fuse box DATSUN PICK-UP 1977 Service Manual

[x] Cancel search | Manufacturer: DATSUN, Model Year: 1977, Model line: PICK-UP, Model: DATSUN PICK-UP 1977Pages: 537, PDF Size: 35.48 MB

Page 188 of 537

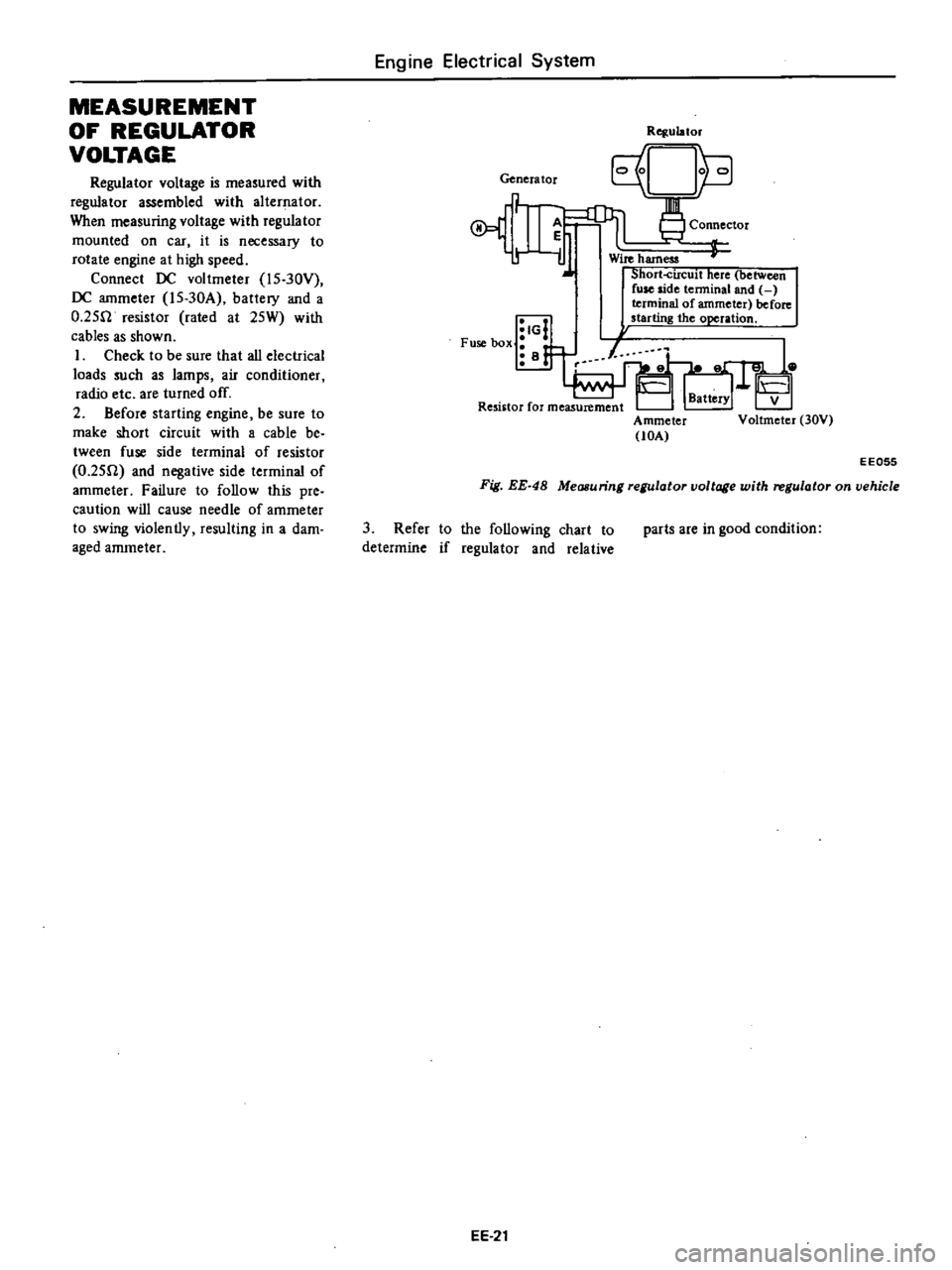

MEASUREMENT

OF

REGULATOR

VOLTAGE

Regulator

voltage

is

measured

with

regulator

assembled

with

alternator

When

measuring

voltage

with

regulator

mounted

on

car

it

is

necessary

to

rotate

engine

at

high

speed

Connect

DC

voltmeter

l5

30Y

DC

ammeter

l5

30A

battery

and

a

O

25fl

resistor

rated

at

25W

with

cables

as

shown

I

Check

to

be

sure

that

all

electrical

loads

such

as

lamps

air

conditioner

radio

etc

are

turned

off

2

Before

starting

engine

be

sure

to

make

short

circuit

with

a

cable

be

tween

fuse

side

terminal

of

resistor

O

25fl

and

negative

side

terminal

of

ammeter

Failure

to

follow

this

pre

caution

will

cause

needle

of

ammeter

to

swing

violently

resulting

in

a

dam

aged

ammeter

Engine

Electrical

System

Genera

tor

A

r

iJ

IG

Fuse

box

i

B

Rqulator

Connector

Wire

harness

Short

circuit

here

between

fuse

side

tenninal

and

terminal

of

ammeter

before

starting

the

operation

Ammeter

lOA

V

Voltmeter

30V

EE055

Fig

EE

48

Measuring

regulator

voltage

with

regulator

on

vehicle

3

Refer

to

the

following

chart

to

determine

if

regulator

and

relative

EE

21

parts

are

in

good

condition

Page 462 of 537

Fuse

M

Body

Electrical

System

YR

Meter

voltage

regulator

Water

temperature

gauge

BE261

Circuit

diagram

of

fuel

gauge

and

water

temperature

gauge

pressure

falls

below

0

4

to

0

6

kg

cm2

5

7

to

8

5

psi

Under

normal

opera

tion

when

the

engine

is

stationary

the

ligh

glows

with

the

ignition

switch

turned

on

When

the

e

gine

is

running

and

oil

pressure

reaches

the

above

range

the

circuit

opens

and

the

light

goes

out

Ignition

switch

YW

B

1

Y

I

Fusible

link

YW

t

Thermal

transmitter

L

Fig

BE

25

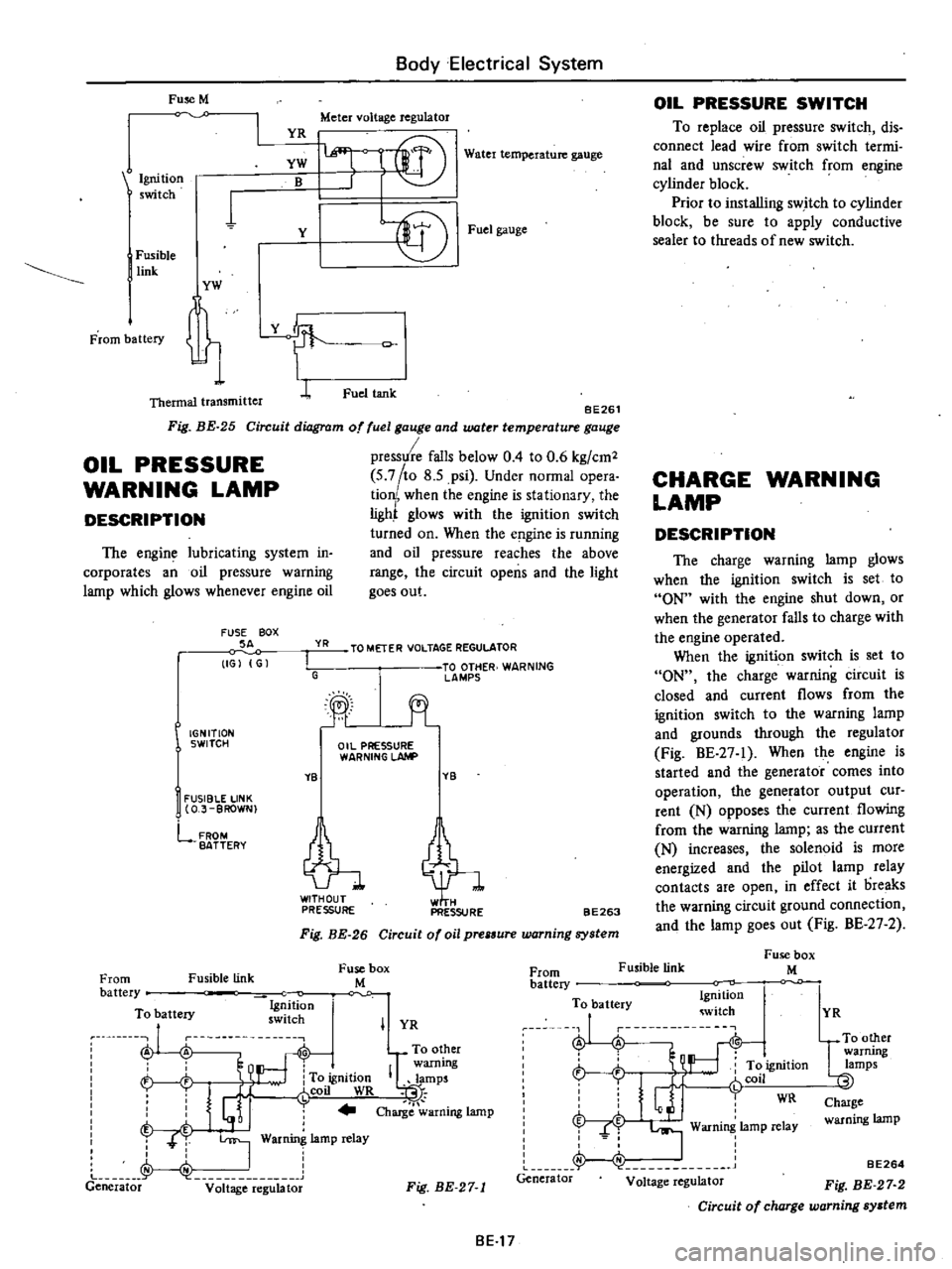

OIL

PRESSURE

WARNING

LAMP

DESCRIPTION

The

engine

lubricating

system

in

corporates

an

oil

pressure

warning

lamp

which

glows

whenever

engine

oil

FUSE

BOX

SA

IGJ

G

YR

I

G

IGNITION

SWITCH

YB

I

FUSIBLE

LINK

O

J

BROWN

lffi

l

f

r@

Fuel

gauge

Fuel

tank

TO

METER

VOLTAGE

REGULATOR

TO

OTHER

WARNING

lAMPS

jt

Oil

PRESSURE

WARNING

LAhlP

YB

tl

PRESSURE

PRESSURE

FROM

BATTERY

BE263

Fig

BE

26

Circuit

of

oil

prelSure

warning

system

Fusible

link

Fuse

box

M

OIL

PRESSURE

SWITCH

To

replace

oil

pressure

switch

dis

connect

lead

wire

from

switch

termi

nal

and

unscrew

switch

from

engine

cylinder

block

Prior

to

installing

switch

to

cylinder

block

be

sure

to

apply

conductive

sealer

to

threads

of

new

switch

CHARGE

WARNING

LAMP

DESCRIPTION

The

charge

warning

lamp

glows

when

the

ignition

switch

is

set

to

ON

with

the

engine

shut

down

or

when

the

generator

falls

to

charge

with

the

engine

operated

When

the

ignition

switch

is

set

to

ON

the

charge

warning

circuit

is

closed

and

current

flows

from

the

ignition

switch

to

the

warning

lamp

and

grounds

through

the

regulator

Fig

BE

27

1

When

the

engine

is

started

and

the

generator

comes

into

operation

the

generator

output

cur

rent

N

opposes

th

current

flowing

from

the

warning

lamp

as

the

current

N

increases

the

solenoid

is

more

energized

and

the

pilot

lamp

relay

contacts

are

open

in

effect

it

oreaks

the

warning

circuit

ground

connection

and

the

lamp

goes

out

Fig

BE

27

2

Fusible

link

Fuse

box

M

From

battery

To

battery

Ig

ition

ru

nu

swllch

A

A

To

other

warning

h

To

ignition

IQlamps

i

J

r

coil

WR

t

I

j

Charge

warning

lamp

T

T

I

War

lamp

relay

J

I

Generator

v

it

ge

e

g

bt

From

battery

To

battery

Ignition

witch

J

i

L

r

t

ft

ignition

r

Glj

fCOil

WR

f

I

Warning

lamp

relay

Generator

Voltage

regulator

I

YR

Fig

BE

27

1

BE17

YR

UTO

other

warrung

lamps

Charge

warning

lamp

BE264

Fig

BE

27

2

Circuit

of

charge

warning

system

Page 469 of 537

Body

Electrical

System

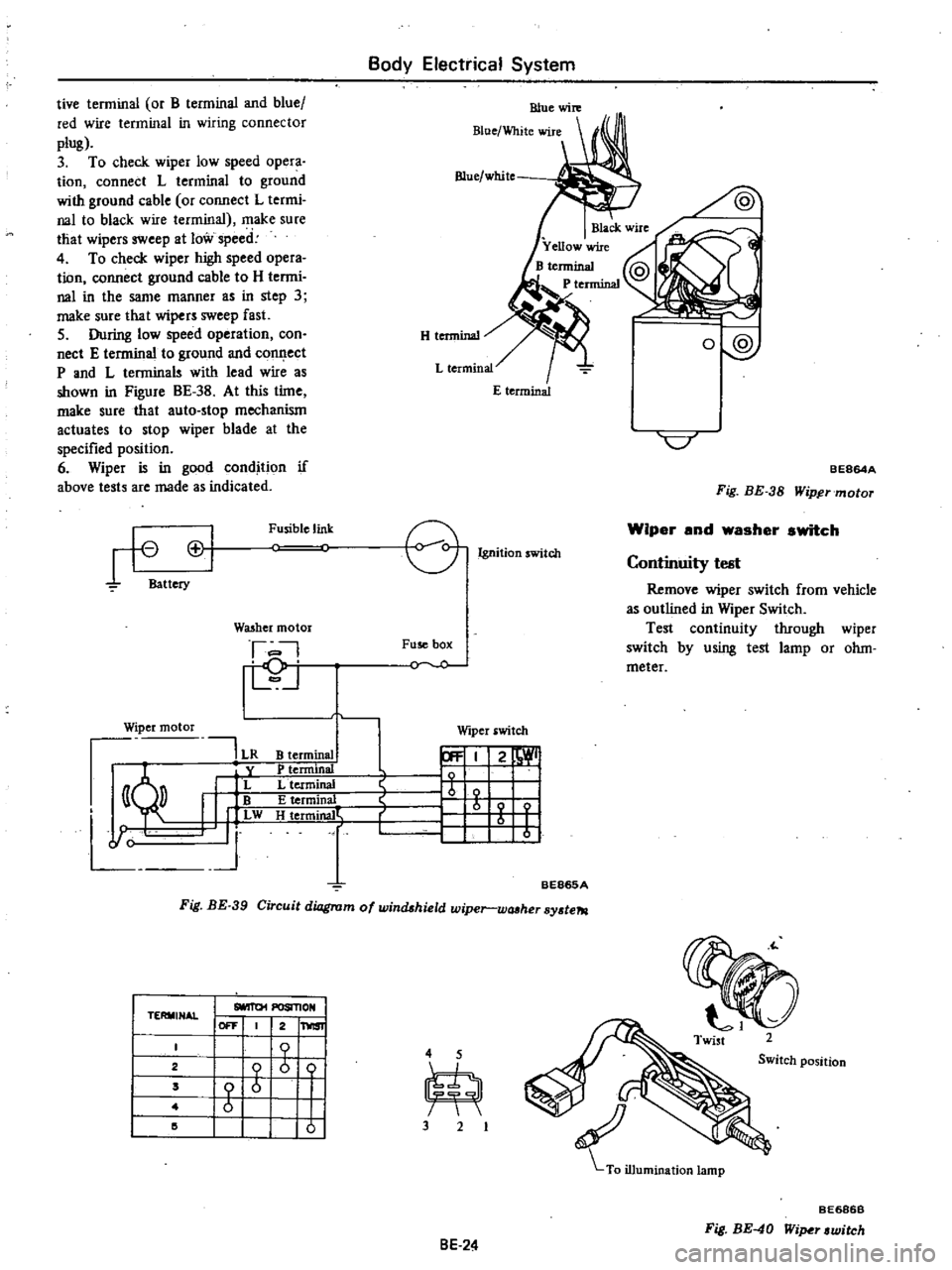

tive

terminal

or

B

terminal

and

blue

red

wire

terminal

in

wiring

connector

plug

3

To

check

wiper

low

speed

opera

tion

connect

L

terminal

to

ground

with

ground

cable

or

connect

L

termi

nal

to

black

wire

terminal

make

sure

that

wipers

sweep

at

low

speed

4

To

check

wiper

high

speed

opera

tion

connect

ground

cable

to

H

termi

nal

in

the

same

manner

as

in

step

3

make

sure

that

wipers

sweep

fast

5

During

low

speed

operation

con

nect

E

terminal

to

ground

and

conl

ect

P

and

L

terminals

with

lead

wire

as

shown

in

Figure

BE

38

At

this

time

make

sure

that

auto

stop

mechanism

actuates

to

stop

wiper

blade

at

the

specified

position

6

Wiper

is

in

good

condition

if

above

tests

are

made

as

indicated

H

tenninal

Blue

white

o

@

C

BE864A

Fig

BE

38

Wipftrmotor

rt

Cl

Battery

Fusible

link

e

Ignition

witch

Wiper

and

washer

switch

I

D

j

Fuse

box

Y

O

Continuity

test

Remove

wiper

switch

from

vehicle

as

outlined

in

Wiper

Switch

Test

continuity

through

wiper

switch

by

using

test

lamp

or

ohm

meter

WQ5hcr

motor

Wiper

motor

191

LR

y

I

L

I

w

J

Wiper

switch

B

terminal

P

tenninal

L

terminal

E

terminal

H

t

rmjrW

r

21

1

b

I

r

1

I

I

BE865A

Fig

BE

39

Circuit

diagram

of

windshield

wiper

wtUher

sy

te7tl

TERMINAL

I

SlOIT01

POSIl10N

I

I

OFF

2

1

1

2

I

b

ii

4

5

Switch

position

2

I

Z

m

Z

I

I

I

I

I

I

I

10

I

3

2

BE686B

Fig

BE

40

Wi

r

witch

8E

24

Page 521 of 537

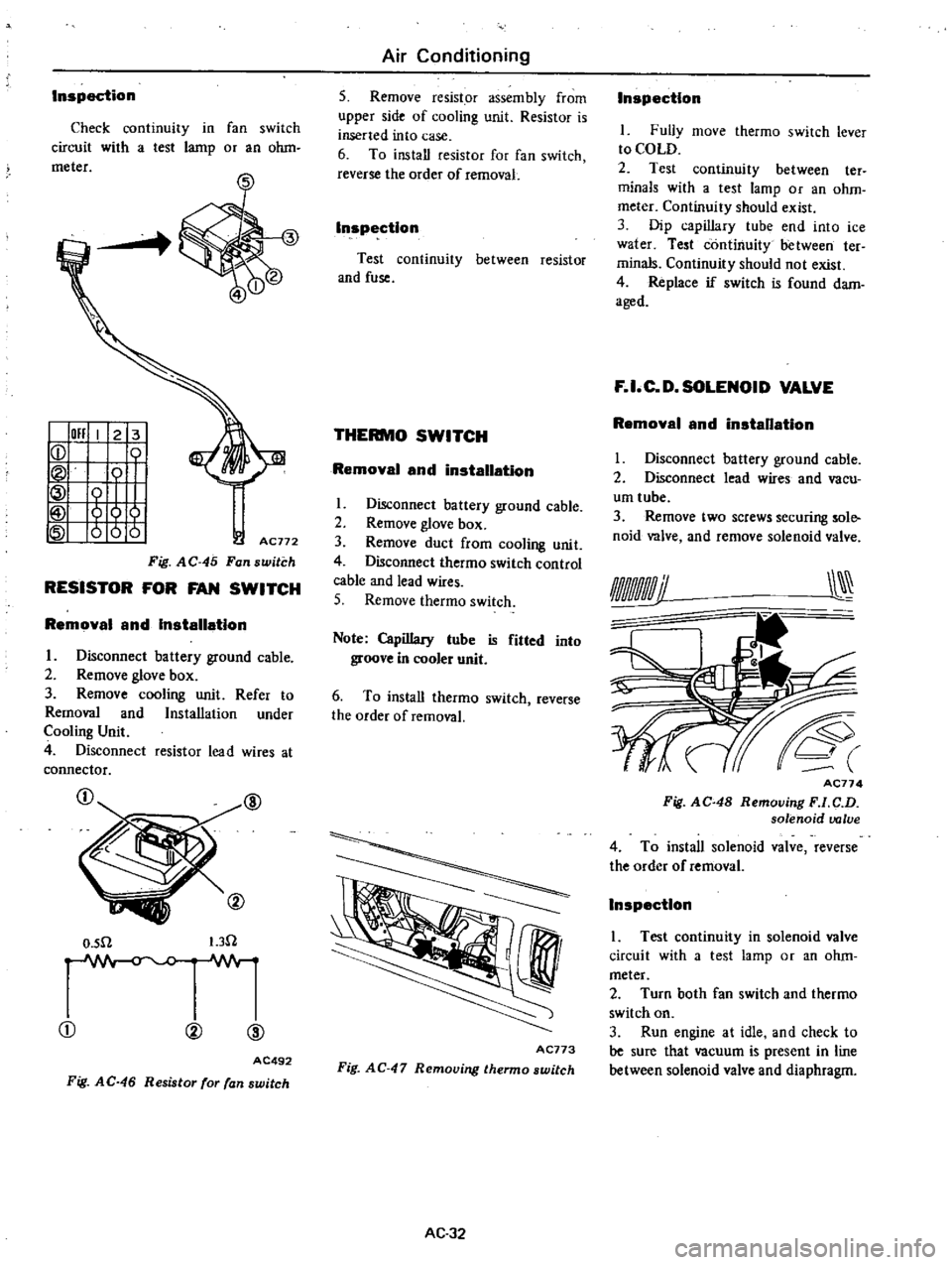

Inspection

Check

continuiry

in

fan

switch

circuit

with

a

test

lamp

or

an

ohm

meter

I

011

I

2

3

ICD

Tt

tt

AC772

Fig

AC

45

Fan

switch

RESISTOR

FOR

FAN

SWITCH

Removal

and

Installation

I

Disconnect

battery

ground

cable

2

Remove

glove

box

3

Remove

cooling

unit

Refer

to

Removal

and

Installation

under

Cooling

Unit

4

Disconnect

resistor

lead

wires

at

connector

@

O

sn

I

3n

CD

00

@

AC492

Fig

AC

46

Resistor

for

fan

switch

Air

Conditioning

5

Remove

resistor

assembly

from

upper

side

of

cooling

unit

Resistor

is

inserted

into

case

6

To

install

res

istor

for

fan

switch

reverse

the

order

of

removaL

Inspection

Test

continuity

between

resistor

and

fuse

THERMO

SWITCH

Removal

and

installation

1

Disconnect

battery

ground

cable

2

Remove

glove

box

3

Remove

duct

from

cooling

unit

4

Disconnect

thermo

switch

control

cable

and

lead

wires

5

Remove

thermo

switch

Note

Capillary

lube

is

fitted

into

groove

in

cooler

unit

6

To

install

thermo

switch

reverse

the

order

of

removal

I

I

AC773

Fig

AC

47

Removing

thermo

switch

AC

32

Inspection

I

Fully

move

thermo

swirch

lever

to

COLD

2

Test

continuity

between

ter

minals

with

a

test

tamp

or

an

ohm

meter

Continuity

should

exist

3

Dip

capillary

tube

end

into

ice

water

Test

continuity

between

ter

minals

Continuity

should

not

exist

4

Replace

if

switch

is

found

dam

aged

F

I

C

D

SOLENOID

VALVE

Removal

and

installation

I

Disconnect

battery

ground

cable

2

Disconnect

lead

wires

and

vacu

um

tube

3

Remove

two

screws

securing

sole

noid

valve

and

remove

solenoid

valve

AC77

4

Fig

AC

48

Removing

F

l

C

D

solenoid

valve

4

To

install

solenoid

valve

reverse

the

order

of

removal

Inspection

1

Test

continuity

in

solenoid

valve

circuit

with

a

test

lamp

or

an

ohm

meter

2

Turn

both

fan

switch

and

thermo

switch

on

3

Run

engine

at

idle

and

check

to

be

sure

that

vacuum

is

present

in

line

between

solenoid

valve

and

diaphragm