ignition DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 655 of 1200

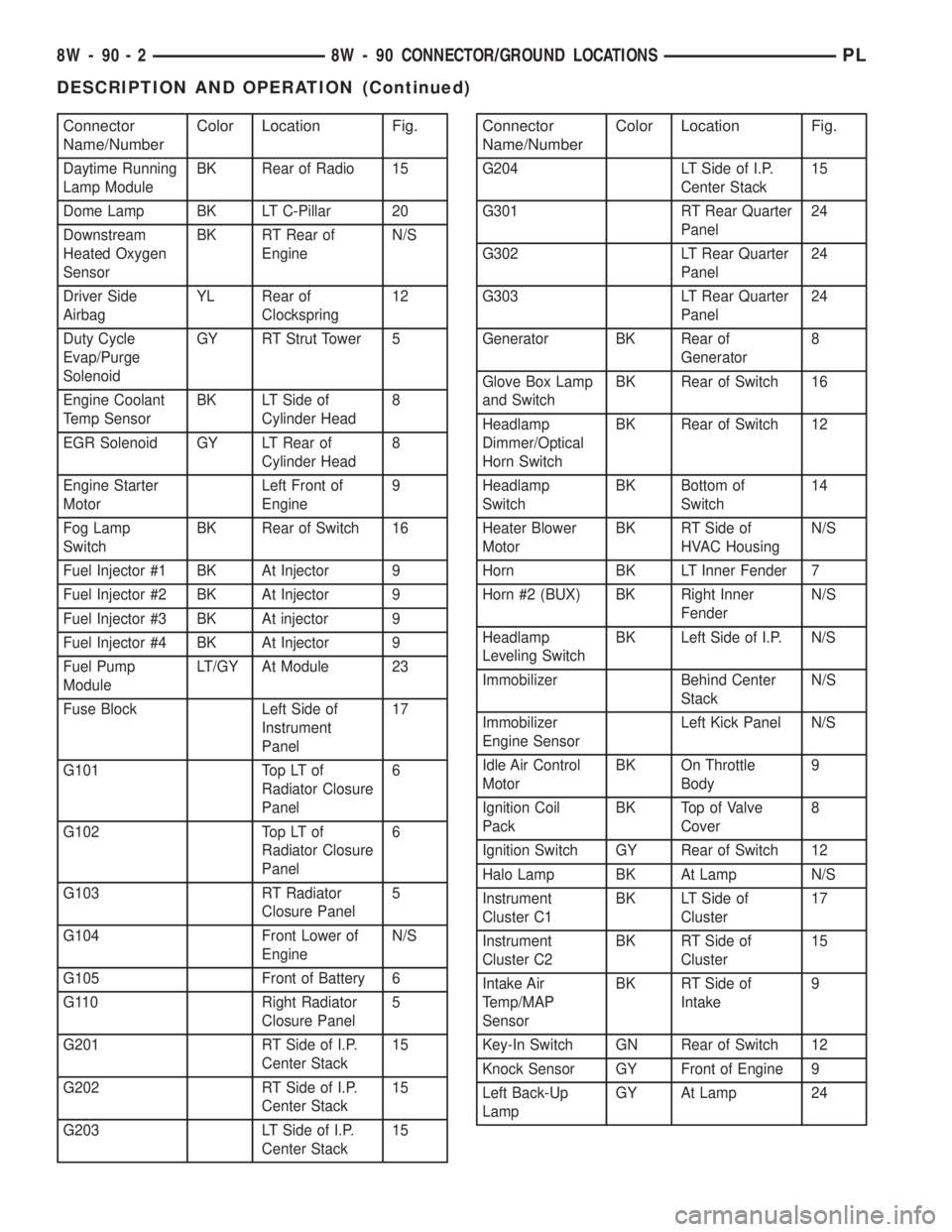

Connector

Name/NumberColor Location Fig.

Daytime Running

Lamp ModuleBK Rear of Radio 15

Dome Lamp BK LT C-Pillar 20

Downstream

Heated Oxygen

SensorBK RT Rear of

EngineN/S

Driver Side

AirbagYL Rear of

Clockspring12

Duty Cycle

Evap/Purge

SolenoidGY RT Strut Tower 5

Engine Coolant

Temp SensorBK LT Side of

Cylinder Head8

EGR Solenoid GY LT Rear of

Cylinder Head8

Engine Starter

MotorLeft Front of

Engine9

Fog Lamp

SwitchBK Rear of Switch 16

Fuel Injector #1 BK At Injector 9

Fuel Injector #2 BK At Injector 9

Fuel Injector #3 BK At injector 9

Fuel Injector #4 BK At Injector 9

Fuel Pump

ModuleLT/GY At Module 23

Fuse Block Left Side of

Instrument

Panel17

G101 Top LT of

Radiator Closure

Panel6

G102 Top LT of

Radiator Closure

Panel6

G103 RT Radiator

Closure Panel5

G104 Front Lower of

EngineN/S

G105 Front of Battery 6

G110 Right Radiator

Closure Panel5

G201 RT Side of I.P.

Center Stack15

G202 RT Side of I.P.

Center Stack15

G203 LT Side of I.P.

Center Stack15

Connector

Name/NumberColor Location Fig.

G204 LT Side of I.P.

Center Stack15

G301 RT Rear Quarter

Panel24

G302 LT Rear Quarter

Panel24

G303 LT Rear Quarter

Panel24

Generator BK Rear of

Generator8

Glove Box Lamp

and SwitchBK Rear of Switch 16

Headlamp

Dimmer/Optical

Horn SwitchBK Rear of Switch 12

Headlamp

SwitchBK Bottom of

Switch14

Heater Blower

MotorBK RT Side of

HVAC HousingN/S

Horn BK LT Inner Fender 7

Horn #2 (BUX) BK Right Inner

FenderN/S

Headlamp

Leveling SwitchBK Left Side of I.P. N/S

Immobilizer Behind Center

StackN/S

Immobilizer

Engine SensorLeft Kick Panel N/S

Idle Air Control

MotorBK On Throttle

Body9

Ignition Coil

PackBK Top of Valve

Cover8

Ignition Switch GY Rear of Switch 12

Halo Lamp BK At Lamp N/S

Instrument

Cluster C1BK LT Side of

Cluster17

Instrument

Cluster C2BK RT Side of

Cluster15

Intake Air

Temp/MAP

SensorBK RT Side of

Intake9

Key-In Switch GN Rear of Switch 12

Knock Sensor GY Front of Engine 9

Left Back-Up

LampGY At Lamp 24

8W - 90 - 2 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

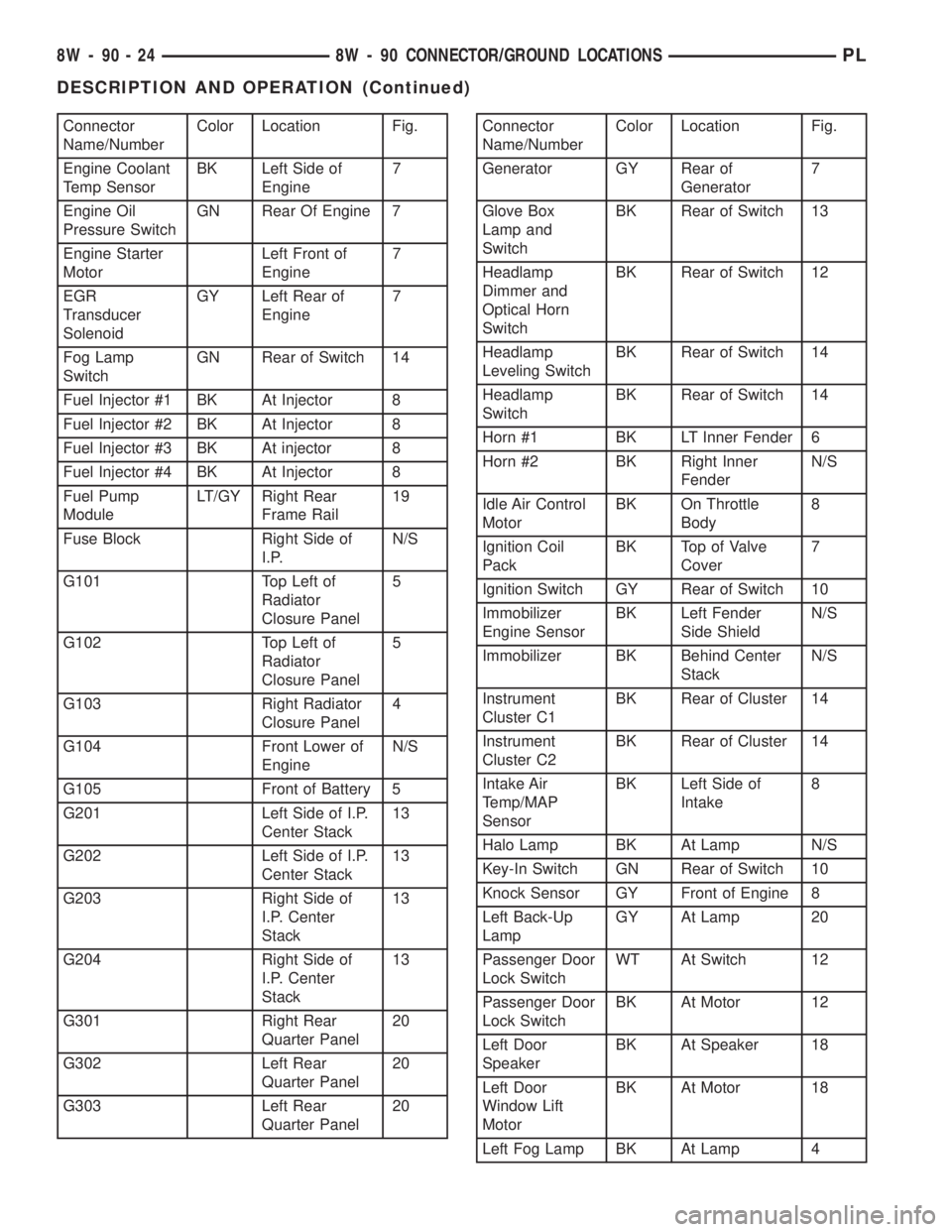

Page 677 of 1200

Connector

Name/NumberColor Location Fig.

Engine Coolant

Temp SensorBK Left Side of

Engine7

Engine Oil

Pressure SwitchGN Rear Of Engine 7

Engine Starter

MotorLeft Front of

Engine7

EGR

Transducer

SolenoidGY Left Rear of

Engine7

Fog Lamp

SwitchGN Rear of Switch 14

Fuel Injector #1 BK At Injector 8

Fuel Injector #2 BK At Injector 8

Fuel Injector #3 BK At injector 8

Fuel Injector #4 BK At Injector 8

Fuel Pump

ModuleLT/GY Right Rear

Frame Rail19

Fuse Block Right Side of

I.P.N/S

G101 Top Left of

Radiator

Closure Panel5

G102 Top Left of

Radiator

Closure Panel5

G103 Right Radiator

Closure Panel4

G104 Front Lower of

EngineN/S

G105 Front of Battery 5

G201 Left Side of I.P.

Center Stack13

G202 Left Side of I.P.

Center Stack13

G203 Right Side of

I.P. Center

Stack13

G204 Right Side of

I.P. Center

Stack13

G301 Right Rear

Quarter Panel20

G302 Left Rear

Quarter Panel20

G303 Left Rear

Quarter Panel20Connector

Name/NumberColor Location Fig.

Generator GY Rear of

Generator7

Glove Box

Lamp and

SwitchBK Rear of Switch 13

Headlamp

Dimmer and

Optical Horn

SwitchBK Rear of Switch 12

Headlamp

Leveling SwitchBK Rear of Switch 14

Headlamp

SwitchBK Rear of Switch 14

Horn #1 BK LT Inner Fender 6

Horn #2 BK Right Inner

FenderN/S

Idle Air Control

MotorBK On Throttle

Body8

Ignition Coil

PackBK Top of Valve

Cover7

Ignition Switch GY Rear of Switch 10

Immobilizer

Engine SensorBK Left Fender

Side ShieldN/S

Immobilizer BK Behind Center

StackN/S

Instrument

Cluster C1BK Rear of Cluster 14

Instrument

Cluster C2BK Rear of Cluster 14

Intake Air

Temp/MAP

SensorBK Left Side of

Intake8

Halo Lamp BK At Lamp N/S

Key-In Switch GN Rear of Switch 10

Knock Sensor GY Front of Engine 8

Left Back-Up

LampGY At Lamp 20

Passenger Door

Lock SwitchWT At Switch 12

Passenger Door

Lock SwitchBK At Motor 12

Left Door

SpeakerBK At Speaker 18

Left Door

Window Lift

MotorBK At Motor 18

Left Fog Lamp BK At Lamp 4

8W - 90 - 24 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 694 of 1200

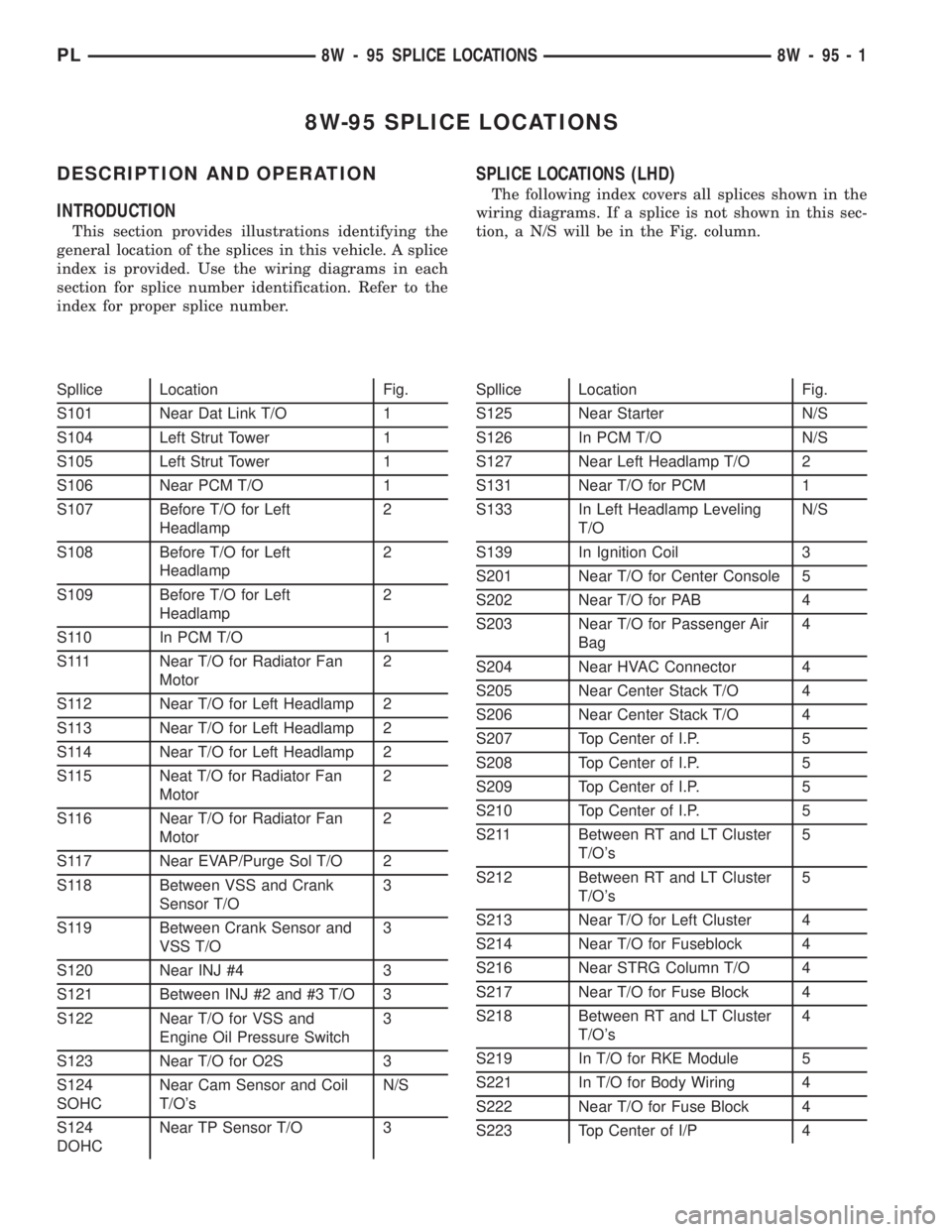

8W-95 SPLICE LOCATIONS

DESCRIPTION AND OPERATION

INTRODUCTION

This section provides illustrations identifying the

general location of the splices in this vehicle. A splice

index is provided. Use the wiring diagrams in each

section for splice number identification. Refer to the

index for proper splice number.

SPLICE LOCATIONS (LHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S101 Near Dat Link T/O 1

S104 Left Strut Tower 1

S105 Left Strut Tower 1

S106 Near PCM T/O 1

S107 Before T/O for Left

Headlamp2

S108 Before T/O for Left

Headlamp2

S109 Before T/O for Left

Headlamp2

S110 In PCM T/O 1

S111 Near T/O for Radiator Fan

Motor2

S112 Near T/O for Left Headlamp 2

S113 Near T/O for Left Headlamp 2

S114 Near T/O for Left Headlamp 2

S115 Neat T/O for Radiator Fan

Motor2

S116 Near T/O for Radiator Fan

Motor2

S117 Near EVAP/Purge Sol T/O 2

S118 Between VSS and Crank

Sensor T/O3

S119 Between Crank Sensor and

VSS T/O3

S120 Near INJ #4 3

S121 Between INJ #2 and #3 T/O 3

S122 Near T/O for VSS and

Engine Oil Pressure Switch3

S123 Near T/O for O2S 3

S124

SOHCNear Cam Sensor and Coil

T/O'sN/S

S124

DOHCNear TP Sensor T/O 3Spllice Location Fig.

S125 Near Starter N/S

S126 In PCM T/O N/S

S127 Near Left Headlamp T/O 2

S131 Near T/O for PCM 1

S133 In Left Headlamp Leveling

T/ON/S

S139 In Ignition Coil 3

S201 Near T/O for Center Console 5

S202 Near T/O for PAB 4

S203 Near T/O for Passenger Air

Bag4

S204 Near HVAC Connector 4

S205 Near Center Stack T/O 4

S206 Near Center Stack T/O 4

S207 Top Center of I.P. 5

S208 Top Center of I.P. 5

S209 Top Center of I.P. 5

S210 Top Center of I.P. 5

S211 Between RT and LT Cluster

T/O's5

S212 Between RT and LT Cluster

T/O's5

S213 Near T/O for Left Cluster 4

S214 Near T/O for Fuseblock 4

S216 Near STRG Column T/O 4

S217 Near T/O for Fuse Block 4

S218 Between RT and LT Cluster

T/O's4

S219 In T/O for RKE Module 5

S221 In T/O for Body Wiring 4

S222 Near T/O for Fuse Block 4

S223 Top Center of I/P 4

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 1

Page 704 of 1200

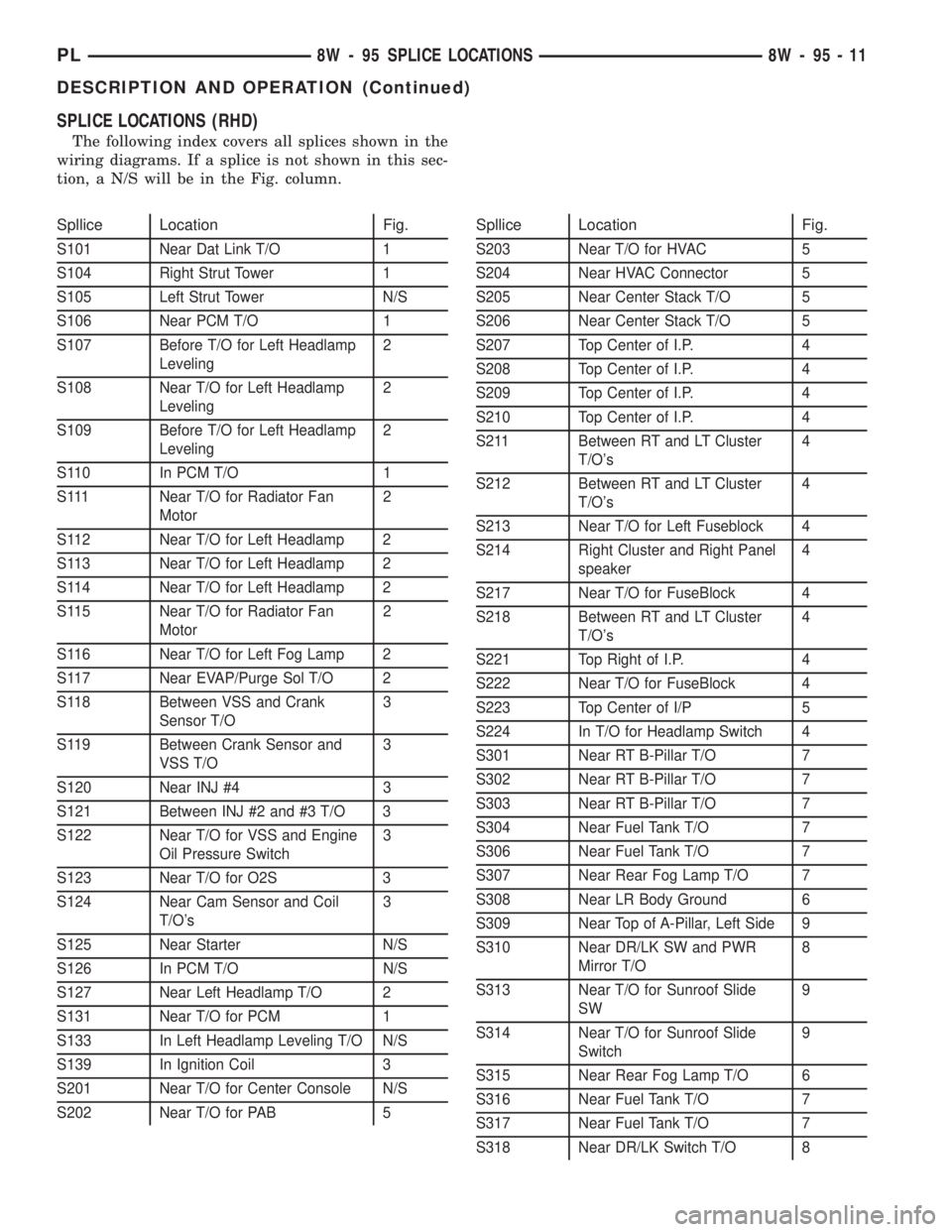

SPLICE LOCATIONS (RHD)

The following index covers all splices shown in the

wiring diagrams. If a splice is not shown in this sec-

tion, a N/S will be in the Fig. column.

Spllice Location Fig.

S101 Near Dat Link T/O 1

S104 Right Strut Tower 1

S105 Left Strut Tower N/S

S106 Near PCM T/O 1

S107 Before T/O for Left Headlamp

Leveling2

S108 Near T/O for Left Headlamp

Leveling2

S109 Before T/O for Left Headlamp

Leveling2

S110 In PCM T/O 1

S111 Near T/O for Radiator Fan

Motor2

S112 Near T/O for Left Headlamp 2

S113 Near T/O for Left Headlamp 2

S114 Near T/O for Left Headlamp 2

S115 Near T/O for Radiator Fan

Motor2

S116 Near T/O for Left Fog Lamp 2

S117 Near EVAP/Purge Sol T/O 2

S118 Between VSS and Crank

Sensor T/O3

S119 Between Crank Sensor and

VSS T/O3

S120 Near INJ #4 3

S121 Between INJ #2 and #3 T/O 3

S122 Near T/O for VSS and Engine

Oil Pressure Switch3

S123 Near T/O for O2S 3

S124 Near Cam Sensor and Coil

T/O's3

S125 Near Starter N/S

S126 In PCM T/O N/S

S127 Near Left Headlamp T/O 2

S131 Near T/O for PCM 1

S133 In Left Headlamp Leveling T/O N/S

S139 In Ignition Coil 3

S201 Near T/O for Center Console N/S

S202 Near T/O for PAB 5

Spllice Location Fig.

S203 Near T/O for HVAC 5

S204 Near HVAC Connector 5

S205 Near Center Stack T/O 5

S206 Near Center Stack T/O 5

S207 Top Center of I.P. 4

S208 Top Center of I.P. 4

S209 Top Center of I.P. 4

S210 Top Center of I.P. 4

S211 Between RT and LT Cluster

T/O's4

S212 Between RT and LT Cluster

T/O's4

S213 Near T/O for Left Fuseblock 4

S214 Right Cluster and Right Panel

speaker4

S217 Near T/O for FuseBlock 4

S218 Between RT and LT Cluster

T/O's4

S221 Top Right of I.P. 4

S222 Near T/O for FuseBlock 4

S223 Top Center of I/P 5

S224 In T/O for Headlamp Switch 4

S301 Near RT B-Pillar T/O 7

S302 Near RT B-Pillar T/O 7

S303 Near RT B-Pillar T/O 7

S304 Near Fuel Tank T/O 7

S306 Near Fuel Tank T/O 7

S307 Near Rear Fog Lamp T/O 7

S308 Near LR Body Ground 6

S309 Near Top of A-Pillar, Left Side 9

S310 Near DR/LK SW and PWR

Mirror T/O8

S313 Near T/O for Sunroof Slide

SW9

S314 Near T/O for Sunroof Slide

Switch9

S315 Near Rear Fog Lamp T/O 6

S316 Near Fuel Tank T/O 7

S317 Near Fuel Tank T/O 7

S318 Near DR/LK Switch T/O 8

PL8W - 95 SPLICE LOCATIONS 8W - 95 - 11

DESCRIPTION AND OPERATION (Continued)

Page 715 of 1200

assure gasket rails are flat. Flatten rails with a ham-

mer on a heavy steel plate if required. Gasket sur-

faces must be free of oil and dirt. Make sure old

gasket material is removed from blind attaching

holes.

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 inch.) diameter or less of seal-

ant to one gasket surface. Be certain the material

surrounds each mounting hole. Excess material can

easily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

The MopartSilicone Rubber Adhesive Sealant gas-

ket material or equivalent should be applied in a con-

tinuous bead approximately 3 mm (0.120 inch) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 inch.)

drop is placed in the center of the gasket contact

area. Uncured sealant may be removed with a shop

towel. Components should be torqued in place while

the sealant is still wet to the touch (within 10 min-

utes). The usage of a locating dowel is recommended

during assembly to prevent smearing material off the

location.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

ENGINE CORE PLUGS

REMOVAL

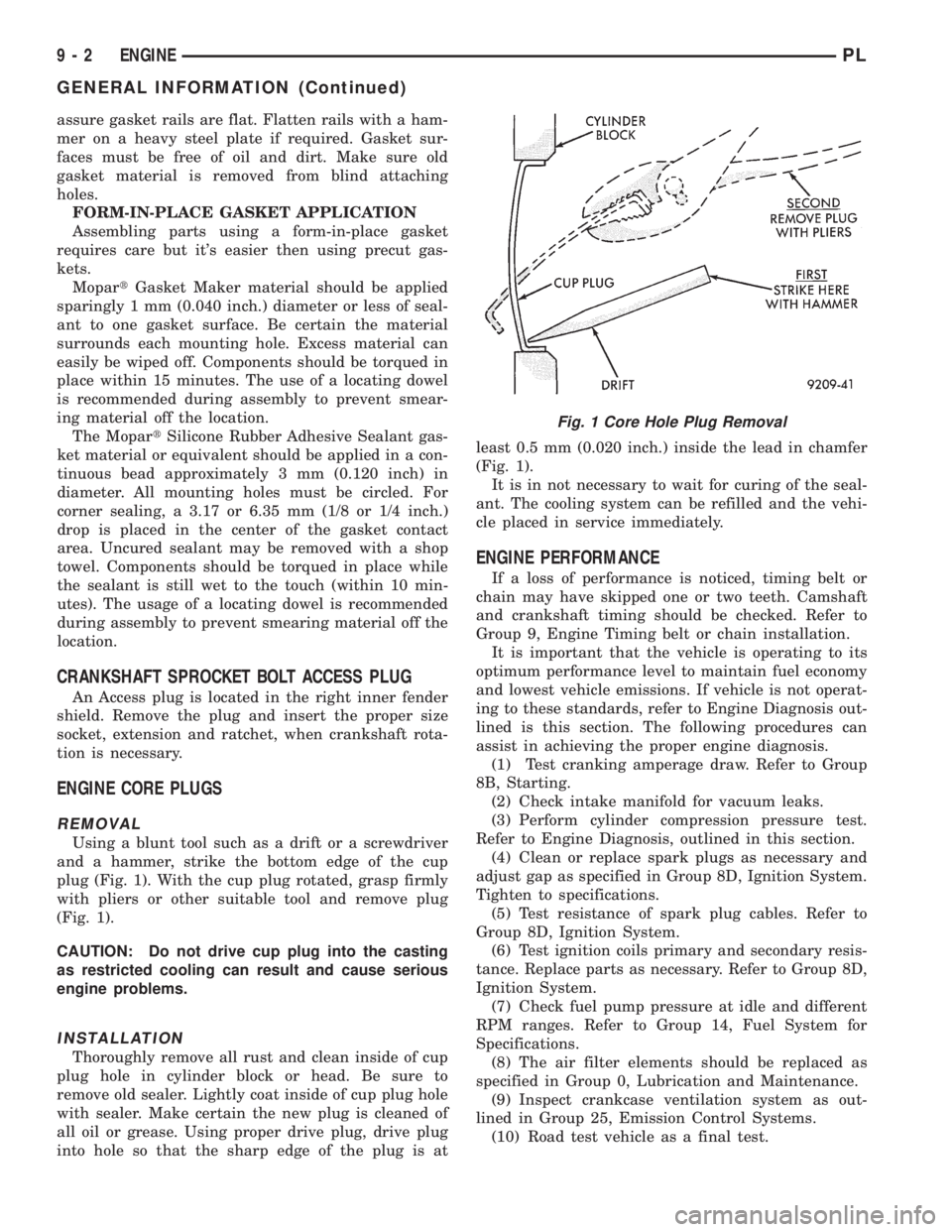

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 1). With the cup plug rotated, grasp firmly

with pliers or other suitable tool and remove plug

(Fig. 1).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly remove all rust and clean inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with sealer. Make certain the new plug is cleaned of

all oil or grease. Using proper drive plug, drive plug

into hole so that the sharp edge of the plug is atleast 0.5 mm (0.020 inch.) inside the lead in chamfer

(Fig. 1).

It is in not necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-

ing to these standards, refer to Engine Diagnosis out-

lined is this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis, outlined in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system as out-

lined in Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.

Fig. 1 Core Hole Plug Removal

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)

Page 720 of 1200

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST........................ 8

CYLINDER COMPRESSION PRESSURE TEST . . 7

ENGINE DIAGNOSISÐMECHANICAL......... 11

ENGINE DIAGNOSISÐPERFORMANCE...... 10GENERAL INFORMATION.................. 7

INSPECTION (ENGINE OIL LEAKS IN

GENERAL)............................ 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS..... 7

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS.. 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM'S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

PLENGINE 9 - 7

Page 721 of 1200

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary

and adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance,.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

9 - 8 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 723 of 1200

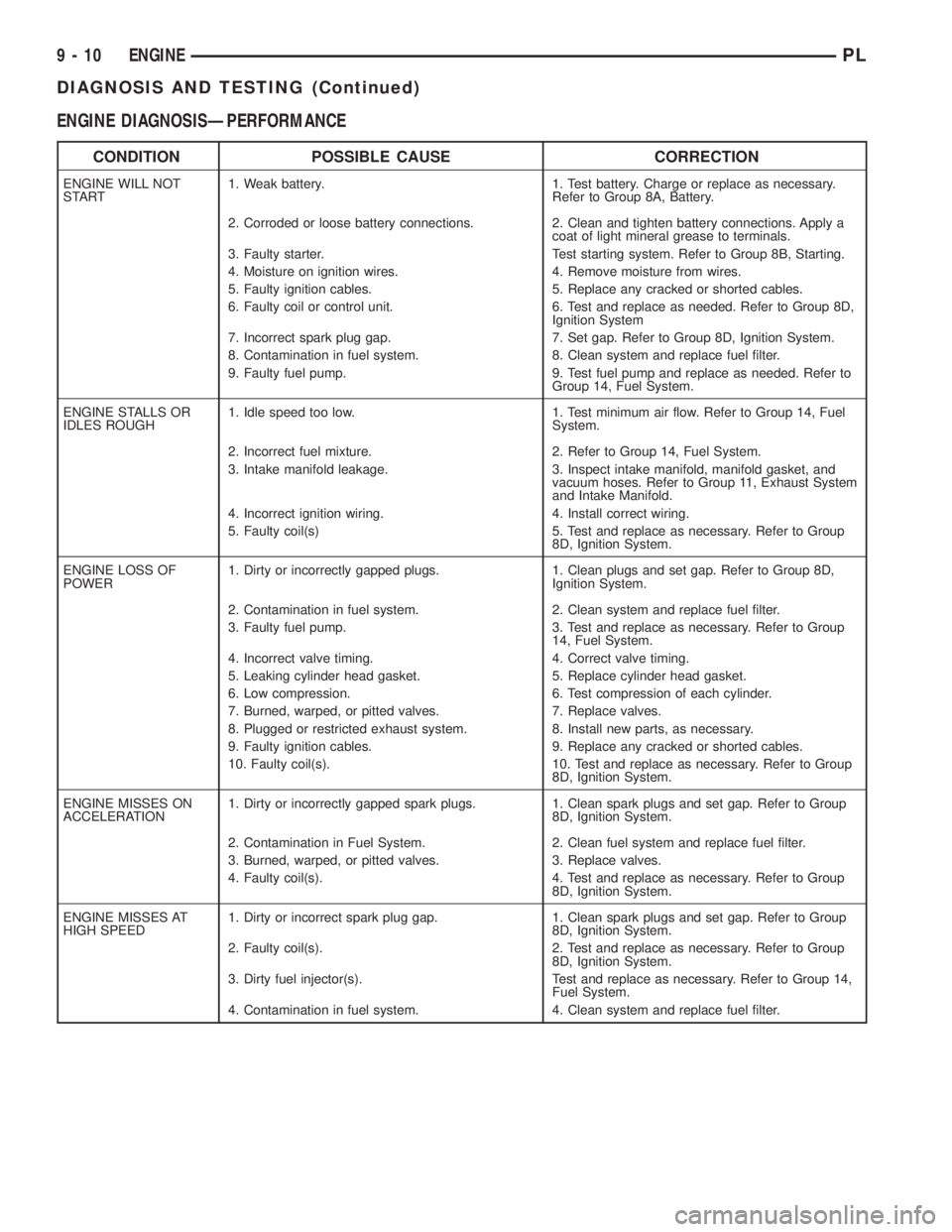

ENGINE DIAGNOSISÐPERFORMANCE

CONDITION POSSIBLE CAUSE CORRECTION

ENGINE WILL NOT

START1. Weak battery. 1. Test battery. Charge or replace as necessary.

Refer to Group 8A, Battery.

2. Corroded or loose battery connections. 2. Clean and tighten battery connections. Apply a

coat of light mineral grease to terminals.

3. Faulty starter. Test starting system. Refer to Group 8B, Starting.

4. Moisture on ignition wires. 4. Remove moisture from wires.

5. Faulty ignition cables. 5. Replace any cracked or shorted cables.

6. Faulty coil or control unit. 6. Test and replace as needed. Refer to Group 8D,

Ignition System

7. Incorrect spark plug gap. 7. Set gap. Refer to Group 8D, Ignition System.

8. Contamination in fuel system. 8. Clean system and replace fuel filter.

9. Faulty fuel pump. 9. Test fuel pump and replace as needed. Refer to

Group 14, Fuel System.

ENGINE STALLS OR

IDLES ROUGH1. Idle speed too low. 1. Test minimum air flow. Refer to Group 14, Fuel

System.

2. Incorrect fuel mixture. 2. Refer to Group 14, Fuel System.

3. Intake manifold leakage. 3. Inspect intake manifold, manifold gasket, and

vacuum hoses. Refer to Group 11, Exhaust System

and Intake Manifold.

4. Incorrect ignition wiring. 4. Install correct wiring.

5. Faulty coil(s) 5. Test and replace as necessary. Refer to Group

8D, Ignition System.

ENGINE LOSS OF

POWER1. Dirty or incorrectly gapped plugs. 1. Clean plugs and set gap. Refer to Group 8D,

Ignition System.

2. Contamination in fuel system. 2. Clean system and replace fuel filter.

3. Faulty fuel pump. 3. Test and replace as necessary. Refer to Group

14, Fuel System.

4. Incorrect valve timing. 4. Correct valve timing.

5. Leaking cylinder head gasket. 5. Replace cylinder head gasket.

6. Low compression. 6. Test compression of each cylinder.

7. Burned, warped, or pitted valves. 7. Replace valves.

8. Plugged or restricted exhaust system. 8. Install new parts, as necessary.

9. Faulty ignition cables. 9. Replace any cracked or shorted cables.

10. Faulty coil(s). 10. Test and replace as necessary. Refer to Group

8D, Ignition System.

ENGINE MISSES ON

ACCELERATION1. Dirty or incorrectly gapped spark plugs. 1. Clean spark plugs and set gap. Refer to Group

8D, Ignition System.

2. Contamination in Fuel System. 2. Clean fuel system and replace fuel filter.

3. Burned, warped, or pitted valves. 3. Replace valves.

4. Faulty coil(s). 4. Test and replace as necessary. Refer to Group

8D, Ignition System.

ENGINE MISSES AT

HIGH SPEED1. Dirty or incorrect spark plug gap. 1. Clean spark plugs and set gap. Refer to Group

8D, Ignition System.

2. Faulty coil(s). 2. Test and replace as necessary. Refer to Group

8D, Ignition System.

3. Dirty fuel injector(s). Test and replace as necessary. Refer to Group 14,

Fuel System.

4. Contamination in fuel system. 4. Clean system and replace fuel filter.

9 - 10 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 734 of 1200

(8) Install A/C compressor and hoses. Refer to

Group 24, Heater and Air Conditioning for procedure.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(10) Install front engine mount. Refer to this sec-

tion for procedure.

(11) Manual transmission: Install power hop

damper.

(12) Install inner splash shield. Install wheels and

tires.

(13)Manual Transmission:Connect clutch cable

and linkages. Refer to Group 6, Manual Transaxle

Clutch.

(14)Automatic Transmission:Connect shifter

and kickdown linkage. Refer to Group 21, Transaxle

for procedures.

(15) Connect fuel line and heater hoses.

(16) Install ground straps. Connect engine and

throttle body connections and harnesses. Refer to

Group 8, Electrical for procedure.

(17) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(18) Install radiator and shroud assembly. Install

radiator hoses. Fill cooling system. Refer to Group 7,

Cooling System for filling procedure.

(19) Install battery tray and battery. Set Power-

train Control Module (PCM) into place.

(20) Install air cleaner and hoses.

(21) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(22) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

(23) Start engine and run until operating temper-

ature is reached.

(24) Adjust transmission linkage, if necessary.

CYLINDER HEAD COVER

REMOVAL

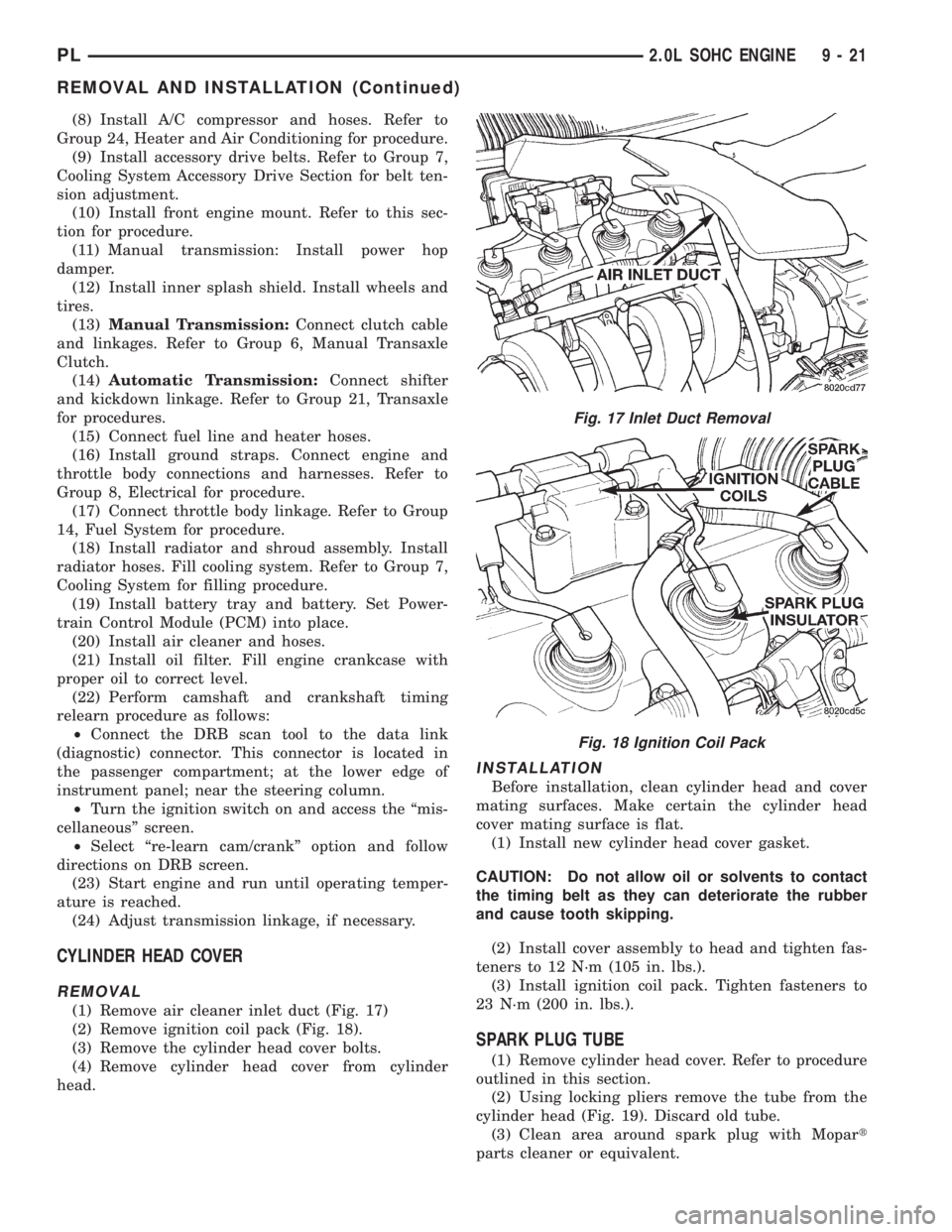

(1) Remove air cleaner inlet duct (Fig. 17)

(2) Remove ignition coil pack (Fig. 18).

(3) Remove the cylinder head cover bolts.

(4) Remove cylinder head cover from cylinder

head.

INSTALLATION

Before installation, clean cylinder head and cover

mating surfaces. Make certain the cylinder head

cover mating surface is flat.

(1) Install new cylinder head cover gasket.

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.

(2) Install cover assembly to head and tighten fas-

teners to 12 N´m (105 in. lbs.).

(3) Install ignition coil pack. Tighten fasteners to

23 N´m (200 in. lbs.).

SPARK PLUG TUBE

(1) Remove cylinder head cover. Refer to procedure

outlined in this section.

(2) Using locking pliers remove the tube from the

cylinder head (Fig. 19). Discard old tube.

(3) Clean area around spark plug with Mopart

parts cleaner or equivalent.

Fig. 17 Inlet Duct Removal

Fig. 18 Ignition Coil Pack

PL2.0L SOHC ENGINE 9 - 21

REMOVAL AND INSTALLATION (Continued)

Page 736 of 1200

²Zero the dial indicator.

²Move camshaft forward to limits of travel and

read dial indicator.

²End play travel: 0.13 - 0.33 mm (0.005 - 0.013

in.).

(5) Install front camshaft seal. Camshaft must be

installed before the camshaft seal is installed. Refer

to procedure outlined in this section.

(6) Install cylinder head. Refer to procedure out-

lined in this section.

(7) Install rear timing belt cover.

(8) Install camshaft sprocket and tighten to 115

N´m (85 ft. lbs.).

(9) Install timing belt tensioner and timing belt.

Refer to procedures outlined in this section.

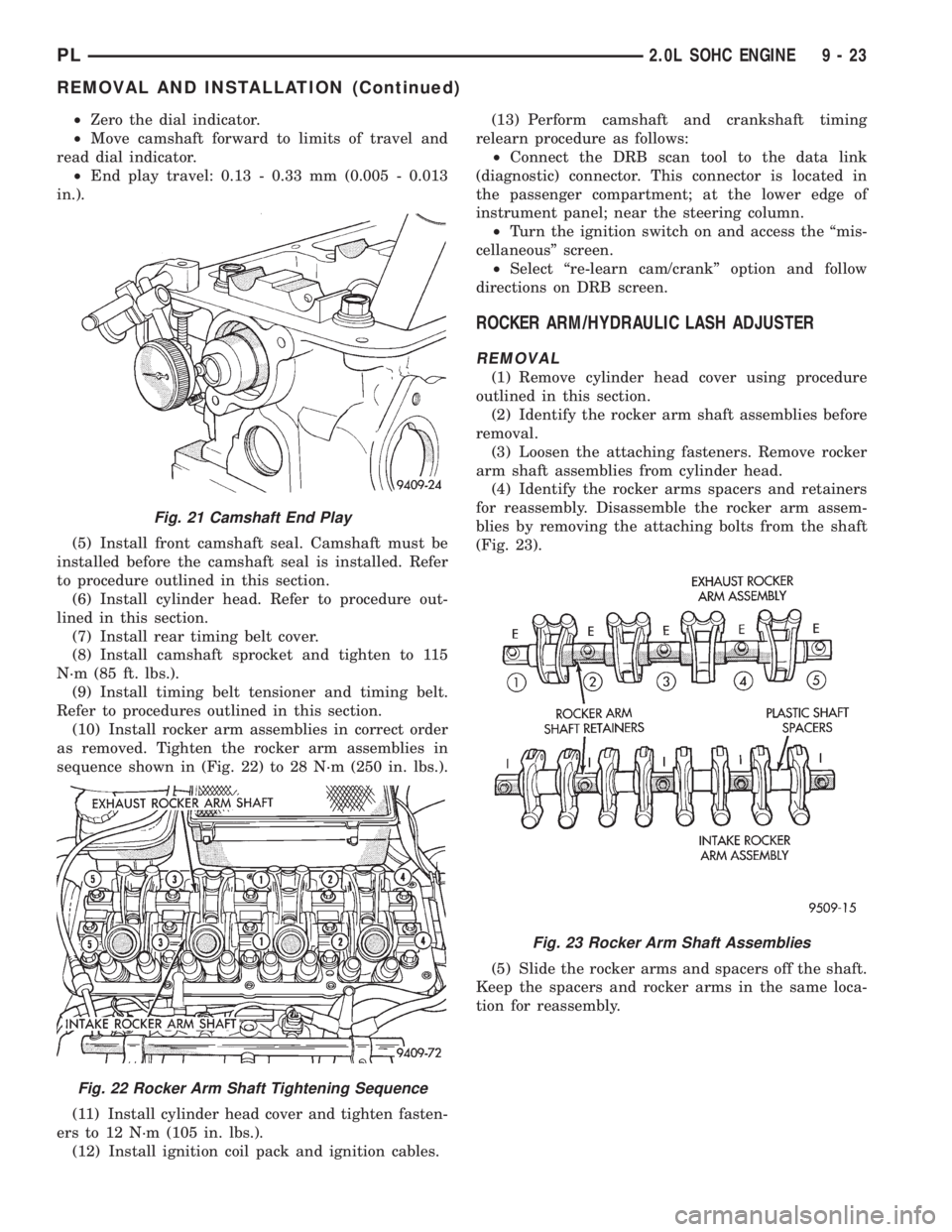

(10) Install rocker arm assemblies in correct order

as removed. Tighten the rocker arm assemblies in

sequence shown in (Fig. 22) to 28 N´m (250 in. lbs.).

(11) Install cylinder head cover and tighten fasten-

ers to 12 N´m (105 in. lbs.).

(12) Install ignition coil pack and ignition cables.(13) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

ROCKER ARM/HYDRAULIC LASH ADJUSTER

REMOVAL

(1) Remove cylinder head cover using procedure

outlined in this section.

(2) Identify the rocker arm shaft assemblies before

removal.

(3) Loosen the attaching fasteners. Remove rocker

arm shaft assemblies from cylinder head.

(4) Identify the rocker arms spacers and retainers

for reassembly. Disassemble the rocker arm assem-

blies by removing the attaching bolts from the shaft

(Fig. 23).

(5) Slide the rocker arms and spacers off the shaft.

Keep the spacers and rocker arms in the same loca-

tion for reassembly.

Fig. 21 Camshaft End Play

Fig. 22 Rocker Arm Shaft Tightening Sequence

Fig. 23 Rocker Arm Shaft Assemblies

PL2.0L SOHC ENGINE 9 - 23

REMOVAL AND INSTALLATION (Continued)