relay DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 479 of 537

Body

Electrical

System

WINDSHIELD

WIPER

AND

WASHER

Condition

Windshield

wiper

motor

does

not

operate

Wiper

operating

speed

is

too

slow

Wiper

speed

cannot

be

changed

correctly

Wiper

motor

continues

to

run

after

switch

is

turned

off

or

wiper

blades

do

not

return

to

correct

position

Probable

cause

Burnt

fuse

Damaged

motor

Check

wiper

motor

as

outlined

in

Inspec

tion

Loose

connection

Faulty

wiper

and

washer

switch

Test

continuity

through

switch

as

outlined

in

Inspection

Open

power

circuit

or

ground

circuit

Damaged

motor

Loose

or

poor

connection

Seized

or

rusted

wiper

linkage

Humming

occurs

on

motor

in

wiper

blade

operating

cycle

Wiper

blades

stick

on

windshield

glass

Raise

arm

and

operate

wiper

without

load

Faulty

wiper

switch

Damaged

motor

Faulty

auto

stop

operation

Poor

connection

Faulty

switch

BE

34

Corrective

action

Correct

cause

and

replace

fuse

Replace

wiper

motor

Repair

Replace

Repair

Replace

motor

Repair

Lubricate

or

replace

Clean

windshield

glass

and

or

replace

wiper

blade

Replace

Replace

Remove

auto

stop

device

cover

and

check

relay

contacts

Clean

dirty

contacts

or

repair

relay

plate

bending

if

necessary

Repair

Replace

Page 481 of 537

CD

m

Cl

@

D

@

I

j

1

To

instrument

harness

IS

To

battery

30

To

check

connector

2

To

full

transistor

amplifier

16

To

fusible

link

3t

To

headlamp

L

U

type

2

California

models

only

17

To

engine

harness

No

2

32

To

sido

marker

lamp

L

B

3

To

hood

switch

18

To

alternator

33

To

front

combination

lamp

L

H

4

To

engine

compartment

lamp

1

9

To

front

combination

lamp

R

n

34

To

horn

Low

ll

l

S

To

washer

motor

20

To

headlamp

R

H

type

2

3S

To

horn

High

l

l

0

6

To

auto

choke

heater

relay

1

To

side

marker

lamp

R

n

36

To

B

C

D

D

cut

olenoid

California

models

7

To

detector

dri

e

counter

22

To

headlamp

R

B

type

1

only

Non

Califunia

model

except

for

Canada

23

To

ground

37

To

block

tcrminal

distributor

California

8

To

ignition

relay

California

models

only

i4

To

thermal

transmitter

models

only

9

To

floor

sensor

relay

California

modeb

only

is

To

distributor

Non

California

models

only

38

To

ignition

coil

Non

California

models

only

n

10

To

inhibitor

relay

A

T

only

26

To

8

C

D

D

cut

solenoid

Non

California

39

To

condenser

t

II

To

head

lamp

relay

models

only

40

To

ignition

coil

and

resistor

@

12

To

horn

relay

27

To

fuel

cut

solenoid

California

models

only

OJ

v

m

13

To

voltage

regulator

28

To

auto

choke

heater

g

e

14

To

cooler

cable

29

To

headlamp

L

R

type

1

OJ

to

o

Q

m

r0

C

1

i

Ql

CIl

Il

l

3

Page 488 of 537

Body

Electrical

System

EMISSION

WARNING

SYSTEM

California

models

CONTENTS

FLOOR

TEMPERATURE

WARNING

SYSTEM

California

models

DESCRIPTION

FLOOR

TEMPERATURE

WARNING

SYSTEM

California

models

DESCRIPTION

The

floor

temperature

warning

system

consists

of

a

floor

temperature

sensing

switch

installed

on

the

vehicle

floor

a

floor

temperature

relay

a

floor

temperature

warning

lamp

and

harnesses

When

the

floor

temperature

rises

to

an

abnormal

level

the

warning

lamp

will

come

on

to

call

the

attention

of

the

driver

i

f

FUSIBLE

LINK

P

BATTERY

IGNITION

SWITCH

BE

43

8E

43

WARNING

LAMP

TROUBLE

SHOOTING

GUIDE

BE

43

BE

44

The

warning

lamp

also

comes

on

during

operation

of

the

starter

motor

permitting

inspection

of

the

lamp

s

condition

The

lamp

goes

out

after

the

engine

starts

Refer

to

Section

EC

for

details

WARNING

LAMP

Bulb

replacement

I

Remove

cluster

lid

2

Twist

warni

ng

lamp

socket

Socket

with

bulb

can

then

be

taken

out

3

Pick

up

bulb

from

socket

IGNITION

RELAY

I

I

4

Installation

is

in

the

reverse

se

quence

of

removaL

Bulb

wattage

Floor

temperature

warning

lamp

17W

Lamp

body

replacement

I

Remove

cluster

lld

2

Disconnect

lead

wire

at

connee

tor

3

Remove

two

screws

retaining

lamp

body

4

Installation

is

in

the

reverse

se

quence

of

removal

FLOOR

I

l

I

SENSOR

RELAY

WARNING

I

LAMP

FLOOR

SENSOR

ON

FLOOR

TEMPERATURE

LOW

OFF

FLOOR

TEMPERATURE

HIGH

7

BE697B

Fig

BE

64

Circuit

diagram

of

floor

temperature

warning

system

BE

43

Page 489 of 537

Body

Electrical

System

TROUBLE

SHOOTING

GUIDE

Condition

Warning

lamp

does

not

light

in

START

posi

tion

of

ignition

switch

Probable

cause

Burnt

or

loose

bulb

Faulty

f1o

r

temperature

relay

Loose

connection

or

open

circuit

BE

44

Corrective

action

Replace

bulb

or

correct

bulb

socket

Conduct

continuity

test

and

repair

or

reo

place

Refer

to

Section

EC

Check

wiring

and

or

repair

if

necessary

Page 491 of 537

OUTLINE

OF

AIR

CONDITIONER

REFRIGERATION

SYSTEM

CONDENSER

COMPRESSOR

RECEIVER

DRYER

COOLING

UNIT

ELECTRICAL

CIRCUIT

OUTLINE

OF

AIR

CONDITIONER

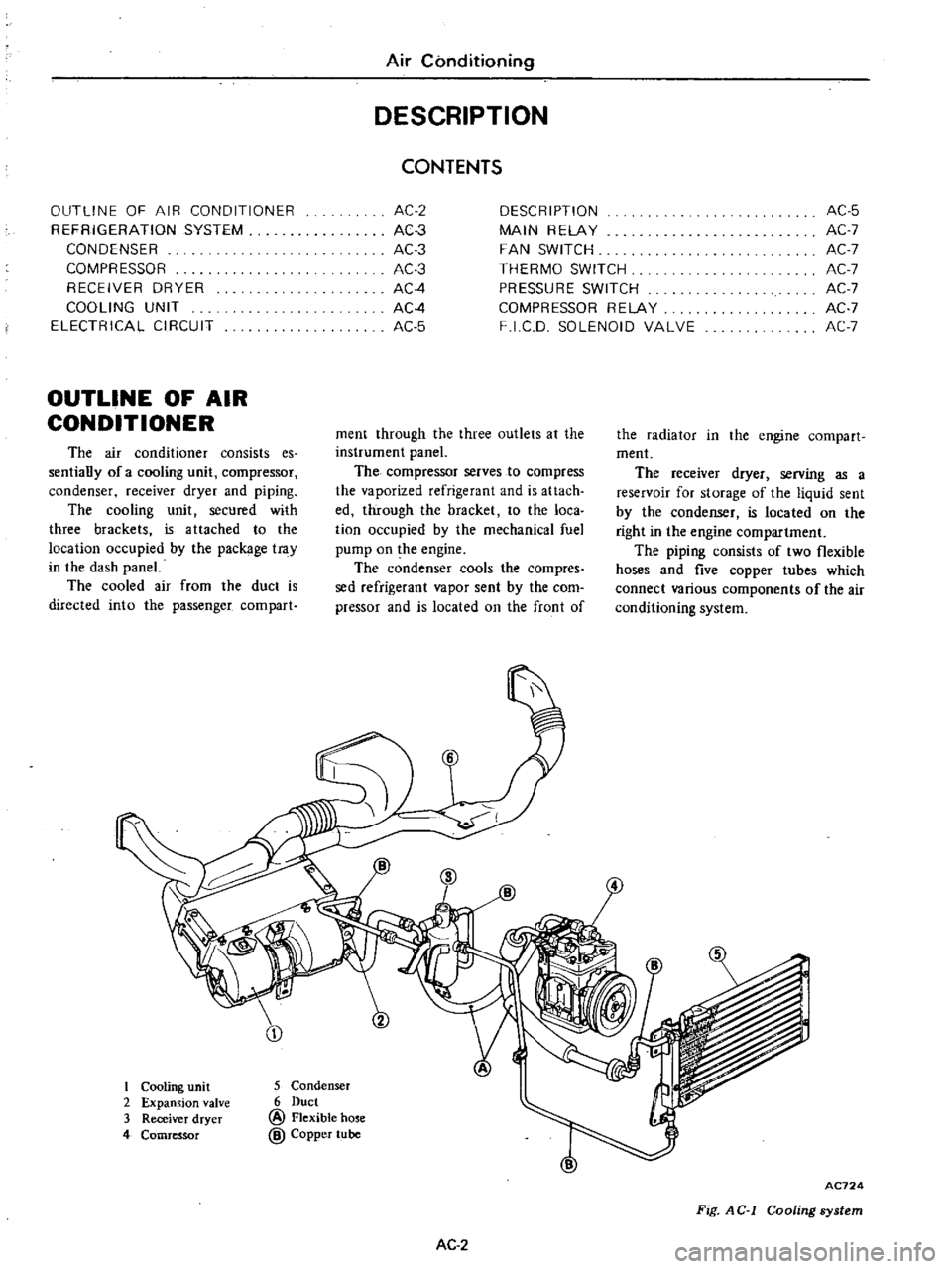

The

air

conditioner

consists

es

sentially

of

a

cooling

unit

compressor

condenser

receiver

dryer

and

piping

The

cooling

unit

secured

with

three

brackets

is

a

ttached

to

the

location

occupied

by

the

package

tray

in

the

dash

panel

The

cooled

air

from

the

duct

is

directed

into

the

passenger

compart

Air

Conditioning

DESCRIPTION

CONTENTS

AC

2

AC3

AC

3

AC3

AC4

AC4

AC

5

DESCRIPTION

MAIN

RELAY

FAN

SWITCH

THERMO

SWITCH

PRESSURE

SWITCH

COMPRESSOR

RELAY

F

I

C

D

SOLENOID

VALVE

AC

5

AC

7

AC

7

AC

7

AC

7

AC

7

AC

7

ment

through

the

three

outlets

at

the

instrument

panel

The

compressor

serves

to

compress

the

vaporized

refrigerant

and

is

attach

ed

through

the

bracket

to

the

loca

tion

occupied

by

the

mechanical

fuel

pump

on

the

engine

The

condenser

cools

the

compres

sed

refrigerant

vapor

sent

by

the

com

pressor

and

is

located

on

the

front

of

the

radiator

in

the

engine

compart

ment

The

receiver

dryer

serving

as

a

reservoir

for

storage

of

the

liquid

sent

by

the

condenser

is

located

on

the

right

in

the

engine

compartment

The

piping

consists

of

two

flexible

hoses

and

five

copper

tubes

which

connect

various

components

of

the

air

conditioning

system

I

Cooling

unit

2

Expansion

valve

3

Receiver

dryer

4

Comressor

5

Condenser

6

Duct

@

Flexible

hose

@

Copper

tube

AC

2

AC724

Fig

AC

1

Cooling

system

Page 493 of 537

Air

Conditioning

RECEIVER

DRYER

The

receiver

dryer

serves

the

pur

pose

of

storing

the

liquid

refrigerant

The

amount

of

the

liquid

refrigerant

flowing

through

the

system

varies

with

the

operating

condition

of

the

air

conditioner

To

be

accurate

the

receiver

dryer

stores

excess

amount

of

refrigerant

when

the

heat

load

is

lowered

It

also

releases

stored

refriger

ant

when

additional

cooling

is

needed

thus

maintaining

the

optimum

flow

of

refrigerant

within

the

system

The

receiver

dryer

includes

a

strainer

and

desiccant

They

have

the

job

of

removing

moisture

and

foreign

particles

as

the

refrigerant

circulates

within

the

system

The

pressure

switch

is

installed

beside

sight

glass

of

receiver

dryer

The

purpose

of

the

switch

is

to

stop

the

compressor

operation

in

the

event

an

excessive

system

pressure

builds

up

on

the

high

pressure

lines

AC728

Fig

A

C

4

Compressor

To

e

ran

ion

alve

From

condenser

5

c

FJi

i

1

Z

i

3

c

o

I

COOLING

UNIT

o

L

o

W

7

R

o

3

J

J

r

t

AC230

I

Prc

surc

switch

2

Sight

glass

3

Strainer

4

De

kcant

Fig

AC

5

Receiver

dryer

The

liquid

refrigerant

evaporates

in

the

evaporator

with

the

aid

of

the

expansion

valve

Consequently

the

air

drawn

by

the

blower

motor

is

cooled

in

passing

through

the

evaporator

The

expansion

valve

restricts

the

liquid

refrigerant

as

it

passes

through

it

and

delivers

sprayed

refrigerant

to

the

evaporator

for

facilitating

refrigerant

evaporation

The

cooling

unit

includes

an

evapo

rator

and

an

expansion

valve

From

the

electrical

point

of

view

the

cooling

unit

consists

of

a

blower

motor

a

resistor

for

fan

speed

control

and

some

switches

and

relays

AC

4

Page 494 of 537

The

refrigerant

within

the

thermo

bulb

changes

in

pressure

through

the

super

heat

condition

of

vaporized

re

frigerant

gas

which

comes

out

of

the

evaporator

causing

the

deflection

of

the

diaphragm

The

lift

of

the

ball

valve

attached

to

the

diaphragm

is

changed

by

the

deflection

of

the

dia

phragm

thus

controlling

the

amount

of

refrigerant

passing

the

orifice

ELECTRICAL

CIRCUIT

DESCRIPTION

The

electrical

circuit

of

the

air

conditioner

consists

of

four

switches

two

relays

a

solenoid

valve

a

fan

motor

and

a

compressor

magnetic

clutch

Air

Conditioning

Diaphragm

Orifice

Valve

ball

AC729

4

Sensing

bulb

Fig

A

C

6

Expansion

value

The

following

wiring

diagram

pro

vides

a

complete

description

of

the

whole

circuit

When

the

ignition

switch

and

the

fan

switch

are

ON

the

main

relay

is

activated

causing

battery

power

to

flow

through

the

fan

motor

and

the

magnetic

clutch

The

magnetic

clutch

is

activated

by

the

thermo

switch

AC

5

000

l

1

Motor

2

Fan

3

Lower

case

4

Cooler

duct

5

Evaporator

6

Expansion

valve

7

Upper

case

8

Resistor

9

Main

relay

10

Thermo

switch

II

Cable

clamp

12

Cable

13

Harness

AC725

Fig

AC

7

Cooling

unit

pressure

switch

and

compressor

relay

The

blower

motor

fan

speed

is

con

trolled

by

the

fan

switch

and

resistor

The

solenoid

valve

is

also

activated

This

in

turn

causes

the

fast

idle

control

device

F

l

C

D

to

increase

engine

speed

when

the

vehicle

is

at

rest

with

the

engine

ON

Page 495 of 537

1

I

6

I

BA

RY

i

Air

Conditioning

BW

c

J

BW

n

B

m

00

L

ELECTRIC

FUEL

PUMP

oB

tl

b@

L

t

FROM

LIGHT

SWITCH

c

J

LW

2

L

rRL

fZP

W

I

FUSE

15A

J

D

CJ

B

1

COMPRESSOR

RELAY

B

GL

I

lL

GL1J

ILLUMINATION

CONTROL

RHEOSTAT

3

ILLUMINATION

LAMP

I

I

MAIN

RELAY

FAN

SWITCH

I

r

1

UE

H

I

I

THERMO

SWITCH

COLOR

CODE

@

IC

PRESSU

1

rlTCH

D

D

G

c

J

oc

I

m

f

F

I

C

D

SOLENOID

COMPRESSOR

FUSE

LR

I

BW

O

W

ov

J

I

IG

0

0

OVJ

AC

6

B

BW

L

LW

LR

W

G

GL

RL

Black

Black

with

white

stripe

Blue

Blue

with

white

stripe

Blue

with

red

stripe

White

Green

Green

with

blue

stripe

Red

with

blue

stripe

IG

BW

t

1

n

L

IGNITION

SWITCH

AC727

Fig

A

C

B

Wiring

diagram

of

air

conditioner

system

Page 496 of 537

MAIN

RELAY

The

main

relay

is

located

on

the

cooling

unit

When

the

ignition

switch

and

fan

switch

are

both

turned

on

the

COll

@

FAN

SWITCH

The

fan

switch

serving

as

a

control

unit

is

installed

on

the

center

console

This

switch

controls

the

blower

motor

speed

through

the

resistor

It

is

also

used

as

a

main

relay

switch

Fig

AC

I0

Fan

switch

THERMO

SWITCH

The

thermo

switch

is

located

on

the

upper

side

of

the

cooling

unit

and

is

controlled

by

the

cable

and

the

con

trollever

attached

to

the

console

box

It

is

so

designed

that

when

the

air

passing

through

the

evaporator

core

is

cooled

down

to

the

predetermined

Air

Conditioning

tacts

in

the

relay

are

closed

Then

electrical

power

from

the

battery

is

supplied

to

the

blower

motor

and

the

electrical

clutch

for

the

compressor

@

Dc

IDe

ID

1

1

l@

@

e

L

J

AC465

Fig

A

C

9

Main

relay

temperature

set

by

the

control

lever

it

automatically

turns

off

When

the

switch

is

turned

off

the

magnetic

clutch

is

turned

off

stopping

the

flow

of

refrigerant

inside

the

cooling

system

and

increasing

the

cooling

system

tem

perature

When

the

air

rises

to

the

pre

determined

temperature

the

thermo

switch

automatically

turns

on

In

this

way

the

temperature

of

the

air

dis

charged

from

the

cooling

unit

is

auto

matically

controlled

as

desired

PRESSURE

SWITCH

The

pressure

switch

is

turned

off

when

refrigerant

pressure

in

the

cooling

system

rises

to

an

abnormally

high

level

28

kg

cm2

398

psi

This

in

turn

turns

off

the

compressor

magnetic

clutch

actuating

the

com

pressor

relay

and

gradually

decreasing

pressure

in

the

cooling

system

When

the

pressure

drops

to

or

below

24

kg

cm2

341

psi

the

pressure

switch

again

turns

on

Thus

cooling

system

refrigerant

pressure

is

automatically

maintained

at

the

proper

value

a

t

all

times

AC

7

COMPRESSOR

RERAY

The

compressor

relay

is

attached

to

the

receiver

dryer

bracket

on

the

right

side

of

the

engine

compartment

This

relay

is

actuated

by

the

fan

switch

thermo

switch

and

pressure

switch

to

turn

on

and

off

the

compressor

magnetic

clutch

cv

1

2

AC731

Fig

A

C

11

Pressure

switch

and

compressor

relay

F

I

C

D

SOLENOID

VALVE

The

F

l

C

D

solenoid

valve

is

at

tached

to

the

dash

panel

in

the

engine

compartment

This

valve

supplies

vacu

um

to

the

F

I

C

D

diaphragm

through

the

vacuum

hose

connected

to

the

engine

intake

manifold

when

the

engine

is

at

idle

and

the

cooling

system

is

ON

thereby

raising

idle

speed

to

the

predetermined

rpm

800

IW

r

e

I

1

s

AC132

Fig

AC

12

F

l

C

D

solenoid

value

Page 513 of 537

Air

Conditioning

BLOWER

MOTOR

DIAGNOSES

Blower

motor

inoperative

Check

fuse

In

fuse

block

15A

W

Single

fuse

15A

at

cooling

unit

I

j

If

OK

Check

the

continuity

and

fitting

of

fan

switch

I

I

If

OK

I

I

Connect

fan

switch

to

wiring

harness

2

Turn

the

ignition

switch

ON

IG

3

Set

fan

switch

at

ON

1

2

or

3

position

Check

the

voltage

for

blower

motor

Blue

lead

wire

is

poweI

source

Blue

wire

with

white

stripe

is

for

grounding

I

I

Voltage

I

I

Check

the

continuity

and

fitting

of

resistance

on

cooling

unit

I

I

If

OK

If

damaged

I

I

Replace

blower

motor

Replace

resistance

AC

24

mown

fuse

Replace

fuse

j

If

damaged

I

I

Replace

fan

switch

No

voltage

Replace

main

relay