belt DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 204 of 1200

COOLING SYSTEM DIAGNOSIS CONT.

CONDITION POSSIBLE CAUSES CORRECTION

INADEQUATE AIR CONDITIONER

PERFORMANCE (COOLING

SYSTEM SUSPECTED)1. Radiator and/or air conditioning

condenser is restricted, obstructed

or dirty.1. Remove restriction and/or clean

as necessary.

2. Electric radiator fan not operating

when a/c is on.2. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

repair as necessary.

3. Engine is overheating ( heat may

be transferred from radiator to A/C

condenser. High underhood

temperature due to engine

overheating may also transfer heat

to A/C components).3. Correct overheating condition.

Refer to Group 7, Cooling.

INADEQUATE HEATER

PERFORMANCE.1. Has a diagnostic trouble code

(DTC) been set?1. Refer to On-Board Diagnostic in

Group 25, and replace thermostat if

necessary.

2. Coolant level low. 2. Refer to testing cooling system

for leaks in this section. Repair as

necessary.

3. Obstructions in heater hose

fittings at engine.3. Remove heater hoses at both

ends and check for obstructions.

Repair as necessary.

4. Heater hose kinked. 4. Locate kinked area and repair as

necessary.

5. Water pump is not pumping

coolant to heater core. When the

engine is fully warmed up, both

heater hoses should be hot to the

touch. The accessory drive belt

may be slipping causing poor water

pump operation.5. Refer to water pump in this

group. Repair as necessary. If

slipping belt is detected, refer to

accessory drive belts in this group.

Repair as necessary.

HEAT ODOR 6. Various heat shields are used at

certain drive line components. One

or more of these shields may be

missing.6. Locate missing shields and

replace or repair as necessary.

PLCOOLING 7 - 11

DIAGNOSIS AND TESTING (Continued)

Page 206 of 1200

ENGINE THERMOSTAT TESTING

The thermostat is operated by a wax filled con-

tainer (pellet) which is sealed. When heated coolant

reaches a predetermined temperature the wax pellet

expands enough to overcome the closing spring and

water pump pressure, which forces the valve to open.

Coolant leakage into the pellet will cause a thermo-

stat to fail open. Do not attempt to free up a thermo-

stat with a screwdriver.The thermostat that opens too soon type failure

mode is included in the on-board diagnosis. The

check engine light will not be lit by an open too soon

condition. If it has failed open, a diagnostic trouble

code (DTC) will be set. Do not change a thermostat

for lack of heater performance or temperature gauge

position, unless a DTC is present. See Diagnosis for

other probable causes. Thermostat failing shut is the

normal long term mode of failure, and normally, only

on high mileage vehicles. The temperature gauge will

indicate this. Refer to Diagnosis in this section.

ACCESSORY DRIVE BELT DIAGNOSIS

CONDITION POSSIBLE CAUSE CORRECTION

INSUFFICIENT ACCESSORY

OUTPUT DUE TO BELT SLIPPAGE1. Belt too loose. 1. Adjust belt tension.

2. Belt excessively glazed or worn. 2. Replace and tighten as specified.

BELT SQUEAL WHEN

ACCELERATING ENGINE1. Belts too loose. 1. Adjust belt tension.

2. Belts glazed. 2. Replace belts.

BELT CHIRP AT IDLE 1. Belts too loose. 1. Adjust belt tension.

2. Foreign material imbedded in

belt.2. Replace belt.

3. Non-uniform belt. 3. Replace belt.

4. Misaligned pulley(s). 4. Align accessories.

5. Non-uniform groove or eccentric

pulley.5. Replace pulley(s).

BELT ROLLED OVER IN GROOVE

OR BELT JUMPS OFF1. Broken cord in belt. 1. Replace belt.

2. Belt too loose, or too tight. 2. Adjust belt tension.

3. Misaligned pulleys. 3. Align accessories.

4. Non-uniform grooves or eccentric

pulley.4. Replace pulley(s).

PLCOOLING 7 - 13

DIAGNOSIS AND TESTING (Continued)

Page 210 of 1200

COOLING SYSTEMÐREFILLING

First clean system to remove old glycol, see Cooling

System Cleaning.

Fill system using antifreeze described in Coolant

section. Fill 50 percent of capacity with 100 percent

glycol. Then complete filling system with water.

Continue filling system until full, this provides bet-

ter heater performance.Be careful not to spill

coolant on drive belts or the generator.

Fill coolant reserve system to at least the FULL

mark with 50/50 solution. It may be necessary to add

coolant to the reserve tank after three or four warm-

up/cool down cycles to maintain coolant level between

the FULL and ADD marks; if any trapped air was

removed from the system.

REMOVAL AND INSTALLATION

WATER PUMP

REMOVAL

(1) Raise vehicle on a hoist. Remove right inner

splash shield.

(2) Remove accessory drive belts and power steer-

ing pump. Refer to Accessory Drive Belt service in

this section.

(3) Drain cooling system. Refer to Cooling System

Draining in this section.

(4) Support engine from the bottom and remove

right engine mount.

(5) Remove power steering pump bracket bolts and

set pump and bracket assembly aside. Power steering

lines do not need to be disconnected.

(6) Remove right engine mount bracket.

(7) Remove timing belt and timing belt tensioner.

Refer to Group 9, Engine for procedure.

(8) Remove camshaft sprockets and inner timing

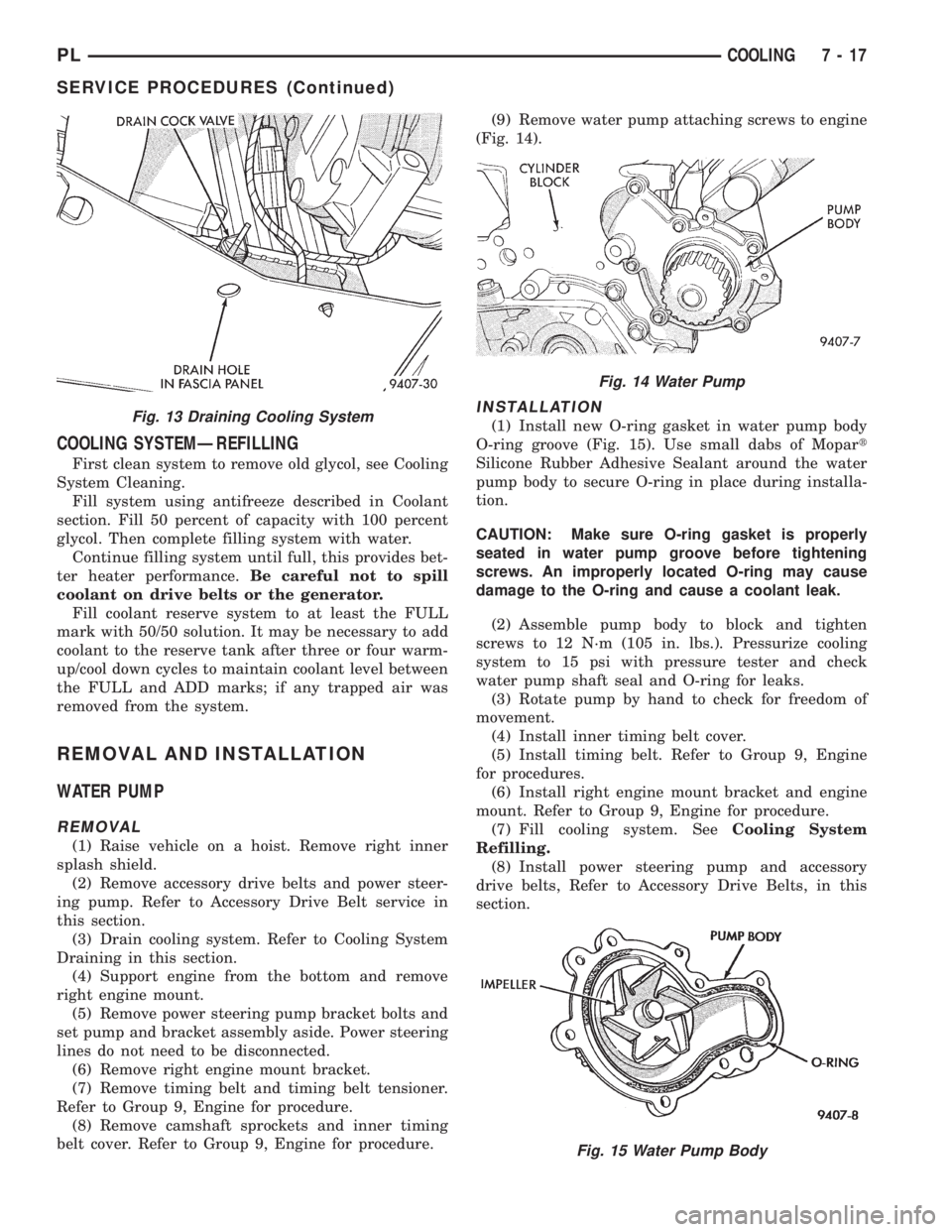

belt cover. Refer to Group 9, Engine for procedure.(9) Remove water pump attaching screws to engine

(Fig. 14).

INSTALLATION

(1) Install new O-ring gasket in water pump body

O-ring groove (Fig. 15). Use small dabs of Mopart

Silicone Rubber Adhesive Sealant around the water

pump body to secure O-ring in place during installa-

tion.

CAUTION: Make sure O-ring gasket is properly

seated in water pump groove before tightening

screws. An improperly located O-ring may cause

damage to the O-ring and cause a coolant leak.

(2) Assemble pump body to block and tighten

screws to 12 N´m (105 in. lbs.). Pressurize cooling

system to 15 psi with pressure tester and check

water pump shaft seal and O-ring for leaks.

(3) Rotate pump by hand to check for freedom of

movement.

(4) Install inner timing belt cover.

(5) Install timing belt. Refer to Group 9, Engine

for procedures.

(6) Install right engine mount bracket and engine

mount. Refer to Group 9, Engine for procedure.

(7) Fill cooling system. SeeCooling System

Refilling.

(8) Install power steering pump and accessory

drive belts, Refer to Accessory Drive Belts, in this

section.Fig. 13 Draining Cooling System

Fig. 14 Water Pump

Fig. 15 Water Pump Body

PLCOOLING 7 - 17

SERVICE PROCEDURES (Continued)

Page 214 of 1200

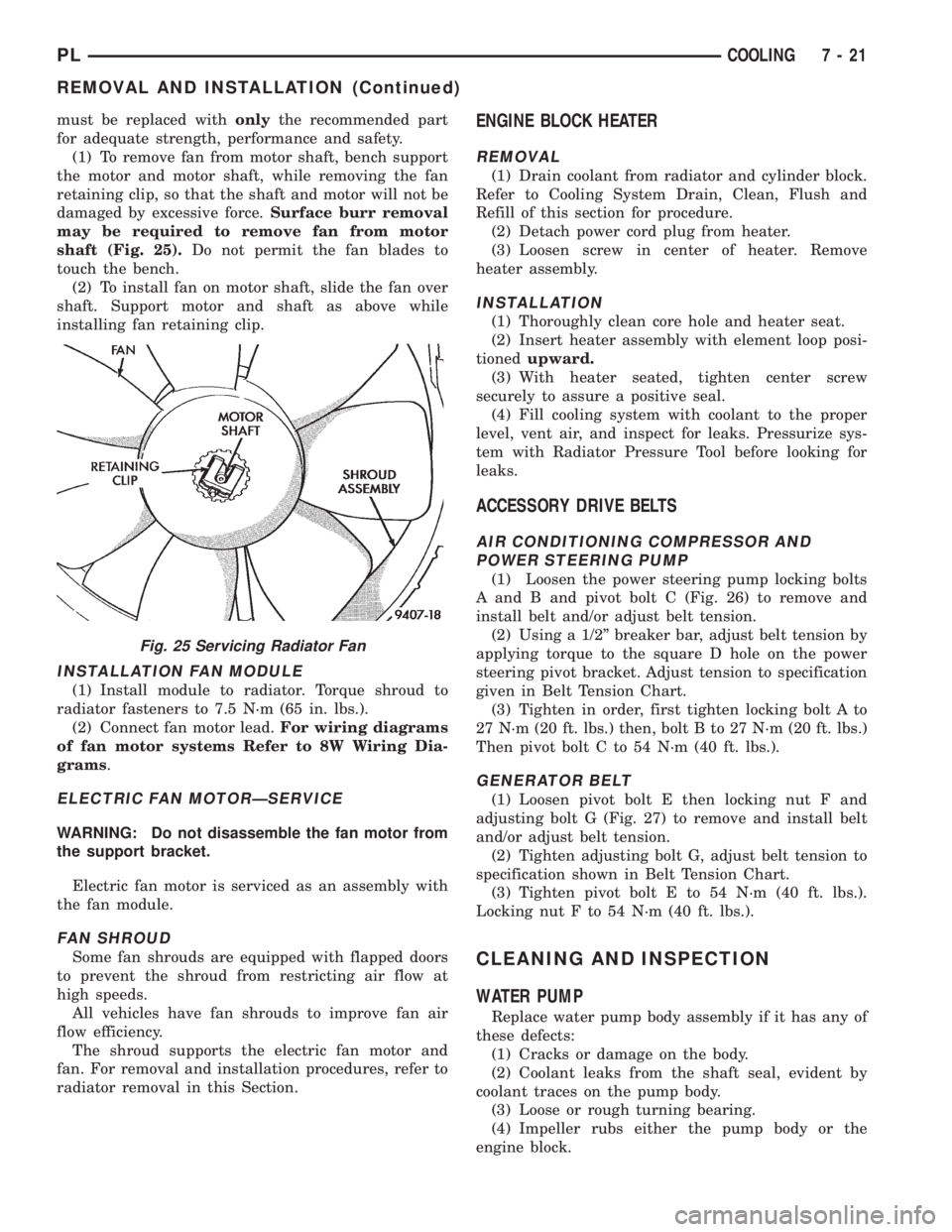

must be replaced withonlythe recommended part

for adequate strength, performance and safety.

(1) To remove fan from motor shaft, bench support

the motor and motor shaft, while removing the fan

retaining clip, so that the shaft and motor will not be

damaged by excessive force.Surface burr removal

may be required to remove fan from motor

shaft (Fig. 25).Do not permit the fan blades to

touch the bench.

(2) To install fan on motor shaft, slide the fan over

shaft. Support motor and shaft as above while

installing fan retaining clip.

INSTALLATION FAN MODULE

(1) Install module to radiator. Torque shroud to

radiator fasteners to 7.5 N´m (65 in. lbs.).

(2) Connect fan motor lead.For wiring diagrams

of fan motor systems Refer to 8W Wiring Dia-

grams.

ELECTRIC FAN MOTORÐSERVICE

WARNING: Do not disassemble the fan motor from

the support bracket.

Electric fan motor is serviced as an assembly with

the fan module.

FAN SHROUD

Some fan shrouds are equipped with flapped doors

to prevent the shroud from restricting air flow at

high speeds.

All vehicles have fan shrouds to improve fan air

flow efficiency.

The shroud supports the electric fan motor and

fan. For removal and installation procedures, refer to

radiator removal in this Section.

ENGINE BLOCK HEATER

REMOVAL

(1) Drain coolant from radiator and cylinder block.

Refer to Cooling System Drain, Clean, Flush and

Refill of this section for procedure.

(2) Detach power cord plug from heater.

(3) Loosen screw in center of heater. Remove

heater assembly.

INSTALLATION

(1) Thoroughly clean core hole and heater seat.

(2) Insert heater assembly with element loop posi-

tionedupward.

(3) With heater seated, tighten center screw

securely to assure a positive seal.

(4) Fill cooling system with coolant to the proper

level, vent air, and inspect for leaks. Pressurize sys-

tem with Radiator Pressure Tool before looking for

leaks.

ACCESSORY DRIVE BELTS

AIR CONDITIONING COMPRESSOR AND

POWER STEERING PUMP

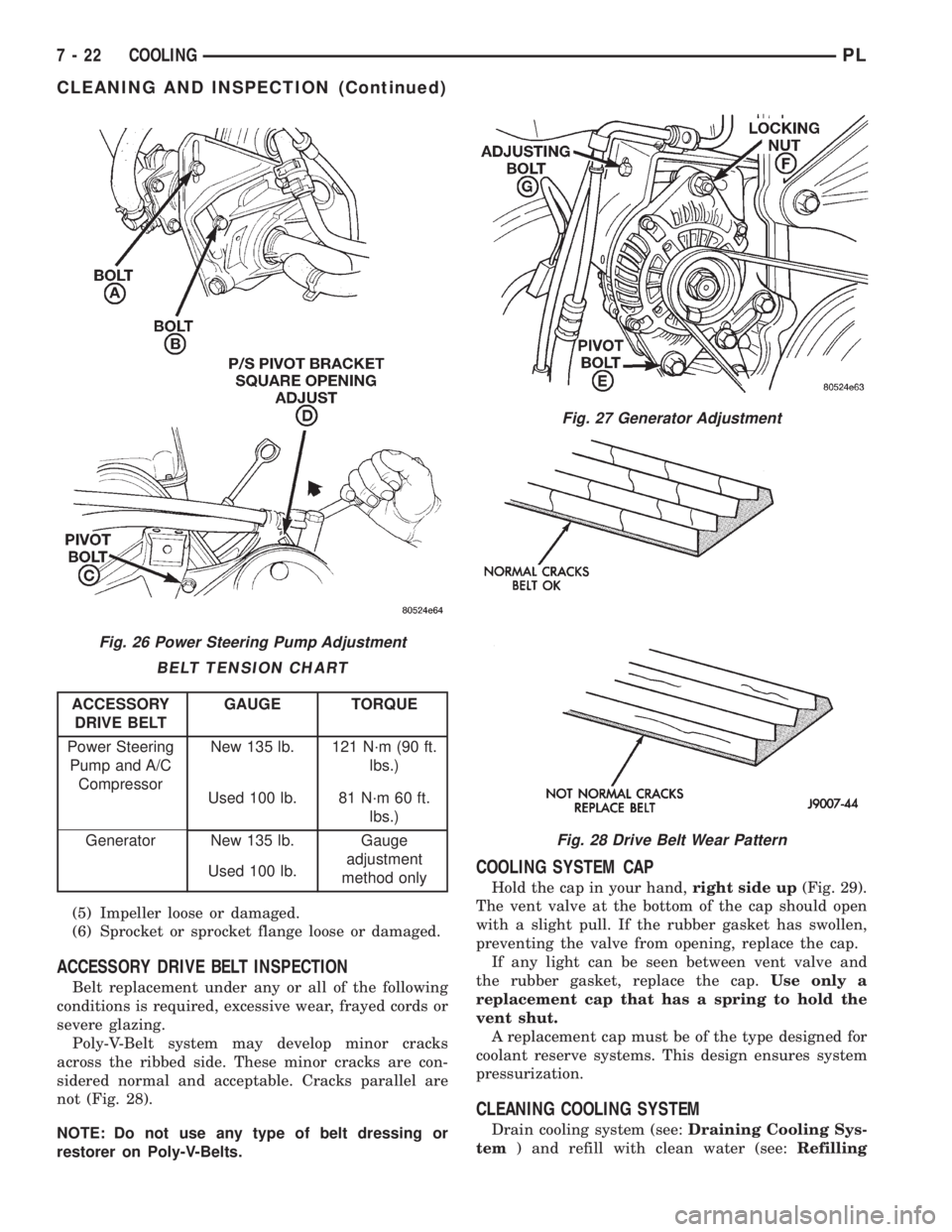

(1) Loosen the power steering pump locking bolts

A and B and pivot bolt C (Fig. 26) to remove and

install belt and/or adjust belt tension.

(2) Using a 1/2º breaker bar, adjust belt tension by

applying torque to the square D hole on the power

steering pivot bracket. Adjust tension to specification

given in Belt Tension Chart.

(3) Tighten in order, first tighten locking bolt A to

27 N´m (20 ft. lbs.) then, bolt B to 27 N´m (20 ft. lbs.)

Then pivot bolt C to 54 N´m (40 ft. lbs.).

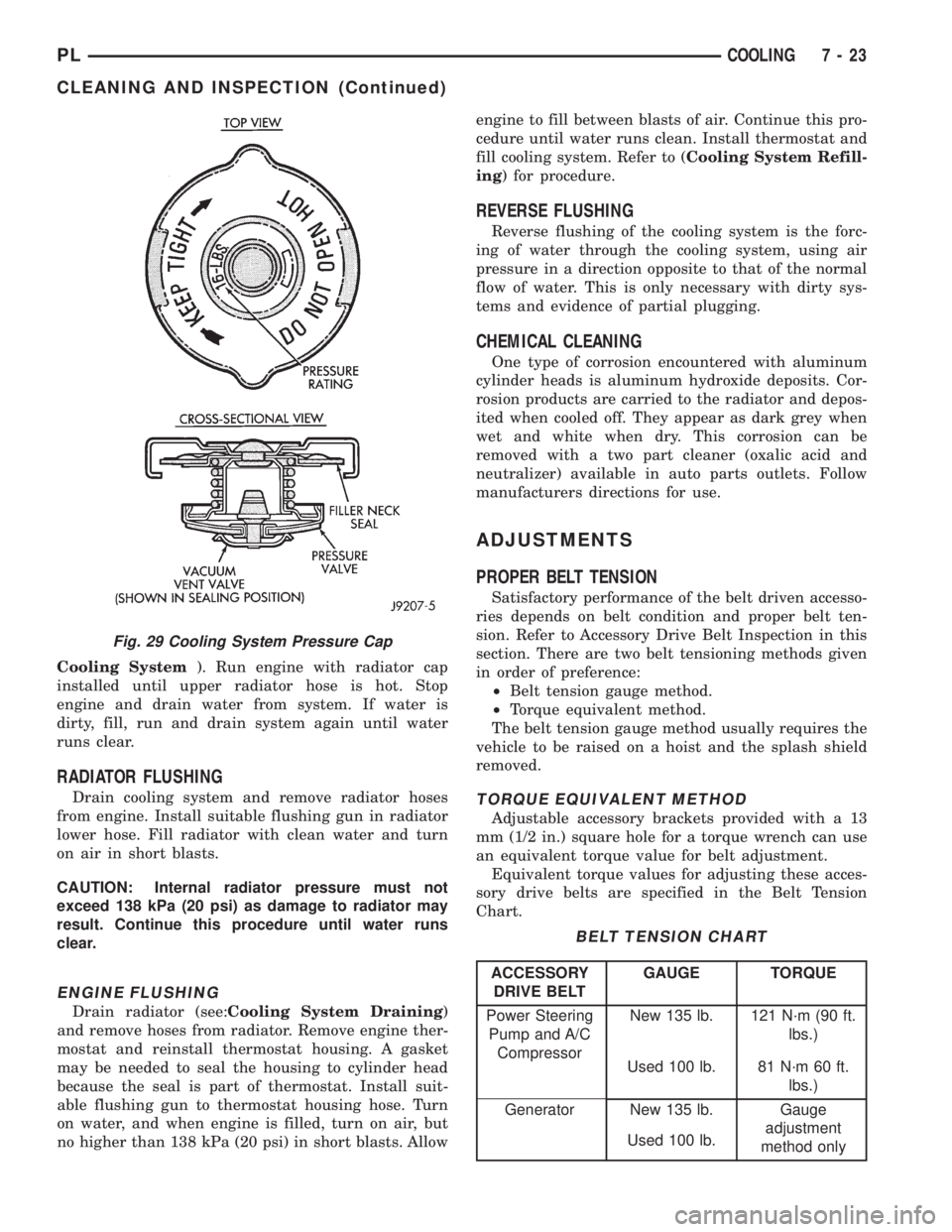

GENERATOR BELT

(1) Loosen pivot bolt E then locking nut F and

adjusting bolt G (Fig. 27) to remove and install belt

and/or adjust belt tension.

(2) Tighten adjusting bolt G, adjust belt tension to

specification shown in Belt Tension Chart.

(3) Tighten pivot bolt E to 54 N´m (40 ft. lbs.).

Locking nut F to 54 N´m (40 ft. lbs.).

CLEANING AND INSPECTION

WATER PUMP

Replace water pump body assembly if it has any of

these defects:

(1) Cracks or damage on the body.

(2) Coolant leaks from the shaft seal, evident by

coolant traces on the pump body.

(3) Loose or rough turning bearing.

(4) Impeller rubs either the pump body or the

engine block.

Fig. 25 Servicing Radiator Fan

PLCOOLING 7 - 21

REMOVAL AND INSTALLATION (Continued)

Page 215 of 1200

(5) Impeller loose or damaged.

(6) Sprocket or sprocket flange loose or damaged.

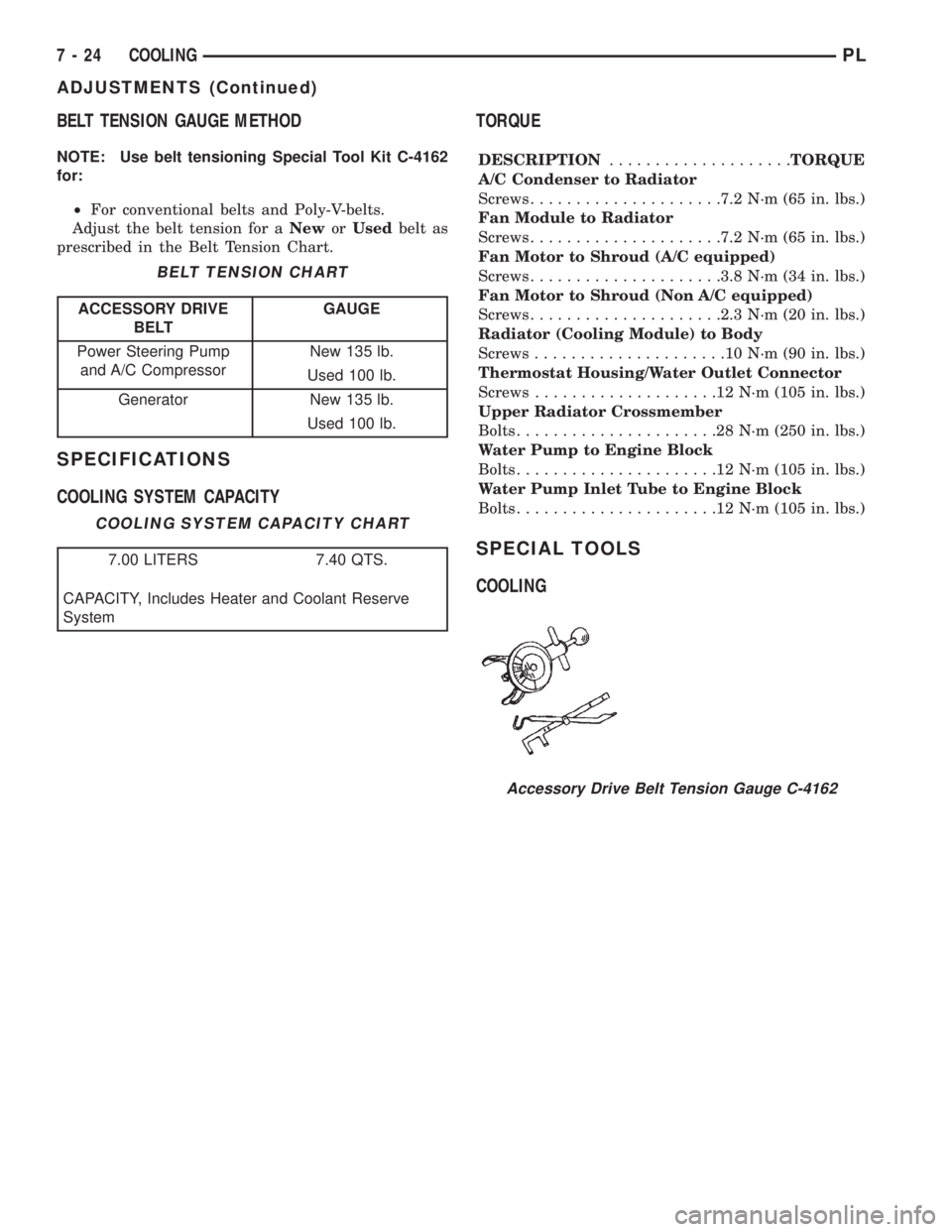

ACCESSORY DRIVE BELT INSPECTION

Belt replacement under any or all of the following

conditions is required, excessive wear, frayed cords or

severe glazing.

Poly-V-Belt system may develop minor cracks

across the ribbed side. These minor cracks are con-

sidered normal and acceptable. Cracks parallel are

not (Fig. 28).

NOTE: Do not use any type of belt dressing or

restorer on Poly-V-Belts.

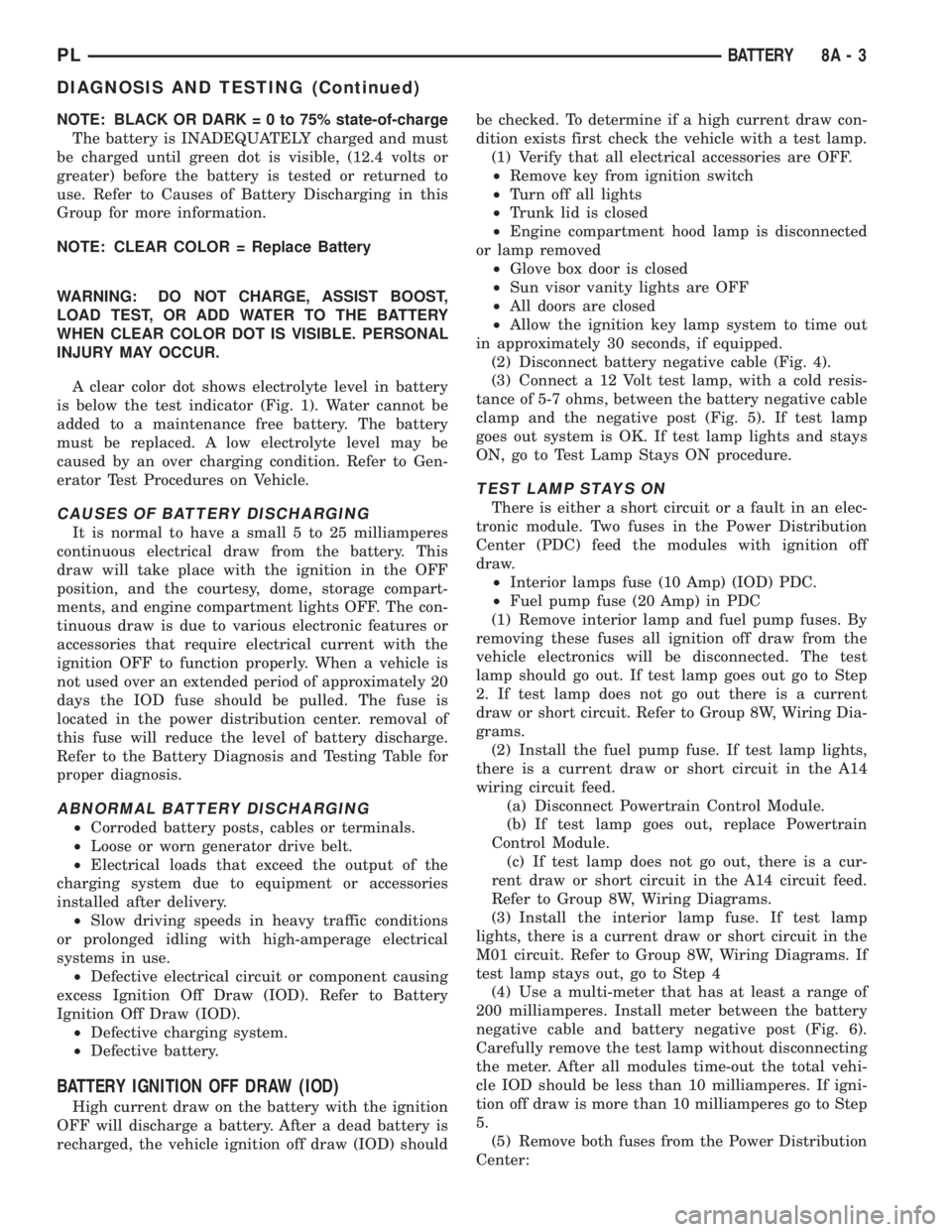

COOLING SYSTEM CAP

Hold the cap in your hand,right side up(Fig. 29).

The vent valve at the bottom of the cap should open

with a slight pull. If the rubber gasket has swollen,

preventing the valve from opening, replace the cap.

If any light can be seen between vent valve and

the rubber gasket, replace the cap.Use only a

replacement cap that has a spring to hold the

vent shut.

A replacement cap must be of the type designed for

coolant reserve systems. This design ensures system

pressurization.

CLEANING COOLING SYSTEM

Drain cooling system (see:Draining Cooling Sys-

tem) and refill with clean water (see:Refilling

Fig. 26 Power Steering Pump Adjustment

BELT TENSION CHART

ACCESSORY

DRIVE BELTGAUGE TORQUE

Power Steering

Pump and A/C

CompressorNew 135 lb. 121 N´m (90 ft.

lbs.)

Used 100 lb. 81 N´m 60 ft.

lbs.)

Generator New 135 lb. Gauge

adjustment

method only Used 100 lb.

Fig. 27 Generator Adjustment

Fig. 28 Drive Belt Wear Pattern

7 - 22 COOLINGPL

CLEANING AND INSPECTION (Continued)

Page 216 of 1200

Cooling System). Run engine with radiator cap

installed until upper radiator hose is hot. Stop

engine and drain water from system. If water is

dirty, fill, run and drain system again until water

runs clear.

RADIATOR FLUSHING

Drain cooling system and remove radiator hoses

from engine. Install suitable flushing gun in radiator

lower hose. Fill radiator with clean water and turn

on air in short blasts.

CAUTION: Internal radiator pressure must not

exceed 138 kPa (20 psi) as damage to radiator may

result. Continue this procedure until water runs

clear.

ENGINE FLUSHING

Drain radiator (see:Cooling System Draining)

and remove hoses from radiator. Remove engine ther-

mostat and reinstall thermostat housing. A gasket

may be needed to seal the housing to cylinder head

because the seal is part of thermostat. Install suit-

able flushing gun to thermostat housing hose. Turn

on water, and when engine is filled, turn on air, but

no higher than 138 kPa (20 psi) in short blasts. Allowengine to fill between blasts of air. Continue this pro-

cedure until water runs clean. Install thermostat and

fill cooling system. Refer to (Cooling System Refill-

ing) for procedure.

REVERSE FLUSHING

Reverse flushing of the cooling system is the forc-

ing of water through the cooling system, using air

pressure in a direction opposite to that of the normal

flow of water. This is only necessary with dirty sys-

tems and evidence of partial plugging.

CHEMICAL CLEANING

One type of corrosion encountered with aluminum

cylinder heads is aluminum hydroxide deposits. Cor-

rosion products are carried to the radiator and depos-

ited when cooled off. They appear as dark grey when

wet and white when dry. This corrosion can be

removed with a two part cleaner (oxalic acid and

neutralizer) available in auto parts outlets. Follow

manufacturers directions for use.

ADJUSTMENTS

PROPER BELT TENSION

Satisfactory performance of the belt driven accesso-

ries depends on belt condition and proper belt ten-

sion. Refer to Accessory Drive Belt Inspection in this

section. There are two belt tensioning methods given

in order of preference:

²Belt tension gauge method.

²Torque equivalent method.

The belt tension gauge method usually requires the

vehicle to be raised on a hoist and the splash shield

removed.

TORQUE EQUIVALENT METHOD

Adjustable accessory brackets provided with a 13

mm (1/2 in.) square hole for a torque wrench can use

an equivalent torque value for belt adjustment.

Equivalent torque values for adjusting these acces-

sory drive belts are specified in the Belt Tension

Chart.

Fig. 29 Cooling System Pressure Cap

BELT TENSION CHART

ACCESSORY

DRIVE BELTGAUGE TORQUE

Power Steering

Pump and A/C

CompressorNew 135 lb. 121 N´m (90 ft.

lbs.)

Used 100 lb. 81 N´m 60 ft.

lbs.)

Generator New 135 lb. Gauge

adjustment

method only Used 100 lb.

PLCOOLING 7 - 23

CLEANING AND INSPECTION (Continued)

Page 217 of 1200

BELT TENSION GAUGE METHOD

NOTE: Use belt tensioning Special Tool Kit C-4162

for:

²For conventional belts and Poly-V-belts.

Adjust the belt tension for aNeworUsedbelt as

prescribed in the Belt Tension Chart.

SPECIFICATIONS

COOLING SYSTEM CAPACITYTORQUE

DESCRIPTION....................TORQUE

A/C Condenser to Radiator

Screws.....................7.2 N´m (65 in. lbs.)

Fan Module to Radiator

Screws.....................7.2 N´m (65 in. lbs.)

Fan Motor to Shroud (A/C equipped)

Screws.....................3.8 N´m (34 in. lbs.)

Fan Motor to Shroud (Non A/C equipped)

Screws.....................2.3 N´m (20 in. lbs.)

Radiator (Cooling Module) to Body

Screws.....................10N´m(90in.lbs.)

Thermostat Housing/Water Outlet Connector

Screws....................12N´m(105 in. lbs.)

Upper Radiator Crossmember

Bolts......................28N´m(250 in. lbs.)

Water Pump to Engine Block

Bolts......................12N´m(105 in. lbs.)

Water Pump Inlet Tube to Engine Block

Bolts......................12N´m(105 in. lbs.)

SPECIAL TOOLS

COOLING

BELT TENSION CHART

ACCESSORY DRIVE

BELTGAUGE

Power Steering Pump

and A/C CompressorNew 135 lb.

Used 100 lb.

Generator New 135 lb.

Used 100 lb.

COOLING SYSTEM CAPACITY CHART

7.00 LITERS 7.40 QTS.

CAPACITY, Includes Heater and Coolant Reserve

System

Accessory Drive Belt Tension Gauge C-4162

7 - 24 COOLINGPL

ADJUSTMENTS (Continued)

Page 220 of 1200

NOTE: BLACK OR DARK=0to75%state-of-charge

The battery is INADEQUATELY charged and must

be charged until green dot is visible, (12.4 volts or

greater) before the battery is tested or returned to

use. Refer to Causes of Battery Discharging in this

Group for more information.

NOTE: CLEAR COLOR = Replace Battery

WARNING: DO NOT CHARGE, ASSIST BOOST,

LOAD TEST, OR ADD WATER TO THE BATTERY

WHEN CLEAR COLOR DOT IS VISIBLE. PERSONAL

INJURY MAY OCCUR.

A clear color dot shows electrolyte level in battery

is below the test indicator (Fig. 1). Water cannot be

added to a maintenance free battery. The battery

must be replaced. A low electrolyte level may be

caused by an over charging condition. Refer to Gen-

erator Test Procedures on Vehicle.

CAUSES OF BATTERY DISCHARGING

It is normal to have a small 5 to 25 milliamperes

continuous electrical draw from the battery. This

draw will take place with the ignition in the OFF

position, and the courtesy, dome, storage compart-

ments, and engine compartment lights OFF. The con-

tinuous draw is due to various electronic features or

accessories that require electrical current with the

ignition OFF to function properly. When a vehicle is

not used over an extended period of approximately 20

days the IOD fuse should be pulled. The fuse is

located in the power distribution center. removal of

this fuse will reduce the level of battery discharge.

Refer to the Battery Diagnosis and Testing Table for

proper diagnosis.

ABNORMAL BATTERY DISCHARGING

²Corroded battery posts, cables or terminals.

²Loose or worn generator drive belt.

²Electrical loads that exceed the output of the

charging system due to equipment or accessories

installed after delivery.

²Slow driving speeds in heavy traffic conditions

or prolonged idling with high-amperage electrical

systems in use.

²Defective electrical circuit or component causing

excess Ignition Off Draw (IOD). Refer to Battery

Ignition Off Draw (IOD).

²Defective charging system.

²Defective battery.

BATTERY IGNITION OFF DRAW (IOD)

High current draw on the battery with the ignition

OFF will discharge a battery. After a dead battery is

recharged, the vehicle ignition off draw (IOD) shouldbe checked. To determine if a high current draw con-

dition exists first check the vehicle with a test lamp.

(1) Verify that all electrical accessories are OFF.

²Remove key from ignition switch

²Turn off all lights

²Trunk lid is closed

²Engine compartment hood lamp is disconnected

or lamp removed

²Glove box door is closed

²Sun visor vanity lights are OFF

²All doors are closed

²Allow the ignition key lamp system to time out

in approximately 30 seconds, if equipped.

(2) Disconnect battery negative cable (Fig. 4).

(3) Connect a 12 Volt test lamp, with a cold resis-

tance of 5-7 ohms, between the battery negative cable

clamp and the negative post (Fig. 5). If test lamp

goes out system is OK. If test lamp lights and stays

ON, go to Test Lamp Stays ON procedure.

TEST LAMP STAYS ON

There is either a short circuit or a fault in an elec-

tronic module. Two fuses in the Power Distribution

Center (PDC) feed the modules with ignition off

draw.

²Interior lamps fuse (10 Amp) (IOD) PDC.

²Fuel pump fuse (20 Amp) in PDC

(1) Remove interior lamp and fuel pump fuses. By

removing these fuses all ignition off draw from the

vehicle electronics will be disconnected. The test

lamp should go out. If test lamp goes out go to Step

2. If test lamp does not go out there is a current

draw or short circuit. Refer to Group 8W, Wiring Dia-

grams.

(2) Install the fuel pump fuse. If test lamp lights,

there is a current draw or short circuit in the A14

wiring circuit feed.

(a) Disconnect Powertrain Control Module.

(b) If test lamp goes out, replace Powertrain

Control Module.

(c) If test lamp does not go out, there is a cur-

rent draw or short circuit in the A14 circuit feed.

Refer to Group 8W, Wiring Diagrams.

(3) Install the interior lamp fuse. If test lamp

lights, there is a current draw or short circuit in the

M01 circuit. Refer to Group 8W, Wiring Diagrams. If

test lamp stays out, go to Step 4

(4) Use a multi-meter that has at least a range of

200 milliamperes. Install meter between the battery

negative cable and battery negative post (Fig. 6).

Carefully remove the test lamp without disconnecting

the meter. After all modules time-out the total vehi-

cle IOD should be less than 10 milliamperes. If igni-

tion off draw is more than 10 milliamperes go to Step

5.

(5) Remove both fuses from the Power Distribution

Center:

PLBATTERY 8A - 3

DIAGNOSIS AND TESTING (Continued)

Page 236 of 1200

CHARGING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

OVERVIEW............................. 1

DESCRIPTION AND OPERATION

BATTERY TEMPERATURE SENSOR.......... 2

CHARGING SYSTEM OPERATION........... 1

ELECTRONIC VOLTAGE REGULATOR......... 2

GENERATOR............................ 2

DIAGNOSIS AND TESTING

BATTERY TEMPERATURE SENSOR.......... 8

CHARGING SYSTEM RESISTANCE TESTS..... 5CHARGING SYSTEM...................... 2

CURRENT OUTPUT TEST.................. 8

ON-BOARD DIAGNOSTIC SYSTEM TEST..... 10

REMOVAL AND INSTALLATION

BATTERY TEMPERATURE SENSOR......... 11

GENERATOR........................... 10

SPECIFICATIONS

GENERATOR RATINGS................... 12

TORQUE.............................. 12

GENERAL INFORMATION

OVERVIEW

The battery, starting, and charging systems oper-

ate with one another, and must be tested as a com-

plete system. In order for the vehicle to start and

charge properly, all of the components involved in

these systems must perform within specifications.

Group 8A covers the battery, Group 8B covers the

starting system, and Group 8C covers the charging

system. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams. We have

separated these systems to make it easier to locate

the information you are seeking within this Service

Manual. However, when attempting to diagnose any

of these systems, it is important that you keep their

interdependency in mind.

The diagnostic procedures used in these groups

include the most basic conventional diagnostic meth-

ods to the more sophisticated On-Board Diagnostics

(OBD) built into the Powertrain Control Module

(PCM). Use of an induction ammeter, volt/ohmmeter,

battery charger, carbon pile rheostat (load tester),

and 12-volt test lamp may be required.

All OBD-sensed systems are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See the

On-Board Diagnostics Test in Group 8C - Charging

System for more information.

DESCRIPTION AND OPERATION

CHARGING SYSTEM OPERATION

The charging system consists of:

²Generator

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch (refer to Group 8D, Ignition Sys-

tem for information)

²Battery (refer to Group 8A, Battery for informa-

tion)

²Battery temperature sensor

²Voltmeter (refer to Group 8E, Instrument Panel

and Gauges for information)

²Wiring harness and connections (refer to Group

8W, Wiring for information)

The charging system is turned on and off with the

ignition switch. When the ignition switch is turned to

the ON position, battery voltage is applied to the

generator rotor through one of the two field termi-

nals to produce a magnetic field. The generator is

driven by the engine through a serpentine belt and

pulley arrangement.

The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry,

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

PLCHARGING SYSTEM 8C - 1

Page 237 of 1200

A battery temperature sensor located on the front

bumper beam is used to sense battery temperature.

This temperature data, along with data from moni-

tored line voltage, is used by the PCM to vary the

battery charging rate. This is done by cycling the

ground path to control the strength of the rotor mag-

netic field. The PCM then compensates and regulates

generator current output accordingly and to maintain

the proper voltage depending on battery tempera-

ture.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including the

EVR (field control) circuitry, are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See On-

Board Diagnostic System Test in this group for more

information.

GENERATOR

The generator is belt-driven by the engine. It is

serviced only as a complete assembly. If the genera-

tor fails for any reason, the entire assembly must be

replaced.

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DC

current is delivered to the vehicle electrical system

through the generator, battery, and ground terminals.

Noise emitting from the generator may be caused

by:

²Worn, loose or defective bearings

²Loose or defective drive pulley

²Incorrect, worn, damaged or misadjusted drive

belt

²Loose mounting bolts

²Misaligned drive pulley

²Defective stator or diode

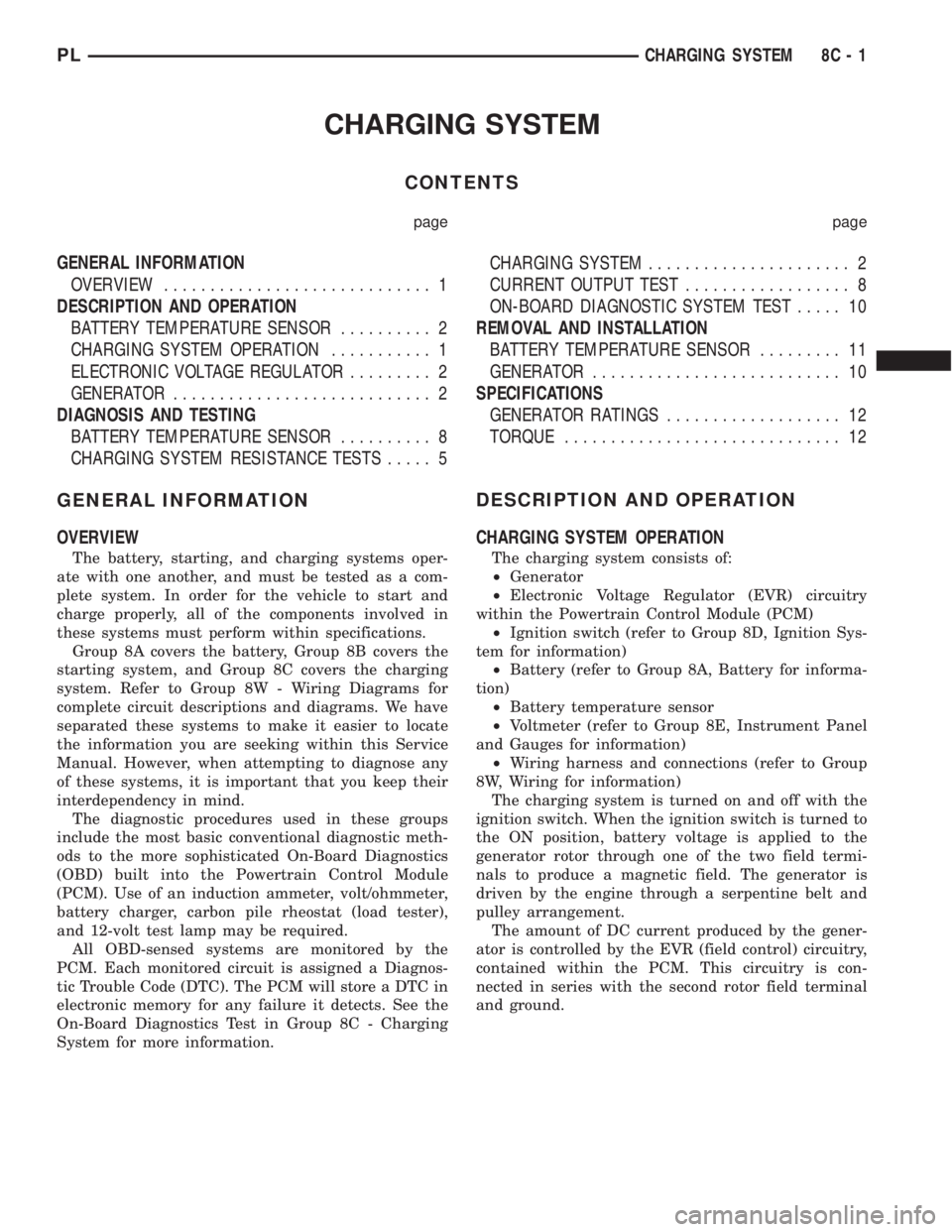

BATTERY TEMPERATURE SENSOR

The battery temperature sensor is used to deter-

mine the battery temperature. This temperature

data, along with data from monitored line voltage, is

used by the PCM to vary the battery charging rate.

System voltage will be higher at colder temperatures

and is gradually reduced at warmer temperatures.

The sensor is located on the bottom of the battery

tray (Fig. 1).

ELECTRONIC VOLTAGE REGULATOR

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

Operation:The amount of DC current produced

by the generator is controlled by EVR circuitry con-

tained within the PCM. This circuitry is connected in

series with the generators second rotor field terminal

and its ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage and bat-

tery temperature (refer to Battery Temperature Sen-

sor for more information). It then compensates and

regulates generator current output accordingly. Also

refer to Charging System Operation for additional

information.

DIAGNOSIS AND TESTING

CHARGING SYSTEM

When the ignition switch is turned to the ON posi-

tion, battery potential will register on the voltmeter.

During engine cranking a lower voltage will appear

on the meter. With the engine running, a voltage

reading higher than the first reading (ignition in ON)

should register.

The following are possible symptoms of a charging

system fault:

²The voltmeter does not operate properly

²An undercharged or overcharged battery condi-

tion occurs.

Fig. 1 Battery Temperature Sensor

8C - 2 CHARGING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)