light DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 978 of 1200

REMOVAL

(1) Using light plier pressure, squeeze the clips

together at the rear of the trough.

(2) Slide the trough over the retaining pin that

locates the trough in the case.

INSTALLATION

(1) Reverse removal procedure to install oil feed

trough.

CLEANING AND INSPECTION

TRANSAXLE

Clean the gears, bearings, shafts, synchronizers,

thrust washers, oil feeder, shift mechanism, gear

case, and bellhousing with solvent. Dry all parts

except the bearings with compressed air. Allow the

bearings to either air dry or wipe them dry with

clean shop towels.

Inspect the gears, bearings, shafts and thrust

washers. Replace the bearings and cups if the rollers

are worn, chipped, cracked, flat spotted, or brin-

nelled, or if the bearing cage is damaged or distorted.

Replace the thrust washers if cracked, chipped, or

worn. Replace the gears if the teeth are chipped,

cracked, or worn thin. Inspect the synchronizers.

Replace the sleeve if worn or damaged in any way.

Replace the stop rings if the friction material is

burned, flaking off, or worn. Check the condition of

the synchro keys and springs. Replace these parts if

worn, cracked, or distorted.

SYNCHRONIZER

CLEAN

Do not attempt to clean the blocking rings in sol-

vent. The friction material will become contaminated.

Place synchronizer components in a suitable holder

and clean with solvent. Air dry.

INSPECT

Proper inspection of components involve:

²Teeth, for wear, scuffed, nicked, burred, or bro-

ken teeth

²Keys, for wear or distortion

²Balls and springs, for distortion, cracks, or wear

If any of these conditions exist in these compo-

nents, replace as necessary.

ADJUSTMENTS

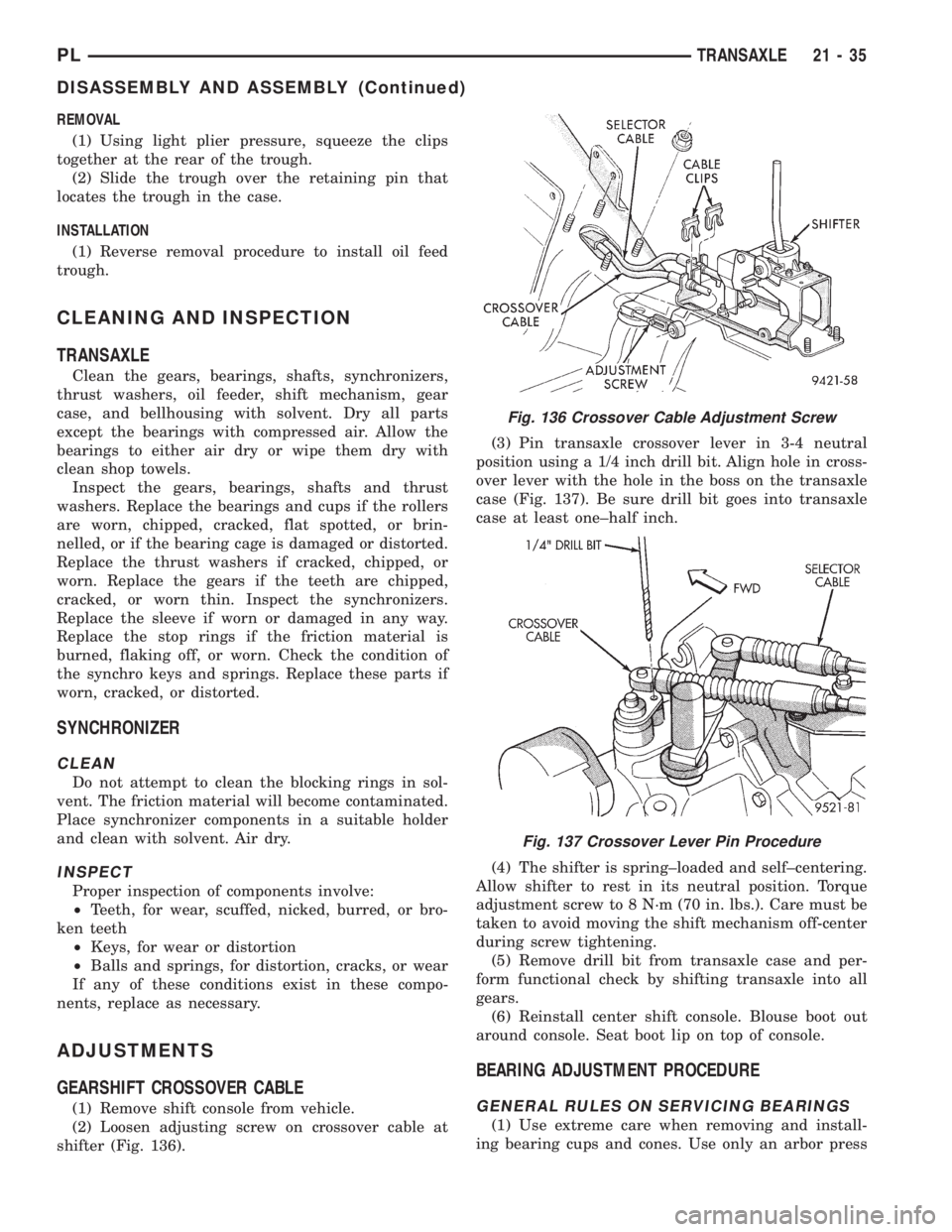

GEARSHIFT CROSSOVER CABLE

(1) Remove shift console from vehicle.

(2) Loosen adjusting screw on crossover cable at

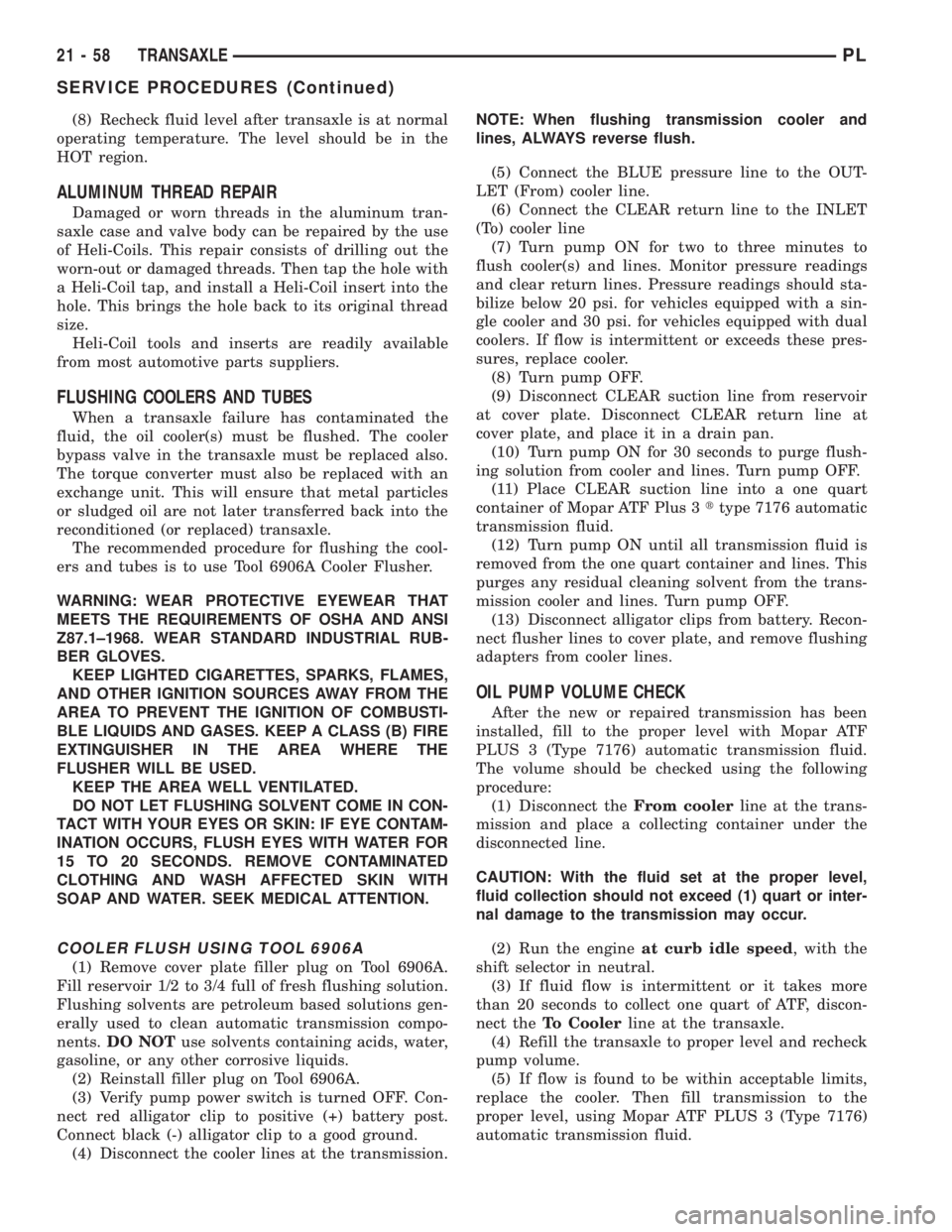

shifter (Fig. 136).(3) Pin transaxle crossover lever in 3-4 neutral

position using a 1/4 inch drill bit. Align hole in cross-

over lever with the hole in the boss on the transaxle

case (Fig. 137). Be sure drill bit goes into transaxle

case at least one±half inch.

(4) The shifter is spring±loaded and self±centering.

Allow shifter to rest in its neutral position. Torque

adjustment screw to 8 N´m (70 in. lbs.). Care must be

taken to avoid moving the shift mechanism off-center

during screw tightening.

(5) Remove drill bit from transaxle case and per-

form functional check by shifting transaxle into all

gears.

(6) Reinstall center shift console. Blouse boot out

around console. Seat boot lip on top of console.

BEARING ADJUSTMENT PROCEDURE

GENERAL RULES ON SERVICING BEARINGS

(1) Use extreme care when removing and install-

ing bearing cups and cones. Use only an arbor press

Fig. 136 Crossover Cable Adjustment Screw

Fig. 137 Crossover Lever Pin Procedure

PLTRANSAXLE 21 - 35

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1001 of 1200

(8) Recheck fluid level after transaxle is at normal

operating temperature. The level should be in the

HOT region.

ALUMINUM THREAD REPAIR

Damaged or worn threads in the aluminum tran-

saxle case and valve body can be repaired by the use

of Heli-Coils. This repair consists of drilling out the

worn-out or damaged threads. Then tap the hole with

a Heli-Coil tap, and install a Heli-Coil insert into the

hole. This brings the hole back to its original thread

size.

Heli-Coil tools and inserts are readily available

from most automotive parts suppliers.

FLUSHING COOLERS AND TUBES

When a transaxle failure has contaminated the

fluid, the oil cooler(s) must be flushed. The cooler

bypass valve in the transaxle must be replaced also.

The torque converter must also be replaced with an

exchange unit. This will ensure that metal particles

or sludged oil are not later transferred back into the

reconditioned (or replaced) transaxle.

The recommended procedure for flushing the cool-

ers and tubes is to use Tool 6906A Cooler Flusher.

WARNING: WEAR PROTECTIVE EYEWEAR THAT

MEETS THE REQUIREMENTS OF OSHA AND ANSI

Z87.1±1968. WEAR STANDARD INDUSTRIAL RUB-

BER GLOVES.

KEEP LIGHTED CIGARETTES, SPARKS, FLAMES,

AND OTHER IGNITION SOURCES AWAY FROM THE

AREA TO PREVENT THE IGNITION OF COMBUSTI-

BLE LIQUIDS AND GASES. KEEP A CLASS (B) FIRE

EXTINGUISHER IN THE AREA WHERE THE

FLUSHER WILL BE USED.

KEEP THE AREA WELL VENTILATED.

DO NOT LET FLUSHING SOLVENT COME IN CON-

TACT WITH YOUR EYES OR SKIN: IF EYE CONTAM-

INATION OCCURS, FLUSH EYES WITH WATER FOR

15 TO 20 SECONDS. REMOVE CONTAMINATED

CLOTHING AND WASH AFFECTED SKIN WITH

SOAP AND WATER. SEEK MEDICAL ATTENTION.

COOLER FLUSH USING TOOL 6906A

(1) Remove cover plate filler plug on Tool 6906A.

Fill reservoir 1/2 to 3/4 full of fresh flushing solution.

Flushing solvents are petroleum based solutions gen-

erally used to clean automatic transmission compo-

nents.DO NOTuse solvents containing acids, water,

gasoline, or any other corrosive liquids.

(2) Reinstall filler plug on Tool 6906A.

(3) Verify pump power switch is turned OFF. Con-

nect red alligator clip to positive (+) battery post.

Connect black (-) alligator clip to a good ground.

(4) Disconnect the cooler lines at the transmission.NOTE: When flushing transmission cooler and

lines, ALWAYS reverse flush.

(5) Connect the BLUE pressure line to the OUT-

LET (From) cooler line.

(6) Connect the CLEAR return line to the INLET

(To) cooler line

(7) Turn pump ON for two to three minutes to

flush cooler(s) and lines. Monitor pressure readings

and clear return lines. Pressure readings should sta-

bilize below 20 psi. for vehicles equipped with a sin-

gle cooler and 30 psi. for vehicles equipped with dual

coolers. If flow is intermittent or exceeds these pres-

sures, replace cooler.

(8) Turn pump OFF.

(9) Disconnect CLEAR suction line from reservoir

at cover plate. Disconnect CLEAR return line at

cover plate, and place it in a drain pan.

(10) Turn pump ON for 30 seconds to purge flush-

ing solution from cooler and lines. Turn pump OFF.

(11) Place CLEAR suction line into a one quart

container of Mopar ATF Plus 3ttype 7176 automatic

transmission fluid.

(12) Turn pump ON until all transmission fluid is

removed from the one quart container and lines. This

purges any residual cleaning solvent from the trans-

mission cooler and lines. Turn pump OFF.

(13) Disconnect alligator clips from battery. Recon-

nect flusher lines to cover plate, and remove flushing

adapters from cooler lines.

OIL PUMP VOLUME CHECK

After the new or repaired transmission has been

installed, fill to the proper level with Mopar ATF

PLUS 3 (Type 7176) automatic transmission fluid.

The volume should be checked using the following

procedure:

(1) Disconnect theFrom coolerline at the trans-

mission and place a collecting container under the

disconnected line.

CAUTION: With the fluid set at the proper level,

fluid collection should not exceed (1) quart or inter-

nal damage to the transmission may occur.

(2) Run the engineat curb idle speed, with the

shift selector in neutral.

(3) If fluid flow is intermittent or it takes more

than 20 seconds to collect one quart of ATF, discon-

nect theTo Coolerline at the transaxle.

(4) Refill the transaxle to proper level and recheck

pump volume.

(5) If flow is found to be within acceptable limits,

replace the cooler. Then fill transmission to the

proper level, using Mopar ATF PLUS 3 (Type 7176)

automatic transmission fluid.

21 - 58 TRANSAXLEPL

SERVICE PROCEDURES (Continued)

Page 1009 of 1200

CAUTION: When reinstalling driveshafts, new drive-

shaft retaining clips must be used. Do not reuse old

clips. Failure to use new clips may result in disen-

gagement of inner constant±velocity joint.

CAUTION: The exhaust flex joint must be discon-

nected from the exhaust manifold anytime the

engine is lowered. If the engine is lowered while the

flex pipe is attached, damage will occur.

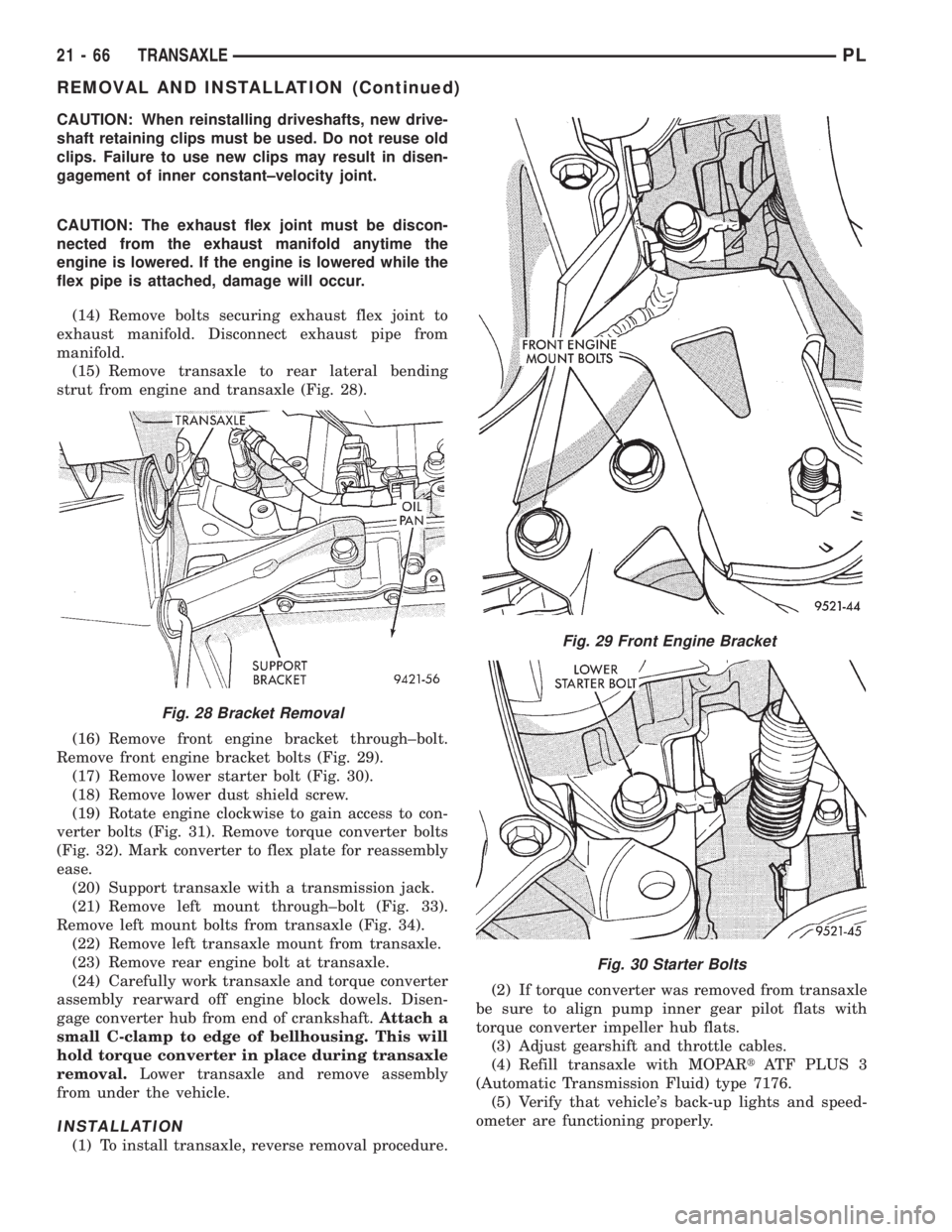

(14) Remove bolts securing exhaust flex joint to

exhaust manifold. Disconnect exhaust pipe from

manifold.

(15) Remove transaxle to rear lateral bending

strut from engine and transaxle (Fig. 28).

(16) Remove front engine bracket through±bolt.

Remove front engine bracket bolts (Fig. 29).

(17) Remove lower starter bolt (Fig. 30).

(18) Remove lower dust shield screw.

(19) Rotate engine clockwise to gain access to con-

verter bolts (Fig. 31). Remove torque converter bolts

(Fig. 32). Mark converter to flex plate for reassembly

ease.

(20) Support transaxle with a transmission jack.

(21) Remove left mount through±bolt (Fig. 33).

Remove left mount bolts from transaxle (Fig. 34).

(22) Remove left transaxle mount from transaxle.

(23) Remove rear engine bolt at transaxle.

(24) Carefully work transaxle and torque converter

assembly rearward off engine block dowels. Disen-

gage converter hub from end of crankshaft.Attach a

small C-clamp to edge of bellhousing. This will

hold torque converter in place during transaxle

removal.Lower transaxle and remove assembly

from under the vehicle.

INSTALLATION

(1) To install transaxle, reverse removal procedure.(2) If torque converter was removed from transaxle

be sure to align pump inner gear pilot flats with

torque converter impeller hub flats.

(3) Adjust gearshift and throttle cables.

(4) Refill transaxle with MOPARtATF PLUS 3

(Automatic Transmission Fluid) type 7176.

(5) Verify that vehicle's back-up lights and speed-

ometer are functioning properly.

Fig. 28 Bracket Removal

Fig. 29 Front Engine Bracket

Fig. 30 Starter Bolts

21 - 66 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1017 of 1200

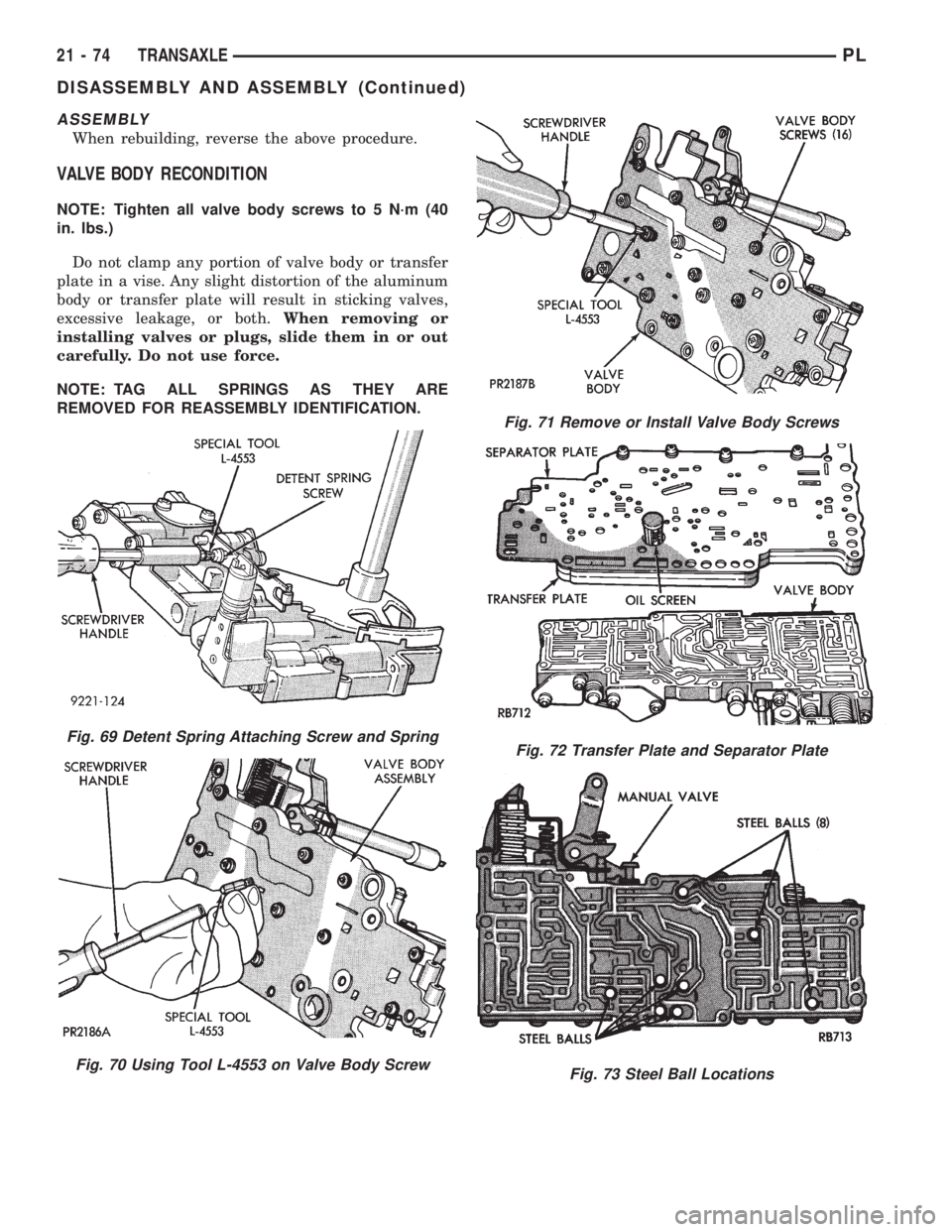

ASSEMBLY

When rebuilding, reverse the above procedure.

VALVE BODY RECONDITION

NOTE: Tighten all valve body screws to 5 N´m (40

in. lbs.)

Do not clamp any portion of valve body or transfer

plate in a vise. Any slight distortion of the aluminum

body or transfer plate will result in sticking valves,

excessive leakage, or both.When removing or

installing valves or plugs, slide them in or out

carefully. Do not use force.

NOTE: TAG ALL SPRINGS AS THEY ARE

REMOVED FOR REASSEMBLY IDENTIFICATION.

Fig. 69 Detent Spring Attaching Screw and Spring

Fig. 70 Using Tool L-4553 on Valve Body Screw

Fig. 71 Remove or Install Valve Body Screws

Fig. 72 Transfer Plate and Separator Plate

Fig. 73 Steel Ball Locations

21 - 74 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1022 of 1200

ASSEMBLY

To reassemble, reverse the above procedure.MEASURING PLATE CLEARANCE

REAR CLUTCH-RECONDITION

INSPECTION

Inspect facing material on all driving discs.

Replace discs that are charred, glazed, or heavily pit-

ted. Discs should also be replaced if they show evi-

dence of material flaking off, or if facing material can

be scraped off easily. Inspect driving disc splines for

wear or other damage. Inspect steel plate and pres-

sure plate surface for burning, scoring, or damaged

driving lugs. Replace if necessary. Inspect plates and

discs for flatness; they must not be warped or cone-

shaped.

Inspect steel plate lug grooves in clutch retainer

for smooth surfaces; plates must travel freely in the

grooves. Note ball check in piston; be sure ball moves

freely. Inspect seal rings surfaces in clutch retainer

for nicks or deep scratches; light scratches will not

interfere with sealing of the seals. Inspect Neoprene

seal rings for deterioration, wear, and hardness.

Fig. 89 Thick Steel Plate and Waved Snap Ring

Fig. 90 Front Clutch (4-Disc Shown)

Fig. 91 Front Clutch Return Spring Snap Ring

Fig. 92 Front Clutch Return Spring and Piston

Fig. 93 Measuring Front Clutch Plate Clearance

PLTRANSAXLE 21 - 79

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1042 of 1200

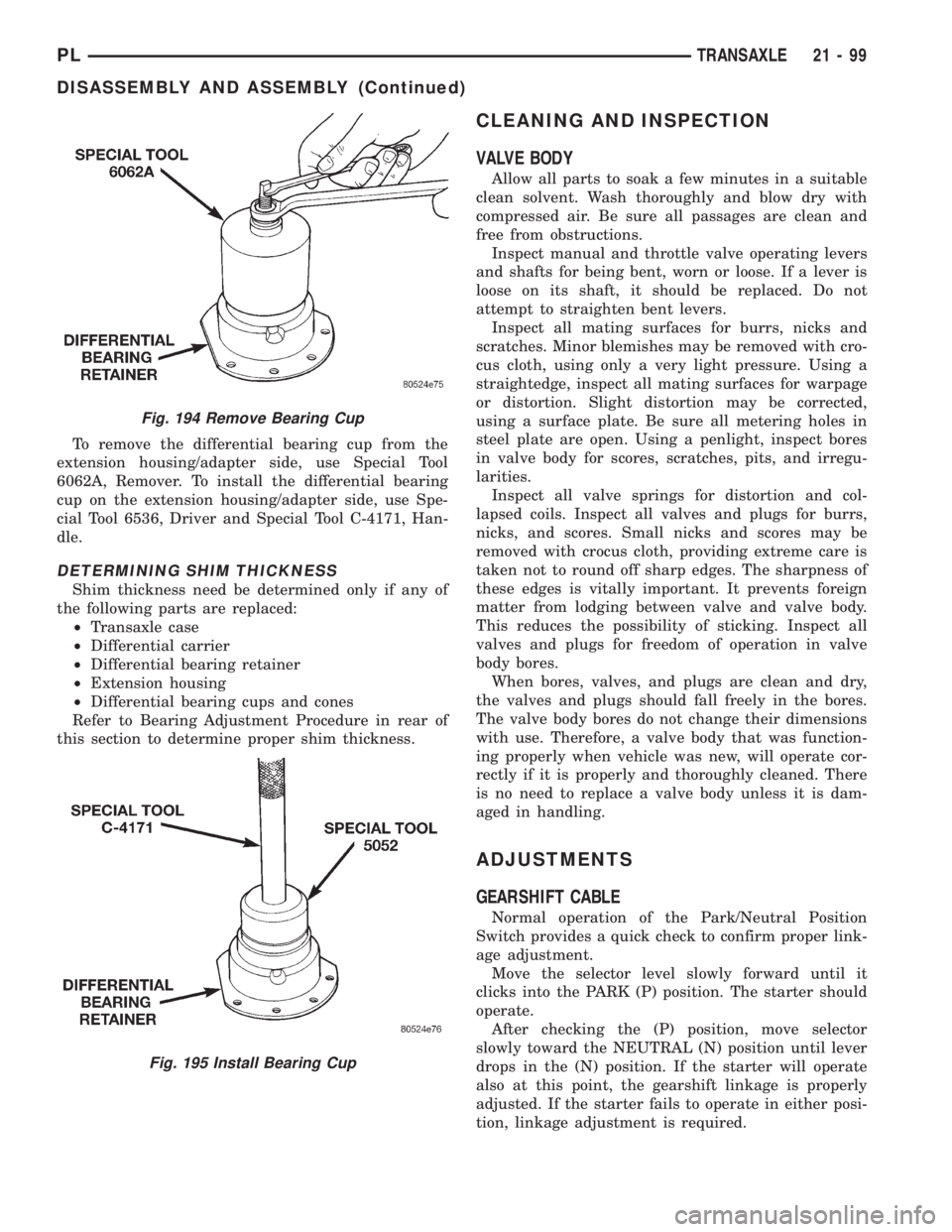

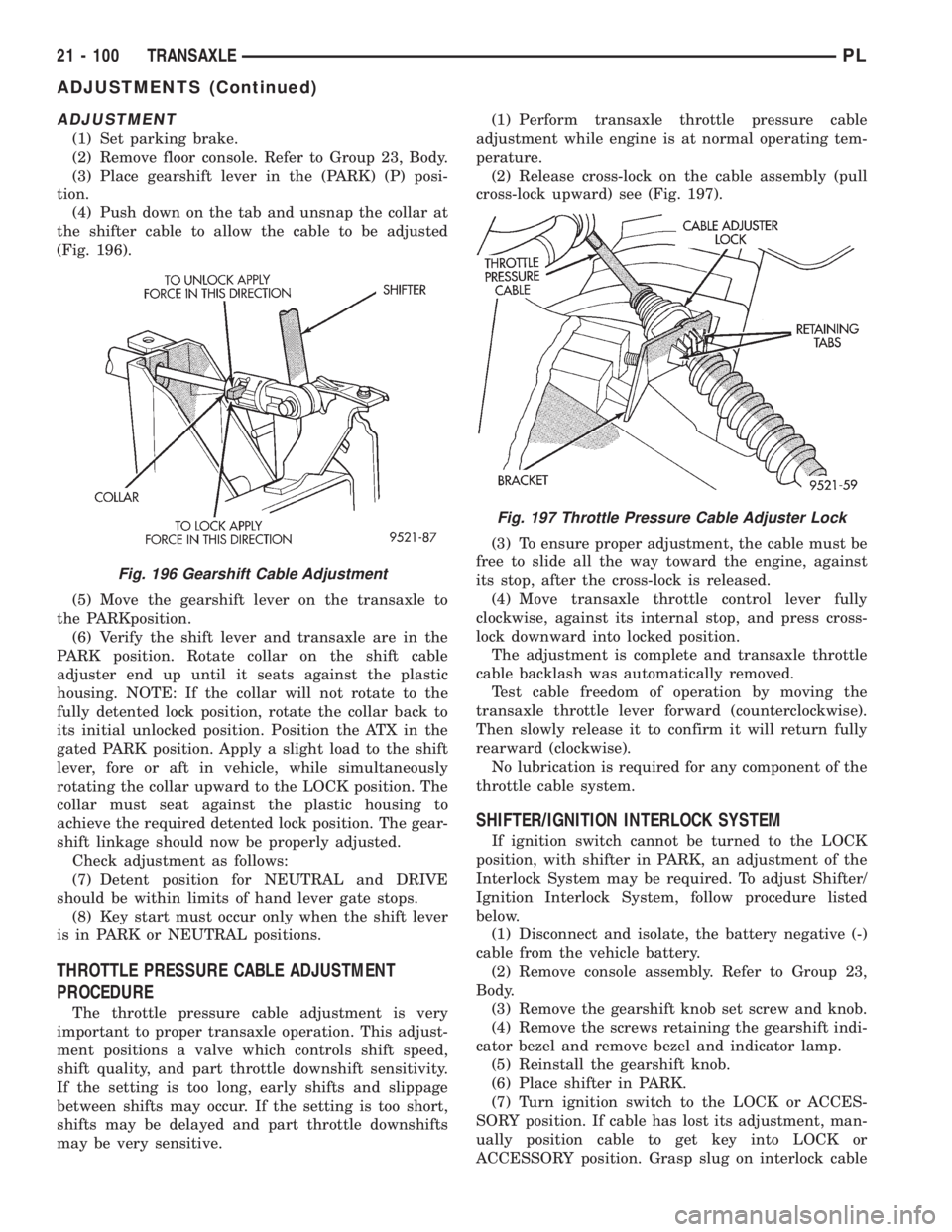

To remove the differential bearing cup from the

extension housing/adapter side, use Special Tool

6062A, Remover. To install the differential bearing

cup on the extension housing/adapter side, use Spe-

cial Tool 6536, Driver and Special Tool C-4171, Han-

dle.

DETERMINING SHIM THICKNESS

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle case

²Differential carrier

²Differential bearing retainer

²Extension housing

²Differential bearing cups and cones

Refer to Bearing Adjustment Procedure in rear of

this section to determine proper shim thickness.

CLEANING AND INSPECTION

VALVE BODY

Allow all parts to soak a few minutes in a suitable

clean solvent. Wash thoroughly and blow dry with

compressed air. Be sure all passages are clean and

free from obstructions.

Inspect manual and throttle valve operating levers

and shafts for being bent, worn or loose. If a lever is

loose on its shaft, it should be replaced. Do not

attempt to straighten bent levers.

Inspect all mating surfaces for burrs, nicks and

scratches. Minor blemishes may be removed with cro-

cus cloth, using only a very light pressure. Using a

straightedge, inspect all mating surfaces for warpage

or distortion. Slight distortion may be corrected,

using a surface plate. Be sure all metering holes in

steel plate are open. Using a penlight, inspect bores

in valve body for scores, scratches, pits, and irregu-

larities.

Inspect all valve springs for distortion and col-

lapsed coils. Inspect all valves and plugs for burrs,

nicks, and scores. Small nicks and scores may be

removed with crocus cloth, providing extreme care is

taken not to round off sharp edges. The sharpness of

these edges is vitally important. It prevents foreign

matter from lodging between valve and valve body.

This reduces the possibility of sticking. Inspect all

valves and plugs for freedom of operation in valve

body bores.

When bores, valves, and plugs are clean and dry,

the valves and plugs should fall freely in the bores.

The valve body bores do not change their dimensions

with use. Therefore, a valve body that was function-

ing properly when vehicle was new, will operate cor-

rectly if it is properly and thoroughly cleaned. There

is no need to replace a valve body unless it is dam-

aged in handling.

ADJUSTMENTS

GEARSHIFT CABLE

Normal operation of the Park/Neutral Position

Switch provides a quick check to confirm proper link-

age adjustment.

Move the selector level slowly forward until it

clicks into the PARK (P) position. The starter should

operate.

After checking the (P) position, move selector

slowly toward the NEUTRAL (N) position until lever

drops in the (N) position. If the starter will operate

also at this point, the gearshift linkage is properly

adjusted. If the starter fails to operate in either posi-

tion, linkage adjustment is required.

Fig. 194 Remove Bearing Cup

Fig. 195 Install Bearing Cup

PLTRANSAXLE 21 - 99

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1043 of 1200

ADJUSTMENT

(1) Set parking brake.

(2) Remove floor console. Refer to Group 23, Body.

(3) Place gearshift lever in the (PARK) (P) posi-

tion.

(4) Push down on the tab and unsnap the collar at

the shifter cable to allow the cable to be adjusted

(Fig. 196).

(5) Move the gearshift lever on the transaxle to

the PARKposition.

(6) Verify the shift lever and transaxle are in the

PARK position. Rotate collar on the shift cable

adjuster end up until it seats against the plastic

housing. NOTE: If the collar will not rotate to the

fully detented lock position, rotate the collar back to

its initial unlocked position. Position the ATX in the

gated PARK position. Apply a slight load to the shift

lever, fore or aft in vehicle, while simultaneously

rotating the collar upward to the LOCK position. The

collar must seat against the plastic housing to

achieve the required detented lock position. The gear-

shift linkage should now be properly adjusted.

Check adjustment as follows:

(7) Detent position for NEUTRAL and DRIVE

should be within limits of hand lever gate stops.

(8) Key start must occur only when the shift lever

is in PARK or NEUTRAL positions.

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE

The throttle pressure cable adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too long, early shifts and slippage

between shifts may occur. If the setting is too short,

shifts may be delayed and part throttle downshifts

may be very sensitive.(1) Perform transaxle throttle pressure cable

adjustment while engine is at normal operating tem-

perature.

(2) Release cross-lock on the cable assembly (pull

cross-lock upward) see (Fig. 197).

(3) To ensure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released.

(4) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position.

The adjustment is complete and transaxle throttle

cable backlash was automatically removed.

Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise).

No lubrication is required for any component of the

throttle cable system.

SHIFTER/IGNITION INTERLOCK SYSTEM

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

Fig. 196 Gearshift Cable Adjustment

Fig. 197 Throttle Pressure Cable Adjuster Lock

21 - 100 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1079 of 1200

REMOVAL AND INSTALLATION

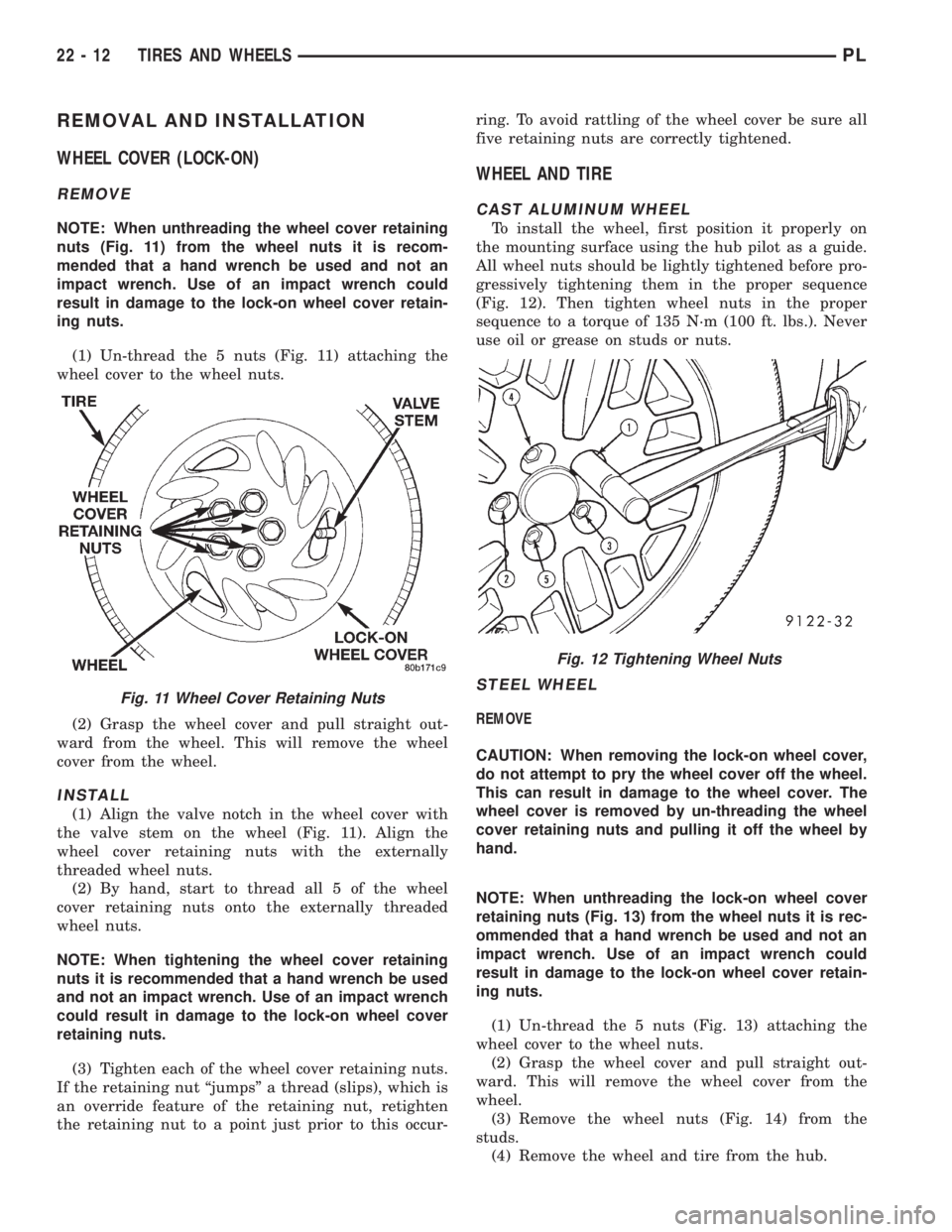

WHEEL COVER (LOCK-ON)

REMOVE

NOTE: When unthreading the wheel cover retaining

nuts (Fig. 11) from the wheel nuts it is recom-

mended that a hand wrench be used and not an

impact wrench. Use of an impact wrench could

result in damage to the lock-on wheel cover retain-

ing nuts.

(1) Un-thread the 5 nuts (Fig. 11) attaching the

wheel cover to the wheel nuts.

(2) Grasp the wheel cover and pull straight out-

ward from the wheel. This will remove the wheel

cover from the wheel.

INSTALL

(1) Align the valve notch in the wheel cover with

the valve stem on the wheel (Fig. 11). Align the

wheel cover retaining nuts with the externally

threaded wheel nuts.

(2) By hand, start to thread all 5 of the wheel

cover retaining nuts onto the externally threaded

wheel nuts.

NOTE: When tightening the wheel cover retaining

nuts it is recommended that a hand wrench be used

and not an impact wrench. Use of an impact wrench

could result in damage to the lock-on wheel cover

retaining nuts.

(3) Tighten each of the wheel cover retaining nuts.

If the retaining nut ªjumpsº a thread (slips), which is

an override feature of the retaining nut, retighten

the retaining nut to a point just prior to this occur-ring. To avoid rattling of the wheel cover be sure all

five retaining nuts are correctly tightened.

WHEEL AND TIRE

CAST ALUMINUM WHEEL

To install the wheel, first position it properly on

the mounting surface using the hub pilot as a guide.

All wheel nuts should be lightly tightened before pro-

gressively tightening them in the proper sequence

(Fig. 12). Then tighten wheel nuts in the proper

sequence to a torque of 135 N´m (100 ft. lbs.). Never

use oil or grease on studs or nuts.

STEEL WHEEL

REMOVE

CAUTION: When removing the lock-on wheel cover,

do not attempt to pry the wheel cover off the wheel.

This can result in damage to the wheel cover. The

wheel cover is removed by un-threading the wheel

cover retaining nuts and pulling it off the wheel by

hand.

NOTE: When unthreading the lock-on wheel cover

retaining nuts (Fig. 13) from the wheel nuts it is rec-

ommended that a hand wrench be used and not an

impact wrench. Use of an impact wrench could

result in damage to the lock-on wheel cover retain-

ing nuts.

(1) Un-thread the 5 nuts (Fig. 13) attaching the

wheel cover to the wheel nuts.

(2) Grasp the wheel cover and pull straight out-

ward. This will remove the wheel cover from the

wheel.

(3) Remove the wheel nuts (Fig. 14) from the

studs.

(4) Remove the wheel and tire from the hub.

Fig. 11 Wheel Cover Retaining Nuts

Fig. 12 Tightening Wheel Nuts

22 - 12 TIRES AND WHEELSPL

Page 1080 of 1200

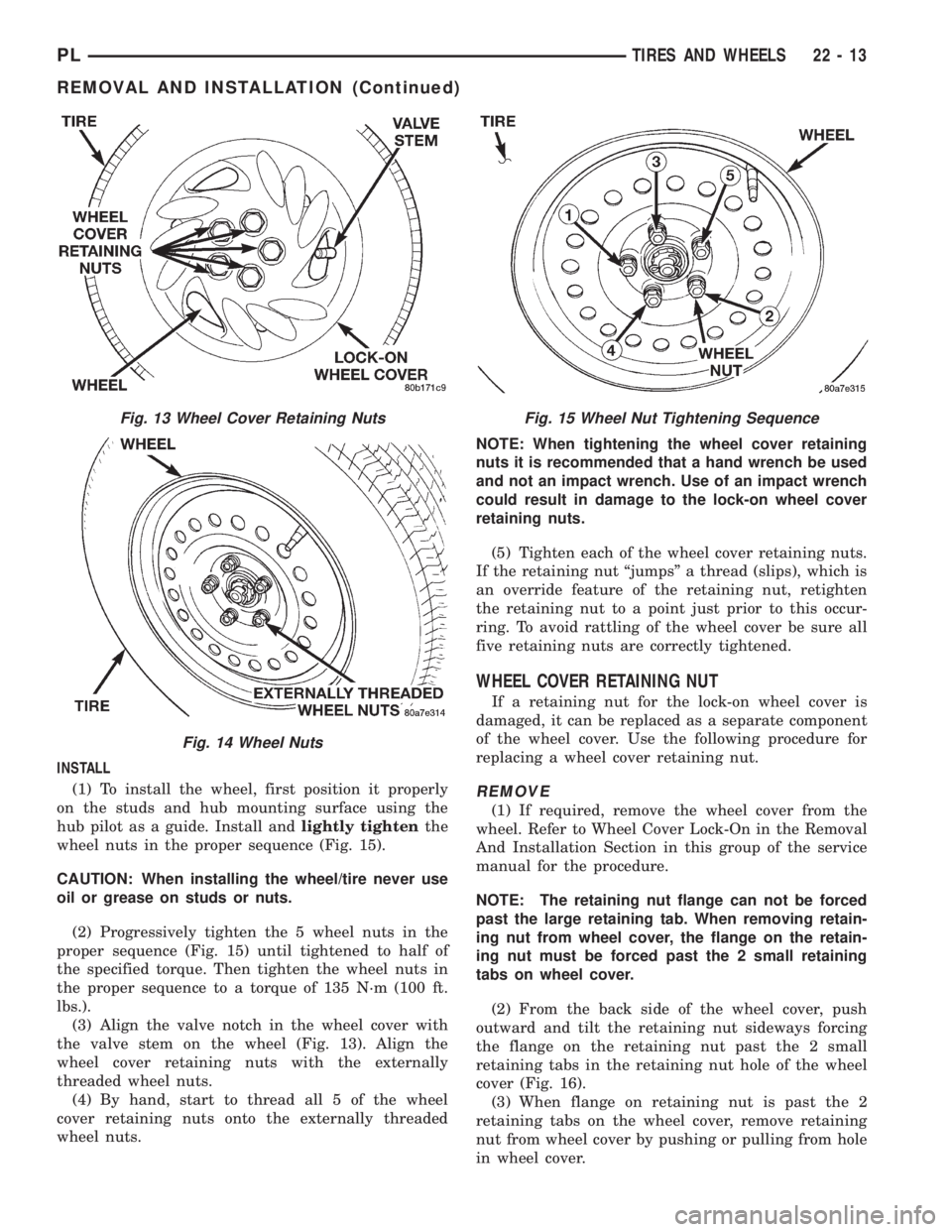

INSTALL

(1) To install the wheel, first position it properly

on the studs and hub mounting surface using the

hub pilot as a guide. Install andlightly tightenthe

wheel nuts in the proper sequence (Fig. 15).

CAUTION: When installing the wheel/tire never use

oil or grease on studs or nuts.

(2) Progressively tighten the 5 wheel nuts in the

proper sequence (Fig. 15) until tightened to half of

the specified torque. Then tighten the wheel nuts in

the proper sequence to a torque of 135 N´m (100 ft.

lbs.).

(3) Align the valve notch in the wheel cover with

the valve stem on the wheel (Fig. 13). Align the

wheel cover retaining nuts with the externally

threaded wheel nuts.

(4) By hand, start to thread all 5 of the wheel

cover retaining nuts onto the externally threaded

wheel nuts.NOTE: When tightening the wheel cover retaining

nuts it is recommended that a hand wrench be used

and not an impact wrench. Use of an impact wrench

could result in damage to the lock-on wheel cover

retaining nuts.

(5) Tighten each of the wheel cover retaining nuts.

If the retaining nut ªjumpsº a thread (slips), which is

an override feature of the retaining nut, retighten

the retaining nut to a point just prior to this occur-

ring. To avoid rattling of the wheel cover be sure all

five retaining nuts are correctly tightened.

WHEEL COVER RETAINING NUT

If a retaining nut for the lock-on wheel cover is

damaged, it can be replaced as a separate component

of the wheel cover. Use the following procedure for

replacing a wheel cover retaining nut.

REMOVE

(1) If required, remove the wheel cover from the

wheel. Refer to Wheel Cover Lock-On in the Removal

And Installation Section in this group of the service

manual for the procedure.

NOTE: The retaining nut flange can not be forced

past the large retaining tab. When removing retain-

ing nut from wheel cover, the flange on the retain-

ing nut must be forced past the 2 small retaining

tabs on wheel cover.

(2) From the back side of the wheel cover, push

outward and tilt the retaining nut sideways forcing

the flange on the retaining nut past the 2 small

retaining tabs in the retaining nut hole of the wheel

cover (Fig. 16).

(3) When flange on retaining nut is past the 2

retaining tabs on the wheel cover, remove retaining

nut from wheel cover by pushing or pulling from hole

in wheel cover.

Fig. 13 Wheel Cover Retaining Nuts

Fig. 14 Wheel Nuts

Fig. 15 Wheel Nut Tightening Sequence

PLTIRES AND WHEELS 22 - 13

REMOVAL AND INSTALLATION (Continued)

Page 1084 of 1200

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK

TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

PLBODY 23 - 3