ignition DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 800 of 1200

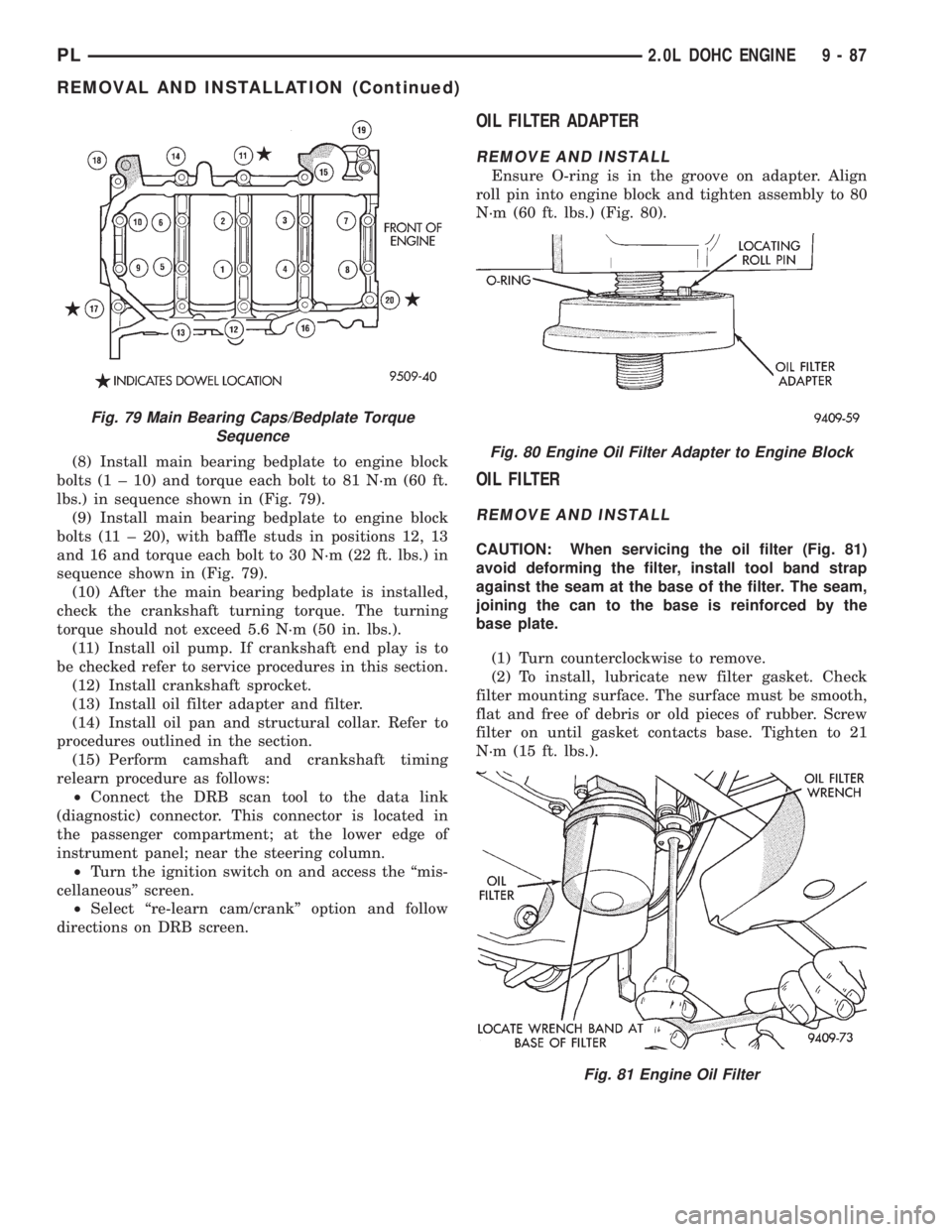

(8) Install main bearing bedplate to engine block

bolts (1 ± 10) and torque each bolt to 81 N´m (60 ft.

lbs.) in sequence shown in (Fig. 79).

(9) Install main bearing bedplate to engine block

bolts (11 ± 20), with baffle studs in positions 12, 13

and 16 and torque each bolt to 30 N´m (22 ft. lbs.) in

sequence shown in (Fig. 79).

(10) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(11) Install oil pump. If crankshaft end play is to

be checked refer to service procedures in this section.

(12) Install crankshaft sprocket.

(13) Install oil filter adapter and filter.

(14) Install oil pan and structural collar. Refer to

procedures outlined in the section.

(15) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

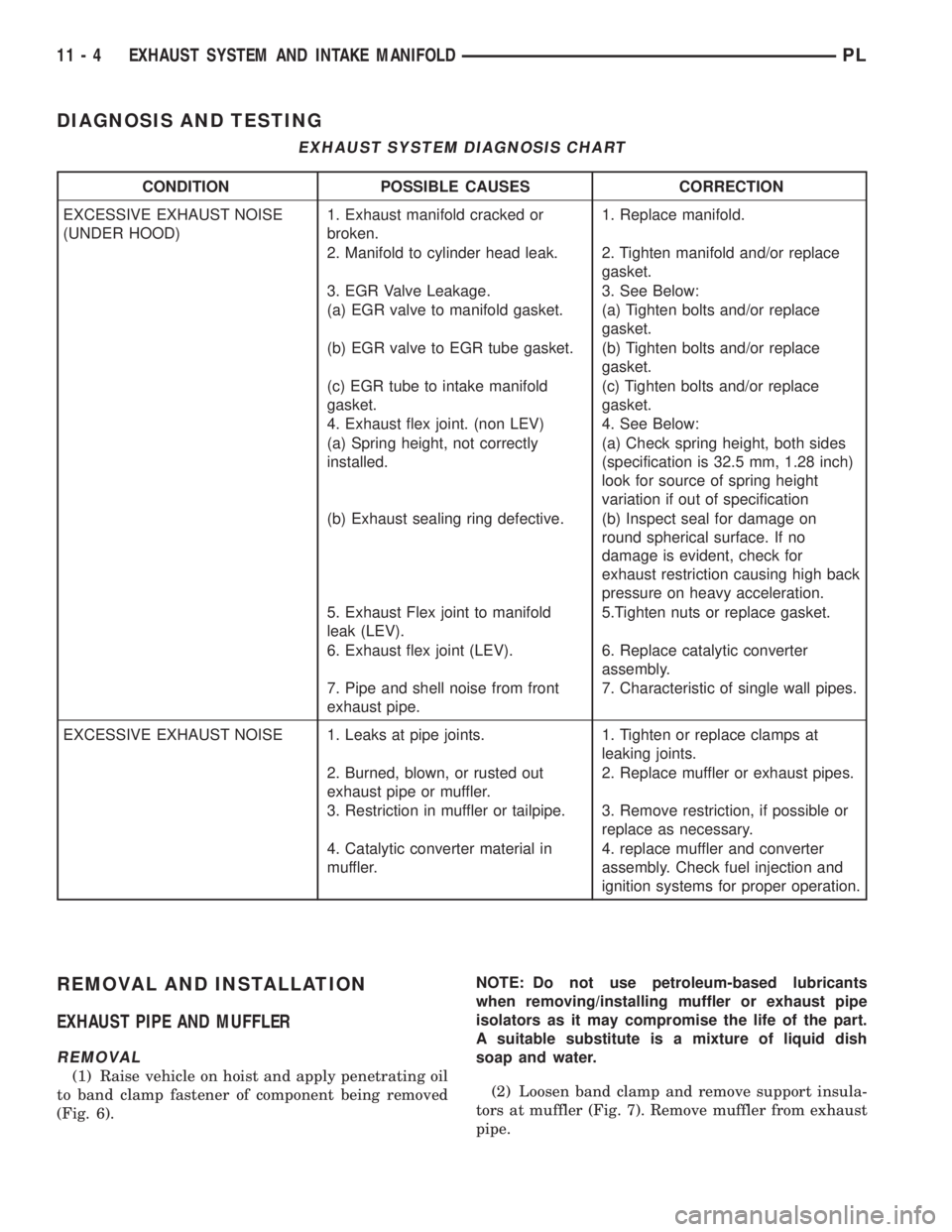

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 80).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 81)

avoid deforming the filter, install tool band strap

against the seam at the base of the filter. The seam,

joining the can to the base is reinforced by the

base plate.

(1) Turn counterclockwise to remove.

(2) To install, lubricate new filter gasket. Check

filter mounting surface. The surface must be smooth,

flat and free of debris or old pieces of rubber. Screw

filter on until gasket contacts base. Tighten to 21

N´m (15 ft. lbs.).

Fig. 79 Main Bearing Caps/Bedplate Torque

Sequence

Fig. 80 Engine Oil Filter Adapter to Engine Block

Fig. 81 Engine Oil Filter

PL2.0L DOHC ENGINE 9 - 87

REMOVAL AND INSTALLATION (Continued)

Page 819 of 1200

DIAGNOSIS AND TESTING

REMOVAL AND INSTALLATION

EXHAUST PIPE AND MUFFLER

REMOVAL

(1) Raise vehicle on hoist and apply penetrating oil

to band clamp fastener of component being removed

(Fig. 6).NOTE: Do not use petroleum-based lubricants

when removing/installing muffler or exhaust pipe

isolators as it may compromise the life of the part.

A suitable substitute is a mixture of liquid dish

soap and water.

(2) Loosen band clamp and remove support insula-

tors at muffler (Fig. 7). Remove muffler from exhaust

pipe.

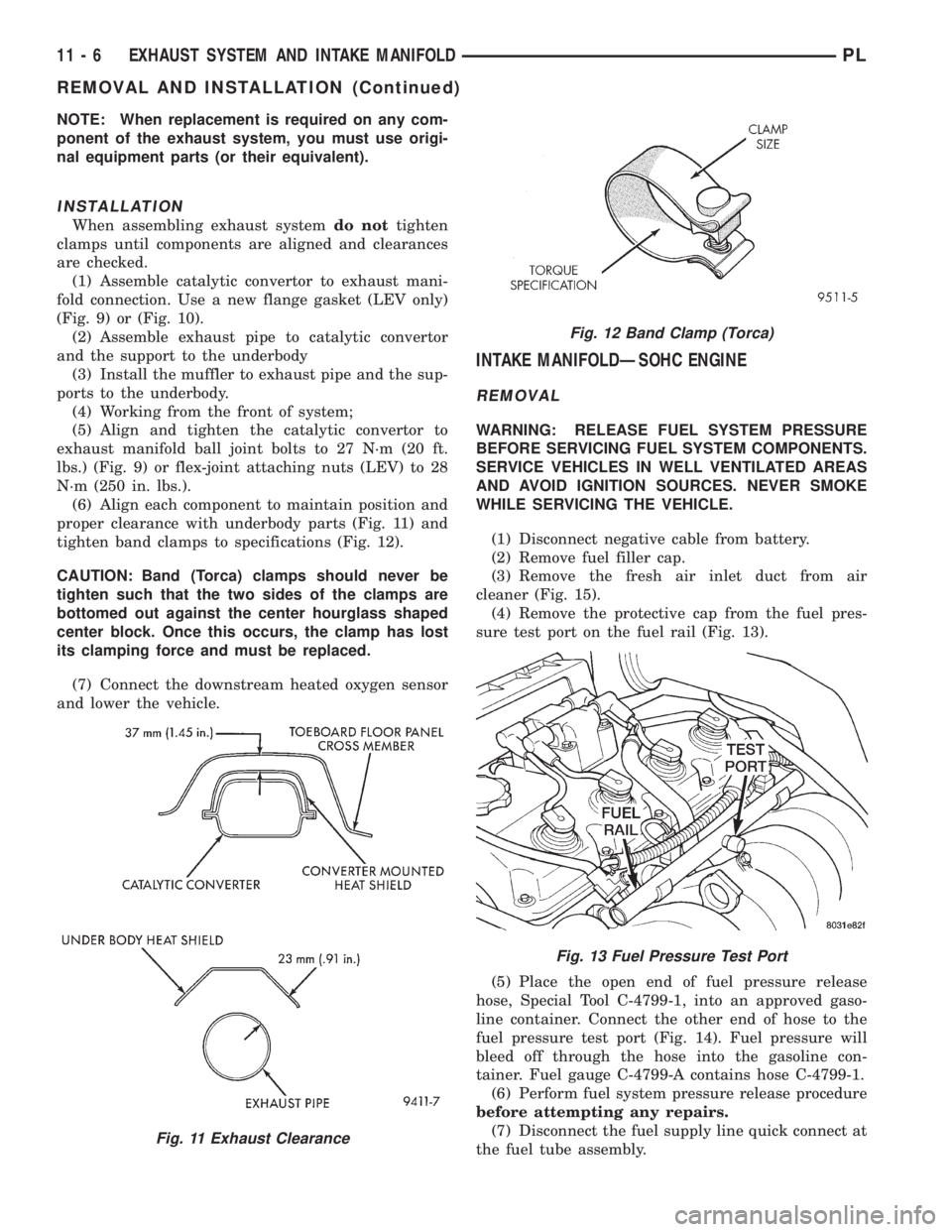

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or

broken.1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace

gasket.

3. EGR Valve Leakage. 3. See Below:

(a) EGR valve to manifold gasket. (a) Tighten bolts and/or replace

gasket.

(b) EGR valve to EGR tube gasket. (b) Tighten bolts and/or replace

gasket.

(c) EGR tube to intake manifold

gasket.(c) Tighten bolts and/or replace

gasket.

4. Exhaust flex joint. (non LEV) 4. See Below:

(a) Spring height, not correctly

installed.(a) Check spring height, both sides

(specification is 32.5 mm, 1.28 inch)

look for source of spring height

variation if out of specification

(b) Exhaust sealing ring defective. (b) Inspect seal for damage on

round spherical surface. If no

damage is evident, check for

exhaust restriction causing high back

pressure on heavy acceleration.

5. Exhaust Flex joint to manifold

leak (LEV).5.Tighten nuts or replace gasket.

6. Exhaust flex joint (LEV). 6. Replace catalytic converter

assembly.

7. Pipe and shell noise from front

exhaust pipe.7. Characteristic of single wall pipes.

EXCESSIVE EXHAUST NOISE 1. Leaks at pipe joints. 1. Tighten or replace clamps at

leaking joints.

2. Burned, blown, or rusted out

exhaust pipe or muffler.2. Replace muffler or exhaust pipes.

3. Restriction in muffler or tailpipe. 3. Remove restriction, if possible or

replace as necessary.

4. Catalytic converter material in

muffler.4. replace muffler and converter

assembly. Check fuel injection and

ignition systems for proper operation.

11 - 4 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

Page 821 of 1200

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble catalytic convertor to exhaust mani-

fold connection. Use a new flange gasket (LEV only)

(Fig. 9) or (Fig. 10).

(2) Assemble exhaust pipe to catalytic convertor

and the support to the underbody

(3) Install the muffler to exhaust pipe and the sup-

ports to the underbody.

(4) Working from the front of system;

(5) Align and tighten the catalytic convertor to

exhaust manifold ball joint bolts to 27 N´m (20 ft.

lbs.) (Fig. 9) or flex-joint attaching nuts (LEV) to 28

N´m (250 in. lbs.).

(6) Align each component to maintain position and

proper clearance with underbody parts (Fig. 11) and

tighten band clamps to specifications (Fig. 12).

CAUTION: Band (Torca) clamps should never be

tighten such that the two sides of the clamps are

bottomed out against the center hourglass shaped

center block. Once this occurs, the clamp has lost

its clamping force and must be replaced.

(7) Connect the downstream heated oxygen sensor

and lower the vehicle.

INTAKE MANIFOLDÐSOHC ENGINE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the fresh air inlet duct from air

cleaner (Fig. 15).

(4) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 13).

(5) Place the open end of fuel pressure release

hose, Special Tool C-4799-1, into an approved gaso-

line container. Connect the other end of hose to the

fuel pressure test port (Fig. 14). Fuel pressure will

bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1.

(6) Perform fuel system pressure release procedure

before attempting any repairs.

(7) Disconnect the fuel supply line quick connect at

the fuel tube assembly.

Fig. 11 Exhaust Clearance

Fig. 12 Band Clamp (Torca)

Fig. 13 Fuel Pressure Test Port

11 - 6 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

REMOVAL AND INSTALLATION (Continued)

Page 823 of 1200

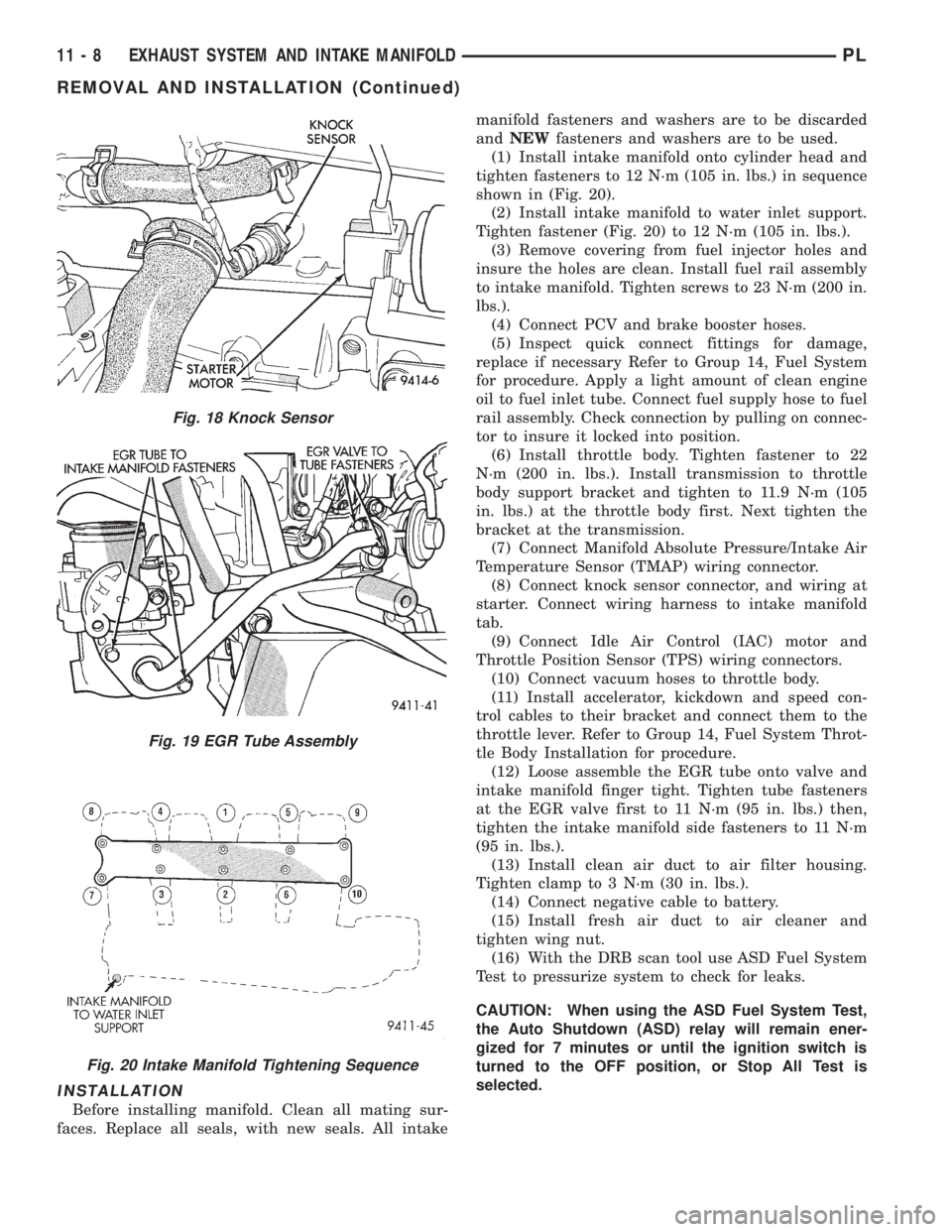

INSTALLATION

Before installing manifold. Clean all mating sur-

faces. Replace all seals, with new seals. All intakemanifold fasteners and washers are to be discarded

andNEWfasteners and washers are to be used.

(1) Install intake manifold onto cylinder head and

tighten fasteners to 12 N´m (105 in. lbs.) in sequence

shown in (Fig. 20).

(2) Install intake manifold to water inlet support.

Tighten fastener (Fig. 20) to 12 N´m (105 in. lbs.).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Install throttle body. Tighten fastener to 22

N´m (200 in. lbs.). Install transmission to throttle

body support bracket and tighten to 11.9 N´m (105

in. lbs.) at the throttle body first. Next tighten the

bracket at the transmission.

(7) Connect Manifold Absolute Pressure/Intake Air

Temperature Sensor (TMAP) wiring connector.

(8) Connect knock sensor connector, and wiring at

starter. Connect wiring harness to intake manifold

tab.

(9) Connect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) wiring connectors.

(10) Connect vacuum hoses to throttle body.

(11) Install accelerator, kickdown and speed con-

trol cables to their bracket and connect them to the

throttle lever. Refer to Group 14, Fuel System Throt-

tle Body Installation for procedure.

(12) Loose assemble the EGR tube onto valve and

intake manifold finger tight. Tighten tube fasteners

at the EGR valve first to 11 N´m (95 in. lbs.) then,

tighten the intake manifold side fasteners to 11 N´m

(95 in. lbs.).

(13) Install clean air duct to air filter housing.

Tighten clamp to 3 N´m (30 in. lbs.).

(14) Connect negative cable to battery.

(15) Install fresh air duct to air cleaner and

tighten wing nut.

(16) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

Fig. 18 Knock Sensor

Fig. 19 EGR Tube Assembly

Fig. 20 Intake Manifold Tightening Sequence

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

REMOVAL AND INSTALLATION (Continued)

Page 824 of 1200

INTAKE MANIFOLDÐDOHC ENGINE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Loosen wing nut on intake and remove fresh

air inlet duct (Fig. 23).

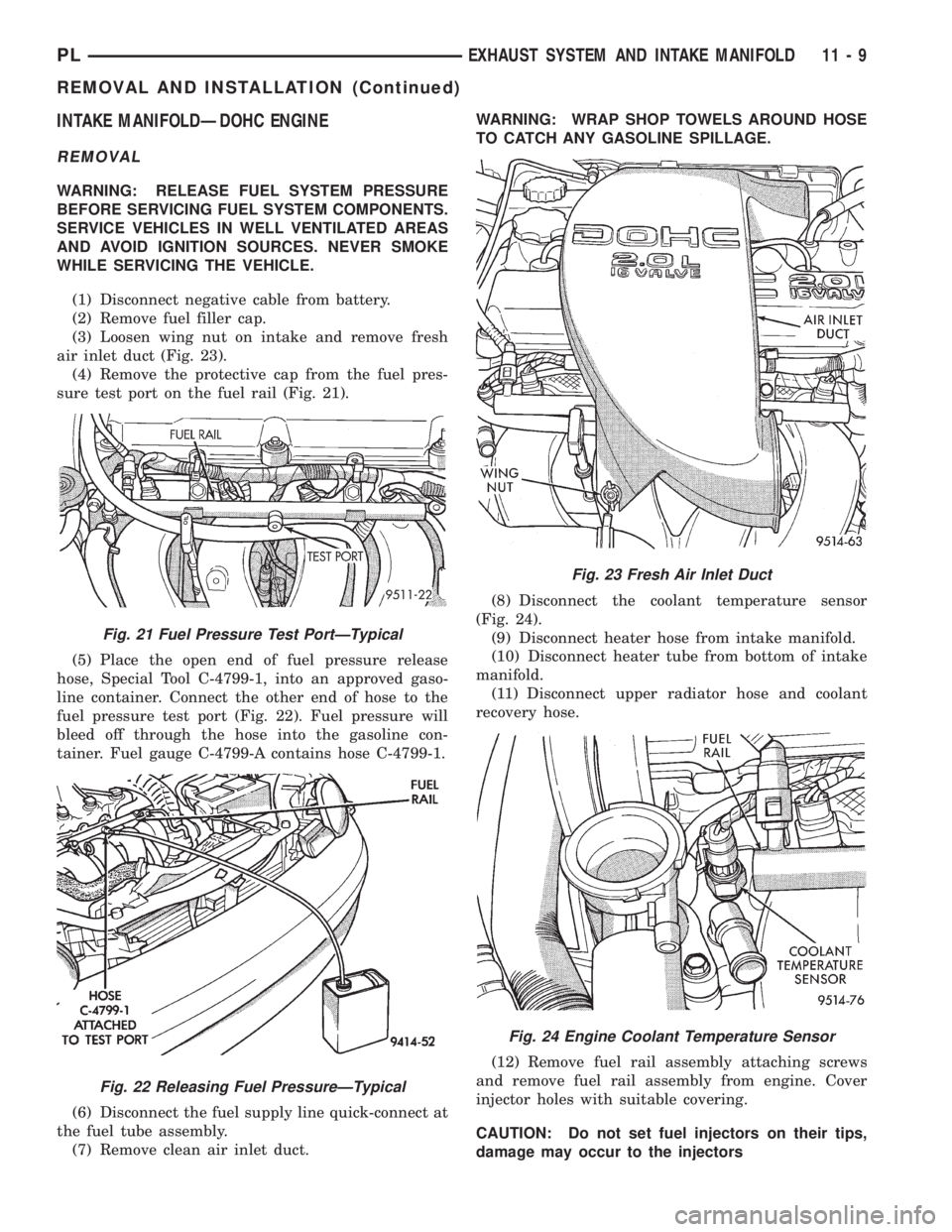

(4) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 21).

(5) Place the open end of fuel pressure release

hose, Special Tool C-4799-1, into an approved gaso-

line container. Connect the other end of hose to the

fuel pressure test port (Fig. 22). Fuel pressure will

bleed off through the hose into the gasoline con-

tainer. Fuel gauge C-4799-A contains hose C-4799-1.

(6) Disconnect the fuel supply line quick-connect at

the fuel tube assembly.

(7) Remove clean air inlet duct.WARNING: WRAP SHOP TOWELS AROUND HOSE

TO CATCH ANY GASOLINE SPILLAGE.

(8) Disconnect the coolant temperature sensor

(Fig. 24).

(9) Disconnect heater hose from intake manifold.

(10) Disconnect heater tube from bottom of intake

manifold.

(11) Disconnect upper radiator hose and coolant

recovery hose.

(12) Remove fuel rail assembly attaching screws

and remove fuel rail assembly from engine. Cover

injector holes with suitable covering.

CAUTION: Do not set fuel injectors on their tips,

damage may occur to the injectors

Fig. 21 Fuel Pressure Test PortÐTypical

Fig. 22 Releasing Fuel PressureÐTypical

Fig. 23 Fresh Air Inlet Duct

Fig. 24 Engine Coolant Temperature Sensor

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 9

REMOVAL AND INSTALLATION (Continued)

Page 826 of 1200

INSTALLATION

Before installing manifolds. Clean all mating sur-

faces. Replace all gaskets, with new.

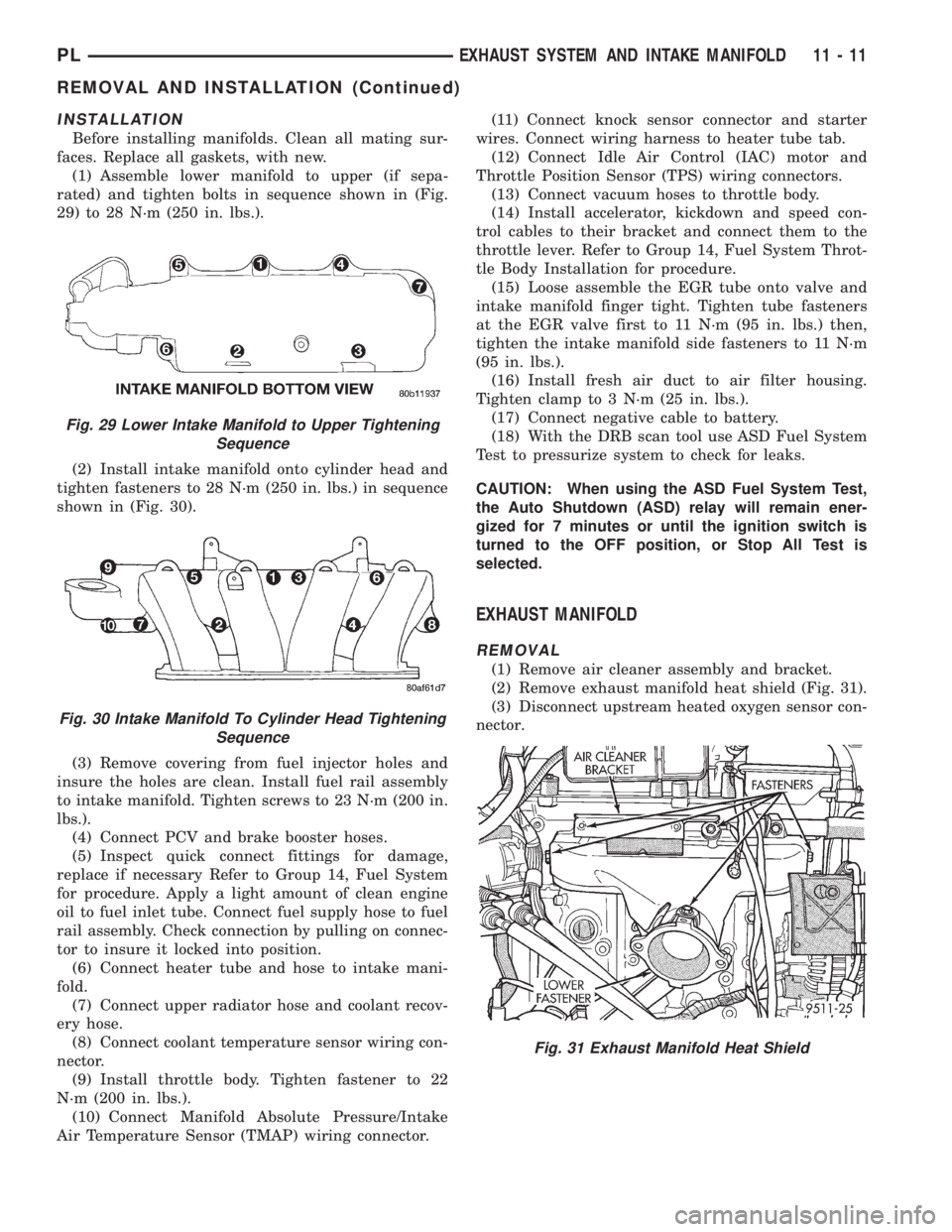

(1) Assemble lower manifold to upper (if sepa-

rated) and tighten bolts in sequence shown in (Fig.

29) to 28 N´m (250 in. lbs.).

(2) Install intake manifold onto cylinder head and

tighten fasteners to 28 N´m (250 in. lbs.) in sequence

shown in (Fig. 30).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Connect heater tube and hose to intake mani-

fold.

(7) Connect upper radiator hose and coolant recov-

ery hose.

(8) Connect coolant temperature sensor wiring con-

nector.

(9) Install throttle body. Tighten fastener to 22

N´m (200 in. lbs.).

(10) Connect Manifold Absolute Pressure/Intake

Air Temperature Sensor (TMAP) wiring connector.(11) Connect knock sensor connector and starter

wires. Connect wiring harness to heater tube tab.

(12) Connect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) wiring connectors.

(13) Connect vacuum hoses to throttle body.

(14) Install accelerator, kickdown and speed con-

trol cables to their bracket and connect them to the

throttle lever. Refer to Group 14, Fuel System Throt-

tle Body Installation for procedure.

(15) Loose assemble the EGR tube onto valve and

intake manifold finger tight. Tighten tube fasteners

at the EGR valve first to 11 N´m (95 in. lbs.) then,

tighten the intake manifold side fasteners to 11 N´m

(95 in. lbs.).

(16) Install fresh air duct to air filter housing.

Tighten clamp to 3 N´m (25 in. lbs.).

(17) Connect negative cable to battery.

(18) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

EXHAUST MANIFOLD

REMOVAL

(1) Remove air cleaner assembly and bracket.

(2) Remove exhaust manifold heat shield (Fig. 31).

(3) Disconnect upstream heated oxygen sensor con-

nector.

Fig. 29 Lower Intake Manifold to Upper Tightening

Sequence

Fig. 30 Intake Manifold To Cylinder Head Tightening

Sequence

Fig. 31 Exhaust Manifold Heat Shield

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 11

REMOVAL AND INSTALLATION (Continued)

Page 847 of 1200

DIAGNOSIS AND TESTING

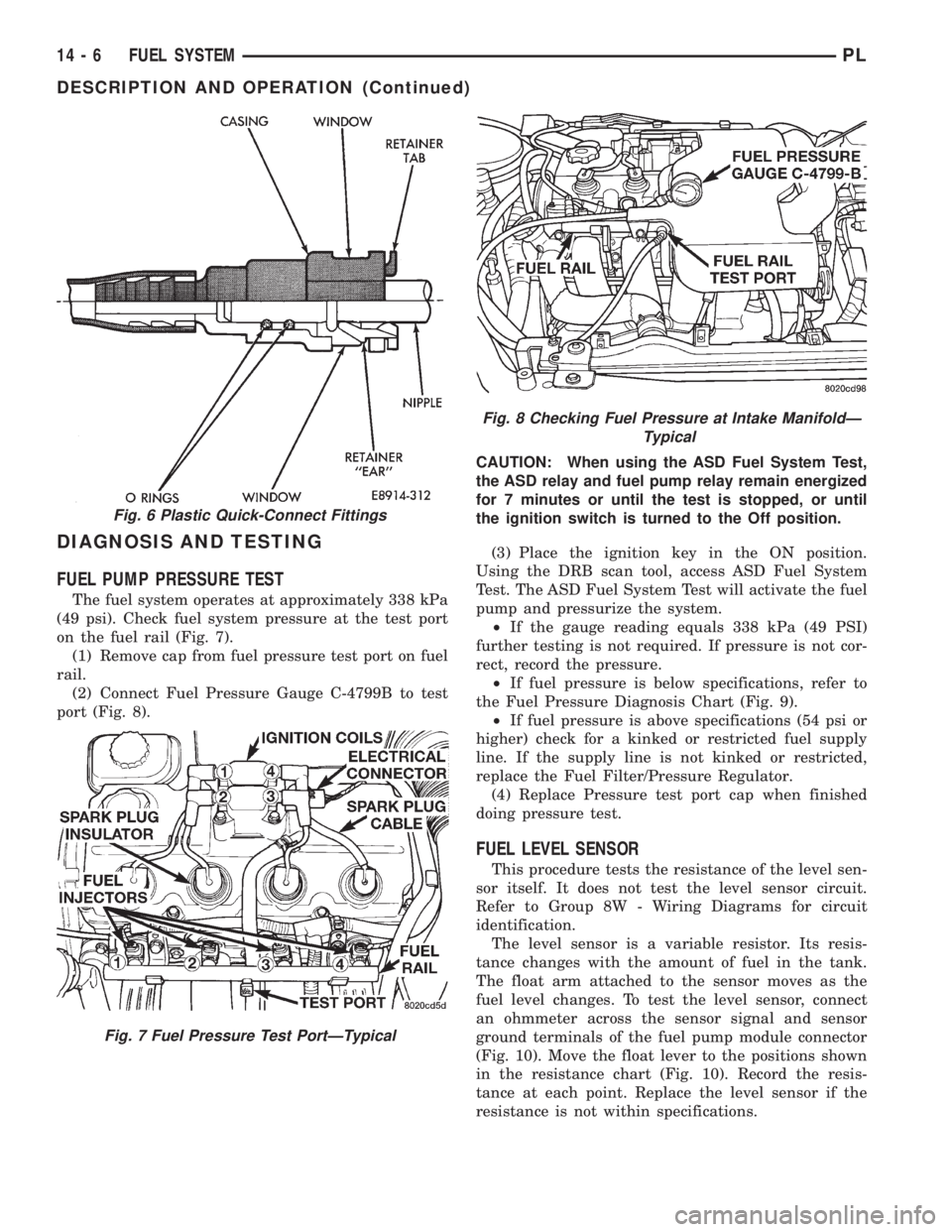

FUEL PUMP PRESSURE TEST

The fuel system operates at approximately 338 kPa

(49 psi). Check fuel system pressure at the test port

on the fuel rail (Fig. 7).

(1) Remove cap from fuel pressure test port on fuel

rail.

(2) Connect Fuel Pressure Gauge C-4799B to test

port (Fig. 8).CAUTION: When using the ASD Fuel System Test,

the ASD relay and fuel pump relay remain energized

for 7 minutes or until the test is stopped, or until

the ignition switch is turned to the Off position.

(3) Place the ignition key in the ON position.

Using the DRB scan tool, access ASD Fuel System

Test. The ASD Fuel System Test will activate the fuel

pump and pressurize the system.

²If the gauge reading equals 338 kPa (49 PSI)

further testing is not required. If pressure is not cor-

rect, record the pressure.

²If fuel pressure is below specifications, refer to

the Fuel Pressure Diagnosis Chart (Fig. 9).

²If fuel pressure is above specifications (54 psi or

higher) check for a kinked or restricted fuel supply

line. If the supply line is not kinked or restricted,

replace the Fuel Filter/Pressure Regulator.

(4) Replace Pressure test port cap when finished

doing pressure test.

FUEL LEVEL SENSOR

This procedure tests the resistance of the level sen-

sor itself. It does not test the level sensor circuit.

Refer to Group 8W - Wiring Diagrams for circuit

identification.

The level sensor is a variable resistor. Its resis-

tance changes with the amount of fuel in the tank.

The float arm attached to the sensor moves as the

fuel level changes. To test the level sensor, connect

an ohmmeter across the sensor signal and sensor

ground terminals of the fuel pump module connector

(Fig. 10). Move the float lever to the positions shown

in the resistance chart (Fig. 10). Record the resis-

tance at each point. Replace the level sensor if the

resistance is not within specifications.

Fig. 8 Checking Fuel Pressure at Intake ManifoldÐ

Typical

Fig. 6 Plastic Quick-Connect Fittings

Fig. 7 Fuel Pressure Test PortÐTypical

14 - 6 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 851 of 1200

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE PROCEDURE

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

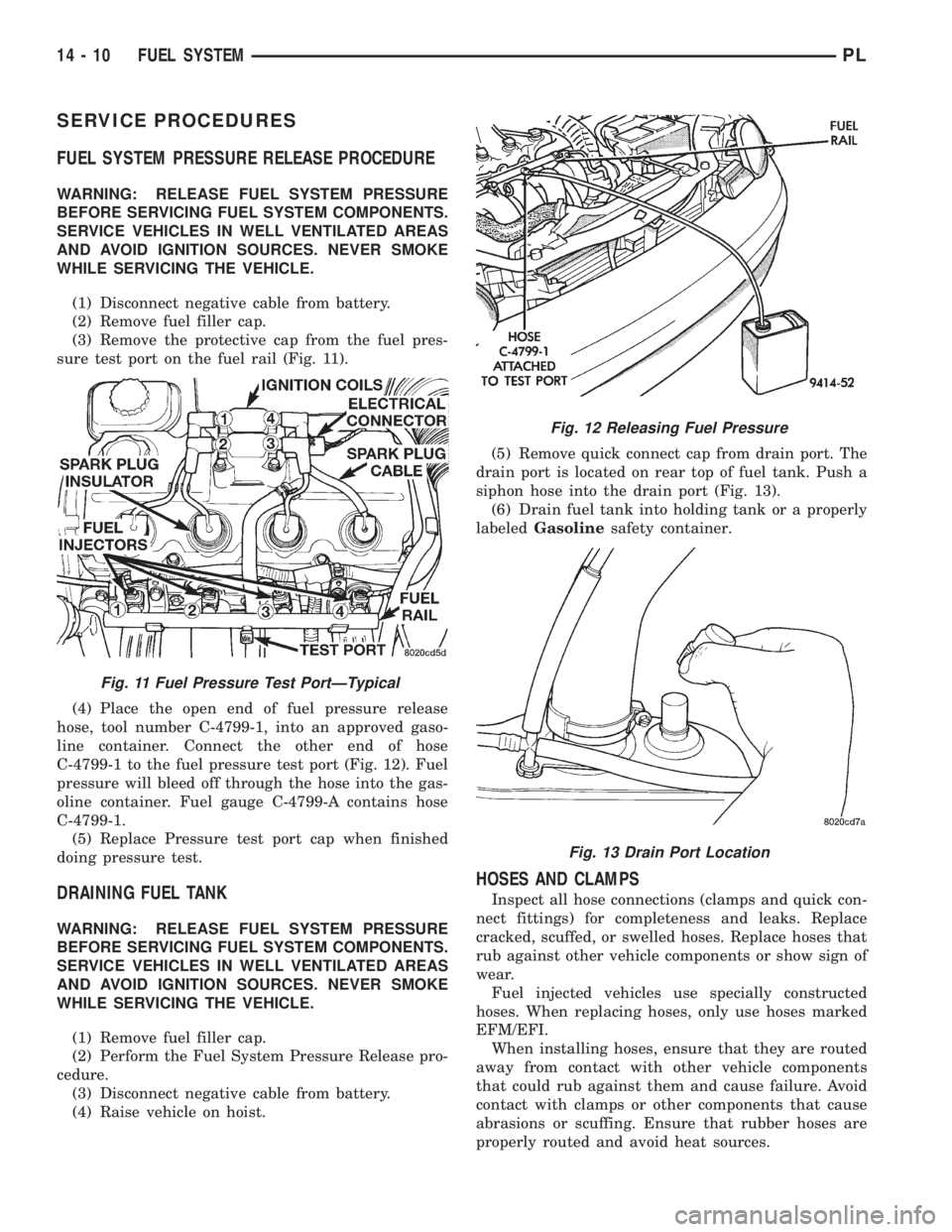

(1) Disconnect negative cable from battery.

(2) Remove fuel filler cap.

(3) Remove the protective cap from the fuel pres-

sure test port on the fuel rail (Fig. 11).

(4) Place the open end of fuel pressure release

hose, tool number C-4799-1, into an approved gaso-

line container. Connect the other end of hose

C-4799-1 to the fuel pressure test port (Fig. 12). Fuel

pressure will bleed off through the hose into the gas-

oline container. Fuel gauge C-4799-A contains hose

C-4799-1.

(5) Replace Pressure test port cap when finished

doing pressure test.

DRAINING FUEL TANK

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap.

(2) Perform the Fuel System Pressure Release pro-

cedure.

(3) Disconnect negative cable from battery.

(4) Raise vehicle on hoist.(5) Remove quick connect cap from drain port. The

drain port is located on rear top of fuel tank. Push a

siphon hose into the drain port (Fig. 13).

(6) Drain fuel tank into holding tank or a properly

labeledGasolinesafety container.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

Fig. 11 Fuel Pressure Test PortÐTypical

Fig. 12 Releasing Fuel Pressure

Fig. 13 Drain Port Location

14 - 10 FUEL SYSTEMPL

Page 852 of 1200

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

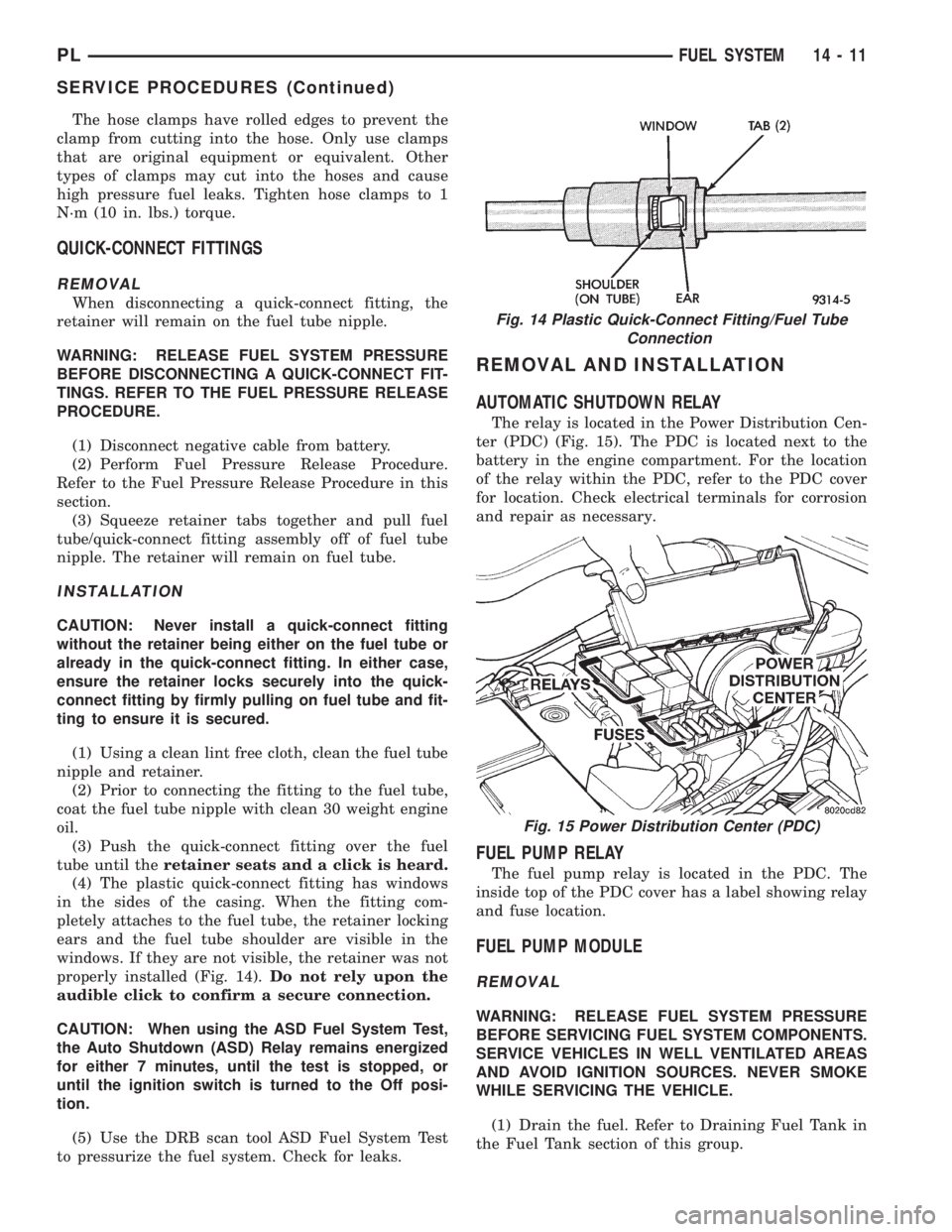

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 14).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY

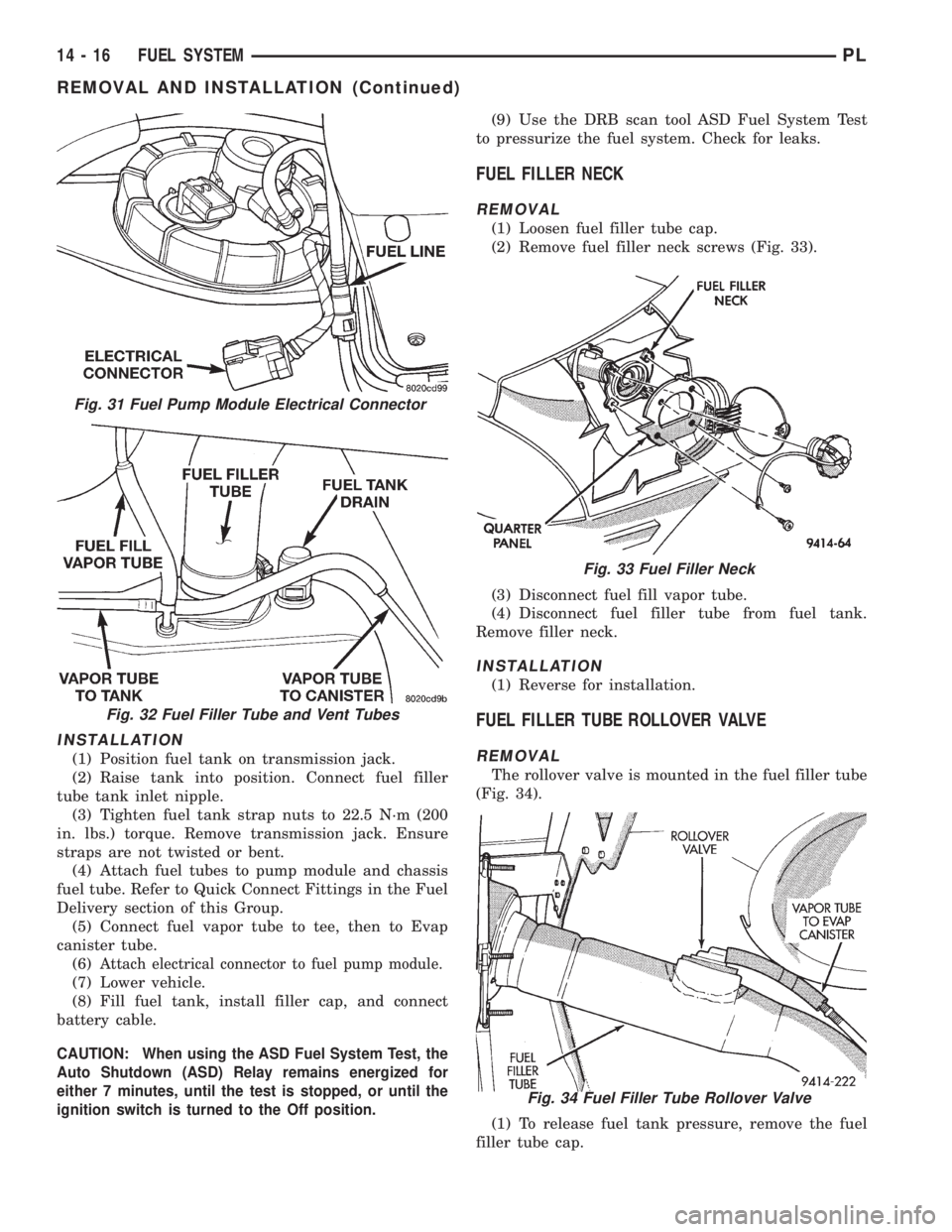

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 15). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

FUEL PUMP MODULE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Drain the fuel. Refer to Draining Fuel Tank in

the Fuel Tank section of this group.

Fig. 14 Plastic Quick-Connect Fitting/Fuel Tube

Connection

Fig. 15 Power Distribution Center (PDC)

PLFUEL SYSTEM 14 - 11

SERVICE PROCEDURES (Continued)

Page 857 of 1200

INSTALLATION

(1) Position fuel tank on transmission jack.

(2) Raise tank into position. Connect fuel filler

tube tank inlet nipple.

(3) Tighten fuel tank strap nuts to 22.5 N´m (200

in. lbs.) torque. Remove transmission jack. Ensure

straps are not twisted or bent.

(4) Attach fuel tubes to pump module and chassis

fuel tube. Refer to Quick Connect Fittings in the Fuel

Delivery section of this Group.

(5) Connect fuel vapor tube to tee, then to Evap

canister tube.

(6)

Attach electrical connector to fuel pump module.

(7) Lower vehicle.

(8) Fill fuel tank, install filler cap, and connect

battery cable.

CAUTION: When using the ASD Fuel System Test, the

Auto Shutdown (ASD) Relay remains energized for

either 7 minutes, until the test is stopped, or until the

ignition switch is turned to the Off position.

(9) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

FUEL FILLER NECK

REMOVAL

(1) Loosen fuel filler tube cap.

(2) Remove fuel filler neck screws (Fig. 33).

(3) Disconnect fuel fill vapor tube.

(4) Disconnect fuel filler tube from fuel tank.

Remove filler neck.

INSTALLATION

(1) Reverse for installation.

FUEL FILLER TUBE ROLLOVER VALVE

REMOVAL

The rollover valve is mounted in the fuel filler tube

(Fig. 34).

(1) To release fuel tank pressure, remove the fuel

filler tube cap.

Fig. 31 Fuel Pump Module Electrical Connector

Fig. 32 Fuel Filler Tube and Vent Tubes

Fig. 33 Fuel Filler Neck

Fig. 34 Fuel Filler Tube Rollover Valve

14 - 16 FUEL SYSTEMPL

REMOVAL AND INSTALLATION (Continued)