fuel pressure DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 21 of 537

Yellow

line

Spark

delay

valve

to

distributor

Spark

delay

valve

to

vacuum

tube

Distributor

to

vacuum

tube

Vacuum

tube

to

carburetor

Vacuum

tube

to

canister

Green

line

Anti

backfire

valve

to

intake

mani

fold

Air

control

valve

to

emergency

air

relief

valve

Intake

manifold

to

vacuum

hose

connector

Intake

manifold

to

canister

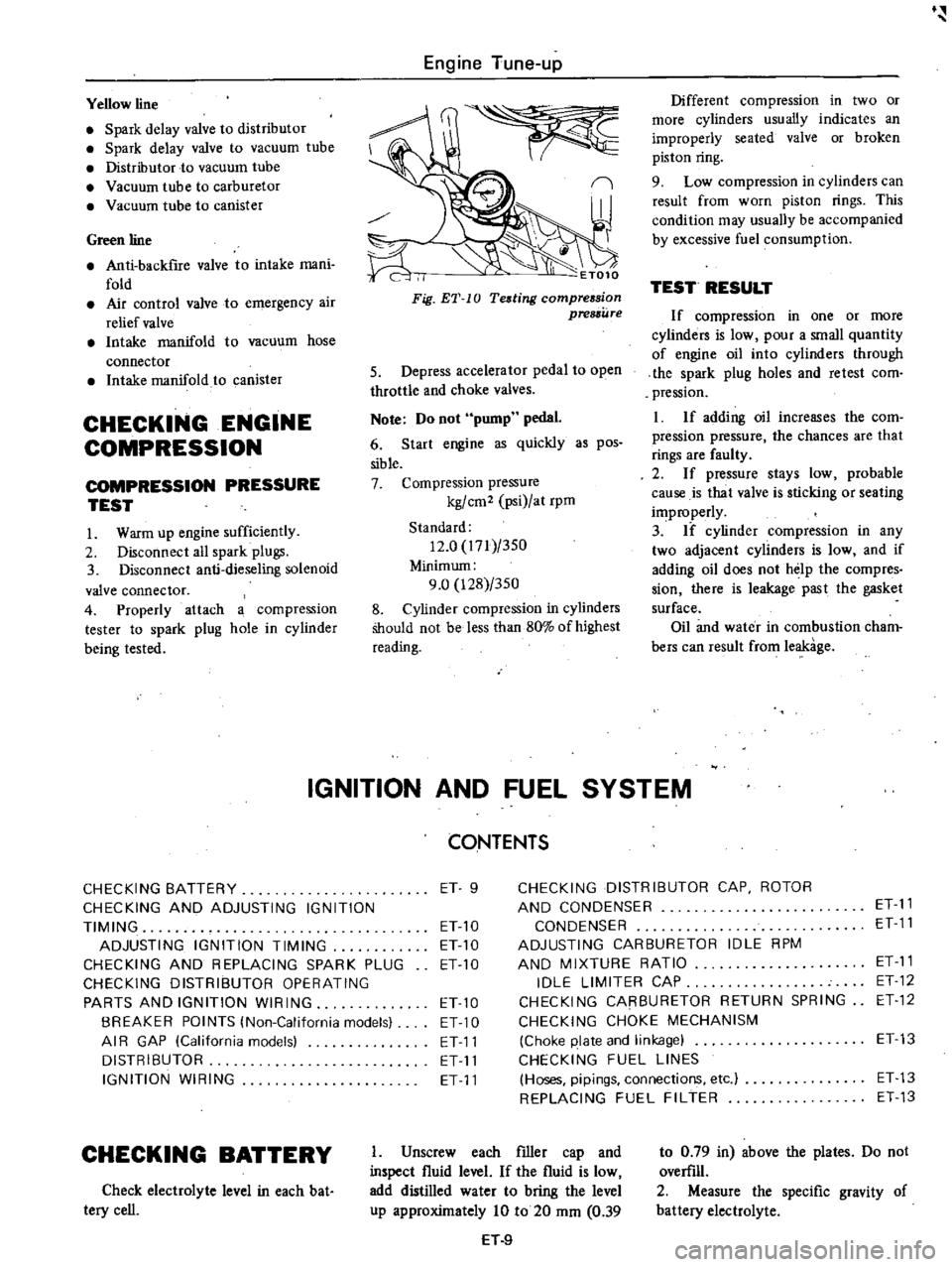

CHECKING

ENGINE

COMPRESSION

COMPRESSION

PRESSURE

TEST

I

Warm

up

engine

sufficiently

2

Disconnect

all

spark

plugs

3

Disconnect

anti

dieseling

solenoid

valve

connector

4

Properly

attach

a

compression

tester

to

spark

plug

hole

in

cylinder

being

tested

Engine

Tune

up

I

ET010

Different

compression

in

two

or

more

cylinders

usually

indicates

an

improperly

seated

valve

or

broken

piston

ring

9

Low

compression

in

cylinders

can

result

from

worn

piston

rings

This

condition

may

usually

be

accompanied

by

excessive

fuel

consumption

TEST

RESULT

If

compression

in

one

or

more

cylinders

is

low

pour

a

small

quantity

of

engine

oil

into

cylinders

through

the

spark

plug

holes

and

retest

com

pression

I

If

adding

oil

increases

the

com

pression

pressure

the

chances

are

that

rings

are

faulty

2

If

pressure

stays

low

probable

cause

is

that

valve

is

sticking

or

seating

improperly

3

If

cylinder

compression

in

any

two

adjacent

cylinders

is

low

and

if

adding

oil

does

not

help

the

compres

sian

there

is

leakage

past

the

gasket

surface

Oil

and

water

in

combustion

cham

bers

can

result

from

leakage

IGNITION

AND

FUEL

SYSTEM

Fig

ET

10

Teding

compression

pressure

5

Depress

accelerator

pedal

to

open

throttle

and

choke

valves

Note

Do

not

pump

pedal

6

Start

engine

as

quickly

as

pos

sible

7

Compression

pressure

kg

cm2

psi

at

rpm

Standard

12

0

171

350

Minimum

9

0

128

350

8

Cylinder

compression

in

cylinders

Should

not

be

less

than

80

of

highest

reading

CONTENTS

CHECKING

BATTERY

ET

9

CHECKING

DISTRIBUTOR

CAP

ROTOR

CHECKING

AND

ADJUSTING

IGNITION

AND

CONDENSER

ET

11

TIMING

ET

10

CONDENSER

ET

11

ADJUSTING

IGNITION

TIMING

ET10

ADJUSTING

CARBURETOR

IDLE

RPM

CHECKING

AND

REPLACING

SPARK

PLUG

ETlO

AND

MIXTURE

RATIO

ET

11

CHECKING

DISTRIBUTOR

OPERATING

IDLE

LIMITER

CAP

ET

12

PARTS

AND

IGNITION

WIRING

ETlO

CHECKING

CARBURETOR

RETURN

SPRING

ET

12

BREAKER

POINTS

lNon

California

models

ET

10

CHECKING

CHOKE

MECHANISM

AI

R

GAP

lCalifornia

models

ET11

Choke

plate

and

linkage

ET13

DISTRIBUTOR

ET

11

CHECKING

FUEL

LINES

IGNITION

WIRING

ET

11

Hoses

pipings

connections

etc

ET

13

REPLACING

FUEL

FILTER

ET

13

CHECKING

BATTERY

Check

electrolyte

level

in

each

bat

tery

cell

I

Unscrew

each

filler

cap

and

inspect

fluid

level

If

the

fluid

is

low

add

distilled

water

to

bring

the

level

up

approximately

10

to

20

mm

0

39

H

9

to

0

79

in

above

the

plates

Do

not

overfill

2

Measure

the

specific

gravity

of

battery

electrolyte

Page 25 of 537

CHECKING

CHOKE

MECHANISM

Choke

plate

and

linkage

1

Check

choke

valve

and

mech

anism

for

free

operation

and

clean

or

replace

if

necessary

A

binding

can

result

from

petroleum

gum

formation

on

choke

shaft

or

from

damage

2

Check

bimetal

cover

setting

Index

mark

on

bimetal

cover

is

usually

set

at

center

of

scale

Note

Always

align

the

index

mark

on

bimetal

cover

with

the

center

index

mark

on

choke

housing

3

Every

day

before

starting

engine

depress

the

accelerator

P

dal

to

see

if

choke

valve

is

closed

automatically

If

it

fails

to

be

closed

the

chances

are

that

link

movement

is

unsmooth

Engine

Tune

up

or

that

bimetal

is

out

of

order

Refer

to

Carburetor

in

Section

EF

CHECKING

FUEL

LINES

Hoses

pipings

connections

etc

Check

fuel

lines

for

loose

con

nections

cracks

and

deterioration

Retighten

loose

connections

and

re

place

any

damaged

or

deformed

parts

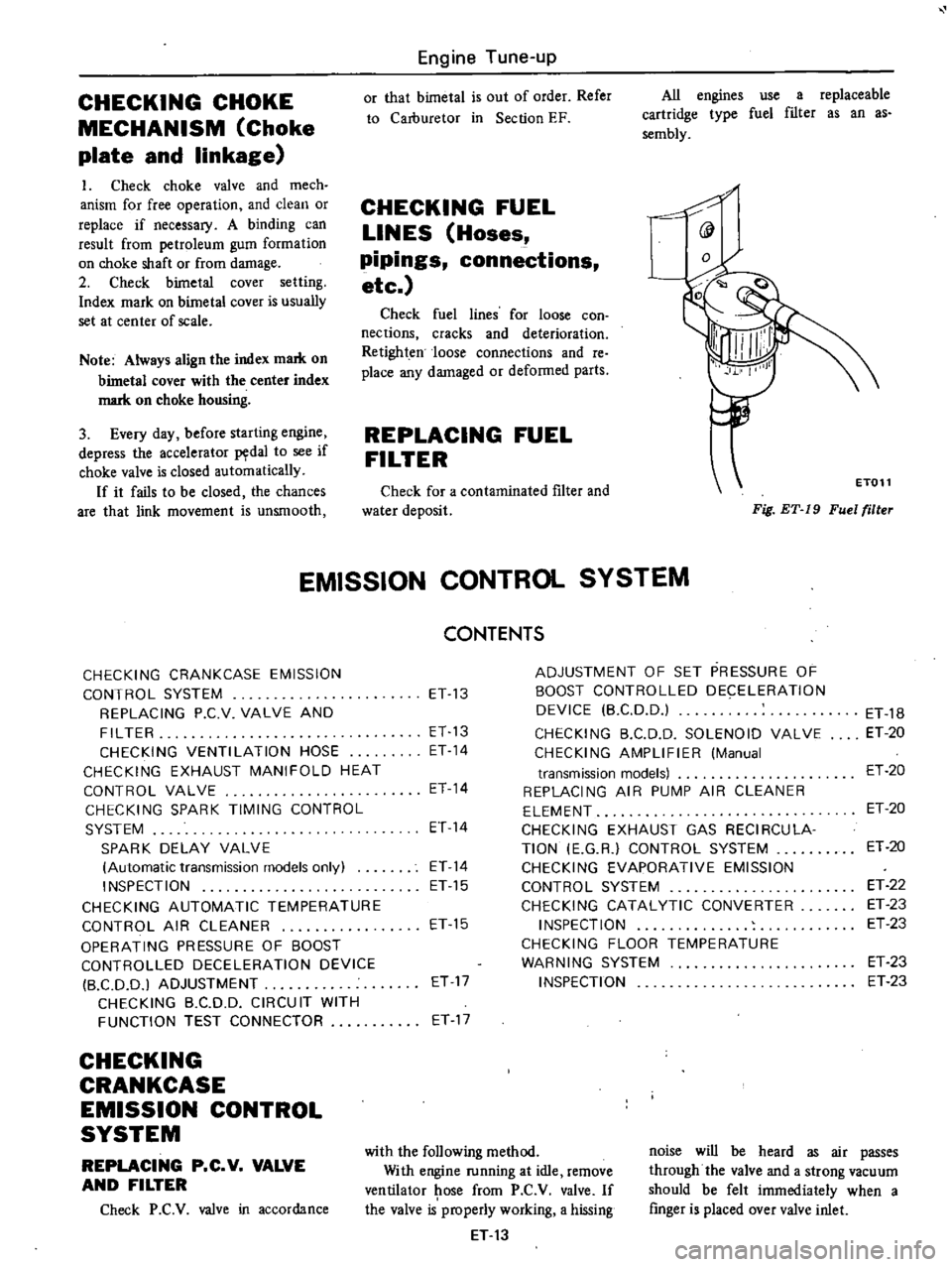

REPLACING

FUEL

FILTER

Check

for

a

contaminated

filter

and

water

deposit

All

engines

use

a

replaceable

cartridge

type

fuel

filter

as

an

as

sembly

@

Fig

ET

19

Fuel

filler

ET011

EMISSION

CONTROL

SYSTEM

CHECKING

CRANKCASE

EMISSION

CONTROL

SYSTEM

REPLACING

P

C

V

VALVE

AND

FILTER

CHECKING

VENTILATION

HOSE

CHECKING

EXHAUST

MANIFOLD

HEAT

CONTROL

VALVE

CHECKING

SPARK

TIMING

CONTROL

SYSTEM

SPARK

DELAY

VALVE

Automatic

transmission

models

only

INSPECTION

CHECKING

AUTOMATIC

TEMPERATURE

CONTROL

AIR

CLEANER

OPERATING

PRESSURE

OF

BOOST

CONTROLLED

DECELERATION

DEVICE

B

CD

D

I

ADJUSTMENT

CHECKING

B

C

DD

CIRCUIT

WITH

FUNCTION

TEST

CONNECTOR

CHECKING

CRANKCASE

EMISSION

CONTROL

SYSTEM

REPLACING

P

C

V

VALVE

AND

FILTER

Check

P

C

V

valve

in

accordance

CONTENTS

ET

13

ET

13

ET

14

ET

14

ET

14

ET

14

ET

15

ET

15

ET

17

ET

17

ADJUSTMENT

OF

SET

PRESSURE

OF

BOOST

CONTROLLED

DECELERATION

DEVICE

B

CD

D

CHECKING

B

C

D

D

SOLENOID

VALVE

CHECKING

AMPLIFIER

Manual

transmission

models

REPLACING

AIR

PUMP

AIR

CLEANER

ELEMENT

CHECKING

EXHAUST

GAS

RECIRCULA

TION

E

G

R

CONTROL

SYSTEM

CHECKING

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

CHECKING

CATALYTIC

CONVERTER

INSPECTION

CHECKING

FLOOR

TEMPERATURE

WARNING

SYSTEM

INSPECTION

with

the

following

method

With

engine

running

at

idle

remove

ventilator

ose

from

P

C

V

valve

If

the

valve

is

properly

working

a

hissing

ET

13

ET

18

ET

20

ET

20

ET

20

ET

20

ET

22

ET

23

ET

23

ET

23

ET

23

noise

will

be

heard

as

air

passes

through

the

valve

and

a

strong

vacuum

should

be

felt

immediately

when

a

finger

is

placed

over

valve

inlet

Page 34 of 537

r

EC350

Fig

ET

43

Cleanill

l

E

G

R

control

lJ

Jlue

Thermal

VBCuum

valve

Dismount

thermal

vacuum

valve

from

engine

Note

Before

dismounting

drain

e

gine

coolant

from

engine

Apply

vacuum

to

thermal

vacuum

valve

and

check

to

be

sure

that

ther

mal

vacuum

valve

opens

or

closes

in

response

to

engine

coolant

tempera

lurt

i1

i

iYCl

lt

lt

U

Thermal

vacuum

valve

should

open

at

a

temperature

of

57

to

630C

134

to

1450F

completing

the

vacuum

passage

Note

Do

not

aUow

water

to

get

inside

the

thermal

vacuum

valve

EC

242

Fig

ET

44

Checkill

lthermallXlCuum

valve

Engine

Tune

up

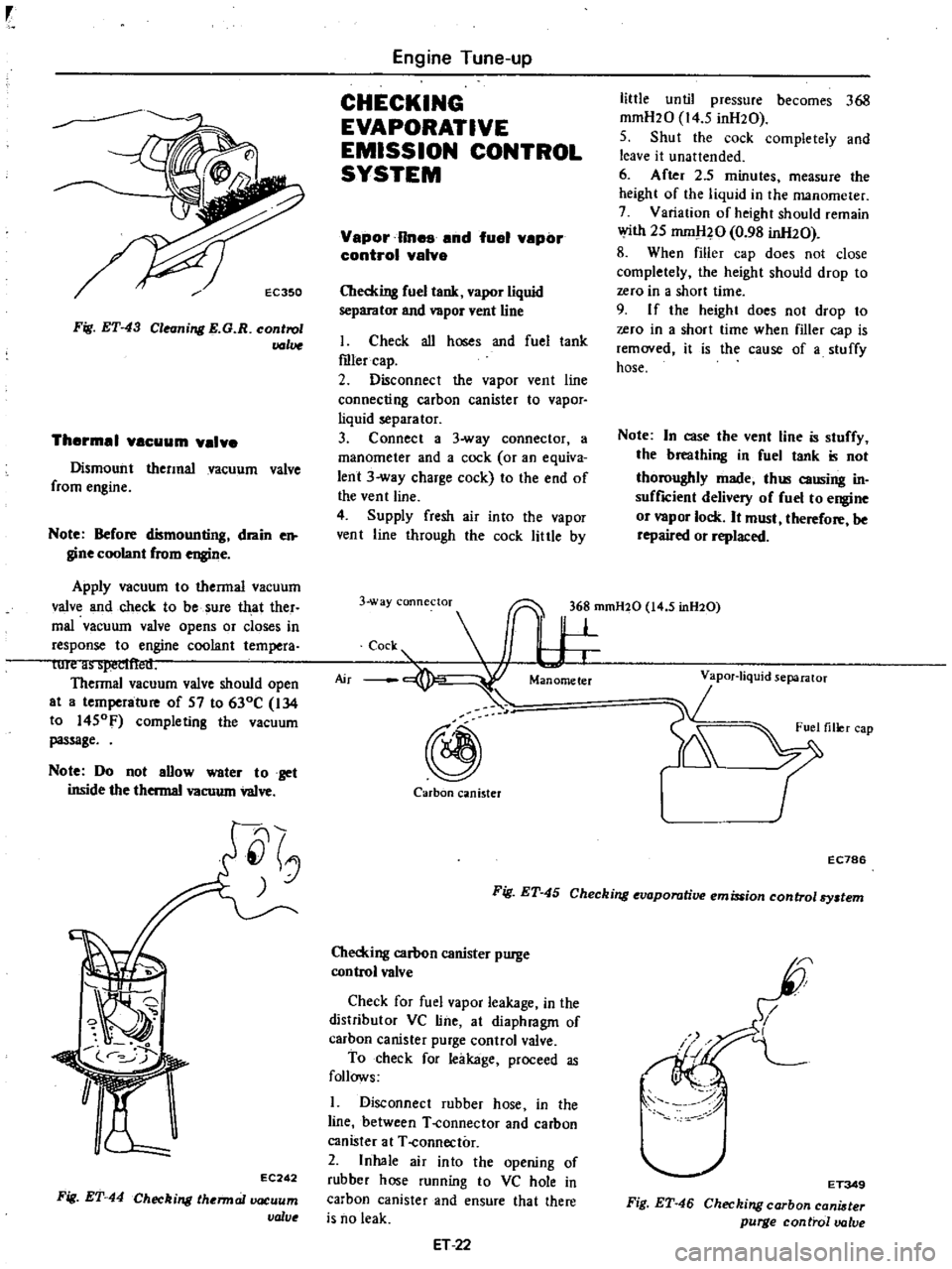

CHECKING

EVAPORATIVE

EMISSION

CONTROL

SYSTEM

Vapor

Rnes

and

fuel

vepor

control

valve

Checking

fuel

tank

vapor

liquid

separator

and

vapor

vent

line

I

Check

all

hoses

and

fuel

tank

roler

cap

2

Disconnect

the

vapor

vent

line

connecting

carbon

canister

to

vapor

liquid

separator

3

Connect

a

3

way

connector

a

manometer

and

a

cock

or

an

equiva

lent

3

way

charge

cock

to

the

end

of

the

vent

line

4

Supply

fresh

air

into

the

vapor

vent

line

through

the

cock

little

by

little

until

pressure

becomes

368

mmH20

14

5

inH20

5

Shut

the

cock

completely

and

leave

it

unattended

6

After

2

5

minutes

measure

the

height

of

the

liquid

in

the

manometer

7

Variation

of

height

should

remain

with

25

mm

l20

0

98

inH20

8

When

filler

cap

does

not

close

completely

the

height

should

drop

to

zero

in

a

short

time

9

I

f

the

height

does

not

drop

to

zero

in

a

short

time

when

filler

cap

is

removed

it

is

the

cause

of

a

stuffy

hose

Note

In

case

the

vent

line

is

stuffy

the

breathing

in

fuel

tank

is

not

thoroughly

made

thl

causing

in

suffICient

delivery

of

fuel

to

engine

or

vapor

lock

It

must

therefore

be

repaired

or

replaced

3

way

connectoT

36

mmH20

14

5

inH20

c

s

I

W

@

Carbon

canister

r

EC786

Fig

ET

45

Checking

evaporative

emission

control

By

tem

Checking

carbon

canister

purge

control

valve

Check

for

fuel

vapor

leakage

in

the

distributor

VC

line

at

diaphragm

of

carhon

canister

purge

control

valve

To

check

for

leakage

proceed

as

follows

1

Disconnect

rubber

hose

in

the

line

between

T

connector

and

carbon

canister

at

T

connector

2

Inhale

air

into

the

opening

of

rubber

hose

running

to

VC

hole

in

carbon

canister

and

ensure

that

there

is

no

leak

ET

22

I

I

L

I

ET349

Fig

ET

46

Checking

carbon

cani

ter

purge

control

valve

Page 42 of 537

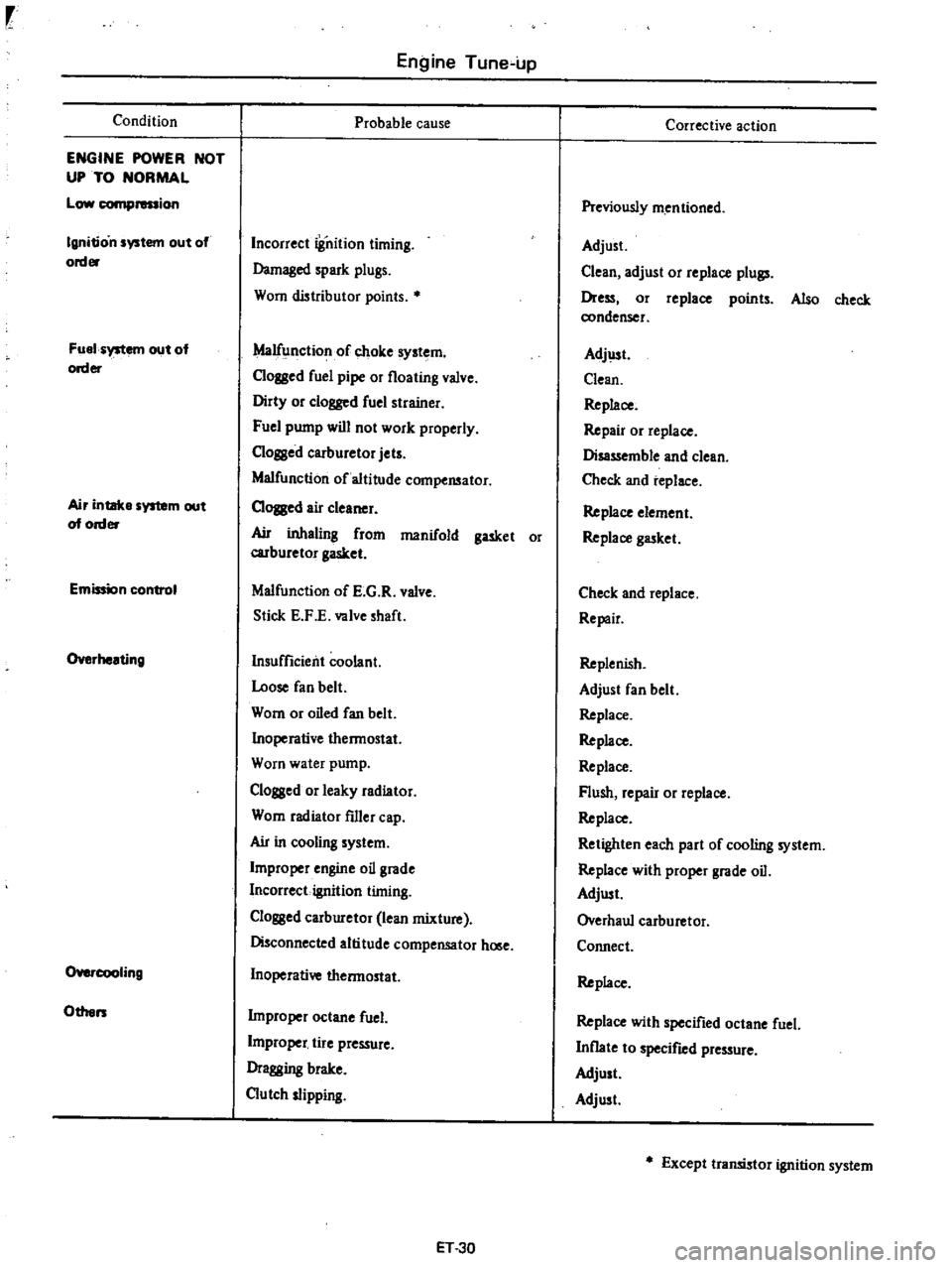

Condition

ENGINE

POWER

NOT

UP

TO

NORMAL

Low

compression

Ignition

system

out

of

order

Fuel

system

out

of

order

Air

intake

system

out

of

order

Emission

control

Overheating

O

cooIing

Others

Engine

Tune

up

Probable

cause

Incorrect

iSnition

timing

Damaged

spark

plugs

Worn

distributor

points

Malfunction

of

choke

system

Clogged

fuel

pipe

or

floating

valve

Dirty

or

clogged

fuel

strainer

Fuel

pump

will

not

work

properly

C10ssed

carburetor

jets

Malfunction

of

altitude

compensator

CIOJBed

air

cleaner

Ail

inhaling

from

manifold

gasket

or

carburetor

gasket

Malfunction

of

E

G

R

valve

Stick

E

F

E

valve

shaft

Insufficient

coolant

Loose

fan

belt

Worn

or

oiled

fan

belt

Inoperative

thermostat

Worn

water

pump

Clogged

or

leaky

radiator

Worn

radiator

filler

cap

Ail

in

cooling

system

Improper

engine

oil

grade

Incorrect

ignition

timing

Clossed

carburetor

lean

mixture

Disconnected

altitude

compensator

hOlle

Inoperative

thermostat

Improper

octane

fuel

L

j

tire

pressure

Dragging

brake

Clutch

slipping

ET

30

Corrective

action

Previously

mentioned

Adjust

Clean

adjust

or

replace

plull

Dress

or

replace

points

Also

check

condenser

Adj

lst

Clean

Replace

Repair

or

replace

Disassemble

and

clean

Check

and

replace

Replace

element

Replace

gasket

Check

and

replace

Repair

Replenish

Adjust

fan

belt

Replace

Replace

Replace

Flush

repair

or

replace

Replace

Retighten

each

part

of

cooling

system

Replace

with

proper

grade

oil

Adjust

Overhaul

carburetor

Connect

Replace

Replace

with

specified

octane

fuel

Inflate

to

specified

pressure

Adjust

Adjust

Except

transistor

ignition

system

Page 44 of 537

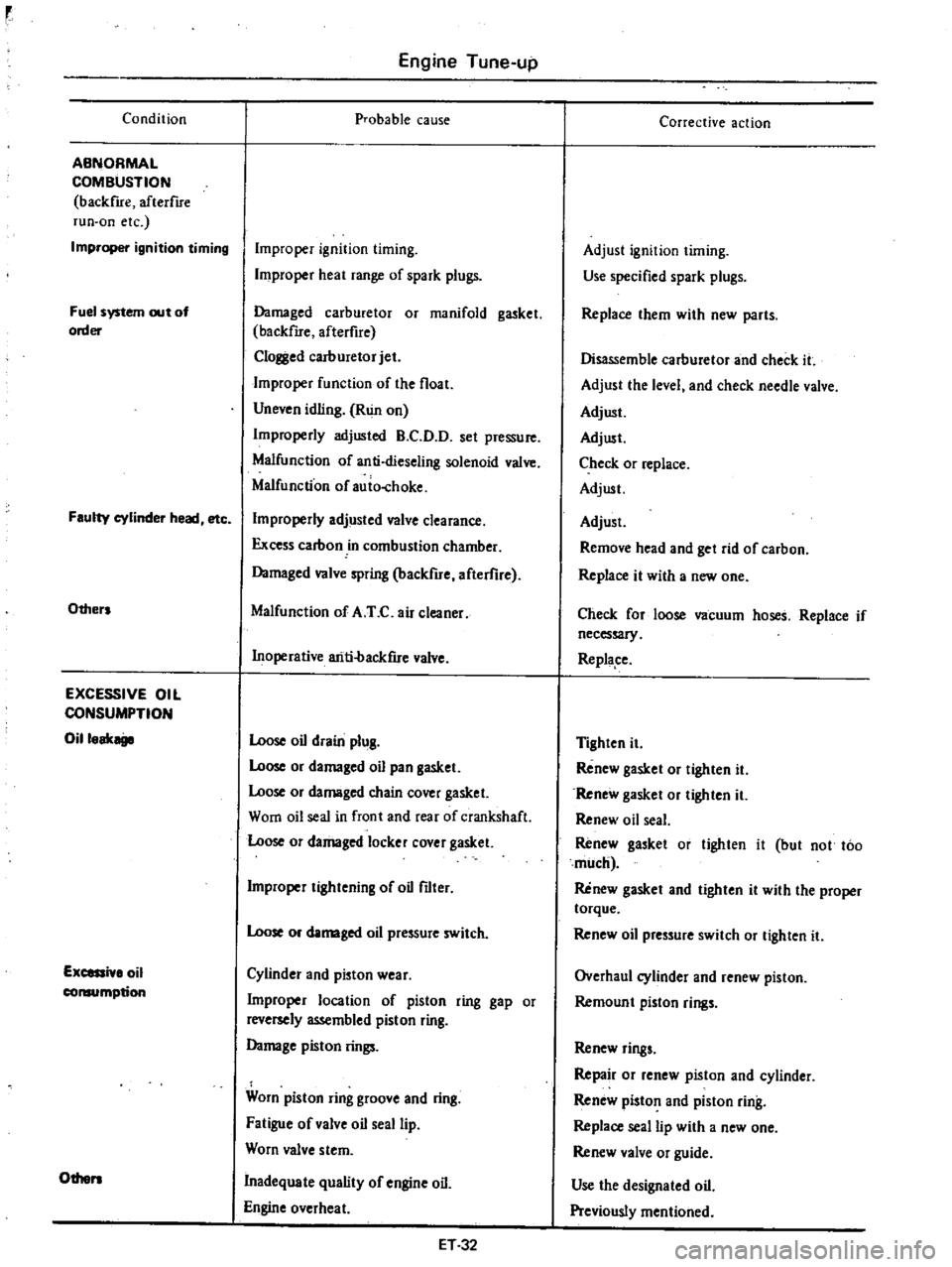

Condition

ABNORMAL

COMBUSTION

backfue

afterflre

run

on

etc

Improper

ignition

timing

Fuel

system

out

of

order

Faulty

cylinder

head

etc

Others

EXCESSIVE

OIL

CONSUMPTION

Oilloak

Excessi

lo

oil

consumption

Others

Engine

Tune

up

probable

cause

Improper

ignition

timing

Improper

heat

range

of

spark

plugs

Damaged

carburetor

or

manifold

gasket

backfue

afterfire

Clol

l

ed

carburetor

jet

Improper

function

of

the

float

Uneven

idling

Run

on

Improperly

adjusted

B

C

D

D

set

pressure

Malfunction

of

anti

dieseling

solenoid

valve

Malfunction

of

auio

choke

Improperly

adjusted

valve

clearance

Excess

carbon

in

combustion

chamber

Damaged

valve

spring

backfire

afterflre

Malfunction

of

A

T

C

air

cleaner

Inoperative

ariti

backfue

valve

Loose

oil

drain

plug

Loose

or

damaged

oil

pan

gasket

Loose

or

damaged

chain

cover

gasket

Worn

oil

seal

in

front

and

rear

of

crankshaft

Loose

or

damaged

locker

cover

gasket

Improper

tightening

of

oil

filter

Loose

or

damaged

oil

pressure

switch

Cylinder

and

pioton

wear

Improper

location

of

piston

ring

gap

or

reversely

assembled

piston

ring

Damage

piston

rings

Worn

piston

ring

groove

and

ring

Fatigue

of

valve

oil

seal

lip

Worn

valve

stem

Inadequate

quality

of

engine

oil

Engine

overheat

ET32

Corrective

action

Adjust

ignition

timing

Use

specified

spark

plugs

Replace

them

with

new

parts

Disassemble

carburetor

and

check

it

Adjust

the

level

and

check

needle

valve

Adjust

Adjust

Check

or

replace

Adjust

Adjust

Remove

head

and

get

rid

of

carbon

Replace

it

with

a

new

one

Check

for

loose

vacuum

hoses

Replace

if

necessary

Replape

Tighten

it

Renew

gasket

or

tighten

it

Renew

gasket

or

tighten

it

Renew

oil

seal

Renew

gasket

or

tighten

it

but

not

too

much

Renew

gasket

and

tighten

it

with

the

proper

torque

Renew

oil

pressure

switch

or

tighten

it

Overhaul

cylinder

and

renew

piston

Remoun

t

piston

rings

Renew

rings

Repair

or

renew

piston

and

cylinder

Renew

piston

and

piston

ring

Replace

seal

lip

with

a

new

one

Renew

valve

or

guide

Use

the

designated

oil

Previously

mentioned

Page 45 of 537

Condition

POOR

FUEL

ECONOMY

Se

the

xplanation

of

the

pow

r

dec

Oth

n

PROBLEM

IN

OTHER

FUNCTIONS

D

cr

d

oil

p

ssure

Excessive

wear

on

the

sliding

parts

Scuffing

of

sliding

parts

Floor

temperature

too

high

California

only

Engine

Tune

up

Probable

cause

Exceeding

idling

revolution

Inoperative

acceleration

recovery

Fuel

leakage

Malfunction

of

B

C

D

D

Malfunction

of

A

r

C

air

cleaner

Inadequate

oil

quality

Overheat

Worn

oil

pump

regulator

valve

Functional

deterioration

of

oil

pump

Blocked

oil

f1lter

Increased

clearance

in

various

sliding

parts

Blocked

oil

strainer

Inoperative

oil

gauge

pressure

switch

Oil

pressure

decreases

Improper

quality

or

contamination

of

oil

Damaged

air

cleaner

Overheat

or

overcoal

Improper

fuel

mixture

Decrease

of

oil

pressure

Insufficient

clearances

Overhea

t

Improper

fuel

mixture

Problem

in

fuel

system

Refer

to

Inspec

tion

of

Fuel

System

Problem

in

ignition

system

Refer

to

In

spection

of

Ignition

System

ET33

Corrective

action

Adjust

it

to

the

designated

rpm

Adjust

it

Repair

or

tighten

the

connection

of

fuel

pipes

Adjust

Check

and

replace

Use

the

designated

oil

Previously

mentioned

Disassemble

oil

pump

and

repair

or

renew

it

Repair

or

replace

it

with

a

new

one

Renew

it

Disassemble

and

replace

the

worn

parts

with

new

ones

Oeanit

Replace

it

with

a

new

one

Previousiy

mentioned

Exchange

the

oil

with

proper

one

and

change

element

Change

elemen

t

Previously

mentioned

Check

the

fuel

system

Previously

mentioned

Readjust

to

the

designated

clearances

Previously

mentioned

Check

the

fuel

system

Check

and

repair

Check

and

repair

Page 49 of 537

r

I

I

PRELIMINARY

CLEANING

AND

INSPECTION

DISASSEMBL

Y

PRELIMINARY

CLEANING

AND

INSt

ECTION

Before

disassembling

engine

note

the

following

I

Fuel

oil

or

water

may

leak

past

cylinder

head

and

block

Prior

to

disassembling

check

cylinder

head

1

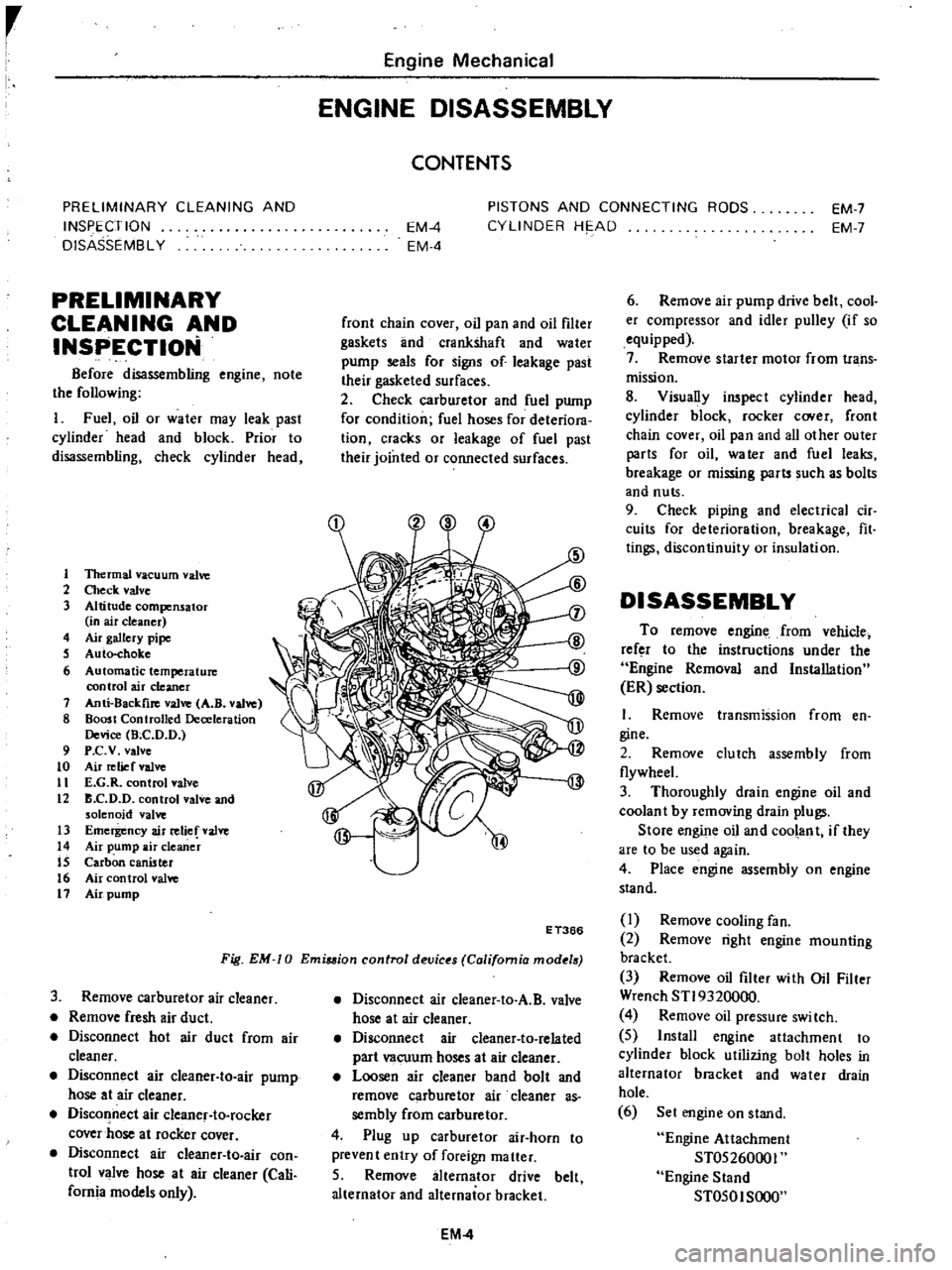

1ltermal

vacuum

valve

2

Check

valve

3

Altitude

compensator

in

air

cleaner

4

Air

gallery

pipe

S

Auto

choke

6

Automatic

temperature

control

air

cleaner

7

Anti

8ackfire

valve

A

B

valve

8

Boost

Controlled

Deceleration

Device

Bee

D

D

9

P

c

v

valve

to

Air

relief

valve

11

E

G

R

control

valve

12

B

C

D

D

control

valve

and

solenoid

valve

13

Emergency

air

relief

valve

14

Air

pump

air

cleaner

IS

Carbon

canister

16

Air

control

valve

11

Air

pump

Engine

Mechanical

ENGINE

DISASSEMBLY

CONTENTS

EM

4

EM

4

PISTONS

AND

CONNECTING

RODS

CYLINDER

HE

AD

EM

7

EM

7

front

chain

cover

oil

pan

and

oil

filter

gaskets

lInd

crankshaft

and

water

pump

seals

for

signs

of

leakage

past

their

gasketed

surfaces

2

Check

carburetor

and

fuel

pump

for

condition

fuel

hoses

for

deteriora

tion

cracks

or

leakage

of

fuel

past

their

jointed

or

connected

surfaces

Fig

EM

0

Emiuion

control

devic

s

California

mod

18

E

T366

3

Remove

carburetor

air

cleaner

Remove

fresh

air

duct

Disconnect

hot

air

duct

from

air

cleaner

Disconnect

air

cleaner

to

air

pump

hose

at

air

cleaner

Disconnect

air

cleanef

to

rocker

cover

hose

at

rocker

cover

Disconnect

air

cIeaner

to

air

con

trol

valve

hose

at

air

cleaner

Cali

fornia

models

only

Disconnect

air

cleaner

to

A

B

valve

hose

at

air

cleaner

Disconnect

air

cleaner

to

related

part

vacuum

hoses

at

air

cleaner

Loosen

air

cleaner

band

bolt

and

remove

carburetor

air

cleaner

as

sembly

from

carburetor

4

Plug

up

carburetor

air

horn

to

prevent

entry

of

foreign

matter

5

Remove

alternator

drive

belt

alternator

and

alternator

bracket

EM

4

6

Remove

air

pump

drive

belt

cool

er

compressor

and

idler

pulley

if

so

equipped

7

Remove

starter

motor

from

trans

mission

8

Visually

inspect

cylinder

head

cylinder

block

rocker

C

Ner

front

chain

cover

oil

pan

and

all

other

outer

parts

for

oil

water

and

fuel

leaks

breakage

or

missing

parts

such

as

bolts

and

nuts

9

Check

piping

and

electrical

cir

cuits

for

deterioration

breakage

fit

tings

discontinuity

or

insulation

DISASSEMBLY

To

remove

engine

from

vehicle

refer

to

the

instructions

under

the

Engine

Removal

and

Installation

ER

section

I

Remove

transmission

from

en

gine

2

Remove

clutch

assembly

from

flywheeL

3

Thoroughly

drain

engine

oil

and

coolan

t

by

removing

drain

plugs

Store

engine

oil

and

coolant

if

they

are

to

be

used

again

4

Place

engine

assembly

on

engine

stand

I

Remove

cooling

fan

2

Remove

right

engine

mounting

bracket

3

Remove

oil

filter

with

Oil

Filter

Wrench

STI9320000

4

Remove

oil

pressure

swi

tch

5

Install

engine

attachment

to

cylinder

block

utilizing

bolt

holes

in

alternator

bracket

and

water

drain

hole

6

Set

engine

on

stand

Engine

Attachment

ST05260001

Engine

Stand

ST050I

SOOO

Page 71 of 537

30

Install

heatshieid

plate

on

mani

fold

assembly

31

Install

air

gallery

pipe

on

ex

haust

manifold

32

Install

manifold

gasket

and

manifold

assembly

on

cylinder

head

Tightening

torque

1

2to

1

6kg

m

8

7

to

11

6

ft

lb

33

Install

blow

by

gas

pipe

on

cyl

inder

block

and

tighten

with

rear

engine

slinger

34

Install

thermostat

housing

gas

ket

thermostat

housing

and

thermo

stat

35

Install

thermal

vacuum

valve

on

thermostat

housing

Before

installing

apply

a

liquid

packing

slightly

to

the

threads

36

Install

FJ

C

D

bracket

on

cylin

der

head

37

Install

E

G

R

passage

and

E

G

R

valve

on

intake

manifold

38

Connect

E

G

R

tube

to

E

G

R

tube

and

exhaust

manifold

39

Install

check

valve

on

air

gallery

pipe

40

Install

air

cleaner

bracket

on

intake

manifold

41

Install

air

control

valve

on

air

cleaner

bracket

California

models

42

Install

vacuum

and

fuel

tubes

combined

on

cylinder

head

43

Install

distributor

assembly

44

Install

heatshield

plate

joint

seat

and

carburetor

Carbure10r

tightening

torque

0

5

to

1

0

kg

m

3

6

to

7

2

ft

lb

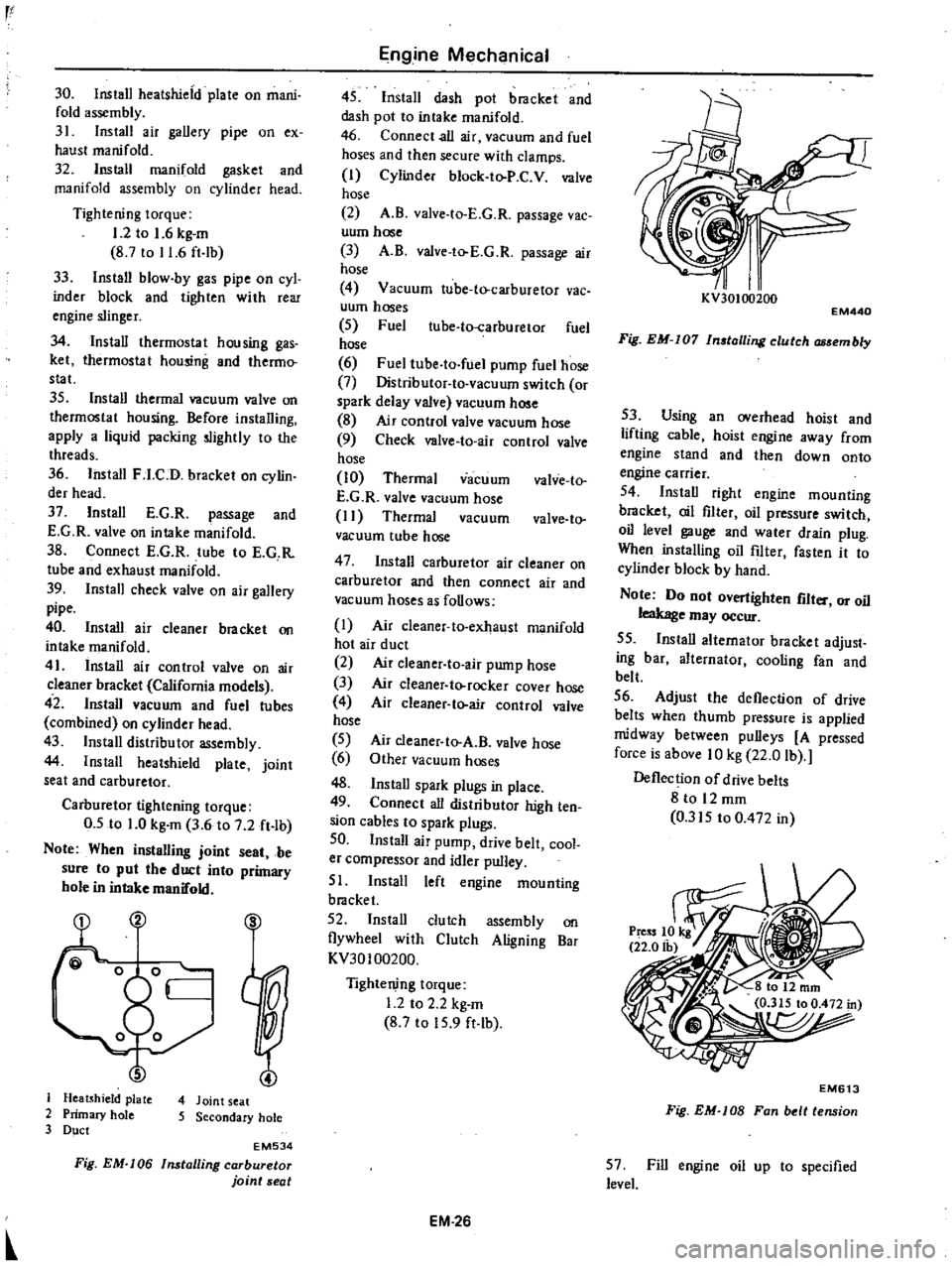

Note

When

instalUng

joint

seat

be

sure

to

put

the

duct

into

primary

hole

in

intake

manifold

S

J

Heatshield

plate

4

Joint

seat

2

Primary

hole

5

Secondary

hole

3

Duct

EM534

Fig

EM

I06

Installing

carburetor

joint

seat

Engine

Mechanical

45

Install

dash

pot

bracket

and

dash

pot

to

intake

manifold

46

Connect

all

air

vacuum

and

fuel

hoses

and

then

secure

with

clamps

I

Cylinder

block

to

P

C

V

valve

hose

2

A

B

valve

to

E

G

R

passage

vac

uum

hose

3

A

B

valve

to

E

G

R

passage

air

hose

4

Vacuum

tube

to

carburetor

vac

uum

hoses

5

Fuel

ube

to

carburetor

fuel

hose

6

Fuel

tube

to

fuel

pump

fuelhose

7

Distributor

to

vacuum

switch

or

spark

delay

valve

vacuum

hose

8

Air

control

valve

vacuum

hose

9

Check

valve

to

air

control

valve

hose

10

Thermal

vacuum

valve

to

E

G

R

valve

vacuum

hose

I

I

Thermal

vacuum

valve

to

vacuum

tube

hose

47

Install

carburetor

air

cleaner

on

carburetor

and

then

connect

air

and

vacuum

hoses

as

follows

I

Air

cleaner

to

exhaust

manifold

hot

air

duct

2

Air

c1eaner

to

air

pump

hose

3

Air

cleaner

to

rocker

cover

hose

4

Air

cleaner

to

air

control

valve

hose

5

6

48

Install

spark

plugs

in

place

49

Connect

all

distributor

high

ten

sion

cables

to

spark

plugs

50

Install

air

pump

drive

belt

cool

er

compressor

and

idler

pulley

51

Install

left

engine

mounting

bracket

52

Install

clutch

assembly

on

flywheel

with

Clutch

Aligning

Bar

KV30100200

Air

cleaner

to

A

B

valve

hose

Other

vacuum

hoses

Tightening

torque

1

2

to

2

2

kg

m

8

7

to

15

9

ft

lb

EM

26

I

I

KV30100200

EM440

Fig

EM

I07

In

talling

clutch

embly

53

Using

an

overhead

hoist

and

lifting

cable

hoist

engine

away

from

engine

stand

and

then

down

onto

engine

carrier

54

Install

right

engine

mounting

bracket

oil

filter

oil

pressure

switch

oil

level

gauge

and

water

drain

plug

When

installing

oil

filter

fasten

it

to

cylinder

block

by

hand

Note

Do

not

overtighten

flit

or

oil

leakage

may

occur

55

Install

alternator

bracket

adjust

ing

bar

alternator

cooling

fan

and

belt

56

Adjust

the

deflection

of

drive

belts

when

thumb

pressure

is

applied

midway

between

pulleys

A

pressed

force

is

above

10

kg

22

0

lb

Deflection

of

drive

belts

8

to

12

mm

0

315

to

0

472

in

EM613

Fig

EM

lOB

Fan

belt

tension

57

Fill

engine

oil

up

to

specified

level

Page 101 of 537

TEMPERATURE

SENSOR

The

temperature

sensor

is

attached

to

the

inside

of

the

air

cleaner

The

bimetal

built

in

the

sensor

detects

the

under

hood

air

temperature

and

opens

or

closes

the

vacuum

passage

in

the

sensor

The

construction

of

the

tempera

ture

sensor

is

shown

in

the

following

CD

V

00

@

I

I

@

j

I

I

1

Protector

cover

Screw

Adjusting

frame

Air

temperature

bi

metal

Rivet

Valve

seat

frame

Lower

frame

Air

bleed

valve

Gasket

Fig

EF

6

Temperature

senior

EF206

VACUUM

MOTOR

AND

AIR

CONTROL

VALVE

The

vacuum

pressure

which

varies

with

opening

of

the

carburetor

throt

tle

acts

upon

the

vacuum

motor

dia

phragm

The

valve

shaft

attached

to

the

diaphragm

is

then

moved

up

or

down

in

response

to

the

vacuum

on

the

diaphragm

This

movement

of

the

valve

shaft

actuates

the

air

control

valve

to

control

the

temperature

of

the

air

to

be

introduced

into

the

air

cleaner

pr

to

I

1

Valve

spring

00

2

Diaphragm

@

3

Retainer

E

F

207

4

Valve

shaft

Fig

EF

7

Vacuum

motor

REMOVAL

AND

INSTALLATION

TEMPERATURE

SENSOR

Removal

Using

pliers

flatten

clip

con

Engine

Fuel

neeting

vacuum

hose

to

sensor

vacuum

tube

I

Pipe

2

Calch

3

Fixed

with

adhesive

4

Hose

5

Tab

6

Clip

7

Gasket

EC019

Fig

EF

B

Removal

of

semor

2

Disconnect

hose

from

sensor

3

Take

off

clip

from

sensor

vacuum

tube

and

dismount

sensor

body

from

air

cleaner

Note

The

gasket

between

sensor

and

air

cleaner

is

bonded

to

the

air

cleaner

side

and

should

not

be

removed

Inatallatlon

Mount

sensor

on

the

specified

position

For

mounting

position

of

sensor

see

the

following

EF717

Fig

EF

9

lalling

se

or

2

Insert

clip

into

vacuum

tube

of

sensor

After

installing

each

vacuum

hose

secure

hose

with

the

clip

Note

Be

sure

to

install

vacuum

hose

correctly

Correct

position

is

R

H

side

to

Nissan

mark

at

the

top

face

of

sensor

for

intake

manifold

L

H

side

for

vacuum

motor

VACUUM

MOTOR

1

Remove

screws

securing

vacuum

motor

to

air

cleaner

2

Disconnect

valve

shaft

attached

to

vacuum

motor

diapluagm

from

air

control

valve

and

remove

cacuum

motor

assembly

from

air

cleaner

3

To

install

reverse

the

removal

procedure

FRESH

AIR

DUCT

I

Disconnect

fresh

air

duct

at

air

cleaner

2

Fresh

air

duct

is

provided

with

projections

on

its

air

inlet

side

end

Hold

fresh

air

duct

with

a

hand

and

carefully

pull

out

from

radiator

core

support

while

turning

it

in

either

direction

3

To

install

reverse

the

removal

procedure

Be

sure

to

insert

projec

lions

of

fresh

air

duct

securely

into

mounting

hole

in

radiator

core

sup

port

EF518

EF

5

Fresh

air

duct

Air

cleaner

Duct

mounting

hole

Radiator

Radiator

core

support

Fig

EF

I0

Removal

of

fresh

air

duct

Page 105 of 537

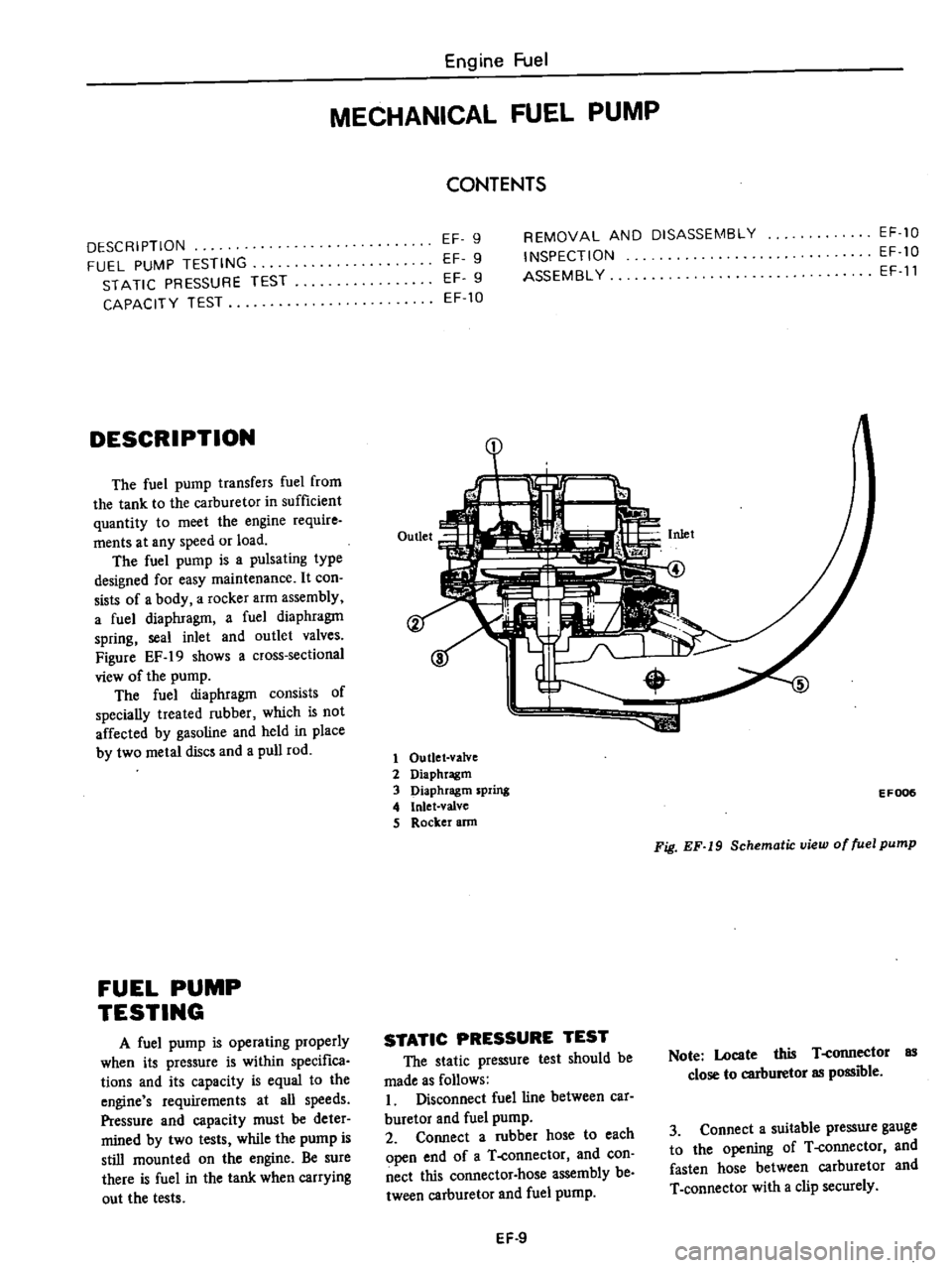

DESCRIPTION

FUEL

PUMP

TESTING

STATIC

PRESSURE

TEST

CAPACITY

TEST

DESCRIPTION

The

fuel

pump

transfers

fuel

from

the

tank

to

the

carburetor

in

sufficient

quantity

to

meet

the

engine

require

ments

at

any

speed

or

load

The

fuel

pump

is

a

pulsating

type

designed

for

easy

maintenance

It

con

sists

of

a

body

a

rocker

arm

assembly

a

fuel

diaphragm

a

fuel

diaphragm

spring

seal

inlet

and

outlet

valves

Figure

EF

19

shows

a

cross

sectional

view

of

the

pump

The

fuel

diaphragm

consists

of

specially

treated

rubber

which

is

not

affected

by

gasoline

and

held

in

place

by

two

metal

discs

and

a

pull

rod

FUEL

PUMP

TESTING

A

fuel

pump

is

operating

properly

when

its

pressure

is

within

specifica

tions

and

its

capacity

is

equal

to

the

engine

s

requirements

at

all

speeds

Pressure

and

capacity

must

be

deter

mined

by

two

tests

while

the

pump

is

still

mounted

on

the

engine

Be

sure

there

is

fuel

in

the

tank

when

carrying

out

the

tests

Engine

Fuel

MECHANICAL

FUEL

PUMP

CONTENTS

EF

9

EF

9

EF

9

EF

10

REMOVAL

AND

DISASSEMBLY

INSPECTION

ASSEMBL

Y

EF

10

EF

10

EF

11

1

1

Outlet

valve

2

Diaphragm

3

Diaphragm

spring

4

Inlet

valve

S

Rocker

ann

EF006

Fig

EF

19

Schematic

view

of

fuel

pump

STATIC

PRESSURE

TEST

The

static

pressure

test

should

be

made

as

follows

I

Disconnect

fuel

line

between

car

buretor

and

fuel

pump

2

Connect

a

rubber

hose

to

each

open

end

of

a

T

connector

and

con

nect

this

connector

hose

assembly

be

tween

carburetor

and

fuel

pump

Note

Locate

this

T

connector

as

close

to

carburetor

as

possible

3

Connect

a

suitable

pressure

gauge

to

the

opening

of

T

connector

and

fasten

hose

between

carburetor

and

T

connector

with

a

clip

securely

EF

9