wheel bolts DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 359 of 537

UPPER

AND

LOWER

LINKS

REMOVAL

AND

INSTALLATION

Removal

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

and

brake

drum

as

an

assembly

3

Remove

wheel

hub

Refer

to

see

tion

Front

Axle

4

Loosen

bolts

retaining

brake

disc

to

knuckle

spindle

and

remove

brake

disc

5

Remove

knuckle

arm

torsion

bar

spimgJ

stabilizer

shock

absorber

and

tension

rod

in

t

ili

order

referring

the

related

sections

6

Remove

upper

fulcrum

bolt

se

curing

knuckle

spindle

support

to

upper

link

assembly

and

disassemble

them

7

Remove

upper

link

bushings

from

knuckle

spindle

support

8

Remove

screw

bushings

from

both

ends

of

lower

link

fulcrum

pin

9

Loosen

nut

at

lower

portion

of

knuckle

spindle

support

from

inside

and

pull

out

cotter

pin

retaining

ful

crum

pin

10

Pull

out

fulcrum

pin

with

drift

and

remove

knuckle

spindle

support

with

knuckle

spindle

from

lower

link

Then

detach

dust

cover

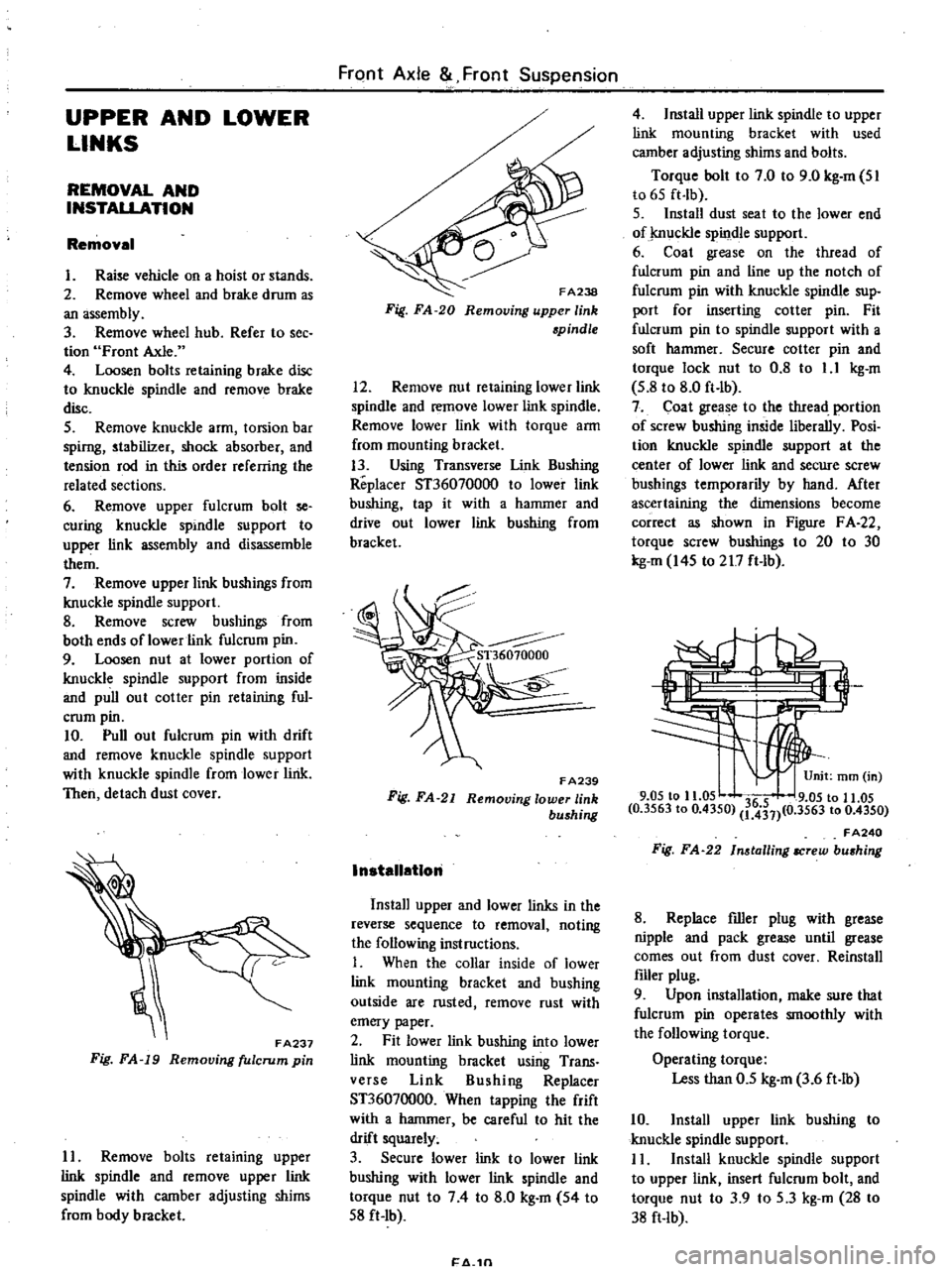

FA237

Fig

FA

19

Removing

fulcrum

pin

II

Remove

bolts

retaining

upper

link

spindle

and

remove

upper

link

spindle

with

camber

adjusting

shims

from

body

bracket

FrClnt

Axle

Front

Suspension

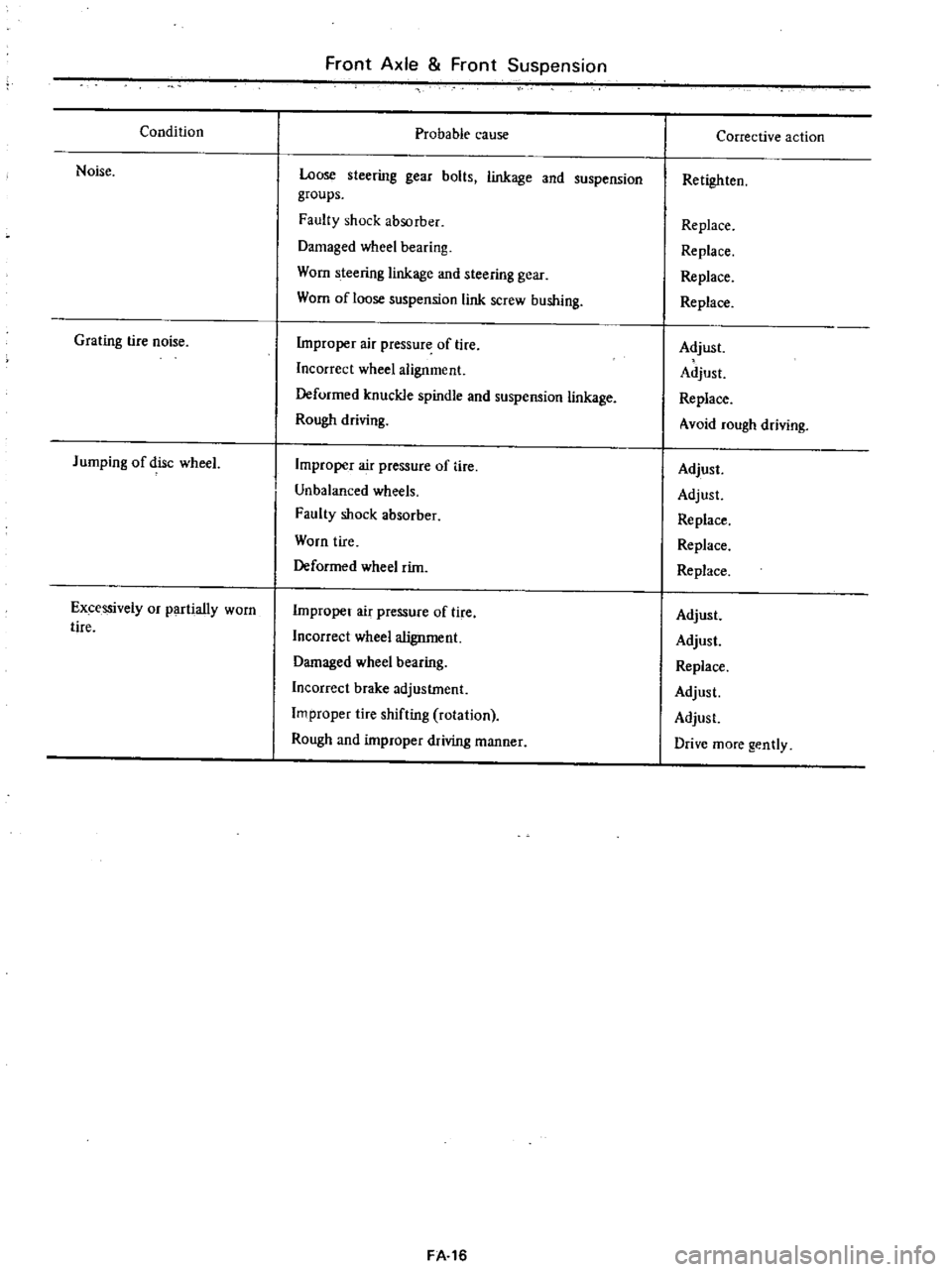

FA238

Fig

FA

20

Removing

upper

link

spindle

12

Remove

nut

retaining

lower

link

spindle

and

remove

lower

link

spindle

Remove

lower

link

with

torque

arm

from

mounting

bracket

13

Using

Transverse

Unk

Bushing

Replacer

ST36070000

to

lower

link

bushing

tap

it

with

a

hammer

and

drive

out

lower

link

bushing

from

bracket

F

A239

Fig

FA

21

Removing

lower

link

bushing

InstallatIon

Install

upper

and

lower

links

in

the

reverse

sequence

to

removal

noting

the

following

instructions

I

When

the

collar

inside

of

lower

link

mounting

bracket

and

bushing

outside

are

rusted

remove

rust

with

emery

paper

2

Fit

lower

link

bushing

into

lower

link

mounting

bracket

using

Trans

verse

Link

Bushing

Replacer

ST36070000

When

tapping

the

frift

with

a

hammer

be

careful

to

hit

the

drift

squarely

3

Secure

lower

link

to

lower

link

bushing

with

lower

link

spindle

and

torque

nut

to

74

to

8

0

kg

m

54

to

S8

ft

Ib

1

4

1n

4

Install

upper

link

spindle

to

upper

link

mounting

bracket

with

used

camber

adjusting

shims

and

bolts

Torque

bolt

to

7

0

to

9

0

kg

m

SI

to

6S

ft

lb

S

Install

dust

seat

to

the

lower

end

of

j

nuckle

spindle

support

6

Coat

grease

on

the

thread

of

fulcrum

pin

and

line

up

the

notch

of

fulcrum

pin

with

knuckle

spindle

sup

port

for

inserting

cotter

pin

Fit

fulcrum

pin

to

spindle

support

with

a

soft

hammer

Secure

cotter

pin

and

torque

lock

nut

to

0

8

to

1

1

kg

m

S

8

to

8

0

ft

lb

7

Coat

grease

to

the

tIuead

portion

of

screw

bushing

inside

liberally

Posi

tion

knuckle

spindle

support

at

the

center

of

lower

link

and

secure

screw

bushings

temporarily

by

hand

Mter

ascertaining

the

dimensions

become

correct

as

shown

in

Figure

F

A

22

torque

screw

bushings

to

20

to

30

kg

m

I4S

to

217

ft

lb

3

9

05

to

11

05

36

5

9

05

to

11

05

0

3563

to

0

4350

1

431

0

3563

to

0

4350

FA240

Fig

FA

22

In

tailing

IICrew

bu

hing

8

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

filler

plug

9

Upon

installation

make

sure

that

fulcrum

pin

operates

smoothly

with

the

following

torque

Operating

torque

Less

than

0

5

kg

m

3

6

ft

lb

10

Install

upper

link

bushing

to

knuckle

spindle

support

I

I

Install

knuckle

spindle

support

to

upper

link

insert

fulcrum

bolt

and

torque

nut

to

3

9

to

S

3

kg

m

28

to

38

ft

lb

Page 365 of 537

Condition

Noise

Grating

tire

noise

Jumping

of

disc

wheeL

Excessively

or

partially

worn

tire

Front

Axle

Front

Suspension

Probable

cause

Loose

steering

gear

bolts

linkage

and

suspension

groups

Faulty

shock

absorber

Damaged

wheel

bearing

Worn

steering

linkage

and

steering

gear

Worn

of

loose

suspension

link

screw

bushing

Improper

air

pressure

of

lire

Incorrect

wheel

alignment

Deformed

knuckle

spindle

and

suspension

linkage

Rough

driving

Improper

air

pressure

of

tire

Unbalanced

wheels

Faulty

shock

absorber

Worn

tire

Deformed

wheel

rim

Improper

air

pressure

of

tire

Incorrect

wheel

alignment

Damaged

wheel

bearing

Incorrect

brake

adjustment

Improper

tire

shifting

rotation

Rough

and

improper

wiving

manner

FA

16

Corrective

action

Retighten

Replace

Replace

Replace

Replace

Adjust

Adjust

Replace

Avoid

rough

driving

Adjust

Adjust

Replace

Replace

Replace

Adjust

Adjust

Replace

Adjust

Adjust

Drive

more

gently

Page 369 of 537

DESCRIPTION

The

rear

axle

assembly

is

of

the

semi

floating

type

in

which

the

vehicle

weight

is

carried

on

the

axle

shafts

through

bearings

enclosed

in

the

bear

ing

cages

on

outer

rear

axle

case

The

axle

case

is

a

pressed

steeJ

Banjo

type

housing

The

rear

axle

assembly

is

attached

to

the

frame

through

semi

elliptic

leaf

springs

and

telescopic

hydraulic

shock

absorbers

Rubber

bushings

at

either

end

of

the

leaf

springs

and

shock

absorbers

are

designed

to

absorb

vibra

tion

and

noise

The

rear

axle

shaft

splines

engage

the

differential

side

gears

with

a

float

ing

fit

The

outer

ends

are

supported

in

the

bearing

cages

by

tapered

roller

bearings

The

bearings

are

lubricated

by

wheel

bearing

grease

The

axle

shaft

oil

seals

are

located

outboard

and

inboard

of

the

bearing

The

bearings

are

se

cured

against

shoulders

on

the

shafts

by

press

fit

and

held

in

place

by

a

large

nuts

The

bearing

cages

hold

the

bearings

against

shoulders

on

the

axle

case

Whee

side

thrust

is

taken

at

the

wheel

bearings

through

the

thrust

block

so

an

axle

shaft

may

be

re

moved

simply

by

removing

the

bolts

holding

the

brake

disc

to

the

bearing

cage

and

the

rear

axle

case

REMOVAL

AND

INSTALLATION

REAR

AXLE

ASSEMBLY

It

is

not

necessary

to

remove

the

reaT

axle

assembly

for

any

normal

repairs

However

if

the

axle

case

is

dam

aged

the

rear

axle

assembly

may

be

removed

and

installed

using

the

fol

lowing

procedures

I

Raise

rear

of

vehicle

high

enough

to

permi

t

working

underneath

Place

a

jack

under

center

of

axle

case

so

it

just

starts

to

raise

rear

axle

assembly

Place

stands

solidly

under

frame

members

on

both

sides

Remove

rear

wheels

Rear

Axle

Rear

Suspension

2

Mark

relationship

across

propeller

shaft

flange

and

companion

flange

of

differential

carrier

so

that

the

original

combination

is

restored

at

assembly

3

Remove

bolts

retaining

center

bearing

bracket

and

connecting

shaft

to

companion

flange

Withdraw

pro

peller

shaft

sleeve

yoke

from

transmis

sion

by

moving

the

shaft

rearward

passing

it

under

rear

axle

4

Disconnect

rear

hand

brake

cable

Q

by

removing

adjusting

nut

@

three

clamps

ID

and

connector

@

Slide

front

cable

rearward

and

discon

nect

rear

cable

@

at

connector

ID

by

removing

three

clamps

ID

5

Disconnect

rear

brake

hose

at

frame

@

Cover

brake

hose

and

pipe

openings

to

prevent

entrance

of

dirt

6

Disconnect

shock

absorbers

at

lower

end

f

and

push

shock

ab

sorbers

up

out

of

the

way

7

Lower

jack

under

axle

case

Re

move

U

bolts

spring

clips

@

to

separate

axle

case

from

spring

8

Place

a

jack

under

center

of

axle

case

Pass

axle

case

through

space

above

spring

and

take

it

out

to

the

side

RA134

Fig

RA

3

Removing

rear

axle

assembly

9

Install

the

axle

case

assembly

in

the

reverse

order

of

removal

RA

3

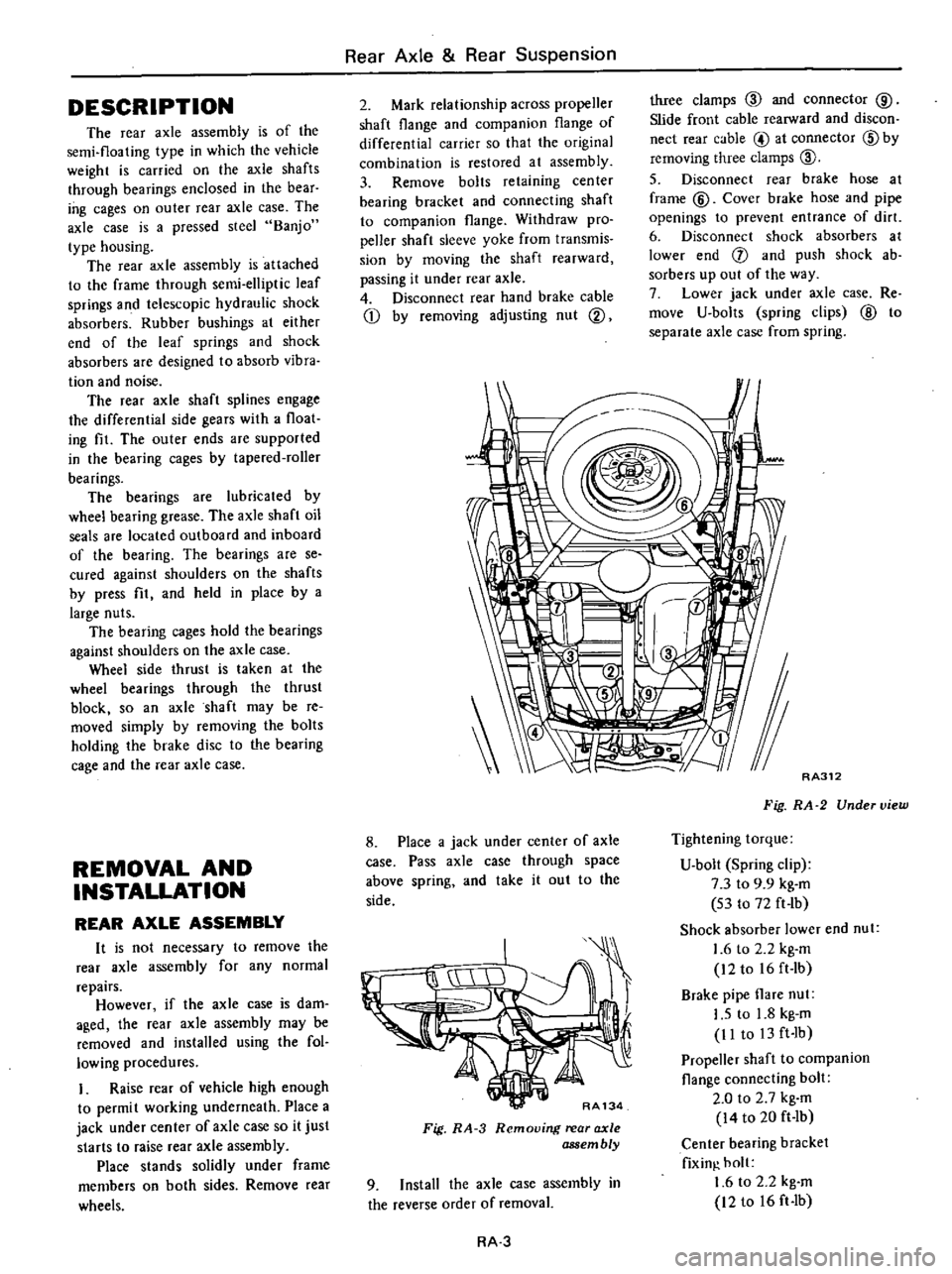

RA312

Fig

RA

2

Under

view

Tightening

torque

U

bolt

Spring

clip

7

3

to

9

9

kg

m

53

to

72

ft

lb

Shock

absorber

lower

end

nut

1

6

to

2

2

kg

m

12to

16ft

Ib

Brake

pipe

flare

nut

I

S

to

1

8

kg

m

II

to

13

ft

Ib

Propeller

shaft

to

companion

flange

connecting

bolt

2

0

to

2

7

kg

m

14

to

20

ft

Ib

Center

bearing

bracket

fixin

holt

1

6

to

2

2

kg

m

12

to

16

ft

Ib

Page 370 of 537

REAR

AXLE

SHAFT

AND

WHEEL

BEARING

I

Raise

rear

of

vehicle

and

support

under

axle

case

on

stands

Remove

rear

wheel

2

Disconnect

rear

hand

brake

cable

by

removing

adjusting

nut

and

clamps

3

Disconnect

brake

tube

at

rear

wheel

cylinder

Cover

brake

tube

and

wheel

cylinder

openings

to

prevent

entrance

of

dirt

4

Remove

brake

drum

Not

If

brake

drum

cannot

be

easily

removed

return

brake

adjuster

install

two

bolts

M8

x

I

2S

in

holes

on

the

flange

face

of

brake

drum

and

tighten

bolts

evenly

until

brake

drum

is

driven

out

5

Remove

nuts

retaining

wheel

bearing

cage

to

brake

disc

I

Jq

AA135

Fig

RA

4

Removing

nuts

AA418

Fig

RA

5

Removing

rear

axle

shaft

assem

bly

7

Remove

oil

seal

in

axle

case

if

necessary

and

install

new

seal

Insure

against

damaging

the

seal

lip

Rear

Axle

Rear

Suspension

8

Position

axle

shaft

in

vise

with

Rear

Axle

Stand

ST07630000

9

Unbend

lock

washer

with

a

screw

driver

Note

Do

not

use

used

lock

washer

again

RAl38

Fig

RA

6

Unbending

lock

washer

10

Remove

lock

nut

using

Rear

Axle

Bearing

Lock

Nut

Wrench

ST38020000

I

AA139

Fig

RA

7

R

mouing

lock

nut

II

Withdraw

wheel

bearing

to

gether

with

bearing

cage

and

brake

disc

using

Rear

Axle

Shaft

Bearing

Puller

HT72480000

HT72480000

r

t

Rvr

G

l

AA343

Fig

RA

8

Removing

bearing

o

12

Remove

oil

seal

in

bearing

cage

if

necessary

13

To

remove

wheel

bearing

outer

race

after

removed

oil

seal

apply

a

brass

drift

to

race

side

surface

and

withdraw

it

by

tapping

the

lop

of

drift

with

a

hammer

Installing

can

be

proceeded

in

the

reverse

order

of

removal

procedure

as

follows

RA

4

I

Fit

wheel

bearing

outer

race

by

tapping

with

a

brass

hammer

evenly

while

fitting

2

Install

a

new

oil

seal

in

bearing

cage

Lubricate

cavity

between

seal

lips

with

wheel

bearing

grease

after

fitting

seal

3

Place

bearing

cage

with

brake

disc

and

bearing

spacer

on

axle

shaft

and

fit

bearing

cone

To

install

bearing

cone

apply

a

brass

drift

to

race

side

surface

and

tapping

the

top

of

drift

with

a

hammer

AA141

Fig

RA

9

Installing

whetl

bearing

4

Place

bearing

lock

washer

Q

and

bearing

nut

lock

washer

@

on

axle

shaft

and

tighten

lock

nut

@

using

Rear

AJde

Bearing

Lock

Nut

Wrench

ST38020000

and

bend

up

lock

wash

er

Notes

a

Be

careful

to

place

the

faced

side

of

nut

to

washer

side

so

that

washer

is

not

damaged

b

Coincide

washer

lip

with

nut

groove

correc

ly

by

tightening

nul

and

bend

washer

carefuljy

so

that

lip

will

nol

be

damaged

Tightening

torque

IS

to

20

kg

m

J08

to

14S

ft

Ib

t

i

i

f

ifii

itf

L

4

S

11

iI

i

j

pu

y

J

t

Mf

i

I

AA142

Fig

RA

IO

Layout

of

ock

nut

Page 371 of 537

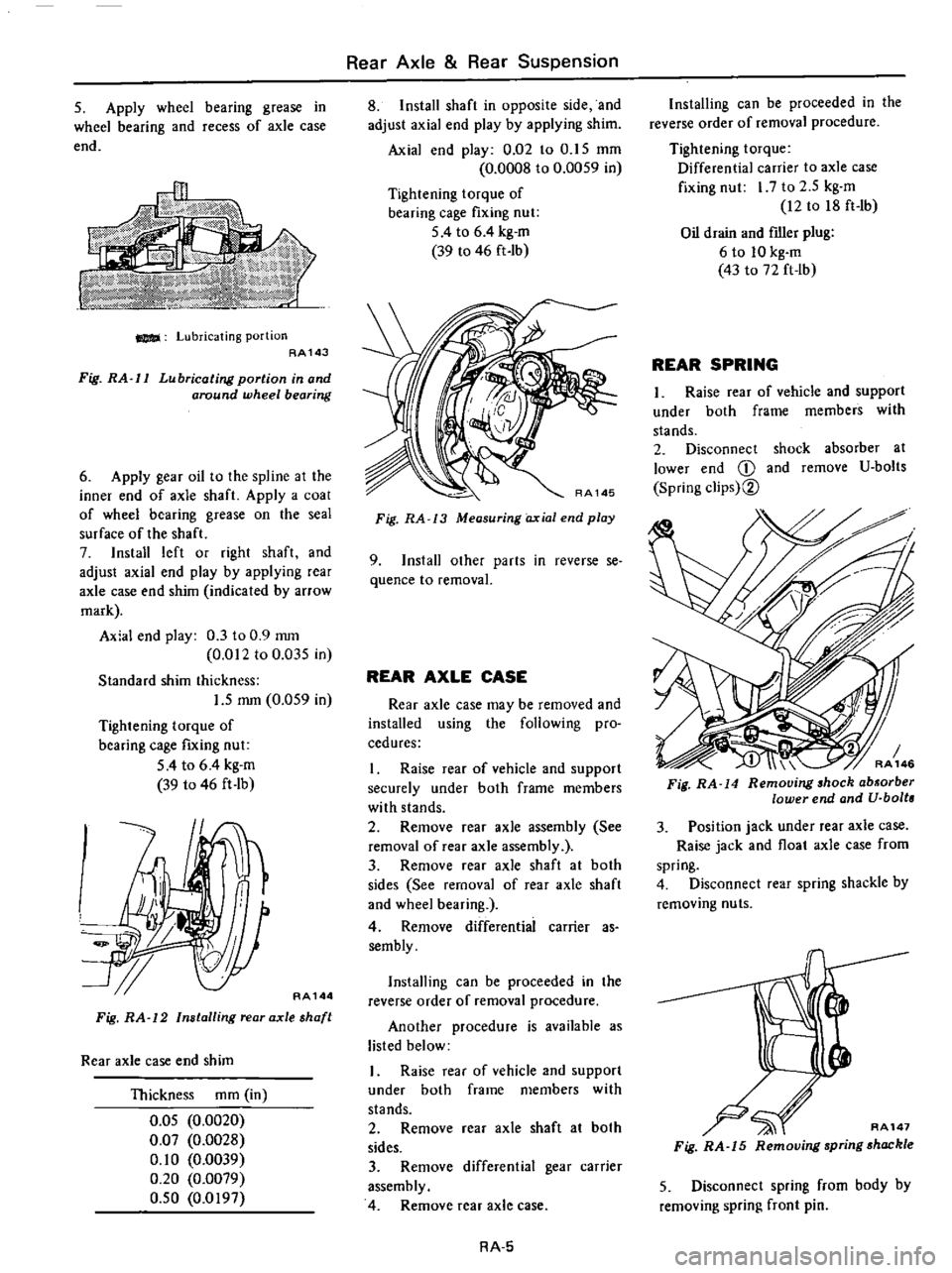

S

Apply

wheel

bearing

grease

in

wheel

bearing

and

recess

of

axle

case

end

Lubricating

portion

AA143

Fig

RA

l1

Lubricating

portion

in

and

around

wheel

bearing

6

Apply

gear

oil

to

the

spline

at

the

inner

end

of

axle

shaft

Apply

a

coal

of

wheel

bearing

grease

on

the

seal

surface

of

the

shaft

7

Install

left

or

right

shaft

and

adjust

axial

end

play

by

applying

rear

axle

case

end

shim

indicated

by

arrow

mark

Axial

end

play

0

3

to

0

9

mOl

0

012

to

0

035

in

Standard

shim

thickness

1

5

mm

0

059

in

Tightening

torque

of

bearing

cage

fIXing

nut

54

to

6

4

kg

m

39

to

46

ft

lb

w

AA144

Fig

RA

12

Installing

rear

axle

shaft

Rear

axle

case

end

shim

Thickness

mOl

in

O

OS

0

0020

0

07

0

0028

0

10

0

0039

0

20

0

0079

O

SO

0

0197

Rear

Axle

Rear

Suspension

8

Install

shaft

in

opposite

side

and

adjust

axial

end

play

by

applying

shim

Axial

end

play

0

02

to

O

IS

mOl

0

0008

to

0

0059

in

Tightening

torque

of

bearing

cage

fixing

nut

5

4

to

6

4

kg

m

39

to

46

ft

Ib

Fig

RA

13

Measuring

axial

end

play

9

Install

other

parts

in

reverse

se

quence

to

removal

REAR

AXLE

CASE

Rear

axle

case

may

be

removed

and

installed

using

the

following

pro

cedures

I

Raise

rear

of

vehicle

and

support

securely

under

both

frame

members

with

stands

2

Remove

rear

axle

assembly

See

removal

of

rear

axle

assembly

3

Remove

rear

axle

shaft

at

both

sides

See

removal

of

rear

axle

shaft

and

wheel

bearing

4

Remove

differentiai

carrier

as

sembly

Installing

can

be

proceeded

in

the

reverse

order

of

removal

procedure

Another

procedure

is

available

as

listed

below

I

Raise

rear

of

vehicle

and

support

under

both

frame

members

with

stands

2

Remove

ear

axle

shaft

at

both

sides

3

Remove

differential

gear

carrier

assembly

4

Remove

rear

axle

case

RA

5

Installing

can

be

proceeded

in

the

reverse

order

of

removal

procedure

Tightening

torque

Differential

carrier

to

axle

case

fixing

nut

I

7

to

2

5

kg

m

12

to

18

ft

Ib

Oil

drain

and

fIller

plug

6

to

10

kg

m

43

to

72

ft

lb

REAR

SPRING

1

Raise

rear

of

vehicle

and

support

under

both

frame

members

with

stands

2

Disconnect

shock

absorber

at

lower

end

CD

and

remove

U

bolts

Spring

clips

2

3

Position

jack

under

rear

axle

case

Raise

jack

and

float

axle

case

from

spring

4

Disconnect

rear

spring

shackle

by

removing

nuts

AA147

Fig

RA

15

Removing

spring

shackle

5

Disconnect

spring

from

body

by

removing

spring

front

pin

Page 372 of 537

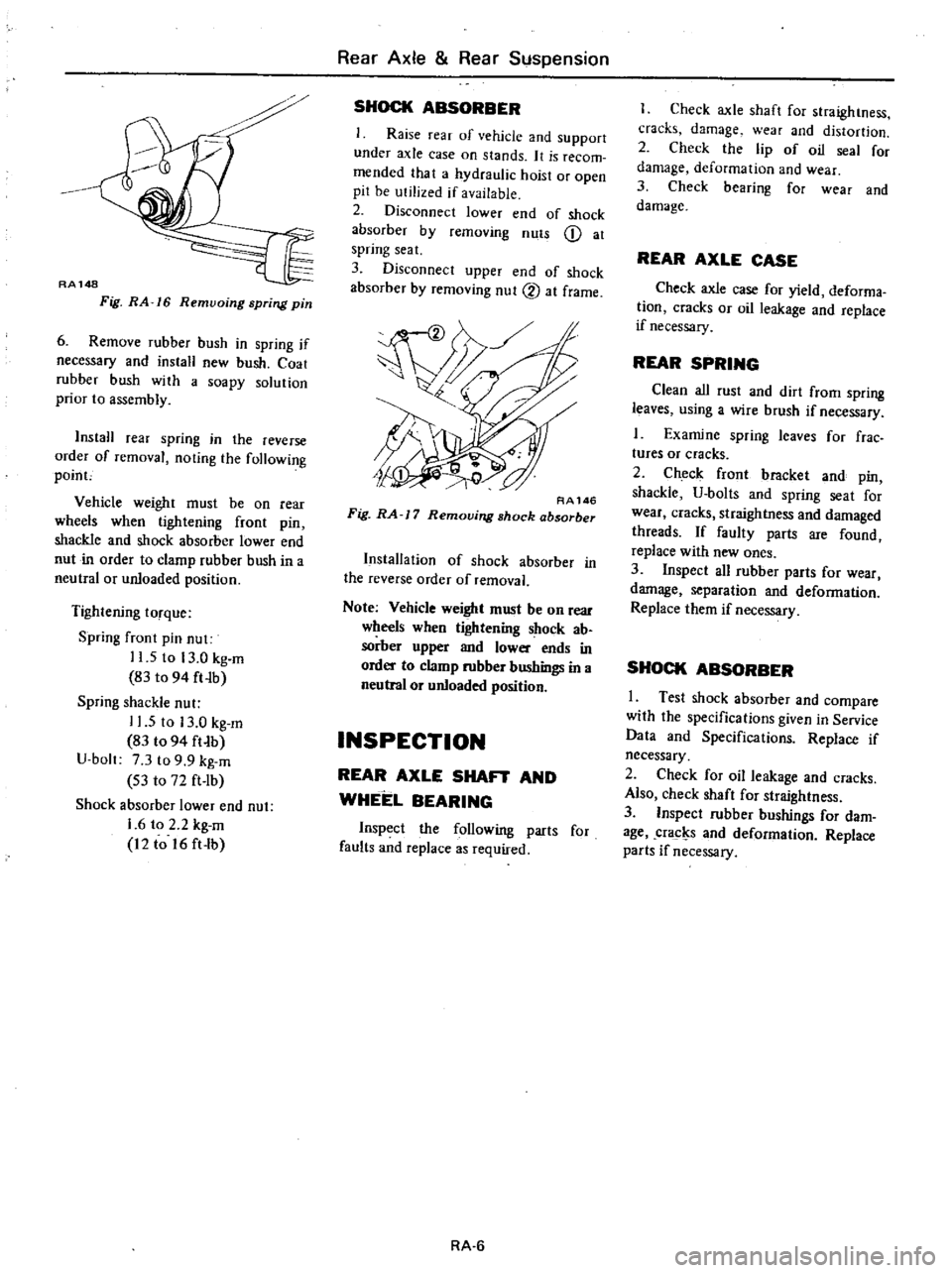

RA148

Fig

RA

16

Remvoing

spring

pin

6

Remove

rubber

bush

in

spring

if

necessary

and

install

new

bush

Coat

rubber

hush

with

a

soapy

solution

prior

to

assembly

InstaH

rear

spring

in

the

reverse

order

of

removal

noting

the

following

poinc

Vehicle

weight

must

be

on

rear

wheels

when

tightening

front

pin

shackle

and

shock

absorber

lower

end

nut

in

order

to

clamp

rubber

bush

in

a

neutral

or

unloaded

position

Tightening

torque

Spring

fTont

pin

nut

11

5

to

13

0

kg

m

83

to

94

ft

Ib

Spring

shackle

nut

11

5

to

13

0

kg

m

83

t094

ft

b

U

bolt

7

3

to

9

9

kg

m

S3

to

72

ft

lb

Shock

absorber

lower

end

nut

1

6

to

2

2

kg

m

12

to

16

ft

lb

Rear

Axle

Rear

Suspension

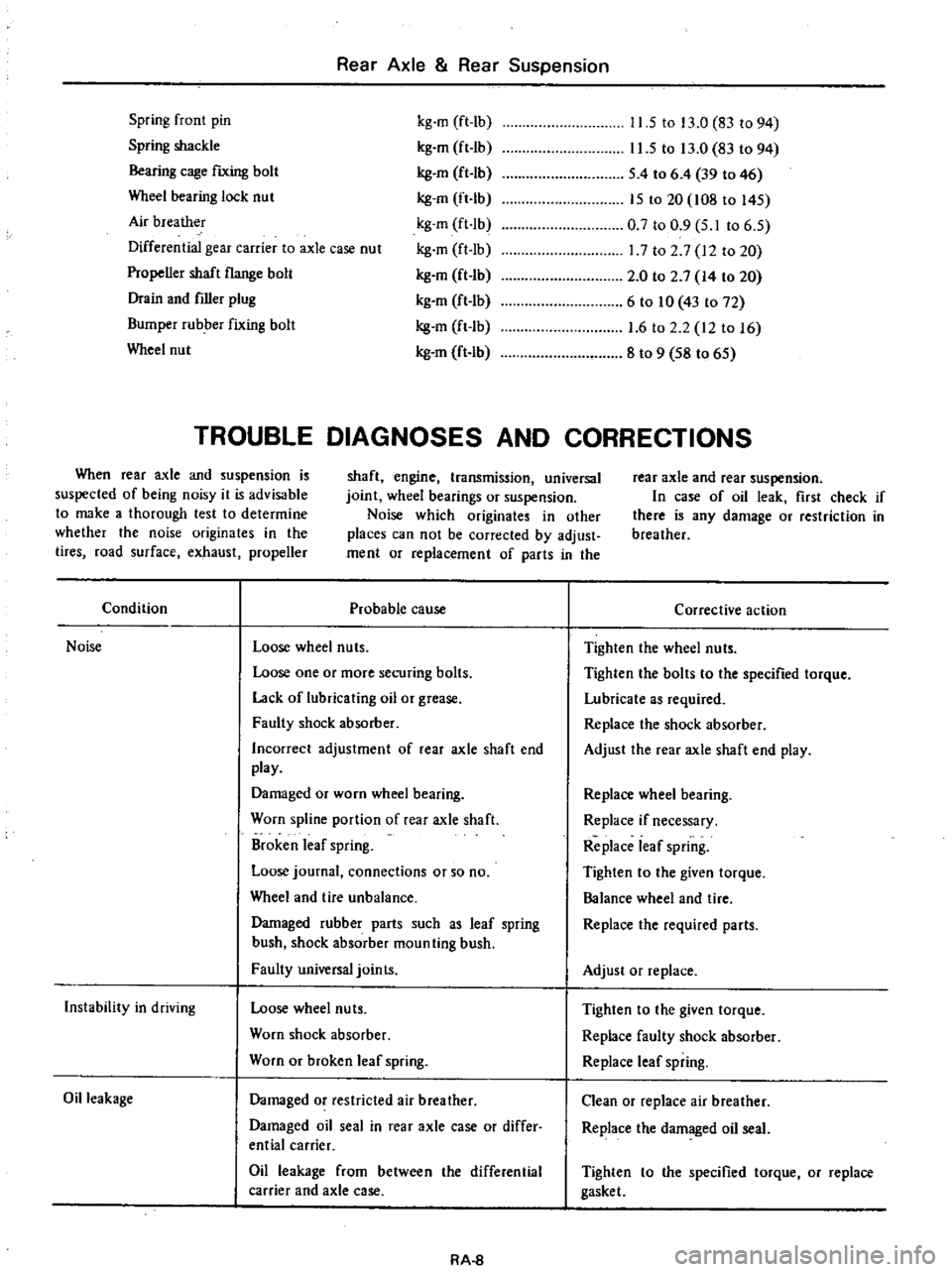

SHOCK

ABSORBER

Raise

rear

of

vehicle

and

support

under

axle

case

on

stands

It

is

recom

mended

that

a

hydraulic

hoist

or

open

pit

be

utilized

if

available

2

Disconnect

lower

end

of

shock

absorber

by

removing

nuts

Q

at

spring

seat

3

Disconnect

upper

end

of

shock

absorber

by

removing

nut

2

at

frame

RA146

Fig

RA

J

7

Removing

shock

absorber

Installation

of

shock

absorber

in

the

reverse

order

of

removal

Note

Vehicle

weight

must

be

on

Tear

wheels

when

tigtrtening

shock

ab

sorber

upper

and

lower

ends

in

order

to

clamp

rubber

bushings

in

a

neutral

or

unloaded

position

INSPECTION

REAR

AXLE

SHAFT

AND

WHEEL

BEARING

Inspect

the

following

parts

for

faults

and

replace

as

required

RA

6

I

Check

axle

shaft

for

straightness

cracks

damage

wear

and

distortion

2

Check

the

lip

of

oil

seal

for

damage

deformation

and

wear

3

Check

bearing

for

wear

and

damage

REAR

AXLE

CASE

Check

axle

case

for

yield

deforma

tion

cracks

or

oil

leakage

and

replace

if

necessary

REAR

SPRING

Clean

all

rust

and

dirt

from

spring

leaves

using

a

wire

brush

if

necessary

1

Examine

spring

leaves

for

frae

tures

or

cracks

2

Check

front

bracket

and

pin

shackle

U

bolts

and

spring

seat

for

wear

cracks

straightness

and

damaged

threads

If

faulty

parts

are

found

replace

with

new

ones

3

Inspect

all

rubber

parts

for

wear

damage

separation

and

deformation

Replace

them

if

necessary

SHOCK

ABSORBER

I

Test

shock

absorber

and

compare

with

the

specifications

given

in

Service

Data

and

Specifications

Replace

if

necessary

2

Check

for

oil

leakage

and

cracks

Also

check

shaft

for

straightness

3

Inspect

rubber

bushings

for

dam

age

cracl

s

and

deformation

Replace

parts

if

necessary

Page 374 of 537

Rear

Axle

Rear

Suspension

Spring

front

pin

Spring

shackle

Bearing

cage

fIXing

bolt

Wheel

bearing

lock

nut

Air

breather

Differential

gear

carrier

to

axle

case

nut

Propeller

shaft

flange

bolt

Drain

and

filler

plug

Bumper

rubber

fixing

bolt

Wheel

nut

kg

m

ft

lb

kg

m

ft

Ib

kg

en

ft

lb

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

Ib

kg

en

ft

Ib

kg

m

ft

Ib

kg

m

ft

Ib

kg

m

ft

lb

11

5

to

13

0

83

to

94

11

5

to

13

0

83

to

94

S

4

to

6

4

39

to

46

IS

to

20

108

to

l4S

0

7

to

0

9

S

I

to

6

S

17

to

2

7

12

to

20

2

0

to

2

7

14

to

20

6

to

10

43

to

72

1

6

to

2

2

12

to

16

8

to

9

S8

to

6S

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

rear

axle

and

suspension

is

suspected

of

being

noisy

it

is

advisable

to

make

a

thorough

test

to

determine

whether

the

noise

originates

in

the

tires

road

surface

exhaust

propeller

shaft

engine

transmission

universal

joint

wheel

bearings

or

suspension

Noise

which

originates

in

other

places

can

not

be

corrected

by

adjust

ment

or

replacement

of

parts

in

the

rear

axle

and

rear

suspension

In

case

of

oil

leak

first

check

if

there

is

any

damage

or

restriction

in

breather

Condition

Probable

cause

Noise

Loose

wheel

nuts

Loose

one

or

more

securing

bolts

Lack

of

lubricating

oil

or

grease

Faulty

shock

absorber

Incorrect

adjustment

of

rear

axle

shaft

end

play

Damaged

or

worn

wheel

bearing

Worn

spline

portion

of

rear

axle

shaft

Broken

leaf

spring

Loose

journal

connections

or

so

no

Wheel

and

tire

unbalance

Damaged

rubber

parts

such

as

leaf

spring

bush

shock

absorber

moun

ting

bush

Faulty

universal

joints

Instability

in

driving

Loose

wheel

nuts

Worn

shock

absorber

Worn

or

broken

leaf

spring

Oil

leakage

Damaged

or

restricted

air

breather

Damaged

oil

seal

in

rear

axle

case

or

differ

ential

carrier

Oil

leakage

from

between

the

differential

carrier

and

axle

case

RA

8

Corrective

action

Tighten

the

wheel

nuts

Tighten

the

bolts

to

the

specified

torque

Lubricate

as

required

Replace

the

shock

absorber

Adjust

the

rear

axle

shaft

end

play

Replace

wheel

bearing

Replace

if

necessary

Replace

leaf

spring

Tighten

to

the

given

torque

Balance

wheel

and

tire

Replace

the

required

parts

Adjust

or

replace

Tighten

to

the

given

torque

Replace

faulty

shock

absorber

Replace

leaf

spring

Clean

or

replace

air

breather

Replace

the

damaged

oil

seal

Tighten

to

the

specified

torque

or

replace

gasket

Page 385 of 537

Ibove

mentioned

st

is

available

when

op

the

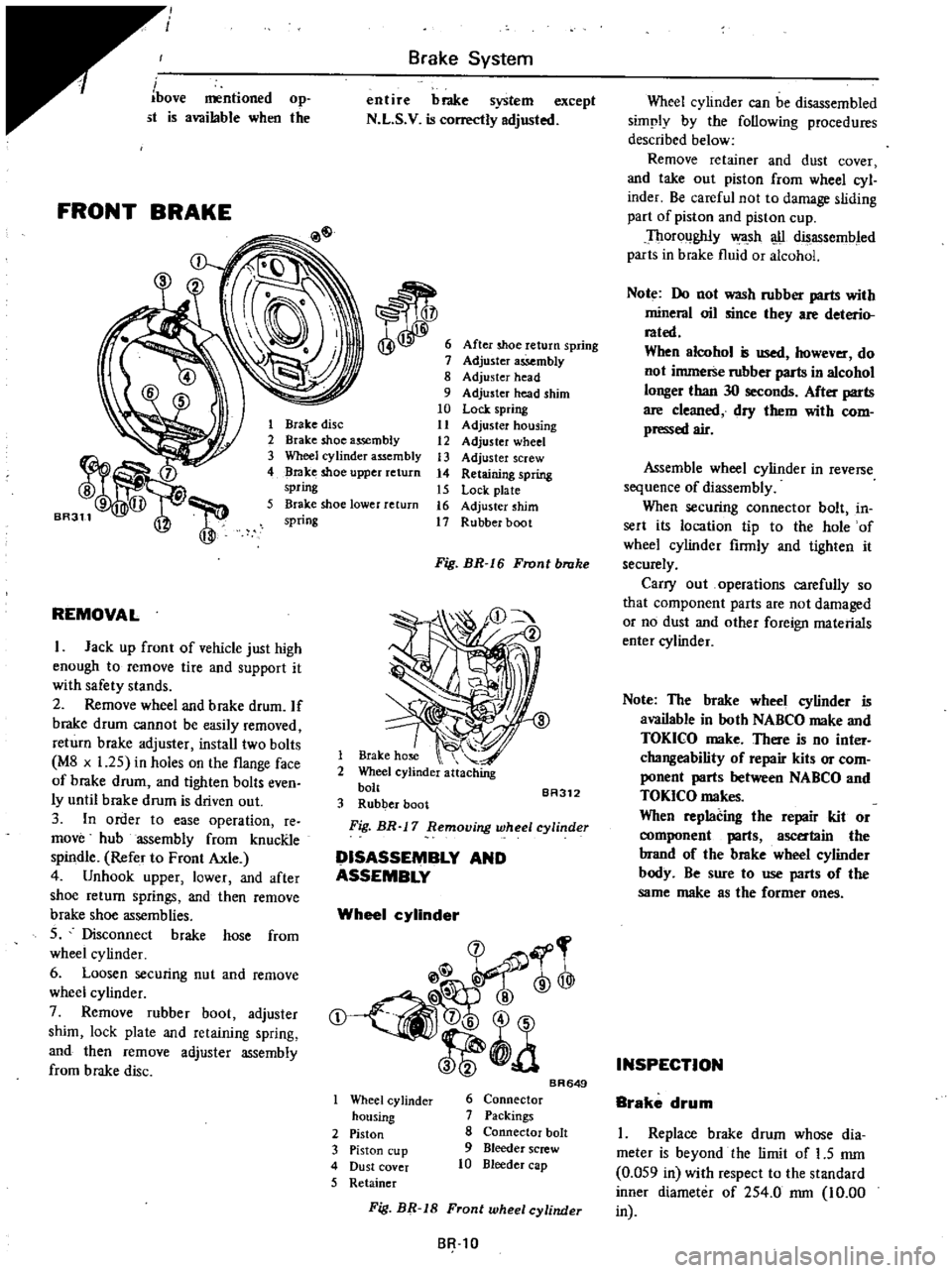

FRONT

BRAKE

Brake

System

entire

brake

system

except

N

L

S

V

is

correctly

adjusted

After

shoe

return

spring

Adjuster

assembly

8

Adjuster

head

9

Adjuster

head

shim

10

Lock

spring

11

Adjuster

housing

12

Adjuster

wheel

13

Adjuster

screw

14

Retaining

spring

15

Lock

plate

16

Adjuster

shim

17

Rubber

boot

1

Brake

disc

2

Brake

shoe

assembly

3

Wheel

cylinder

assembly

4

Brake

shoe

upper

return

spring

5

Brake

shoe

lower

return

spring

REMOVAL

I

Jack

up

front

of

vehicle

just

high

enough

to

remove

tire

and

support

it

with

safety

stands

2

Remove

wheel

and

brake

drum

If

brake

drum

cannot

be

easily

removed

return

brake

adjuster

install

two

bolts

M8

x

1

25

in

holes

on

the

flange

face

of

brake

drum

and

tighten

bolts

even

ly

until

brake

drum

is

driven

out

3

In

order

to

ease

operation

re

move

hub

assembly

from

knucRle

spindle

Refer

to

Front

Axle

4

Unhook

upper

lower

and

after

shoe

return

springs

and

then

remove

brake

shoe

assemblies

S

Disconnect

brake

hose

from

wheel

cy

linder

6

Loosen

securing

nut

and

remove

wheel

cylinder

7

Remove

rubber

boot

adjuster

shim

lock

plate

and

retaining

spring

and

then

remove

adjuster

assembly

from

brake

disc

Fig

BR

I

6

Front

brake

1

Brake

hose

2

Wheel

cylinder

attaching

bolt

BA312

3

Rubber

boot

Fig

BR

17

Removing

wheel

cylinder

DISASSEMBLY

AND

ASSEMBLY

Wheel

cylinder

@

rr

l

@

t

a

Wheel

cy

linder

housing

2

Piston

3

Piston

cup

4

Dust

cover

5

Retainer

BR649

6

Connector

7

Packings

8

Connector

bolt

9

Bleeder

screw

10

Bleeder

cap

Wheel

cylinder

can

be

disassembled

simply

by

the

following

procedures

described

below

Remove

retainer

and

dust

cover

and

take

out

piston

from

wheel

cyl

inder

Be

careful

not

to

damage

sliding

part

of

piston

and

piston

cup

Thoroughly

wa

sh

u

disassembled

parts

in

brake

fluid

or

alcohol

Note

Do

not

wash

rubber

parts

with

mineral

oil

since

they

are

deterio

rated

When

alcohol

is

used

however

do

not

immerse

rubber

parts

in

alcohol

longer

than

30

seconds

After

parts

are

cleaned

dry

them

with

com

pressed

air

Assemble

wheel

cylinder

in

reverse

sequence

of

diassembly

When

securing

connector

bolt

in

sert

its

location

tip

to

the

hole

of

wheel

cylinder

firmly

and

tighten

it

securely

Carry

out

operations

carefully

so

that

component

parts

are

not

damaged

or

no

dust

and

other

foreign

materials

enter

cylinder

Note

The

brake

wheel

cylinder

is

available

in

both

NABCO

make

and

TOKICO

make

There

is

no

inter

changeability

of

repair

kits

or

com

ponent

parts

between

NABCO

and

TOKICO

makes

When

replacing

the

repair

kit

or

ent

parts

ascertain

the

brand

of

the

brake

wheel

cylinder

body

Be

sure

to

use

parts

of

the

same

make

as

the

former

ones

INSPECTION

Brake

drum

I

Replace

brake

drum

whose

dia

meter

is

beyond

the

limit

of

1

5

mm

0

OS9

in

with

respect

to

the

standard

inner

diameter

of

2S4

0

rom

10

00

SR

tO

Fig

BR

18

Front

wheel

cylinder

in

Page 398 of 537

Condition

Brake

chatters

Brake

squeals

Pedal

pulsates

Brakes

fade

Brakes

drag

Unbalanced

brakes

Brake

System

Probable

cause

Groove

or

out

of

round

brake

drum

Loose

or

bent

brake

disc

Distorted

brake

shoes

or

pads

Grease

or

brake

fluid

on

linings

Dirty

or

scored

brake

drums

Distorted

brake

shoes

or

bent

support

plate

Weak

or

broken

brake

shoe

retaining

spring

or

return

spring

Glazed

or

contaminated

brake

lining

Out

of

round

or

off

center

drum

Brake

fluid

has

too

low

boiling

point

Use

of

improper

linings

or

brake

linings

are

contaminated

Brake

drums

are

out

of

round

Hydraulic

connections

master

cylinder

and

wheel

cylinders

are

corroded

or

damaged

Bleed

screw

is

open

Pedal

linkage

is

binding

or

push

rod

adjust

ment

is

too

long

Master

cylinder

compensator

part

is

ob

structed

Seized

master

cylinder

piston

Poor

shoe

condition

Poor

wheel

cylinder

condition

Deformation

of

piston

cups

Hand

brake

will

not

return

Clogged

master

cylinder

return

port

Improper

tire

inflation

Improper

adjustment

of

shoe

to

drum

clear

anee

Grease

oil

mud

or

water

on

linings

or

pads

Mud

in

brake

drum

Deterioration

of

linings

or

pads

Excessive

wear

of

linings

or

pads

BR

23

Corrective

action

Grind

or

replace

as

required

Tighten

support

plate

bolts

to

specified

torque

or

replace

plate

Replace

as

necessary

Replace

linings

Blowout

assembly

with

compressed

air

or

refinish

drum

Replace

faulty

unit

Replace

if

faulty

Cam

ground

lining

to

eliminate

glaze

If

it

doesn

t

replace

linings

Turn

drum

or

replace

as

necessary

Drain

and

fill

system

with

approved

fluid

Replace

linings

Repair

or

replace

as

necessary

Repair

as

necessary

Close

screw

and

bleed

system

Lubricate

linkage

check

pedal

return

spring

for

condition

and

adjust

push

rod

as

neces

sary

Blowout

foreign

matter

with

compressed

air

Disassemble

master

cylinder

and

replace

piston

Bleed

system

Clean

and

repair

Repair

or

replace

Replace

Check

and

repair

Clean

Inflate

to

correct

pressure

Readjust

Clean

brake

mechanism

and

check

for

cause

of

problem

Replace

linings

or

pads

Clean

Replace

Replace

Page 399 of 537

Condition

Pedal

yields

under

slight

pressure

Brake

System

Probable

cause

Wheel

cylinder

in

poor

condition

Poor

sliding

condition

of

brake

shoe

Looseness

of

cylinder

body

or

back

plate

securing

bolts

Scored

or

out

of

round

drums

Sticking

wheel

cylinder

cups

Deformation

of

back

plate

Incorrect

adjustment

of

wheel

bearings

Incorrect

adjustment

of

wheel

alignment

Looseness

of

leaf

spring

securing

U

bolts

Faulty

N

L

S

V

Deteriorated

check

valve

Ex

ternalleaks

Leakage

on

master

cylinder

BR

24

Corrective

action

Repair

or

replace

Adjust

Fasten

or

replace

Recondition

or

replace

brake

drum

as

reo

quired

Check

for

improper

lining

contact

with

drum

and

grind

lining

if

necessary

Recondition

or

replace

cylinder

Replace

Adjust

or

replace

Adjust

Tighten

or

replace

Replace

Replace

check

valve

and

bleed

system

Check

master

cylinder

piping

and

wheel

cylinder

for

leaks

and

repair

Overhaul

master

cylinder