maintenance DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 402 of 537

DESCRIPTION

MAINTENANCE

AND

SERVICE

TIRE

INFLATION

TIRE

REPAIR

WHEEL

REPAIR

WEAR

DESCRIPTION

The

620

series

models

are

equipped

with

4lV

14

wheels

with

25

mOl

0

98

in

offset

All

tires

are

tubeless

Wheel

and

Tire

WHEEL

AND

TIRE

CONTENTS

WT2

WT

2

WT2

WT2

WT

2

WT

2

TIRE

ROTATION

CHANGING

TIRE

INSPECTION

WHEEL

BALANCE

WHEEL

AND

TIRE

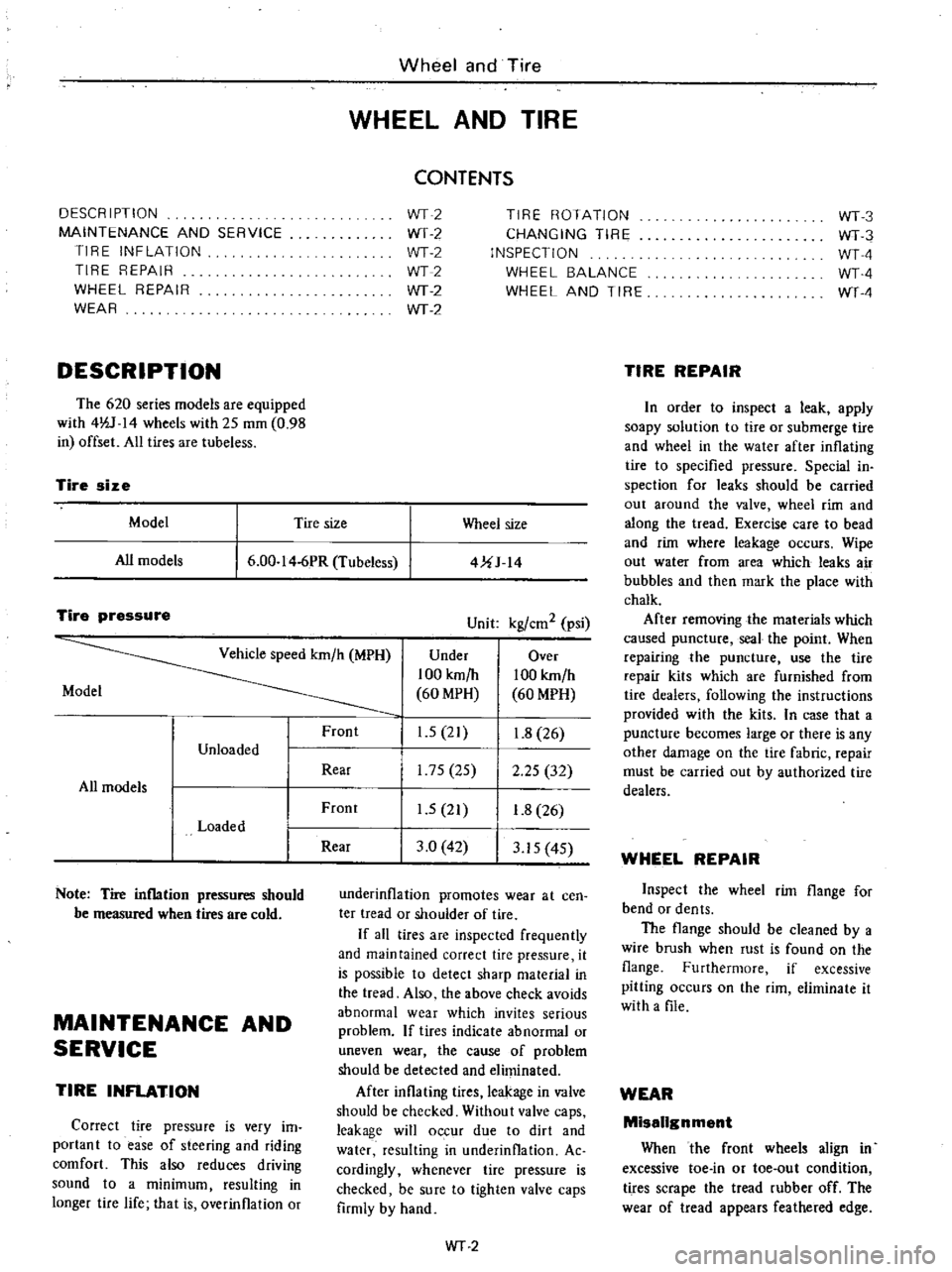

Tire

size

Model

Tire

size

Wheel

size

All

models

6

00

I

4

6PR

Tubeless

4UJ

14

Tire

pressure

Unit

kgl

em

2

psi

Vehicle

speed

km

h

MPH

Under

Over

100

km

h

100

km

h

Model

60

MPH

60

MPH

Front

1

5

21

1

8

26

Unloaded

Rear

175

25

2

25

32

All

models

Front

1

5

21

1

8

26

Loaded

Rear

3

0

42

3

15

4S

Note

Tire

inflation

pressures

should

be

measured

when

tires

are

cold

MAINTENANCE

AND

SERVICE

TIRE

INFLATION

Correct

tire

pressure

is

very

im

portant

to

ease

of

steering

and

riding

comfort

This

also

reduces

driving

sound

to

a

minimum

resulting

in

longer

tire

life

that

is

overinflation

or

underinflation

promotes

wear

at

cen

ter

tread

or

shouider

of

tire

If

aU

tires

are

inspected

frequently

and

maintained

correct

tire

pressure

it

is

possible

to

detect

sharp

material

in

the

tread

Also

the

above

check

avoids

abnormal

wear

which

invites

serious

problem

If

tires

indicate

abnormal

or

uneven

wear

the

cause

of

problem

should

be

detected

and

eliminated

After

inflating

tires

leakage

in

valve

should

be

checked

Without

valve

caps

leakage

will

occur

due

to

dirt

and

water

resulting

in

underinflation

Ac

cordingly

whenever

tire

pressure

is

checked

be

sure

to

tighten

valve

caps

firmly

by

hand

WT

2

WT3

WT3

WTA

WTA

WT

4

TIRE

REPAIR

In

order

to

inspect

a

leak

apply

soapy

solution

to

tire

or

submerge

tire

and

wheei

in

the

water

after

inflating

tire

to

specified

pressure

Special

in

spection

for

leaks

should

be

carried

out

around

the

valve

wheel

rim

and

along

the

tread

Exercise

care

to

bead

and

rim

where

leakage

occurs

Wipe

out

water

from

area

which

leaks

air

bubbles

and

then

mark

the

place

with

chalk

After

removing

the

materials

which

caused

puncture

seal

the

point

When

repairing

the

puncture

use

the

tire

repair

kits

which

are

furnished

from

tire

dealers

following

the

instructions

provided

with

the

kits

In

case

that

a

puncture

becomes

large

or

there

is

any

other

damage

on

the

tire

fabric

repair

must

be

carried

out

by

authorized

tire

dealers

WHEEL

REPAIR

Inspect

the

wheel

rim

flange

for

bend

or

dents

The

flange

should

be

cleaned

by

a

wire

brush

when

rust

is

found

on

the

flange

Furthermore

if

excessive

pitting

occurs

on

the

rim

eliminate

it

with

a

file

WEAR

Missilgnment

When

the

front

wheels

align

in

excessive

toe

in

or

toe

out

condition

tires

scrape

the

tread

rubber

off

The

wear

of

tread

appears

feathered

edge

Page 418 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

AND

INSTALLATION

Accelerator

wire

I

Remove

air

cleaner

assembly

2

Disconnect

accelerator

wire

from

carburetor

3

Loosen

lock

nut

and

disconnect

accelerator

wire

outer

case

from

wire

holder

See

Figure

FE

I

4

Remove

spring

clamp

and

discon

nect

accelerator

wire

from

accelerator

pedal

arm

S

Remove

two

screws

securing

ac

celerator

wire

outer

case

to

body

and

detach

accelerator

wire

6

To

install

reverse

the

order

of

removal

Apply

recommended

multi

purpose

grease

slightly

to

portion

MG

shown

in

Figure

FE

I

Accelerator

pedal

assembly

I

Remove

spring

clamp

then

dis

connect

accelerator

wire

from

tip

of

pedal

ann

2

Remove

two

screws

securing

ac

celerator

pedal

bracket

to

body

3

Remove

accelerator

pedal

from

dash

panel

See

Figure

FE

I

4

To

install

reverse

the

order

of

removal

INSPECTION

I

Check

accelerator

pedal

return

spring

for

rust

fatigue

or

damage

Replace

if

necessary

2

Check

accelerator

wire

cases

and

fastening

locations

for

rust

damage

or

looseness

Repair

or

replace

if

necessary

ADJUSTMENT

Accelerstor

pedal

and

wire

Adjust

pedal

stopper

bolt

Section

A

so

as

to

obtain

specifi

ed

height

E

as

shown

in

Figure

FE

I

Secure

pedal

stopper

bolt

with

stopper

lock

nut

Refer

to

Figure

FE

I

E

78

mOl

3

07

in

Tightening

torque

01

nut

0

38

to

0

4S

kg

m

2

7

to

3

2

ft

b

2

Release

auto

choke

effect

since

throttle

lever

is

opened

by

fast

idle

earn

until

engine

warms

up

I

Keep

choke

valve

fully

open

with

fingers

2

Pull

throttle

lever

up

by

hand

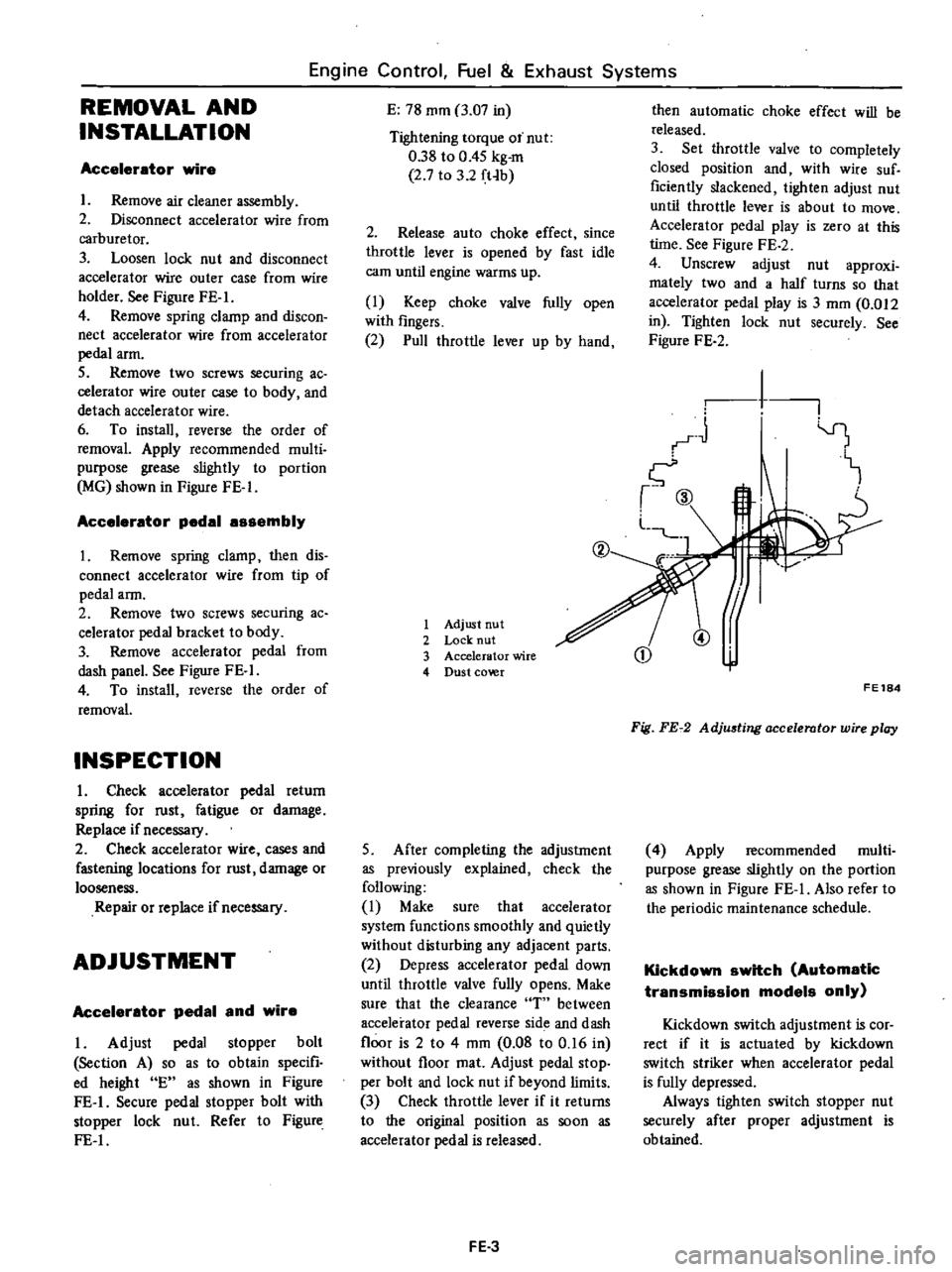

1

Adjust

nut

2

Lock

nut

3

Accelerator

wire

4

Dust

co

r

5

After

completing

the

adjustment

as

previously

explained

check

the

following

I

Make

sure

that

accelerator

system

functions

smoothly

and

quietly

without

disturbing

any

adjacent

parts

2

Depress

accelerator

pedal

down

until

throttle

valve

fully

opens

Make

sure

that

the

clearance

T

between

accelerator

pedal

reverse

side

and

dash

floor

is

2

to

4

mm

0

08

to

0

16

in

without

floor

mat

Adjust

pedal

stop

per

bolt

and

lock

nut

if

beyond

limits

3

Check

throttle

lever

if

it

returns

to

the

original

position

as

soon

as

accelerator

pedal

is

released

FE

3

then

automatic

choke

effect

will

be

released

3

Set

throttle

valve

to

completely

closed

position

and

with

wire

suf

ficiently

slackened

lighten

adjust

nut

until

throttle

lever

is

about

to

move

Accelerator

pedal

play

is

zero

at

this

lime

See

Figure

FE

2

4

Unscrew

adjust

nut

approxi

mately

two

and

a

half

turns

so

that

accelerator

pedal

play

is

3

mOl

0

012

in

Tighten

lock

nut

securely

See

Figure

FE

2

1

I

1

CD

@

FE184

Fig

FE72

AdjU6ting

accelerator

wire

play

4

Apply

recommended

multi

purpose

grease

slightly

on

the

portion

as

shown

in

Figure

FE

I

Also

refer

to

the

periodic

maintenance

schedule

Kickdown

switch

Automatic

transmission

models

only

Kickdown

switch

adjustment

is

cor

rect

if

it

is

actuated

by

kickdown

switch

striker

when

accelerator

pedal

is

fully

depressed

Always

tighten

switch

stopper

nut

securely

after

proper

adjustment

is

obtained

Page 421 of 537

Engine

Control

Fuel

Exhaust

Systems

2

Remove

fuel

filter

INSPECTION

Fuel

tanle

Check

fuel

tank

for

cracks

or

deformation

If

necessary

replace

2

Fuel

hose

Inspect

all

hoses

for

cracks

fatigue

sweating

or

deterioration

Replace

any

hose

that

is

damaged

3

Fuel

tube

Replace

any

fuel

tube

that

is

crack

ed

rusted

collapsed

or

deformed

Note

Inspect

hoses

and

tubes

ac

cording

to

the

periodic

mainte

nance

schedule

4

Fuel

filter

Replace

fuel

filter

according

to

the

periodic

maintenance

schedule

or

when

it

is

clogged

or

restricted

DESCRIPTION

REMOVAL

DESCRIPTION

The

exhaust

systems

installed

on

the

non

California

models

differ

in

specifications

from

those

installed

on

the

California

models

Fuel

filter

is

of

a

cartridge

type

and

cannot

be

cleaned

Always

replace

with

a

new

one

5

Fuel

tank

gauge

unit

Check

gauge

unit

for

rust

deforma

tion

or

deterioration

If

necessary

replace

INSTALLATION

To

install

reverse

the

order

of

removal

Observe

the

following

I

Install

hose

clamps

securely

Do

not

tighten

excessively

to

avoid

damaging

hoses

2

Fasten

clips

holding

fuel

tube

on

under

body

securely

Failure

to

follow

this

caution

could

result

in

damage

to

the

surface

of

fuel

tube

3

Do

not

kink

or

twist

hose

and

tube

when

they

are

routed

EXHAUST

SYSTEM

CONTENTS

FE

6

FE

8

INSPECTION

INSTAllATION

Non

California

models

The

exhaust

system

consists

of

a

front

exhaust

tube

a

main

muffler

assembly

with

rear

tube

mounting

hangers

brackets

and

a

heat

insulator

FE

6

4

Install

fIller

hose

after

fuel

tank

has

been

mounted

in

place

Failure

to

follow

this

caution

could

result

in

leakage

from

around

hose

connections

5

When

installing

fuel

tank

gauge

unit

align

the

projection

of

tank

gauge

unit

with

the

notch

in

fuel

tank

and

tighten

it

securely

Be

sure

to

install

gauge

unit

with

O

ring

in

place

6

Run

engine

and

check

for

leaks

at

connections

Tightening

torque

Drain

plug

5

0

to

6

0

kg

m

36

to

43

ft

Ib

Fuel

tank

securing

bolt

0

8

to

1

I

kg

m

6

to

8

ft

Ib

Reservoir

tank

securing

bolt

032

to

0

44

kg

m

2

to

3

ft

Ib

FE

8

FE

8

California

models

The

exhaust

system

cOllsists

of

a

front

exhaust

tube

a

catalytic

conver

ter

assembly

a

center

tube

a

main

muffler

assembly

with

rear

tube

mounting

hangers

brackets

and

heat

insulators

The

catalytic

converter

is

COD

nected

to

the

front

tube

and

the

center

tube

with

bolts

and

nuts

Page 447 of 537

DESCRIPTION

Cables

are

covered

with

color

coded

vinyl

for

easy

identification

In

the

wiring

diagram

colors

are

indicated

by

one

or

two

alphabetical

letters

It

is

recommended

that

the

battery

be

disconnected

before

performing

any

electrical

service

other

than

bulb

or

fuse

replacement

In

addition

to

fuses

a

fusible

link

has

been

installed

to

protect

wiring

The

fusible

link

functions

almost

the

same

as

a

fuse

though

its

eharac

teristics

are

slightly

different

than

normal

fuses

CABLE

COLORS

Cable

colors

are

indicated

by

one

or

two

alphabetical

letters

B

Black

Be

Brown

G

Green

L

Blue

Lg

Light

green

R

Red

W

White

Y

Yellow

The

main

cable

is

generally

coded

with

a

single

color

The

others

are

coded

with

a

two

tone

color

as

follows

BW

Black

with

white

stripe

gR

Light

green

with

red

stripe

INSPECTION

Inspect

all

electrical

circuits

refer

ring

to

wiring

or

circuit

diagrams

Circuits

should

be

tested

for

conti

nuity

or

short

circuit

with

a

conven

tional

test

lamp

or

low

reading

volt

meter

Before

inspection

of

circuit

ensure

that

I

Each

electrical

component

part

or

cable

is

securely

fastened

to

its

con

nector

or

terminal

2

Each

connection

is

firmly

in

place

and

free

from

rust

and

dirt

3

No

cable

covering

shows

any

evidence

of

cracks

deterioration

or

other

damage

4

Each

terminal

is

at

a

safe

distance

away

from

any

adjacent

metal

parts

5

Each

cable

is

fastened

to

its

proper

connector

or

terminal

Body

Electrical

System

BODY

ELECTRICAL

WIRING

6

Each

grounding

bolt

is

firmly

pbnted

7

Wiring

is

kept

away

from

any

adjacent

parts

with

sharp

edges

or

high

temperature

parts

such

as

exhaust

pipe

8

Wiring

is

kept

away

from

any

rotating

or

working

parts

fan

pulley

fan

belt

etc

9

Cables

between

ftxed

portions

and

moving

parts

are

long

enough

to

withstand

shocks

and

vibratory

forces

Notes

a

Before

starting

to

inspect

and

repair

any

part

of

electrical

system

or

other

parts

which

may

lead

to

a

short

circuit

disconnect

cables

at

battery

terminals

as

follows

Disconnect

cable

at

negative

terminal

and

then

disconnect

cable

at

positive

terminal

Before

connecting

cables

to

battery

terminal

be

sure

to

clean

terminals

with

a

rag

Fasten

cable

at

positive

terminal

and

then

ground

cable

at

negative

terminal

Apply

grease

to

top

of

these

terminals

to

prevent

rust

from

developing

on

them

b

Never

use

a

screwdriver

or

senrice

tool

to

conduct

a

continuity

test

Use

test

leads

c

Never

ground

an

open

circuit

or

circuits

under

no

load

Use

a

test

lamp

12V

3W

or

circuit

tester

as

a

load

FUSE

AND

FUSIBLE

LINK

DESCRIPTION

The

fuse

and

fusible

link

are

protec

tive

devices

used

in

an

electrical

cir

cuit

When

current

increases

beyond

rated

amperage

fusible

metal

melts

and

the

circuit

is

broken

BE

2

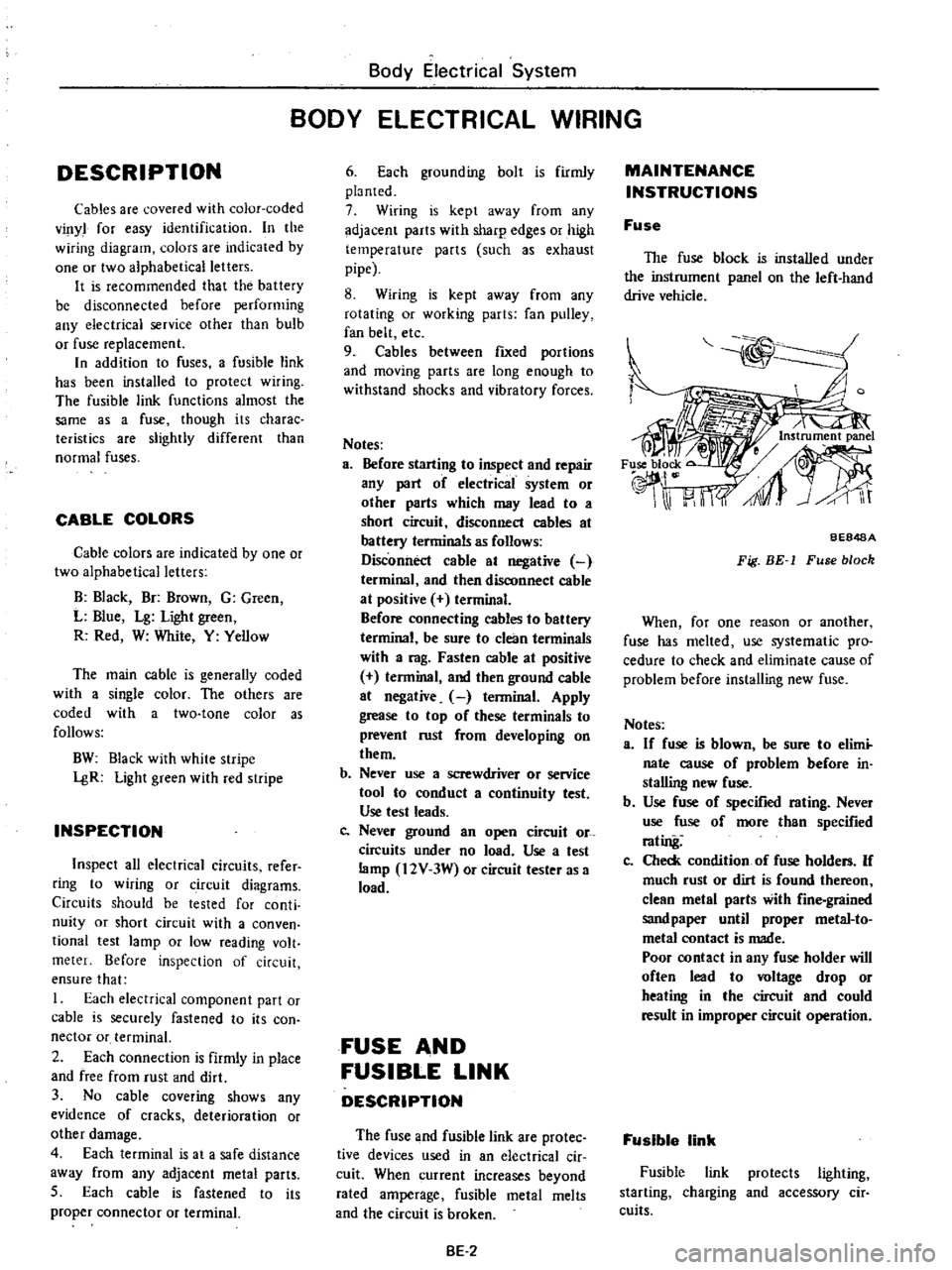

MAINTENANCE

INSTRUCTIONS

Fuse

The

fuse

block

is

installed

under

the

instrument

panel

on

the

left

hand

drive

vehicle

BE848A

Fig

BE

1

Fuse

block

When

for

one

reason

or

another

fuse

has

melted

use

systematic

pro

cedure

to

check

and

eliminate

cause

of

problem

before

installing

new

fuse

Notes

a

If

fuse

is

blown

be

sure

to

elimi

nate

cause

of

problem

before

in

stalling

new

fuse

b

Use

fuse

of

specified

rating

Never

use

fuse

of

more

than

specified

rating

Co

Check

condition

of

fuse

holders

If

much

rust

or

dirt

is

found

thereon

clean

metal

parts

with

fine

grained

sandpaper

until

proper

metal

to

metal

contact

is

made

Poor

contact

in

any

fuse

holder

will

often

lead

to

voltage

drop

or

heating

in

the

circuit

and

could

result

in

improper

circuit

operation

Fusible

link

Fusible

link

protects

lighting

starting

charging

and

accessory

cir

cuits

Page 497 of 537

REFRIGERAi

H

R

12

COMPRESSOR

OIL

MAINTENANCE

PERIODIC

MAINTENANCE

AND

SEASON

IN

INSPECTION

GENERAL

SERVICE

INSTRUCTION

SAFETY

PRECAUTIONS

EV

ACUA

TlNG

AND

CHARGING

SYSTEM

HANDLING

MANIFOLD

GAUGE

HANDLING

SERVICE

VALVE

HANDLING

CAN

TAP

DISCHARGING

SYSTEM

REFRIGERANT

R

12

The

refrigerant

used

in

the

air

conditioner

is

generally

called

Re

frigerant

12

R

12

No

other

refrig

erant

than

the

above

refrigerant

should

be

used

This

refrigerant

is

usually

available

in

a

small

can

or

a

cylinder

In

either

case

it

is

liquefied

under

high

pressure

in

the

container

Refrigerant

evaporates

easily

has

a

low

evaporation

point

and

moreover

since

the

latent

heat

of

the

refrigerant

is

large

it

can

abSorb

a

large

amount

of

heat

wh

err

e

vaporating

Extreme

care

must

be

exercised

when

handling

the

refrigerant

COMPRESSOR

OIL

The

SUNISO

5GS

or

SUNISO

351

should

be

used

as

refrigeration

lubricant

Mixing

of

the

two

is

allowable

The

refrigeration

lubricant

should

be

used

to

assure

the

successful

com

pressor

operation

Use

of

oils

other

than

recommended

or

mixing

of

the

oil

with

other

oils

would

cause

chemical

reaction

or

lead

to

lowered

viscosity

or

deficient

lubrication

The

oil

absorbs

moisture

as

it

con

tacts

the

air

This

points

out

the

need

for

care

not

to

expose

it

to

atmos

phere

for

an

extended

period

of

time

Air

Conditioning

GENERAL

SERVICE

CONTENTS

EVACUATING

SYSTEM

CHARGING

REFRIGERANT

CHECKING

FOR

LEAKS

HALIDE

LEAK

DETECTOR

ELECTRIC

LEAK

DETECTOR

REFRIGERANT

LEVEL

CHECK

SIGHT

GLASS

PERFORMANCE

TEST

COMPRESSOR

OIL

LEVEL

CHECK

PERFORMANCE

TEST

REFRIGERANT

LEAKS

AC

8

AC

8

AC

8

AC

8

AC

8

AC

9

AC

9

AC

9

AC10

AC

11

AC

12

MAINTENANCE

PERIODIC

MAINTENANCE

AND

SEASON

IN

INSPECTION

Both

periodic

maintenance

and

season

in

inspection

are

most

essential

to

enable

the

air

conditioner

to

give

full

performance

Perform

the

following

checks

Start

engine

and

check

refrigerant

level

through

sight

glass

on

receiver

dryer

For

details

refer

to

relative

topics

under

Refrigerant

Level

Check

2

Check

the

entire

sysiein

for

sign

of

refrigerant

leaks

Refer

to

relative

topics

under

Checking

for

Leaks

and

Refrigerant

Leaks

If

any

trace

of

oil

is

noted

at

and

around

connection

fittings

it

is

a

sure

indication

that

refrigerant

is

leaking

This

condition

can

be

corrected

easily

by

retightening

the

joints

If

any

joint

on

line

is

suspected

of

small

amount

of

leakage

use

a

leak

detector

to

locate

leaking

points

3

Check

compressor

drive

belts

for

proper

deflection

Season

off

Observe

the

following

maintenance

tips

to

allow

the

air

conditioner

to

operate

normally

in

the

next

season

I

Keep

the

entire

system

free

from

AC

8

AC12

AC

13

AC15

AC15

AC16

AC

16

AC16

AC

17

AC17

AC

17

AC18

refrigerant

leakage

by

periodically

checking

for

refrigerant

gas

leak

even

out

of

season

2

Turn

the

compressor

for

10

minutes

at

least

once

a

month

by

running

the

engine

at

1

500

rpm

c

ENERAL

SERVICE

INSTRUCTION

The

servicing

of

the

air

conditioner

should

be

carried

out

only

by

well

trained

servicemen

This

chapter

de

scribes

essential

points

of

servicing

Jf

a

Jarge

amount

of

dirt

and

sand

enter

the

system

they

will

be

carried

with

refrigerant

and

may

clog

the

system

or

scratch

rotating

parts

This

points

out

the

need

for

care

in

servicing

the

system

That

is

disconnecting

joints

should

be

carried

out

in

a

dean

place

Water

should

not

be

allowed

to

get

inside

the

system

The

refrigerant

does

not

readily

mix

with

water

However

the

presence

of

even

a

minute

amount

of

water

will

cause

a

chemical

reaction

at

high

tem

perature

which

will

in

turn

produce

hydrochloric

acid

HCl

Since

hydrochloric

acid

is

highly

corro

sive

to

metals

the

aluminum

and

copper

piping

etc

will

become

corroded

and

the

refrigeration

system

will

become

clogged

Page 514 of 537

Air

Conditioning

REMOVAL

AND

INSTALLATION

COMPRESSOR

REMOVAL

INSTALLATION

IDLER

PULLEY

FAN

BELT

TENSION

ADJUSTMENT

REMOVAL

AND

INSTALLATION

INSPECTION

COOLING

UNIT

REMOVAL

AND

INSTALLATION

DISASSEMBLY

AND

ASSEMBLY

INSPECTION

RECEIVER

DRYER

AND

PIPING

COMPRESSOR

REMOVAL

I

Remove

battery

2

Disconnect

compressor

lead

wire

at

connector

3

Loosen

idler

pulley

lock

nut

then

adjusting

bolt

Remove

compressor

drive

belt

from

compressor

pulley

AC477

Fig

AC

28

Removing

drive

belt

4

Discharge

system

Refer

to

Dis

charging

System

under

General

Service

section

CONTENTS

AC

25

AC25

AC26

AC

27

AC

27

AC27

AC

27

AC27

AC

27

AC

2B

AC

29

AC

29

REMOVAL

AND

INSTALLATION

INSPECTION

WIRING

HARNESS

AND

COMPONENTS

WIRING

DIAGRAM

MAINTENANCE

MAIN

RELAY

COMPRESSOR

RELAY

FAN

SWITCH

RESISTOR

FOR

FAN

SWITCH

THERMO

SWITCH

F

I

C

D

SOLENOID

VALVE

AC29

AC29

AC30

AC30

AC31

AC31

AC31

AC31

AC32

AC32

AC

32

5

Remove

flexible

hose

fixing

plate

and

disconnect

low

and

high

pressure

flexible

hoses

from

compressor

Notes

a

Use

two

wrenches

when

disconnect

ing

pipe

joints

b

Plug

flexible

hose

and

compressor

joint

openings

immediately

after

disconnection

to

prevent

entry

of

dust

moisture

laden

air

etc

Fig

AC

29

Disconnecting

ftexible

hoses

from

compressor

6

Remove

bolts

securing

fuel

tube

to

compressor

attachment

AC

25

Y

1

L

AC744

7

Remove

four

bolts

securing

com

pressor

to

its

bracket

Compressor

and

attachment

can

now

be

detached

as

an

assembly

Notes

a

There

are

a

total

of

four

bolts

two

on

upper

side

of

bracket

and

two

on

lower

side

of

compreSsor

Loosen

upper

bolts

and

remove

lower

bolts

When

removing

upper

bolts

securely

hold

compressor

with

one

hand

b

When

installing

temporarily

tighten

upper

bolts

then

tighten

lower

bolts

Page 520 of 537

MAINTENANCE

Replace

any

wiring

harness

which

is

cracked

deteriorated

or

poorly

in

sulated

Always

replace

wire

with

those

of

the

same

diameter

Do

not

use

wire

of

smaller

diameter

Where

necessary

securely

retain

wire

harnesses

with

clips

or

tapes

so

that

they

will

not

be

frayed

or

worn

by

vibration

Notes

a

Repair

or

replace

any

electrical

part

which

is

questionable

or

likely

to

cause

a

short

circuit

When

disconnecting

battery

cables

always

disconnect

ground

cable

be

fore

positive

cable

Clean

battery

and

terminals

before

connecting

cables

then

connect

positive

cable

and

ground

cable

in

that

order

Apply

a

coat

of

grease

to

terminals

to

prevent

rust

formation

b

Do

not

attempt

to

conduct

a

con

tinuity

test

with

a

screwdriver

or

service

tools

always

use

test

lead

wires

c

Do

not

ground

terminals

when

circuits

are

open

or

unloaded

always

use

a

test

lamp

12V

3W

or

circuit

tester

as

a

load

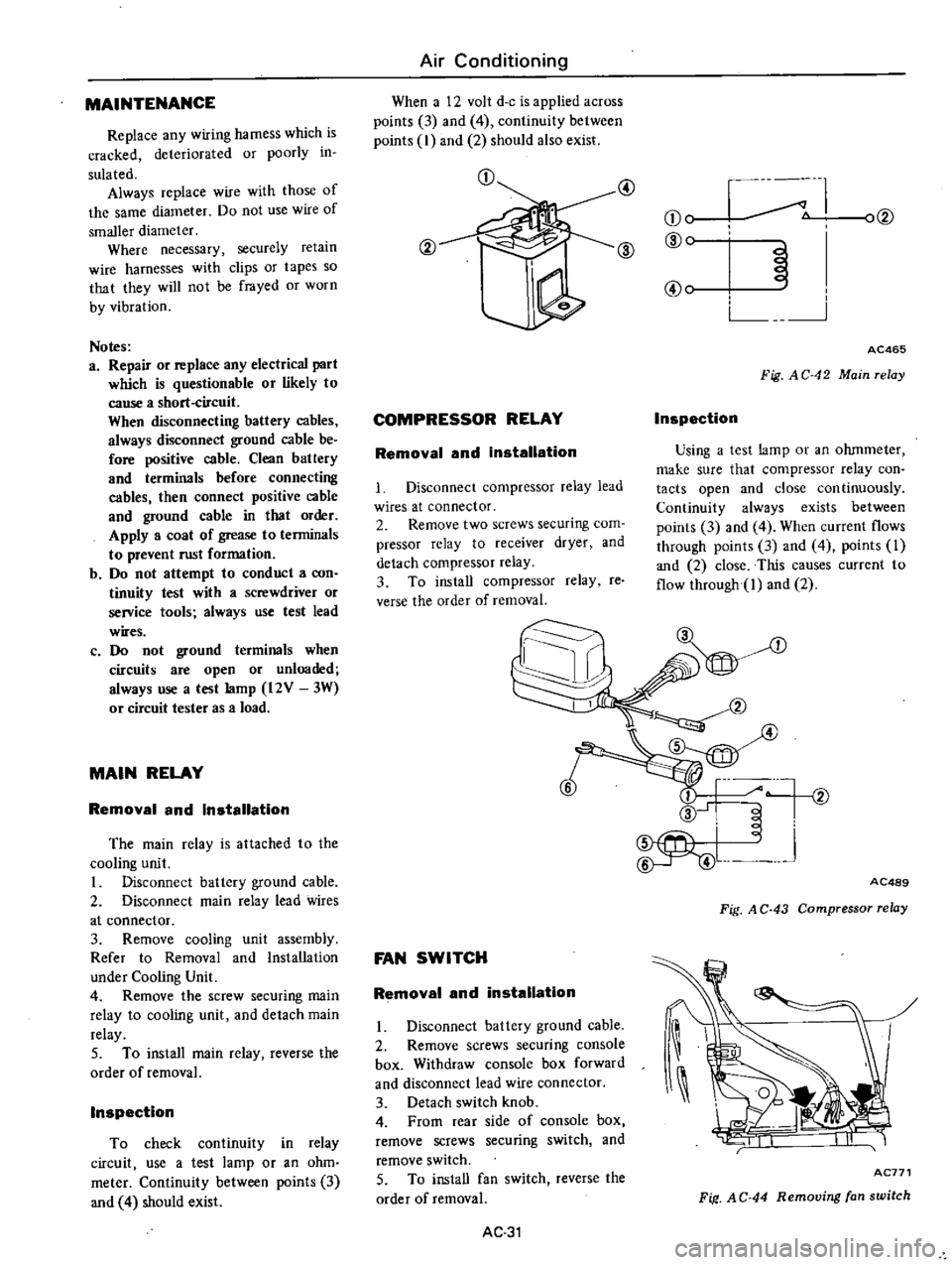

MAIN

RELAY

Removal

and

Installation

The

main

relay

is

attached

to

the

cooling

unit

I

Disconnect

battery

ground

cable

2

Disconnect

main

relay

lead

wires

at

connector

3

Remove

cooling

unit

assembly

Refer

to

Removal

and

Installation

under

Cooling

Unit

4

Remove

the

screw

securing

main

relay

to

cooling

unit

and

detach

main

relay

5

To

install

main

relay

reverse

the

order

of

removal

Inspection

To

check

continuity

in

relay

circuit

use

a

test

lamp

or

an

ohm

meter

Continuity

between

points

3

and

4

should

exist

Air

Conditioning

When

a

12

volt

d

c

is

applied

across

points

3

and

4

continuity

between

points

I

and

2

should

also

exist

CD

00

COMPRESSOR

RELAY

Removal

and

installation

Disconnect

compressor

relay

lead

wires

at

connector

2

Remove

two

screws

securing

com

pressor

relay

to

receiver

dryer

and

detach

compressor

relay

3

To

install

compressor

relay

reo

verse

the

order

of

removal

@

I

ul

CDe

JOO

ID

IDe

@e

L

AC465

Fig

AC

42

Main

relay

Inspection

Using

a

test

lamp

or

an

ohmmeter

make

sure

that

compressor

relay

con

tacts

open

and

close

con

tinuously

Continuity

always

exists

between

points

3

and

4

When

current

flows

through

points

3

and

4

points

1

and

2

close

This

causes

current

to

flow

through

1

and

2

FAN

SWITCH

Removal

and

installation

1

Disconnect

battery

ground

cable

2

Remove

screws

securing

console

box

Withdraw

console

box

forward

and

disconnect

lead

wire

connector

3

Detach

switch

knob

4

From

rear

side

of

console

box

remove

screws

securing

switch

and

remove

switch

5

To

install

fan

switch

reverse

the

order

of

removal

AC

31

i

t

v

J

AC489

Fig

A

C

43

Compressor

relay

AC771

Fif

AC

44

Removing

fan

switch

Page 531 of 537

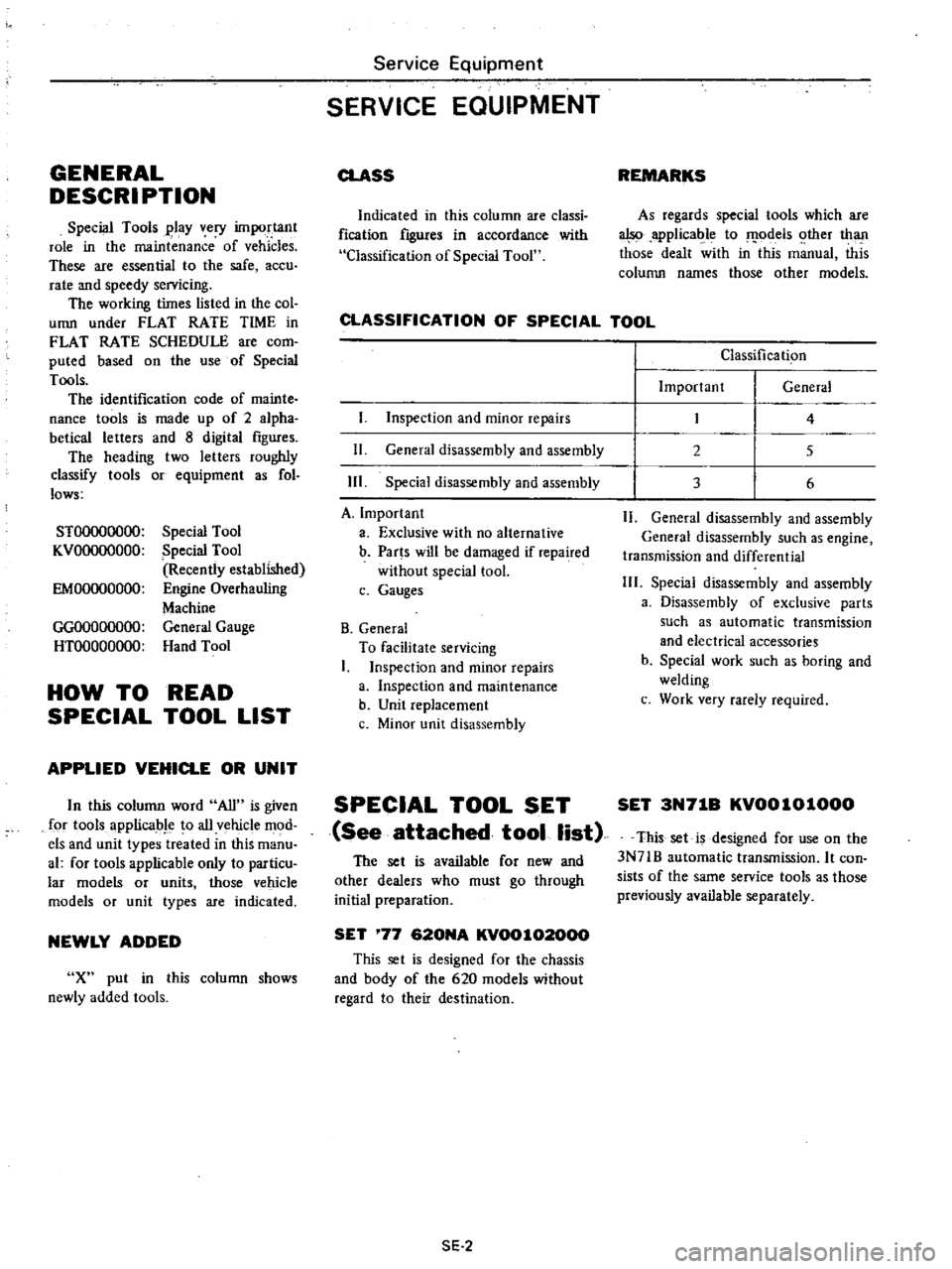

GENERAL

DESCRI

PTION

Special

Tools

play

very

important

role

in

the

maintenance

of

vehicles

These

are

essential

to

the

safe

accu

rate

and

speedy

servicing

The

working

times

listed

in

the

col

umn

under

FLAT

RATE

TIME

in

FLAT

RATE

SCHEDULE

are

com

puted

based

on

the

use

of

Special

Tools

The

identification

code

of

mainte

nance

tools

is

made

up

of

2

alpha

betical

letters

and

8

digital

figures

The

heading

two

letters

roughly

classify

tools

or

equipment

as

fol

lows

STOOOOOOOO

KVOOOOOOOO

Special

Tool

Special

Tool

Recently

established

Engine

Overhauling

Machine

General

Gauge

Hand

Tool

EMOOOOOOOO

GGOOOOOOOO

HTOOOOOOOO

HOW

TO

READ

SPECIAL

TOOL

LIST

APPLIED

VEHICLE

OR

UNIT

In

this

column

word

All

is

given

for

tools

applicable

to

all

vehicle

mod

els

and

unit

types

treated

in

this

manu

al

for

tools

applicable

only

to

particu

lar

models

or

units

those

vehicle

models

or

unit

types

are

indicated

NEWLY

ADDED

X

put

in

this

column

shows

newly

added

tools

Service

Equipment

SERVICE

EQUIPMENT

CLASS

Indicated

in

this

column

are

classi

fication

ftg1ll

es

in

accordance

with

Classification

of

Speciai

Tool

REMARKS

As

regards

special

tools

which

are

also

applicable

to

models

other

than

those

dealt

ith

U

this

m

inual

this

coluITUl

names

those

other

models

CLASSIFICATION

OF

SPECIAL

TOOL

I

Inspection

and

minor

repairs

11

General

disassembly

and

assembly

Ill

Special

disassembly

and

assembly

A

Important

a

Exclusive

with

no

alternative

b

Parts

will

be

damaged

if

repaired

without

special

tool

c

Gauges

B

General

To

facilitate

servicing

I

Inspection

and

minor

repairs

a

Inspection

and

maintenance

b

Unit

replacement

c

Minor

unit

disassembly

SPECIAL

TOOL

SET

See

attached

tool

list

The

set

is

available

for

new

and

other

dealers

who

must

go

through

initial

preparation

SET

77

620NA

KV00102000

This

set

is

designed

for

the

chassis

and

body

of

the

620

models

without

regard

to

their

destination

SE

2

Classification

Important

General

2

3

4

5

6

11

General

disassembly

and

assembly

General

disassembly

such

as

engine

transmission

and

differential

111

Special

disassembly

and

assembly

a

Disassembly

of

exclusive

parts

such

as

automatic

transmission

and

electrical

accessories

b

Special

work

such

as

boring

and

welding

c

Work

very

rarely

required

SET

3N71B

KV0010l000

This

set

is

designed

for

use

on

the

3N71B

automatic

transmission

It

con

sists

of

the

same

service

tools

as

those

previously

available

separately