load capacity DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 198 of 1200

SELECTION AND ADDITIVES

The use of aluminum cylinder heads, intake mani-

folds DOHC, and water pumps requires special corro-

sion protection. MopartAntifreeze or the equivalent

is recommended for best engine cooling without cor-

rosion. When mixed only to a freeze point of -37ÉC

(-35ÉF) to -59ÉC (-50ÉF). If it looses color or becomes

contaminated, drain, flush, and replace with fresh

properly mixed solution.

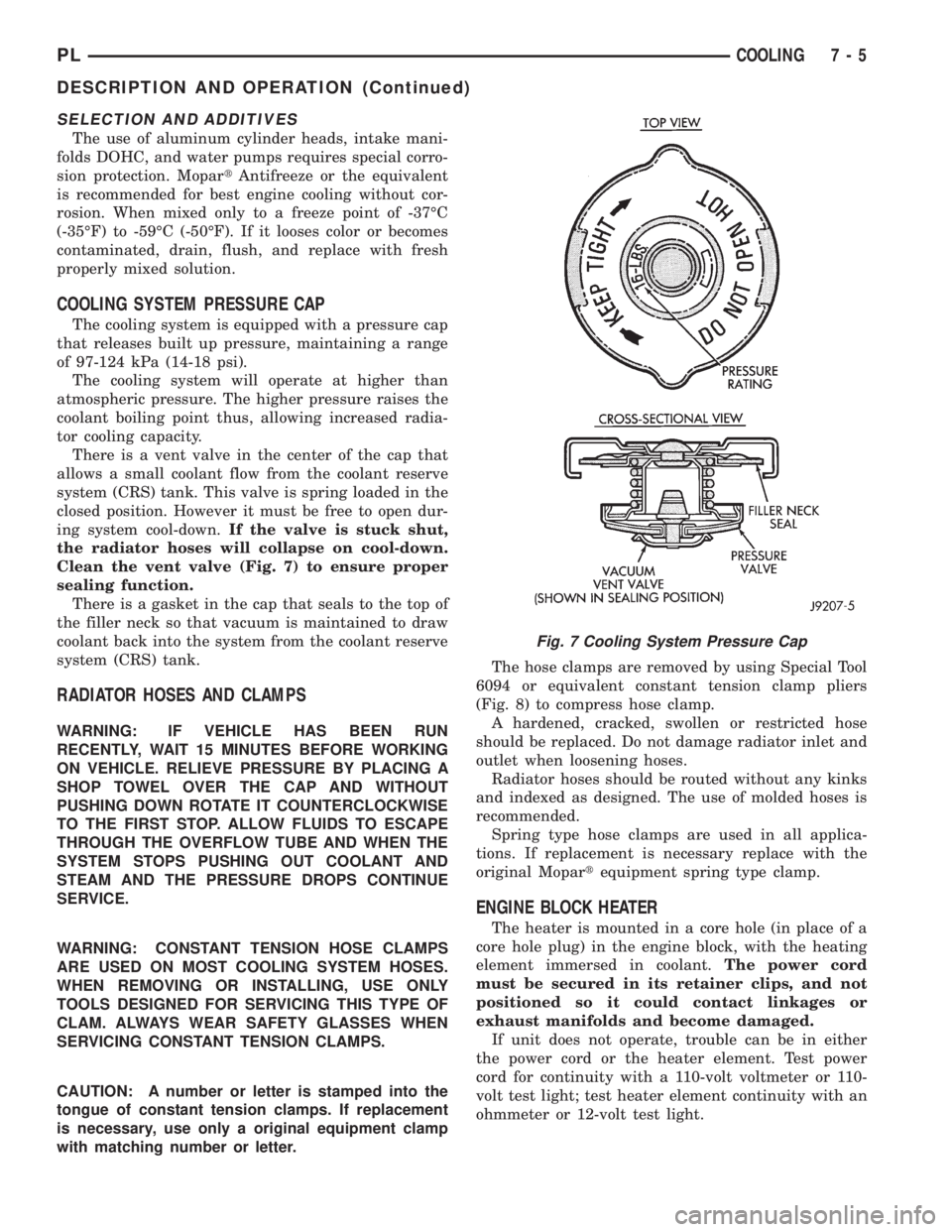

COOLING SYSTEM PRESSURE CAP

The cooling system is equipped with a pressure cap

that releases built up pressure, maintaining a range

of 97-124 kPa (14-18 psi).

The cooling system will operate at higher than

atmospheric pressure. The higher pressure raises the

coolant boiling point thus, allowing increased radia-

tor cooling capacity.

There is a vent valve in the center of the cap that

allows a small coolant flow from the coolant reserve

system (CRS) tank. This valve is spring loaded in the

closed position. However it must be free to open dur-

ing system cool-down.If the valve is stuck shut,

the radiator hoses will collapse on cool-down.

Clean the vent valve (Fig. 7) to ensure proper

sealing function.

There is a gasket in the cap that seals to the top of

the filler neck so that vacuum is maintained to draw

coolant back into the system from the coolant reserve

system (CRS) tank.

RADIATOR HOSES AND CLAMPS

WARNING: IF VEHICLE HAS BEEN RUN

RECENTLY, WAIT 15 MINUTES BEFORE WORKING

ON VEHICLE. RELIEVE PRESSURE BY PLACING A

SHOP TOWEL OVER THE CAP AND WITHOUT

PUSHING DOWN ROTATE IT COUNTERCLOCKWISE

TO THE FIRST STOP. ALLOW FLUIDS TO ESCAPE

THROUGH THE OVERFLOW TUBE AND WHEN THE

SYSTEM STOPS PUSHING OUT COOLANT AND

STEAM AND THE PRESSURE DROPS CONTINUE

SERVICE.

WARNING: CONSTANT TENSION HOSE CLAMPS

ARE USED ON MOST COOLING SYSTEM HOSES.

WHEN REMOVING OR INSTALLING, USE ONLY

TOOLS DESIGNED FOR SERVICING THIS TYPE OF

CLAM. ALWAYS WEAR SAFETY GLASSES WHEN

SERVICING CONSTANT TENSION CLAMPS.

CAUTION: A number or letter is stamped into the

tongue of constant tension clamps. If replacement

is necessary, use only a original equipment clamp

with matching number or letter.The hose clamps are removed by using Special Tool

6094 or equivalent constant tension clamp pliers

(Fig. 8) to compress hose clamp.

A hardened, cracked, swollen or restricted hose

should be replaced. Do not damage radiator inlet and

outlet when loosening hoses.

Radiator hoses should be routed without any kinks

and indexed as designed. The use of molded hoses is

recommended.

Spring type hose clamps are used in all applica-

tions. If replacement is necessary replace with the

original Mopartequipment spring type clamp.

ENGINE BLOCK HEATER

The heater is mounted in a core hole (in place of a

core hole plug) in the engine block, with the heating

element immersed in coolant.The power cord

must be secured in its retainer clips, and not

positioned so it could contact linkages or

exhaust manifolds and become damaged.

If unit does not operate, trouble can be in either

the power cord or the heater element. Test power

cord for continuity with a 110-volt voltmeter or 110-

volt test light; test heater element continuity with an

ohmmeter or 12-volt test light.

Fig. 7 Cooling System Pressure Cap

PLCOOLING 7 - 5

DESCRIPTION AND OPERATION (Continued)

Page 218 of 1200

BATTERY

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)........ 1

CHARGING TIME REQUIRED............... 1

DIAGNOSIS AND TESTING

BATTERY BUILT-IN TEST INDICATOR........ 2

BATTERY IGNITION OFF DRAW (IOD)........ 3

BATTERY LOAD TEST..................... 5

BATTERY OPEN CIRCUIT VOLTAGE TEST..... 6

BATTERY TEMPERATURE SENSOR.......... 6

SERVICE PROCEDURES

BATTERY CHARGING..................... 6CHARGING COMPLETELY DISCHARGED

BATTERY............................. 7

VISUAL INSPECTION..................... 7

REMOVAL AND INSTALLATION

BATTERY TRAY.......................... 9

BATTERY............................... 8

FRESH AIR INLET TUBE REMOVAL.......... 9

SPECIFICATIONS

BATTERY SPECIFICATIONS............... 10

TORQUE.............................. 10

GENERAL INFORMATION

INTRODUCTION

The battery stores, stabilizes, and delivers electri-

cal current to operate various electrical systems in

the vehicle. The determination of whether a battery

is good or bad is made by its ability to accept a

charge. It also must supply high-amperage current

for a long enough period to be able to start the vehi-

cle. The capability of the battery to store electrical

current comes from a chemical reaction. This reac-

tion takes place between the sulfuric acid solution

(electrolyte) and the lead +/- plates in each cell of the

battery. As the battery discharges, the plates react

with the acid from the electrolyte. When the charging

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

in the electrolyte is measured as specific gravity

using a hydrometer. The original equipment (OE)

battery is equipped with a hydrometer (test indica-

tor) built into the battery cover. The specific gravity

indicates the battery's state-of-charge. The OE bat-

tery is sealed and water cannot be added.

The battery is vented to release gases that are cre-

ated when the battery is being charged and dis-

charged. The battery top, posts, and terminals should

be cleaned when other under hood maintenance is

performed.

When the electrolyte level is below the top of the

plates, Yellow/Clear in the test Indicator, the battery

must be replaced. The battery must be completely

charged, and the battery top, posts, and cable clampsmust be cleaned before diagnostic procedures are per-

formed.DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)

A completely normal vehicle will have a small

amount of current drain on the battery with the key

out of the ignition. It can range from 4 to 10 milli-

amperes after all the modules time out. If a vehicle

will not be operated for approximately a 20 days, the

IOD fuse should be disconnected to minimize the

vehicle electrical drain on the battery. The IOD fuse

is located in the Power Distribution Center (PDC).

Refer to the PDC to locate the cover proper fuse.

CHARGING TIME REQUIRED

WARNING: NEVER EXCEED 20 AMPS WHEN

CHARGING A COLD -1ÉC (30ÉF) BATTERY. PER-

SONAL INJURY MAY RESULT.

The time required to charge a battery will vary

depending upon the following factors.

SIZE OF BATTERY

A completely discharged large heavy-duty battery

may require more recharging time than a completely

discharged small capacity battery. Refer to Battery

Charging Timetable for proper charging times.

PLBATTERY 8A - 1

Page 219 of 1200

TEMPERATURE

A longer time will be needed to charge a battery at

-18ÉC (0ÉF) than at 27ÉC (80ÉF). When a fast charger

is connected to a cold battery, current accepted by

battery will be very low at first. In time, the battery

will accept a higher rate as battery temperature

warms.

CHARGER CAPACITY

A charger which can supply only five amperes will

require a much longer period of charging than a

charger that can supply 20 amperes or more.

STATE OF CHARGE

A completely discharged battery requires more

charging time than a partially charged battery. Elec-

trolyte is nearly pure water in a completely dis-

charged battery. At first, the charging current

amperage will be low. As water is converted back to

sulfuric acid inside the battery, the current amp rate

will rise. Also, the specific gravity of the electrolyte

will rise, bringing the green ball (Fig. 1) into view at

approximately 75 percent state-of-charge.

DIAGNOSIS AND TESTING

BATTERY BUILT-IN TEST INDICATOR

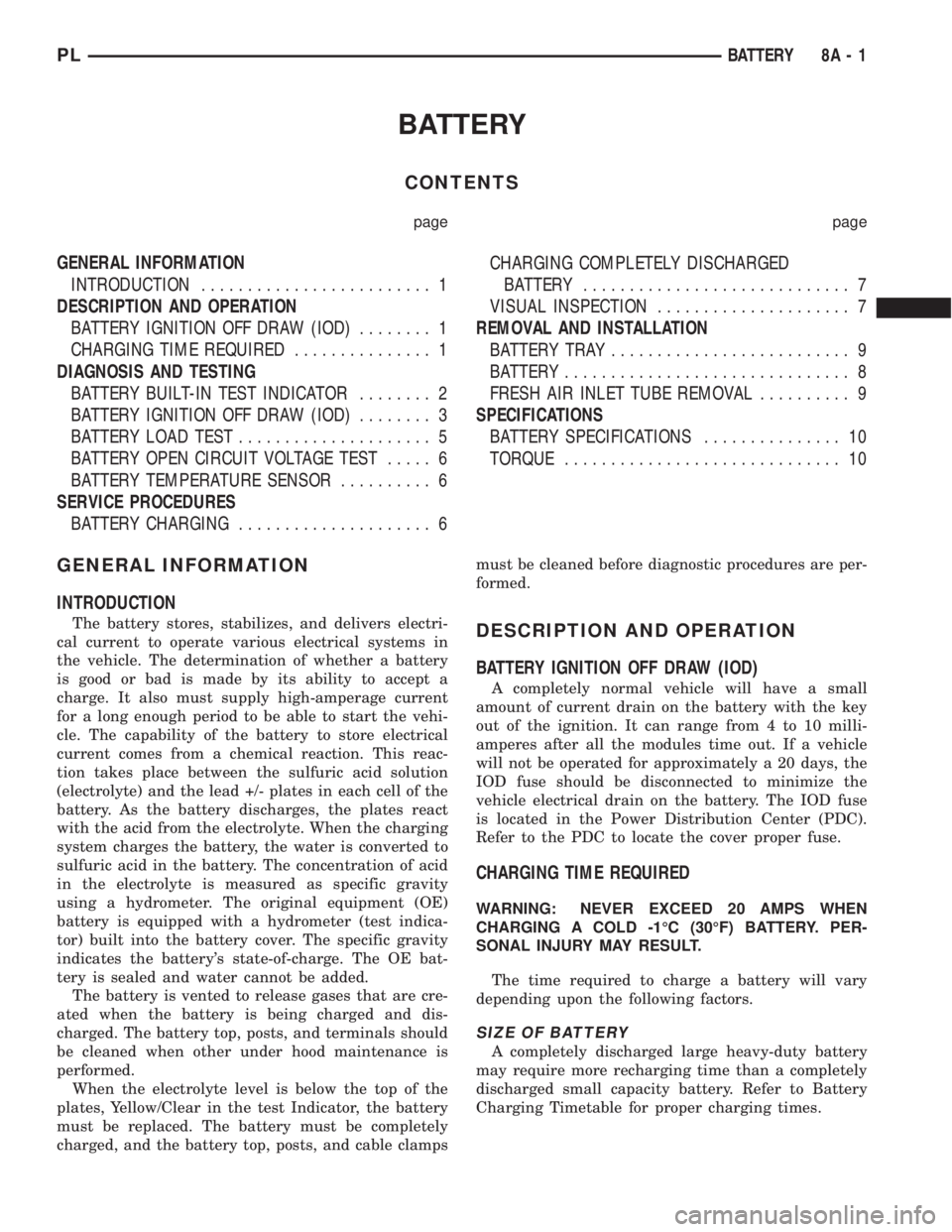

USING TEST INDICATOR

The Test Indicator (Fig. 1), (Fig. 2) and (Fig. 3)

measures the specific gravity of the electrolyte. Spe-

cific Gravity (SG) of the electrolyte will show state-

of-charge (voltage). The test indicator WILL NOT

show cranking capacity of the battery. Refer to Bat-

tery Load Test for more information. Look into the

sight glass (Fig. 1), (Fig. 3) and note the color of the

indicator. Refer to the following description of colors:

NOTE: GREEN = 75 to 100% state-of-charge

The battery is adequately charged for further test-

ing and may be returned to use. If the vehicle will

not crank for a maximum 15 seconds, refer to BAT-

TERY LOAD TEST in this Group for more informa-

tion.

BATTERY CHARGING TIMETABLE

Charging

Amperage5

Amperes10

Amperes20

Amperes

Open Circuit

VoltageHours Charging at 21ÉC (70ÉF)

12.25 to

12.396 hours 3 hours 1.5 hours

12.00 to

12.248 hours 4 hours 2 hours

11.95 to

11.9912 hours 6 hours 3 hours

10.00 to

11.9414 hours 7 hours 3.5 hours

less than

10.00See Charging Completely Discharged

Battery

Fig. 1 Reading Test Indicator

Fig. 2 Battery Construction and Test Indicator

Fig. 3 Test Indicator

8A - 2 BATTERYPL

DESCRIPTION AND OPERATION (Continued)

Page 223 of 1200

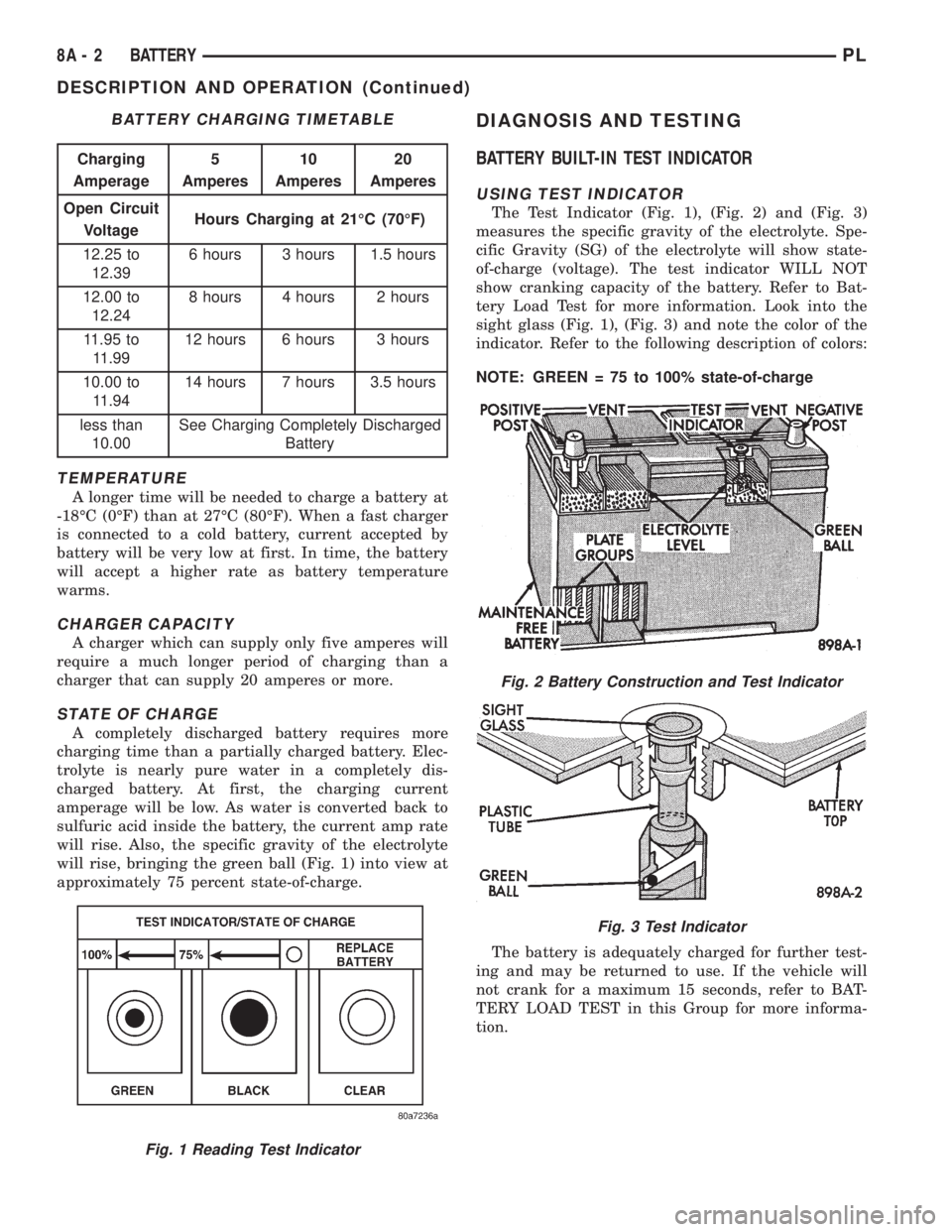

exposure over the preceding several hours. If the bat-

tery has been charged or boosted a few minutes prior

to the test, the battery would be slightly warmer.

Refer to Battery Load Test Temperatures Table for

proper voltage/temperature reading:

(6) If battery passes load test, it is in good condi-

tion and further tests are not necessary. If it fails

load test, it should be replaced.

BATTERY OPEN CIRCUIT VOLTAGE TEST

An open circuit voltage no load test shows the

state of charge of a battery and whether it is ready

for a load test at 50 percent of the battery's cold

crank rating. Refer to Battery Load Test. If a battery

has open circuit voltage reading of 12.4 volts or

greater, and will not pass the load test, replace the

battery because it is defective. To test open circuit

voltage, perform the following operation.

(1) Remove both battery cables, negative cable

first. Battery top, cables and posts should be clean. If

green dot is not visible in indicator, charge the bat-

tery. Refer to Battery Charging Procedures.

(2) Connect a Volt/Ammeter/Load tester to the bat-

tery posts (Fig. 7). Rotate the load control knob of theCarbon pile rheostat to apply a 300 amp load. Apply

this load for 15 seconds to remove the surface charge

from the battery, and return the control knob to off

(Fig. 8).

(3) Allow the battery to stabilize for 2 minutes,

and then verify the open circuit voltage (Fig. 10).

(4) This voltage reading will approximate the state

of charge of the battery. It will not reveal battery

cranking capacity. Refer to Battery Open Circuit

Voltage Table.

BATTERY TEMPERATURE SENSOR

For Battery Temperature Sensor refer to Group 8C

Generator.

SERVICE PROCEDURES

BATTERY CHARGING

A battery is considered fully charged when it will

meet all the following requirements.

²It has an open circuit voltage charge of at least

12.4 volts.

²It passes the 15 second load test. Refer to Bat-

tery Load Test.

²The built in test indicator dot is GREEN (Fig.

1).

NOTE: The battery cannot be refilled with water, it

must be replaced.

Fig. 9 Load 50% Cold Crank Rating

BATTERY LOAD TEST TEMPERATURES

Minimum

VoltageTemperature

ÉF ÉC

9.6 volts 70É and above 21É and above

9.5 volts 60É 16É

9.4 volts 50É 10É

9.3 volts 40É 4É

9.1 volts 30É -1É

8.9 volts 20É -7É

8.7 volts 10É -12É

8.5 volts 0É -18É

Fig. 10 Testing Open Circuit Voltage

BATTERY OPEN CIRCUIT VOLTAGE

Open Circuit Volts Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

8A - 6 BATTERYPL

DIAGNOSIS AND TESTING (Continued)

Page 224 of 1200

WARNING: DO NOT CHARGE A BATTERY THAT

HAS EXCESSIVELY LOW ELECTROLYTE LEVEL.

BATTERY MAY SPARK INTERNALLY AND

EXPLODE. EXPLOSIVE GASES FORM OVER THE

BATTERY. DO NOT SMOKE, USE FLAME, OR CRE-

ATE SPARKS NEAR BATTERY. DO NOT ASSIST

BOOST OR CHARGE A FROZEN BATTERY. BAT-

TERY CASING MAY FRACTURE. BATTERY ACID IS

POISON, AND MAY CAUSE SEVERE BURNS. BAT-

TERIES CONTAIN SULFURIC ACID. AVOID CON-

TACT WITH SKIN, EYES, OR CLOTHING. IN THE

EVENT OF CONTACT, FLUSH WITH WATER AND

CALL PHYSICIAN IMMEDIATELY. KEEP OUT OF

REACH OF CHILDREN.

CAUTION: Disconnect the battery NEGATIVE cable

first, before charging battery to avoid damage to

electrical systems. Lift the red battery boot cover

from the positive cable clamp. Do not exceed 16.0

volts while charging battery. Refer to the instruc-

tions supplied with charging equipment

Battery electrolyte may bubble inside of battery

case while being charged properly. If the electrolyte

boils violently, or is discharged from the vent holes

while charging, immediately reduce charging rate or

turn off charger. Evaluate battery condition. Battery

damage may occur if charging is excessive.

Some battery chargers are equipped with polarity

sensing devices to protect the charger or battery from

being damaged if improperly connected. If the bat-

tery state of charge is too low for the polarity sensor

to detect, the sensor must be bypassed for charger to

operate. Refer to operating instructions provided

with battery charger being used.

CAUTION: Charge battery until test indicator

appears green. Do not overcharge.

It may be necessary to jiggle the battery or vehicle

to bring the green dot in the test indicator into view.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine cranking

capacity. Refer to Battery Load Test in this Group. If

the battery passes the load test, the battery is OK to

use. If battery will not pass the load test, it must be

replaced. Properly clean and inspect battery hold

downs, tray, terminals, cables, posts, and top before

completing service.

CHARGING COMPLETELY DISCHARGED BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless procedure is

properly followed, a good battery may be needlessly

replaced. Refer to Battery Charging Rate Table for

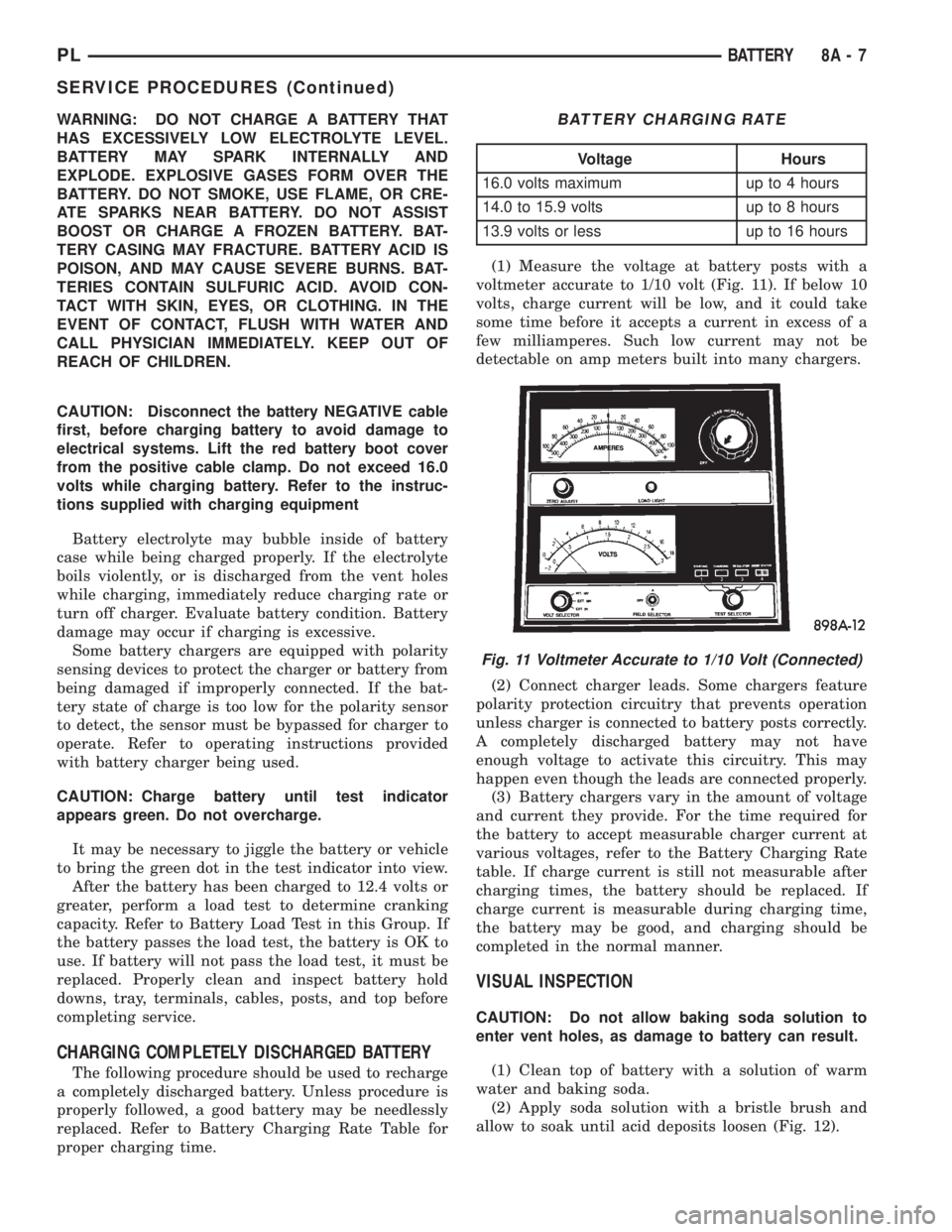

proper charging time.(1) Measure the voltage at battery posts with a

voltmeter accurate to 1/10 volt (Fig. 11). If below 10

volts, charge current will be low, and it could take

some time before it accepts a current in excess of a

few milliamperes. Such low current may not be

detectable on amp meters built into many chargers.

(2) Connect charger leads. Some chargers feature

polarity protection circuitry that prevents operation

unless charger is connected to battery posts correctly.

A completely discharged battery may not have

enough voltage to activate this circuitry. This may

happen even though the leads are connected properly.

(3) Battery chargers vary in the amount of voltage

and current they provide. For the time required for

the battery to accept measurable charger current at

various voltages, refer to the Battery Charging Rate

table. If charge current is still not measurable after

charging times, the battery should be replaced. If

charge current is measurable during charging time,

the battery may be good, and charging should be

completed in the normal manner.

VISUAL INSPECTION

CAUTION: Do not allow baking soda solution to

enter vent holes, as damage to battery can result.

(1) Clean top of battery with a solution of warm

water and baking soda.

(2) Apply soda solution with a bristle brush and

allow to soak until acid deposits loosen (Fig. 12).

BATTERY CHARGING RATE

Voltage Hours

16.0 volts maximum up to 4 hours

14.0 to 15.9 volts up to 8 hours

13.9 volts or less up to 16 hours

Fig. 11 Voltmeter Accurate to 1/10 Volt (Connected)

PLBATTERY 8A - 7

SERVICE PROCEDURES (Continued)

Page 227 of 1200

WARNING: TO PROTECT THE HANDS FROM BAT-

TERY ACID, A SUITABLE PAIR OF HEAVY DUTY

RUBBER GLOVES, NOT THE HOUSEHOLD TYPE,

SHOULD BE WORN WHEN REMOVING OR SERVIC-

ING A BATTERY. SAFETY GLASSES ALSO SHOULD

BE WORN.

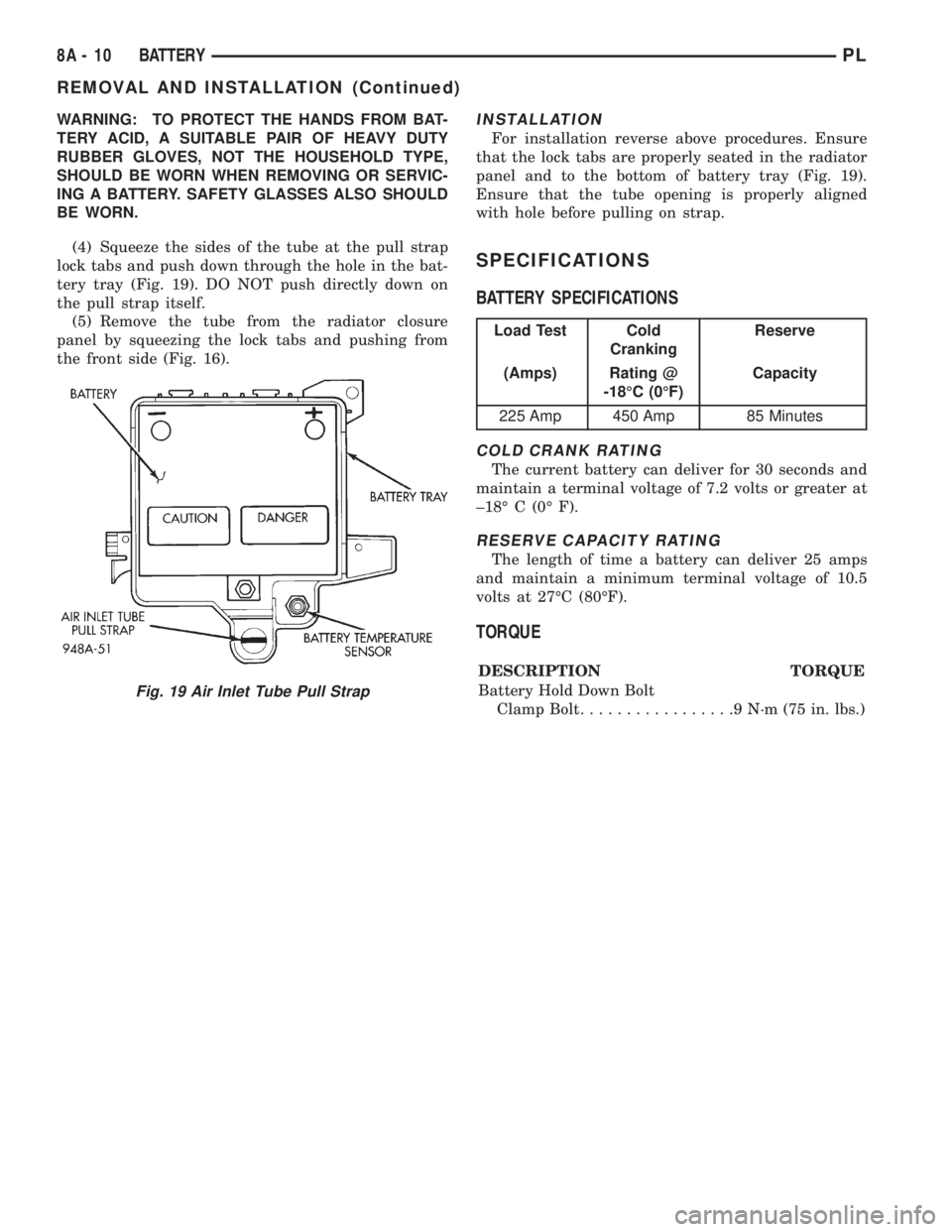

(4) Squeeze the sides of the tube at the pull strap

lock tabs and push down through the hole in the bat-

tery tray (Fig. 19). DO NOT push directly down on

the pull strap itself.

(5) Remove the tube from the radiator closure

panel by squeezing the lock tabs and pushing from

the front side (Fig. 16).INSTALLATION

For installation reverse above procedures. Ensure

that the lock tabs are properly seated in the radiator

panel and to the bottom of battery tray (Fig. 19).

Ensure that the tube opening is properly aligned

with hole before pulling on strap.

SPECIFICATIONS

BATTERY SPECIFICATIONS

COLD CRANK RATING

The current battery can deliver for 30 seconds and

maintain a terminal voltage of 7.2 volts or greater at

±18É C (0É F).

RESERVE CAPACITY RATING

The length of time a battery can deliver 25 amps

and maintain a minimum terminal voltage of 10.5

volts at 27ÉC (80ÉF).

TORQUE

DESCRIPTION TORQUE

Battery Hold Down Bolt

Clamp Bolt.................9N´m(75in.lbs.)

Fig. 19 Air Inlet Tube Pull Strap

Load Test Cold

CrankingReserve

(Amps) Rating @

-18ÉC (0ÉF)Capacity

225 Amp 450 Amp 85 Minutes

8A - 10 BATTERYPL

REMOVAL AND INSTALLATION (Continued)

Page 1070 of 1200

weather temperature varies widely. Tire pressure will

decrease when the outdoor temperature drops.

Inflation pressures specified on the placard are

always the cold inflation pressure of the tire. Cold

inflation pressure is obtained after the vehicle has

not been operated for at least 3 hours, or the vehicle

is driven less than one mile after being inoperative

for 3 hours. Tire inflation pressures may increase

from 2 to 6 pounds per square inch (psi) during oper-

ation. Do not reduce this normal pressure build-up.

WARNING: OVER OR UNDER INFLATED TIRES

CAN AFFECT VEHICLE HANDLING. THE TIRE CAN

FAIL SUDDENLY, RESULTING IN LOSS OF VEHICLE

CONTROL.

TIRE PRESSURE FOR HIGH SPEED OPERATION

Chrysler Corporation advocates driving at safe

speeds within posted speed limits. Where speed lim-

its allow the vehicle to be driven at high speeds, cor-

rect tire inflation pressure is very important. For

speeds up to and including 120 km/h (75 mph), tires

must be inflated to the pressures shown on the tire

placard. For continuous speeds in excess of 120 km/h

(75 mph), tires must be inflated to the maximum

pressure specified on the tire sidewall.

Vehicles loaded to the maximum capacity should

not be driven at continuous speeds above 75 mph

(120 km/h).

For emergency vehicles that are driven at speeds

over 90 mph (144 km/h), special high speed tires

must be used. Consult tire manufacturer for correct

inflation pressure recommendations.

REPLACEMENT TIRES

The original equipment tires provide a proper bal-

ance of many characteristics such as:

²Ride

²Noise

²Handling

²Durability

²Tread life

²Traction

²Rolling resistance

²Speed capability

It is recommend that tires equivalent to the origi-

nal equipment tires be used when replacement is

needed.

Failure to use equivalent replacement tires may

adversely affect the safety and handling of the vehi-

cle.

The use of oversize tires not listed in the specifica-

tion charts may cause interference with vehicle com-

ponents. Under extremes of suspension and steering

travel, interference with vehicle components may

cause tire damage.WARNING: FAILURE TO EQUIP THE VEHICLE WITH

TIRES HAVING ADEQUATE SPEED CAPABILITY

CAN RESULT IN SUDDEN TIRE FAILURE.

DIAGNOSIS AND TESTING

PRESSURE GAUGES

A quality air pressure gauge is recommended to

check tire pressure. After checking the air pressure,

replace valve cap finger tight.

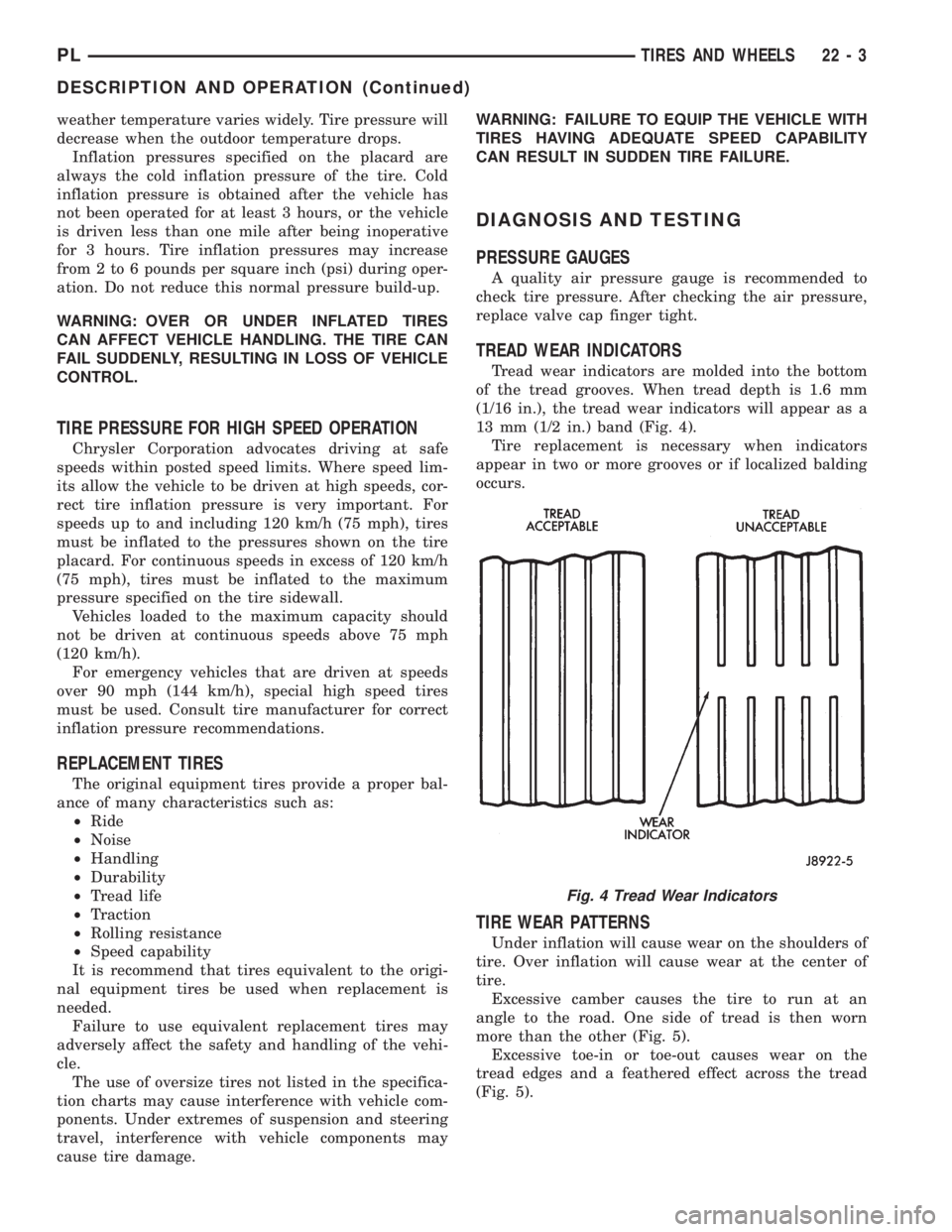

TREAD WEAR INDICATORS

Tread wear indicators are molded into the bottom

of the tread grooves. When tread depth is 1.6 mm

(1/16 in.), the tread wear indicators will appear as a

13 mm (1/2 in.) band (Fig. 4).

Tire replacement is necessary when indicators

appear in two or more grooves or if localized balding

occurs.

TIRE WEAR PATTERNS

Under inflation will cause wear on the shoulders of

tire. Over inflation will cause wear at the center of

tire.

Excessive camber causes the tire to run at an

angle to the road. One side of tread is then worn

more than the other (Fig. 5).

Excessive toe-in or toe-out causes wear on the

tread edges and a feathered effect across the tread

(Fig. 5).

Fig. 4 Tread Wear Indicators

PLTIRES AND WHEELS 22 - 3

DESCRIPTION AND OPERATION (Continued)

Page 1075 of 1200

WHEELS

INDEX

page page

DESCRIPTION AND OPERATION

WHEEL COVER (LOCK-ON)................. 8

WHEEL INFORMATION.................... 8

DIAGNOSIS AND TESTING

TIRE AND WHEEL RUNOUT................ 9

WHEEL INSPECTION...................... 9

SERVICE PROCEDURES

TIRE AND WHEEL BALANCE............... 10REMOVAL AND INSTALLATION

WHEEL AND TIRE....................... 12

WHEEL COVER (LOCK-ON)................ 12

WHEEL COVER RETAINING NUT........... 13

SPECIFICATIONS

WHEEL SPECIFICATIONS................. 14

DESCRIPTION AND OPERATION

WHEEL INFORMATION

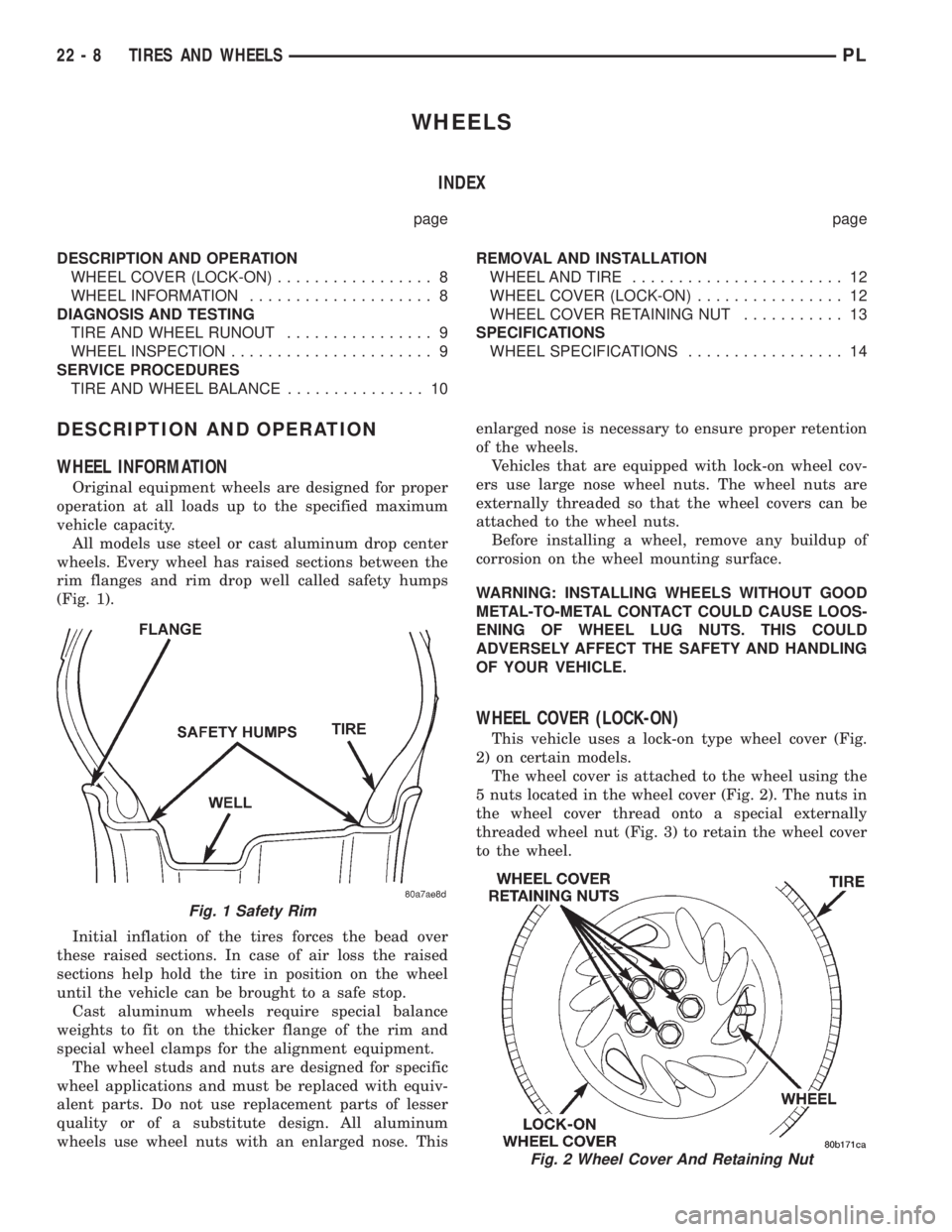

Original equipment wheels are designed for proper

operation at all loads up to the specified maximum

vehicle capacity.

All models use steel or cast aluminum drop center

wheels. Every wheel has raised sections between the

rim flanges and rim drop well called safety humps

(Fig. 1).

Initial inflation of the tires forces the bead over

these raised sections. In case of air loss the raised

sections help hold the tire in position on the wheel

until the vehicle can be brought to a safe stop.

Cast aluminum wheels require special balance

weights to fit on the thicker flange of the rim and

special wheel clamps for the alignment equipment.

The wheel studs and nuts are designed for specific

wheel applications and must be replaced with equiv-

alent parts. Do not use replacement parts of lesser

quality or of a substitute design. All aluminum

wheels use wheel nuts with an enlarged nose. Thisenlarged nose is necessary to ensure proper retention

of the wheels.

Vehicles that are equipped with lock-on wheel cov-

ers use large nose wheel nuts. The wheel nuts are

externally threaded so that the wheel covers can be

attached to the wheel nuts.

Before installing a wheel, remove any buildup of

corrosion on the wheel mounting surface.

WARNING: INSTALLING WHEELS WITHOUT GOOD

METAL-TO-METAL CONTACT COULD CAUSE LOOS-

ENING OF WHEEL LUG NUTS. THIS COULD

ADVERSELY AFFECT THE SAFETY AND HANDLING

OF YOUR VEHICLE.

WHEEL COVER (LOCK-ON)

This vehicle uses a lock-on type wheel cover (Fig.

2) on certain models.

The wheel cover is attached to the wheel using the

5 nuts located in the wheel cover (Fig. 2). The nuts in

the wheel cover thread onto a special externally

threaded wheel nut (Fig. 3) to retain the wheel cover

to the wheel.

Fig. 1 Safety Rim

Fig. 2 Wheel Cover And Retaining Nut

22 - 8 TIRES AND WHEELSPL

Page 1076 of 1200

The wheel cover retaining nut (Fig. 2) is retained

in the wheel cover and will stay on the wheel cover

when un-threaded from the wheel nut. If required,

the retaining nut can be removed from the wheel

cover and replaced as a separate part of the wheel

cover.

The lock-on wheel cover can not be removed from

the wheel until all 5 wheel cover retaining nuts are

un-threaded from the wheel nuts. Then the lock-on

wheel cover can be removed by hand from the wheel.

DIAGNOSIS AND TESTING

WHEEL INSPECTION

Inspect wheels for:

²Excessive run out

²Dents or cracks

²Damaged wheel lug nut holes

²Air Leaks from any area or surface of the rim

NOTE: Do not attempt to repair a wheel by ham-

mering, heating or welding.

If a wheel is damaged an original equipment

replacement wheel should be used. When obtaining

replacement wheels, they should be equivalent in

load carrying capacity. The diameter, width, offset,

pilot hole and bolt circle of the wheel should be the

same as the original wheel.

WARNING: FAILURE TO USE EQUIVALENT

REPLACEMENT WHEELS MAY ADVERSELY AFFECT

THE SAFETY AND HANDLING OF THE VEHICLE.

USED WHEELS ARE NOT RECOMMENDED. THE

SERVICE HISTORY OF THE WHEEL MAY HAVE

INCLUDED SEVERE TREATMENT OR VERY HIGH

MILEAGE. THE RIM COULD FAIL WITHOUT WARN-

ING.

TIRE AND WHEEL RUNOUT

NOTE: Runout should always be measured off the

vehicle and on a suitable balance machine.Radial run out is the difference between the high

and low points on the outer edge of the tire or wheel.

Lateral run out is the total side±to±side wobble of

the tire or wheel.

Radial run out of more than 1.5 mm (.060 inch)

measured at the center line of the tread may cause

the vehicle to shake.

Lateral run out of more than 2.0 mm (.080 inch)

measured at the side of the tire as close to the tread

as possible may cause the vehicle to shake.

Sometimes radial run out can be reduced by relo-

cating the wheel and tire on the wheel studs (See

Method 1). If this does not reduce run out to an

acceptable level, the tire can be rotated on the wheel.

(See Method 2).

METHOD 1 (RELOCATE WHEEL ON HUB)

Check accuracy of the wheel mounting surface;

adjust wheel bearings.

Drive vehicle a short distance to eliminate tire flat

spotting from a parked position.

Verify all wheel nuts are tightened and properly

torqued in the correct sequence (Fig. 4).

Use run out gauge D-128-TR to determine run out

(Fig. 5).

Fig. 3 Wheel Nut And Wheel Cover Retaining Nut

Fig. 4 Tightening Wheel Nuts

Fig. 5 Run Out Gauge

PLTIRES AND WHEELS 22 - 9

DESCRIPTION AND OPERATION (Continued)

Page 1139 of 1200

outlets in various combinations using the mode selec-

tor. There are 17 different mode selections possible.

Air flow velocity can be adjusted with the blower

speed selector switch on the instrument panel.

On A/C equipped vehicles the ambient air intake

can be controlled by opening and closing the recircu-

lating air door. When placed in RECIRC, air that is

inside vehicle is removed continuously and recircu-

lated through unit housing. Ambient air cannot be

controlled on vehicles without A/C. The system uses

outside air at all times.

The air conditioning compressor can be engaged by

turning the fan switch counterclockwise from the off

position. It can also be engaged by placing the mode

control in the defrost position. This will remove heat

and humidity from the air before it is directed

through or around the heater core.

SYSTEM OIL LEVEL

It is important to have the correct amount of oil in

the A/C system to ensure proper lubrication of the

compressor. Too little oil will result in damage to the

compressor. Too much oil will reduce the cooling

capacity of the system and consequently result in

higher discharge air temperatures.

NOTE: The oil used in the compressor is ND8 PAG

R-134a refrigerant oil. Only refrigerant oil of the

same type should be used to service the system.

Do not use any other oil. The oil container should

be kept tightly capped until it is ready for use.

Tightly cap afterwards to prevent contamination

from dirt and moisture. Refrigerant oil will quickly

absorb any moisture it comes in contact with. Spe-

cial effort must be used to keep all R-134a system

components moisture-free. Moisture in the oil is

very difficult to remove and will cause a reliability

problem with the compressor.

It will not be necessary to check oil level in the

compressor or to add oil unless there has been an oil

loss. Oil loss at a leak point will be evident by the

presence of a wet, shiny surface around the leak.

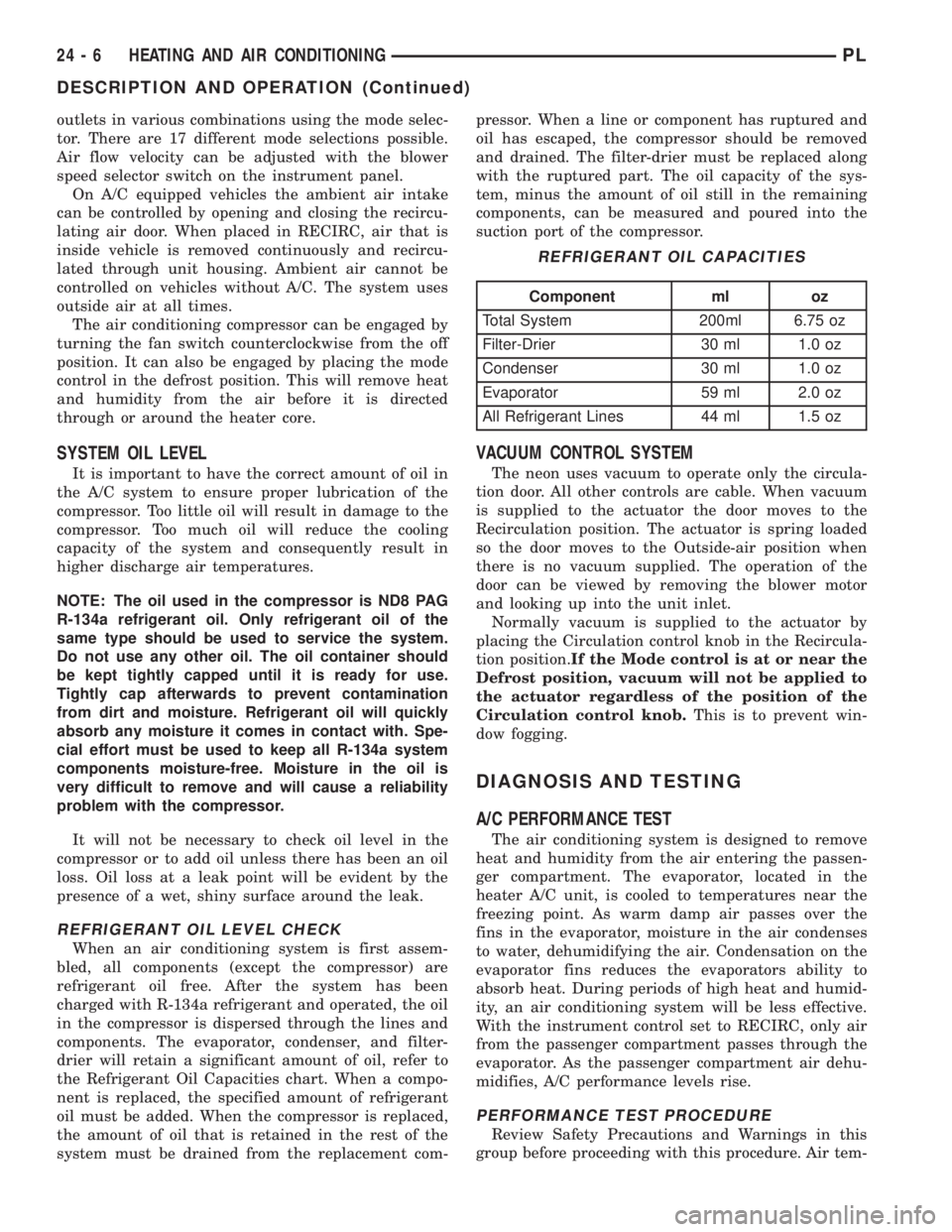

REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assem-

bled, all components (except the compressor) are

refrigerant oil free. After the system has been

charged with R-134a refrigerant and operated, the oil

in the compressor is dispersed through the lines and

components. The evaporator, condenser, and filter-

drier will retain a significant amount of oil, refer to

the Refrigerant Oil Capacities chart. When a compo-

nent is replaced, the specified amount of refrigerant

oil must be added. When the compressor is replaced,

the amount of oil that is retained in the rest of the

system must be drained from the replacement com-pressor. When a line or component has ruptured and

oil has escaped, the compressor should be removed

and drained. The filter-drier must be replaced along

with the ruptured part. The oil capacity of the sys-

tem, minus the amount of oil still in the remaining

components, can be measured and poured into the

suction port of the compressor.

VACUUM CONTROL SYSTEM

The neon uses vacuum to operate only the circula-

tion door. All other controls are cable. When vacuum

is supplied to the actuator the door moves to the

Recirculation position. The actuator is spring loaded

so the door moves to the Outside-air position when

there is no vacuum supplied. The operation of the

door can be viewed by removing the blower motor

and looking up into the unit inlet.

Normally vacuum is supplied to the actuator by

placing the Circulation control knob in the Recircula-

tion position.If the Mode control is at or near the

Defrost position, vacuum will not be applied to

the actuator regardless of the position of the

Circulation control knob.This is to prevent win-

dow fogging.

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to RECIRC, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, A/C performance levels rise.

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings in this

group before proceeding with this procedure. Air tem-

REFRIGERANT OIL CAPACITIES

Component ml oz

Total System 200ml 6.75 oz

Filter-Drier 30 ml 1.0 oz

Condenser 30 ml 1.0 oz

Evaporator 59 ml 2.0 oz

All Refrigerant Lines 44 ml 1.5 oz

24 - 6 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)