light DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1100 of 1200

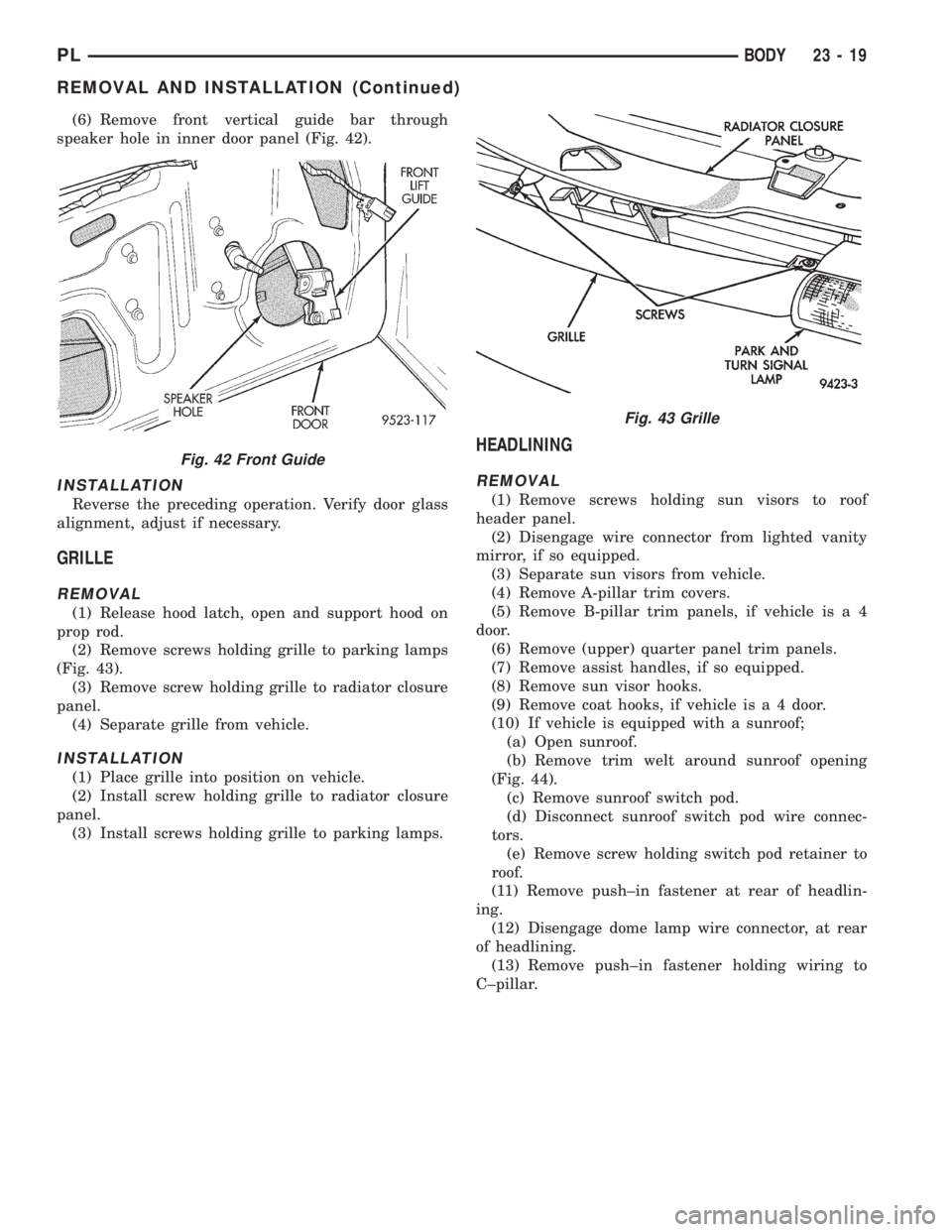

(6) Remove front vertical guide bar through

speaker hole in inner door panel (Fig. 42).

INSTALLATION

Reverse the preceding operation. Verify door glass

alignment, adjust if necessary.

GRILLE

REMOVAL

(1) Release hood latch, open and support hood on

prop rod.

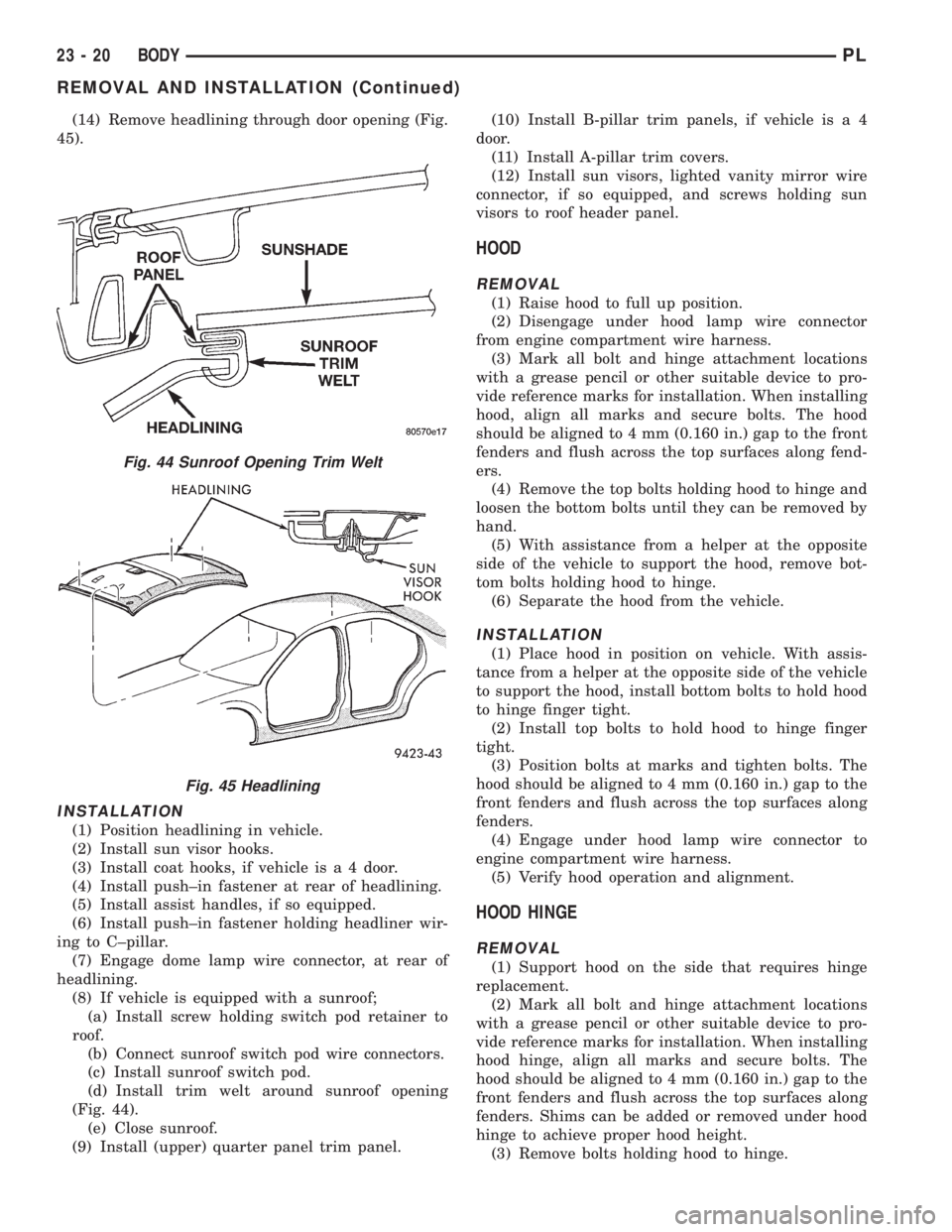

(2) Remove screws holding grille to parking lamps

(Fig. 43).

(3) Remove screw holding grille to radiator closure

panel.

(4) Separate grille from vehicle.

INSTALLATION

(1) Place grille into position on vehicle.

(2) Install screw holding grille to radiator closure

panel.

(3) Install screws holding grille to parking lamps.

HEADLINING

REMOVAL

(1) Remove screws holding sun visors to roof

header panel.

(2) Disengage wire connector from lighted vanity

mirror, if so equipped.

(3) Separate sun visors from vehicle.

(4) Remove A-pillar trim covers.

(5) Remove B-pillar trim panels, if vehicle is a 4

door.

(6) Remove (upper) quarter panel trim panels.

(7) Remove assist handles, if so equipped.

(8) Remove sun visor hooks.

(9) Remove coat hooks, if vehicle is a 4 door.

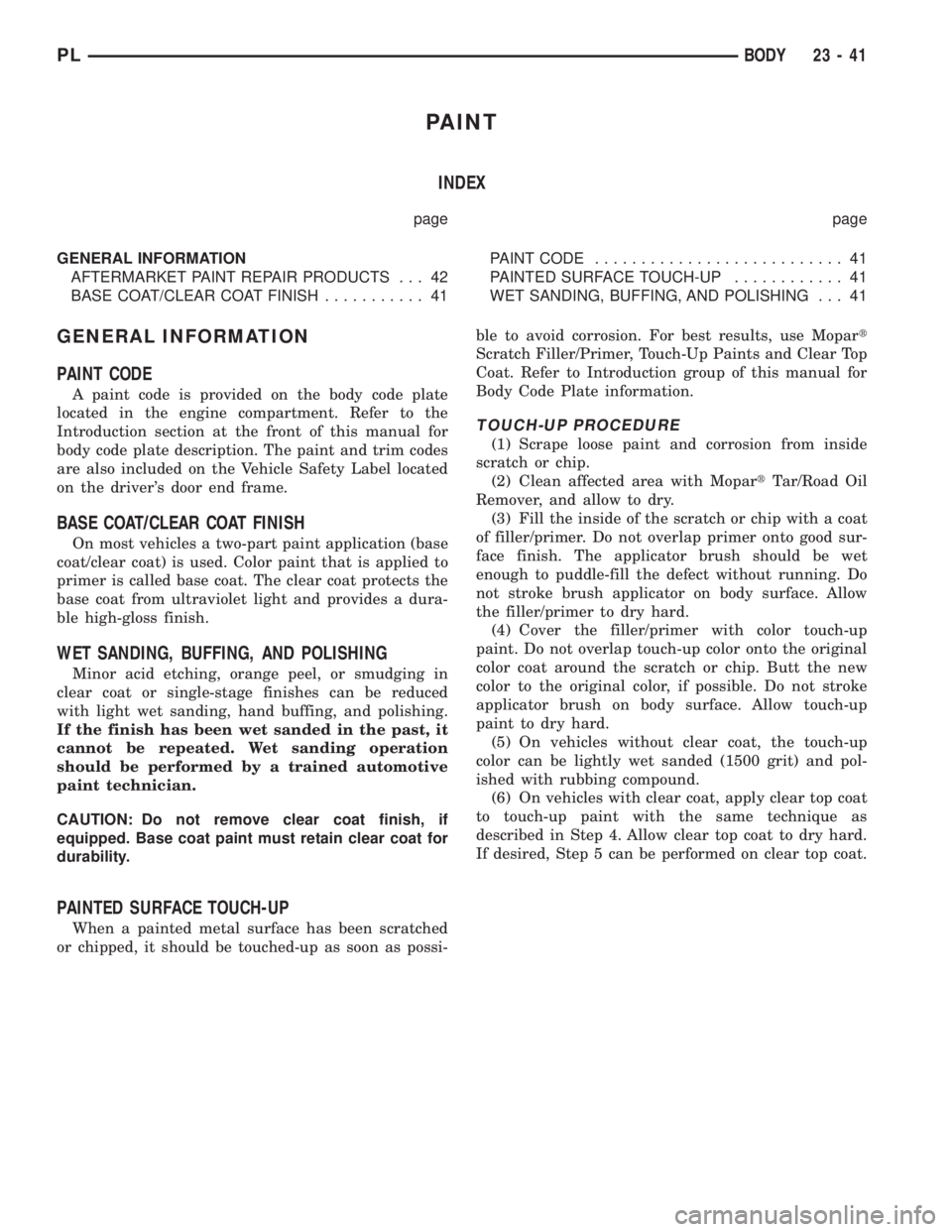

(10) If vehicle is equipped with a sunroof;

(a) Open sunroof.

(b) Remove trim welt around sunroof opening

(Fig. 44).

(c) Remove sunroof switch pod.

(d) Disconnect sunroof switch pod wire connec-

tors.

(e) Remove screw holding switch pod retainer to

roof.

(11) Remove push±in fastener at rear of headlin-

ing.

(12) Disengage dome lamp wire connector, at rear

of headlining.

(13) Remove push±in fastener holding wiring to

C±pillar.

Fig. 42 Front Guide

Fig. 43 Grille

PLBODY 23 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1101 of 1200

(14) Remove headlining through door opening (Fig.

45).

INSTALLATION

(1) Position headlining in vehicle.

(2) Install sun visor hooks.

(3) Install coat hooks, if vehicle is a 4 door.

(4) Install push±in fastener at rear of headlining.

(5) Install assist handles, if so equipped.

(6) Install push±in fastener holding headliner wir-

ing to C±pillar.

(7) Engage dome lamp wire connector, at rear of

headlining.

(8) If vehicle is equipped with a sunroof;

(a) Install screw holding switch pod retainer to

roof.

(b) Connect sunroof switch pod wire connectors.

(c) Install sunroof switch pod.

(d) Install trim welt around sunroof opening

(Fig. 44).

(e) Close sunroof.

(9) Install (upper) quarter panel trim panel.(10) Install B-pillar trim panels, if vehicle is a 4

door.

(11) Install A-pillar trim covers.

(12) Install sun visors, lighted vanity mirror wire

connector, if so equipped, and screws holding sun

visors to roof header panel.

HOOD

REMOVAL

(1) Raise hood to full up position.

(2) Disengage under hood lamp wire connector

from engine compartment wire harness.

(3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When installing

hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.

(4) Remove the top bolts holding hood to hinge and

loosen the bottom bolts until they can be removed by

hand.

(5) With assistance from a helper at the opposite

side of the vehicle to support the hood, remove bot-

tom bolts holding hood to hinge.

(6) Separate the hood from the vehicle.

INSTALLATION

(1) Place hood in position on vehicle. With assis-

tance from a helper at the opposite side of the vehicle

to support the hood, install bottom bolts to hold hood

to hinge finger tight.

(2) Install top bolts to hold hood to hinge finger

tight.

(3) Position bolts at marks and tighten bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders.

(4) Engage under hood lamp wire connector to

engine compartment wire harness.

(5) Verify hood operation and alignment.

HOOD HINGE

REMOVAL

(1) Support hood on the side that requires hinge

replacement.

(2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When installing

hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height.

(3) Remove bolts holding hood to hinge.

Fig. 44 Sunroof Opening Trim Welt

Fig. 45 Headlining

23 - 20 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1122 of 1200

PAINT

INDEX

page page

GENERAL INFORMATION

AFTERMARKET PAINT REPAIR PRODUCTS . . . 42

BASE COAT/CLEAR COAT FINISH........... 41PAINT CODE........................... 41

PAINTED SURFACE TOUCH-UP............ 41

WET SANDING, BUFFING, AND POLISHING . . . 41

GENERAL INFORMATION

PAINT CODE

A paint code is provided on the body code plate

located in the engine compartment. Refer to the

Introduction section at the front of this manual for

body code plate description. The paint and trim codes

are also included on the Vehicle Safety Label located

on the driver's door end frame.

BASE COAT/CLEAR COAT FINISH

On most vehicles a two-part paint application (base

coat/clear coat) is used. Color paint that is applied to

primer is called base coat. The clear coat protects the

base coat from ultraviolet light and provides a dura-

ble high-gloss finish.

WET SANDING, BUFFING, AND POLISHING

Minor acid etching, orange peel, or smudging in

clear coat or single-stage finishes can be reduced

with light wet sanding, hand buffing, and polishing.

If the finish has been wet sanded in the past, it

cannot be repeated. Wet sanding operation

should be performed by a trained automotive

paint technician.

CAUTION: Do not remove clear coat finish, if

equipped. Base coat paint must retain clear coat for

durability.

PAINTED SURFACE TOUCH-UP

When a painted metal surface has been scratched

or chipped, it should be touched-up as soon as possi-ble to avoid corrosion. For best results, use Mopart

Scratch Filler/Primer, Touch-Up Paints and Clear Top

Coat. Refer to Introduction group of this manual for

Body Code Plate information.

TOUCH-UP PROCEDURE

(1) Scrape loose paint and corrosion from inside

scratch or chip.

(2) Clean affected area with MopartTar/Road Oil

Remover, and allow to dry.

(3) Fill the inside of the scratch or chip with a coat

of filler/primer. Do not overlap primer onto good sur-

face finish. The applicator brush should be wet

enough to puddle-fill the defect without running. Do

not stroke brush applicator on body surface. Allow

the filler/primer to dry hard.

(4) Cover the filler/primer with color touch-up

paint. Do not overlap touch-up color onto the original

color coat around the scratch or chip. Butt the new

color to the original color, if possible. Do not stroke

applicator brush on body surface. Allow touch-up

paint to dry hard.

(5) On vehicles without clear coat, the touch-up

color can be lightly wet sanded (1500 grit) and pol-

ished with rubbing compound.

(6) On vehicles with clear coat, apply clear top coat

to touch-up paint with the same technique as

described in Step 4. Allow clear top coat to dry hard.

If desired, Step 5 can be performed on clear top coat.

PLBODY 23 - 41

Page 1129 of 1200

SYMPTOM POSSIBLE CAUSE

Wind noise from sunroof.²Front of glass panel too high or rear too low.

²Glass panel not centered in opening.

²Faulty glass panel seal.

Glass panel hangs up or snaps between

vent and open.²Glass panel improperly adjusted.

²Glass panel seal has inconsistent compression.

Rattles from open sunroof while driving²Loose attaching hardware.

²Weak springs on wind deflector.

²Sunshade out of the track.

Rattles from closed sunroof while driving²Loose attaching hardware.

²Wind deflector contacting glass panel or drain trough.

²Sunshade out of the track.

REMOVAL AND INSTALLATION

SUNROOF PROCEDURE INFORMATION

The numbered call-outs in the following ser-

vice procedures refer the numbered parts

found in the figure at the end of this section.

SUNROOF CABLES

REMOVAL

(1) Remove sunroof glass panel (4). Refer to proce-

dure found in this section.

(2) Cycle the sunroof mechanism to the full for-

ward position.

CAUTION: Do not remove sunroof drive motor

unless sunroof mechanism is in the full forward

position.

(3) Remove sunroof drive motor (10). Refer to pro-

cedure found in this section.

(4) Remove front locator (7 or 8) for appropriate

sunroof cable.

(5) Disengage sunroof cable from sunroof mecha-

nism (9).

(6) Pull sunroof cable from drive tube (2 or 3).

INSTALLATION

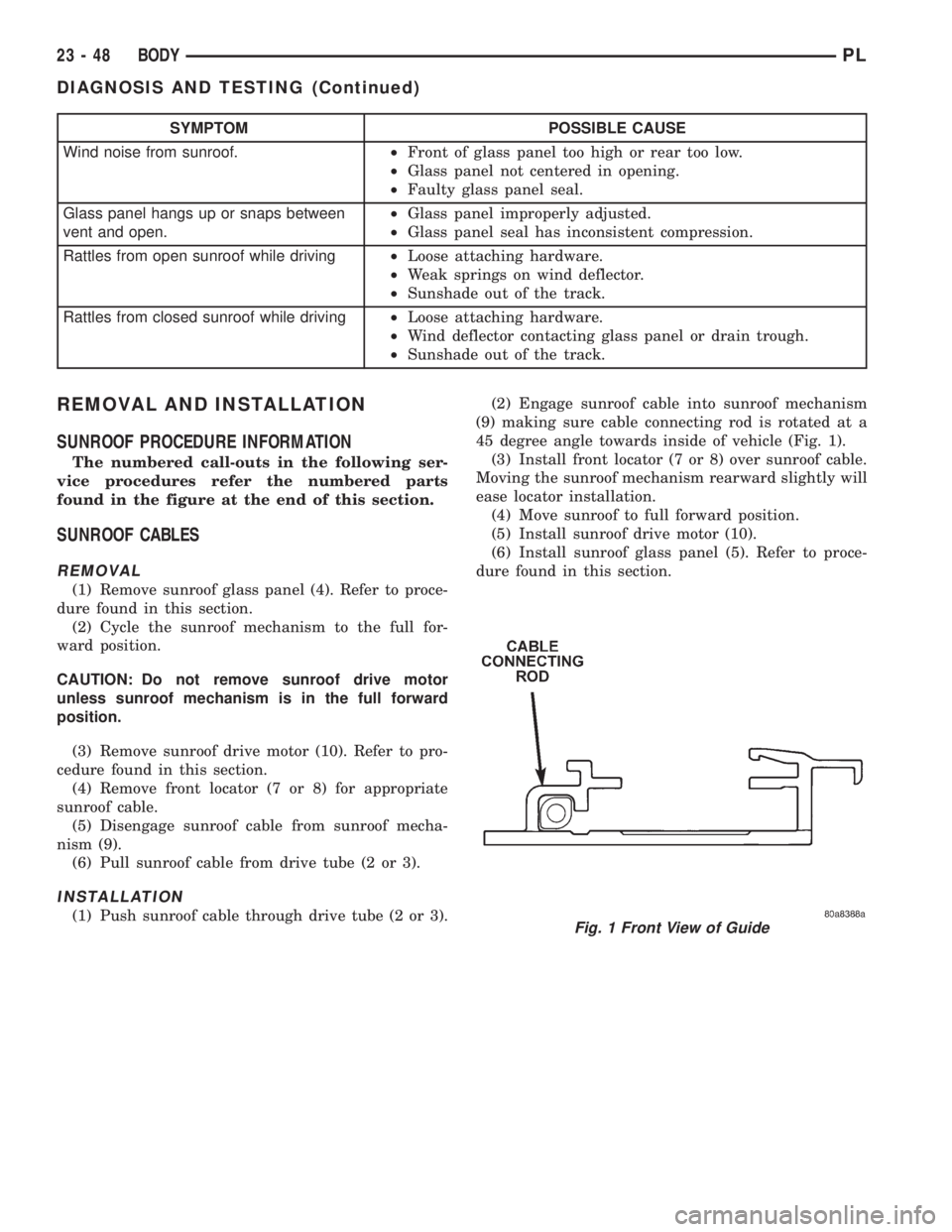

(1) Push sunroof cable through drive tube (2 or 3).(2) Engage sunroof cable into sunroof mechanism

(9) making sure cable connecting rod is rotated at a

45 degree angle towards inside of vehicle (Fig. 1).

(3) Install front locator (7 or 8) over sunroof cable.

Moving the sunroof mechanism rearward slightly will

ease locator installation.

(4) Move sunroof to full forward position.

(5) Install sunroof drive motor (10).

(6) Install sunroof glass panel (5). Refer to proce-

dure found in this section.Fig. 1 Front View of Guide

23 - 48 BODYPL

DIAGNOSIS AND TESTING (Continued)

Page 1131 of 1200

INSTALLATION

(1) With the aid of a helper, hold the sunroof glass

panel in the closed position and engage the drive

motor (10) into the sunroof drive cables.

(2) Install screws holding drive motor to bracket.

(3) Connect wire harness to drive motor.

(4) Install headlining.

SUNROOF GLASS PANEL

REMOVAL

(1) Position sunroof sunshade (4) in full rearward

position.

(2) Remove six glass attachment screws.

(3) Push glass panel upward from underside until

glass panel clears the roof panel.

(4) Lift glass panel from vehicle.

INSTALLATION

(1) Position glass panel (4) in opening in vehicle

roof.

(2) Install, but do not tighten, glass attachment

screws.

(3) With the aid of a helper, hold the glass panel in

position and tighten glass attachment screws.

(4) Verify the correct glass height. Refer to Glass

Height Adjustment procedure in this section.

SUNROOF GUIDE AND MECHANISM ASSEMBLY

REMOVAL

(1) Remove sunroof glass panel (4). Refer to proce-

dure in this section.

(2) Remove front locator (7 or 8).

(3) Disengage cable from mechanism (9).

(4) Remove screws holding sunroof guide (5) and

mechanism (9) assembly to sunroof module.

(5) Lift assembly from module.

(6) Rotate assembly to disengage wind deflector

(13) from assembly.

INSTALLATION

(1) Engage wind deflector (13) into guide (5) and

mechanism (9) assembly.

(2) Position assembly onto module and install

screws holding assembly to sunroof module.

(3) Engage drive cable to mechanism.

(4) Install front locator (7 or 8 ). It may ease

installation to move sunroof mechanism slightly rear-

ward.

(5) Install sunroof glass panel. Refer to procedure

found in this section.

SUNROOF MODULE

REMOVAL

(1) Remove headlining.

(2) Remove fasteners attaching sunroof module to

vehicle roof and support braces.

(3) With the aid of a helper, separate sunroof mod-

ule from roof.

(4) Remove sunroof module from vehicle.

INSTALLATION

(1) With the aid of a helper, position sunroof mod-

ule in vehicle.

(2) Install fasteners holding sunroof module to

vehicle roof.

(3) Tighten all fasteners, starting from the front

and working rearward and then the motor bracket.

(4) Adjust glass panel for flushness to roof. Refer

to glass adjustment procedure in this section.

(5) Install headlining.

(6) Verify correct operation.

SUNROOF SUNSHADE

REMOVAL

(1) Remove sunroof glass panel (4). Refer to proce-

dure found in this section.

(2) Slide sunshade (11) to full forward position.

(3) Disengage slide blocks on one side of sunshade

from sunshade guide (6).

(4) Lift and pull sunshade out of opposite sun-

shade guide.

INSTALLATION

(1) Place sunshade with cloth side down and

install one side's slide blocks into the track on the

sunshade guide (6).

(2) Slide the other side's slide blocks to fully

inward position and insert them into the sunshade

guide (6).

(3) Verify that all four slide blocks are fully

engaged in the sunshade guide (6).

(4) Slide sunshade (11) fully rearward.

(5) Install sunroof glass panel (4). Refer to proce-

dure found in this section.

SUNROOF WIND DEFLECTOR

REMOVAL

(1) Open sunroof to full open position.

(2) Pull one end of wind deflector flap out of the

wind deflector beam (13).

(3) Release corner piece locking tab and separate

corner piece from wind deflector beam.

(4) Rotate corner piece outboard to release tab

from roof flange.

23 - 50 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1144 of 1200

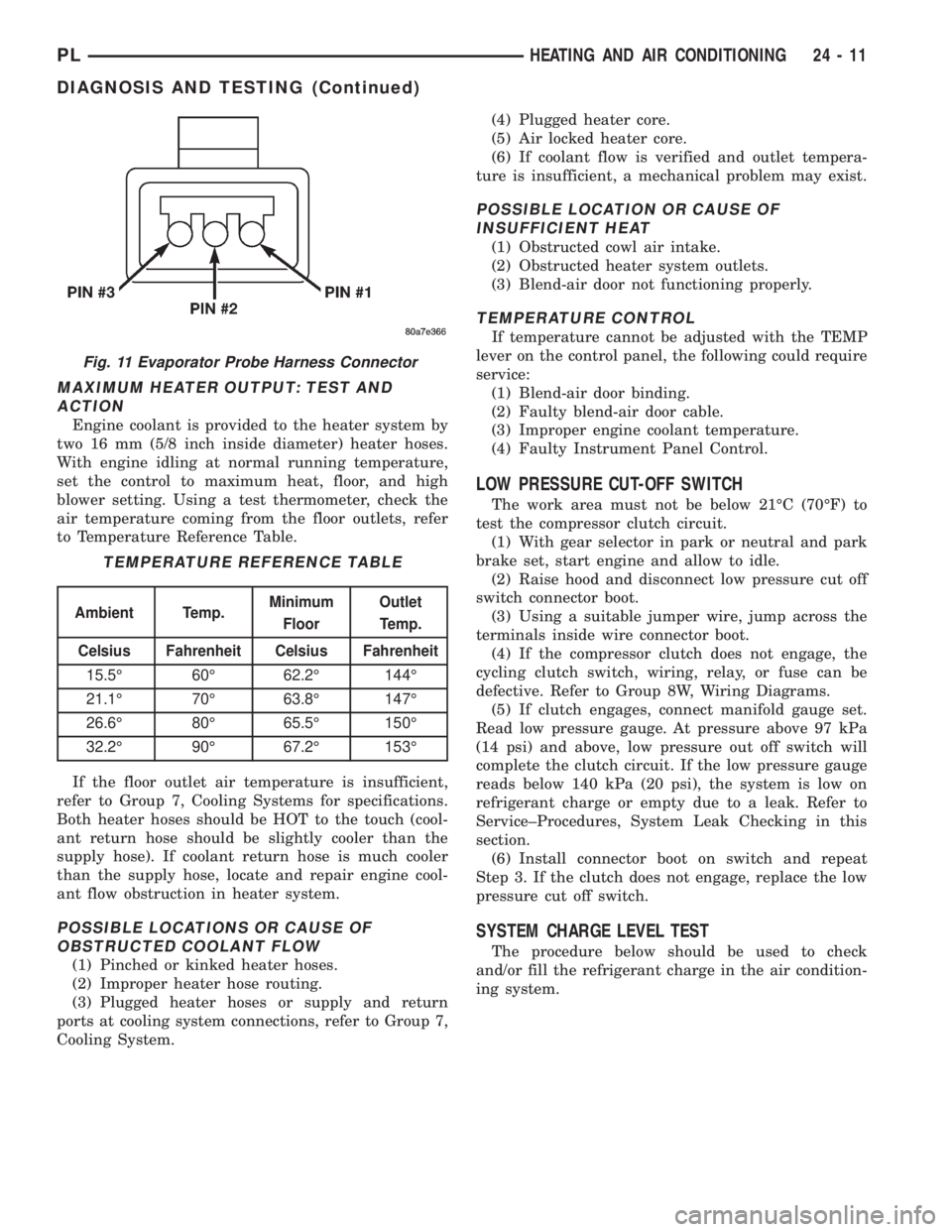

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference Table.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door cable.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

LOW PRESSURE CUT-OFF SWITCH

The work area must not be below 21ÉC (70ÉF) to

test the compressor clutch circuit.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Raise hood and disconnect low pressure cut off

switch connector boot.

(3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot.

(4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams.

(5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, low pressure out off switch will

complete the clutch circuit. If the low pressure gauge

reads below 140 kPa (20 psi), the system is low on

refrigerant charge or empty due to a leak. Refer to

Service±Procedures, System Leak Checking in this

section.

(6) Install connector boot on switch and repeat

Step 3. If the clutch does not engage, replace the low

pressure cut off switch.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

Fig. 11 Evaporator Probe Harness Connector

TEMPERATURE REFERENCE TABLE

Ambient Temp.Minimum

FloorOutlet

Temp.

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

PLHEATING AND AIR CONDITIONING 24 - 11

DIAGNOSIS AND TESTING (Continued)