light DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 747 of 1200

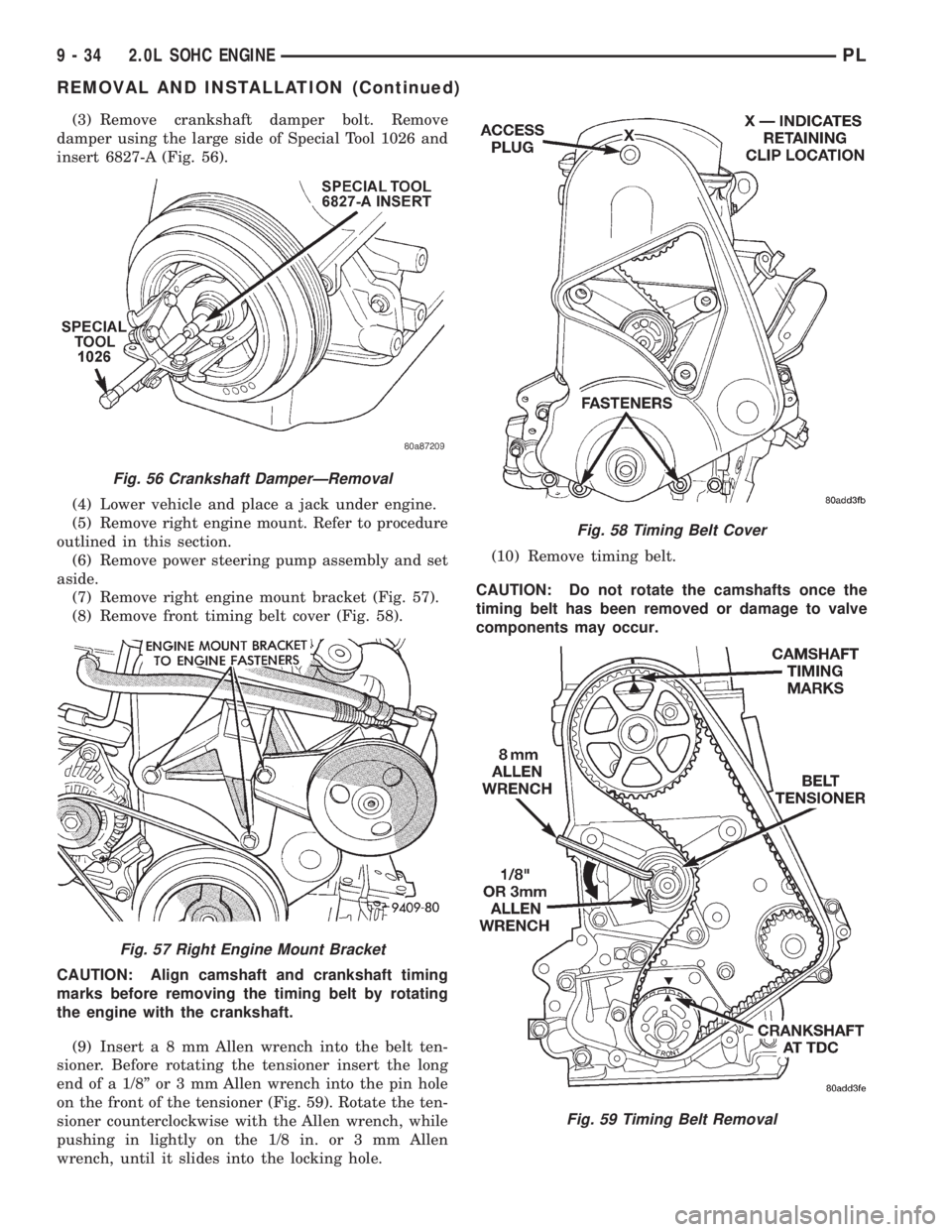

(3) Remove crankshaft damper bolt. Remove

damper using the large side of Special Tool 1026 and

insert 6827-A (Fig. 56).

(4) Lower vehicle and place a jack under engine.

(5) Remove right engine mount. Refer to procedure

outlined in this section.

(6) Remove power steering pump assembly and set

aside.

(7) Remove right engine mount bracket (Fig. 57).

(8) Remove front timing belt cover (Fig. 58).

CAUTION: Align camshaft and crankshaft timing

marks before removing the timing belt by rotating

the engine with the crankshaft.

(9) Inserta8mmAllen wrench into the belt ten-

sioner. Before rotating the tensioner insert the long

end of a 1/8º or 3 mm Allen wrench into the pin hole

on the front of the tensioner (Fig. 59). Rotate the ten-

sioner counterclockwise with the Allen wrench, while

pushing in lightly on the 1/8 in. or 3 mm Allen

wrench, until it slides into the locking hole.(10) Remove timing belt.

CAUTION: Do not rotate the camshafts once the

timing belt has been removed or damage to valve

components may occur.

Fig. 56 Crankshaft DamperÐRemoval

Fig. 57 Right Engine Mount Bracket

Fig. 58 Timing Belt Cover

Fig. 59 Timing Belt Removal

9 - 34 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 757 of 1200

PISTON AND CONNECTING ROD

REMOVAL

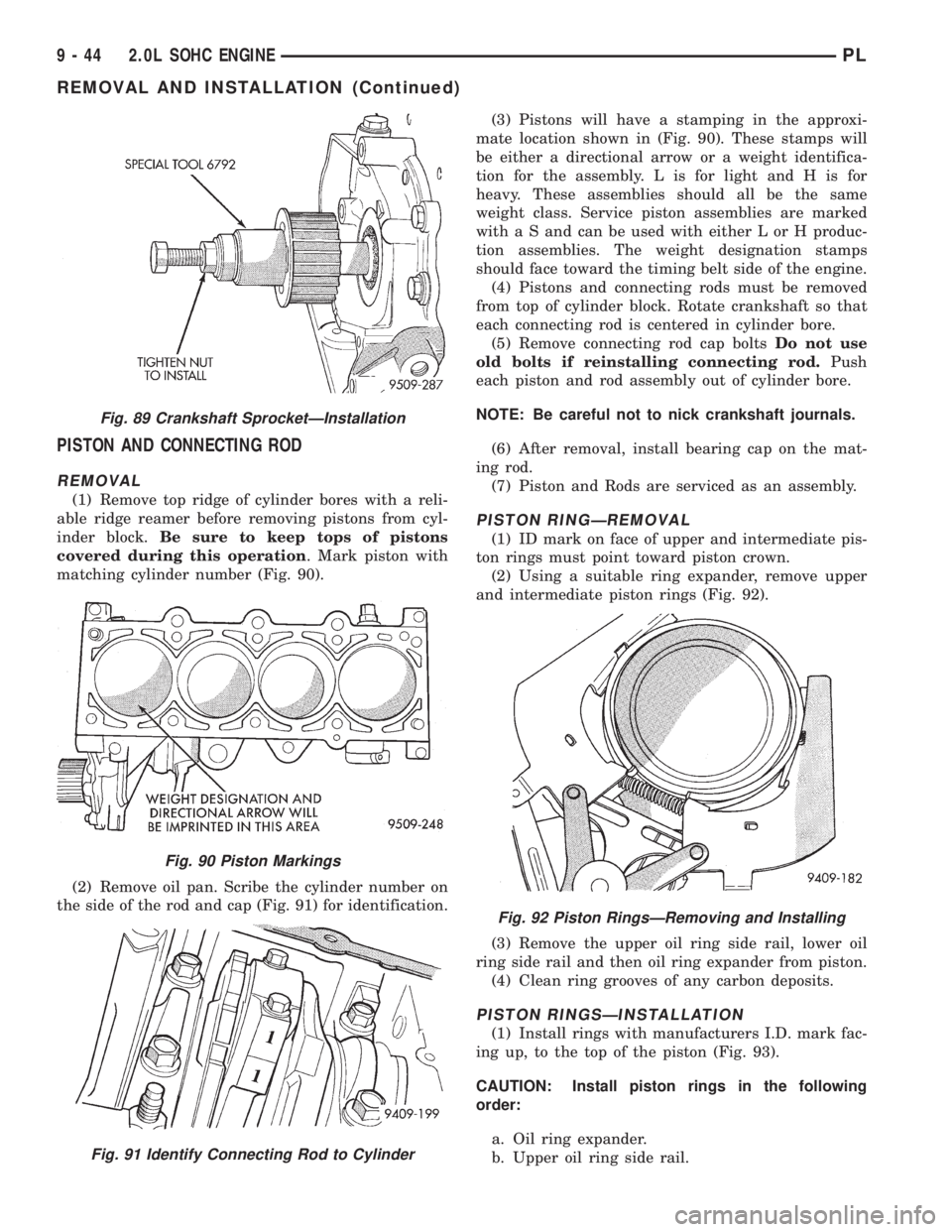

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 90).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 91) for identification.(3) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 90). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove connecting rod cap boltsDo not use

old bolts if reinstalling connecting rod.Push

each piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

(6) After removal, install bearing cap on the mat-

ing rod.

(7) Piston and Rods are serviced as an assembly.

PISTON RINGÐREMOVAL

(1) ID mark on face of upper and intermediate pis-

ton rings must point toward piston crown.

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 92).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Clean ring grooves of any carbon deposits.

PISTON RINGSÐINSTALLATION

(1) Install rings with manufacturers I.D. mark fac-

ing up, to the top of the piston (Fig. 93).

CAUTION: Install piston rings in the following

order:

a. Oil ring expander.

b. Upper oil ring side rail.

Fig. 89 Crankshaft SprocketÐInstallation

Fig. 90 Piston Markings

Fig. 91 Identify Connecting Rod to Cylinder

Fig. 92 Piston RingsÐRemoving and Installing

9 - 44 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 761 of 1200

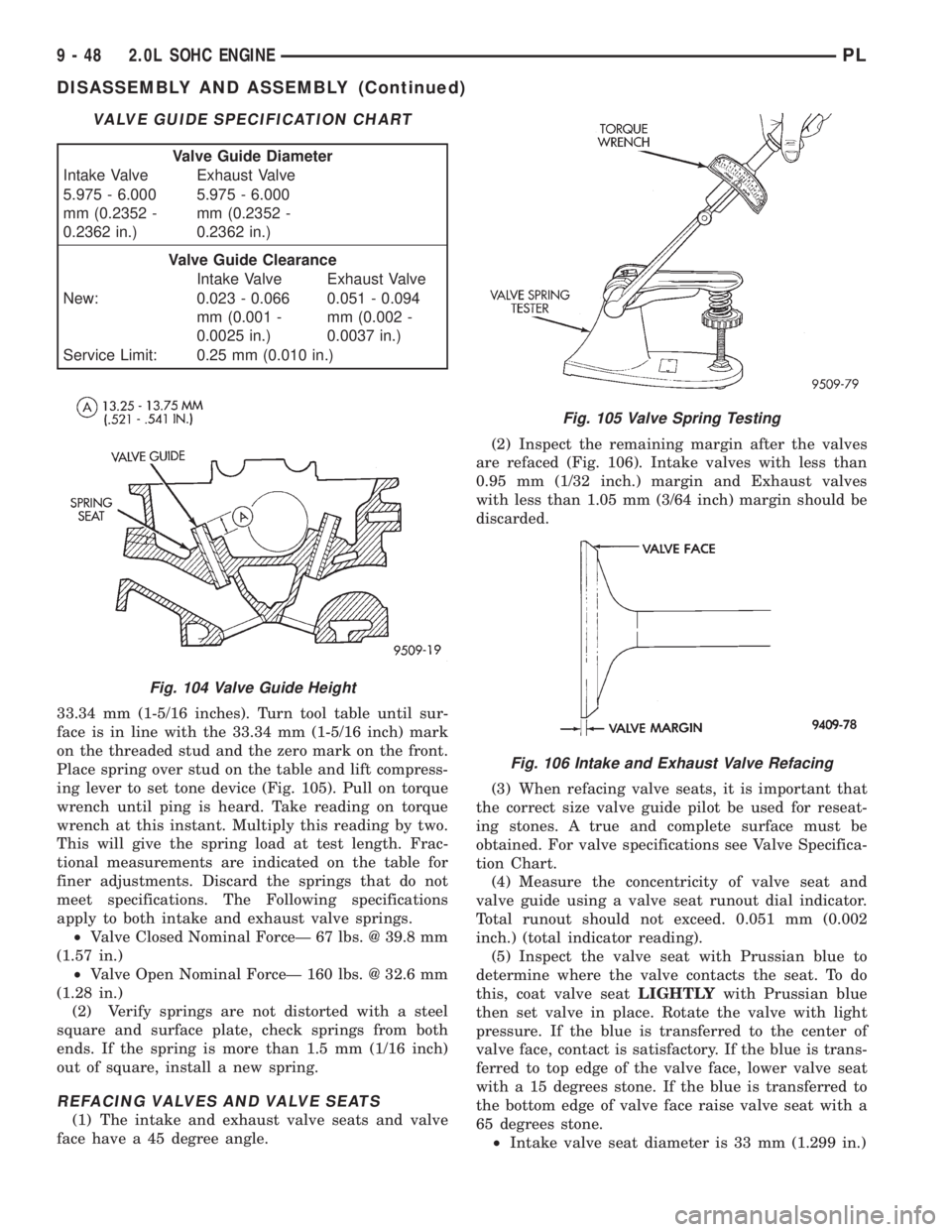

33.34 mm (1-5/16 inches). Turn tool table until sur-

face is in line with the 33.34 mm (1-5/16 inch) mark

on the threaded stud and the zero mark on the front.

Place spring over stud on the table and lift compress-

ing lever to set tone device (Fig. 105). Pull on torque

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.

This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The Following specifications

apply to both intake and exhaust valve springs.

²Valve Closed Nominal ForceÐ 67 lbs. @ 39.8 mm

(1.57 in.)

²Valve Open Nominal ForceÐ 160 lbs. @ 32.6 mm

(1.28 in.)

(2) Verify springs are not distorted with a steel

square and surface plate, check springs from both

ends. If the spring is more than 1.5 mm (1/16 inch)

out of square, install a new spring.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 degree angle.(2) Inspect the remaining margin after the valves

are refaced (Fig. 106). Intake valves with less than

0.95 mm (1/32 inch.) margin and Exhaust valves

with less than 1.05 mm (3/64 inch) margin should be

discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for reseat-

ing stones. A true and complete surface must be

obtained. For valve specifications see Valve Specifica-

tion Chart.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

²Intake valve seat diameter is 33 mm (1.299 in.)

VALVE GUIDE SPECIFICATION CHART

Valve Guide Diameter

Intake Valve Exhaust Valve

5.975 - 6.000

mm (0.2352 -

0.2362 in.)5.975 - 6.000

mm (0.2352 -

0.2362 in.)

Valve Guide Clearance

Intake Valve Exhaust Valve

New: 0.023 - 0.066

mm (0.001 -

0.0025 in.)0.051 - 0.094

mm (0.002 -

0.0037 in.)

Service Limit: 0.25 mm (0.010 in.)

Fig. 104 Valve Guide Height

Fig. 105 Valve Spring Testing

Fig. 106 Intake and Exhaust Valve Refacing

9 - 48 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 763 of 1200

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 108). Make sure

measurements are taken from top of spring seat to

the bottom surface of spring retainer. If height is

greater than 40.18 mm (1.58 in.), install a 0.762 mm

(0.030 in.) spacer under the valve spring seat to

bring spring height back within specification.

(5) Install rocker arm shafts as previously

described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster/s to bleed down before rotating

cam.

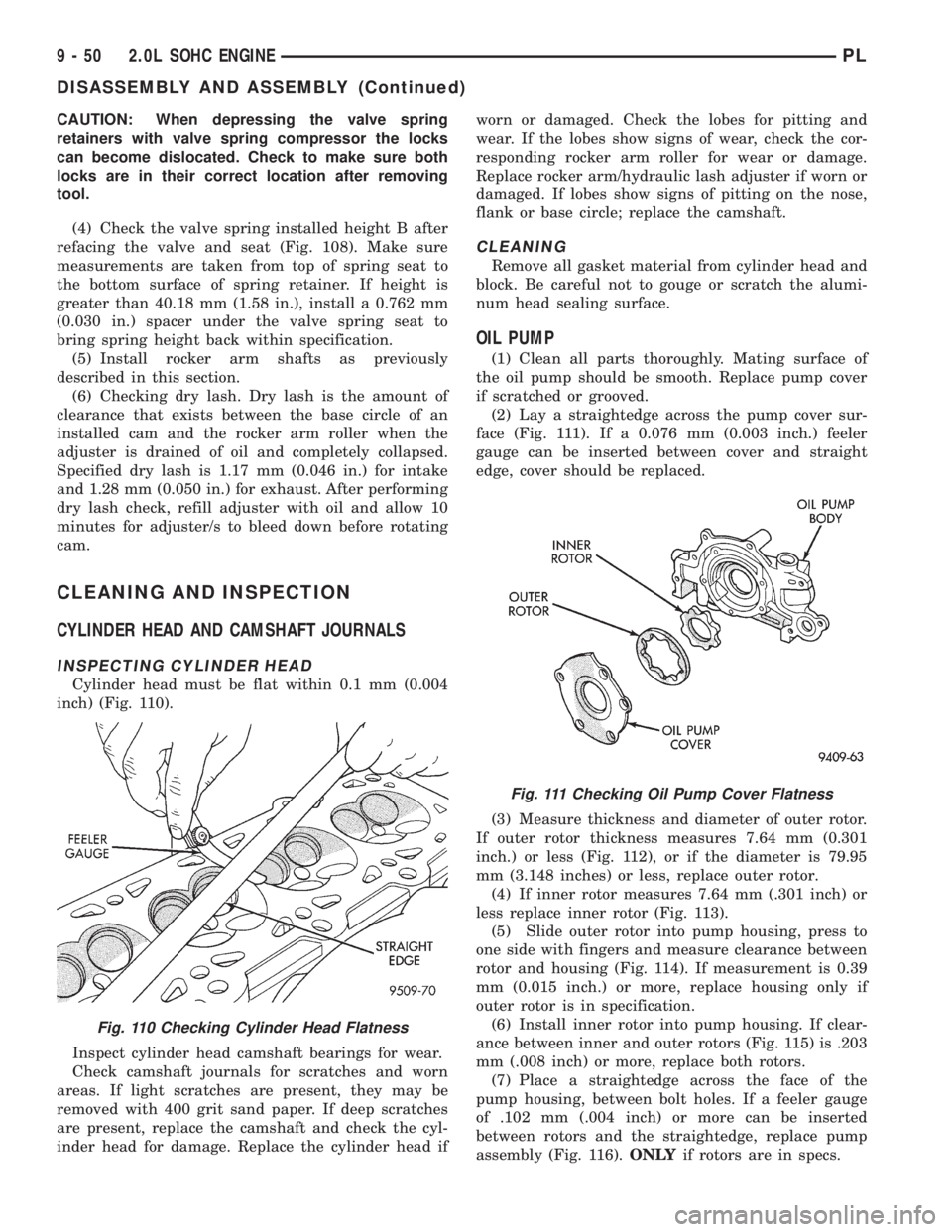

CLEANING AND INSPECTION

CYLINDER HEAD AND CAMSHAFT JOURNALS

INSPECTING CYLINDER HEAD

Cylinder head must be flat within 0.1 mm (0.004

inch) (Fig. 110).

Inspect cylinder head camshaft bearings for wear.

Check camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head ifworn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.

Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

CLEANING

Remove all gasket material from cylinder head and

block. Be careful not to gouge or scratch the alumi-

num head sealing surface.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 111). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 112), or if the diameter is 79.95

mm (3.148 inches) or less, replace outer rotor.

(4) If inner rotor measures 7.64 mm (.301 inch) or

less replace inner rotor (Fig. 113).

(5) Slide outer rotor into pump housing, press to

one side with fingers and measure clearance between

rotor and housing (Fig. 114). If measurement is 0.39

mm (0.015 inch.) or more, replace housing only if

outer rotor is in specification.

(6) Install inner rotor into pump housing. If clear-

ance between inner and outer rotors (Fig. 115) is .203

mm (.008 inch) or more, replace both rotors.

(7) Place a straightedge across the face of the

pump housing, between bolt holes. If a feeler gauge

of .102 mm (.004 inch) or more can be inserted

between rotors and the straightedge, replace pump

assembly (Fig. 116).ONLYif rotors are in specs.

Fig. 110 Checking Cylinder Head Flatness

Fig. 111 Checking Oil Pump Cover Flatness

9 - 50 2.0L SOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 792 of 1200

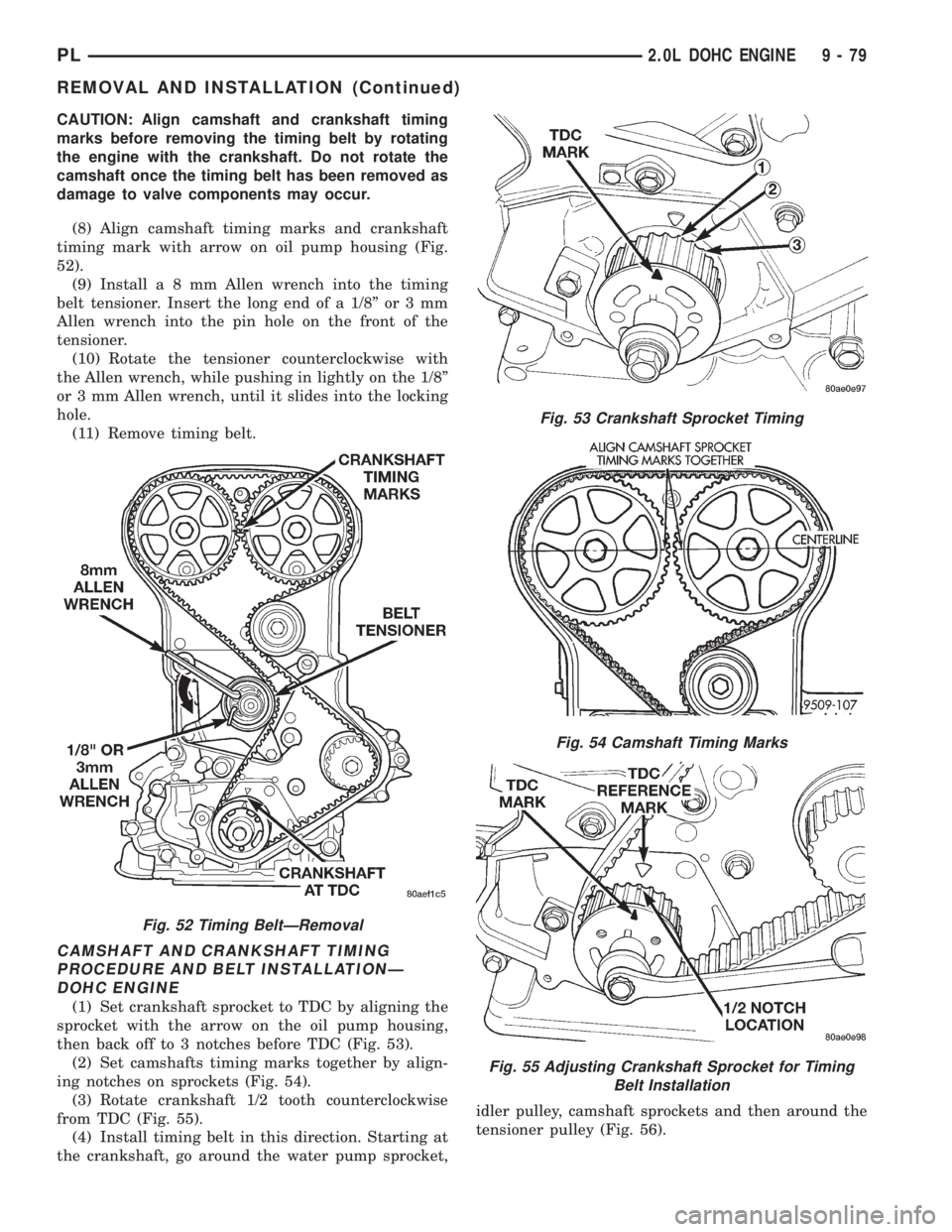

CAUTION: Align camshaft and crankshaft timing

marks before removing the timing belt by rotating

the engine with the crankshaft. Do not rotate the

camshaft once the timing belt has been removed as

damage to valve components may occur.

(8) Align camshaft timing marks and crankshaft

timing mark with arrow on oil pump housing (Fig.

52).

(9) Installa8mmAllen wrench into the timing

belt tensioner. Insert the long end of a 1/8º or 3 mm

Allen wrench into the pin hole on the front of the

tensioner.

(10) Rotate the tensioner counterclockwise with

the Allen wrench, while pushing in lightly on the 1/8º

or 3 mm Allen wrench, until it slides into the locking

hole.

(11) Remove timing belt.

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE AND BELT INSTALLATIONÐ

DOHC ENGINE

(1) Set crankshaft sprocket to TDC by aligning the

sprocket with the arrow on the oil pump housing,

then back off to 3 notches before TDC (Fig. 53).

(2) Set camshafts timing marks together by align-

ing notches on sprockets (Fig. 54).

(3) Rotate crankshaft 1/2 tooth counterclockwise

from TDC (Fig. 55).

(4) Install timing belt in this direction. Starting at

the crankshaft, go around the water pump sprocket,idler pulley, camshaft sprockets and then around the

tensioner pulley (Fig. 56).

Fig. 52 Timing BeltÐRemoval

Fig. 53 Crankshaft Sprocket Timing

Fig. 54 Camshaft Timing Marks

Fig. 55 Adjusting Crankshaft Sprocket for Timing

Belt Installation

PL2.0L DOHC ENGINE 9 - 79

REMOVAL AND INSTALLATION (Continued)

Page 802 of 1200

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.)

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 85).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 86).

(8) Install oil pump pick-up tube and oil pan.

(9) Install Timing Belt. Refer to procedure outlined

in this section.

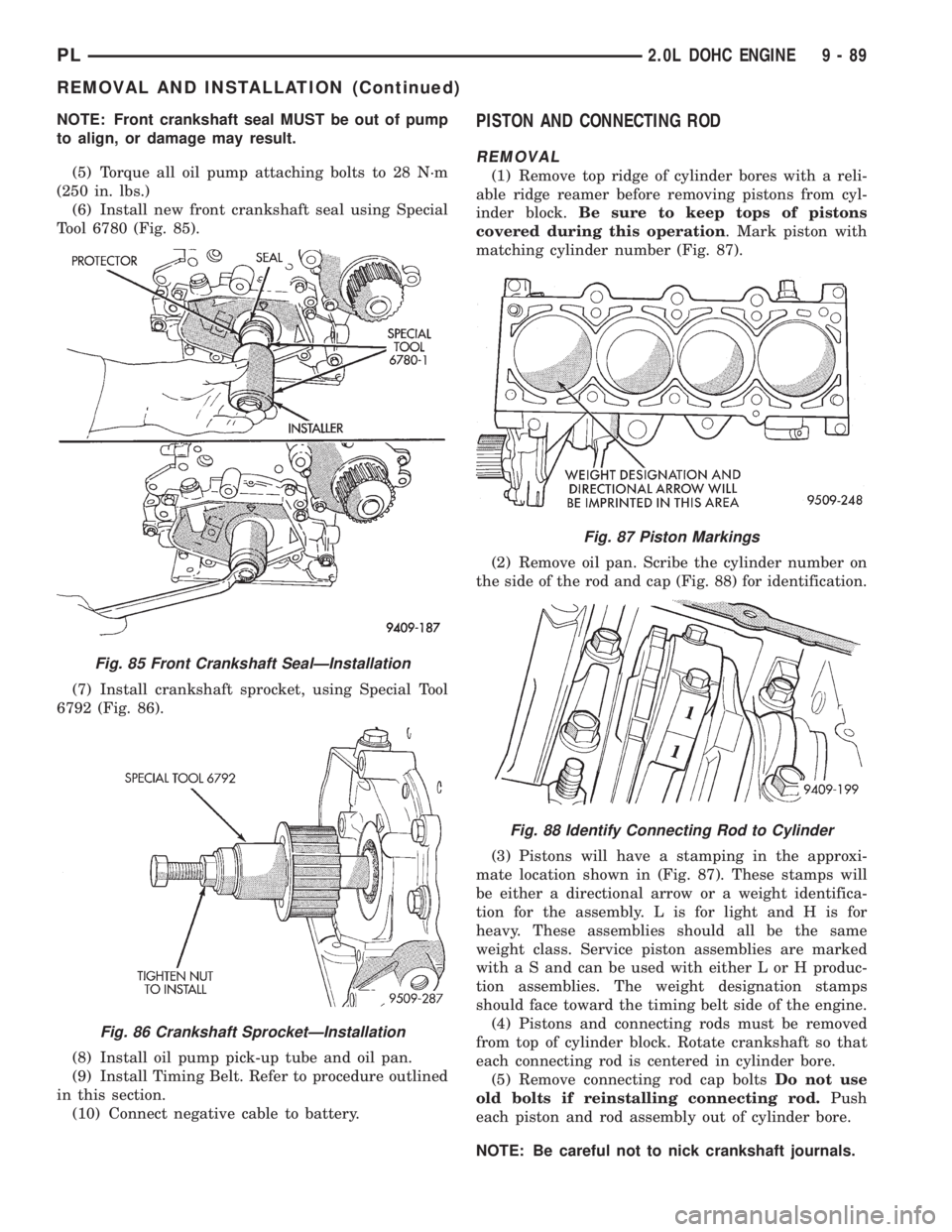

(10) Connect negative cable to battery.PISTON AND CONNECTING ROD

REMOVAL

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 87).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 88) for identification.

(3) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 87). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove connecting rod cap boltsDo not use

old bolts if reinstalling connecting rod.Push

each piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

Fig. 85 Front Crankshaft SealÐInstallation

Fig. 86 Crankshaft SprocketÐInstallation

Fig. 87 Piston Markings

Fig. 88 Identify Connecting Rod to Cylinder

PL2.0L DOHC ENGINE 9 - 89

REMOVAL AND INSTALLATION (Continued)

Page 805 of 1200

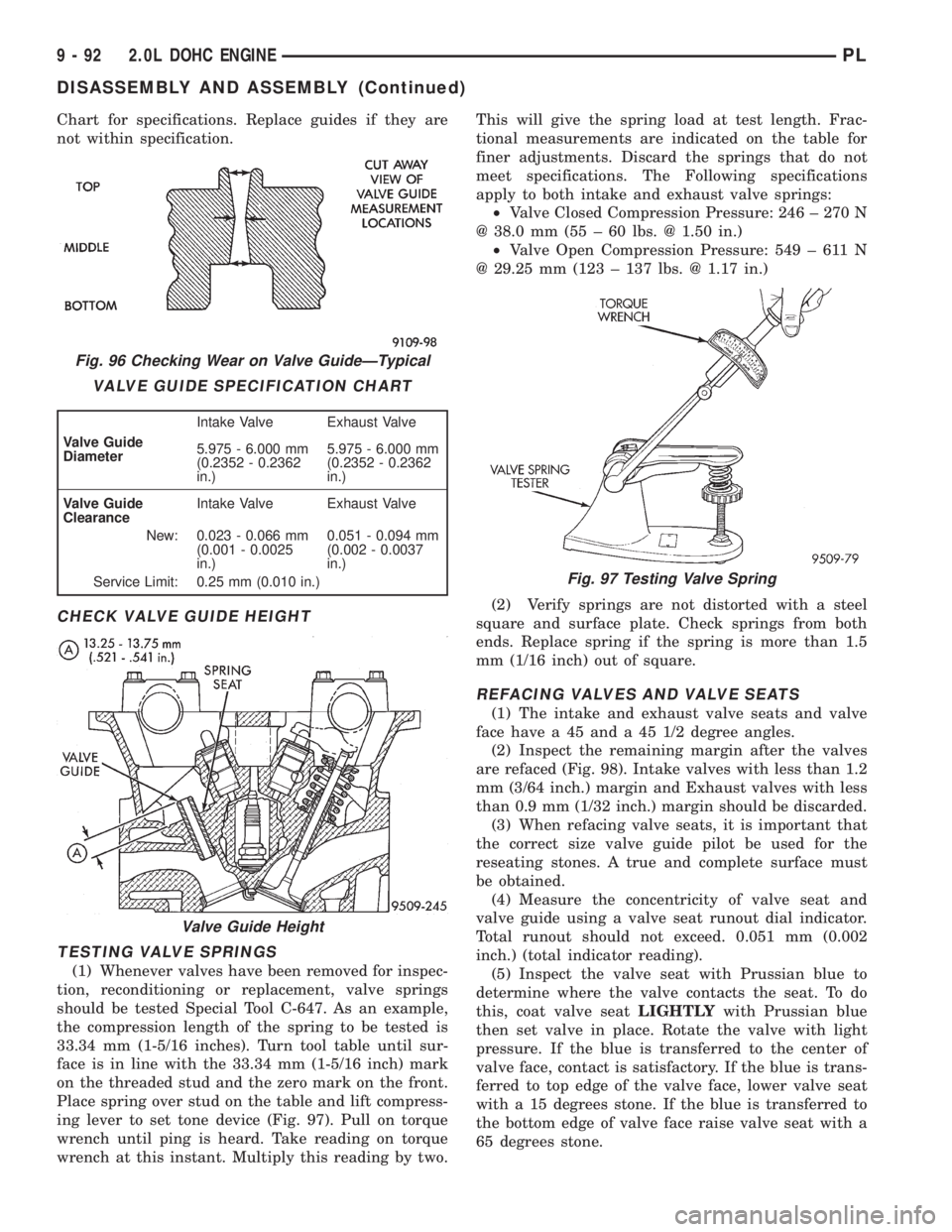

Chart for specifications. Replace guides if they are

not within specification.

CHECK VALVE GUIDE HEIGHT

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested Special Tool C-647. As an example,

the compression length of the spring to be tested is

33.34 mm (1-5/16 inches). Turn tool table until sur-

face is in line with the 33.34 mm (1-5/16 inch) mark

on the threaded stud and the zero mark on the front.

Place spring over stud on the table and lift compress-

ing lever to set tone device (Fig. 97). Pull on torque

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The Following specifications

apply to both intake and exhaust valve springs:

²Valve Closed Compression Pressure: 246 ± 270 N

@ 38.0 mm (55 ± 60 lbs. @ 1.50 in.)

²Valve Open Compression Pressure: 549 ± 611 N

@ 29.25 mm (123 ± 137 lbs. @ 1.17 in.)

(2) Verify springs are not distorted with a steel

square and surface plate. Check springs from both

ends. Replace spring if the spring is more than 1.5

mm (1/16 inch) out of square.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 and a 45 1/2 degree angles.

(2) Inspect the remaining margin after the valves

are refaced (Fig. 98). Intake valves with less than 1.2

mm (3/64 inch.) margin and Exhaust valves with less

than 0.9 mm (1/32 inch.) margin should be discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for the

reseating stones. A true and complete surface must

be obtained.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

Fig. 96 Checking Wear on Valve GuideÐTypical

VALVE GUIDE SPECIFICATION CHART

Valve Guide

DiameterIntake Valve Exhaust Valve

5.975 - 6.000 mm

(0.2352 - 0.2362

in.)5.975 - 6.000 mm

(0.2352 - 0.2362

in.)

Valve Guide

ClearanceIntake Valve Exhaust Valve

New: 0.023 - 0.066 mm

(0.001 - 0.0025

in.)0.051 - 0.094 mm

(0.002 - 0.0037

in.)

Service Limit: 0.25 mm (0.010 in.)

Valve Guide Height

Fig. 97 Testing Valve Spring

9 - 92 2.0L DOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 807 of 1200

CAUTION: If oversize valves are used, there is only

one oversize valve available. The same stem seal is

used on both the standard and oversize valve.

(3) Install valve springs and retainers. Compress

valve springs only enough to install locks, taking

care not to misalign the direction of compression.

Nicked valve stems may result from misalignment of

the valve spring compressor.

CAUTION: When depressing the valve spring

retainers with valve spring compressor the locks

can become dislocated. Check to make sure both

locks are in their correct location after removing

tool.

(4) Check the valve spring installed height B after

refacing the valve and seat (Fig. 100). Make sure

measurements are taken from top of spring seat to

the bottom surface of spring retainer. If height is

greater than 38.75 mm (1.525 in.), install a 7.620

mm (0.030 inch.) spacer under the valve spring seat

to bring spring height back within specification.

(5) Install cam followers and camshaft as previ-

ously described in this section.

(6) Checking dry lash. Dry lash is the amount of

clearance that exists between the base circle of an

installed cam and the rocker arm roller when the

adjuster is drained of oil and completely collapsed.

Specified dry lash is 1.17 mm (0.046 in.) for intake

and 1.28 mm (0.050 in.) for exhaust. After performing

dry lash check, refill adjuster with oil and allow 10

minutes for adjuster or adjusters to bleed down

before rotating cam.

CLEANING AND INSPECTION

CYLINDER HEAD AND CAMSHAFT JOURNALS

INSPECTING CYLINDER HEAD

Cylinder head must be flat within 0.1 mm (0.004

inch) (Fig. 102).Inspect cylinder head camshaft bearings for wear.

Check camshaft journals for scratches and worn

areas. If light scratches are present, they may be

removed with 400 grit sand paper. If deep scratches

are present, replace the camshaft and check the cyl-

inder head for damage. Replace the cylinder head if

worn or damaged. Check the lobes for pitting and

wear. If the lobes show signs of wear, check the cor-

responding rocker arm roller for wear or damage.

Replace rocker arm/hydraulic lash adjuster if worn or

damaged. If lobes show signs of pitting on the nose,

flank or base circle; replace the camshaft.

CLEANING

Remove all gasket material from cylinder head and

block. Be careful not to gouge or scratch the alumi-

num head sealing surface.

OIL PUMP

(1) Clean all parts thoroughly. Mating surface of

the oil pump should be smooth. Replace pump cover

if scratched or grooved.

(2) Lay a straightedge across the pump cover sur-

face (Fig. 103). If a 0.076 mm (0.003 inch.) feeler

gauge can be inserted between cover and straight

edge, cover should be replaced.

(3) Measure thickness and diameter of outer rotor.

If outer rotor thickness measures 7.64 mm (0.301

inch.) or less (Fig. 104), or if the diameter is 79.95

mm (3.148 inches) or less, replace outer rotor.

(4) If inner rotor measures 7.64 mm (.301 inch) or

less replace inner rotor (Fig. 105).

(5) Slide outer rotor into pump housing, press to

one side with fingers and measure clearance between

rotor and housing (Fig. 106). If measurement is 0.39

mm (0.015 inch.) or more, replace housing only if

outer rotor is in specification.

Fig. 101 Valve Stem Oil Seal ToolFig. 102 Checking Cylinder Head Flatness

9 - 94 2.0L DOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 818 of 1200

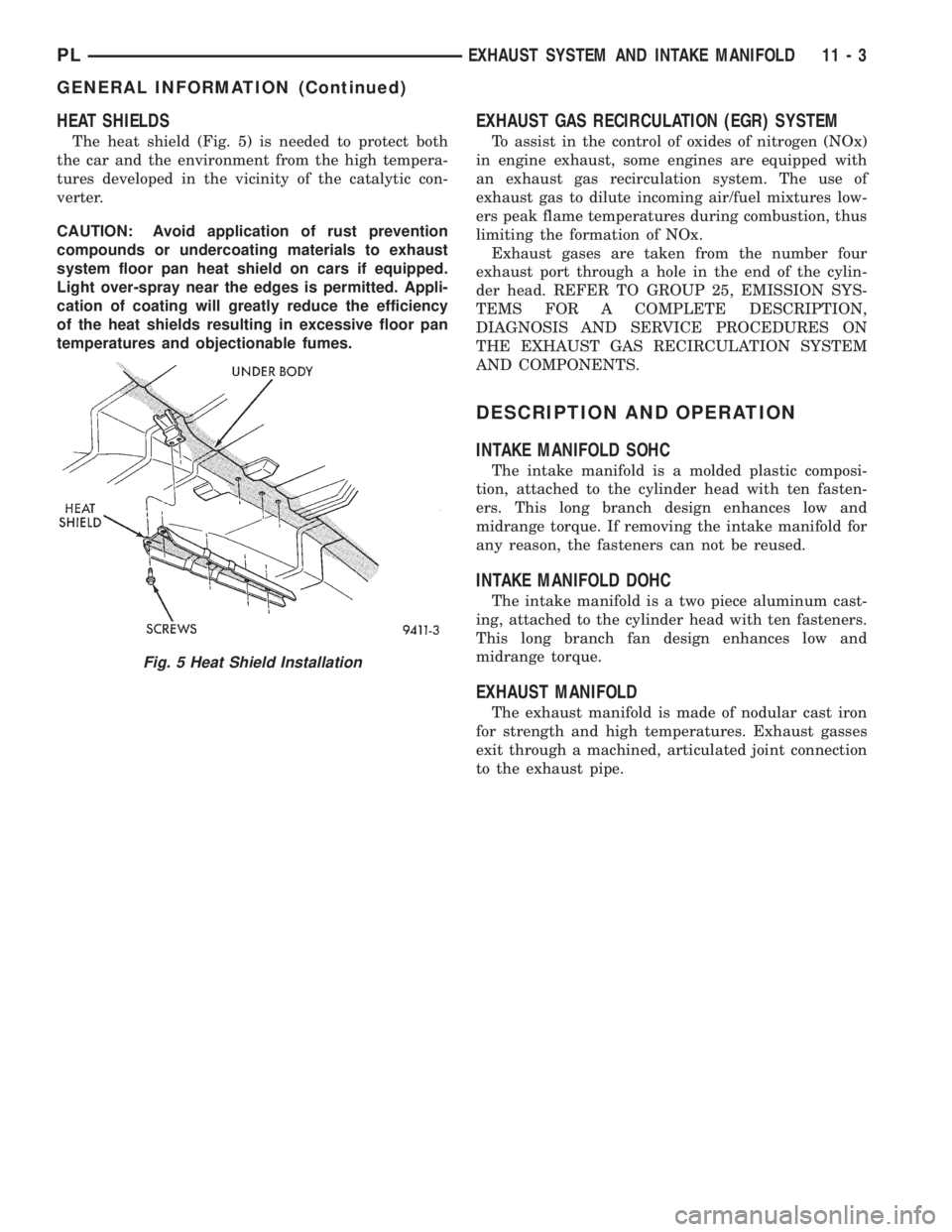

HEAT SHIELDS

The heat shield (Fig. 5) is needed to protect both

the car and the environment from the high tempera-

tures developed in the vicinity of the catalytic con-

verter.

CAUTION: Avoid application of rust prevention

compounds or undercoating materials to exhaust

system floor pan heat shield on cars if equipped.

Light over-spray near the edges is permitted. Appli-

cation of coating will greatly reduce the efficiency

of the heat shields resulting in excessive floor pan

temperatures and objectionable fumes.

EXHAUST GAS RECIRCULATION (EGR) SYSTEM

To assist in the control of oxides of nitrogen (NOx)

in engine exhaust, some engines are equipped with

an exhaust gas recirculation system. The use of

exhaust gas to dilute incoming air/fuel mixtures low-

ers peak flame temperatures during combustion, thus

limiting the formation of NOx.

Exhaust gases are taken from the number four

exhaust port through a hole in the end of the cylin-

der head. REFER TO GROUP 25, EMISSION SYS-

TEMS FOR A COMPLETE DESCRIPTION,

DIAGNOSIS AND SERVICE PROCEDURES ON

THE EXHAUST GAS RECIRCULATION SYSTEM

AND COMPONENTS.

DESCRIPTION AND OPERATION

INTAKE MANIFOLD SOHC

The intake manifold is a molded plastic composi-

tion, attached to the cylinder head with ten fasten-

ers. This long branch design enhances low and

midrange torque. If removing the intake manifold for

any reason, the fasteners can not be reused.

INTAKE MANIFOLD DOHC

The intake manifold is a two piece aluminum cast-

ing, attached to the cylinder head with ten fasteners.

This long branch fan design enhances low and

midrange torque.

EXHAUST MANIFOLD

The exhaust manifold is made of nodular cast iron

for strength and high temperatures. Exhaust gasses

exit through a machined, articulated joint connection

to the exhaust pipe.

Fig. 5 Heat Shield Installation

PLEXHAUST SYSTEM AND INTAKE MANIFOLD 11 - 3

GENERAL INFORMATION (Continued)

Page 823 of 1200

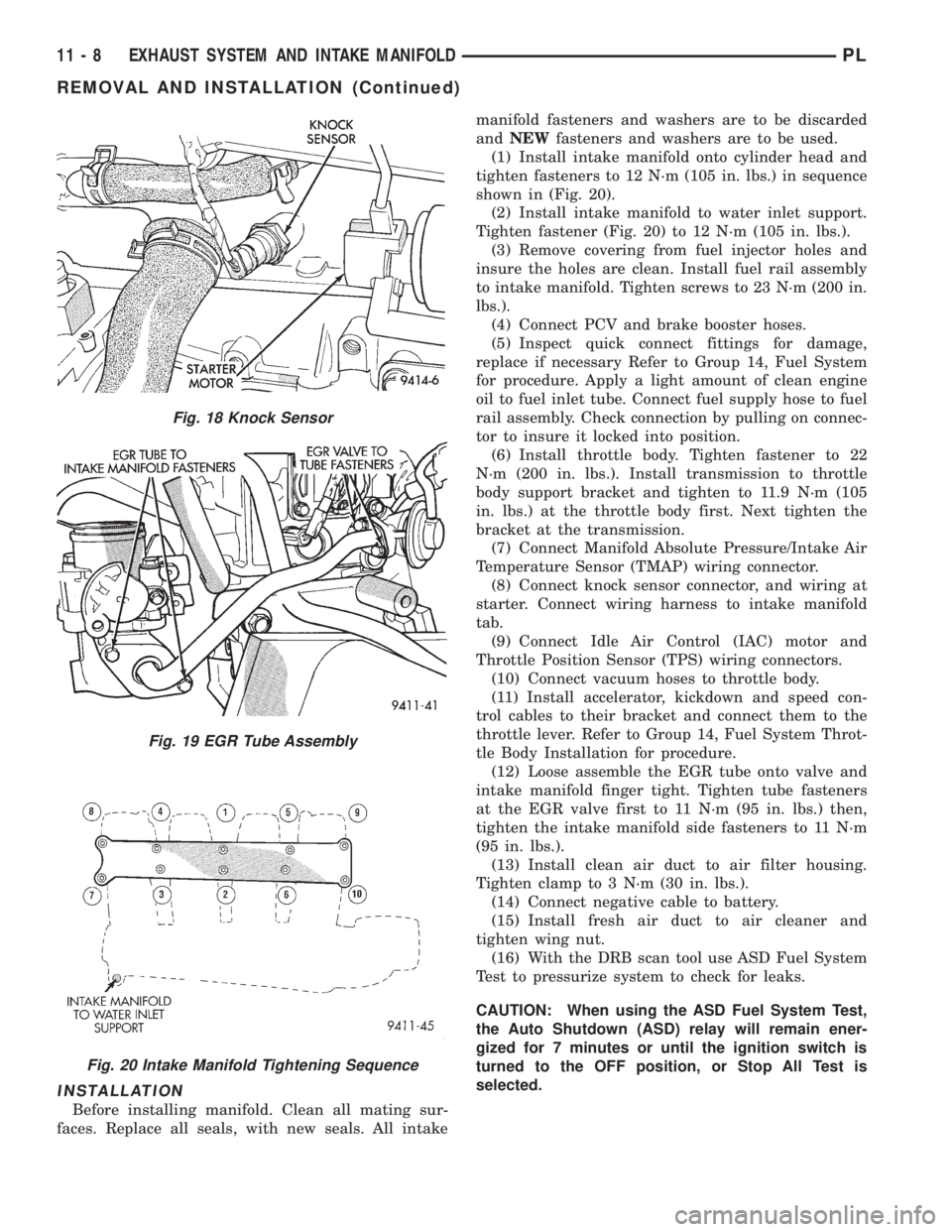

INSTALLATION

Before installing manifold. Clean all mating sur-

faces. Replace all seals, with new seals. All intakemanifold fasteners and washers are to be discarded

andNEWfasteners and washers are to be used.

(1) Install intake manifold onto cylinder head and

tighten fasteners to 12 N´m (105 in. lbs.) in sequence

shown in (Fig. 20).

(2) Install intake manifold to water inlet support.

Tighten fastener (Fig. 20) to 12 N´m (105 in. lbs.).

(3) Remove covering from fuel injector holes and

insure the holes are clean. Install fuel rail assembly

to intake manifold. Tighten screws to 23 N´m (200 in.

lbs.).

(4) Connect PCV and brake booster hoses.

(5) Inspect quick connect fittings for damage,

replace if necessary Refer to Group 14, Fuel System

for procedure. Apply a light amount of clean engine

oil to fuel inlet tube. Connect fuel supply hose to fuel

rail assembly. Check connection by pulling on connec-

tor to insure it locked into position.

(6) Install throttle body. Tighten fastener to 22

N´m (200 in. lbs.). Install transmission to throttle

body support bracket and tighten to 11.9 N´m (105

in. lbs.) at the throttle body first. Next tighten the

bracket at the transmission.

(7) Connect Manifold Absolute Pressure/Intake Air

Temperature Sensor (TMAP) wiring connector.

(8) Connect knock sensor connector, and wiring at

starter. Connect wiring harness to intake manifold

tab.

(9) Connect Idle Air Control (IAC) motor and

Throttle Position Sensor (TPS) wiring connectors.

(10) Connect vacuum hoses to throttle body.

(11) Install accelerator, kickdown and speed con-

trol cables to their bracket and connect them to the

throttle lever. Refer to Group 14, Fuel System Throt-

tle Body Installation for procedure.

(12) Loose assemble the EGR tube onto valve and

intake manifold finger tight. Tighten tube fasteners

at the EGR valve first to 11 N´m (95 in. lbs.) then,

tighten the intake manifold side fasteners to 11 N´m

(95 in. lbs.).

(13) Install clean air duct to air filter housing.

Tighten clamp to 3 N´m (30 in. lbs.).

(14) Connect negative cable to battery.

(15) Install fresh air duct to air cleaner and

tighten wing nut.

(16) With the DRB scan tool use ASD Fuel System

Test to pressurize system to check for leaks.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) relay will remain ener-

gized for 7 minutes or until the ignition switch is

turned to the OFF position, or Stop All Test is

selected.

Fig. 18 Knock Sensor

Fig. 19 EGR Tube Assembly

Fig. 20 Intake Manifold Tightening Sequence

11 - 8 EXHAUST SYSTEM AND INTAKE MANIFOLDPL

REMOVAL AND INSTALLATION (Continued)