oil level DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 96 of 537

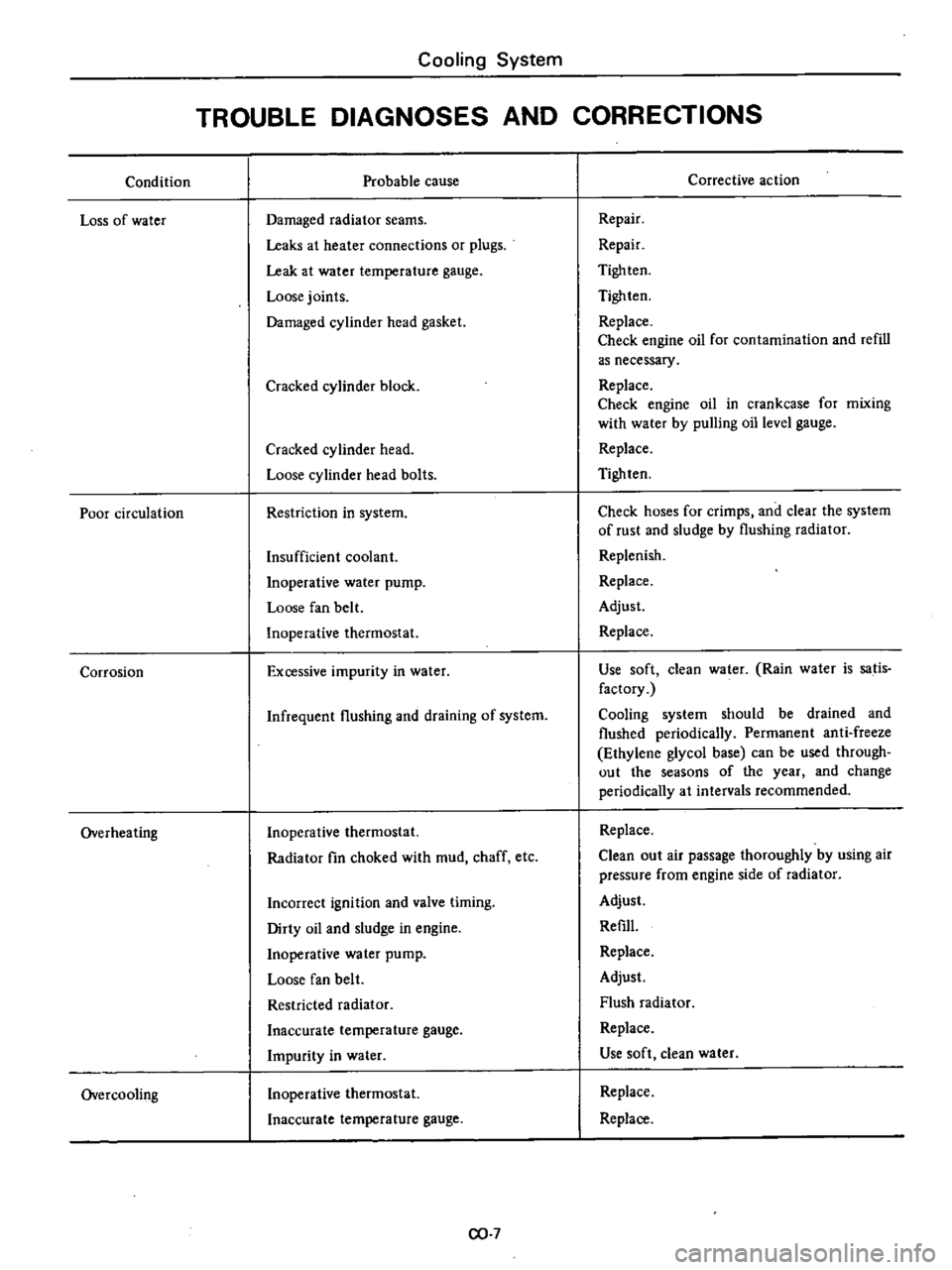

Condition

Loss

of

water

Poor

circulation

Corrosion

Overheating

Overcooling

Cooling

System

TROUBLE

DIAGNOSES

AND

CORRECTIONS

Probable

cause

Damaged

radiator

seams

Leaks

at

heater

connections

or

plugs

Leak

at

water

temperature

gauge

Loose

joints

Damaged

cylinder

head

gasket

Cracked

cylinder

block

Cracked

cylinder

head

Loose

cylinder

head

bolts

Restriction

in

system

Insufficient

coolant

Inoperative

water

pump

Loose

fan

belt

Inoperative

thermostat

Excessive

impurity

in

water

Infrequent

flushing

and

draining

of

system

Inoperative

thermostat

Radiator

fin

choked

with

mud

chaff

etc

Incorrect

ignition

and

valve

timing

Dirty

oil

and

sludge

in

engine

Inoperative

water

pump

Loose

fan

belt

Restricted

radiator

Inaccurate

temperature

gauge

Impurity

in

water

Inoperative

thermostat

Inaccurate

temperature

gauge

CO

7

Corrective

action

Repair

Repair

Tigh

ten

Tighten

Replace

Check

engine

oil

for

contamination

and

refill

as

necessary

Replace

Check

engine

oil

in

crankcase

for

mixing

with

water

by

pulling

oil

level

gauge

Replace

Tighten

Check

hoses

for

crimps

and

clear

the

system

of

rust

and

sludge

by

flushing

radiator

Replenish

Replace

Adjust

Replace

Use

soft

clean

water

Rain

water

is

satis

factory

Cooling

system

should

be

drained

and

flushed

periodically

Permanent

anti

freeze

Ethylene

glycol

base

can

be

used

through

out

the

seasons

of

the

year

and

change

periodically

at

intervals

recommended

Replace

Clean

out

air

passage

thoroughly

by

using

air

pressure

from

engine

side

of

radiator

Adjust

Refill

Replace

Adjust

Flush

radiator

Replace

Use

soft

clean

water

Replace

Replace

Page 107 of 537

3

Check

diaphragm

for

small

holes

carcks

or

wear

4

Check

rocker

arm

for

wear

at

the

mating

portion

with

camshaft

5

Check

rocker

arm

pin

for

wear

A

worn

pin

may

cause

oil

leakage

6

Check

all

other

components

for

any

abnormalities

and

replace

if

neces

sary

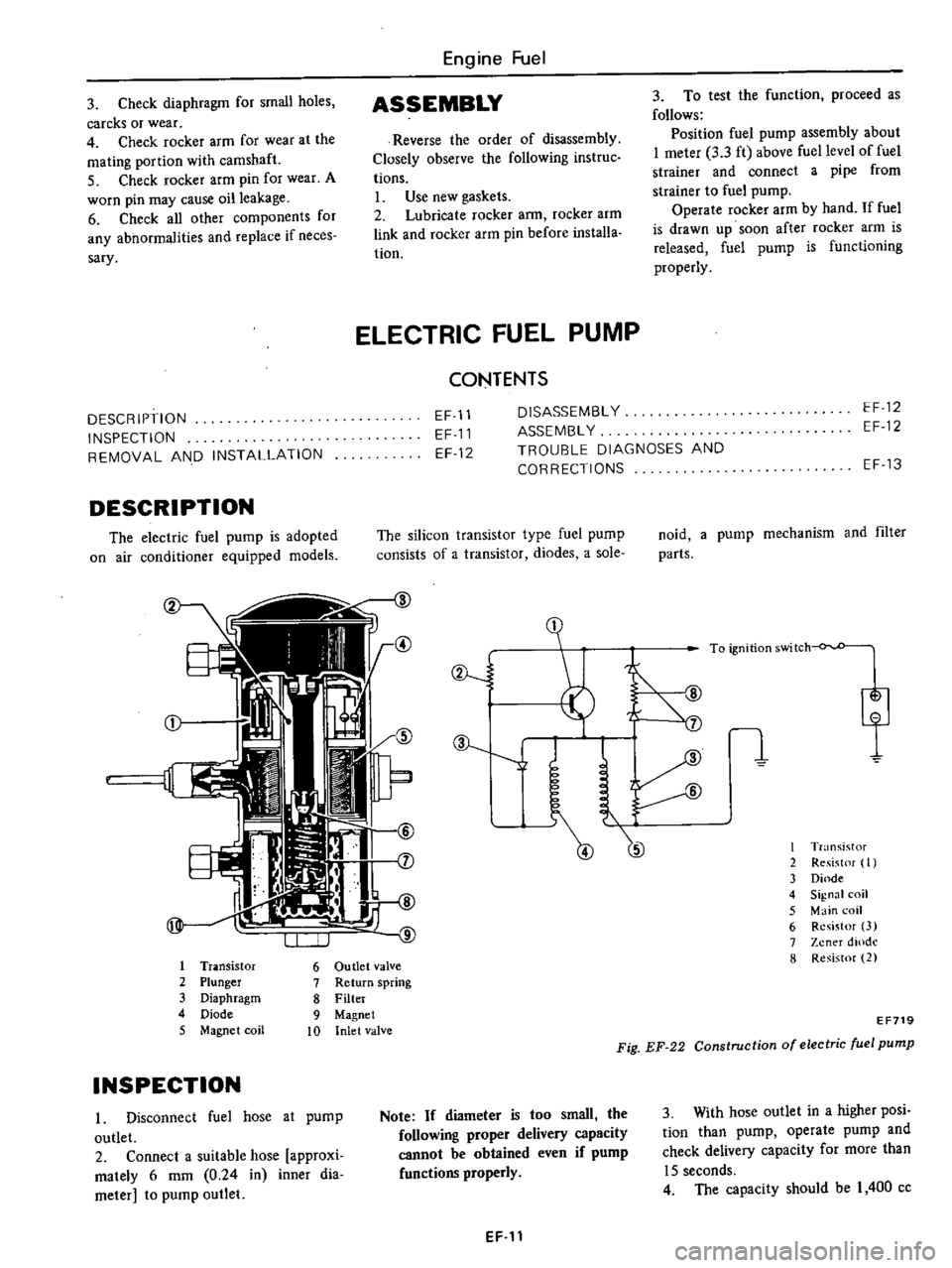

DESCRIPTION

INSPECTION

REMOVAL

AND

INSTALLATION

DESCRIPTION

The

electric

fuel

pump

is

adopted

on

air

conditioner

equipped

models

Engine

Fuel

ASSEMBLY

Reverse

the

order

of

disassembly

Closely

observe

the

following

instruc

tions

L

Use

new

gaskets

2

Lubricate

rocker

ann

rocker

arm

link

and

rocker

arm

pin

before

installa

tion

3

To

test

the

function

proceed

as

follows

Position

fuel

pump

assembly

about

I

meter

3

3

ft

above

fuel

level

of

fuel

strainer

and

connect

a

pipe

from

strainer

to

fuel

pump

Operate

rocker

arm

by

hand

If

fuel

is

drawn

up

soon

after

rocker

arm

is

released

fuel

pump

is

functioning

properly

ELECTRIC

FUEL

PUMP

CONTENTS

EF

11

EF

11

EF

12

DISASSEMBL

Y

ASSEMBL

Y

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EF

12

EF

12

The

silicon

transistor

type

fuel

pump

consists

of

a

transistor

diodes

a

sole

I

Tr

lOsistor

6

Ou

tIet

valve

2

Plunger

7

Return

spring

3

Diaphragm

8

Filter

4

Diode

9

Magnet

5

Magnet

coil

10

Inlet

valve

INSPECTION

I

Disconnect

fuel

hose

at

pump

outlet

2

Connect

a

suitable

hose

approxi

mately

6

mm

0

24

in

inner

dia

meter

to

pump

outlet

ev

J

J

Note

If

diameter

is

too

small

the

following

proper

delivery

capacity

cannot

be

obtained

even

if

pump

functions

properly

EF

11

EF

13

noid

a

pump

mechanism

and

filter

parts

I

T

nsistor

2

Re

ist

f

I

3

Dinde

4

Signal

coil

5

Main

coil

6

Resistor

3

7

Zener

dlOdl

8

Resistor

2

EF719

Fig

EF

22

Construction

of

electric

fuel

pump

3

With

hose

outlet

in

a

higher

posi

tion

than

pump

operate

pump

and

check

delivery

capacity

for

more

than

15

seconds

4

The

capacity

should

be

I

400

cc

Page 135 of 537

There

are

three

types

of

control

system

These

are

J

Closed

type

CIllnkcase

emission

control

system

Emission

Control

System

of

GENERAL

DESCRIPTION

2

Exhaust

emission

control

system

3

Evaporative

ell

lhsion

control

sys

tem

Pericxiic

inspection

and

required

seCV1Clng

of

these

systems

should

be

carried

out

to

reduce

harmful

emis

sions

to

a

minimum

CRANKCASE

EMISSION

CONTROL

SYSTEM

c

01

Lkf

If

1

TIL

II

tll

1

j

GUuuu

DESCRIPTION

This

system

returns

blow

by

gas

to

both

the

intake

manifold

and

carbure

tor

air

cleaner

The

positive

crankcase

ventilation

p

C

V

valve

is

provided

to

conduct

crankcase

blow

by

gas

to

the

intake

manifold

During

partial

throttle

operation

of

the

engine

the

intake

manifold

sucks

the

blow

by

gas

through

the

P

C

V

valve

Normally

the

capacity

of

the

valve

is

sufficient

to

handle

any

blow

by

and

a

small

amount

of

ventilating

air

4

c

Fresh

air

Blow

by

gas

The

ventilating

air

is

then

drawn

from

the

dust

side

of

the

cadlUretor

air

cleaner

tluough

the

tube

con

necting

carburetor

air

cleaner

to

rock

er

cover

into

the

crankcase

Under

full

tluottle

condition

the

manifold

vacuwn

is

insufficient

to

draw

the

blow

by

flow

tluough

the

valve

and

its

flow

goes

through

the

tube

connection

in

the

reverse

diree

tion

On

vehicles

with

an

excessively

high

blow

by

some

of

the

flow

will

go

through

the

tube

connection

to

carbu

retor

air

cleaner

under

all

conditions

1

Sealtypc

oil

level

gauge

2

Bame

plate

3

Flame

arrester

4

Filler

5

P

C

Y

valve

6

Steel

net

7

Bame

plate

EC716

Fig

EC

l

Crankcase

miaion

control

ay

tem

EC

2

INSPECTION

P

c

V

VALVE

AND

FILTER

Checking

P

C

V

valve

in

accord

ance

with

the

following

method

With

engine

running

at

idle

remove

the

ventilator

hose

from

P

C

V

valve

if

the

valve

is

working

a

hissing

noise

will

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuwn

should

be

felt

immediately

when

a

fmger

is

placed

over

valve

inlet

Replace

P

C

V

valve

and

filter

in

accordance

with

the

maintenance

schedule

VENTILATION

HOSE

1

Check

hoses

and

hose

connec

tions

for

leaks

2

Disconnect

all

hoses

and

clean

with

compressed

air

If

any

hose

cannot

be

free

of

obstructions

replace

Ensure

that

flame

arrester

is

surely

inserted

in

hose

between

air

cleaner

and

rocker

cover

Page 229 of 537

Inspection

Note

To

clean

or

wash

all

parts

of

master

cylinder

operating

cylinder

and

piping

clean

brake

fluid

must

be

used

Never

use

minera10ils

llUch

as

gasoline

and

kerosene

It

will

ruin

the

rubber

parts

of

the

hydrau

lic

system

I

Check

cylinder

and

piston

for

uneven

wear

or

damage

and

if

neces

sary

replace

2

If

the

clearance

between

cylinder

and

piston

is

more

than

0

15

mm

0

0059

in

replace

cylinder

3

Renew

piston

cup

when

dis

assembled

It

must

also

be

replaced

when

wear

or

deformation

due

to

fatigue

or

damage

is

found

4

Damaged

dust

cover

oil

reservoir

or

cap

should

be

replaced

Return

spring

and

valve

spring

must

also

be

replaced

when

they

are

broken

or

weak

5

Replace

clutch

hose

and

tube

if

any

abnormal

sign

of

damage

or

de

fro

ti

n

is

found

OPERATING

CYLINDER

Removal

and

installation

Removal

1

Detach

clutch

hose

from

operat

ing

cylinder

2

Remove

two

bolts

securing

op

erating

cylinder

to

clutch

housing

Installation

Install

in

the

reverse

order

of

re

moval

Observe

the

following

instructions

Bleed

air

thoroughly

from

clutch

hydraulic

system

2

Do

not

install

return

spring

or

clutch

will

not

be

disengaged

properly

Tightening

torque

Operating

cylinder

securing

bolt

2

5

to

3

5

kg

m

18

to

25

ft

lb

Bleeder

screw

0

7

to

0

9

kg

m

5

1

to

6

5

ft

Ib

Clutch

hose

connector

1

7

to

2

0

kg

m

12

to

14

ft

b

CLUTCH

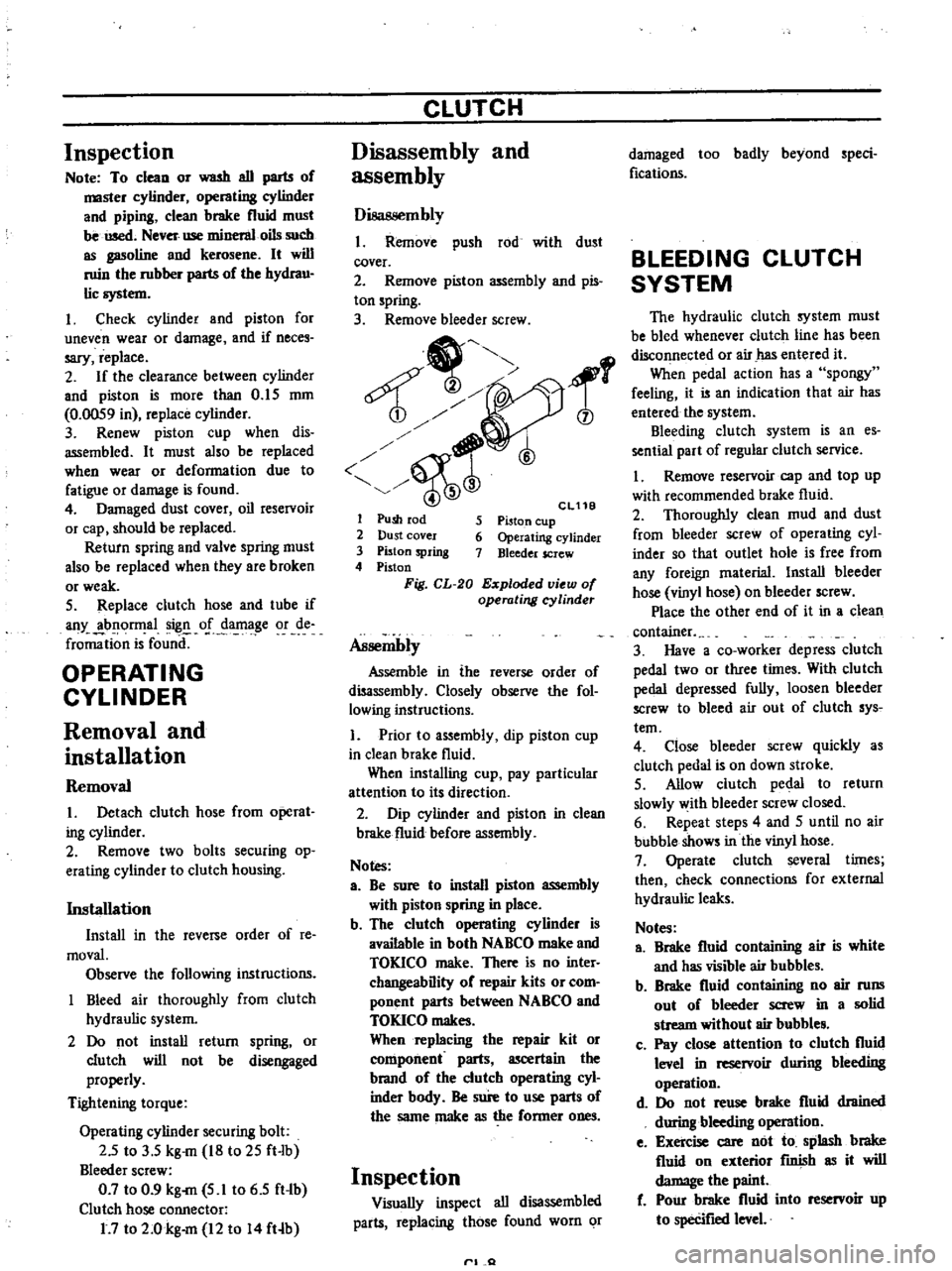

Disassembly

and

assembly

Disassembly

1

Remove

push

rod

with

dust

cover

2

Remove

piston

assembly

and

pis

ton

spring

3

Remove

bleeder

screw

1

6

Cl11B

5

Piston

cup

6

Operating

cylinder

7

Bleeder

screw

1

Push

rod

2

Dust

cover

3

Piston

spring

4

Piston

Fig

CL

20

Exploded

view

of

operating

cyUnder

Assembly

Assemble

in

the

reverse

order

of

disassembly

Closely

observe

the

fol

lowing

instructions

1

Prior

to

assembly

dip

piston

cup

in

clean

brake

fluid

When

installing

cup

pay

particular

attention

to

its

direction

2

Dip

cylinder

and

piston

in

clean

brake

fluid

before

assembly

Notes

a

Be

sure

to

install

piston

assembly

with

piston

spring

in

place

b

The

clutch

operating

cylinder

is

available

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKICO

makes

When

replacing

the

repair

kit

or

component

parts

ascertain

the

brand

of

the

clutch

operating

cyl

inder

bndy

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

Inspection

Visually

inspect

all

disassembled

parts

replacing

those

found

worn

or

rl

Q

damaged

too

badly

beyond

speci

fications

BLEEDING

CLUTCH

SYSTEM

The

hydraulic

clutch

system

must

be

bled

whenever

clutch

line

has

been

disconnected

or

air

has

entered

it

When

pedal

action

has

a

spongy

feeling

it

is

an

indication

that

air

has

entered

the

system

Bleeding

clutch

system

is

an

es

sential

part

of

regular

clutch

service

I

Remove

reservoir

cap

and

top

up

with

recommended

brake

fluid

2

Thoroughly

clean

mud

and

dust

from

bleeder

screw

of

operating

cyl

inder

so

that

outlet

hole

is

free

from

any

foreign

rnaterial

Install

bleeder

hose

vinyl

hose

on

bleeder

screw

Place

the

other

end

of

it

in

a

clean

container

3

Have

a

co

worker

depress

clutch

pedal

two

or

three

times

With

clu

tch

pedal

depressed

fully

loosen

bleeder

screw

to

bleed

air

out

of

clutch

sys

tern

4

Close

bleeder

screw

quickly

as

clutch

pedal

is

on

down

stroke

5

Allow

clutch

pedal

to

return

slowly

with

bleeder

screw

closed

6

Repeat

steps

4

and

5

until

no

air

bubble

shows

in

the

vinyl

hose

7

Operate

clutch

several

times

then

check

connections

for

external

hydraulic

leaks

Notes

a

Brake

fluid

containing

air

is

white

and

has

visible

air

bubbles

b

Brake

fluid

containing

no

air

runs

out

of

bleeder

screw

in

a

solid

stream

without

air

bubble

c

Pay

close

attention

to

clutch

fluid

level

in

reservoir

during

bleeding

operation

d

Do

not

reuse

brake

fluid

drained

during

bleeding

operation

e

Exercise

care

not

to

splash

brake

fluid

on

exterior

fInish

as

it

will

damage

the

paint

f

Pour

brake

fluid

into

reservoir

up

to

specifIed

level

Page 248 of 537

5

Apply

a

light

coat

of

multi

purpose

grease

to

withdrawal

lever

release

bearing

and

bearing

sleeve

in

stall

them

on

clutch

housing

After

connecting

them

with

holder

spring

instaU

dust

cover

on

clutch

housing

6

Install

control

lever

temporarily

and

shift

control

lever

through

all

gears

to

make

sure

that

gears

opera

Ie

smoothly

Note

Install

drain

plug

and

filler

plug

ith

sealant

in

place

Manual

Transmission

INSTALLATION

Install

the

transmission

in

the

reo

verse

order

uf

removal

paying

atten

tion

to

the

following

points

1

Before

installing

dean

mating

surfaces

of

engine

rear

plate

and

trans

mission

case

2

Before

installing

lightly

apply

grease

to

spline

parts

of

clutch

disc

and

main

drive

gear

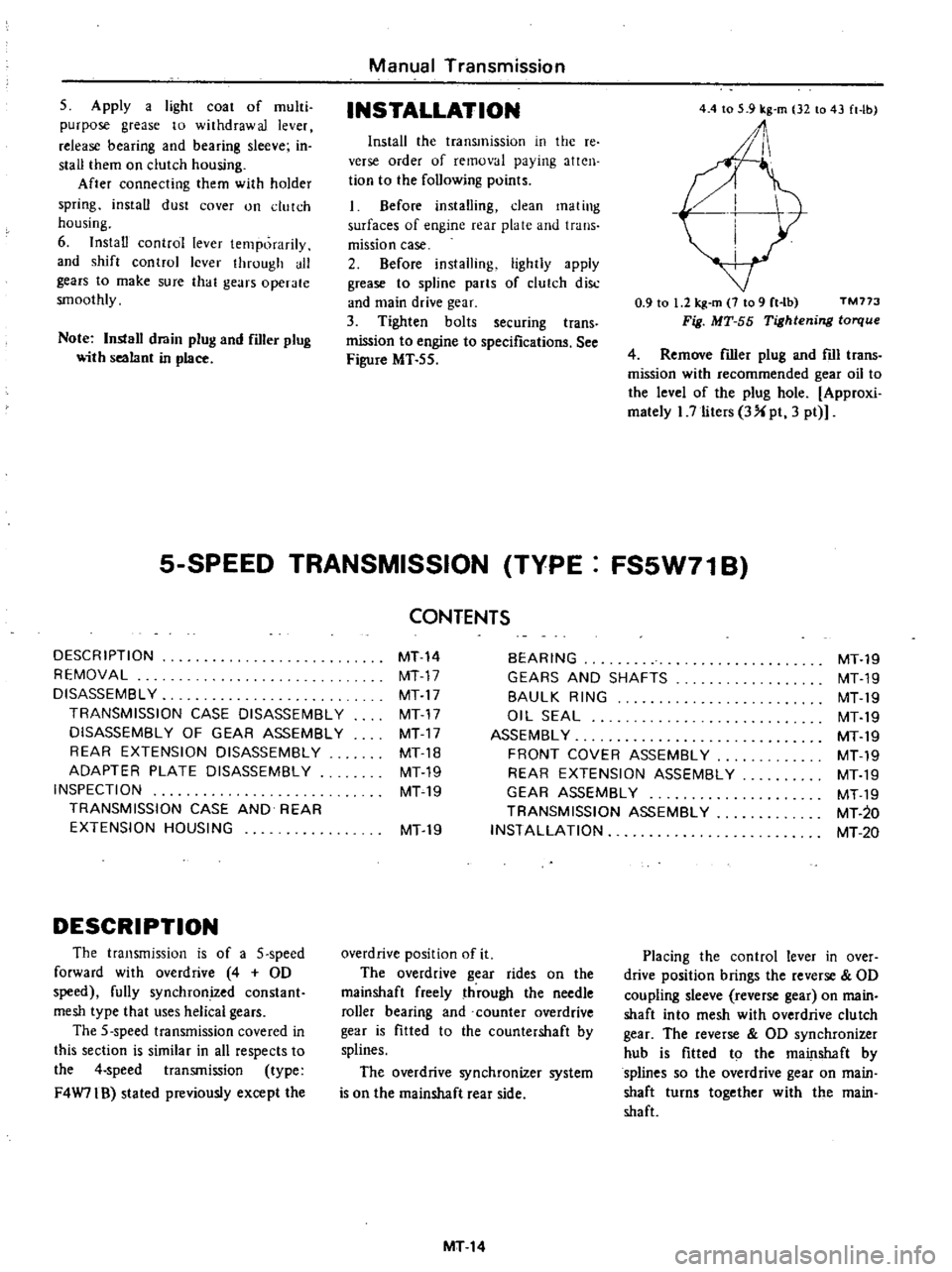

3

Tighten

bolts

securing

trans

mission

to

engine

to

specifications

See

Figure

MT

55

5

SPEED

TRANSMISSION

TYPE

DESCRIPTION

REMOVAL

DISASSEMBL

Y

TRANSMISSION

CASE

DISASSEMBLY

DISASSEMBL

Y

OF

GEAR

ASSEMBLY

REAR

EXTENSION

DISASSEMBLY

ADAPTER

PLATE

DISASSEMBLY

INSPECTION

TRANSMISSION

CASE

AND

REAR

EXTENSION

HOUSING

DESCRIPTION

The

transmission

is

of

a

5

speed

forward

with

overdrive

4

OD

speed

fully

synchronized

constant

mesh

type

that

uses

helical

gears

The

5

speed

transmission

covered

in

this

section

is

similar

in

all

respects

to

the

4

speed

transmission

type

F4W71B

stated

previously

except

the

CONTENTS

MT14

MT17

MT17

MT17

MT17

MT18

MT19

MT19

4

4

to

5

9

kg

m

32

to

43

ft

Ib

1

0

9

to

1

2

kg

m

7

to

9

rt

lb

TM773

Fig

MT

55

Tightening

torque

4

Remove

filler

plug

and

fIll

trans

mission

with

recommended

gear

oil

to

the

level

of

the

plug

hole

Approxi

mately

I

7

liters

3

pt

3

pt

FS5W71B

BEARING

GEARS

AND

SHAFTS

BAULK

RING

OIL

SEAL

ASSEMBL

Y

FRONT

COVER

ASSEMBLY

REAR

EXTENSION

ASSEMBLY

GEAR

ASSEMBLY

TRANSMISSION

ASSEMBLY

INSTALLATION

MT19

overdrive

position

of

it

The

overdrive

gear

rides

on

the

mainshaft

freely

through

the

needle

roller

bearing

and

counter

overdrive

gear

is

fitted

to

the

countershaft

by

splines

The

overdrive

synchronizer

system

is

on

the

mainshaft

rear

side

MT14

MT19

MT19

MT19

MT19

MT19

MT19

MT19

MT19

MT

20

MT20

Placing

the

control

lever

in

over

drive

position

brings

the

reverse

OD

coupling

sleeve

reverse

gear

on

main

shaft

into

mesh

with

overdrive

clutch

gear

The

reverse

OD

synchronizer

hub

is

fItted

to

the

mainshaft

by

splines

so

the

overdrive

gear

on

main

shaft

turns

together

with

the

main

shaft

Page 266 of 537

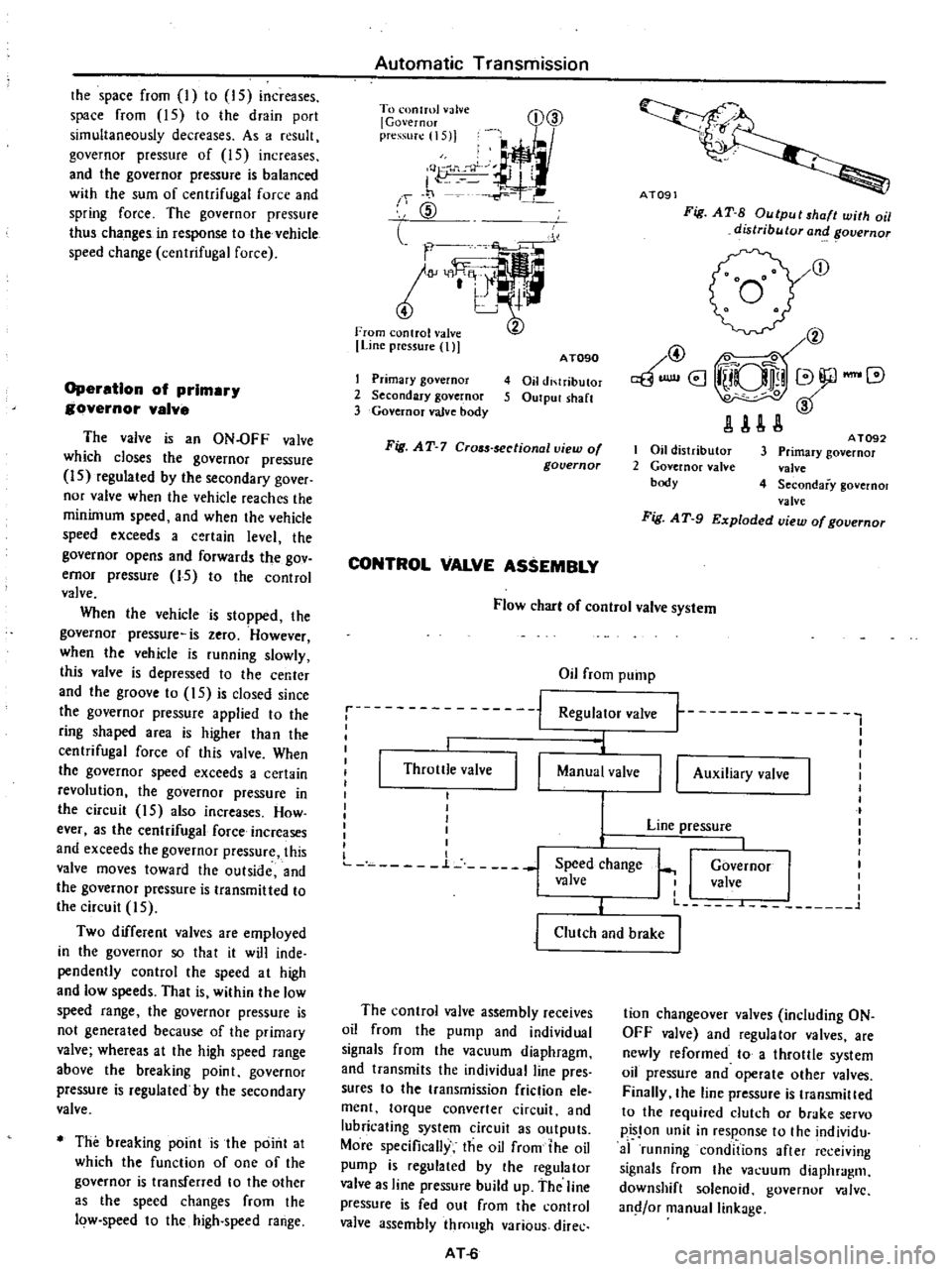

the

space

from

I

to

IS

increases

space

from

15

to

the

drain

port

simultaneously

decreases

As

a

resull

governor

pressure

of

15

increases

and

the

governor

pressure

is

balanced

with

the

sum

of

centrifugal

force

and

spring

force

The

governor

pressure

thus

changes

in

response

to

the

vehicle

speed

change

centrifugal

force

Operation

of

prlmar

governor

valve

The

valve

is

an

ON

OFF

valve

which

closes

the

governor

pressure

IS

regulated

by

the

secondary

gover

nor

valve

when

the

vehicle

reaches

the

minimum

speed

and

when

the

vehicle

speed

exceeds

a

certain

level

the

governor

opens

and

forwards

the

gov

ernor

pressure

15

to

the

control

valve

When

the

vehicle

is

stopped

the

governor

pressure

is

zero

However

when

the

vehicle

is

running

slowly

this

valve

is

depressed

to

Ihe

center

and

the

groove

to

15

is

closed

since

the

governor

pressure

applied

to

the

ring

shaped

area

is

higher

than

the

centrifugal

force

of

this

valve

When

the

governor

speed

exceeds

a

certain

revolution

the

governor

pressure

in

the

circuit

15

also

increases

How

ever

as

the

centrifugal

force

increases

and

exceeds

the

governor

pressure

this

valve

moves

toward

the

outside

and

the

governor

pressure

is

transmitted

to

the

circuil

5

Two

different

valves

are

employed

in

the

governor

so

that

it

will

inde

pendently

control

the

speed

at

high

and

low

speeds

That

is

within

the

low

speed

range

the

governor

pressure

is

not

generated

because

of

the

primary

valve

whereas

at

the

high

speed

range

above

the

breaking

point

governor

pressure

is

regulated

by

the

secondary

valve

The

breaking

point

is

the

point

at

which

the

function

of

one

of

the

governor

is

transferred

to

the

other

as

the

speed

changes

from

the

low

speed

to

the

high

speed

range

Automatic

Transmission

To

onlml

valve

l

Governor

pre

S1I

1I5

j

I

Q

J

J

f

1

1

CID

l

l

m

Line

pressure

t

D@

I

Primary

governor

2

Secondary

governor

3

Governor

valve

body

AT090

4

Oil

di

lributor

5

Output

sh

lft

Fig

AT

7

Cr05s

sectionallliew

of

governor

CONTROL

VALVE

ASSEMBLY

Ai09

Fig

AT

S

Output

shaft

with

oil

distributor

and

overnor

r

@

@

0

aBUlllI8

iUQlli

V

JlAU

I

Oil

distributor

2

Governor

nlve

body

A

T092

3

Primary

governor

valve

4

Secondary

governol

valve

Fig

A

T

9

Exploded

view

of

governor

Flow

cbar

of

control

valve

system

Oil

from

pump

Regulator

valve

1

I

i

j

Throttle

valve

I

I

l

Manual

valve

I

I

I

I

I

I

I

L

n

L

j

Speed

change

valve

I

I

t

t

I

I

I

I

I

I

Governor

I

I

valve

I

I

I

L

L

1

II

Auxiliary

valve

Line

pressure

j

Clutch

and

brake

The

control

valve

assembly

receives

oil

from

the

pump

and

individual

signals

from

the

vacuum

diaphragm

and

transmits

the

individual

line

pres

sures

to

the

transmission

friction

ele

ment

torque

converter

circuit

and

lubricating

system

circuit

as

outputs

More

specifically

the

oil

from

the

oil

pump

is

regulated

by

the

regulator

valve

as

line

pressure

build

up

the

line

pressure

is

fed

out

from

the

control

valve

assembly

through

various

direc

AT

6

tion

changeover

valves

including

ON

OFF

valve

and

regulator

valves

are

newly

reformed

to

a

throllle

system

oil

pressure

and

operate

other

valves

Finally

the

line

pressure

is

transmilled

to

the

required

dutch

or

brake

servo

pisJon

unit

in

response

to

the

individu

af

running

conditions

after

re

ejving

signals

from

the

va

uum

diaphragm

downshift

solenoid

governor

V

dlvc

and

or

manual

linkage

Page 268 of 537

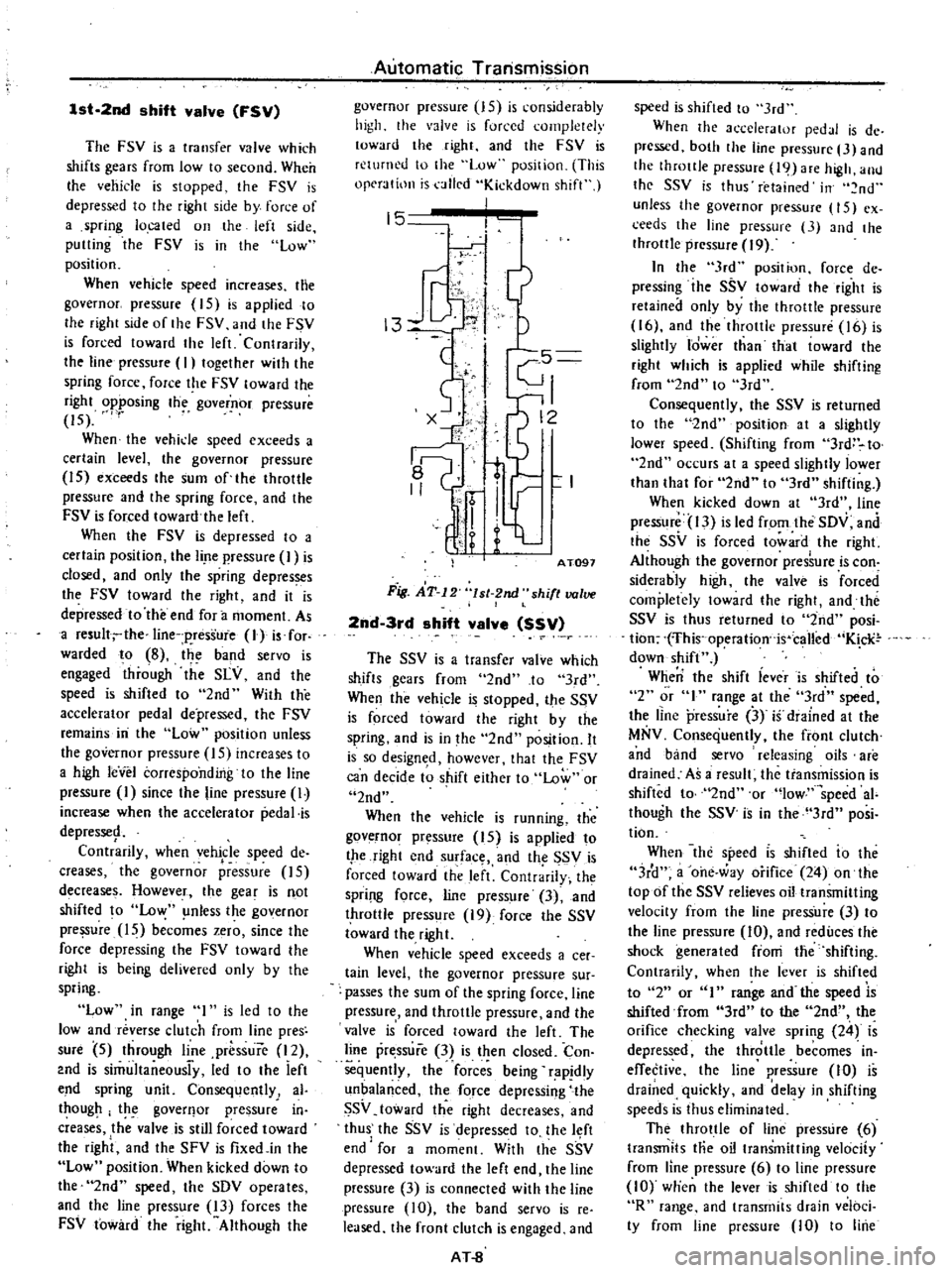

1st

2nd

shift

valve

FSV

The

FSV

is

a

transfer

valve

which

shifts

gears

from

low

to

second

When

Ihe

vehicle

is

stopped

the

FSV

is

depressed

to

the

right

side

by

force

of

a

spring

located

on

the

left

side

putting

the

FSV

is

in

the

low

position

When

vehicle

speed

increases

the

governor

pressure

15

is

applied

to

Ihe

right

side

of

the

FSV

and

the

FSV

is

forced

toward

the

left

Contrarily

the

line

pressure

I

togelher

with

the

spring

force

force

the

FSV

toward

the

right

opposing

the

governor

pressure

15

When

the

vehide

speed

exceeds

a

certain

level

the

governor

pressure

15

exceeds

the

sum

of

the

throttle

pressure

and

Ihe

spring

force

and

the

FSV

is

forced

toward

the

left

When

the

FSV

is

depressed

10

a

certain

position

the

lire

pressure

I

is

closed

and

only

the

spring

depresses

the

FSV

toward

the

right

and

it

is

depressed

to

the

end

for

a

moment

As

a

resull

the

line

p

ressure

lJ

is

for

warded

to

8

the

band

servo

is

engaged

through

the

SLY

and

the

speed

is

shifted

to

2nd

With

the

accelerator

pedal

depressed

the

FSV

remains

iIi

the

Low

position

unless

the

governor

pressure

IS

increases

to

a

high

leVel

corresponding

to

the

line

pressure

I

since

the

line

pressure

I

increase

when

the

accelerator

pedal

is

depresse9

Contrarily

when

vehicle

speed

de

creases

the

governor

pressure

15

decrease

Howeve

f

the

gear

is

not

shifted

to

Low

nless

the

governor

pressure

15

becomes

zero

since

the

force

depressing

the

FSV

toward

the

right

is

being

delivered

only

by

the

spring

Low

in

range

I

is

led

to

the

low

and

reverse

clutch

from

line

pres

sure

5

through

line

prbssure

12

2nd

is

simultaneousi

y

led

to

the

ieft

end

spring

unit

Consequently

al

thougp

the

goverflor

pressure

in

creases

the

valve

is

still

forced

toward

the

right

and

the

SFV

is

fixedjn

the

Low

position

When

kicked

down

to

the

2nd

speed

the

SDV

operates

and

the

line

pressure

13

forces

the

FSV

toward

the

right

Although

the

Automatic

Transmission

governor

pressure

15

is

considerably

high

the

valve

is

forced

completely

toward

the

right

and

the

FSV

is

returned

to

the

Low

position

This

operation

is

alled

Kickdown

shift

15

j

13

1

c5

I

0

t

r

I

I

q

1

AT091

Fig

AT

12

lsl

2nd

shift

valve

2nd

3rd

shift

valve

SSV

The

SSV

is

a

transfer

valve

which

shifts

gears

from

2nd

to

3rd

When

the

vehicle

is

stopped

the

SSV

is

forced

toward

the

right

by

the

spring

and

is

in

the

2nd

position

It

is

so

design

d

however

that

the

FSV

can

decide

to

shift

either

to

Low

or

2nd

When

the

vehicle

is

running

the

governor

pressure

15

is

applied

to

the

right

end

surface

and

th

SSV

is

forced

toward

the

left

Contrarily

the

Spri

l

force

line

pressure

3

and

throttle

press

re

19

force

the

SSV

toward

the

right

When

vehicle

speed

exceeds

a

cee

tain

level

the

governor

pressure

sur

passes

the

sum

of

the

spring

force

line

pressure

and

throttle

pressure

and

the

valve

is

forced

toward

the

left

The

line

pressure

3

is

then

closed

Con

sequently

the

forces

being

rapjdly

unbalanced

the

force

depressing

the

SSV

toward

the

right

decreases

and

thus

the

SSV

is

depressed

to

the

l

ft

end

for

a

moment

With

Ihe

SSV

depressed

toward

the

left

end

lhe

line

pressure

3

is

connected

with

the

line

pressure

10

the

band

servo

is

re

leased

the

front

clutch

is

engaged

and

AT

8

speed

is

shifted

to

3rd

When

the

accelerator

pedJI

is

de

prcssed

both

the

line

pressure

3

and

the

throttle

pressure

19

are

high

allll

the

SSV

is

thus

retained

in

nd

unless

the

governor

pressure

15

ex

ceeds

the

line

pressure

3

and

the

throttle

pressure

19

In

the

3rd

position

force

de

pressing

ihe

SSV

toward

the

right

is

retained

only

by

the

throttle

pressure

16

and

the

throttle

pressure

16

is

slightly

Idwer

than

that

toward

the

right

which

is

applied

while

shifting

from

2nd

to

3rd

Consequently

the

SSV

is

returned

to

the

2nd

position

at

a

slightly

lower

speed

Shifting

from

3rd

to

2nd

occurs

at

a

speed

slightly

lower

than

that

for

2nd

to

3rd

shifting

When

kicked

down

at

3rd

line

pressure

13

is

led

from

the

SDV

and

the

SSV

is

forced

toward

the

right

Although

the

governor

pres

ure

is

con

siderably

high

the

valve

is

forced

completely

loward

the

right

and

tht

SSV

is

thus

returned

to

2nd

posi

tion

fhis

operation

is

called

K

cli

down

shift

When

the

shift

iever

is

shifted

to

2

or

I

range

at

the

3rd

speed

the

line

pressure

3

if

diained

at

the

MNV

Consequently

the

front

clutch

and

band

servo

releasing

oils

are

drained

As

a

result

the

transmission

is

shifted

to

2nd

or

low

speed

ai

though

the

SSV

is

in

the

3rd

posi

tion

When

the

specd

IS

shifted

io

the

3r

1

a

one

way

orifice

24

on

the

topof

the

SSV

relieves

oil

transmitting

velocity

from

the

line

pressure

3

to

the

line

pressure

10

and

reduces

the

shock

generated

fioni

the

shifting

Contrarily

when

the

lever

is

shifted

to

2

or

I

range

and

the

speed

is

shifted

from

3rd

to

the

2nd

the

orifice

checking

valve

spring

24

is

depressed

the

throttle

becomes

in

effective

the

line

pressure

10

is

drained

quickly

and

delay

in

shifting

speeds

is

thus

eliminated

The

throttle

of

line

pressure

6

transmits

Hie

oil

transmitting

velocity

from

line

pressure

6

to

line

pressurc

10

wtien

the

lever

is

shifted

to

the

R

range

and

transmits

drain

veloci

ty

from

line

pressure

10

to

line

Page 269 of 537

3

Jit

f

ng

valve

24

1

3

L

l

r

I

Js

I

i

ilr

t

pressure

6

when

shif

ing

from

3rd

to

2nd

at

D

range

Thus

the

throttle

of

line

pressure

6

reduces

the

shock

generated

fro

shifting

A

plug

in

the

SSV

left

end

readjust

the

throttle

piessu

e

I

6

which

varies

depending

on

the

engine

throttle

con

dition

to

a

throttle

pressure

19

suiled

to

the

sp

ed

change

control

Moreover

the

plug

is

a

valve

which

applies

line

P

esspre

13

in

lieu

of

the

throttle

pressure

to

the

SSV

and

the

FSV

when

kickdowri

is

performed

When

the

throttle

pressure

16

is

applied

to

the

left

side

of

this

plug

and

the

plug

is

epressed

toward

the

right

a

slight

space

is

formed

from

the

throttle

pressure

6

10

19

A

throt

tIepressu

19

w

1iFh

is

lower

by

the

pressure

loss

equivalent

to

this

space

is

rH

1

Pressure

Odifier

valve

PMV

I

Compared

to

the

operating

pressure

required

in

starting

th

vehicle

the

ppwer

trimsinitting

capacity

of

the

clutch

that

is

required

operating

pres

sure

may

be

lower

when

the

vehicle

is

once

started

When

the

line

pressure

is

retained

at

a

high

level

up

to

a

high

vehicle

speed

shock

gerieraled

from

the

shirring

increases

arid

the

oil

pump

loss

also

jncrdases

In

order

to

prevent

his

the

t

lrott

le

pressure

must

be

l

hanged

over

with

the

operation

of

the

governor

pressure

15

to

reduce

Ihe

line

pressure

The

PMV

is

used

for

this

purposc

Automatic

Transmission

generated

the

piessure

loss

is

adde

d

to

the

spring

force

and

the

plug

is

lhus

forced

back

from

the

right

to

the

left

When

this

pressure

19

increases

ex

cessively

the

plug

is

further

depressed

toward

the

left

space

from

the

lhrot

tle

pressure

19

to

the

drain

circuit

13

increases

and

the

throttle

press

ure

19

decreases

Thus

the

plug

is

balanced

imd

the

throttle

pressure

19

is

reduced

to

Ii

certain

value

against

the

throttle

pressure

6

Wheri

performing

kickdowri

the

SDV

moves

a

high

line

pressure

is

led

to

the

circuit

19

from

the

line

pressure

circuit

13

which

had

been

drained

the

plug

is

forced

toward

the

left

and

circuit

19

becomes

equal

to

the

line

pressure

13

I

W

15

I

A

TOgS

Fig

iT

13

2nd

3rd

shift

vallJe

I

When

the

governor

pressuie

IS

which

is

applied

to

the

right

side

of

the

PMV

is

low

the

valve

is

forced

toward

the

right

by

the

throttle

ines

sure

16

applied

to

the

area

differ

ence

of

the

value

and

the

spring

foice

and

t

he

circuit

from

circuit

16

to

circuit

18

is

closed

However

when

vehicle

speed

increases

andl

the

gaver

nor

pressure

15

exceeds

a

certain

level

the

governor

pressure

toward

the

left

which

is

applied

to

the

right

side

exceeds

the

spring

force

and

the

throt

tle

pressure

16

toward

thc

right

the

valve

is

depressed

loward

the

lefi

and

the

throttle

pressure

is

led

from

circuit

AT

9

16

to

circuit

18

This

throttle

pressure

18

is

applied

to

the

top

of

the

PRV

and

the

force

of

the

line

pressure

source

7

is

reduced

Contra

rily

when

the

vehicle

speed

decreases

arid

the

governor

ipressure

15

de

creases

the

force

toward

the

fight

exceeds

ithe

governor

pressure

the

valve

is

forced

back

toward

the

right

and

the

throttle

pressure

18

is

drained

to

the

spring

unit

This

valve

is

sWitched

when

the

throttle

pressure

and

the

governor

pressure

are

high

or

when

tIiey

are

both

Tow

i

i

I

11

18

16

n

r

I

I

15

AT099

Fig

AT

14

Pre

ure

modifier

valve

Vacuum

thro

le

valve

VTV

The

vacuum

t

rottle

valve

is

a

regula

tor

valve

whiCh

uses

the

line

pressure

7

for

the

pressure

source

and

regulates

the

throttle

pressure

16

I

which

is

proportioned

t

the

force

of

the

vacuum

diaphragm

The

vacuum

dia

phragm

yories

depending

on

the

engine

throt

le

condition

negative

pressure

in

the

inta

e

line

When

the

line

pressure

7

is

ap

plied

to

the

bottom

through

the

valve

hole

and

the

v

a

ve

is

forced

upward

space

from

the

line

pressure

7

to

the

throttle

pressure

16

is

dosed

and

the

space

from

the

Ihrottle

pressure

16

to

the

drain

circuit

17

is

about

to

open

In

this

operation

the

throttle

pressure

16

becomes

lower

than

the

linep

s

ureY

btthe

p

e

sur

9

iv

alenl

of

the

loss

of

space

and

Ihe

force

depressing

tlie

rod

if

the

vaeuum

diaphragm

is

balanced

wit

Ii

thethrot

tie

pressure

16

a

pplied

upward

tOlthe

bottom

When

the

erigine

torque

is

high

Ihe

negative

pressure

in

the

intake

iirie

rises

tending

ioward

atmospheric

pressure

and

the

force

of

the

rod

to

depress

the

valve

increases

As

a

result

the

valve

is

depressed

downward

the

Page 271 of 537

2nd

3rd

timln

valve

TMV

This

valve

is

a

transfer

valve

which

switches

the

by

pass

circuit

of

the

orifice

22

in

the

front

clutch

pres

sure

circuit

II

in

response

to

vehicle

speed

and

throttle

condition

A

force

created

when

the

governor

pressure

IS

is

applied

to

the

bottom

of

the

TMV

constitutes

the

upward

force

and

a

force

created

when

the

spring

force

and

the

throttle

pressure

are

applied

to

the

top

of

the

TMV

consti

tutes

the

downward

force

When

the

throttle

pressure

16

is

lower

than

the

governor

pressure

IS

Automatic

Transmission

the

upward

force

exceeds

the

down

ward

force

the

valve

is

locked

upward

and

passage

from

circuit

l0

2nd

from

the

Top

to

circuit

II

is

closed

Consequently

the

line

pressure

10

is

led

to

the

front

clutch

circuit

II

through

the

orifice

22

and

the

oil

pressure

is

thus

transmitted

slowly

However

under

normal

shifting

the

throttle

pressure

16

has

a

pressure

exceeding

a

certain

level

and

the

downward

force

e

xceeds

the

upward

force

As

a

result

the

valve

is

locked

downward

the

passage

from

circuit

10

to

circuit

II

is

opened

and

the

orifice

22

is

bypassed

ATll

AT104

Fig

JlT

19

2nd

3rd

timing

valve

Page 298 of 537

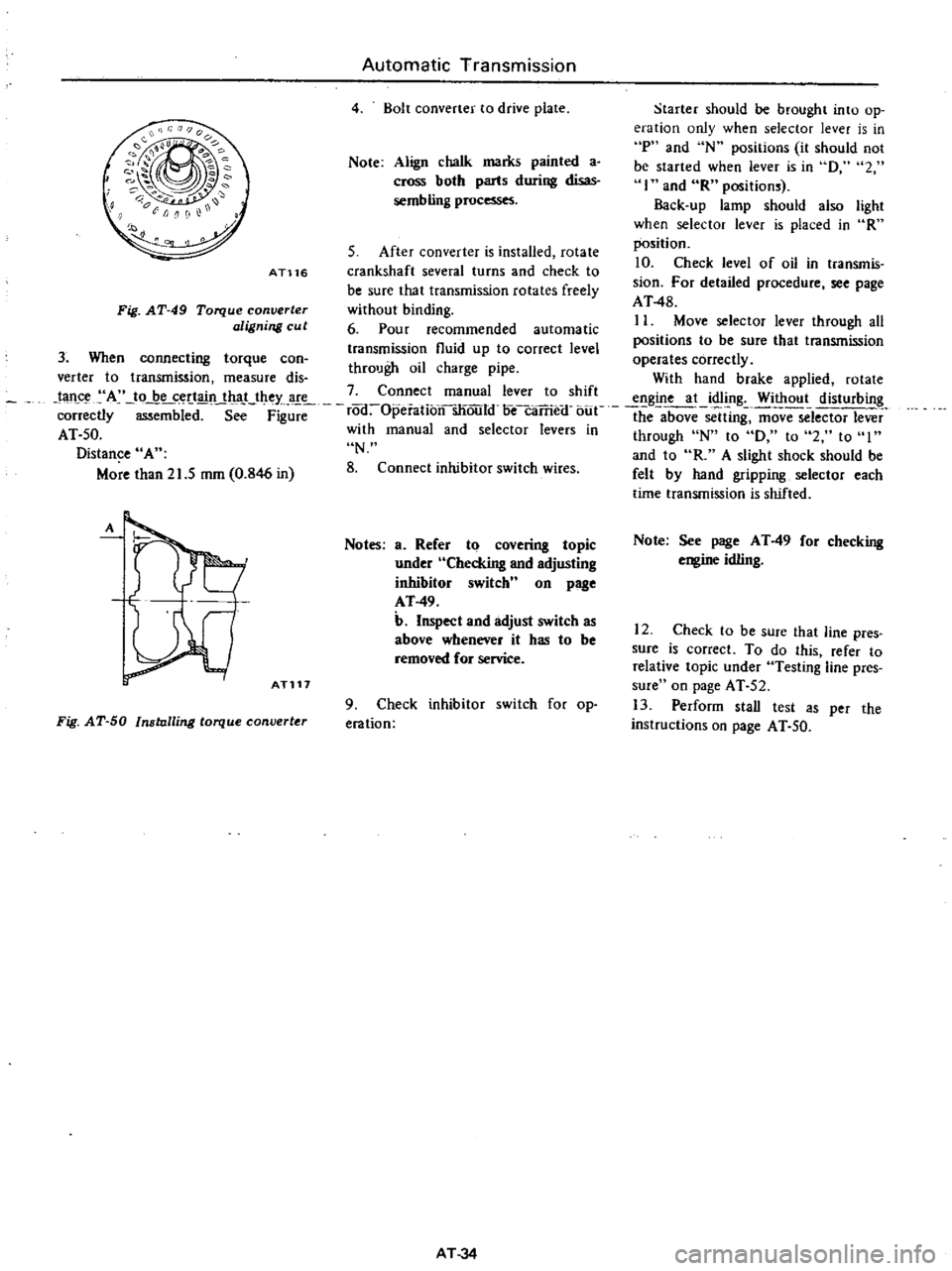

Starter

should

be

brought

into

op

eration

only

when

selector

lever

is

in

P

and

N

positions

it

should

not

be

started

when

lever

is

in

D

2

I

and

R

positions

Back

up

lamp

should

also

light

when

selector

lever

is

placed

in

R

position

S

After

converter

is

installed

rotate

10

Check

level

of

oil

in

transmis

crankshaft

several

turns

and

check

to

be

sure

that

transmission

rotates

freely

sion

For

detailed

procedure

see

page

AT48

without

binding

6

Pour

recommended

automatic

II

Move

selector

lever

through

aU

positions

to

be

sure

that

transmission

transmission

fluid

up

to

correct

level

operates

correctly

through

oil

charge

pipe

verter

to

transmission

measure

dis

With

hand

brake

applied

rotate

tan

A

to

be

certain

that

they

are

7

Connect

manual

lever

to

shift

engine

at

idling

Without

disturbing

correctly

mbi

d

S

F

rod

Opeiationsliould

oecaTrie

f

bue

the

above

sclUng

ffiovTSelector

lever

AT

50

with

manual

and

selector

levers

in

through

N

to

D

to

2

to

I

Distance

A

N

and

to

R

A

slight

shock

should

be

More

than

21

5

mm

0

846

in

8

Connect

inhibitor

switch

wires

felt

by

hand

gripping

selector

each

time

transmission

is

shifted

Automatic

Transmission

4

Bolt

converter

to

drive

plate

Note

Align

chalk

marks

painted

a

cross

both

parts

during

disas

sembling

processes

AT116

Fig

AT

49

Torque

converter

aligning

cu

t

3

When

connecting

torque

can

A

ATl17

Notes

a

Refer

to

covering

topic

under

Checking

and

adjusting

inhibitor

switch

n

on

page

AT

49

b

Inspect

and

adjust

switch

as

above

whenever

it

has

to

be

removed

for

service

Fig

AT

50

Installing

torque

converter

9

Check

inhibitor

switch

for

op

eration

AT

34

Note

See

page

AT

49

for

checking

engine

idling

12

Check

to

be

sure

that

line

pres

sure

is

correct

To

do

this

refer

to

relative

topic

under

Testing

line

pres

sure

on

page

AT

52

13

Perform

stall

test

as

per

the

instructions

on

page

AT

50