

air

bleed

@

See

Figure

EF

31

Vacuum

control

solenoid

valve

operation

Manual

transmission

models

The

vacuum

control

solenoid

valve

is

con

troDed

by

a

speed

detecting

switch

that

is

actuated

by

the

speed

ometer

needle

As

the

vehicle

speed

falls

below

10

MPH

this

switch

is

activated

pro

ducing

a

signal

This

signal

actuates

the

amplifier

to

open

the

vacuum

control

solenoid

valve

Automatic

transmission

models

When

the

shift

lever

is

in

N

or

P

position

the

inhibitor

switch

mounted

on

the

transmission

turns

on

to

open

the

vacuum

control

solenoid

valve

Page 115 of 537

I

Air

jet

2

Diaphragm

II

3

Mixture

control

valve

4

Coasting

air

bleed

II

5

Mixture

air

passage

6

Secondary

baHel

7

Intake

manifold

8

Boost

passage

9

Vacuum

control

solenoid

valve

10

Vacuum

control

valve

II

Diaphragm

I

Engine

Fuel

12

Secondary

main

jet

13

Coasting

jet

14

Coasting

air

bleed

I

15

Inhibitor

switch

N

P

ON

for

automatic

transmission

16

Amplifier

1

7

Speed

de

tecting

swi

tch

below

10

M

P

H

ON

for

manual

transmission

1

W

j

I

t

i

J

l

J

18

Ignition

switch

CID

1

1

fI3

6

@

I

r

101

@

i

r

@

JJ

Note

Broken

line

applies

only

to

Automatic

Transmission

I

Ignition

switch

2

Amplifier

3

Speed

detecting

switch

below

10

M

P

H

ON

for

manual

transmission

4

Inhibitor

switch

N

p

ON

for

automatic

transmission

5

Solenoid

valve

6

Vacuum

control

valve

7

Altitude

corrector

LlJ

I

I

l

f

L8

J

l

EF231

Fig

EF

31

Schematic

drawing

of

B

C

D

D

Non

California

models

1

J

ru

I

r

lJ

i7

I

To

intake

manifold

To

air

cleaner

E

F235

Note

Broken

line

applies

only

to

Automatic

Transmission

Fig

EF

32

Schematic

drawing

of

RC

D

D

California

models

EF

19

Page 116 of 537

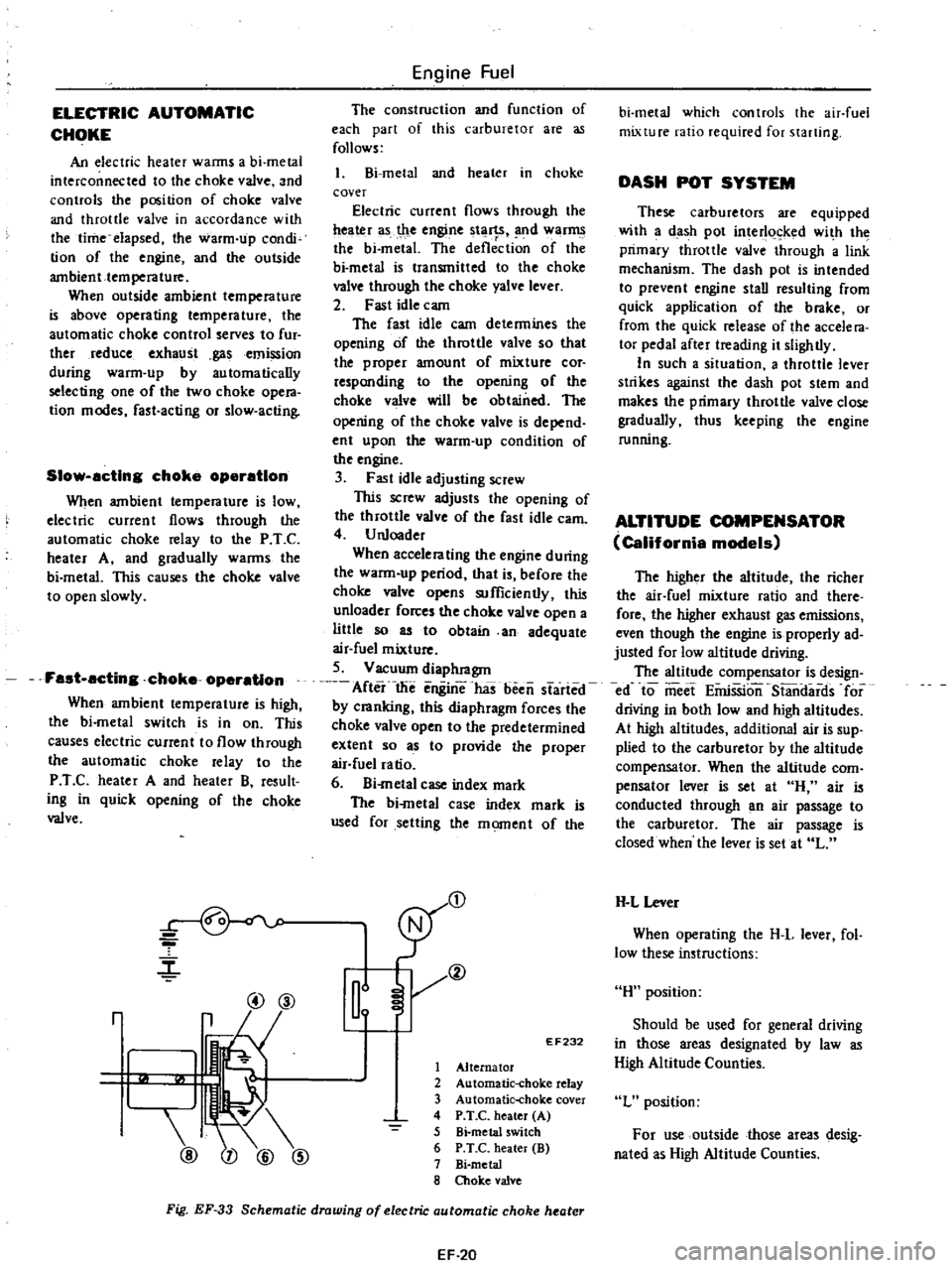

ELECTRIC

AUTOMATIC

CHOKE

An

electric

heater

wanns

a

bi

metal

interconnected

to

the

choke

valve

and

controls

the

position

of

choke

valve

and

throttle

valve

in

accordance

with

the

time

elapsed

the

warm

up

condi

tion

of

the

engine

and

the

outside

ambient

temperature

When

outside

ambient

temperature

is

above

operating

temperature

the

automatic

choke

control

serves

to

fur

ther

reduce

exhaust

gasemission

during

warm

up

by

automatically

selecting

one

of

the

two

choke

opera

tion

modes

fast

acting

or

slow

acting

Slow

acting

choke

operation

When

ambient

temperature

is

low

electric

current

flows

through

the

automatic

choke

relay

to

the

P

T

C

heater

A

and

gradually

warms

the

bi

metal

This

causes

the

choke

valve

to

open

slowly

Fast

acting

choke

operation

When

ambient

temperature

is

high

the

bi

metal

switch

is

in

on

This

causes

electric

current

to

flow

through

the

automatic

choke

relay

to

the

P

T

C

heater

A

and

heater

B

result

ing

in

quick

opening

of

the

choke

valve

r

@@

r

@

Engine

Fuel

The

construction

and

function

of

each

part

of

this

carburetor

are

as

follows

l

Bi

metal

and

heater

in

choke

cover

Electric

current

flows

through

the

ttea

r

as

t

le

engine

tl

1

SI

nd

war

the

bi

metal

The

deflection

of

the

bi

metal

is

transmitted

to

the

choke

valve

through

the

choke

yalve

lever

2

Fast

idle

cam

The

fast

idle

cam

determines

the

opening

of

the

throttle

valve

so

that

the

proper

amount

of

mixture

cor

responding

to

the

opening

of

the

choke

valve

will

be

obtained

The

opening

of

the

choke

valve

is

depend

ent

upon

the

warm

up

condition

of

the

engine

3

Fast

idle

adjusting

screw

This

screw

adjusts

the

opening

of

the

throttle

valve

of

the

fast

idle

earn

4

U

nloader

When

accelerating

the

engine

during

the

warm

up

period

that

is

before

the

choke

valve

opens

sufficiently

this

unloader

forces

the

choke

valve

open

a

liUle

so

as

to

obtain

an

adequate

air

fuel

mixture

5

Vacuum

diaphragm

After

the

enginThas

been

started

by

cranking

this

diaphragm

forces

the

choke

valve

open

to

the

predetermined

extent

so

as

to

provide

the

proper

air

fuel

ratio

6

Bi

metal

case

index

mark

The

bi

metal

case

index

mark

is

used

for

setting

the

moment

of

the

D

Il

EF232

1

Alternator

2

Automatic

choke

relay

3

Automatic

choke

cover

4

P

T

C

heater

A

5

Bi

metal

switch

6

P

T

C

heater

B

7

Bi

metal

8

Choke

valve

Fig

EF

33

Schematic

drawing

of

electric

automatic

choke

heater

EF

20

bi

metal

which

controls

the

air

fuel

mixture

ratio

required

for

starting

DASH

POT

SYSTEM

These

carburetors

are

equipped

with

a

dash

pot

interl

ked

wi

h

the

primary

throttle

valve

through

a

link

mechanism

The

dash

pot

is

intended

to

prevent

engine

stall

resulting

from

quick

application

of

the

brake

or

from

the

quick

release

of

the

accele

ra

tor

pedal

after

treading

it

slightly

In

such

a

situation

a

throttle

lever

strikes

against

the

dash

pot

stem

and

makes

the

primary

throttle

valve

close

gradually

thus

keeping

the

engine

running

ALTITUDE

COMPENSATOR

California

models

The

higher

the

altitude

the

richer

the

air

fuel

mixture

ratio

and

there

fore

the

higher

exhaust

gas

emissions

even

though

the

engine

is

properly

ad

justed

for

low

altitude

driving

The

altitude

compensator

is

design

ed

to

meet

EiiriSSion

S13ndards

for

driving

in

both

low

and

high

altitudes

At

high

altitudes

additional

air

is

sup

plied

to

the

carburetor

by

the

altitude

compensator

When

the

altitude

com

pensator

lever

is

set

at

H

air

is

conducted

through

an

air

passage

to

the

carburetor

The

air

passage

is

closed

when

the

lever

is

set

at

L

H

L

Lever

When

operating

the

H

L

lever

fol

low

these

instructions

H

position

Should

be

used

for

general

driving

in

those

areas

designated

by

law

as

High

Altitude

Counties

L

position

For

use

outside

those

areas

desig

nated

as

High

Altitude

Counties

Page 117 of 537

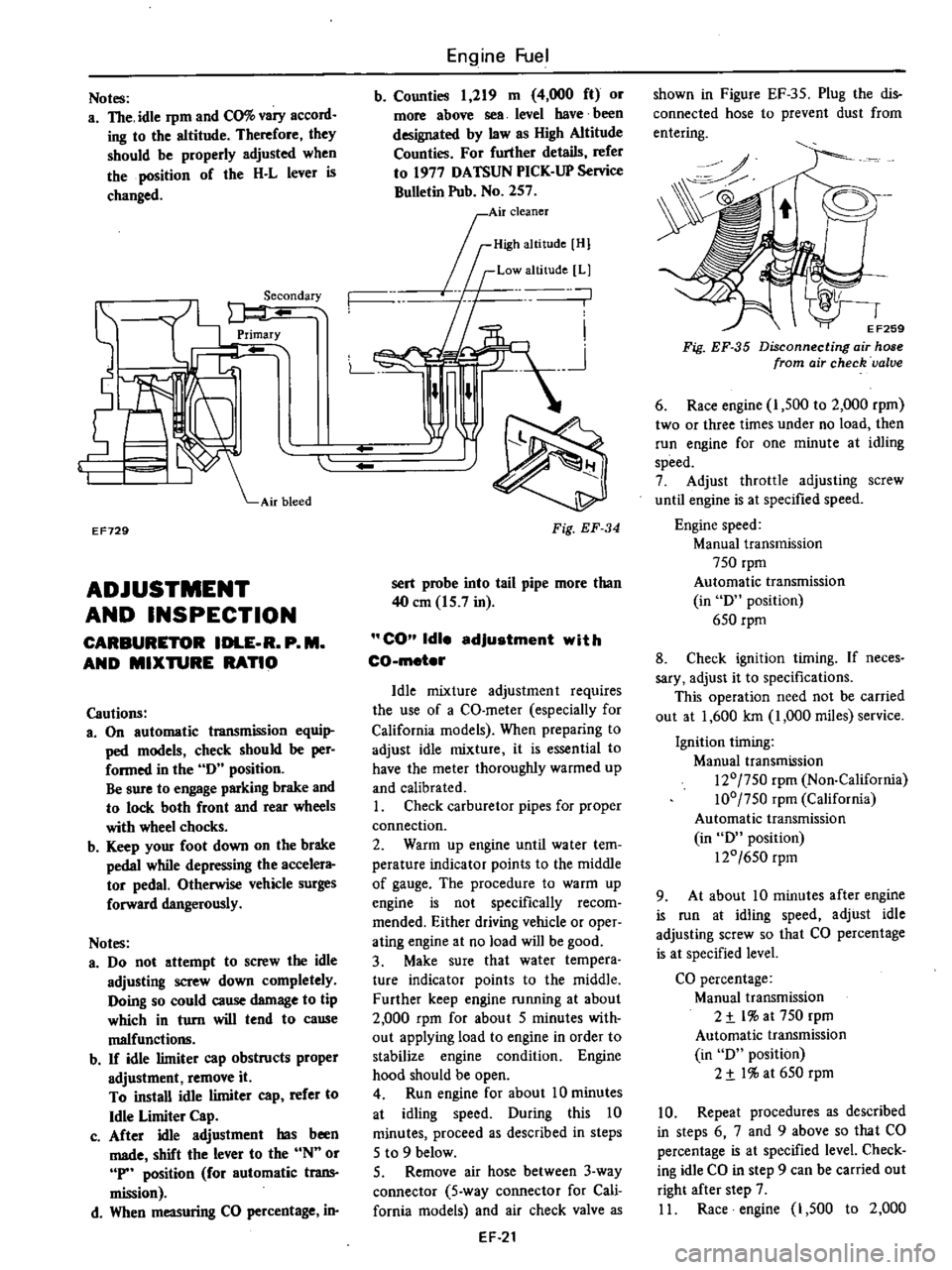

Notes

a

The

idle

rpm

and

CO

vary

accord

ing

to

the

altitude

Therefore

they

should

be

properly

adjusted

when

the

position

of

the

H

L

lever

is

changed

EF729

ADJUSTMENT

AND

INSPECTION

CARBURETOR

IDLE

R

P

M

AND

MIXTURE

RATIO

Cautions

3

On

automatic

transmission

equi

ped

models

check

should

be

per

formed

in

the

0

position

Be

sure

to

engage

parking

brake

and

to

lock

both

front

and

rear

wheels

with

wheel

chocks

b

Keep

your

foot

down

on

the

brake

pedal

while

depressing

the

accelera

tor

pedal

Otherwise

vehicle

surges

forward

dangerously

Notes

a

00

not

attempt

to

screw

the

idle

adjusting

screw

down

completely

Ooing

so

could

cause

damage

to

tip

which

in

turn

will

tend

to

cause

malfunctio11ll

b

If

idle

limiter

cap

obstructs

proper

adjustment

remove

it

To

install

idle

limiter

cap

refer

to

Idle

Limiter

Cap

c

After

idle

adjustment

has

been

made

shift

the

lever

to

the

N

or

P

position

for

automatic

trans

mission

d

When

measuring

CO

percentage

in

Engine

Fuel

b

Counties

1

219

m

4

000

ft

or

more

above

sea

level

have

been

designated

by

law

as

High

Altitude

Counties

For

further

details

refer

to

1977

OATSUN

PICK

UP

Service

Bulletin

Pub

No

257

0

I

Air

cleaner

rID

mOl

If

Low

altitude

Ll

n

n

L

n

Fig

EF

34

sert

probe

into

tail

pipe

more

than

40

em

15

7

in

CO

Idle

adjustment

with

CO

meter

Idle

mixture

adjustment

requires

the

use

of

a

CO

meter

especially

for

California

models

When

preparing

to

adjust

idle

mixture

it

is

essential

to

have

the

meter

thoroughly

warmed

up

and

calibrated

I

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tem

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

tempera

ture

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

with

out

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

Ouring

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

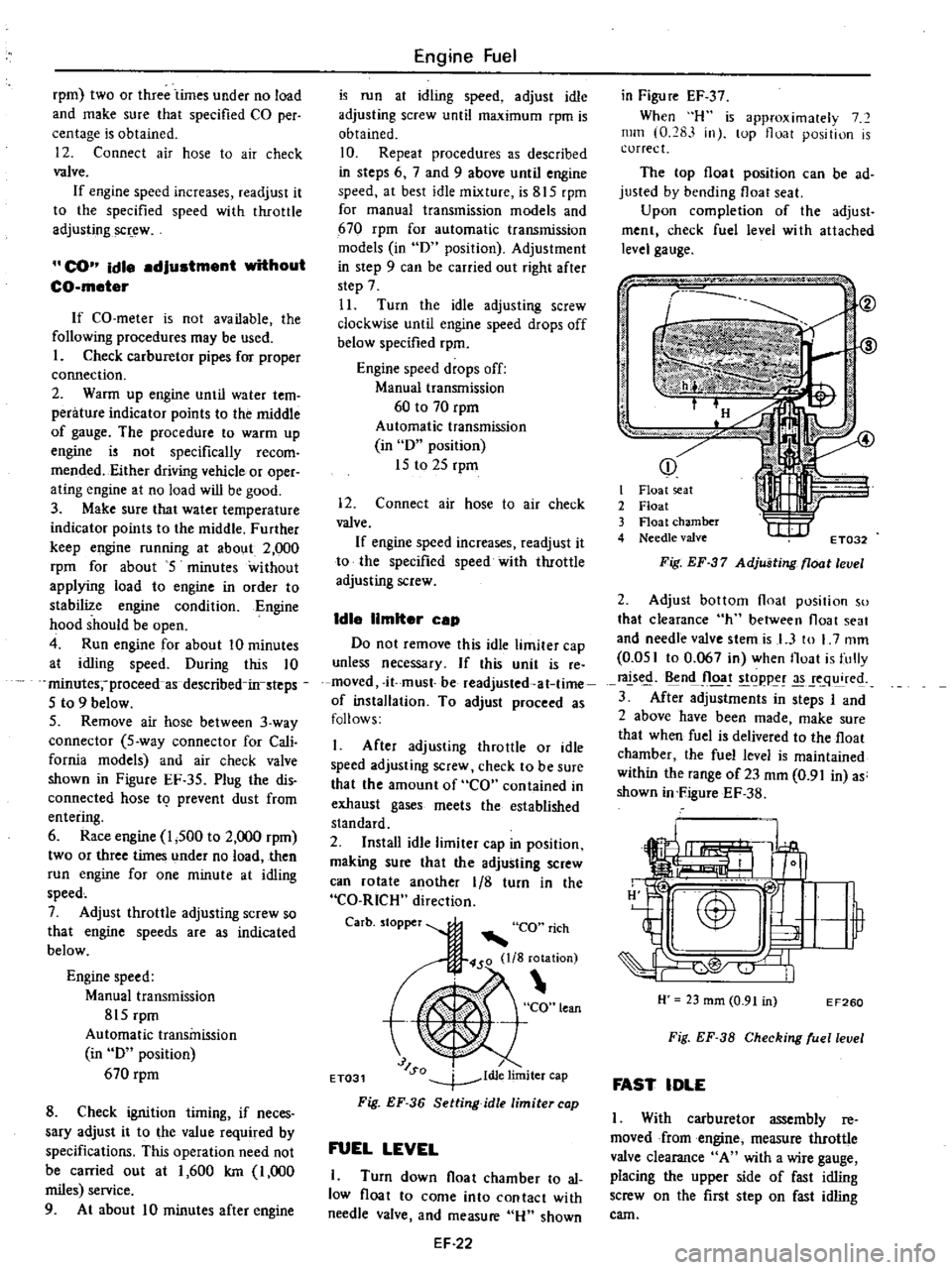

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

models

and

air

check

valve

as

EF

21

shown

in

Figure

EF

35

Plug

the

dis

connected

hose

to

prevent

dust

from

entering

0

o

EF259

Fig

EF

35

Disconnecting

air

hose

from

air

check

valve

6

Race

engine

I

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

until

engine

is

at

specified

speed

Engine

speed

Manual

transmission

750

rpm

Automatic

transmission

in

0

position

650

rpm

8

Check

ignition

timing

If

neces

sary

adjust

it

to

specifications

This

operation

need

not

be

carried

out

at

1

600

Ian

1

000

miles

service

Ignition

timing

Manual

transmission

120

750

rpm

Non

California

100

750

rpm

California

Automatic

transmission

in

0

position

120

650

rpm

9

At

about

10

minutes

after

engine

is

run

at

idling

speed

adjust

idle

adjusting

screw

so

that

CO

percentage

is

at

specified

level

CO

percentage

Manual

transmission

2

t

l

at

750

rpm

Automatic

transmission

in

0

position

2

t

I

at

650

rpm

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

so

that

CO

percentage

is

at

specified

level

Check

ing

idle

CO

in

step

9

can

be

carried

out

right

after

step

7

II

Race

engine

1

500

to

2

000

Page 118 of 537

rpm

two

or

three

iimes

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjustingsqew

CO

idle

edJustment

without

CO

meter

If

CO

meter

is

not

available

the

following

procedures

may

be

used

L

Check

carburetor

pipes

for

proper

connection

2

Warm

up

engine

until

water

tem

perature

indicator

points

to

the

middle

of

gauge

The

procedure

to

warm

up

engine

is

not

specifically

recom

mended

Either

driving

vehicle

or

oper

ating

engine

at

no

load

will

be

good

3

Make

sure

that

water

temperature

indicator

points

to

the

middle

Further

keep

engine

running

at

about

2

000

rpm

for

about

5

minutes

without

applying

load

to

engine

in

order

to

stabilize

engine

condition

Engine

hood

should

be

open

4

Run

engine

for

about

10

minutes

at

idling

speed

During

this

10

minutes

proceed

as

described

in

steps

5

to

9

below

5

Remove

air

hose

between

3

way

connector

5

way

connector

for

Cali

fornia

models

and

air

check

valve

shown

in

Figure

EF

35

Plug

the

dis

connected

hose

19

prevent

dust

from

entering

6

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

one

minute

at

idling

speed

7

Adjust

throttle

adjusting

screw

so

that

engine

speeds

are

as

indicated

below

Engine

speed

Manual

transmission

815

rpm

Automatic

transmission

in

D

position

670

rpm

8

Check

ignition

timing

if

neces

sary

adjust

it

to

the

value

required

by

specifications

This

operation

need

not

be

carried

out

at

1

600

km

1

000

miles

service

9

At

about

10

minutes

after

engine

Engine

Fuel

is

run

at

idling

speed

adjust

idle

adjusting

screw

until

maximum

rpm

is

obtained

10

Repeat

procedures

as

described

in

steps

6

7

and

9

above

until

engine

speed

at

best

idle

mixture

is

815

rpm

for

manual

transmission

models

and

670

rpm

for

automatic

transmission

models

in

D

position

Adjustment

in

step

9

can

be

carried

out

right

after

step

7

11

Turn

the

idle

adjusting

screw

clockwise

until

engine

speed

drops

off

below

specified

rpm

Engine

speed

drops

off

Manual

transmission

60

to

70

rpm

Automatic

transmission

in

D

position

15

to

25

rpm

12

Connect

air

hose

to

air

check

valve

If

engine

speed

increases

readjust

it

to

the

specified

speed

with

throttle

adjusting

screw

Idle

limiter

cep

Do

not

remove

this

idle

limiter

cap

unless

necessary

If

this

unit

is

re

moved

it

must

be

readjusted

at

lime

of

installation

To

adjust

proceed

as

follows

I

After

adjusting

throttle

or

idle

speed

adjusting

screw

check

to

be

sure

that

the

amount

of

CO

contained

in

exhaust

gases

meets

the

established

standard

2

Install

idle

limiter

cap

in

position

making

sure

that

the

adjusting

screw

can

rotate

another

1

8

turn

in

the

CO

RICH

direction

Carbo

to

per

CO

rich

450

lIS

rotation

t

CO

lean

J

SQ

dl

lim

ET031

1

e

Iter

cap

Fig

EF

36

Setting

idle

limiter

cap

FUEL

LEVEL

1

Turn

down

float

chamber

to

al

low

float

to

come

into

contact

with

needle

valve

and

measure

Hu

shown

EF

22

in

Figu

re

EF

37

When

H

is

approximalely

7

mill

0

283

in

lOp

float

position

is

correct

The

top

float

position

can

be

ad

justed

by

bending

float

seat

Upon

completion

of

the

adjust

ment

check

fuel

level

wi

th

attached

level

gauge

p

j

i

I

it

I

Float

seat

2

Float

3

Float

chamber

4

Needle

valve

t

I

IIf

ET032

Fig

EF

37

Adjusting

float

level

2

Adjust

bottom

float

position

so

that

clearance

h

between

float

seat

and

needle

valve

stemis

I

3

to

L

7

mm

0

051

to

0

067

in

when

Iloat

is

fully

rals

n

Jloa

t

goppe

q

re

3

After

adjustments

in

steps

I

and

2

above

have

been

made

make

sure

that

when

fuel

is

delivered

to

the

float

chamber

the

fuel

level

is

maintained

within

the

range

of23

mm

0

91

in

as

shown

in

FigureEF

38

H

23

mm

0

91

in

EF260

Fig

EF

38

Checking

ruellevel

FAST

IDLE

I

With

carburetor

assembly

reo

moved

from

engine

measure

throttle

valve

clearance

A

with

a

wire

gauge

placing

the

upper

side

of

fast

idling

screw

on

the

first

step

on

fast

idling

cam

Page 119 of 537

EC527

Fig

EF

39

Mea

uring

throttle

valve

clearance

MfT

AfT

3

To

check

fast

idling

cam

setting

by

engine

speed

proceed

as

follows

Warm

up

engine

sufficiently

Set

Engine

Fuel

Fast

idling

earn

steps

o

04th

l

2nd

1st

EC528

Fig

EF

40

Fast

idling

cam

steps

2

The

clearance

should

be

specified

value

in

the

following

table

If

not

ad

just

the

clearance

by

turning

fast

idling

screw

Clearance

A

mm

in

1

33

to

I

47

0

0524

to

0

0579

1

58

to

1

72

0

0622

to

0

0677

fast

idling

cam

at

2nd

step

and

read

engine

speed

Fast

idling

cam

is

prop

erly

set

if

engine

speed

is

within

Engine

speed

rpm

Fast

idling

earn

MfT

AfT

VACUUM

BREAK

I

Close

choke

valve

completely

2

Hold

choke

valve

by

stretching

a

rubber

band

between

choke

piston

lever

and

stationary

part

of

carburetor

3

Grip

vacuum

break

rod

with

pliers

and

pull

straight

out

4

Under

this

condition

adjust

the

clearance

between

choke

valve

and

carburetor

body

B

in

Figure

EF

42

to

specified

value

by

bending

vacuum

brake

rod

I

900

to

2

800

2nd

step

2

200

to

3

200

S

B

j

CK

iXo

LL

r

I

il

L

J

1

Choke

piston

rod

2

Choke

spring

3

Choke

piston

EF516

4

Diaphragm

cover

5

Choke

piston

lever

6

Choke

valve

Fig

EF

42

Adjusting

vacuum

break

EF

23

Z

ET033

Fast

idling

carn

Nut

Fast

idling

screw

Choke

valve

Choke

connecting

rod

Throttle

valve

Fig

EF

41

Adjusting

the

clearance

of

throttle

valve

Fast

idling

earn

1st

step

specifications

below

Clearance

A

in

2nd

step

is

reference

value

Clearance

A

mm

in

0

94

to

1

18

0

0370

to

0

0465

L16

to

I

40

0

0457

to

0

0551

CHOKE

UNLOADER

Close

choke

valve

completely

2

Hold

choke

valve

by

stretching

a

rubber

band

between

choke

piston

lever

and

stationary

part

of

carburetor

3

Pull

throttle

lever

until

full

open

Under

this

condition

adjust

clear

ance

between

choke

valve

and

carbure

tor

body

to

2

45

mm

0

096

in

by

bending

unloader

tongue

Note

Make

sure

that

throttle

valve

opens

when

carburetor

is

mounted

on

the

vehicle

If

throttle

valve

rails

to

open

un

loader

becomes

inoperative

resulr

ing

in

poor

acceleration

after

engine

is

started

Page 120 of 537

ELECTRIC

AUTOMATIC

CHOKE

Checklna

automatic

choke

heater

circuit

with

function

test

connector

Caution

Do

not

altach

test

leads

of

a

circuit

tester

to

those

other

than

designated

Refer

to

figure

Ef

43

I

With

engine

not

running

check

for

continuity

between

A

and

B

as

shown

in

figure

Ef

43

If

continuity

exists

heater

is

func

tioning

properly

If

continuity

d

s

not

exist

check

for

disconnected

connector

or

open

P

T

e

heater

circuit

2

With

engine

running

at

idle

check

for

presence

of

voltage

across

A

and

B

as

shown

in

figure

EF

43

If

voltmeter

reading

is

12

volts

d

c

heater

circuit

is

functioning

properly

If

vohmeter

reading

is

zero

check

for

disconnected

connector

open

circuit

or

faulty

automatic

choke

relay

3

Replace

faulty

parts

J

j

N

j

EF710

1

ignition

key

2

Automatic

choke

relay

Engine

stop

OFF

Engine

start

ON

3

Automatic

choke

heateI

4

Function

test

connector

5

Altema

tor

Fig

EF

43

Checking

oulomalic

choke

heater

circuit

with

fu

nc

non

led

connector

Engine

Fuel

Automatic

choke

I

Before

starting

engine

fully

de

press

al

celerator

pedaJ

to

ensure

that

choke

valve

doses

properly

Push

choke

valve

with

a

finger

and

heck

for

binding

3

Check

0

be

sure

that

bi

rnetal

cover

index

mark

is

set

at

the

cen

leT

of

choke

housing

index

mark

a

s

shown

in

Figure

EF

44

Note

Do

not

set

b

metal

cover

index

mark

at

any

position

except

the

center

of

choke

housing

index

marl

tE

jL

J

Thermostat

cover

Bi

metal

chamber

2

Thermostat

housing

3

Groove

ET034

Fig

EF

44

Bi

metol

tting

4

Check

automatic

choke

heater

source

wiring

for

proper

connection

then

start

engine

5

After

warming

up

the

engine

see

that

choke

valve

is

fully

open

6

If

automatic

choke

heater

source

wiring

is

normal

and

choke

valve

does

not

operate

after

warm

up

replace

hi

metal

co

t

er

Automatic

choke

relay

I

Remove

automatic

choke

relay

Auto

choke

heater

relay

EF278

Fig

EF

45

Location

of

automatic

choke

relay

EF

24

2

Make

an

operational

check

of

automatic

choke

relay

as

shown

in

Figure

EF

46

Apply

2

volts

d

c

across

termi

nals

I

and

3

to

ensure

that

i

ontinuity

exists

between

terminals

2

and

4

Check

t

lal

continuity

does

not

exist

between

terminals

2

and

4

when

no

voltage

is

applied

across

them

If

results

satisfies

the

above

automatic

choke

relay

is

functioning

properly

if

not

replace

choke

relay

1

2

3

y

4

EF723

Fig

EF

46

Checking

automatic

choke

relay

Automatic

choke

heater

I

Measure

resistance

of

choke

heater

as

shown

in

figure

EF

47

spe

ified

re

s

an

ce

is

3

7

to

8

9

ohms

F

EF261

Fig

EF

47

Automatic

choke

heater

check

2

If

measured

value

is

not

within

the

specification

replace

bi

metal

cover

INTERLOCK

OPENING

OF

PRIMARY

AND

SECONDARY

THROTnE

VALVE

Figure

EF

48

shows

primary

throt

tie

valve

opened

SO

When

primary

throtlle

valve

is

opened

50

the

adjust

plate

integrated

with

throttle

valve

is

in

contact

with

return

plate

at

A

Page 121 of 537

When

throttle

valve

is

opened

fur

ther

locking

arm

is

detached

from

secondary

throttle

arm

permitting

see

ondary

system

to

start

operation

Linkage

between

primary

and

see

ondary

throttles

will

function

properly

if

distance

between

throttle

valve

and

inner

wall

of

throttle

chamber

is

74

mm

0

291

in

Adjustment

is

made

by

bending

connecting

link

I

L

l

1

4

CAl

Secondary

prm

ary

I

Jl

I

7

t

@

1

Roller

4

Adjust

plate

2

Connecting

lever

5

Throttle

c

amber

3

Return

plate

6

Throttle

valve

Fig

EF

48

Adjusting

interlock

opening

DASH

POT

1

Idling

speed

of

engine

and

mix

ture

must

be

well

tuned

up

and

engine

sufficiently

warm

2

Turn

throttle

valve

by

hand

and

read

engine

speed

when

dash

pot

just

touches

stopper

lever

3

Adjust

position

of

dash

pot

by

turning

nut

until

engine

speed

is

in

the

specified

range

Specified

engine

speed

Manual

transmission

1

900

to

2

100

rpm

Automatic

transmission

1

650

to

1

850

rpm

4

Tighten

lock

nuts

5

Make

sure

that

engine

speed

drops

smoothly

from

2

000

to

1

000

rpm

in

about

three

seconds

Engine

Fuel

Fig

EF

49

Adjusting

dash

pot

ACCELERATING

PUMP

I

Visually

inspect

accelerating

pump

cover

for

any

sign

of

fuel

leaks

2

If

fuel

leaks

are

found

check

gasket

and

replace

if

necessary

ANTI

DIESELING

SOLENOID

VALVE

If

engine

does

not

stop

when

igni

tion

switch

is

turned

off

this

indicates

that

a

striking

closed

solenoid

valve

is

shutting

off

supply

of

fuel

to

engine

If

harness

is

in

good

condition

replace

solencid

valve

as

a

unit

Notes

a

Tightening

torque

is

1

8

to

3

5

kg

m

13

to

25

ft

Ib

b

After

replacement

star

engine

and

check

to

be

sure

that

fuel

is

not

leaking

and

that

anti

dieseling

sol

noid

is

in

good

condition

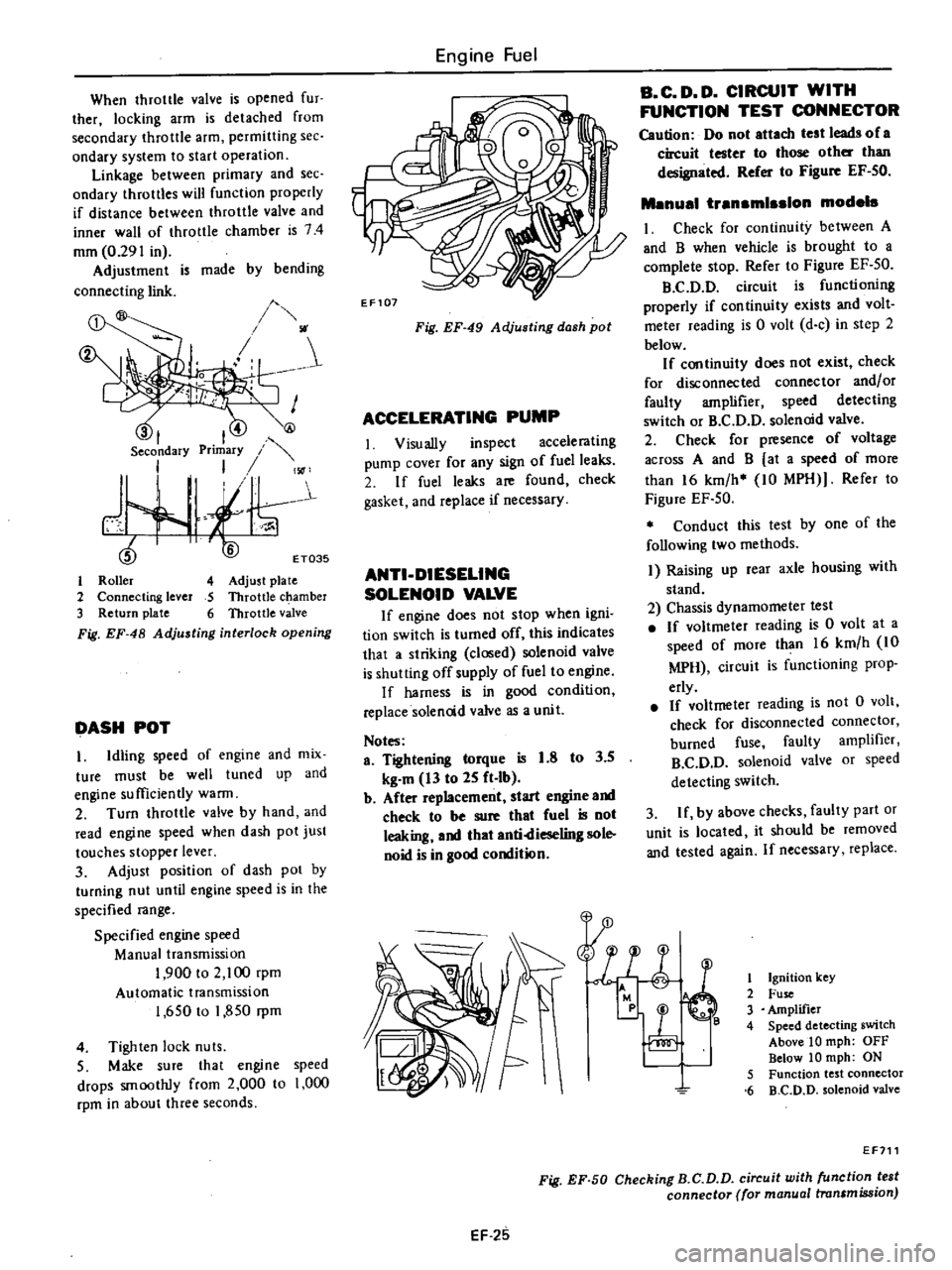

B

C

D

D

CIRCUIT

WITH

FUNCTION

TEST

CONNECTOR

Caution

Do

not

attach

test

leads

of

a

circuit

tester

to

those

other

than

designated

Refer

to

Figure

EF

50

Menuel

trensmlsslon

models

I

Check

for

continuity

between

A

and

B

when

vehicle

is

brought

to

a

complete

stop

Refer

to

Figure

EF

50

B

C

D

D

circuit

is

functioning

properly

if

continuity

exists

and

volt

meter

reading

is

0

volt

d

c

in

step

2

below

If

continuity

does

not

exist

check

for

disconnected

connector

and

or

faulty

amplifier

speed

detecting

switch

or

B

C

D

D

solenoid

valve

2

Check

for

presence

of

voltage

across

A

and

B

at

a

speed

of

more

than

16

km

h

10

MPH

Refer

to

Figure

EF

50

Conduct

this

test

by

one

of

the

following

two

methods

I

Raising

up

rear

axle

housing

with

stand

2

Chassis

dynamometer

test

If

voltmeter

reading

is

0

volt

at

a

speed

of

more

than

16

km

h

10

MPH

circuit

is

functioning

prop

erly

If

voltmeter

reading

is

not

0

volt

check

for

disconnected

connector

burned

fuse

faulty

amplifier

B

C

D

D

solenoid

valve

or

speed

detecting

switch

3

If

by

above

checks

faulty

part

or

unit

is

located

it

should

be

removed

and

tested

again

If

necessary

replace

1

P4

11

0

8

l

1

Ignition

Icey

2

Fuse

3

Amplifier

4

Speed

detecting

switch

Above

10

mph

OFF

Below

10

mph

ON

5

Function

test

connector

6

B

C

D

D

solenoid

valve

EF711

Fig

EF

50

Checking

B

C

D

D

circuit

with

function

test

connector

for

manual

transmission

EF

25