ECU DODGE DAKOTA 2004 3.G Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2004, Model line: DAKOTA, Model: DODGE DAKOTA 2004 3.GPages: 300, PDF Size: 5.23 MB

Page 197 of 300

Wheel9style trailer, this range of loading on the9King

Pin9should be between 15% and 25%.) Loads balanced

over the wheels or biased toward9heavier in the rear9

can cause the trailer to sway severely side to side

which will cause loss of control of vehicle and trailer.

Failure to load trailers heavier in front is the cause of

many trailer accidents.

²Donotinterconnect the hydraulic brake system of

your vehicle with that of the trailer. This could cause

inadequate braking and possible personal injury.

²Trailer brakes are recommended for trailers over 1,000

lbs. (454 kg) and required for trailers in excess of 2,000

lbs. (907 kg).

²Use an approved trailer harness and connector. If a

hitch is ordered, the proper wiring will be provided.

²When hauling cargo or towing a trailer, do not over-

load your vehicle or trailer. Overloading can cause a

loss of control, poor performance or damage to brakes,

axle, engine, transmission, steering, suspension, chas-

sis structure or tires.

²Make certain that the load is secured in the trailer and

will not shift during travel. When trailering cargo that

cannot be fully secured, dynamic load shifts can occur

that may be difficult for the driver to control.

²All trailer hitches should be professionally installed on

your vehicle.

²Safety chains must always be used between your

vehicle and trailer.

²Connect trailer lighting and brakes using factory har-

nesses only. Do not cut or splice any wiring to the

brake circuits.

Trailer and Tongue Weight

Gross Trailer Weight (GTW) means the weight of the

trailer plus the weight of all cargo and equipment loaded

on the trailer when in actual underway towing condition.

The recommended way to measure GTW is to put your

fully loaded trailer on a vehicle scale. The entire weight

of the trailer must be supported by the scale.

Tongue Weight is the weight placed on the vehicle's

trailer hitch by the trailer. Always load a trailer with 60%

STARTING AND OPERATING 197

5

Page 199 of 300

![DODGE DAKOTA 2004 3.G Owners Manual 2.GTW

3.Tongue weight rating for the trailer hitch uti-

lized (This requirement may limit the ability to

always achieve the 10% to 15% range of tongue

weight [15% to 25% for a(5th Wheel(style trailer] DODGE DAKOTA 2004 3.G Owners Manual 2.GTW

3.Tongue weight rating for the trailer hitch uti-

lized (This requirement may limit the ability to

always achieve the 10% to 15% range of tongue

weight [15% to 25% for a(5th Wheel(style trailer]](/img/12/5586/w960_5586-198.png)

2.GTW

3.Tongue weight rating for the trailer hitch uti-

lized (This requirement may limit the ability to

always achieve the 10% to 15% range of tongue

weight [15% to 25% for a(5th Wheel(style trailer]

as a percentage of total trailer weight.)

4.GAWR ratings

NOTE:

Towing a trailer equipped with more than the

standard lighting (turn, tail, stop and backup lights) may

cause an abnormally high electrical current draw through

the headlight switch, causing the switch to fail. To

prevent a recurring switch failure install a trailer tow

wiring harness overlay kit with relay to bypass headlight

switch (available from your dealer).

Trailer Towing Information (Maximum Trailer

Weight Ratings)

(Trailer Towing Guide(

NOTE:

For trailer towing information (maximum

trailer weight ratings) refer to the following website

address:http:// www.dodge.com/towing.

In Canada, refer to the following website address:

http:// www.dodge.ca.

Trailer Towing Requirements

All Dodge Dakota trucks are intended to tow trailers up

to 2,000 lbs. without added equipment or alterations to

standard equipment. Your vehicle may be factory

equipped for safe towing of trailers weighing over 2,000

lbs. with the Trailer Tow Package. The electrical part of

this package includes an instruction sheet, a 7/4 pin

adaptor, a wiring pigtail for an aftermarket electric trailer

brake controller, and three relays that must be installed

into the power distribution center. These items are stored

in the glove box. Also included in the Trailer Tow

Package are two fuses and a relay that are located on the

driver's side of the engine compartment on a harness

near the Power Distribution Center. This relay and the

fuses power up the trailer towing option. See your Dodge

dealer for further information.

If you regularly pull a trailer, regardless of the trailer size,

stop and turn signals on the trailer are recommended for

motoring safety. To handle the additional electrical load

STARTING AND OPERATING 199

5

Page 210 of 300

²In the Club Cab the jack and tools are stowed in a floor

compartment located under the rear seat on the pas-

senger's side of the vehicle. The seat cushion can be

lifted to a vertical position to allow access to this

compartment.

Jack Removal and Stowage

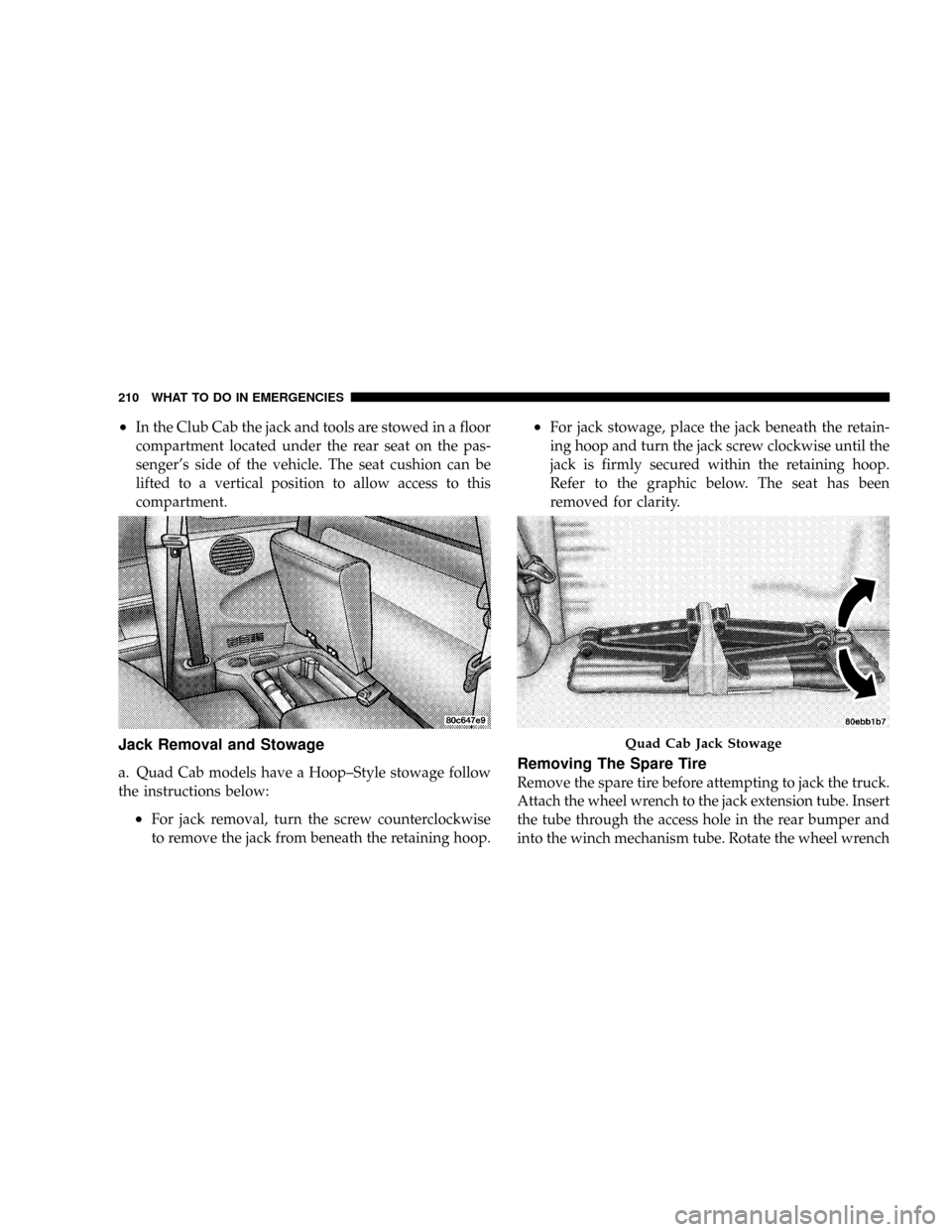

a. Quad Cab models have a Hoop±Style stowage follow

the instructions below:

²For jack removal, turn the screw counterclockwise

to remove the jack from beneath the retaining hoop.

²For jack stowage, place the jack beneath the retain-

ing hoop and turn the jack screw clockwise until the

jack is firmly secured within the retaining hoop.

Refer to the graphic below. The seat has been

removed for clarity.

Removing The Spare Tire

Remove the spare tire before attempting to jack the truck.

Attach the wheel wrench to the jack extension tube. Insert

the tube through the access hole in the rear bumper and

into the winch mechanism tube. Rotate the wheel wrench

Quad Cab Jack Stowage

210 WHAT TO DO IN EMERGENCIES

Page 242 of 300

Insure nylon tubing in these areas has not melted or

collapsed.

Inspect all hose clamps and couplings to make sure they

are secure and no leaks are present.

NOTE:Fluids such as oil, power steering fluid, and

brake fluid are used during assembly plant operations to

ease the assembly of hoses to couplings. Therefore, oil

wetness at the hose-coupling area is not necessarily an

indication of leakage. Actual dripping of hot fluid when

systems are under pressure (during vehicle operation),

should be noted before hose is replaced based on leakage.

You are urged to use only manufacturer specified hoses

and clamps, or their equivalent in material and specifi-

cation, in any fuel system servicing. It is mandatory to

replace all clamps that have been loosened or removed

during service. Care should be taken in installing new

clamps to insure they are properly torqued.

Positive Crankcase Ventilation (PCV) Valve

Proper operation of the crankcase ventilation system

requires that the PCV valve be free of sticking or plug-

ging because of deposits. Deposits can accumulate in thePCV valve and passage with increasing mileage. Have

the PCV valve, hoses, and passages checked for proper

operation at the intervals specified. If the valve is

plugged or sticking, replace with a new valve.Do not

attempt to clean the oil PCV valve!Check ventilating

hose for indication of damage or plugging with deposits.

Replace if necessary.

242 MAINTAINING YOUR VEHICLE

Page 257 of 300

2. Rotate the bulb and socket assembly 1/4 turn and pull

it from housing.

3. The bulb can be removed from the sockets by pulling

it straight out.

License Lights

1. Rotate the socket 1/4 turn counterclockwise.

2. Pull the bulb from socket.

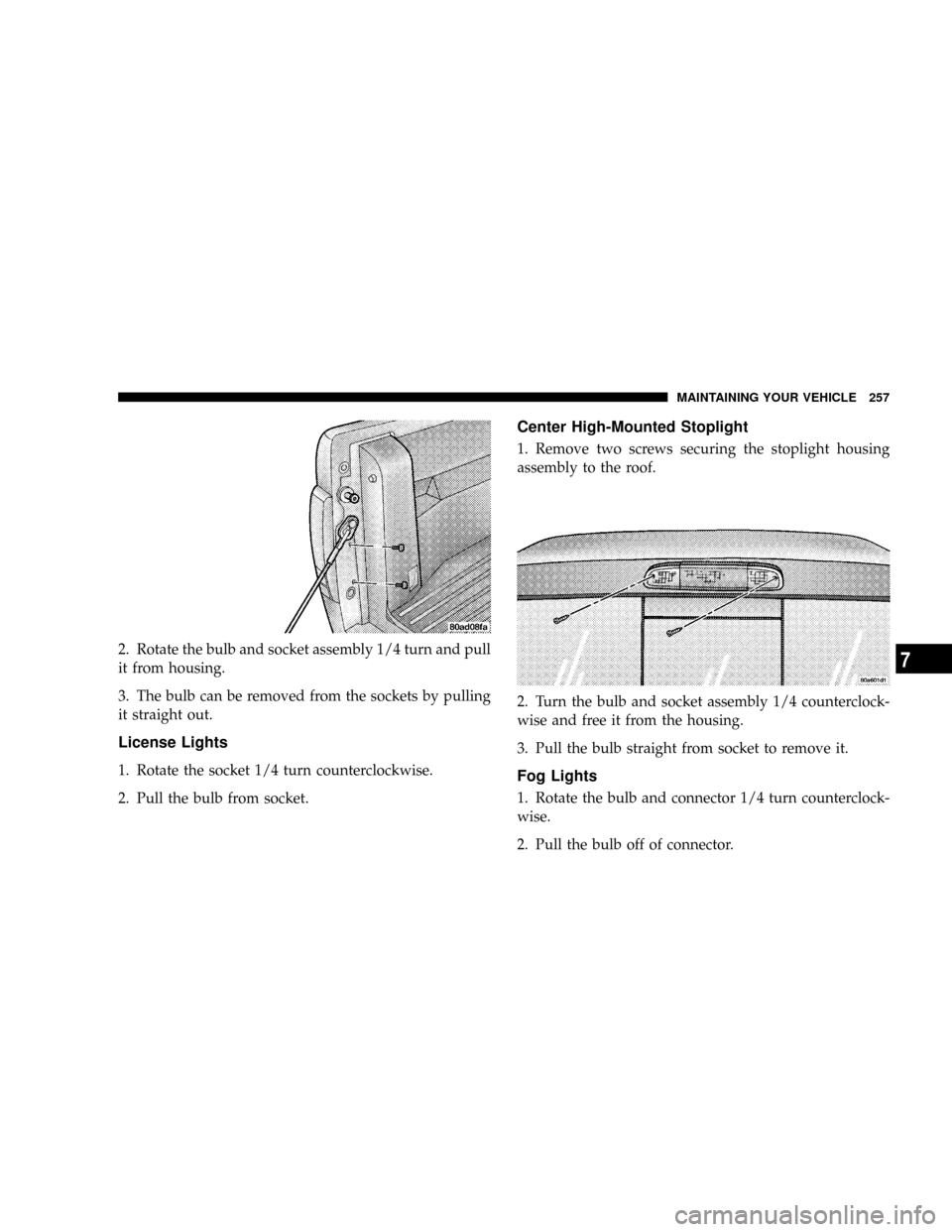

Center High-Mounted Stoplight

1. Remove two screws securing the stoplight housing

assembly to the roof.

2. Turn the bulb and socket assembly 1/4 counterclock-

wise and free it from the housing.

3. Pull the bulb straight from socket to remove it.

Fog Lights

1. Rotate the bulb and connector 1/4 turn counterclock-

wise.

2. Pull the bulb off of connector.

MAINTAINING YOUR VEHICLE 257

7

Page 297 of 300

Shifting out of Transfer Case Neutral (N) . . . 204

Reformulated Gasoline................... 184

Refrigerant............................ 234

Release, Hood.......................... 66

Remote Keyless Entry.................... 17

Remote Sound System Controls............ 130

Replacement Tires...................... 180

Reporting Safety Defects................. 284

Restraints, Child......................38,45

Restraints, Occupant..................... 24

Rocking Vehicle When Stuck.............. 167

Rotation, Tires......................183,264

Safety Checks Inside Vehicle............... 54

Safety Checks Outside Vehicle.............. 54

Safety Defects, Reporting................. 284

Safety Information, Tire.................. 167

Safety Tips............................. 53

Schedule, Maintenance................... 263

Seat Belt Maintenance................... 252

Seat Belts............................24,25

And Pregnant Women.................. 30

Child Restraint......................38,52Extender............................ 31

Front Seat............................ 25

Inspection........................... 54

Reminder........................... 101

Seats................................. 61

Adjustment.......................... 61

Bench............................... 63

Easy Entry........................... 64

Lumbar Support....................... 63

Reclining............................ 62

Security Alarm.......................21,102

Selection of Coolant..................... 259

Selection of Oil........................ 228

Self-Adjusting Brakes.................... 243

Sentry Key............................. 9

Service and Maintenance..............262,263

Service Assistance...................... 280

Service Contract........................ 282

Service Manuals........................ 284

Setting the Clock....................... 105

Shift Speeds, Manual Transmission.......... 151

Shifting.............................. 146

Manual Transmission.................. 150

INDEX 297

10