washer fluid DODGE DURANGO 2021 Owners Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2021, Model line: DURANGO, Model: DODGE DURANGO 2021Pages: 340, PDF Size: 20.38 MB

Page 8 of 340

6

IN CASE OF EMERGENCY

HAZARD WARNING FLASHERS ........................ 243

ASSIST AND SOS MIRROR — IF EQUIPPED...... 243

JACKING AND TIRE CHANGING ........................ 247 Preparations For Jacking ............................ 247

Jack Location ................................................. 248

Spare Tire Stowage ....................................... 249

Spare Tire Removal ....................................... 249

Jacking Instructions ..................................... 251

JUMP STARTING .................................................. 255

Preparations For Jump Start......................... 255Jump Starting Procedure .............................. 256

REFUELING IN EMERGENCY –

IF EQUIPPED ........................................................ 257

IF YOUR ENGINE OVERHEATS ............................ 258

MANUAL PARK RELEASE ................................... 258

FREEING A STUCK VEHICLE .............................. 260

TOWING A DISABLED VEHICLE .........................261

Rear Wheel Drive Models ............................. 262

All Wheel Drive Models ................................. 263

ENHANCED ACCIDENT RESPONSE SYSTEM

(EARS) .................................................................. 263

EVENT DATA RECORDER (EDR) ......................... 263

SERVICING AND MAINTENANCE

SCHEDULED SERVICING ................................... 264

Maintenance Plan ......................................... 265

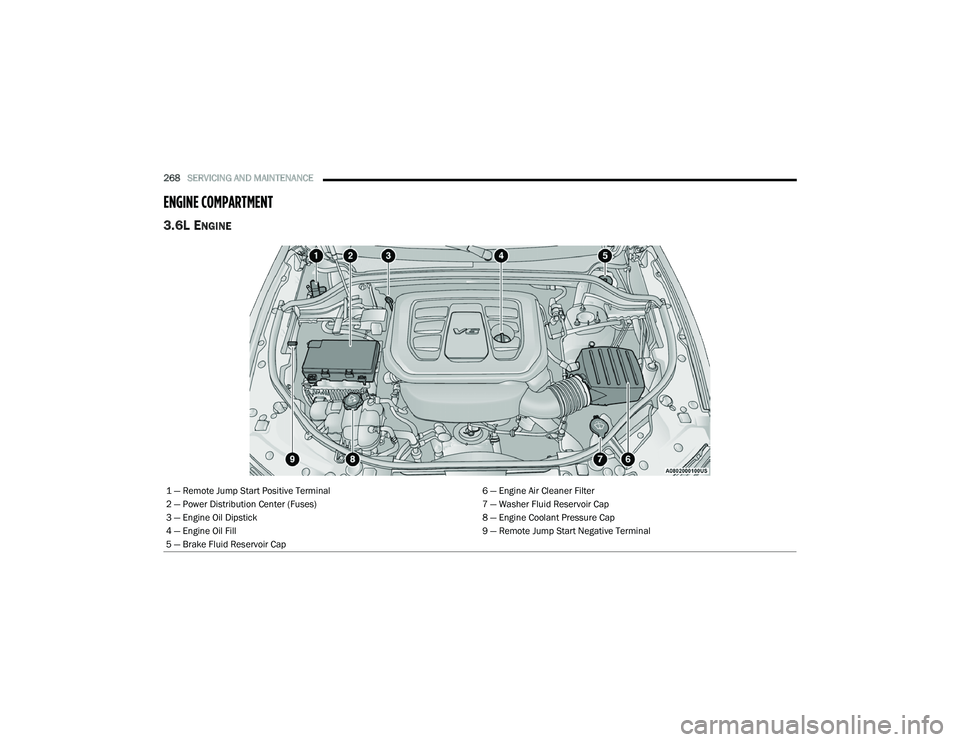

ENGINE COMPARTMENT .................................... 268

3.6L Engine ................................................... 268

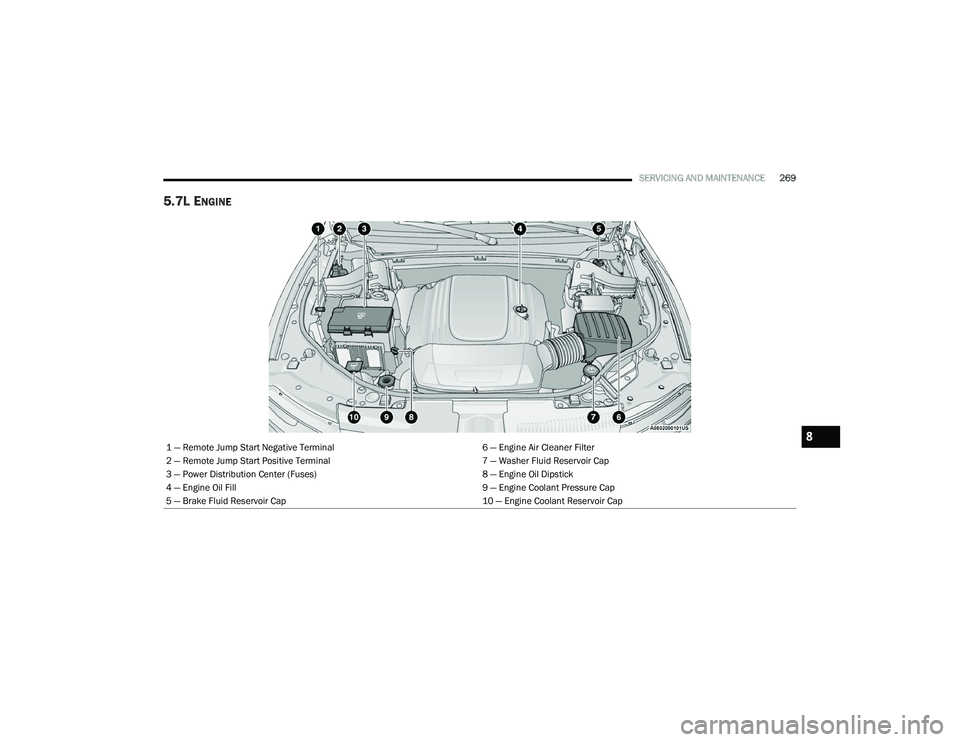

5.7L Engine ................................................... 269

Checking Oil Level ......................................... 270

Adding Washer Fluid .................................... 270

Maintenance-Free Battery ........................... 270Pressure Washing ......................................... 271

VEHICLE MAINTENANCE..................................... 271

Engine Oil ...................................................... 271

Engine Oil Filter ............................................ 272

Engine Air Cleaner Filter ............................ 272

Air Conditioner Maintenance ..................... 273

Accessory Drive Belt Inspection ................... 275Body Lubrication .......................................... 276

Windshield Wiper Blades ............................. 276

Exhaust System ............................................ 279

Cooling System .............................................. 280

Brake System ............................................... 283

Automatic Transmission ............................... 284

Front/Rear Axle Fluid ................................... 285Transfer Case ............................................... 285

Fuses.............................................................. 286

Bulb Replacement......................................... 293 TIRES ..................................................................... 295

Tire Safety Information ................................. 295

Tires — General Information ........................ 303Tire Types....................................................... 306Spare Tires — If Equipped ............................ 307

Wheel And Wheel Trim Care ........................ 309Snow Traction Devices ................................. 310

Tire Rotation Recommendations ................ 312

DEPARTMENT OF TRANSPORTATION

UNIFORM TIRE QUALITY GRADES .................... 312

Treadwear...................................................... 312

Traction Grades ............................................. 313Temperature Grades..................................... 313

STORING THE VEHICLE .................................... 313

BODYWORK .......................................................... 313 Protection From Atmospheric Agents .......... 313

Body And Underbody Maintenance ............. 314

Preserving The Bodywork ............................. 314

INTERIORS ........................................................... 315

Seats And Fabric Parts ................................. 315

Plastic And Coated Parts .............................. 315

Leather Surfaces........................................... 316

Glass Surfaces ............................................. 316

21_WD_OM_EN_USC_t.book Page 6

Page 13 of 340

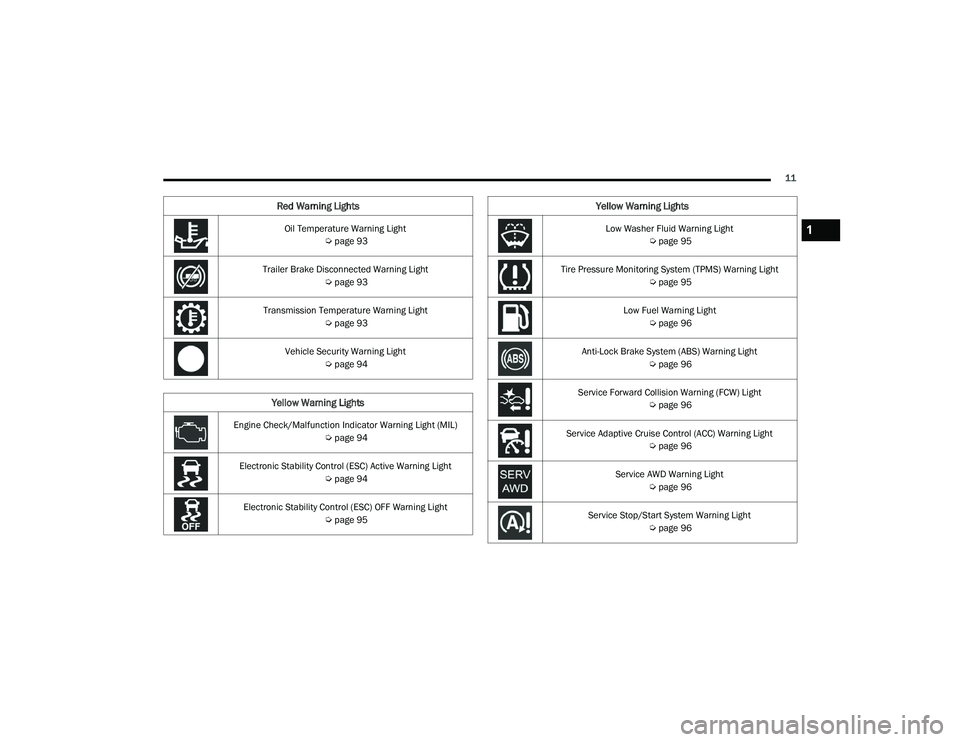

11

Oil Temperature Warning Light Úpage 93

Trailer Brake Disconnected Warning Light Úpage 93

Transmission Temperature Warning Light Úpage 93

Vehicle Security Warning Light Úpage 94

Yellow Warning Lights

Engine Check/Malfunction Indicator Warning Light (MIL)

Úpage 94

Electronic Stability Control (ESC) Active Warning Light Úpage 94

Electronic Stability Control (ESC) OFF Warning Light Úpage 95

Red Warning Lights

Low Washer Fluid Warning Light

Úpage 95

Tire Pressure Monitoring System (TPMS) Warning Light Úpage 95

Low Fuel Warning Light Úpage 96

Anti-Lock Brake System (ABS) Warning Light Úpage 96

Service Forward Collision Warning (FCW) Light Úpage 96

Service Adaptive Cruise Control (ACC) Warning Light Úpage 96

Service AWD Warning Light Úpage 96

Service Stop/Start System Warning Light Úpage 96

Yellow Warning Lights

1

21_WD_OM_EN_USC_t.book Page 11

Page 56 of 340

54GETTING TO KNOW YOUR VEHICLE

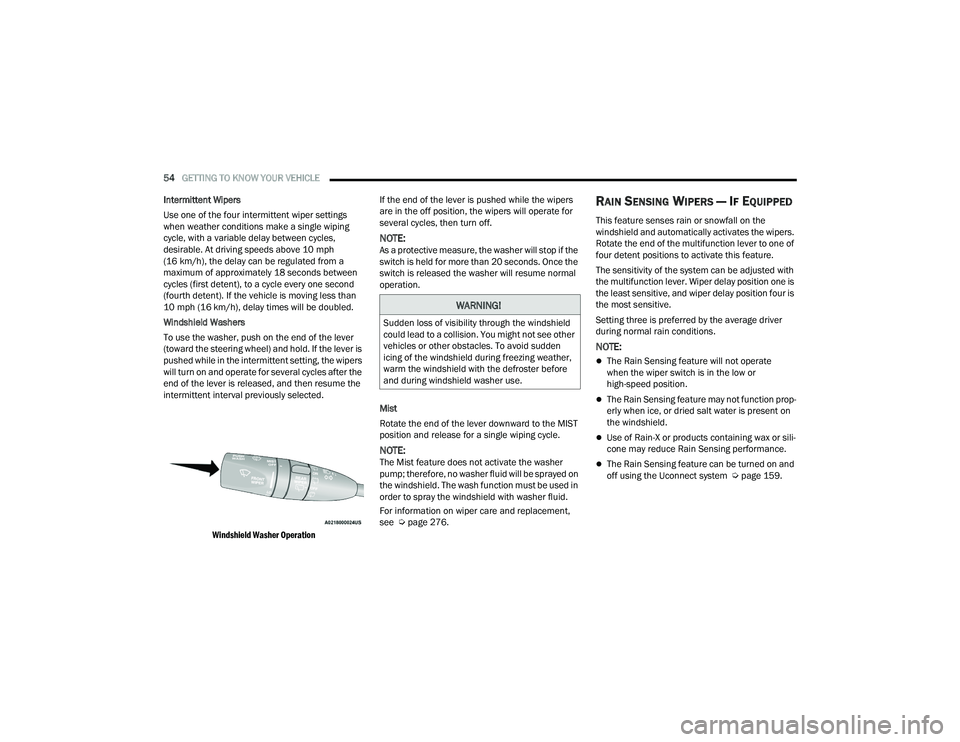

Intermittent Wipers

Use one of the four intermittent wiper settings

when weather conditions make a single wiping

cycle, with a variable delay between cycles,

desirable. At driving speeds above 10 mph

(16 km/h), the delay can be regulated from a

maximum of approximately 18 seconds between

cycles (first detent), to a cycle every one second

(fourth detent). If the vehicle is moving less than

10 mph (16 km/h), delay times will be doubled.

Windshield Washers

To use the washer, push on the end of the lever

(toward the steering wheel) and hold. If the lever is

pushed while in the intermittent setting, the wipers

will turn on and operate for several cycles after the

end of the lever is released, and then resume the

intermittent interval previously selected.

Windshield Washer Operation

If the end of the lever is pushed while the wipers

are in the off position, the wipers will operate for

several cycles, then turn off.

NOTE:As a protective measure, the washer will stop if the

switch is held for more than 20 seconds. Once the

switch is released the washer will resume normal

operation.

Mist

Rotate the end of the lever downward to the MIST

position and release for a single wiping cycle.

NOTE:The Mist feature does not activate the washer

pump; therefore, no washer fluid will be sprayed on

the windshield. The wash function must be used in

order to spray the windshield with washer fluid.

For information on wiper care and replacement,

see Ú

page 276.

RAIN SENSING WIPERS — IF EQUIPPED

This feature senses rain or snowfall on the

windshield and automatically activates the wipers.

Rotate the end of the multifunction lever to one of

four detent positions to activate this feature.

The sensitivity of the system can be adjusted with

the multifunction lever. Wiper delay position one is

the least sensitive, and wiper delay position four is

the most sensitive.

Setting three is preferred by the average driver

during normal rain conditions.

NOTE:

The Rain Sensing feature will not operate

when the wiper switch is in the low or

high-speed position.

The Rain Sensing feature may not function prop -

erly when ice, or dried salt water is present on

the windshield.

Use of Rain-X or products containing wax or sili-

cone may reduce Rain Sensing performance.

The Rain Sensing feature can be turned on and

off using the Uconnect system Ú page 159.

WARNING!

Sudden loss of visibility through the windshield

could lead to a collision. You might not see other

vehicles or other obstacles. To avoid sudden

icing of the windshield during freezing weather,

warm the windshield with the defroster before

and during windshield washer use.

21_WD_OM_EN_USC_t.book Page 54

Page 88 of 340

86GETTING TO KNOW YOUR INSTRUMENT PANEL

Vehicles Equipped With Keyless Enter ‘n Go —

Ignition

Use the steering wheel instrument cluster display

controls for the following procedure(s):

1. Without pressing the brake pedal, push the ENGINE START/STOP button and place the

ignition in the ON/RUN position (do not start

the engine).

2. Push and release the down arrow button to

scroll downward through the main menu to

“Vehicle Info.”

3. Push and release the right arrow button to access the ”Oil Life” screen.

4. Push and hold the OK button to reset oil life. If

conditions are met, the gauge and numeric

display will update to show 100%. If conditions

are not met a pop-up message of “To reset oil

life engine must be off with ignition in run” will

be displayed (for five seconds), and the user

will remain at the Oil Life screen.

5. Push and release the up or down arrow

button to exit the submenu screen.

NOTE:If the indicator message illuminates when you start

the vehicle, the oil change indicator system did not

reset. If necessary, repeat this procedure. Secondary Method Of Resetting Engine Oil Life

1. Without pressing the brake pedal, push the

ENGINE START/STOP button and place the

ignition to the ON/RUN position (do not start

the engine).

2. Fully press the accelerator pedal, slowly, three times within 10 seconds.

3. Without pushing the brake pedal, push the ENGINE START/STOP button once to return the

ignition to the OFF position.

NOTE:If the indicator message illuminates when you start

the vehicle, the oil change indicator system did not

reset. If necessary, repeat this procedure.

DISPLAY AND MESSAGES

Includes the following, but not limited to:

Front Seat Belts Unbuckled

Driver Seat Belt Unbuckled

Passenger Seat Belt Unbuckled

Traction Control Off

Washer Fluid Low

Oil Pressure Low

Oil Change Due

Fuel Low

Service Anti-lock Brake System

Service Electronic Throttle Control

Service Power Steering

Cruise Off

Cruise Ready

ACC Override

Cruise Set To XXX mph or km/h

Tire Pressure Screen With Low Tire(s)

Service Tire Pressure System

Park Brake Engaged

Brake Fluid Low

Engine Temperature Hot

Lights On

Right Front Turn Signal Light Out

Right Rear Turn Signal Light Out

Left Front Turn Signal Light Out

Left Rear Turn Signal Light Out

Ignition or Accessory On

Vehicle Not In Park

Remote Start Active Push Start Button

Remote Start Canceled Fuel Low

Remote Start Canceled Door Open

Remote Start Canceled Hood Open

21_WD_OM_EN_USC_t.book Page 86

Page 97 of 340

GETTING TO KNOW YOUR INSTRUMENT PANEL95

The ESC OFF Indicator Light and the ESC Indi-

cator Light come on momentarily each time the

ignition is placed in the ON/RUN or ACC/ON/

RUN position.

The ESC system will make buzzing or clicking

sounds when it is active. This is normal; the

sounds will stop when ESC becomes inactive.

This light will come on when the vehicle is in an

ESC event.

Electronic Stability Control (ESC) OFF

Warning Light

This warning light indicates the ESC is off.

Each time the ignition is turned to

ON/RUN or ACC/ON/RUN, the ESC

system will be on, even if it was turned off

previously.

Low Washer Fluid Warning Light —

If Equipped

This warning light will illuminate when the

windshield washer fluid is low

Ú page 270.

Tire Pressure Monitoring System (TPMS)

Warning Light

The warning light switches on and a

message is displayed to indicate that the

tire pressure is lower than the

recommended value and/or that slow

pressure loss is occurring. In these cases, optimal

tire duration and fuel consumption may not be

guaranteed.

Should one or more tires be in the condition

mentioned above, the display will show the

indications corresponding to each tire.

Each tire, including the spare (if provided), should

be checked monthly when cold and inflated to the

inflation pressure recommended by the vehicle

manufacturer on the vehicle placard or tire

inflation pressure label. If your vehicle has tires of

a different size than the size indicated on the vehicle placard or tire inflation pressure label, you

should determine the proper tire inflation pressure

for those tires.

As an added safety feature, your vehicle has been

equipped with a TPMS that illuminates a low tire

pressure telltale when one or more of your tires is

significantly underinflated. Accordingly, when the

low tire pressure telltale illuminates, you should

stop and check your tires as soon as possible, and

inflate them to the proper pressure. Driving on a

significantly underinflated tire causes the tire to

overheat and can lead to tire failure. Underinflation

also reduces fuel efficiency and tire tread life, and

may affect the vehicle’s handling and stopping

ability.

Please note that the TPMS is not a substitute for

proper tire maintenance, and it is the driver’s

responsibility to maintain correct tire pressure,

even if underinflation has not reached the level to

trigger illumination of the TPMS low tire pressure

telltale.

Your vehicle has also been equipped with a TPMS

malfunction indicator to indicate when the system

is not operating properly. The TPMS malfunction

indicator is combined with the low tire pressure

telltale. When the system detects a malfunction,

the telltale will flash for approximately one minute

and then remain continuously illuminated. This

sequence will continue upon subsequent vehicle

start-ups as long as the malfunction exists.

CAUTION!

Do not continue driving with one or more flat

tires as handling may be compromised. Stop the

vehicle, avoiding sharp braking and steering. If a

tire puncture occurs, repair immediately using

the dedicated tire repair kit and contact an

authorized dealer as soon as possible.

3

21_WD_OM_EN_USC_t.book Page 95

Page 266 of 340

264

SERVICING AND MAINTENANCE

SCHEDULED SERVICING

Your vehicle is equipped with an automatic oil

change indicator system. The oil change indicator

system will remind you that it is time to take your

vehicle in for scheduled maintenance.

Based on engine operation conditions, the oil

change indicator message will illuminate. This

means that service is required for your vehicle.

Operating conditions such as frequent short-trips,

trailer tow, extremely hot or cold ambient

temperatures, and E85 fuel usage will influence

when the “Oil Change Required” message is

displayed. Have your vehicle serviced as soon as

possible, within the next 500 miles (805 km).An authorized dealer will reset the oil change

indicator message after completing the scheduled

oil change.

NOTE:Under no circumstances should oil change

intervals exceed 10,000 miles (16,000 km),

12 months or 350 hours of engine run time,

whichever comes first. The 350 hours of engine

run or idle time is generally only a concern for

fleet customers.

Once A Month Or Before A Long Trip:

Check engine oil level

Check windshield washer fluid level

Check the tire pressure and look for unusual

wear or damage

Check the fluid levels of the coolant reservoir,

brake master cylinder and fill as needed

Check function of all interior and exterior lights

21_WD_OM_EN_USC_t.book Page 264

Page 270 of 340

268SERVICING AND MAINTENANCE

ENGINE COMPARTMENT

3.6L ENGINE

1 — Remote Jump Start Positive Terminal 6 — Engine Air Cleaner Filter

2 — Power Distribution Center (Fuses) 7 — Washer Fluid Reservoir Cap

3 — Engine Oil Dipstick 8 — Engine Coolant Pressure Cap

4 — Engine Oil Fill 9 — Remote Jump Start Negative Terminal

5 — Brake Fluid Reservoir Cap

21_WD_OM_EN_USC_t.book Page 268

Page 271 of 340

SERVICING AND MAINTENANCE269

5.7L ENGINE

1 — Remote Jump Start Negative Terminal 6 — Engine Air Cleaner Filter

2 — Remote Jump Start Positive Terminal 7 — Washer Fluid Reservoir Cap

3 — Power Distribution Center (Fuses) 8 — Engine Oil Dipstick

4 — Engine Oil Fill 9 — Engine Coolant Pressure Cap

5 — Brake Fluid Reservoir Cap 10 — Engine Coolant Reservoir Cap8

21_WD_OM_EN_USC_t.book Page 269

Page 272 of 340

270SERVICING AND MAINTENANCE

CHECKING OIL LEVEL

To ensure proper engine lubrication, the engine oil

must be maintained at the correct level. Check the oil

level at regular intervals, such as every fuel stop. The

best time to check the engine oil level is about five

minutes after a fully warmed up engine is shut off.

Checking the oil while the vehicle is on level ground

will improve the accuracy of the oil level readings.

There are four possible dipstick types:

Crosshatched zone.

Crosshatched zone marked SAFE.

Crosshatched zone marked with MIN at the

low end of the range and MAX at the high end of

the range.

Crosshatched zone marked with dimples at the

MIN and the MAX ends of the range.

NOTE:Always maintain the oil level within the crosshatch

markings on the dipstick.

Adding 1 quart (1.0 liter) of oil when the reading is

at the low end of the dipstick range will raise the oil

level to the high end of the range marking.

ADDING WASHER FLUID

The instrument cluster display will indicate when

the washer fluid level is low. When the sensor

detects a low fluid level, the windshield will light on

the vehicle graphic outline and the “WASHER

FLUID LOW” message will be displayed.

The fluid reservoir for the windshield washers and

the rear window washer is shared. The fluid

reservoir is located in the engine compartment, be

sure to check the fluid level at regular intervals. Fill

the reservoir with windshield washer solvent only

(not radiator antifreeze). When refilling the washer

fluid reservoir, take some washer fluid and apply it

to a cloth or towel and wipe clean the wiper blades,

this will help blade performance. To prevent

freeze-up of your windshield washer system in cold

weather, select a solution or mixture that meets or

exceeds the temperature range of your climate.

This rating information can be found on most

washer fluid containers.

MAINTENANCE-FREE BATTERY

Your vehicle is equipped with a maintenance-free

battery. Water will never have to be added, and

periodic maintenance is not required.

CAUTION!

Overfilling or underfilling the crankcase will

cause aeration or loss of oil pressure. This could

damage your engine.

WARNING!

Commercially available windshield washer

solvents are flammable. They could ignite and

burn you. Care must be exercised when filling or

working around the washer solution.

WARNING!

Battery fluid is a corrosive acid solution and

can burn or even blind you. Do not allow

battery fluid to contact your eyes, skin, or

clothing. Do not lean over a battery when

attaching clamps Úpage 255. If acid

splashes in eyes or on skin, flush the area

immediately with large amounts of water.

Battery gas is flammable and explosive. Keep

flame or sparks away from the battery. Do not

use a booster battery or any other booster

source with an output greater than 12 Volts.

Do not allow cable clamps to touch each

other.

Battery posts, terminals, and related accesso -

ries contain lead and lead compounds. Wash

hands after handling.

21_WD_OM_EN_USC_t.book Page 270

Page 278 of 340

276SERVICING AND MAINTENANCE

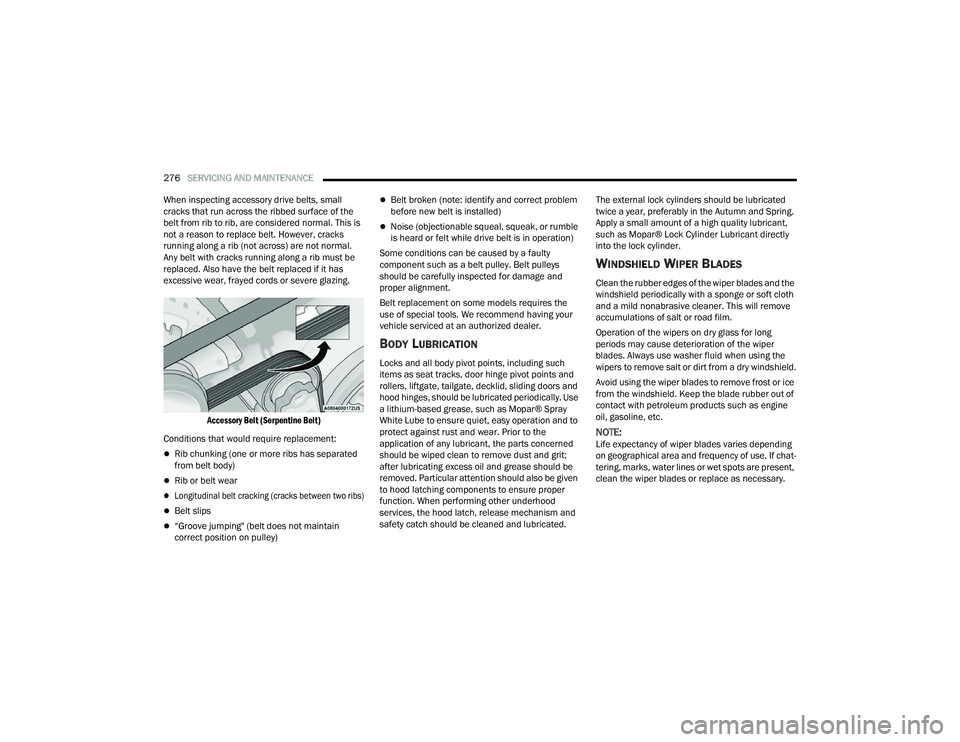

When inspecting accessory drive belts, small

cracks that run across the ribbed surface of the

belt from rib to rib, are considered normal. This is

not a reason to replace belt. However, cracks

running along a rib (not across) are not normal.

Any belt with cracks running along a rib must be

replaced. Also have the belt replaced if it has

excessive wear, frayed cords or severe glazing.

Accessory Belt (Serpentine Belt)

Conditions that would require replacement:

Rib chunking (one or more ribs has separated

from belt body)

Rib or belt wear

Longitudinal belt cracking (cracks between two ribs)

Belt slips

“Groove jumping" (belt does not maintain

correct position on pulley)

Belt broken (note: identify and correct problem

before new belt is installed)

Noise (objectionable squeal, squeak, or rumble

is heard or felt while drive belt is in operation)

Some conditions can be caused by a faulty

component such as a belt pulley. Belt pulleys

should be carefully inspected for damage and

proper alignment.

Belt replacement on some models requires the

use of special tools. We recommend having your

vehicle serviced at an authorized dealer.

BODY LUBRICATION

Locks and all body pivot points, including such

items as seat tracks, door hinge pivot points and

rollers, liftgate, tailgate, decklid, sliding doors and

hood hinges, should be lubricated periodically. Use

a lithium-based grease, such as Mopar® Spray

White Lube to ensure quiet, easy operation and to

protect against rust and wear. Prior to the

application of any lubricant, the parts concerned

should be wiped clean to remove dust and grit;

after lubricating excess oil and grease should be

removed. Particular attention should also be given

to hood latching components to ensure proper

function. When performing other underhood

services, the hood latch, release mechanism and

safety catch should be cleaned and lubricated. The external lock cylinders should be lubricated

twice a year, preferably in the Autumn and Spring.

Apply a small amount of a high quality lubricant,

such as Mopar® Lock Cylinder Lubricant directly

into the lock cylinder.

WINDSHIELD WIPER BLADES

Clean the rubber edges of the wiper blades and the

windshield periodically with a sponge or soft cloth

and a mild nonabrasive cleaner. This will remove

accumulations of salt or road film.

Operation of the wipers on dry glass for long

periods may cause deterioration of the wiper

blades. Always use washer fluid when using the

wipers to remove salt or dirt from a dry windshield.

Avoid using the wiper blades to remove frost or ice

from the windshield. Keep the blade rubber out of

contact with petroleum products such as engine

oil, gasoline, etc.

NOTE:Life expectancy of wiper blades varies depending

on geographical area and frequency of use. If chat

-

tering, marks, water lines or wet spots are present,

clean the wiper blades or replace as necessary.

21_WD_OM_EN_USC_t.book Page 276