wheel torque DATSUN PICK-UP 1977 User Guide

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 332 of 537

PROPELLER

SHAFT

8l

DIFFERENTIALCAAR

ER

CHECKING

AND

CQRRECTING

UNBALANCED

PROPELLER

SHAFT

anced

propeller

shaft

proceed

as

follows

I

Remove

undercoating

and

other

foreign

materials

which

could

upset

shaft

balance

and

check

shaft

vibra

tion

by

road

test

2

If

shaft

vibration

is

noted

during

To

check

and

correct

an

unbal

SERVICE

DATA

Pe

issible

dynamic

unbalance

Axi

play

of

spider

journal

Journal

swinging

torque

Propeller

shaft

front

and

rear

out

of

round

Tightening

torque

Shaft

to

conipanion

flange

Gear

carrier

bolt

Self

locking

nut

front

shaft

Flange

yo

e

rear

shaft

to

companion

flange

front

shaft

bolt

Center

bearing

bracket

to

cross

member

bolt

road

test

disconnect

propeller

shaft

at

differential

carrier

companion

flange

rotate

companion

flange

180

degrees

and

reinstall

propeller

shaft

3

Again

check

shaft

vibration

If

vibration

still

persists

replace

pro

peller

shaft

assembly

gr

cm

in

oz

3S

0

49

at

S

800

rpm

mm

in

Less

than

0

02

0

0008

kg

em

in

Ib

Less

than

IS

O

13

mm

in

Less

than

0

6

0

024

kg

m

ft

lb

kg

m

ft

Ib

kg

m

ft

lb

kg

m

ft

lb

2

4

to

3

3

17

to

24

20

0

to

24

0

l4S

to

174

2

4

to

3

3

17

to

24

1

6

to

2

2

12

to

16

TROUBLE

DIAGNOSES

AND

CQRRECTIONS

Condition

Probable

cause

Vibration

during

at

medium

or

high

speed

Worn

or

damaged

universal

joint

needle

bearing

Unbalance

due

to

bent

or

dented

propeller

shaft

Loose

propeller

shaft

installation

Worn

transmission

rear

extension

bushing

Damaged

center

bearing

or

insulator

Tight

universal

joints

Undercoating

or

mud

on

the

shaft

causing

unbalance

Tire

unbalance

Balance

weights

missing

PD

4

Corrective

action

Replace

I

l

eplace

Retighten

Replace

Replace

Impact

yokes

with

hammer

to

free

up

Replace

joint

if

unable

to

free

up

or

if

joint

feels

rough

when

rotated

by

hand

Clean

up

shaft

Balance

wheel

and

tire

assembly

or

replace

from

known

good

vehicle

Replace

Page 342 of 537

PROPELLER

SHAFT

DIFFERENTIAl

CARRIER

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

a

differential

carrier

is

sus

pected

of

being

noisy

it

is

advisable

to

make

a

thorough

lest

to

determine

whether

the

noise

originates

in

the

Condition

Noise

on

drive

coast

and

float

Noise

on

turn

Knocking

sound

during

starting

or

gear

shifting

tires

road

surface

exhaust

universal

joint

propeller

shaft

wheel

bearings

engine

transmission

or

differential

carrier

Noise

which

originates

in

other

Probable

cause

Shortage

of

oil

Incorrect

tooth

contact

between

ring

gear

and

drive

pinion

Incorrect

backlash

between

ring

gear

and

drive

pinion

Seized

up

or

damaged

ring

gear

and

drive

pinion

Seized

up

damaged

or

broken

drive

pinion

bearing

Seized

up

damaged

or

broken

side

bearing

Loose

bolts

or

nuts

fIXing

ring

gear

bearing

cap

etc

Seized

up

damaged

or

broken

side

and

pinion

mate

Seized

up

damaged

or

broken

side

gear

and

pinion

thrust

washer

Pinion

mates

too

tight

on

their

shaft

Excessive

backlash

Incorrect

backlash

ring

ar

to

drive

pinion

or

side

gear

to

pinionmate

Worn

gears

or

case

Worn

rear

axle

shaft

and

side

gear

spline

Drjve

pinion

bearing

under

p

reload

Loose

drive

pinion

nut

Loose

bolts

or

nuts

ftxing

ring

gear

bearing

cap

etc

PD

14

places

cannot

be

corrected

by

adjust

ment

or

replacement

of

parts

in

dif

ferential

carrier

Corrective

action

Supply

gear

oil

Rebuild

gear

carrier

if

necessary

Adjust

tooth

contact

or

replace

the

hypoid

gear

set

Adjust

backlash

or

replace

the

hypoid

gear

set

if

necessary

Replace

the

hypoid

gear

set

Replace

the

pinion

bearing

and

faulty

parts

Replace

the

side

bearing

and

faulty

parts

Clamp

them

to

specified

torque

and

replace

faulty

parts

Replace

faulty

parts

Replace

faulty

parts

Replace

faulty

parts

Adjust

backlash

Replace

worn

parts

Replace

worn

parts

Adjust

preload

Repair

or

replace

Clamp

them

or

replace

if

necessary

Page 352 of 537

The

design

of

the

front

suspension

adopts

the

independent

double

wishbone

type

suspension

used

the

torsion

bar

spring

Both

the

upper

and

lower

links

are

installed

on

the

bracket

which

is

welded

on

the

frame

A

1d

the

above

links

swing

to

allow

the

knuckle

spindle

to

move

freely

in

a

vertical

dimension

The

top

and

bottom

of

the

knuckle

spindle

support

are

connected

to

the

upper

link

through

rubber

bushing

and

to

the

lower

lick

through

screw

bushing

The

tension

rod

held

by

the

brack

ets

on

the

chassis

frame

and

lower

lick

wiih

rubber

bushings

bears

the

force

of

fore

and

aft

direction

The

front

end

of

the

torsion

bar

spring

is

installed

to

the

torque

arm

which

attaches

to

the

lower

link

The

opposite

end

is

installed

to

the

spring

anchor

that

secures

to

chassis

frame

firmly

The

both

ends

of

the

torsion

bar

spring

are

serrated

The

shock

absorber

is

double

action

telescopic

hydraulic

type

The

upper

stem

is

attached

to

the

bracket

of

the

chassis

frame

The

lower

insulated

bracket

is

bolted

to

the

lower

lick

The

bumper

rubber

secured

to

the

bracket

Of

the

frame

limits

the

verti

cal

motion

of

the

suspension

lick

The

knuckle

spindle

is

connecied

to

the

k

ufkle

spindle

arm

by

the

king

pin

The

king

pin

bushings

are

fitted

to

the

upper

and

lower

arm

portIOns

of

the

knuckle

spindle

and

seals

are

provided

at

the

portions

mentioned

to

keep

water

and

dirt

from

enteri

g

The

knuckle

arm

is

connected

to

the

lower

end

of

the

knuckle

spindle

to

transmit

ttLe

movement

of

the

steering

wheel

to

the

knuckle

spindle

The

wheel

hub

is

supported

by

two

taper

roller

bearings

on

the

knuckle

spindle

Tlie

brake

drum

and

wheel

are

secured

to

ihe

hub

by

the

hub

bolts

Front

Axle

Front

Suspension

FRONT

AXLE

REMOVAL

AND

INSTALLATION

Removal

I

Jack

up

and

support

vehicle

on

the

stands

at

the

frame

in

a

safe

manner

2

Remove

front

wheel

3

Re

ove

brake

hose

together

with

connector

from

wheel

cylinder

4

Remove

brake

drum

S

Remove

hub

cap

and

then

remove

cotter

pin

adjusting

cap

and

spindle

nut

from

knuckle

spindle

6

Remove

wheel

hub

outer

and

inner

wheel

bearings

bearing

washer

and

grease

seal

from

knuckle

spindle

7

Remove

brake

disc

assembly

from

the

flange

of

knuckle

spindle

8

Remove

knuckle

arm

from

knuckle

spindle

9

Remove

king

pin

lock

bolt

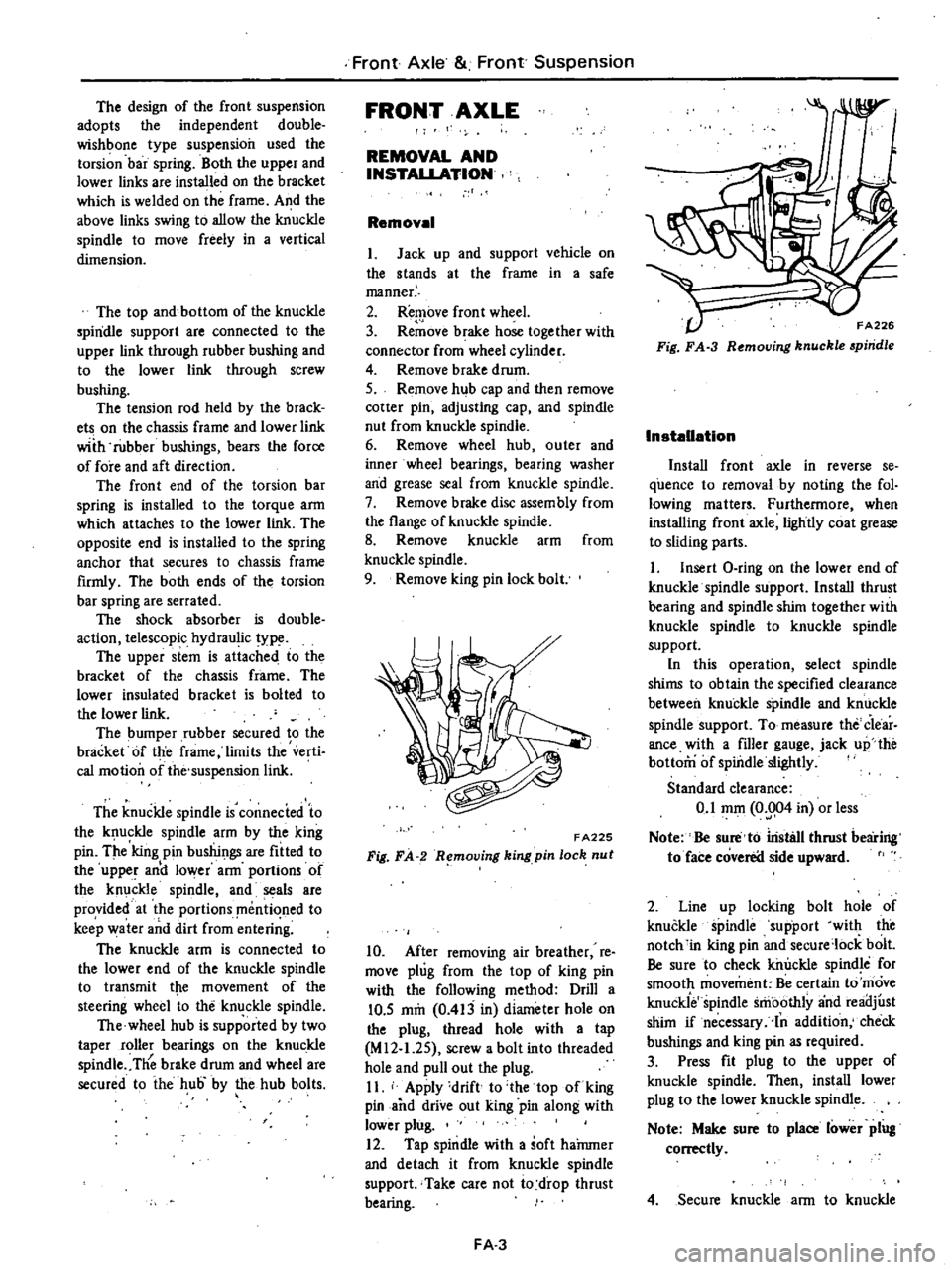

FA225

Fig

FA

R

mol1ing

king

pin

loch

nut

10

After

removing

air

breather

re

move

plug

from

the

top

of

king

pin

with

the

following

method

Drill

a

10

5

mm

0

413

in

diameter

hole

on

the

plug

thread

hole

with

a

tap

M

12

1

2S

screw

a

bolt

into

threaded

hole

and

pull

out

the

plug

II

Apply

drift

to

the

top

of

king

pin

and

drive

out

king

pin

along

with

lower

plug

12

Tap

spindle

with

a

soft

haJnmer

and

detach

it

from

knuckle

spindle

support

Take

care

not

io

drop

thrust

bearing

FA

3

FA226

Fig

FA

3

R

moving

knuckle

piridle

Installation

Install

front

axle

in

reverse

se

quence

to

removal

by

noting

the

fol

lowing

matters

Furthermore

when

installing

front

axle

lightly

coat

grease

to

sliding

parts

I

Insert

O

ring

on

the

lower

end

of

knuckle

spindle

support

Install

thrust

bearing

and

spindle

shim

together

with

knuckle

spindle

to

knuckle

spindle

support

In

this

operation

select

spindle

shims

to

obtain

the

specified

clearance

between

knuckle

spindle

and

knuckle

spindle

support

To

measure

the

Clear

ance

with

a

filler

gauge

jack

up

the

bottom

of

spindle

slightly

Standard

clearance

0

1

mOl

0

004

in

or

less

Note

Be

sure

to

iristsll

thrust

bearing

to

face

coverea

side

upward

2

Line

up

locking

bolt

hole

of

knuckle

spindle

support

with

the

notch

in

king

pin

and

secure

lock

bolt

Be

sure

to

check

killJckle

spindle

for

smooth

movement

Be

certain

to

move

knuckie

spindle

smoothly

and

reailjust

shim

if

necessary

In

addition

check

bushings

and

king

pin

as

required

3

Press

fit

plug

to

the

upper

of

knuckle

spindle

Then

install

lower

plug

to

the

lower

knuckle

spindle

Note

Make

sure

to

place

lower

plug

conectly

4

Secure

knuckle

arm

to

knuckle

Page 353 of 537

spindle

and

torque

bolt

to

10

3

to

12

1

kg

m

75

to

88

ft

lb

Bend

lock

plate

to

engaged

flats

on

boll

head

Note

When

disassembled

discard

used

lock

plate

5

Pack

grea

to

the

upP

r

and

lower

bushings

on

knuckle

spindle

until

grease

c

omes

out

from

gr

ease

seal

6

Fill

wheel

hub

and

cap

with

grease

up

to

the

described

level

See

Figure

F

A

4

FA141

Fig

FA

4

Gre

ing

wheel

hub

7

Pack

roller

and

cone

assembly

and

the

cavity

of

grease

seal

lip

with

grease

8

Coat

grease

to

the

thread

of

knuckle

spindle

bearing

washer

and

bearing

lock

nul

9

Secure

wheel

hub

bearings

bear

ing

washer

and

spindle

nut

on

knuckle

spindle

and

adju

t

bearing

preload

referring

to

the

paragraph

Wheel

bearing

adjustment

Note

Be

sure

to

obtain

correct

pre

load

on

wheel

bearings

for

the

pu

rpose

of

ving

their

long

life

taking

care

to

keep

wheel

be8rlngs

grease

seal

bearing

washer

and

spin

dle

nut

clean

when

installing

them

WHEEL

BEARING

D

TM

NT

Wrong

adjustment

of

wheel

bear

ing

causes

abnonnal

wear

and

score

on

the

bearings

and

knuckle

spindle

Front

Axle

Front

Suspension

To

attain

proper

preload

on

wheel

bearings

proceed

the

following

opera

tions

I

Torque

spindle

nut

to

3

0

to

3

S

kg

m

22

to

25

ft

lb

using

torque

wrench

FA227

Fig

FA

5

Tightening

apindle

nut

2

Rotate

wheel

hub

a

few

turns

clockwise

and

counterclockwise

to

seat

bearings

Then

retighten

spindle

nut

to

the

same

tightening

torque

Be

certain

to

rotate

hub

smoothly

3

Back

off

spindle

nut

in

range

from

40

to

70

degrees

Locate

adjust

ing

cap

on

spindle

nut

so

as

to

align

the

castellation

on

the

cap

with

the

cotter

pin

hole

in

the

spindle

4

Check

the

hub

rotation

If

hub

rotates

properly

measure

bearing

rota

tion

starting

torque

If

measured

torque

is

deviated

from

the

specified

value

r

place

beari

gs

r

re

dju

st

The

starting

torque

can

be

mea

sured

by

a

spring

balance

as

shown

in

Figure

F

A

6

Spring

balance

indication

at

hub

bolt

New

bearing

2

1

kg

4

Ib

o

ess

Used

bearing

1

0

kg

2

2

lb

or

less

Notes

a

When

measuring

the

starting

force

pull

the

spring

balance

toward

tan

gential

direction

against

normal

line

connected

between

hub

boll

and

spindle

center

b

Axial

play

is

permissible

to

exist

in

0

1

mm

0

004

in

or

less

FA

4

fA22S

Fig

FA

6

Mea

uring

bearing

rotation

atarting

torque

S

Install

a

new

cotter

pin

Bend

the

ends

of

coller

pin

around

the

castel

lated

flange

of

adjusting

cap

Then

install

hub

cap

DISASSEMBLY

AND

ASSEMBLY

Knuckle

spindle

I

Drive

spindle

bushing

and

grease

seal

out

of

knuckle

spindle

with

KiTlg

Pin

Bush

Drift

ST3S380000

Discard

bushing

and

grease

seal

when

disas

sembled

2

After

cleaning

king

pin

bores

thoroughly

install

bushing

carefully

by

using

the

above

special

tpol

Posi

tion

bushing

in

accordance

With

the

instructions

fIlled

in

Figure

F

A

7

and

FA

8

34

mm

1

34

in

Upper

side

in

lower

boss

I

I

1

II

I

Pla

ce

this

position

in

line

with

grease

nipple

hole

Upper

side

in

upper

boss

FA229

Fig

FA

7

King

pin

bu

hing

Page 357 of 537

SHOCK

ABSORBER

REMOVAL

AND

INSTAUATION

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Hold

the

upper

stem

of

shock

absorber

and

remove

outs

washer

and

rubber

bushing

4

Remove

bolt

from

the

lower

end

of

shock

absorber

FA232

Fig

FA

13

Shock

absorber

S

Retain

lower

rubber

bushing

in

position

install

the

lower

end

of

shock

absorber

to

the

bracket

of

lower

link

and

torque

the

bolt

to

3

1

to

4

1

kg

m

23

to

30

ft

lb

Note

Insert

the

bolt

from

the

front

side

of

vehicle

6

Install

the

upper

end

of

shock

absorber

to

body

bracket

and

tighten

lock

n

Jt

to

the

specifjcations

Tightening

torque

1

6

to

2

2

kg

m

121016

ft

lb

INSPECTION

I

Check

shock

absorber

for

visible

defects

and

oil

leaks

Place

shock

absorber

vertically

in

a

vise

and

hand

stroke

shock

absorber

as

outlined

be

low

Extend

and

compress

shock

ab

sorber

as

faI

as

possible

travelling

as

long

as

possible

If

smooth

hydraulic

resistance

is

not

present

in

bqth

Iirection

replace

absorber

2

Replace

rubber

bushing

if

crack

or

deterioration

is

detected

Front

Axle

Front

Suspension

Specifications

for

shock

absorber

Model

Item

Piston

stroke

mm

in

Damping

force

kg

lb

0

3

m

sec

0

98

ft

sec

j

Rebound

Compression

STABILIZER

REMOVAL

AND

INSTAUATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

secUring

nut

at

the

lower

link

side

of

stabilizer

4

Remove

bolt

securing

stabilizer

mounting

bracket

to

chassis

frame

Install

stabilizer

in

the

reverse

se

quence

to

removal

noting

the

follow

ing

instructions

S

Attach

stabilizer

mounting

brack

et

to

chassis

frame

tightening

bolt

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

torque

6

Install

stabilizer

lower

link

side

to

connecting

rod

and

tighten

nut

to

the

specifications

as

shown

in

Figure

FA

14

Then

torque

lock

nut

toJ

6

to

2

2

kg

m

12

to

16

ft

lb

F

A233

Fig

FA

14

Stabilizer

detail

INSPECTION

Check

stabilizer

for

deformation

FA

S

All

models

110

4

3

76

168

38

84

and

rubber

bushings

for

crack

wear

and

deterioration

Replace

if

ne

cessary

TENSION

POD

REMOVAL

AND

INSTALLATION

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Remove

nuts

CD

from

both

ends

of

tension

rod

4

Remove

bracket

bolt

@

from

the

front

end

of

tension

rod

and

remove

tension

rod

with

bracket

CD

@

f

A234

Fig

FA

15

Ten

ion

rod

Install

tension

rod

in

reverse

00

qunce

to

removal

noting

the

following

instructions

Page 358 of 537

s

Install

tension

rod

at

rear

end

tighten

nut

to

make

the

distance

of

rubber

bushing

to

be

33

4

mm

1

315

in

and

torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

6

Install

tension

rod

bracket

to

chassis

frame

bracket

and

torque

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

When

two

rubber

bushings

are

dif

ferent

in

size

arrange

adjusting

nut

Standard

dimension

is

11

0

mOl

0

433

in

as

shown

in

Figure

FA

16

Torque

lock

nut

to

1

6

to

2

2

kg

m

12

to

16

ft

lb

Il

0

11

0

0

433

t

lP

33

4

1

315

I

11

0

0

433

1

0

11

0

0

433

Adjusting

nut

Y

i

w

36

6

l

441

Unit

mm

in

FA235

Fig

FA

16

Tension

rod

detail

INSPECTION

I

Check

tension

rod

for

bend

and

the

thread

for

faulty

condition

Repair

or

replace

as

required

2

Check

bushing

rubber

for

wear

and

deterioration

Replace

if

neces

sary

TORSION

BAR

SPRING

REMOVAL

AND

INSTALLATION

Removal

1

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

3

Loosen

nuts

at

spring

anchor

bolt

Front

Axle

Front

Suspension

4

Remove

dust

cover

at

the

rear

end

of

torsion

bar

spring

and

detach

snap

ring

S

Withdraw

torsion

bar

spring

rear

ward

after

pulling

ou

t

anchor

arm

realWard

I

nstallalation

Install

torsion

bar

spring

in

the

reverse

sequence

of

removal

noting

the

following

instructions

I

Coat

grease

on

the

serrations

of

torsion

bar

spring

and

install

it

to

torque

arm

Note

Be

sure

to

install

right

and

left

torsion

bar

springs

correctly

They

can

be

identified

with

R

Right

and

L

Left

marked

on

the

end

surface

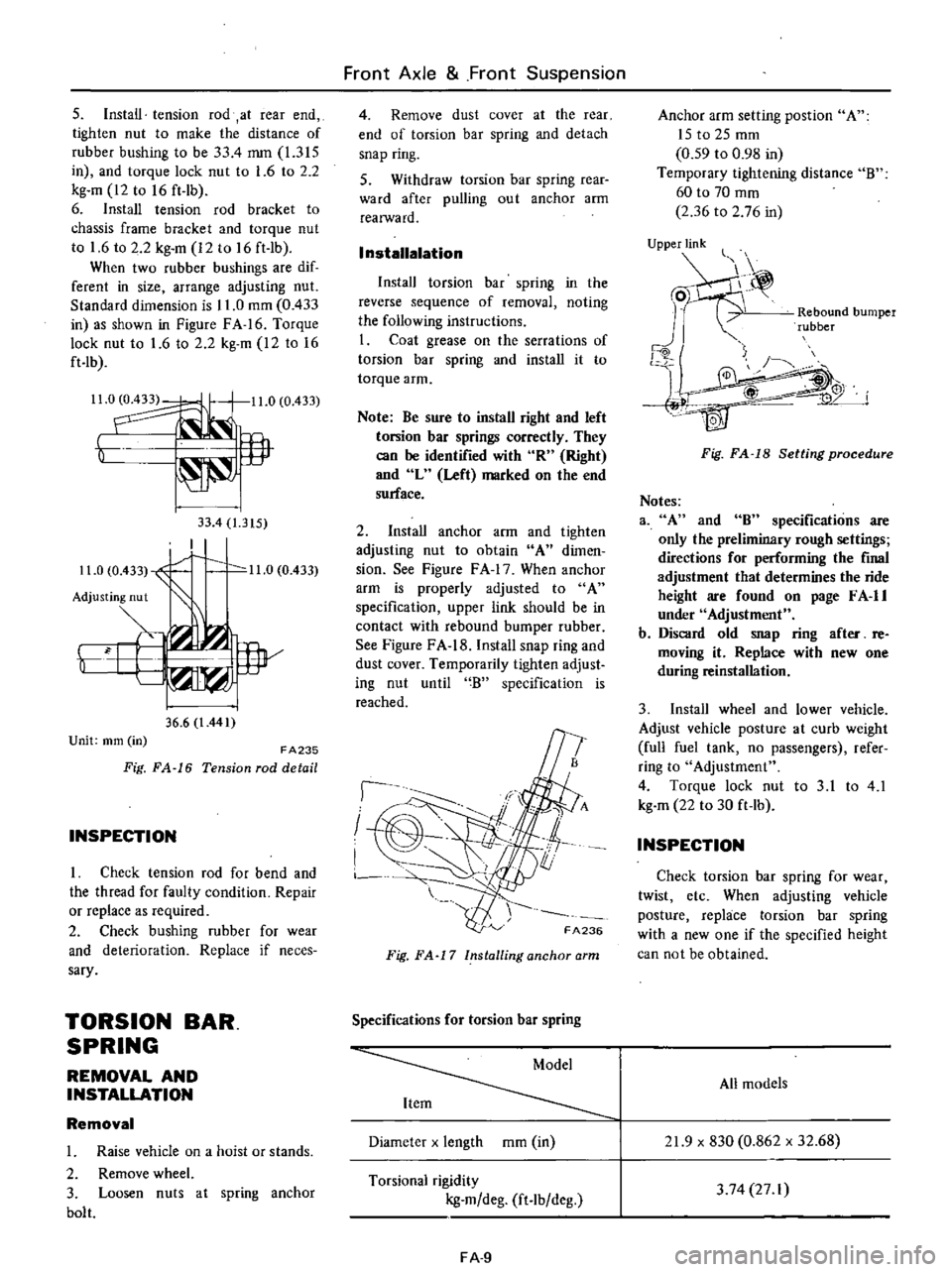

2

Install

anchor

arm

and

tighten

adjusting

nut

to

obtain

A

dimen

sion

See

Figure

F

A

17

When

anchor

arm

is

properly

adjusted

to

A

specification

upper

link

should

be

in

contact

with

rebound

bumper

rubber

See

Figure

FA

18

Install

snap

ring

and

dust

cover

Temporarily

tighten

adjust

ing

nut

until

B

specification

is

reached

I

I

I

FA236

Fig

FA

17

Installing

anchor

arm

Specifications

for

torsion

bar

spring

Diameter

x

length

mOl

in

Torsional

rigidity

kg

m

deg

ft

lb

deg

FA

9

Anchor

arm

setting

post

ion

A

ISt02Smm

0

59

to

0

98

in

Temporary

tightening

distance

B

60

to

70

mOl

2

36

to

2

76

in

UjPPje

Rebound

bumper

rubber

j

4W

Fig

FA

18

Setting

procedure

Notes

3

A

and

8

specifications

are

only

the

preliminary

rough

settings

directions

for

performing

the

final

adjustment

that

determines

the

ride

height

are

found

on

page

F

A

II

under

Adjustment

b

Discard

old

snap

ring

after

re

moving

it

Replace

with

new

one

during

reinstallation

3

Install

wheel

and

lower

vehicle

Adjust

vehicle

posture

at

curb

weight

full

fuel

tank

no

passengers

refer

ring

to

Adjustment

4

Torque

lock

nut

to

3

1

to

4

1

kg

m

22

to

30

ft

lb

INSPECTION

Check

torsion

bar

spring

for

wear

twist

etc

When

adjusting

vehicle

posture

replace

torsion

bar

spring

with

a

new

one

if

the

specified

height

can

not

be

obtained

All

models

21

9

x

830

0

862

x

32

68

3

74

27

I

Page 359 of 537

UPPER

AND

LOWER

LINKS

REMOVAL

AND

INSTALLATION

Removal

I

Raise

vehicle

on

a

hoist

or

stands

2

Remove

wheel

and

brake

drum

as

an

assembly

3

Remove

wheel

hub

Refer

to

see

tion

Front

Axle

4

Loosen

bolts

retaining

brake

disc

to

knuckle

spindle

and

remove

brake

disc

5

Remove

knuckle

arm

torsion

bar

spimgJ

stabilizer

shock

absorber

and

tension

rod

in

t

ili

order

referring

the

related

sections

6

Remove

upper

fulcrum

bolt

se

curing

knuckle

spindle

support

to

upper

link

assembly

and

disassemble

them

7

Remove

upper

link

bushings

from

knuckle

spindle

support

8

Remove

screw

bushings

from

both

ends

of

lower

link

fulcrum

pin

9

Loosen

nut

at

lower

portion

of

knuckle

spindle

support

from

inside

and

pull

out

cotter

pin

retaining

ful

crum

pin

10

Pull

out

fulcrum

pin

with

drift

and

remove

knuckle

spindle

support

with

knuckle

spindle

from

lower

link

Then

detach

dust

cover

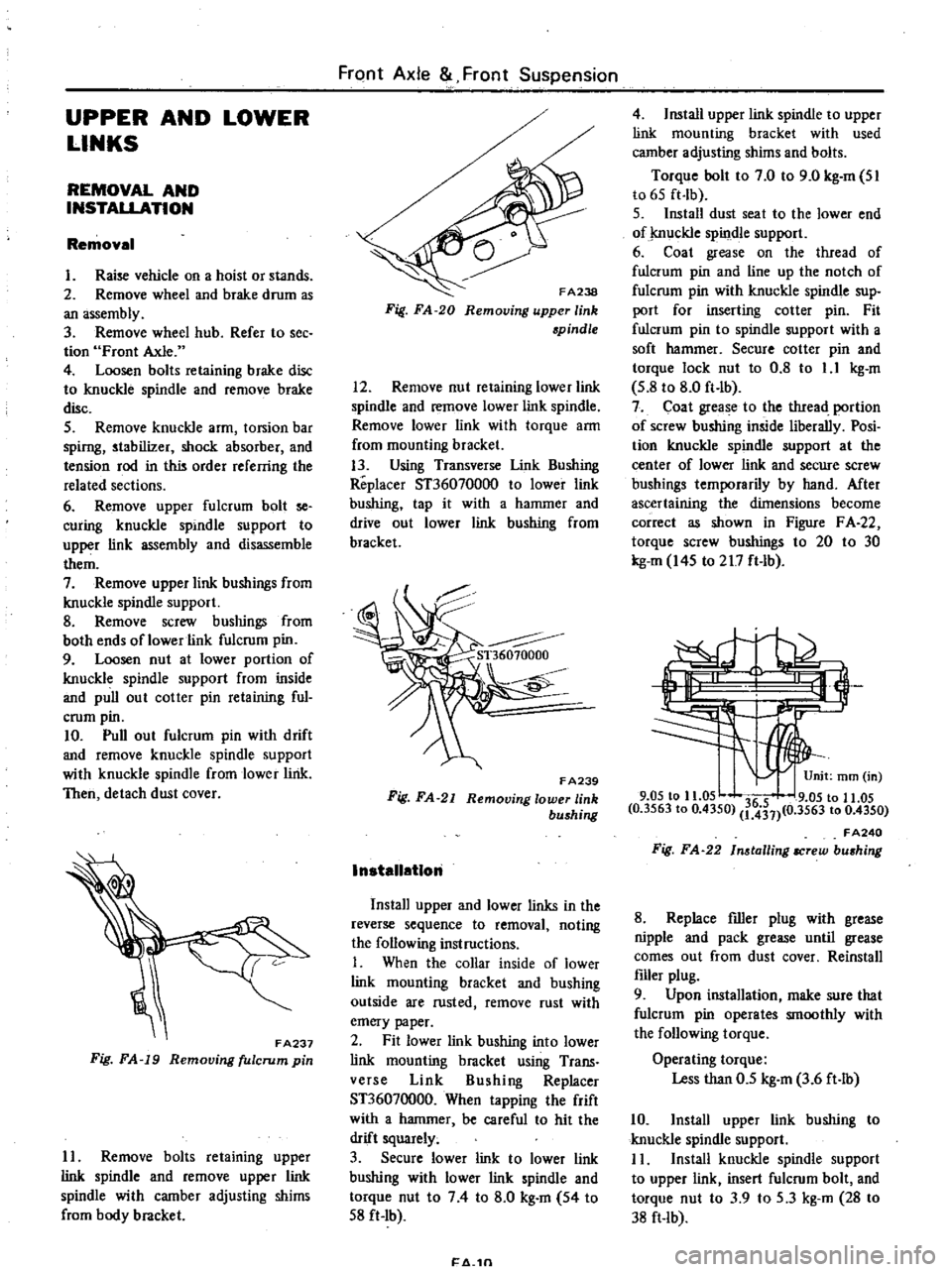

FA237

Fig

FA

19

Removing

fulcrum

pin

II

Remove

bolts

retaining

upper

link

spindle

and

remove

upper

link

spindle

with

camber

adjusting

shims

from

body

bracket

FrClnt

Axle

Front

Suspension

FA238

Fig

FA

20

Removing

upper

link

spindle

12

Remove

nut

retaining

lower

link

spindle

and

remove

lower

link

spindle

Remove

lower

link

with

torque

arm

from

mounting

bracket

13

Using

Transverse

Unk

Bushing

Replacer

ST36070000

to

lower

link

bushing

tap

it

with

a

hammer

and

drive

out

lower

link

bushing

from

bracket

F

A239

Fig

FA

21

Removing

lower

link

bushing

InstallatIon

Install

upper

and

lower

links

in

the

reverse

sequence

to

removal

noting

the

following

instructions

I

When

the

collar

inside

of

lower

link

mounting

bracket

and

bushing

outside

are

rusted

remove

rust

with

emery

paper

2

Fit

lower

link

bushing

into

lower

link

mounting

bracket

using

Trans

verse

Link

Bushing

Replacer

ST36070000

When

tapping

the

frift

with

a

hammer

be

careful

to

hit

the

drift

squarely

3

Secure

lower

link

to

lower

link

bushing

with

lower

link

spindle

and

torque

nut

to

74

to

8

0

kg

m

54

to

S8

ft

Ib

1

4

1n

4

Install

upper

link

spindle

to

upper

link

mounting

bracket

with

used

camber

adjusting

shims

and

bolts

Torque

bolt

to

7

0

to

9

0

kg

m

SI

to

6S

ft

lb

S

Install

dust

seat

to

the

lower

end

of

j

nuckle

spindle

support

6

Coat

grease

on

the

thread

of

fulcrum

pin

and

line

up

the

notch

of

fulcrum

pin

with

knuckle

spindle

sup

port

for

inserting

cotter

pin

Fit

fulcrum

pin

to

spindle

support

with

a

soft

hammer

Secure

cotter

pin

and

torque

lock

nut

to

0

8

to

1

1

kg

m

S

8

to

8

0

ft

lb

7

Coat

grease

to

the

tIuead

portion

of

screw

bushing

inside

liberally

Posi

tion

knuckle

spindle

support

at

the

center

of

lower

link

and

secure

screw

bushings

temporarily

by

hand

Mter

ascertaining

the

dimensions

become

correct

as

shown

in

Figure

F

A

22

torque

screw

bushings

to

20

to

30

kg

m

I4S

to

217

ft

lb

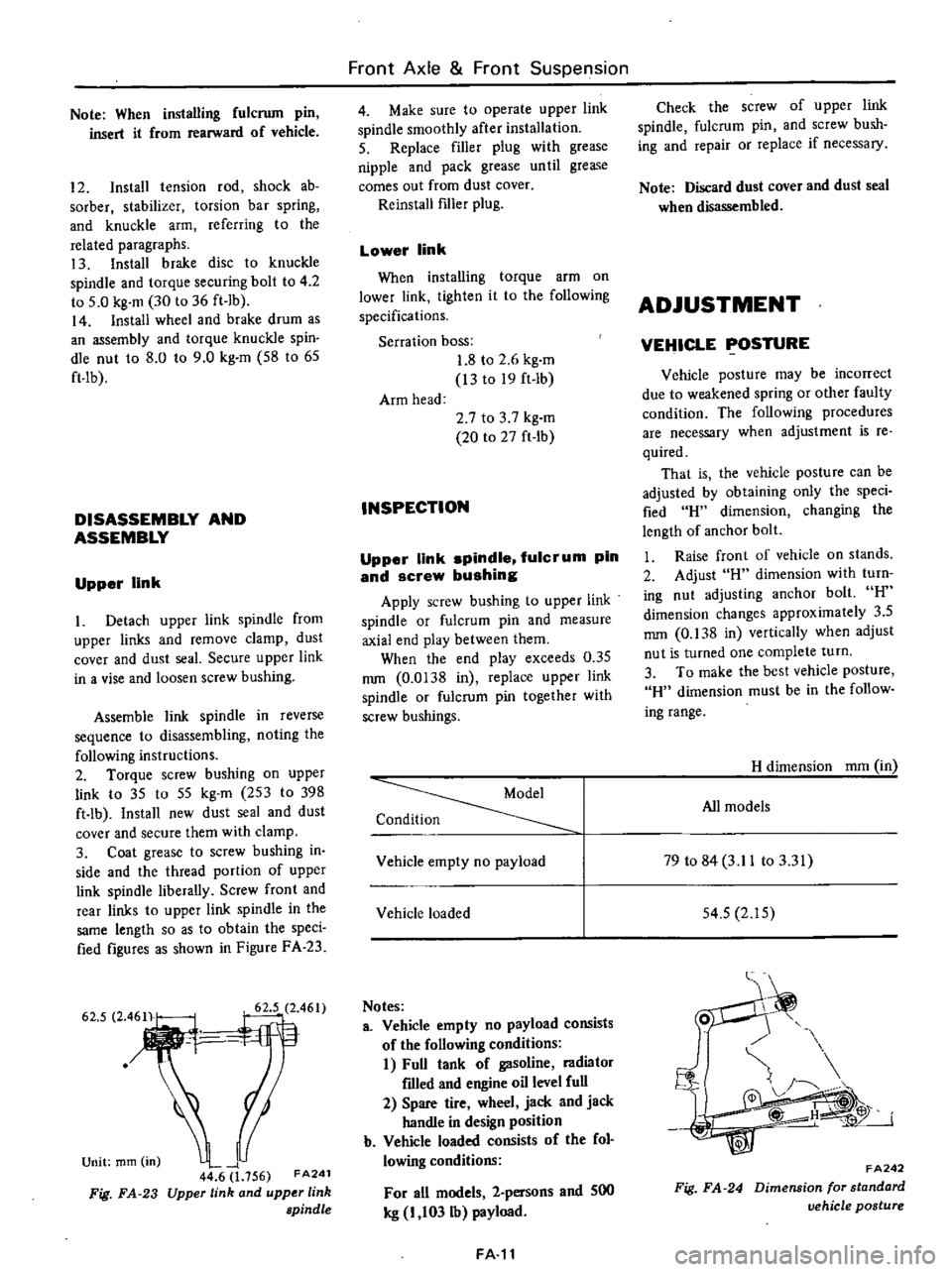

3

9

05

to

11

05

36

5

9

05

to

11

05

0

3563

to

0

4350

1

431

0

3563

to

0

4350

FA240

Fig

FA

22

In

tailing

IICrew

bu

hing

8

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

filler

plug

9

Upon

installation

make

sure

that

fulcrum

pin

operates

smoothly

with

the

following

torque

Operating

torque

Less

than

0

5

kg

m

3

6

ft

lb

10

Install

upper

link

bushing

to

knuckle

spindle

support

I

I

Install

knuckle

spindle

support

to

upper

link

insert

fulcrum

bolt

and

torque

nut

to

3

9

to

S

3

kg

m

28

to

38

ft

lb

Page 360 of 537

Note

When

installing

fulcrum

pin

insert

it

from

rearward

of

vehicle

12

Install

tension

rod

shock

ab

sorber

I

stabilizer

torsion

bar

spring

and

knuckle

arm

referring

to

the

related

paragraphs

13

Install

brake

disc

to

knuckle

spindle

and

torque

securing

bolt

to

4

2

to

5

0

kg

m

30

to

36

ft

Ib

14

Install

wheel

and

brake

drum

as

an

assembly

and

torque

knuckle

spin

dle

nut

to

8

0

to

9

0

kg

m

58

to

65

ft

Ib

DISASSEMBLY

AND

ASSEMBLY

Upper

link

I

Detach

upper

link

spindle

from

upper

links

and

remove

clamp

dust

cover

and

dust

seal

Secure

upper

link

in

a

vise

and

loosen

screw

bushing

Assemble

link

spindle

in

reverse

sequence

to

disassembling

noting

the

following

instructions

2

Torque

screw

bushing

on

upper

link

to

3S

to

55

kg

m

253

to

398

ft

Ib

Install

new

dust

seal

and

dust

cover

and

secure

them

with

clamp

3

Coat

grease

to

screw

bushing

in

side

and

the

thread

portion

of

upper

link

spindle

liberally

Screw

front

and

rear

links

to

upper

link

spindle

in

the

same

length

so

as

to

obtain

the

speci

fied

figures

as

shown

in

Figure

FA

23

Unit

mm

in

I

44

6

1

156

FA2

Upper

link

and

upper

link

spindle

Fig

FA

23

Front

Axle

Front

Suspension

4

Make

sure

to

operate

upper

link

spindle

smoothly

after

installation

5

Replace

filler

plug

with

grease

nipple

and

pack

grease

until

grease

comes

out

from

dust

cover

Reinstall

f1ller

plug

Lower

link

When

installing

torque

arm

on

lower

link

tighten

it

to

the

following

specifications

Serration

boss

1

8

to

2

6

kg

m

13

to

19

ft

Ib

Arm

head

2

7

to

3

7

kg

m

20

to

27

ft

tb

INSPECTION

Upper

link

spindle

fulcrum

pin

and

screw

bushing

Apply

screw

bushing

to

upper

link

spindle

or

fulcrum

pin

and

measure

axial

end

play

between

them

When

the

end

play

exceeds

0

35

mm

0

0138

in

replace

upper

link

spindle

or

fulcrum

pin

together

with

screw

bushings

Condition

Vehicle

empty

no

payload

Vehicle

loaded

Notes

a

Vehicle

empty

no

payload

consists

of

the

following

conditions

I

Full

tank

of

gasoline

radiator

f1lled

and

engine

oil

level

full

2

Spare

tire

wheel

jack

and

jack

handle

in

design

position

b

Vehicle

loaded

consists

of

the

fol

lowing

conditions

For

all

models

2

persons

and

SIlO

leg

I

103lb

payload

FA

Check

the

screw

of

upper

link

spindle

fulcrum

pin

and

screw

bush

ing

and

repair

or

replace

if

necessary

Note

Discard

dust

cover

and

dust

seal

when

disassembled

ADJUSTMENT

VEHICLE

POSTURE

Vehicle

posture

may

be

incorrect

due

to

weakened

spring

or

other

faulty

condition

The

following

procedures

are

necessary

when

adjustment

is

Ie

quired

That

is

the

vehicle

posture

can

be

adjusted

by

obtaining

only

the

speci

fied

H

dimension

changing

the

length

of

anchor

bolt

I

Raise

front

of

vehicle

on

stands

2

Adjust

H

dimension

with

turn

ing

nut

adjusting

anchor

bolt

H

dimension

changes

approximately

3

5

mm

0

J38

in

vertically

when

adjust

nut

is

turned

one

complete

turn

3

To

make

the

best

vehicle

posture

H

dimension

must

be

in

the

follow

ing

range

H

dimension

mOl

in

All

models

79

to

84

3

11

to

3

31

54

5

2

15

o

i

Fig

FA

24

FA242

Dimension

for

standard

vehicle

postl4re

Page 362 of 537

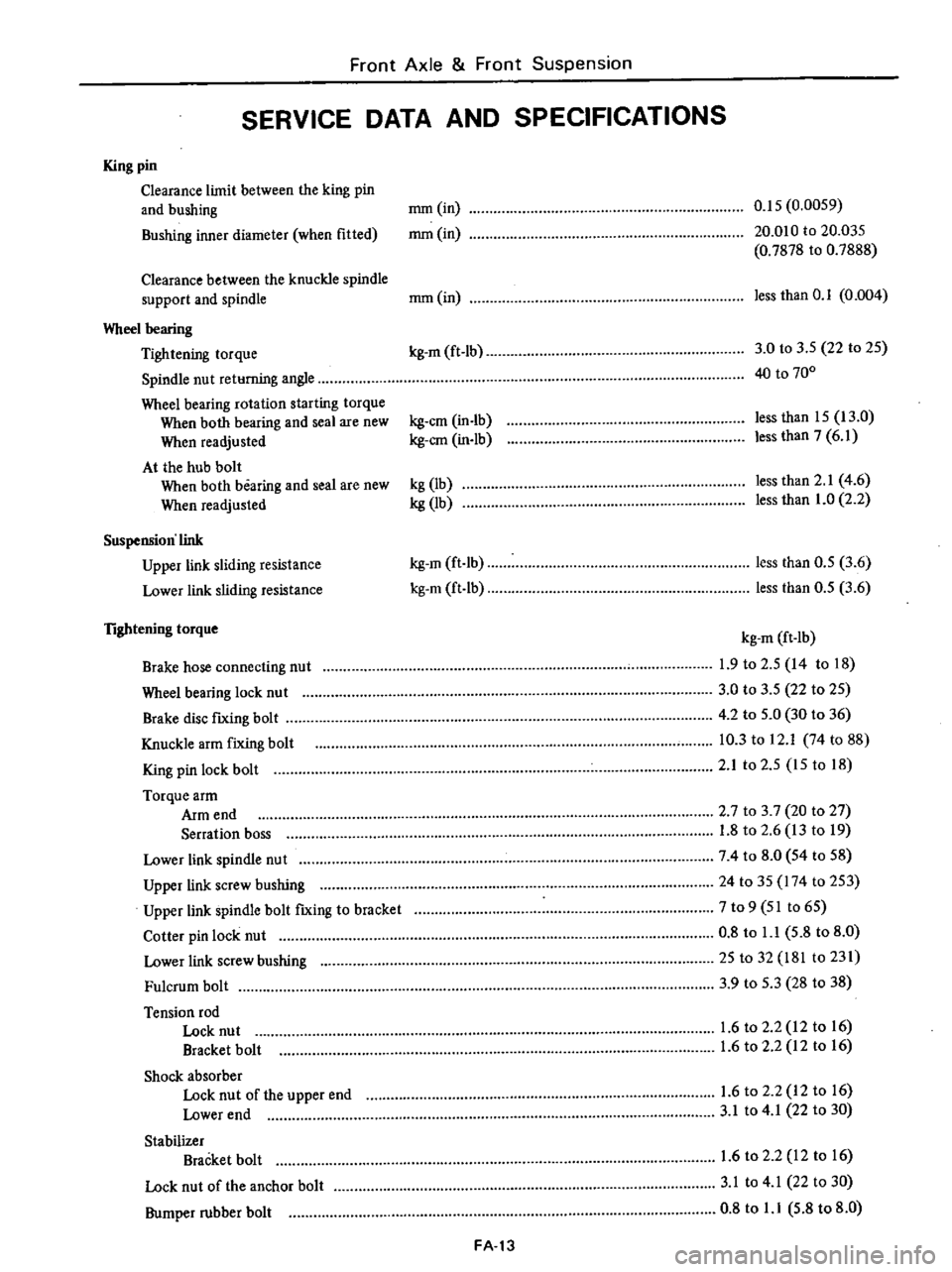

Front

Axle

Front

Suspension

SERVICE

DATA

AND

SPECIFICATIONS

King

pin

Clearance

limit

between

the

king

pin

and

bushing

mm

in

0

15

0

0059

Bushing

inner

diameter

when

fitted

mm

in

20

010

to

20

035

0

7878

to

0

7888

Clearance

between

the

knuckle

spindle

support

and

spindle

mm

in

less

than

0

1

0

004

Wheel

bearing

Tightening

torque

kg

m

ft

Ib

3

0

to

3

S

22

to

2S

Spindle

nut

returning

angle

40

to

700

Wheel

bearing

rotation

starting

torque

When

both

bearing

and

seal

are

new

kg

em

in

Ib

less

than

IS

13

0

When

readjusted

kg

em

in

lb

less

than

7

6

1

At

the

hub

bolt

When

both

bearing

and

seal

are

new

kg

lb

less

than

2

1

4

6

When

readjusted

kg

lb

less

than

1

0

2

2

Suspension

link

Upper

link

sliding

resistance

kg

m

ft

Ib

less

than

O

S

3

6

Lower

link

sliding

resistance

kg

m

ft

lb

less

than

O

S

3

6

lightening

torque

kg

m

ft

Ib

Brake

hose

connecting

nut

1

9

to

2

S

14

to

18

Wheel

bearing

lock

nu

t

3

0

to

3

5

22

to

2S

Brake

disc

fIXing

bolt

4

2

to

S

O

30

to

36

Knuckle

arm

fixing

bolt

10

3

to

12

1

74

to

88

King

pin

lock

bolt

2

1

to

2

S

IS

to

18

Torque

arm

Arm

end

2

7

to

3

7

20

to

27

Serration

boss

1

8

to

2

6

13

to

19

Lower

link

spindle

nut

74

to

8

0

S4

to

58

Upper

link

screw

bushing

24

to

35

174

to

2S3

Upper

link

spindle

bolt

fIXing

to

bracket

7

to

9

51

to

6S

Cotter

pin

lock

nut

0

8

to

l

l

5

8

to

8

0

Lower

link

screw

bushing

25

to

32

181

to

231

Fulcrum

bolt

3

9

to

S

3

28

to

38

Tension

rod

Lock

nut

1

6

to

2

2

12

to

16

Bracket

bolt

1

6

to

2

2

12

to

16

Shock

absorber

Lock

nut

of

the

upper

end

1

6

to

2

2

12

to

16

Lower

end

3

1

to

4

1

22

to

30

Stabilizer

Bracket

bolt

1

6

to

2

2

12

to

16

Lock

nut

of

the

anchor

bolt

3

1

to

4

1

22

to

30

Bumper

rubber

bolt

0

8

to

l

l

5

8

to

8

0

FA

13

Page 368 of 537

Rear

Axle

Rear

Suspension

REAR

AXLE

AND

REAR

SUSPENSION

DESCRIPTION

REMOVAL

AND

INSTALLATION

Rear

axle

assembly

Rear

axle

shaft

and

wheel

bearing

Rear

axle

case

Rear

spring

1

1

1

Air

breather

2

Thrust

block

3

Nut

T

3

1

to

4

1

kg

m

22

to

30

ft

lb

4

Shock

absorber

mounting

rubber

bush

5

Rear

spring

clip

V

bolt

6

Rear

axle

oil

seal

spacer

7

Rear

axle

shaft

oil

seal

Supply

wheel

bearing

grease

to

oil

seal

lip

when

assembly

8

Rear

axle

bearing

lock

nut

T

15

to

20

kg

m

10810

145

ft

b

9

Rear

axle

bearing

lock

washer

10

Plain

washer

11

Rear

axle

bearing

cage

12

Road

wheel

bolt

13

Road

wheel

nut

T

8t09kg

m

58

to

65

fl

Ib

CONTENTS

RA

3

RA

3

RA

3

RA

4

RA

5

RA

5

Shock

absorber

tNSPECTION

Rear

axle

shaft

and

wheel

bearing

Rear

axle

case

Rear

spring

Shock

absorber

RA

6

RA

fJ

RA

6

RA6

RA

fJ

RA

fJ

4

I

J

i

I

L

J

@

14

Wheel

bearing

15

Rear

axle

bearing

grease

seat

Supply

wheel

bearing

grease

to

oil

seal

lip

when

assembly

16

Rear

axle

bearing

spacer

17

Rear

axle

shaft

18

Grease

catcher

19

Bearing

cage

bolt

20

Rear

axle

case

end

shim

21

Nut

T

5

4

to

6

4

kg

m

391046

ft

lb

22

Rear

spring

pad

23

Rear

spring

24

Nut

T

7

3

to

9

9

kg

m

53

to

72

ft4b

25

Nut

T

1

610

2

2kg

m

12

to

16

fHb

26

Shock

absorber

rubber

bush

27

Shock

absorber

Fig

RA

I

RA

2

o

RA132

28

Rear

axle

case

29

Filler

ptug

T

6toIOkg

m

43

to

72

ft4b

Oil

capacity

about

1

0

liter

1

US

qt

7

8

Imp

qt

30

Drain

plug

T

6to

10kg

m

43

to

72

fHb

31

Nut

T

11

5

to

13

0

kg

m

83

to

94

fHb

32

Rear

spring

rear

bush

33

Rear

spring

34

Rear

spring

shackle

35

Nut

T

1

1

5

to

13

0

kg

m

83

to

94

fHb

36

Rear

spring

37

Rear

spring

front

bush

38

Rear

spring

front

pin

T

Tightening

torque

Crou

uctional

view

of

rear

a

xl

and

uapension