tow DATSUN PICK-UP 1977 Owner's Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 269 of 537

3

Jit

f

ng

valve

24

1

3

L

l

r

I

Js

I

i

ilr

t

pressure

6

when

shif

ing

from

3rd

to

2nd

at

D

range

Thus

the

throttle

of

line

pressure

6

reduces

the

shock

generated

fro

shifting

A

plug

in

the

SSV

left

end

readjust

the

throttle

piessu

e

I

6

which

varies

depending

on

the

engine

throttle

con

dition

to

a

throttle

pressure

19

suiled

to

the

sp

ed

change

control

Moreover

the

plug

is

a

valve

which

applies

line

P

esspre

13

in

lieu

of

the

throttle

pressure

to

the

SSV

and

the

FSV

when

kickdowri

is

performed

When

the

throttle

pressure

16

is

applied

to

the

left

side

of

this

plug

and

the

plug

is

epressed

toward

the

right

a

slight

space

is

formed

from

the

throttle

pressure

6

10

19

A

throt

tIepressu

19

w

1iFh

is

lower

by

the

pressure

loss

equivalent

to

this

space

is

rH

1

Pressure

Odifier

valve

PMV

I

Compared

to

the

operating

pressure

required

in

starting

th

vehicle

the

ppwer

trimsinitting

capacity

of

the

clutch

that

is

required

operating

pres

sure

may

be

lower

when

the

vehicle

is

once

started

When

the

line

pressure

is

retained

at

a

high

level

up

to

a

high

vehicle

speed

shock

gerieraled

from

the

shirring

increases

arid

the

oil

pump

loss

also

jncrdases

In

order

to

prevent

his

the

t

lrott

le

pressure

must

be

l

hanged

over

with

the

operation

of

the

governor

pressure

15

to

reduce

Ihe

line

pressure

The

PMV

is

used

for

this

purposc

Automatic

Transmission

generated

the

piessure

loss

is

adde

d

to

the

spring

force

and

the

plug

is

lhus

forced

back

from

the

right

to

the

left

When

this

pressure

19

increases

ex

cessively

the

plug

is

further

depressed

toward

the

left

space

from

the

lhrot

tle

pressure

19

to

the

drain

circuit

13

increases

and

the

throttle

press

ure

19

decreases

Thus

the

plug

is

balanced

imd

the

throttle

pressure

19

is

reduced

to

Ii

certain

value

against

the

throttle

pressure

6

Wheri

performing

kickdowri

the

SDV

moves

a

high

line

pressure

is

led

to

the

circuit

19

from

the

line

pressure

circuit

13

which

had

been

drained

the

plug

is

forced

toward

the

left

and

circuit

19

becomes

equal

to

the

line

pressure

13

I

W

15

I

A

TOgS

Fig

iT

13

2nd

3rd

shift

vallJe

I

When

the

governor

pressuie

IS

which

is

applied

to

the

right

side

of

the

PMV

is

low

the

valve

is

forced

toward

the

right

by

the

throttle

ines

sure

16

applied

to

the

area

differ

ence

of

the

value

and

the

spring

foice

and

t

he

circuit

from

circuit

16

to

circuit

18

is

closed

However

when

vehicle

speed

increases

andl

the

gaver

nor

pressure

15

exceeds

a

certain

level

the

governor

pressure

toward

the

left

which

is

applied

to

the

right

side

exceeds

the

spring

force

and

the

throt

tle

pressure

16

toward

thc

right

the

valve

is

depressed

loward

the

lefi

and

the

throttle

pressure

is

led

from

circuit

AT

9

16

to

circuit

18

This

throttle

pressure

18

is

applied

to

the

top

of

the

PRV

and

the

force

of

the

line

pressure

source

7

is

reduced

Contra

rily

when

the

vehicle

speed

decreases

arid

the

governor

ipressure

15

de

creases

the

force

toward

the

fight

exceeds

ithe

governor

pressure

the

valve

is

forced

back

toward

the

right

and

the

throttle

pressure

18

is

drained

to

the

spring

unit

This

valve

is

sWitched

when

the

throttle

pressure

and

the

governor

pressure

are

high

or

when

tIiey

are

both

Tow

i

i

I

11

18

16

n

r

I

I

15

AT099

Fig

AT

14

Pre

ure

modifier

valve

Vacuum

thro

le

valve

VTV

The

vacuum

t

rottle

valve

is

a

regula

tor

valve

whiCh

uses

the

line

pressure

7

for

the

pressure

source

and

regulates

the

throttle

pressure

16

I

which

is

proportioned

t

the

force

of

the

vacuum

diaphragm

The

vacuum

dia

phragm

yories

depending

on

the

engine

throt

le

condition

negative

pressure

in

the

inta

e

line

When

the

line

pressure

7

is

ap

plied

to

the

bottom

through

the

valve

hole

and

the

v

a

ve

is

forced

upward

space

from

the

line

pressure

7

to

the

throttle

pressure

16

is

dosed

and

the

space

from

the

Ihrottle

pressure

16

to

the

drain

circuit

17

is

about

to

open

In

this

operation

the

throttle

pressure

16

becomes

lower

than

the

linep

s

ureY

btthe

p

e

sur

9

iv

alenl

of

the

loss

of

space

and

Ihe

force

depressing

tlie

rod

if

the

vaeuum

diaphragm

is

balanced

wit

Ii

thethrot

tie

pressure

16

a

pplied

upward

tOlthe

bottom

When

the

erigine

torque

is

high

Ihe

negative

pressure

in

the

intake

iirie

rises

tending

ioward

atmospheric

pressure

and

the

force

of

the

rod

to

depress

the

valve

increases

As

a

result

the

valve

is

depressed

downward

the

Page 270 of 537

space

from

the

throttle

pressure

16

to

the

drain

17

decreases

and

the

space

from

the

line

pressure

7

to

Ihe

throttle

pressure

16

increases

Consequently

the

throttle

pressure

16

increases

and

the

valve

is

bal

anced

Contrarily

when

the

engine

torque

lowers

and

the

negative

pr

sure

in

the

intake

line

lowers

tending

toward

vacuum

the

force

of

the

rod

depressing

the

valve

decreases

and

the

throttle

pressure

16

also

decreases

When

pressure

regulated

by

the

throt

tle

back

p

valve

described

in

the

subsequent

paragraph

is

led

to

circuit

17

a

high

pressure

is

applied

through

the

space

from

the

circuit

17

to

the

throttle

pressure

16

Consequently

the

VTV

is

unbalanced

the

throttle

pressure

16

becomes

equal

to

the

back

up

pressure

17

and

the

valve

is

locked

upward

I

16

III

AT100

Fig

AT

15

Vacuum

throttle

valIN

Throttle

back

up

valve

TBY

Usually

this

valve

is

depressed

downward

by

the

spring

force

and

circuit

17

is

drained

upward

As

soon

as

the

lever

is

shifted

either

to

2

or

I

range

line

pressure

is

led

from

circuit

4

the

line

pressure

is

applied

to

the

area

difference

of

the

valve

the

valve

is

forced

upward

the

space

from

circuit

4

to

circuit

17

is

closed

and

with

the

space

from

circuit

Automatic

Transmission

17

to

Ihe

upper

drain

about

to

open

the

back

up

pressure

17

which

is

lower

than

the

line

pressure

4

by

the

pressure

loss

due

to

the

space

from

circuit

4

to

circuit

17

is

balanced

with

the

spring

force

Further

when

gear

is

shifted

from

2nd

to

Low

at

the

range

I

line

pressure

is

led

from

circuit

12

and

the

line

pressure

is

applied

pward

to

the

bottom

of

the

valve

through

the

valve

hole

Consequently

the

valve

is

forced

upward

and

locked

As

a

result

the

space

from

the

line

pressure

4

to

the

back

up

pressure

17

is

closed

completely

and

the

back

up

pressure

17

is

drained

upward

AT101

Fig

AT

16

Throttle

back

up

lJ

Jlve

Solenoid

downshift

valve

SDY

This

valve

is

a

transfer

valve

which

leads

the

line

pressure

7

to

13

and

transmits

the

same

to

the

FSV

and

SSV

when

a

kickdown

signal

is

re

ceived

from

the

downshift

solenoid

Usually

the

solenoid

push

rod

and

valve

are

locked

upward

by

the

spring

in

the

lower

end

and

the

circuit

from

line

pressure

4

to

line

pressure

13

is

opened

When

kickdown

is

performed

the

push

rod

operates

Ihe

valve

is

de

pressed

downward

and

the

circuit

from

line

pressure

7

to

line

pressure

13

opens

Line

pressure

13

opposes

the

governor

pressure

15

at

Ihe

SSV

and

FSV

thus

accomplishing

the

downshift

operation

AT

10

r

AT102

Fig

AT

17

Solenoid

dow

hift

valve

Second

lock

valve

SLY

This

valve

is

a

transfer

valve

which

assists

the

shift

valve

in

determining

the

fixed

2nd

speed

at

the

2

range

In

the

D

range

the

sum

of

the

spring

force

and

line

pressure

3

APplied

upward

xce

ds

the

linepres

sure

2

which

is

applied

to

the

valve

area

difference

as

a

downward

force

As

a

result

the

valve

is

locked

upward

and

the

circuit

from

line

pressure

8

to

line

pressure

9

is

opened

Consequently

the

FSV

becomes

the

2nd

speed

condition

and

line

pressure

is

led

to

the

band

servo

engaging

circuit

9

only

when

line

pressure

1

is

released

to

line

pressure

8

In

the

2

range

the

upward

force

is

retained

only

on

the

spring

and

the

downward

line

pressure

2

exceeds

the

upward

force

As

a

result

Ihe

valve

is

locked

downward

line

pressure

2

is

released

to

9

regardless

of

the

operating

condition

of

the

FSV

and

the

band

servo

is

engaged

J

2

8

ATl03

3

Fig

AT

18

Second

lock

lJ

Jlve

Page 302 of 537

I

i

0

t

V

iL

1

0

ST25570001

j

w

1

h

AT130

Fig

AT

64

Removing

hex

head

slotted

bolt

19

Blowout

low

and

reverse

brake

piston

by

directing

a

jet

of

air

into

holeJn

cylinder

See

F

igure

AT

65

Fig

AT

65

Removing

piston

20

Remove

band

servo

loosening

attaching

bolts

Note

If

difficulty

is

encountered

in

removing

retainer

direct

a

jet

of

air

toward

release

side

as

shown

in

Figure

AT

66

II

AP

fW

l

1

A

T132

Fig

AT

fiB

Removing

bond

servo

21

Pry

snap

rings

CD

from

both

ends

of

parking

brake

lever

@

and

remove

the

lever

Back

off

manual

shaft

lock

nut

ID

and

remove

manual

plale

@

and

parking

rod

CID

See

Figure

AT

67

Automatic

Transmission

Up

@

J1i

ll

J

t

i

p

lli

l

1

I

l

P

l

1

Ii

@

j

Y

L

l

rr

i

J

ry

j

AT133

Fig

AT

67

Removing

manual

plate

22

Remove

inhibitor

switch

and

manual

shaft

by

loosening

two

secur

ing

bolts

INSPECTION

Torque

c

onverter

housing

transmission

c

ase

and

rear

extension

I

Check

for

damage

or

cracking

if

necessary

replace

2

Check

for

dents

or

score

marks

on

mating

surfaces

Repair

as

nee

essary

3

If

rear

extension

bushing

is

worn

or

cracked

replace

it

as

an

assembly

of

bushing

and

rear

extension

housing

Gaskets

and

O

ring

1

Always

use

new

gaskets

when

the

units

are

to

be

disassembled

2

Check

O

rings

for

burrs

or

crack

ing

If

necessary

replace

with

new

rings

011

distributor

I

Check

for

signs

of

wear

on

seal

ring

and

ring

groove

replacing

with

new

ones

if

found

worn

beyond

use

Check

that

clearance

between

seal

ring

and

ring

groove

is

correct

If

out

of

specification

replace

whichever

is

worn

beyond

limits

Correct

clearance

is

from

0

04

to

0

16

mm

0

0016

to

0

0063

in

See

Figure

AT

68

AT

J8

j

Clearance

1

61

Seal

dng

0

j

J

I

I

AT134

ig

A

r

68

Me

q

sur

ingseal

r

ing

to

ring

groove

clearance

ASSEMBLY

Assembly

is

in

reverse

order

of

disassembly

However

observe

the

fol

lowing

assembly

notes

After

installing

piston

of

low

and

reverse

orake

assemble

thrust

spring

ring

return

spring

thrust

washer

and

one

way

clutch

inner

race

Torque

hex

head

slotted

bolt

to

L3to

1

8

kg

m

9

to

13

ft

ib

using

Hex

head

Ex

tension

ST2SS7000

ST2SS70000

Torque

Wrench

GG93010000

and

Socket

Extension

ST2S490000

ST2SS

12001

See

Figure

AT

69

ST2557000t

ST25490000

I

GG930JOOOO

A

T135

Fig

AT

69

Installing

ont

woy

clutch

inner

race

2

After

low

and

reverse

brake

has

been

assembled

measure

the

clearance

between

snap

ring

CD

and

retaining

plate

@

Select

proper

thickness

of

retaining

plate

to

give

correct

ring

to

plate

clearance

See

Figure

AT

70

Low

and

reverse

brake

clearance

0

80

to

1

05

rom

0

0315

to

0

0413

in

Page 303 of 537

Fig

AT

70

Measuring

ring

to

plate

clearance

Available

retaining

plate

Thickness

mm

in

1l

8

0

465

12

0

0472

12

2

0480

124

0488

12

6

0496

12

8

0

504

For

inspection

procedure

for

low

and

reverse

brake

see

page

AT

42

for

Assembly

3

Install

one

way

clutch

so

that

the

arrow

mark

is

toward

front

of

vehicle

It

should

be

free

to

rotate

only

in

clockwise

direction

See

Figure

AT

71

mITIJ

o

oml

AT137

Fig

AT

71

One

way

clutch

4

After

installing

rear

extension

torque

attaching

bolts

to

2

0

to

2

5

kg

m

14

to

18

ft

lb

Place

manual

lever

in

P

range

and

check

to

be

sure

that

rear

output

shaft

is

securely

blocked

5

Tighten

servo

retainer

temporari

ly

at

this

stage

of

assembly

6

Place

rear

clutch

assembly

with

needle

bearing

on

front

assembly

Automatic

Transmission

7

Install

rear

clutch

hub

and

front

planetary

carrier

as

shown

in

Figure

AT

72

AT142

Fig

AT

72

Installing

planetary

carrier

8

Assemble

connecting

shell

and

other

parts

up

to

front

Clutch

in

reverse

order

of

disassembly

AT143

Fig

AT

73

Installing

connecting

shell

9

Adjust

total

end

play

and

front

end

playas

follows

Front

end

play

L

r

L

CD

I

r

L

11

I

J

Total

end

play

@

Front

clutch

thrust

washer

2

Oil

pump

cover

3

Front

clutch

4

Rear

clutch

AT138

5

Trammission

case

6

Oil

pump

gasket

7

Oil

pump

cover

bearing

race

Fig

AT

74

End

play

1

Measure

the

distance

A

and

C

by

vernier

calipers

as

shown

in

Figure

AT

75

AT

39

i

Rear

c

clutch

N

edle

bearing

Bearing

race

I

Fig

AT

75

AT139

Measuring

the

distance

A

and

C

2

Measure

the

distance

B

and

D

of

oil

pump

cover

as

shown

in

Figure

AT

76

I

L

I

Oiipi

mp

AT140

Fig

AT

76

Measuring

the

distance

B

and

D

Adjustment

of

total

end

play

Select

oil

pump

cover

bearing

race

by

calculating

the

following

formula

TT

A

B

W

where

T

T

Required

thickness

of

oil

pump

cover

bearing

race

mm

in

A

Measured

distance

A

mm

in

B

Measured

distance

B

mm

in

W

Thickness

of

bearing

race

temporarily

inserted

mm

in

Available

oil

pump

cover

bearing

race

Thickness

mm

in

1

2

0

047

I

4

0

055

1

6

0

063

1

8

0

071

2

0

0

079

2

2

0

087

Specified

total

end

play

0

25100

50

mm

0

0098

to

0

0197

in

Page 313 of 537

In

these

cases

the

transmission

must

be

repaired

Notes

a

In

checking

oil

level

use

special

paper

cloth

to

handle

the

level

gauge

and

be

careful

not

to

let

the

scraps

of

paper

and

cloth

stick

to

the

gauge

b

Insert

the

gauge

fully

and

take

it

out

quickly

before

splashing

oil

adheres

to

the

gauge

Then

observe

the

level

c

Use

automatic

transmission

fluid

having

DEXRON

identifications

only

in

the

3N71B

automatic

trans

mission

d

Pay

attention

because

the

oil

to

be

used

differs

from

that

used

in

the

Nissan

Full

Automatic

TranSJTIis

sion

3N71A

Never

mix

the

oils

INSPECTION

AND

REPAIR

OF

OIL

LEAKAGE

When

oil

leakage

takes

place

the

portion

near

the

leakage

is

covered

with

oil

presenting

difficulty

in

detecting

the

spot

Therefore

the

places

where

oil

seals

and

gaskets

are

equipped

are

enumerated

below

11

Converter

housing

Rubber

ring

of

oil

pump

housing

Oil

seal

of

oil

pump

housing

Oil

seal

of

engine

crankshaft

Bolts

of

converter

housing

to

case

2

Trarismission

and

rear

extension

Junction

of

transm

ss

ion

and

rear

extension

J

Oil

cooler

tube

connectors

Oil

pan

Oil

pressure

inspection

holes

Refer

to

Figure

AT

il2

Mounting

portion

of

vacuum

dia

phragm

and

downshift

solenoid

Breather

and

oil

charging

pipe

Speedometer

pinion

sleeve

Oil

se

l

of

rear

extension

To

exactly

locate

the

place

of

oil

leaka

le

proceed

as

follows

Place

the

vehicle

in

a

pit

and

by

sampling

the

leaked

oil

determine

if

it

is

the

torque

converter

oil

The

torque

converter

oil

has

a

color

like

r

d

wine

So

it

is

easily

distinguished

from

engine

oil

or

gear

oil

Automatic

rransmission

Wipe

off

the

leaking

oil

and

dust

and

deiecl

the

spol

of

oil

eakage

l

se

nonflammable

organic

solve

t

s

ch

as

carbon

tetrachloride

for

wiping

Raise

the

oil

tcmperalure

by

op

erating

the

engine

and

shift

the

lever

to

D

to

increase

the

oil

pressure

The

spot

of

oil

lcakage

will

then

be

found

more

easily

Note

As

oil

leakage

from

the

breaih

er

does

not

take

place

except

when

running

at

high

speed

it

is

impos

sible

to

locate

this

leakage

with

vehicle

stationary

CHECKING

ENGINE

IDLING

REVOLUTION

The

engine

idling

revolution

should

be

properly

adjusted

If

the

engine

revolution

is

too

low

the

engine

does

not

operate

smoothly

and

if

too

high

a

strong

shock

or

creep

develops

when

changing

over

from

N

to

D

or

R

CHECKING

AND

ADJUSTING

KICK

DOWN

SWITCH

AND

DOWNSHIFT

SOLENOID

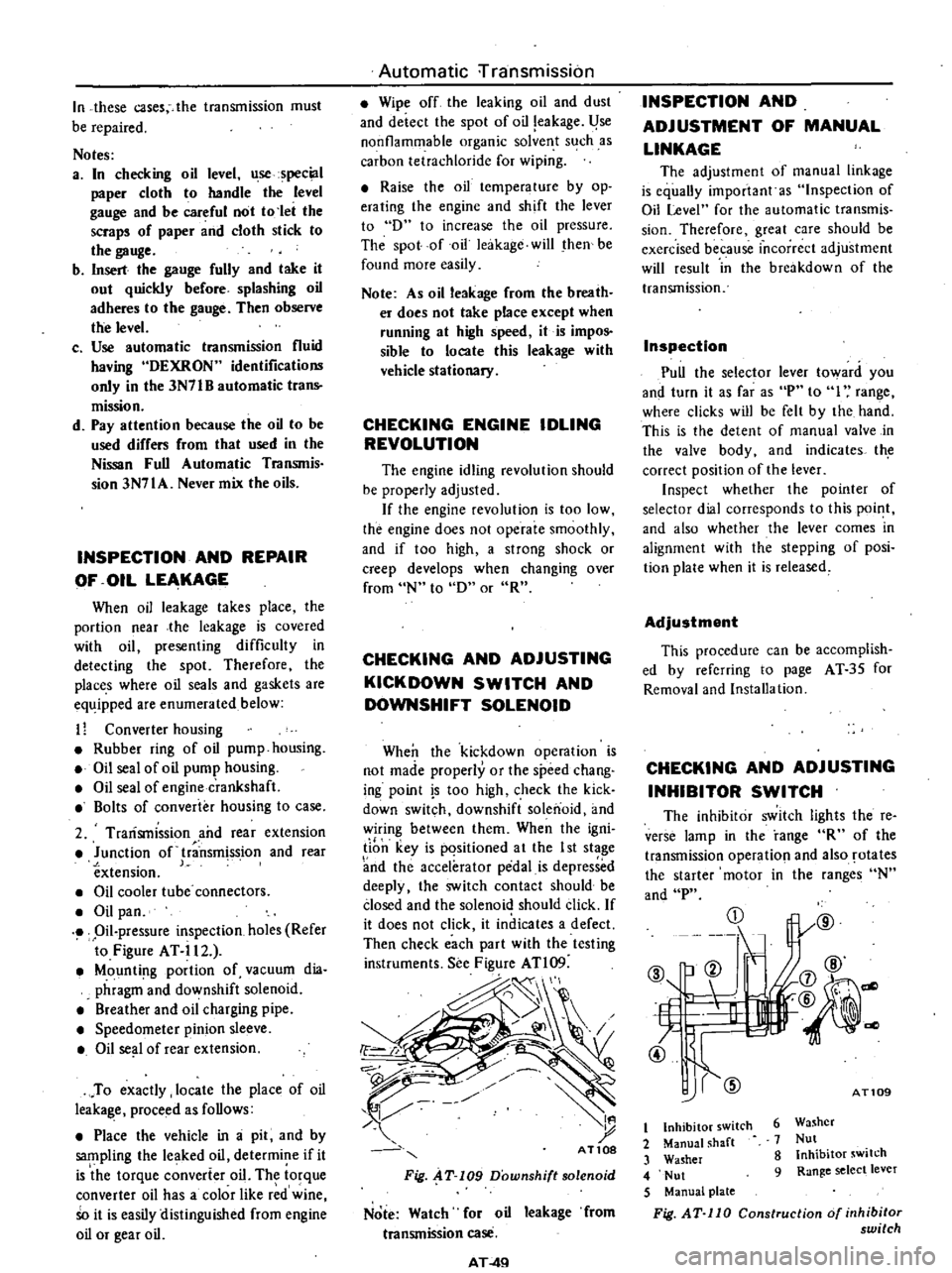

When

the

kickdown

operation

is

not

made

properly

or

the

speed

chang

ing

point

s

too

high

check

the

kick

down

switch

downshift

solenoid

and

wiring

between

them

When

the

igni

li

n

key

is

pqsitioned

a

t

the

I

st

stage

nd

the

accelerator

pedal

is

depressed

deeply

the

switch

contact

should

be

closed

and

the

solenoid

should

click

If

it

does

not

click

it

indicates

a

defect

Then

check

each

part

with

the

testing

instruments

See

Figure

ATl09

d

I

t

AT10S

Fig

AT

109

Downshift

solenoid

Note

Watch

for

oil

leakage

from

transmission

case

AT

4Q

INSPECTION

AND

ADJUSTMENT

OF

MANUAL

LINKAGE

The

adjustmcnt

of

manual

linkage

is

equaUy

important

as

Inspection

of

Oil

Level

for

the

automatic

transmis

sion

Thereforc

great

care

should

be

exercised

because

incorrect

adjustment

will

rcsult

in

the

brcakdown

of

the

transmission

Inspection

Pull

the

selector

lever

toward

you

and

turn

it

as

far

as

P

to

I

range

wherc

clicks

will

be

felt

by

the

hand

This

is

the

detcnt

of

manual

valve

in

the

valve

body

and

indicates

th

correct

position

of

the

lever

Inspect

whether

the

pointer

of

selector

dial

corresponds

to

this

point

and

also

whether

the

lever

comes

in

alignment

with

the

stepping

of

posi

tion

plate

when

it

is

released

Adjustment

This

procedure

can

be

accomplish

ed

by

refcrring

to

page

AT

35

for

Removal

and

Installa

tion

CHECKING

AND

ADJUSTING

INHIBITOR

SWITCH

The

inhibitor

switch

lights

the

re

verse

lamp

in

the

range

R

of

the

transmission

operatio

l

and

also

rotates

the

starter

motor

in

the

ranges

N

and

P

CD

@

b

ell

If

L

t

7

4l

@

1l

j7

@

@

@

dl

AT109

6

Washer

7

Nut

8

Inhibitor

switch

9

Range

select

lever

t

Inhibitor

switch

2

Manual

shaft

3

Washer

4

Nut

5

Manual

plate

Fig

AT

110

Construction

of

inhibitor

switch

Page 353 of 537

spindle

and

torque

bolt

to

10

3

to

12

1

kg

m

75

to

88

ft

lb

Bend

lock

plate

to

engaged

flats

on

boll

head

Note

When

disassembled

discard

used

lock

plate

5

Pack

grea

to

the

upP

r

and

lower

bushings

on

knuckle

spindle

until

grease

c

omes

out

from

gr

ease

seal

6

Fill

wheel

hub

and

cap

with

grease

up

to

the

described

level

See

Figure

F

A

4

FA141

Fig

FA

4

Gre

ing

wheel

hub

7

Pack

roller

and

cone

assembly

and

the

cavity

of

grease

seal

lip

with

grease

8

Coat

grease

to

the

thread

of

knuckle

spindle

bearing

washer

and

bearing

lock

nul

9

Secure

wheel

hub

bearings

bear

ing

washer

and

spindle

nut

on

knuckle

spindle

and

adju

t

bearing

preload

referring

to

the

paragraph

Wheel

bearing

adjustment

Note

Be

sure

to

obtain

correct

pre

load

on

wheel

bearings

for

the

pu

rpose

of

ving

their

long

life

taking

care

to

keep

wheel

be8rlngs

grease

seal

bearing

washer

and

spin

dle

nut

clean

when

installing

them

WHEEL

BEARING

D

TM

NT

Wrong

adjustment

of

wheel

bear

ing

causes

abnonnal

wear

and

score

on

the

bearings

and

knuckle

spindle

Front

Axle

Front

Suspension

To

attain

proper

preload

on

wheel

bearings

proceed

the

following

opera

tions

I

Torque

spindle

nut

to

3

0

to

3

S

kg

m

22

to

25

ft

lb

using

torque

wrench

FA227

Fig

FA

5

Tightening

apindle

nut

2

Rotate

wheel

hub

a

few

turns

clockwise

and

counterclockwise

to

seat

bearings

Then

retighten

spindle

nut

to

the

same

tightening

torque

Be

certain

to

rotate

hub

smoothly

3

Back

off

spindle

nut

in

range

from

40

to

70

degrees

Locate

adjust

ing

cap

on

spindle

nut

so

as

to

align

the

castellation

on

the

cap

with

the

cotter

pin

hole

in

the

spindle

4

Check

the

hub

rotation

If

hub

rotates

properly

measure

bearing

rota

tion

starting

torque

If

measured

torque

is

deviated

from

the

specified

value

r

place

beari

gs

r

re

dju

st

The

starting

torque

can

be

mea

sured

by

a

spring

balance

as

shown

in

Figure

F

A

6

Spring

balance

indication

at

hub

bolt

New

bearing

2

1

kg

4

Ib

o

ess

Used

bearing

1

0

kg

2

2

lb

or

less

Notes

a

When

measuring

the

starting

force

pull

the

spring

balance

toward

tan

gential

direction

against

normal

line

connected

between

hub

boll

and

spindle

center

b

Axial

play

is

permissible

to

exist

in

0

1

mm

0

004

in

or

less

FA

4

fA22S

Fig

FA

6

Mea

uring

bearing

rotation

atarting

torque

S

Install

a

new

cotter

pin

Bend

the

ends

of

coller

pin

around

the

castel

lated

flange

of

adjusting

cap

Then

install

hub

cap

DISASSEMBLY

AND

ASSEMBLY

Knuckle

spindle

I

Drive

spindle

bushing

and

grease

seal

out

of

knuckle

spindle

with

KiTlg

Pin

Bush

Drift

ST3S380000

Discard

bushing

and

grease

seal

when

disas

sembled

2

After

cleaning

king

pin

bores

thoroughly

install

bushing

carefully

by

using

the

above

special

tpol

Posi

tion

bushing

in

accordance

With

the

instructions

fIlled

in

Figure

F

A

7

and

FA

8

34

mm

1

34

in

Upper

side

in

lower

boss

I

I

1

II

I

Pla

ce

this

position

in

line

with

grease

nipple

hole

Upper

side

in

upper

boss

FA229

Fig

FA

7

King

pin

bu

hing

Page 409 of 537

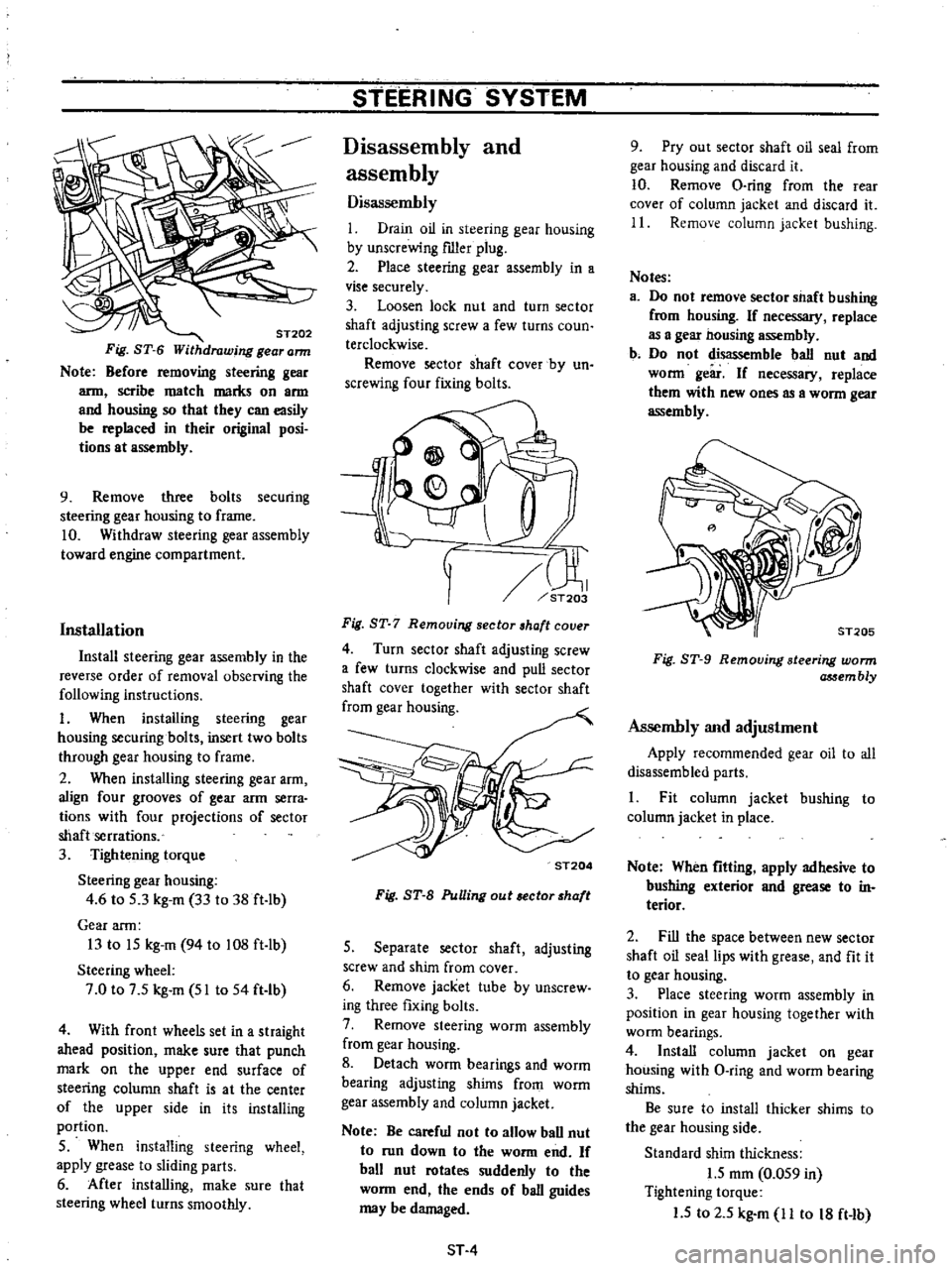

ST202

Fig

ST

6

Withdrawing

gear

ann

Note

Before

removing

steering

gear

arm

scribe

match

marks

on

arm

and

housing

so

that

they

can

easily

be

replaced

in

their

original

posi

tions

at

assembly

9

Remove

three

bolts

securing

steering

gear

housing

to

frame

10

Withdraw

steering

gear

assembly

toward

engine

compartment

Installation

Install

steering

gear

assembly

in

the

reverse

order

of

removal

observing

the

following

instructions

I

When

installing

steering

gear

housing

securing

bolts

insert

two

bolts

through

gear

housing

to

frame

2

When

installing

steering

gear

arm

align

four

grooves

of

gear

arm

serra

tions

with

four

projections

of

sector

shaft

serrations

3

Tightening

torque

Steering

gear

housing

4

6

to

S

3

kg

m

33

to

38

ft

lb

Gear

arm

13

to

IS

kg

m

94

to

108

ft

lb

Steering

wheel

7

0

to

7

S

kg

m

51

to

54

ft

Ib

4

With

front

wheels

set

in

a

straight

ahead

position

make

sure

that

punch

mark

on

the

upper

end

surface

of

steering

column

shaft

is

at

the

center

of

the

upper

side

in

its

installing

portion

S

When

installing

steering

wheel

apply

grease

to

sliding

parts

6

After

installing

make

sure

that

steering

wheel

turns

smoothly

STEERING

SYSTEM

Disassembly

and

assembly

Disassembly

I

Drain

oil

in

steering

gear

housing

by

unscrewing

fIller

plug

2

Place

steering

gear

assembly

in

a

vise

securely

3

Loosen

lock

nut

and

turn

sector

shaft

adjusting

screw

a

few

turns

coun

terclockwise

Remove

sector

shaft

cover

by

un

screwing

four

fixing

bolts

rn

ST203

Fig

ST

7

Remouing

sector

haft

couer

4

Turn

sector

shaft

adjusting

screw

a

few

turns

clockwise

and

pull

sector

shaft

cover

together

with

sector

shaft

from

gear

housing

ST204

Fig

ST

B

PuUing

out

ector

haft

S

Separate

sector

shaft

adjusting

screw

and

shim

from

cover

6

Remove

jacket

tube

by

unscrew

ing

three

fixing

bolts

7

Remove

steering

worm

assembly

from

gear

housing

8

Detach

worm

bearings

and

worm

bearing

adjusting

shims

from

worm

gear

assembly

and

column

jacket

Note

Be

careful

not

to

allow

ball

nut

to

run

down

to

the

worm

end

If

ball

nut

rotates

suddenly

to

the

worm

end

the

ends

of

ball

guides

may

be

damaged

ST

4

9

Pry

out

sector

shaft

oil

seal

from

gear

housing

and

discard

it

10

Remove

O

ring

from

the

rear

cover

of

column

jacket

and

discard

it

11

Remove

column

jacket

bushing

Notes

a

Do

not

remove

sector

shaft

bushing

from

housing

If

necessary

replace

as

a

gea2

nousing

assembly

b

Do

not

disassemble

ball

nut

and

worm

geir

If

necessary

replace

them

with

new

ones

as

a

worm

gear

assembly

Fig

ST

9

Removing

steering

worm

assem

bly

Assembly

and

adjustment

Apply

recommended

gear

oil

to

all

disassembled

parts

1

Fit

column

jacket

bushing

to

column

jacket

in

place

Note

When

fitting

apply

adhesive

to

bushing

exterior

and

grease

to

in

terior

2

Fill

the

space

between

new

sector

shaft

oil

seal

lips

with

grease

and

fit

it

to

gear

housing

3

Place

steering

worm

assembly

in

position

in

gear

housing

together

with

worm

bearings

4

Install

column

jacket

on

gear

housing

with

O

ring

and

worm

bearing

shims

Be

sure

to

install

thicker

shims

to

the

gear

housing

side

Standard

shim

thickness

1

5

mOl

0

OS9

in

Tightening

torque

1

5

to

2

S

kg

m

11

to

18

ft

Ib

Page 410 of 537

Available

worm

bearing

adjusting

shim

No

Thickness

mOl

in

I

0

762

0

0300

2

0

2S4

0

0100

3

0

127

0

0050

4

O

OSO

0

0020

5

Adjust

the

worm

bearing

preload

with

Preload

Gauge

ST3127S000

by

selecting

suitable

bearing

shims

so

that

the

initial

turning

torque

of

steering

column

is

the

specified

value

Initial

turning

torque

of

steering

column

shaft

New

worm

bearing

4

0

to

6

0

kg

em

S6

to

83

in

oz

Used

worm

bearing

2

4

to

4

4

kg

em

33

to

61

in

oz

6

Insert

adjusting

screw

into

the

T

shaped

groove

at

the

sector

shaft

head

and

adjust

the

end

play

between

sector

shaft

and

adjusting

screw

until

it

is

within

0

01

to

0

03

mm

0

0004

to

0

0012

in

by

choosing

suitable

adjusting

shims

Available

sector

shaft

adjusting

screw

shim

No

Thickness

mOl

in

I

1

57S

0

0620

2

1

550

0

0610

3

1

525

0

0600

4

I

S00

0

OS91

S

1

475

0

0581

6

I

4S0

0

0571

7

Rotate

ball

nut

by

hand

until

it

is

in

the

center

of

its

trovel

then

install

sector

shaft

together

with

adjusting

screw

in

gear

housing

ensuring

that

the

center

gear

of

sector

shaft

engages

with

that

of

ball

nut

STEERING

SYSTEM

8

Install

sector

shaft

cover

to

gear

housing

Be

sure

to

apply

sealant

to

each

face

of

sector

shaft

cover

packing

when

installing

cover

9

By

turning

adjusting

screw

coun

terclockwise

attach

sector

shaft

cover

to

gear

housing

and

then

temporarily

secure

it

with

its

fixing

bolts

10

Pull

sector

shaft

toward

cover

approximately

2

to

3

mOl

0

08

to

0

12

in

by

turning

adjusting

screw

counterclockwise

and

tighten

sector

shaft

cover

fixing

bolts

to

l

S

to

2

5

kg

m

11

to

18

ft

Ib

II

Push

sector

shaft

against

ball

nut

gear

by

gradually

turning

adjusting

screw

clockwise

until

sector

shaft

gear

lightly

meshes

with

ball

nut

gear

and

then

temporarily

secure

adjusting

screw

with

lock

nut

12

Install

gear

arm

to

sector

shaft

and

move

sector

shaft

several

times

from

the

side

of

gear

arm

and

make

sure

that

it

turns

smoothly

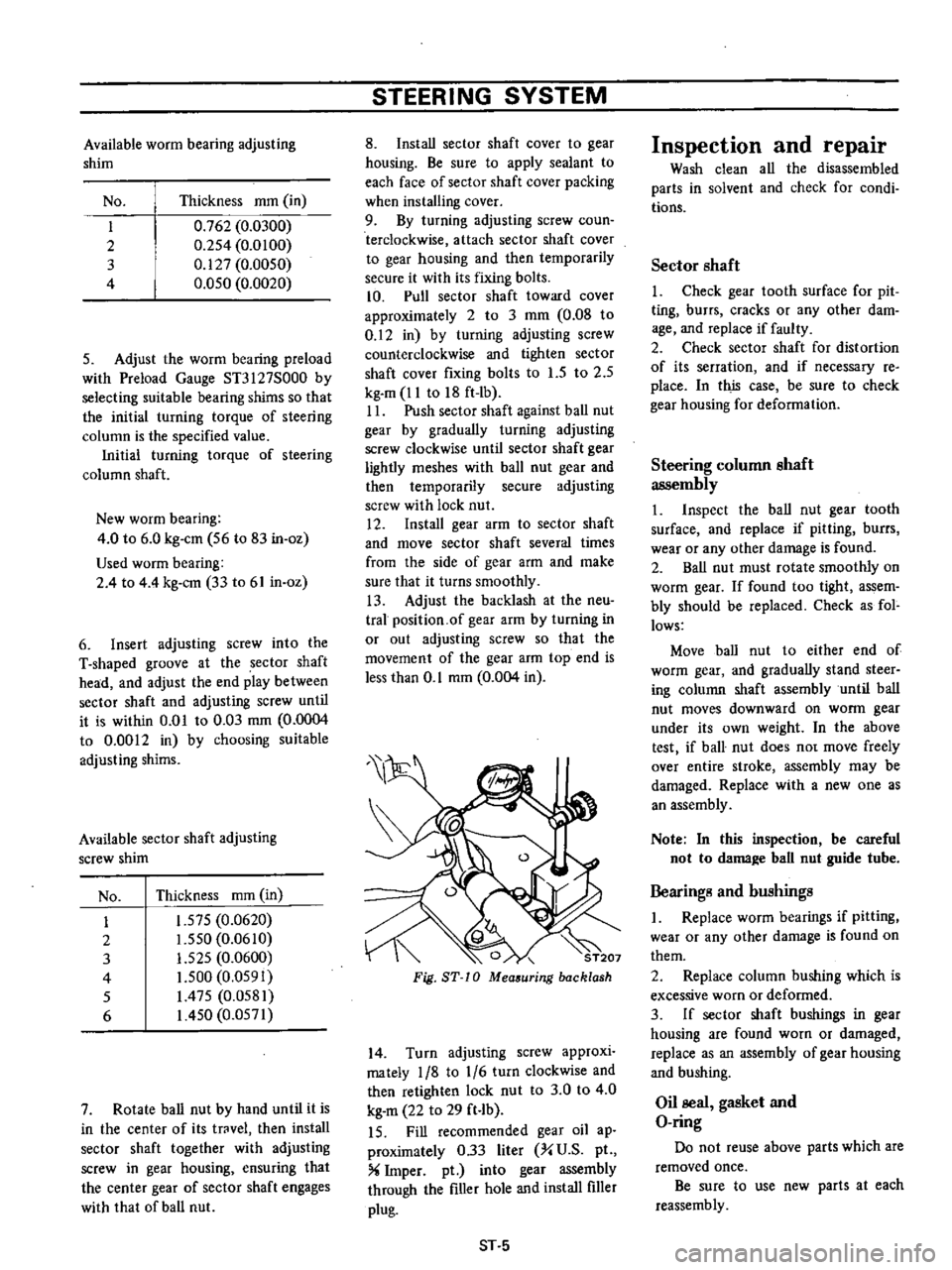

13

Adjust

the

backlash

at

the

neu

tral

position

of

gear

arm

by

turning

in

or

out

adjusting

screw

so

that

the

movement

of

the

gear

arm

top

end

is

less

than

0

1

mOl

0

004

in

0

ST207

Fig

ST

10

Mea

uring

backlash

14

Turn

adjusting

screw

approxi

mately

1

8

to

1

6

turn

clockwise

and

then

retighten

lock

nut

to

3

0

to

4

0

kg

m

22

to

29

ft

Ib

IS

Fill

recommended

gear

oil

ap

proximately

0

33

liter

X

U

S

pI

X

Imper

pt

into

gear

assembly

through

the

filler

hole

and

install

filler

plug

ST

5

Inspection

and

repair

Wash

clean

all

the

disassembled

parts

in

solvent

and

check

for

condi

tions

Sector

shaft

1

Check

gear

tooth

surface

for

pit

ting

burrs

cracks

or

any

other

dam

age

and

replace

if

faulty

2

Check

sector

shaft

for

distortion

of

its

serration

and

if

necessary

re

place

In

this

case

be

sure

to

check

gear

housing

for

deformation

Steering

column

shaft

assembly

1

Inspect

the

ball

nut

gear

tooth

surface

and

replace

if

pitting

burrs

wear

or

any

other

damage

is

found

2

Ball

nut

must

rotate

smootWy

on

worm

gear

If

found

too

tight

assem

bly

should

be

replaced

Check

as

fol

lows

Move

ball

nut

to

either

end

of

worm

gear

and

gradually

stand

steer

ing

column

shaft

assembly

until

ball

nut

moves

downward

on

worm

gear

under

its

own

weight

In

the

above

test

if

ball

nut

does

no

move

freely

over

entire

stroke

assembly

may

be

damaged

Replace

with

a

new

one

as

an

assembly

Note

In

this

inspection

be

careful

not

to

dama

e

ball

nut

guide

tube

Bearings

and

bushings

I

Replace

worm

bearings

if

pitting

wear

or

any

other

damage

is

found

on

them

2

Repiace

column

bushing

which

is

excessive

worn

or

deformed

3

If

sector

shaft

bushings

in

gear

housing

are

found

worn

or

damaged

replace

as

an

assembly

of

gear

housing

and

bushing

Oil

seal

gasket

and

O

ring

Do

not

reuse

above

parts

which

are

removed

once

Be

sure

to

use

new

parts

at

each

reassembly

Page 423 of 537

Engine

Control

Fuel

Exhaust

Systems

REMOVAL

Non

California

models

I

Remove

exhaust

tube

U

bolt

clamp

2

Break

sealant

off

at

front

tube

to

main

muffler

connectio

n

3

Remove

rear

tube

mounting

bolt

and

remove

muffler

assembly

with

rear

tube

4

Remove

front

tube

heat

insulator

5

Remove

nuts

securing

front

tube

to

exhaust

manifold

and

remove

front

tube

mounting

bolts

Then

detach

front

tube

When

disconnecting

the

exhaust

tube

connections

pay

attention

to

the

following

point

I

Break

old

se

lant

off

at

t

1e

connection

by

lightly

tapping

around

the

tube

witlJ

a

hammer

and

twisting

muffler

See

Figures

FE

7

and

FE

8

2

Using

a

rubber

hammer

tap

on

the

front

end

of

muffler

while

pushing

it

toward

rear

The

mumer

assembly

can

then

be

taken

out

See

Figure

FE

9

FE187

Fig

FE

7

Breaking

Bealant

FEl88

Fig

FE

8

Twisting

muffler

ijl

4

FE189

Fig

FE

9

Tapping

muffler

with

Q

rubber

hammer

California

models

I

Remove

all

heat

insulators

2

Remove

exhaust

tube

U

bolt

clamp

3

Break

sealant

off

at

center

tube

to

main

muffler

connection

4

Remove

rear

tube

mounting

bolt

and

remove

muffler

assembly

with

rear

tube

5

Remove

bolts

securing

catalytic

converter

to

center

tube

and

remove

center

tube

mounting

bolts

Then

detach

center

tube

6

Remove

bolts

and

nuts

securing

catalytic

converter

to

front

tube

and

detach

catalytic

converter

7

Remove

nuts

securing

front

tube

to

exhaust

manifold

and

remove

front

tube

mounting

bolts

Then

detach

front

tube

INSPECTION

I

Check

muffler

and

tubes

for

cracks

Qr

damage

Replace

any

part

that

is

damaged

beyond

limits

2

Replace

bracket

and

mounting

insulator

that

are

cracked

fatigued

or

sweated

FE

8

INSTALLATION

Install

the

exhaust

system

assembly

in

reverse

order

of

removal

Observe

the

following

Notes

a

Insert

front

tube

until

it

touches

emboss

b

When

there

is

110

clearance

between

front

tube

and

floor

or

propeUer

shaft

turn

tube

along

center

line

of

tube

in

the

manifold

connecting

unit

and

obtain

proper

clearance

c

Check

all

tube

connections

for

ex

haust

gas

leaks

and

entire

system

for

unusual

noises

with

engine

running

d

After

installation

check

that

mounting

brackets

and

mounting

rubbers

are

free

from

undue

stress

If

any

of

the

above

parts

is

not

installed

properly

excessive

noises

or

vibrations

may

be

transmitted

to

the

vehicle

body

e

Tightening

torque

Exhaust

manifold

to

front

tube

nut

1

9

to

2

5

kg

m

14

to

18

ft

lb

U

bolt

securing

nut

1

9

to

2

1

kg

m

14

to

15

ft

lb

Mounting

bracket

bolt

1

0

to

1

2

kg

m

710

9

ft

lb

Front

tube

mounting

bracket

bolt

california

models

1

9

to

2

1

kg

m

14

to

15

ft

lb

Catalytic

converter

to

front

and

center

tube

bolt

California

models

3

2

to

4

3

kg

m

23

to

31

ft

Ib

If

exhaust

tubes

are

separated

at

connection

t

renew

muffler

assembly

etc

use

the

Genuine

Nissan

Sealant

Exhaust

Sealant

Kit

20720

N2225

or

equivalent

See

Figure

FE

IO

to

eliminate

gas

leakage

at

the

joint

Be

sure

to

observe

the

following

Page 440 of 537

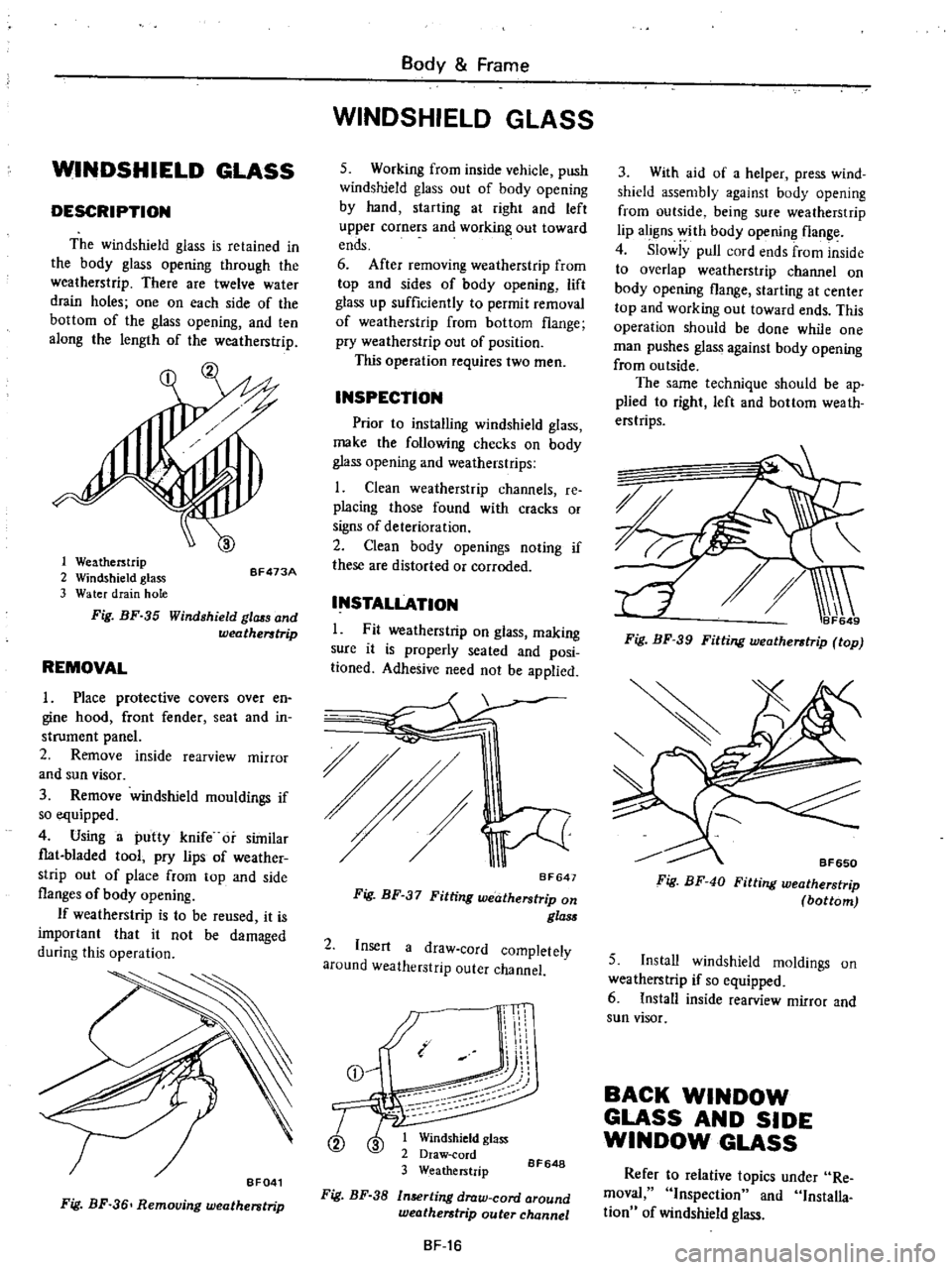

WINDSHIELD

GLASS

DESCRIPTION

The

windshield

glass

is

retained

in

the

body

glass

opening

through

the

weatherstrip

There

are

twelve

water

drain

holes

one

on

each

side

of

the

bottom

of

the

glass

opening

and

ten

along

the

length

of

the

weatherstrip

1

Weatherstrip

2

Windshield

glass

3

Water

drain

hole

Fig

BF

35

Windshield

glass

and

weatherstrip

BF473A

REMOVAL

1

Place

protective

covers

over

en

gine

hood

front

fender

seat

and

in

strument

panel

2

Remove

inside

rearview

mirror

and

sun

visor

3

Remove

windshield

mouldings

if

so

equipped

4

Using

a

putty

knife

or

similar

flat

bladed

tool

pry

lips

of

weather

strip

out

of

place

from

top

and

side

flanges

of

body

opening

If

weatherstrip

is

to

be

reused

it

is

important

that

it

not

be

damaged

during

this

operation

BF041

Fig

BF

36

Removing

weatherstrip

Body

Frame

WINDSHIELD

GLASS

5

Working

from

inside

vehicle

push

windshield

glass

out

of

body

opening

by

hand

starting

at

right

and

left

upper

COIners

and

working

out

toward

ends

6

After

removing

weatherstrip

from

top

and

sides

of

body

opening

lift

glass

up

sufficiently

to

permit

removal

of

weatherstrip

from

bottom

flange

pry

weatherstrip

out

of

position

This

operation

requires

two

men

INSPECTION

Prior

to

installing

windshield

glass

make

the

following

checks

on

body

glass

opening

and

weatherstrips

I

Clean

weatherstrip

channels

re

placing

those

found

with

cracks

or

signs

of

deterioration

2

Clean

body

openings

noting

if

these

are

distorted

or

corroded

INSTALLATION

L

Fit

weatherstrip

on

glass

making

sure

it

is

properly

seated

and

posi

tioned

Adhesive

need

not

be

applied

0

BF641

Fig

BF

37

Fitting

weatherstrip

on

glass

2

Insert

a

draw

cord

completely

around

weatherstrip

outer

channel

Q

i

I

dYii

1

Windshield

glass

2

Draw

cord

3

Weatherstrip

Fig

BF

38

In8erting

draw

cord

around

weatherstrip

outer

channel

8F648

BF

16

3

With

aid

of

a

helper

press

wind

shield

assembly

against

body

opening

from

outside

being

sure

weatherstrip

lip

aligns

ith

body

opening

flange

4

Slowly

pull

cord

ends

from

inside

to

overlap

weatherstrip

channel

on

body

opening

flange

starting

at

center

top

and

working

out

toward

ends

This

operation

should

be

done

while

one

man

pushes

glass

against

body

opening

from

outside

The

same

technique

should

be

ap

plied

to

right

left

and

bottom

wea

th

erstrips

Fig

BF

39

Fitting

weatherstrip

top

BF650

Fig

BF

40

Fitting

weatherstrip

bottom

5

Install

windshield

moldings

on

weatherstrip

if

so

equipped

6

Install

inside

rearview

mirror

and

sun

visor

BACK

WINDOW

GLASS

AND

SIDE

WINDOW

GLASS

Refer

to

relative

topics

under

Re

moval

Inspection

and

Installa

tion

of

windshield

glass