torque DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 131 of 537

Engine

Fuel

SERVICE

DATA

AND

SPECIFICATIONS

Airclelllcr

Ail

control

val

partially

opem

Air

ntrol

valve

fuUy

opens

Idle

ompensatoI

partially

opens

Hi

mettiNo

l

Bi

metal

No

2

Idle

ompen

tor

fully

opens

Bi

metal

No

1

Hi

metd

No

2

Fuels

Stem

Fuel

prtuure

Fuel

pump

apacHy

C

rbu

tor

C

rbu

tor

type

Carburetor

model

Oc

oF

oCe

F

oCe

F

Oc

OF

kpJcm2

poi

US

pt

min

at

rpm

Outlet

diameter

Venturi

diameter

Main

jet

Main

air

bleed

Slow

jet

Power

val

Float

level

U

fuel

preuure

rom

in

mm

in

mm

in

kg

cm2

psi

Adjustment

Engine

idling

Ignition

timing

Idle

speed

CO

at

mloro

Fuel

level

adjustment

Gap

between

Ive

stem

and

noat

at

mm

in

H

H

h

Fast

idle

adjwtmcnt

Fast

idle

earn

tint

step

Gap

between

throttle

IYe

and

carburetor

body

mm

in

Vacuum

break

adjustment

Gap

between

choke

alve

and

carburetor

body

mm

in

Choke

unloadel

adjusttncnt

Gap

between

choke

alw

and

carburetor

body

rom

in

Bi

metalsettinl

Bi

metal

resistance

at

2Ioe

700F

n

Bi

metalsettina

lnterloc

k

opcnina

of

primary

and

secondary

throtUc

valves

mmOn

Duh

pot

adjustment

without

loadin

I

m

Anti

diclClinasolenoid

valV

C

tiahtenina

torque

ka

m

in

lb

a

c

D

D

set

p

JSure

0

m

sea

level

and

760

mmHg

30

inlla

atmospheric

pressure

J

mmHa

inHg

R

C

D

D

tiahteninl

torque

kg

m

n

b

Nl

n

California

modell

Manual

transmiSsion

I

Automatic

transmission

California

modeb

Manual

transmission

I

Automatic

transmission

30

to

54

86

to

129

above

55

131

30

to

54

86

to

129

above

55

131

60

to

70

140

to

158

70

to

90

158

to

194

60

to

70

140

to

158

70

to

90

158

to

194

above

70

158

above

90

194

above

70

158

above

90

194

0

21

to

0

27

2

99

to

3

84

t

OOO

2

i

I

OOO

0

21

to

0

27

2

99

to

3

84

1

000

2

i

I

OOO

Strombcra

type

OCH340

7A

DCH340

48A

Stromt

rg

type

DCH34Q

45B

DCH340

46A

Primary

Secondary

Primary

Secondary

Primary

Secondary

Primary

Secondary

30

I8t

340

339

30

1

181

34

1

339

30

1

181

34

1

339

30

1

181

34

1

339

24

0

945

310

220

24

0

945

31

1

220

24

0

945

31

1

220

24

0

945

31

1

220

199

1160

199

1160

1101

1160

101

1160

170

160

170

160

170

60

170

1

60

148

1100

148

1100

148

1100

148

180

143

143

140

140

23

0

906

23

0

906

23

0

906

23

0

906

0

17

2

408

0

17

2

40B

0

17

2

408

0

17

2

408

1201750

rpm

CO

2

1

120

650

rpm

0

100

750rpm

C02

t

1

120

650

rpm

0

position

CO

2

t

1

position

CO

2

t

1

7

2

0

283

7

2

0

283

7

2

0

283

7

2

0

283

23

0

906

23

0

906

23

0

906

23

0

906

1

3

to

1

7

1

3

to

1

7

1

3

to

1

7

1

3

to

1

7

0

051

to

0

067

0

051

to

0

067

0

051

to

0

067

0

051

to

0

067

1

33

to

1

47

1

58

to

1

72

1

33

to

1

47

1

58

to

1

72

0

0524

to

0

0579

0

0622

to

0

0677

0

0524

to

0

0579

0

0622

to

0

0677

1

42

0

056

1

42

0

056

1

42

0

056

1

5

0

059

2

45

0

096

2

45

0

096

2

4

0

096

2

45

0

096

3

7

to

8

9

3

7

to

8

9

3

7

to

B

9

3

7

to

8

9

Center

of

the

ndex

mark

Center

of

the

index

mark

7

38

0

291

7

38

0

291

7

38

0

290

7

38

0

291

1

900

to

2

100

1

650

to

1

850

1

900

to

2

100

1

650

to

1

850

180

to

350

156

to

304

180

to

350

156

to

304

180

to

350

156

to

304

180

to

350

156

to

304

510

to

550

490

to

530

510

to

550

490

to

530

20

1

to

21

7

19

3

to

20

9

20

1

to

21

7

19

3

to

20

9

20

to

40

17

4

to

34

1

20

to

40

11

4

to

34

7

20

to

40

17

4

to

34

7

20

to

40

17

4

to

34

1

EF

35

Page 147 of 537

9

From

air

pump

l

h

1

Not

actuated

REMOVAL

AND

INSTALLATION

Air

p

mp

sir

cleaner

Remove

air

hose

then

detach

air

cleaner

from

hoodledge

Air

cleaner

element

and

Ii

r

deancr

lower

body

are

built

into

a

unit

construction

Replace

air

cleaner

clcl

nen

and

lower

body

as

an

assembly

J

J

tt

c

t

o

J

EC

323

Fig

EC

26

Replacing

oir

cleaner

element

Air

pum

Remove

air

hoses

from

air

pump

2

Loosen

air

pump

adjusting

bar

mounting

bolts

and

air

pump

mount

ing

bolts

then

remove

air

pump

drive

bell

3

Remove

air

pump

pulley

4

Remove

air

pump

from

bracket

Air

control

valve

California

models

l

Disconnect

air

hoses

and

a

vacu

um

hose

from

air

control

valve

2

Remove

air

con

trol

valve

from

bracket

E

A

R

valve

California

modela

Remove

vacuum

pipe

and

air

hose

and

dismount

E

A

R

valve

Emission

Control

System

o

jJ

To

Intake

mamfold

rF

vacuum

r

To

air

cleaner

From

air

pump

EC781

Fig

EC

27

Locotion

of

E

A

R

wive

Antl

backflravalve

Disconnect

air

hose

and

vacuum

hose

from

anti

backfire

valve

Check

valve

Disconnect

hose

and

remove

check

valve

from

air

gallery

pipe

Air

ganery

pIpe

andinJactlon

nozzles

It

is

very

difficult

to

remove

the

air

gallery

from

the

exhaust

manifold

without

bending

the

pipe

which

could

result

in

fractures

or

leakage

There

fore

removal

of

the

air

gallery

pipe

and

injection

nozzles

should

be

under

taken

only

when

they

are

damaged

I

Lubricate

around

the

connecting

portion

of

air

injection

nozzle

and

air

gallery

with

engine

oil

2

Hold

air

injection

nozzle

hexagon

head

with

a

wrench

and

unfasten

flare

screw

connecting

ait

gallery

to

injec

tion

nozzle

Remove

air

gallery

EC

14

To

intake

manifold

vaCUl

lm

r

Y

4

9

Gf

T

I

To

air

cleaner

I

Actuated

EC299

Fig

EC

25

Operation

of

air

control

value

Notes

a

Apply

engine

011

to

rews

several

times

during

above

work

b

Be

atreful

not

to

damage

other

parts

3

Unfasten

air

injection

nozzle

from

cylinder

head

applying

engine

oil

to

screwed

portion

several

times

4

Check

air

gallery

and

nozzle

for

fractures

or

leakage

Clean

air

injection

nozzle

with

a

wire

brush

5

At

time

of

installation

hold

air

injection

nozzle

hexagon

head

with

a

wrench

and

tighten

air

gallery

flange

screw

to

a

torque

of

5

0

to

5

9

kg

m

36

to

43

ft

lb

6

Check

cylinder

head

air

injection

nozzle

and

air

gallery

for

leaks

with

engine

running

Air

pump

relief

vslve

Loosen

carburetor

air

cleaner

mounting

sc

ews

and

remove

air

pump

relief

valve

InstallatIon

Install

in

the

reverse

order

of

reo

moval

DISASSEMBLY

AND

ASSEMBLY

Disassembly

of

air

pump

1

Remove

four

pulley

drive

bolts

and

remove

pulley

from

hub

2

Secure

air

pump

drive

hub

in

a

vise

as

shewn

in

Figure

EC

28

and

remove

four

end

cover

bolts

Page 149 of 537

Emission

Control

System

Assembl

of

air

pump

I

Front

bearing

Support

the

rear

end

face

of

air

pump

housing

with

RotOL

Adapter

STl9890000

Press

front

bearing

into

place

with

a

press

arid

Bearing

Ptessing

Tool

STl9940000

I

I

STl9940000

X8

03

Fig

EC

35

Pressing

ball

bearing

L

2

Bearing

cover

Torque

four

bearing

cover

securing

bolts

to

0

1

to

0

2

kg

m

0

7

to

1

4

ft

lb

3

Rotor

shaft

Support

the

inward

bottom

of

rotor

with

Rotor

Stand

STl9920000

Press

rotor

into

place

with

a

press

and

Bearing

Drive

STl9910000

until

the

stepped

portion

of

rotor

shaft

touches

front

bearing

inner

race

C

1

ST

19910000

ST19920000

I

EC3Q7

Fig

EC

36

Pressing

rotor

shaft

Notes

a

Be

sure

to

drive

front

bearing

inner

race

in

b

After

rotor

is

installed

in

place

ensure

that

the

rotor

end

is

pos

tioned

below

the

end

face

of

air

pump

housing

Position

of

rotor

end

below

air

pump

housing

0

050

to

0

150

mm

0

0020

to

0

0059

in

4

Air

pump

drive

hub

Support

the

inward

bottom

of

rotor

with

Rotor

Stand

STl9920000

EC

16

EC562

Fig

EC

34

Componenbr

of

two

vane

type

Press

drive

hub

into

place

with

a

pre

and

Bearing

Driver

STI

991

0000

until

the

end

face

of

drive

hub

touches

froE

c

ing

in

n

c

j

STt9910000

STl9920000

e

r

EC308

Fig

EC

37

Pressing

air

pump

drive

hub

5

Carbon

shoe

1

Place

air

pump

drive

hub

in

a

vise

2

Clean

carbon

dust

etc

from

shoe

grooves

3

Align

rotor

with

housing

proper

ly

Refer

to

Figure

EC

38

Then

insert

carbon

shoes

into

place

noting

their

directions

Page 150 of 537

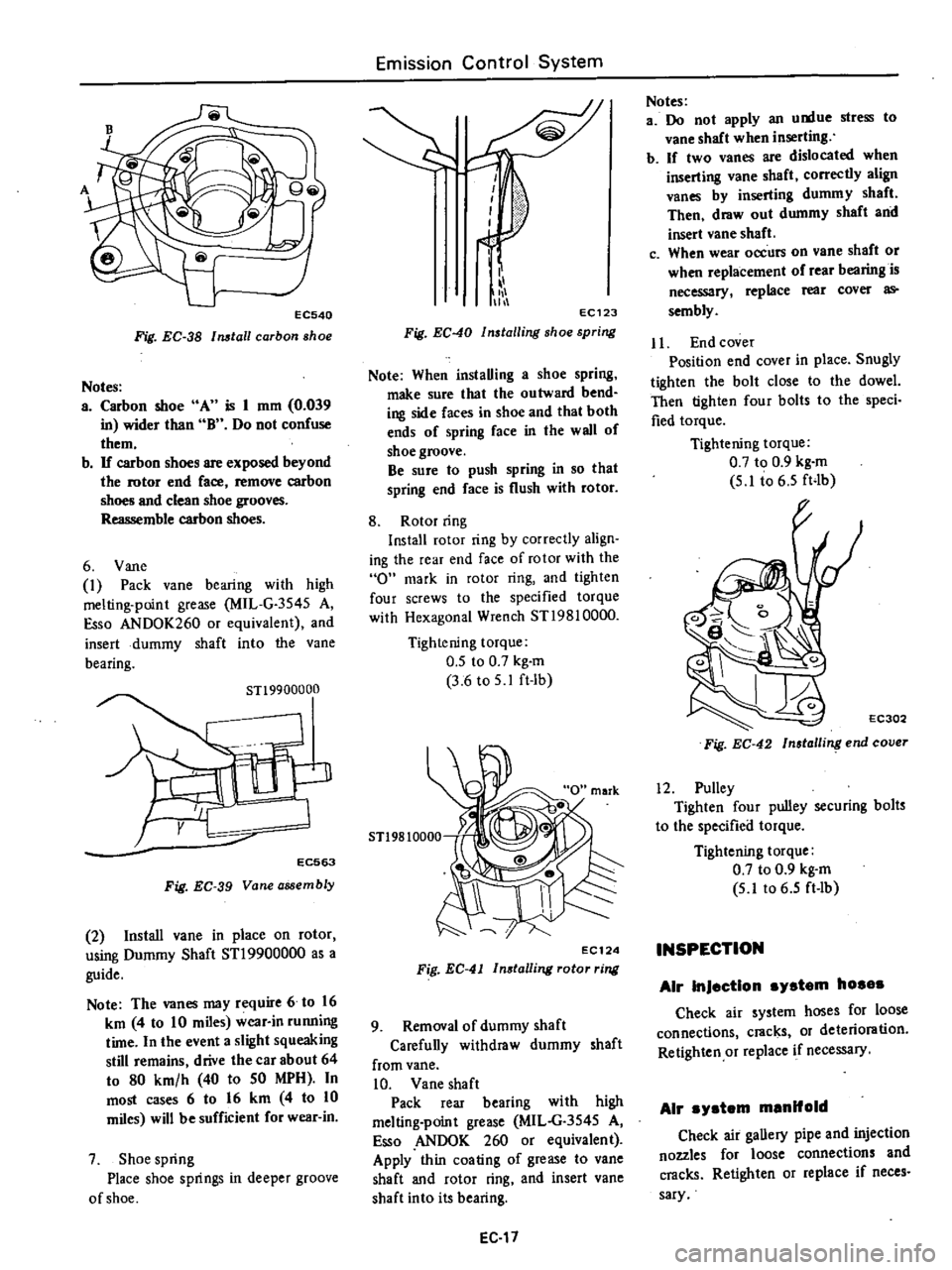

EC540

Fig

EC

38

Install

carbon

shoe

Notes

a

Carbon

shoe

A

is

1

mm

0

039

in

wider

than

B

Do

not

confuse

them

b

If

carbon

shoes

are

exposed

beyond

the

rotor

end

face

remove

carbon

shoes

and

clean

shoe

grooves

Reassemble

carbon

shoes

6

Vane

1

Pack

vane

bearing

with

high

melting

point

grease

MIL

G

3545

A

Esso

ANDOK260

or

equivalent

and

insert

dummy

shaft

into

the

Vane

bearing

STl9900000

EC563

Fig

EC

39

Vane

assembly

2

Install

vane

in

place

on

rotor

using

Dummy

Shaft

STl9900000

as

a

guide

Note

The

vanes

may

require

6

to

16

km

4

to

10

miles

wear

in

running

time

In

the

event

a

slight

squeaking

still

remains

drive

the

car

about

64

to

80

km

h

40

to

50

MPH

In

most

cases

6

to

16

km

4

to

10

miles

will

be

sufficient

for

wear

in

7

Shoe

spring

Place

shoe

springs

in

deeper

groove

of

shoe

Emission

Control

System

i

111

11

EC123

Fig

EC

40

Installing

shoe

spring

Note

When

instaUing

a

shoe

spring

make

sure

that

the

outward

bend

ing

side

faces

in

shoe

and

that

both

ends

of

spring

face

in

the

wall

of

shoe

groove

Be

sure

to

push

spring

in

so

that

spring

end

face

is

flush

with

rotor

8

Rotor

ring

Install

rotor

ring

by

correctly

align

ing

the

rear

end

face

of

rotor

with

the

0

mark

in

rotor

ring

and

tighten

four

screws

to

the

specified

torque

with

Hexagonal

Wrench

ST19810000

Tightening

torque

0

5

to

0

7

kg

m

3

6

to

5

1

ft

lb

5T19810000

EC124

Fig

EC

41

In8talling

rotor

ring

9

Removal

of

dummy

shaft

Carefuny

withdraw

dummy

shaft

from

vane

10

Vane

shaft

Pack

rear

bearing

with

high

melting

point

grease

MIL

G

3545

A

so

ANDOK

260

or

equivalent

Apply

thin

coating

of

grease

to

vane

shaft

and

rotor

ring

and

insert

vane

shaft

into

its

bearing

EC

17

Notes

a

Do

not

apply

an

u

tue

stress

to

vane

shaft

when

inserting

b

If

two

vanes

are

dislocated

when

inserting

vane

shaft

correctly

align

vanes

by

inserting

dummy

shaft

Then

draw

out

dummy

shaft

and

insert

vane

shaft

c

When

wear

occurs

on

vane

shaft

or

when

replacement

of

rear

bearing

is

necessary

replace

rear

cover

as

sembly

Jl

End

cover

Position

end

cover

in

place

Snugly

tighten

the

bolt

close

to

the

dowel

Then

tighten

four

bolts

to

the

speci

fied

torque

Tightening

torque

0

7

to

0

9

kg

m

5

1

t06

5

ft4b

EC302

Fig

EC

42

Insla

ling

end

cover

12

Pulley

Tighten

four

pulley

securing

bolts

to

the

specified

torque

Tightening

torque

0

7

to

0

9

kg

m

5

lt06

5

ft

lb

INSPECTION

Air

InJection

system

hosas

Check

air

system

hoses

for

loose

connections

cracks

or

deterioration

Retighten

or

replace

if

necessary

Air

ystem

manifold

Check

air

gaUery

pipe

and

injection

nozzles

for

loose

connections

and

cracks

Retighten

or

replace

if

neces

sary

Page 160 of 537

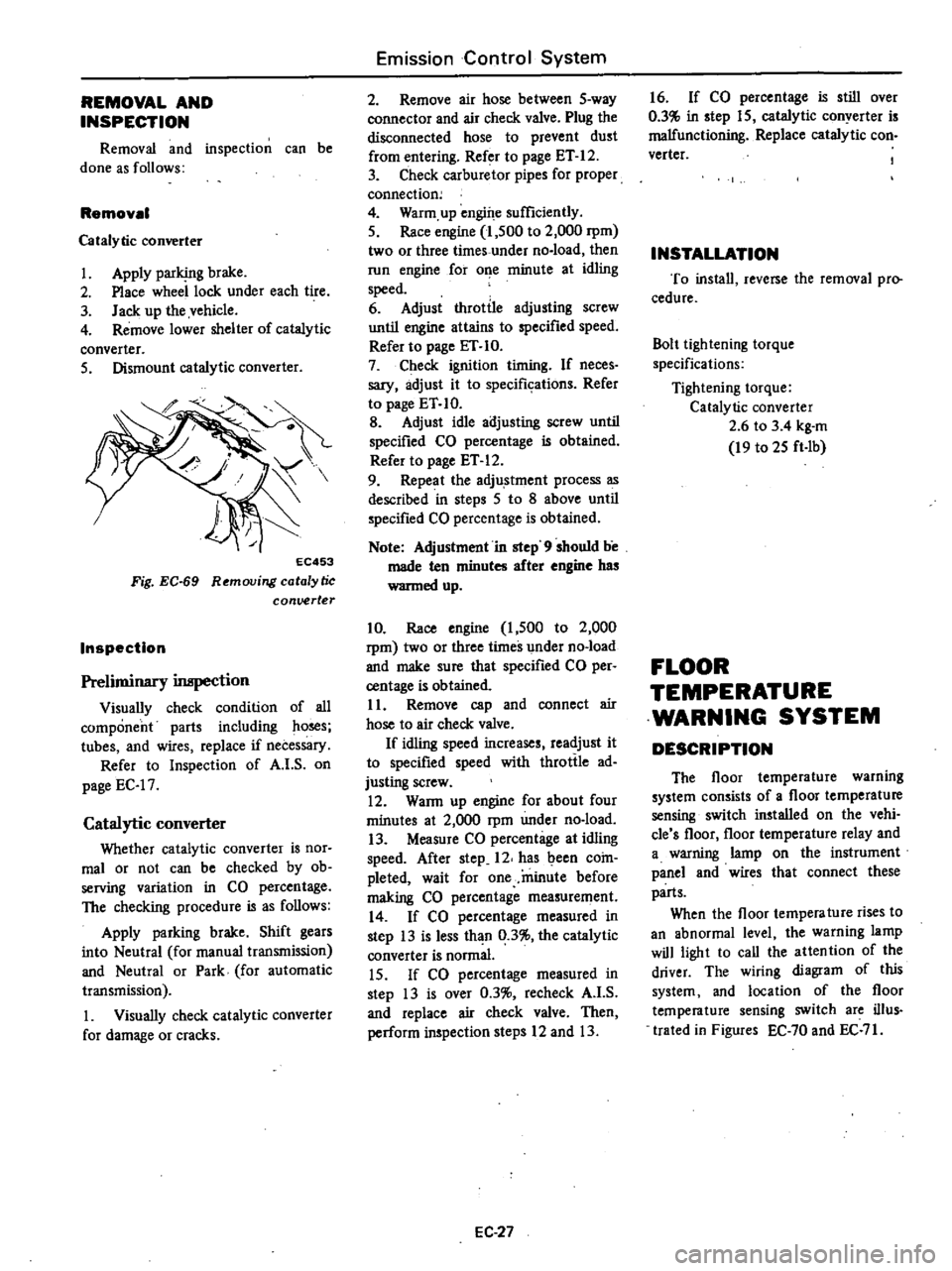

REMOVAL

AND

INSPECTION

Removal

and

inspection

can

be

done

as

follows

Removal

Catalytic

converter

1

Apply

parking

brake

2

Place

wheel

lock

under

each

tire

3

Jack

up

the

vehicle

4

Remove

lower

shelter

of

catalytic

converter

5

Dismount

catalytic

converter

EC453

Fig

EC

69

Removing

catalytic

conuerter

Inspection

Preliminary

inspection

Visually

check

condition

of

all

component

parts

including

ho

s

tubes

and

wires

replace

if

necessary

Refer

to

Inspection

of

A

I

S

on

page

EC

17

Catalytic

converter

Whether

catalytic

converter

is

nor

mal

or

not

can

be

checked

by

ob

serving

variation

in

CO

percentage

The

checking

procedure

is

as

follows

Apply

parking

brake

Shift

gears

into

Neutral

for

manual

transmission

and

Neutral

or

Park

for

automatic

transmission

1

Visually

check

catalytic

converter

for

damage

or

cracks

Emission

Control

System

2

Remove

air

hose

between

5

way

connector

and

air

check

valve

Plug

the

disconnected

hose

to

prevent

dust

from

entering

Refer

to

page

ET

12

3

Check

carburetor

pipes

for

proper

connection

4

Warm

up

engine

sufficiently

5

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

then

run

engine

for

o

e

minute

at

idling

speed

6

Adjust

throttle

adjusting

screw

until

engine

attains

to

specified

speed

Refer

to

page

ET

10

7

Check

ignition

timing

If

neces

sary

adjust

it

to

specifkations

Refer

to

page

ET

10

B

Adjust

idle

adjusting

screw

until

specified

CO

percentage

is

obtained

Refer

to

page

ET

12

9

Repeat

the

adju

stment

process

as

described

in

steps

5

to

8

above

until

specified

CO

percentage

is

obtained

Note

Adjustment

in

step

9

should

be

made

ten

minutes

after

engine

has

wanned

up

10

Race

engine

1

500

to

2

000

rpm

two

or

three

times

under

no

load

and

make

sure

that

specified

CO

per

centage

is

obtained

11

Remove

cap

and

connect

air

hose

to

air

check

valve

If

idling

speed

increases

readjust

it

to

specified

speed

with

throttle

ad

justing

screw

12

WaRn

up

engine

for

about

four

minutes

at

2

000

rpm

under

no

load

13

Measure

CO

percentage

at

idling

speed

After

step

12

has

been

coin

pleted

wait

for

one

minute

before

making

CO

percentage

measurement

14

If

CO

percentage

measured

in

step

13

is

less

than

0

3

the

catalytic

converter

is

normal

15

If

CO

percentage

measured

in

step

13

is

over

0

3

recheck

A

I

S

and

replace

air

check

valve

Then

perform

inspection

steps

12

and

13

EC

27

16

If

CO

percentage

is

still

over

0

3

in

step

15

catalytic

conyerter

is

malfunctioning

Replace

catalytic

con

verter

INSTALLATION

To

install

reverse

the

removal

pro

cedure

Bolt

lightening

torque

specifications

Tightening

torque

Catalytic

converter

2

6

to

3

4

kg

m

19

to

25

ft

Ib

FLOOR

TEMPERATURE

WARNING

SYSTEM

DESCRIPTION

The

floor

temperature

warning

system

consists

of

a

floor

temperature

sensing

switch

installed

on

the

vehi

cle

s

floor

floor

temperature

relay

and

a

warning

lamp

on

the

instrument

panel

and

wires

that

connect

these

parts

When

the

floor

tempera

ture

rises

to

an

abnormal

level

the

warning

lamp

will

light

to

call

the

attention

of

the

driver

The

wiring

diagram

of

this

system

and

location

of

the

floor

temperature

sensing

switch

are

ilIus

trated

in

Figures

EC

70

and

EC

71

Page 173 of 537

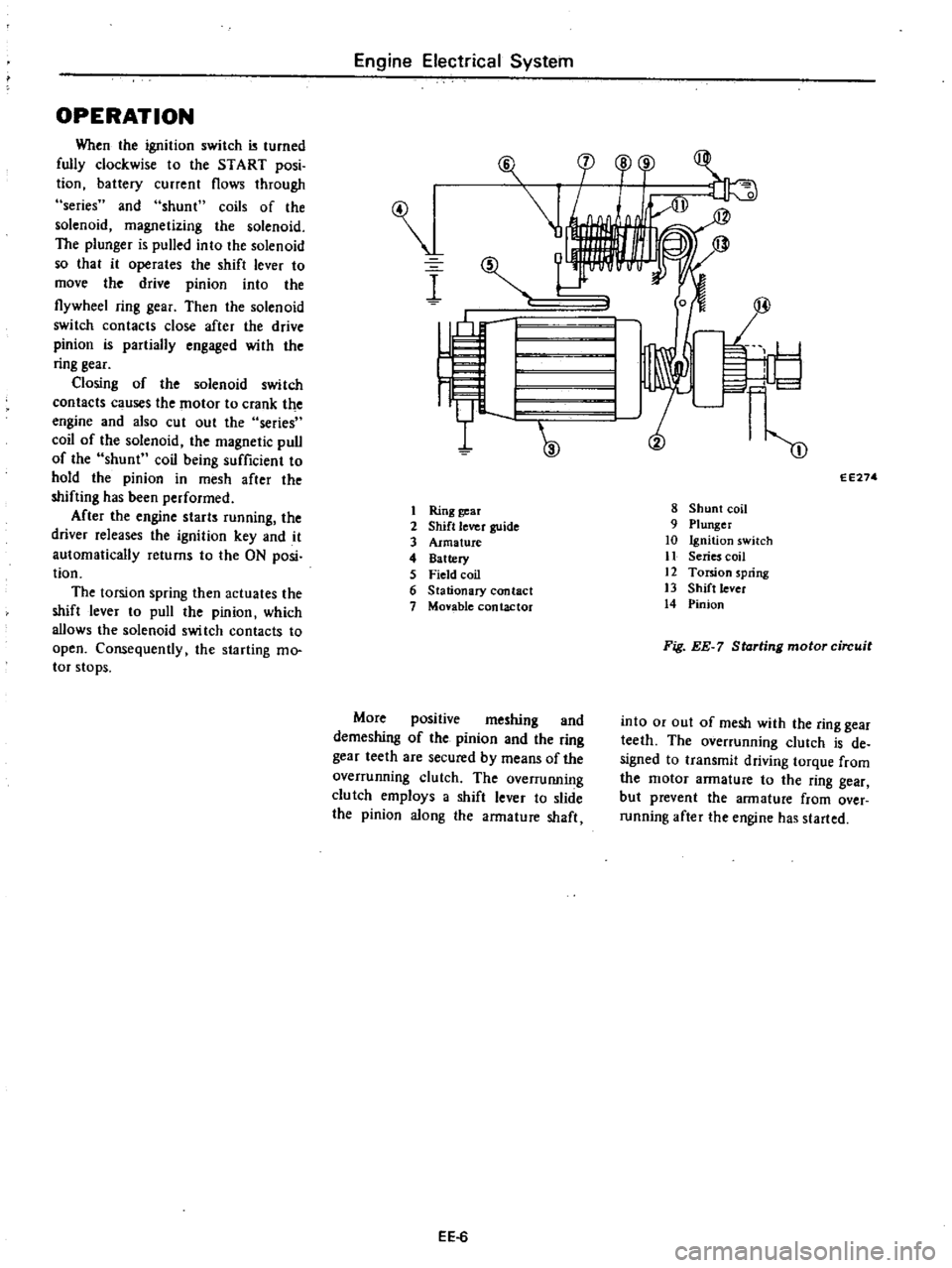

OPERATION

When

the

ignition

switch

turned

fully

clockwise

to

the

START

posi

tion

battery

current

flows

through

series

and

shunt

coils

of

the

solenoid

magnetizing

the

solenoid

The

plunger

is

pulled

into

the

solenoid

so

that

it

operates

the

shift

lever

to

move

the

drive

pinion

into

the

flywheel

ring

gear

Then

the

solenoid

switch

contacts

close

after

the

drive

pinion

is

partially

engaged

with

the

ring

gear

Closing

of

the

solenoid

switch

contacts

c

uses

the

motor

to

crank

the

engine

and

also

cut

out

the

series

coil

of

the

solenoid

the

magnetic

pull

of

the

shunt

coil

being

sufficient

to

hold

the

pinion

in

mesh

after

the

shifting

has

been

performed

After

the

engine

starts

running

the

driver

releases

the

ignition

key

and

it

automatically

returns

to

the

ON

posi

tion

The

torsion

spring

then

actuates

the

shift

lever

to

pull

the

pinion

which

allows

the

solenoid

swi

tch

contacts

to

open

Consequently

the

starting

mo

tor

stops

Engine

Electrical

System

I

I

Ring

gear

2

Shift

lever

guide

3

Armature

4

Battery

5

Field

coil

6

Stationary

contact

7

Monble

contactor

More

positive

meshing

and

demeshing

of

the

pinion

and

the

ring

gear

teeth

are

secured

by

means

of

the

overrunning

clutch

The

overruIUling

clutch

employs

a

shift

lever

to

slide

the

pinion

along

the

armature

shaft

EE

6

F

l

cp

o

r

1

I

I

W

m

EE274

8

Shunt

coil

9

Plunger

10

Ignition

switch

11

Series

coil

12

Torsion

spring

13

Shift

lever

14

Pinion

Fig

EE

7

Starting

motor

circuit

into

or

out

of

mesh

with

the

ring

gear

teeth

The

overrunning

clutch

is

de

signed

to

transmit

driving

torque

from

the

motor

armature

to

the

ring

gear

but

prevent

the

armature

from

over

running

after

the

engine

has

started

Page 185 of 537

If

current

flows

in

both

positive

and

negative

directions

diode

is

short

circuited

If

current

flows

in

one

direc

tion

only

diode

is

in

good

condition

Test

probe

of

a

circuit

t

ter

e

Gl

terminal

EEl

plate

EJ

plate

terminal

terminal

e

plate

e

plate

terminal

e

plate

@

plate

Xl

plate

e

plate

INSPECTION

OF

BRUSH

Check

movement

of

brush

and

if

movement

is

not

smooth

check

brush

holder

and

clean

if

necessary

Check

brush

for

wear

If

it

is

worn

down

to

less

than

the

specified

limit

replace

brush

assembly

Check

brush

pig

tail

and

if

dam

aged

replace

Brush

wear

limiting

line

EE127

Fig

EE

41

Bnlsh

wear

limil

Engine

Electrical

System

If

there

is

a

faulty

diode

replace

all

diodes

ix

diode

as

an

assembly

See

table

below

These

diodes

are

unserviceable

Conduction

o

o

o

SPRING

PRESSURE

TEST

With

brush

projected

approximate

ly

2

mm

0

079

in

from

brush

holder

measure

brush

spring

pressure

by

the

use

of

a

pring

balance

Normally

the

rated

pressure

of

a

new

brush

spring

is

255

to

345

gr

9

0

to

12

202

Morevover

when

brush

is

worn

pressure

decrease

approximately

20

g

0

7

02

per

1

mm

0

0039

in

wear

t

m

0

079

in

or

f

EEO

9

Fig

EE

42

M

CJ

uring

pring

preaure

EE

lB

ASSEMBLY

Reassemble

alternator

in

the

reverse

sequence

of

disassembly

noting

the

following

I

When

soldering

each

stator

coil

lead

wire

to

diode

assembly

terminal

carry

out

the

operation

as

fast

as

pas

sible

2

When

installing

diode

A

terminal

install

insulating

bush

correctly

1

Imulating

bush

2

A

terminal

bolt

3

Diode

cover

4

Rear

cover

5

Diode

a

sembly

EE347

Fig

EE

43

Sectional

view

of

diode

and

A

term

inal

3

Tighten

pulley

nut

with

tighten

ing

torque

of

3

5

to

4

0

kg

m

25

3

to

29

0

ft

Ib

When

pulley

is

tightened

make

sure

that

deflection

of

V

groove

is

less

than

0

3

mm

0

01

IS

in

q

ffl

t

EE051

Fig

EE

44

Tightening

pulley

nut

Page 214 of 537

DESCRIPTION

INSPECTION

CLEANING

AND

REGAP

DESCRIPTION

The

spark

plugs

are

of

the

conven

tional

type

having

14

mm

0

551

in

threads

The

spark

plug

gaps

are

1

0

to

1

1

mm

0

039

to

0

043

in

on

Cali

fomia

models

and

0

8

to

0

9

mm

0

031

to

0

035

in

on

non

California

models

The

inspection

and

cleaning

should

be

made

every

suitable

mainte

nance

period

If

necessary

replace

Note

All

spark

plugs

installed

on

an

engine

must

be

of

the

same

brand

and

the

same

number

of

heat

range

INSPECTION

L

Remove

spark

plug

wire

by

pulling

on

boot

not

on

wire

itself

2

Remove

spark

plugs

3

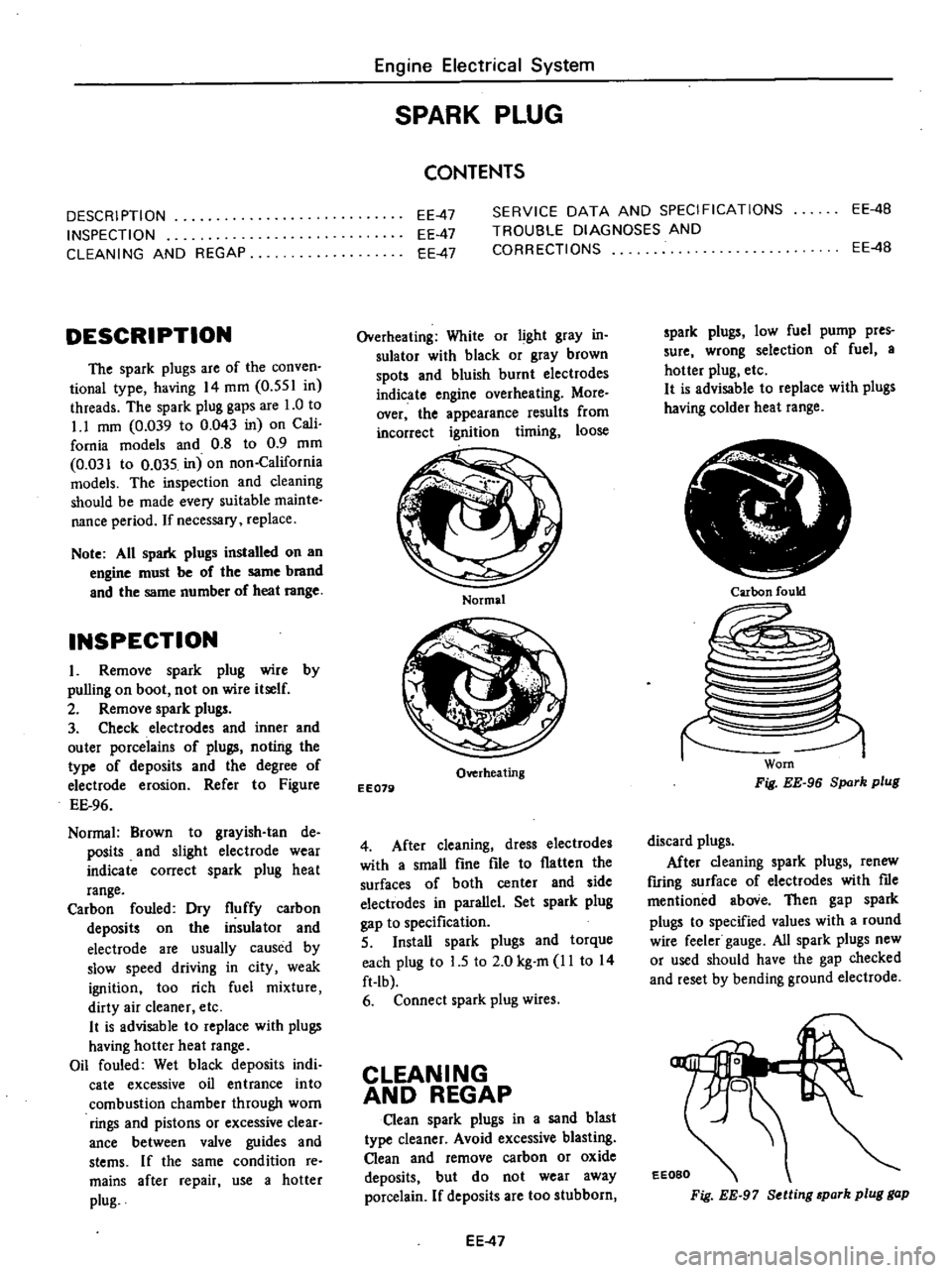

Check

electrodes

and

inner

and

outer

porcelains

of

plugs

noting

the

type

of

deposits

and

the

degree

of

electrode

erosion

Refer

to

Figure

EE

96

Normal

Brown

to

grayish

tan

de

posits

and

slight

electrode

wear

indicate

correct

spark

plug

heat

range

Carbon

fouled

Dry

fluffy

carbon

deposits

on

the

insulator

and

electrode

are

usually

caused

by

slow

speed

driving

in

city

weak

ignition

too

rich

fuel

mixture

dirty

air

cleaner

etc

It

is

advisable

to

replace

with

plugs

having

hotter

heat

range

Oil

fouled

Wet

black

deposits

indi

cate

excessive

oil

entrance

into

combustion

chamber

through

worn

rings

and

pistons

or

excessive

clear

ance

between

valve

guides

and

stems

If

the

same

condition

re

mains

after

repair

use

a

hotter

plug

Engine

Electrical

System

SPARK

PLUG

CONTENTS

EE

4B

EE

47

EE

47

EE

47

SERVICE

DATA

AND

SPECIFICATIONS

TROUBLE

DIAGNOSES

AND

CORRECTIONS

EE

4B

Overheating

White

or

light

gray

in

sulator

with

black

or

gray

brown

spots

and

bluish

burnt

electrodes

indicate

engine

overheating

More

over

the

appearance

results

from

incorrect

ignition

timing

loose

Normal

Overheating

EE079

4

After

cleaning

dress

electrodes

with

a

smaU

fine

file

to

flatten

the

surfaces

of

both

center

and

side

electwdes

in

parallel

Set

spark

plug

gap

to

specification

5

InstaU

spark

plugs

and

torque

each

plug

to

L5

to

2

0

kg

m

11

to

14

ft

Ib

6

Connect

spark

plug

wires

CLEANING

AND

REGAP

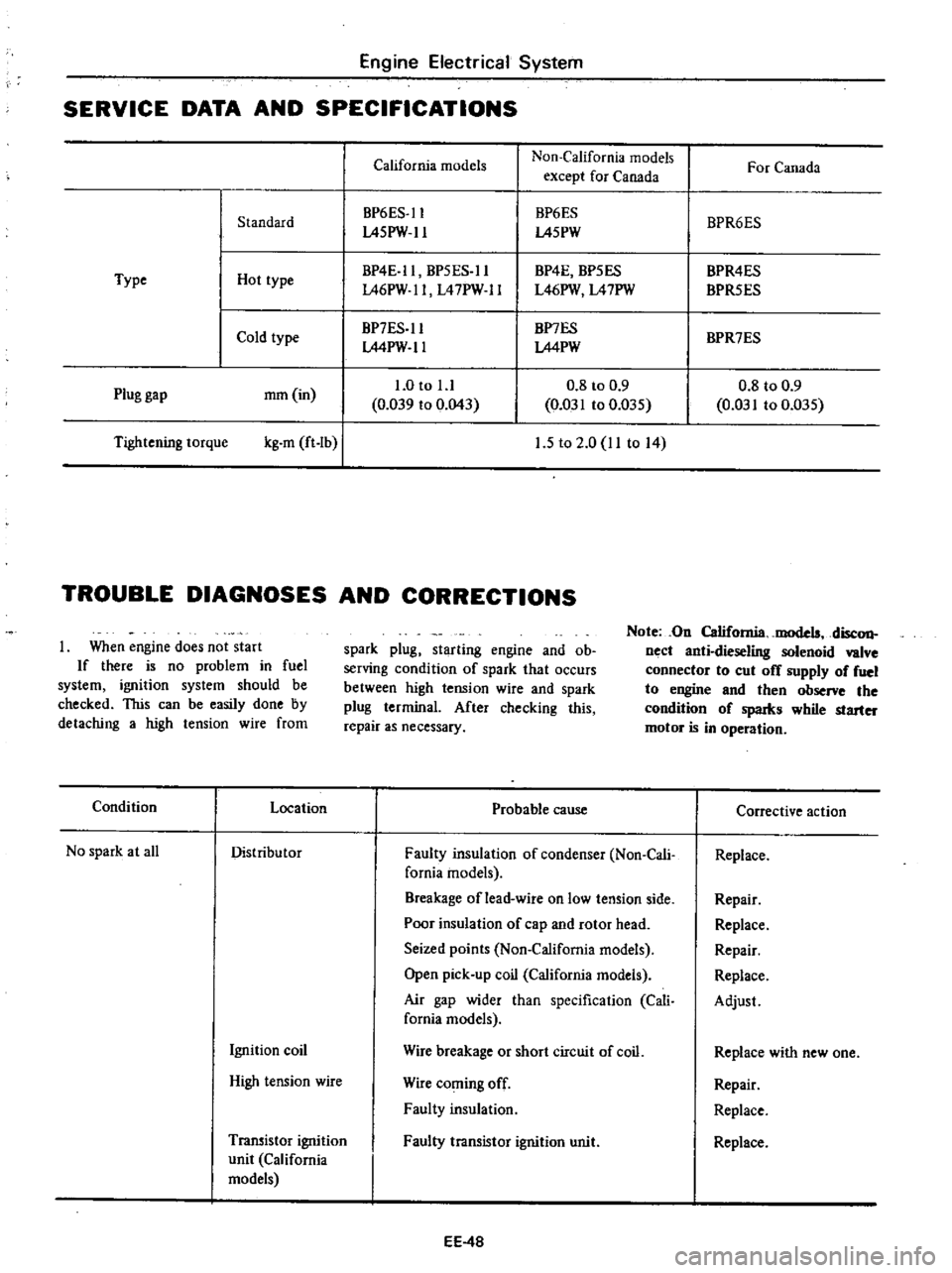

Clean

spark

plugs

in

a

sand

blast

type

cleaner

Avoid

excessive

blasting

Clean

and

remove

carbon

or

oxide

deposits

but

do

not

wear

away

porcelain

If

deposits

are

too

stubborn

EE

47

spark

plugs

low

fuel

pump

pres

sure

wrong

selection

of

fuel

a

hotter

plug

etc

It

is

advisable

to

replace

with

plugs

having

colder

heat

range

Ir

i

Carbon

fould

Worn

Fig

EE

96

Spark

plug

discard

plugs

After

cleaning

spark

plugs

renew

firing

surface

of

electrodes

with

me

mentioned

aboVe

Then

gap

spark

plugs

to

specified

values

with

a

round

wire

feeler

gauge

All

spark

plugs

new

or

used

should

have

the

gap

checked

and

reset

by

bending

ground

electrode

EEOBO

Fig

EE

97

Setting

park

plug

gap

Page 215 of 537

Engine

Electrical

System

SERVICE

DATA

AND

SPECIFICATIONS

California

models

Non

California

models

For

Canada

except

for

Canada

BP6ES

ll

BP6ES

BPR6ES

Standard

L45PW

ll

L45PW

BP4E

ll

BP5ES

ll

BP4E

BP5ES

BPR4ES

Type

Hot

type

L46PW

ll

L47PW

ll

L46PW

L47PW

BPR5ES

Cold

type

BP7ES

ll

BP7ES

BPR7ES

LMPW

ll

LMPW

1

0

to

l

l

0

8

to

0

9

0

8

to

0

9

Plug

gap

mm

in

0

039

to

0

043

0

031

to

0

D35

0

031

to

0

035

Tightening

torque

kg

m

ft

Ib

I

1

5

to

2

0

11

to

14

TROUBLE

DIAGNOSES

AND

CORRECTIONS

When

engine

does

not

start

If

there

is

no

problem

in

fuel

system

ignition

system

should

be

checked

This

can

be

easily

done

by

detaching

a

high

tension

wire

from

spark

plug

starting

engine

and

ob

serving

condition

of

spark

that

occurs

between

high

tension

wire

and

spark

plug

terminal

After

checking

this

repair

as

necessary

Note

On

California

models

disc

on

nect

anti

dieseling

solenoid

valve

connector

to

cut

off

supply

of

fuel

to

engine

and

then

observe

the

condition

of

spaIks

while

starter

motor

is

in

operation

Condition

Location

Probable

cause

Corrective

action

No

spark

at

all

Distributor

Faulty

insulation

of

condenser

Non

Cali

Replace

fomia

models

Breakage

of

lead

wire

on

low

tension

side

Repair

Poor

insulation

of

cap

and

rotor

head

Replace

Seized

points

Non

California

models

Repair

Open

pick

up

coil

California

models

Replace

Air

gap

wider

than

specification

Cali

Adjust

fornia

models

Ignition

coil

Wire

breakage

or

short

circuit

of

coil

Replace

with

new

one

High

tension

wire

Wire

coming

off

Repair

Faulty

insulation

Replace

Transistor

ignition

Faulty

transistor

ignition

unit

Replace

unit

California

models

EE

4B

Page 219 of 537

Engine

Removal

Installation

ENGINE

REMOVAL

AND

INSTAllATION

REMOVAL

INSTALLATION

ENGINE

MOUNTING

INSULATORS

REMOVAL

It

is

much

easier

to

remove

engine

and

transmission

as

a

single

unit

than

to

remove

them

separately

After

re

moval

engine

can

be

separated

from

transntission

assembly

Notes

a

Be

sure

to

hoist

engine

and

jack

up

transmission

in

a

safe

manner

b

Use

fender

cove

to

protect

vehicle

body

1

Remove

battery

2

Scribe

hood

hinge

location

for

proper

reinstallation

and

remove

hood

Note

Have

an

assistant

help

you

so

as

to

prevent

damage

to

body

3

Drain

radiator

coolant

4

Disconnect

upper

and

lower

radiator

hoses

from

engine

5

Remove

two

oil

cooler

hoses

from

lower

end

of

radiator

Auto

ma

tic

transmission

models

only

6

Remove

radiator

shroud

7

Remove

four

bolts

securing

radia

tor

and

detach

radiator

Note

Always

tighten

securing

bolt

at

upper

right

hand

side

together

with

body

harness

terminal

8

Remove

carburetor

air

cleaner

as

follows

Remove

fresh

air

duct

Remove

hot

air

duct

Loosen

air

cleaner

band

bolt

and

air

cleaner

supporting

bolts

Disconnect

air

cleaner

ta

air

pump

hose

Disconnect

air

cleaner

to

rocker

cover

hose

at

rocker

cover

Disconnect

air

cleaner

to

air

control

valve

hose

California

models

only

CONTENTS

ER

2

ER

3

ER

3

FRONT

INSULATOR

REAR

INSULATOR

TIGHTENING

TORQUE

ER

4

ER

4

ER

4

Disconnect

air

deaner

to

A

B

valve

hose

Disconnect

air

cleaner

ta

vacuum

hoses

Note

Protect

carburetor

from

dust

and

foreign

matter

by

placing

cover

over

air

inlet

opening

9

Disconnect

fuel

pump

to

fuel

fdter

hose

and

return

hose

10

Disconnect

carbon

canister

hose

on

engine

side

II

Disconnect

air

pump

air

C1eaner

to

al

p

p

hose

12

Disconnect

following

cables

wires

and

hoses

Engine

ground

cable

Accelerator

wire

at

carburetor

High

tension

cable

between

ignition

coil

and

distributor

Wire

to

distributor

at

body

ter

minal

Wire

to

oil

pressure

switch

Wires

to

thermal

transmitter

Wires

to

B

C

p

D

cut

solenoid

Non

California

models

only

auto

choke

heater

and

anti

dieseling

solenoid

Wires

to

alternator

Wires

to

starter

motor

Heater

inlet

and

outlet

hoses

if

so

equipped

Vacuum

hose

of

Master

Vac

at

in

taJce

manifold

Wires

for

back

up

lamp

switch

Cable

to

speedometer

13

Remove

transmission

control

linkage

from

transmission

Manual

transmission

models

I

Detach

rubber

boot

2

Remove

E

ring

and

control

lever

pin

from

transmission

striking

rod

guide

and

remove

control

lever

ER

2

Fig

ER

l

Automatic

transmission

models

I

Disconnect

selector

range

lever

from

manual

shaft

2

Disconnect

wires

at

inhibitor

switch

and

down

shift

solenoid

14

Air

conditioner

equipped

models

need

following

procedures

1

After

removing

flexible

hose

support

remove

four

comi

ressor

se

curing

bolts

Then

move

the

com

pressor

to

battery

support

2

Remove

vacuum

hoses

of

F

LC

D

solenoid

valve

3

Remove

F

LC

D

actuator

15

Remove

two

bolts

securing

clutch

operating

cylinder

Then

dis

connect

operating

cylinder

and

flexi

ble

tube

as

an

assembly

Manual

transmission

models

only

16

Disconnect

front

exhaust

tube

from

exhaust

manifold

17

Remove

propeller

shaft

I

Disconnect

propeller

shaft

center

bearing

bracket

from

third

crossmember

2

Disconnect

propeller

shaft

from

companion

flange

of

differential

carrier

3

Remove

propeller

shaft

from

transmission

and

plug

up

rear

end

of

extension

housing

of

transmission

to

prevent

oil

leakage

18

Attach

a

suitable

wire

or

chain

to

lift

engine

19

Remove

front

engine

mounting

bolts

at

engine

mounting

front

sup

port