key DODGE NEON 1999 Service User Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 229 of 1200

To disable the ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for proper relay location.

FEED CIRCUIT RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition system also must be disabled

to prevent engine start while performing the follow-

ing tests.

(1) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) With all wiring harnesses and components

properly connected, perform the following:

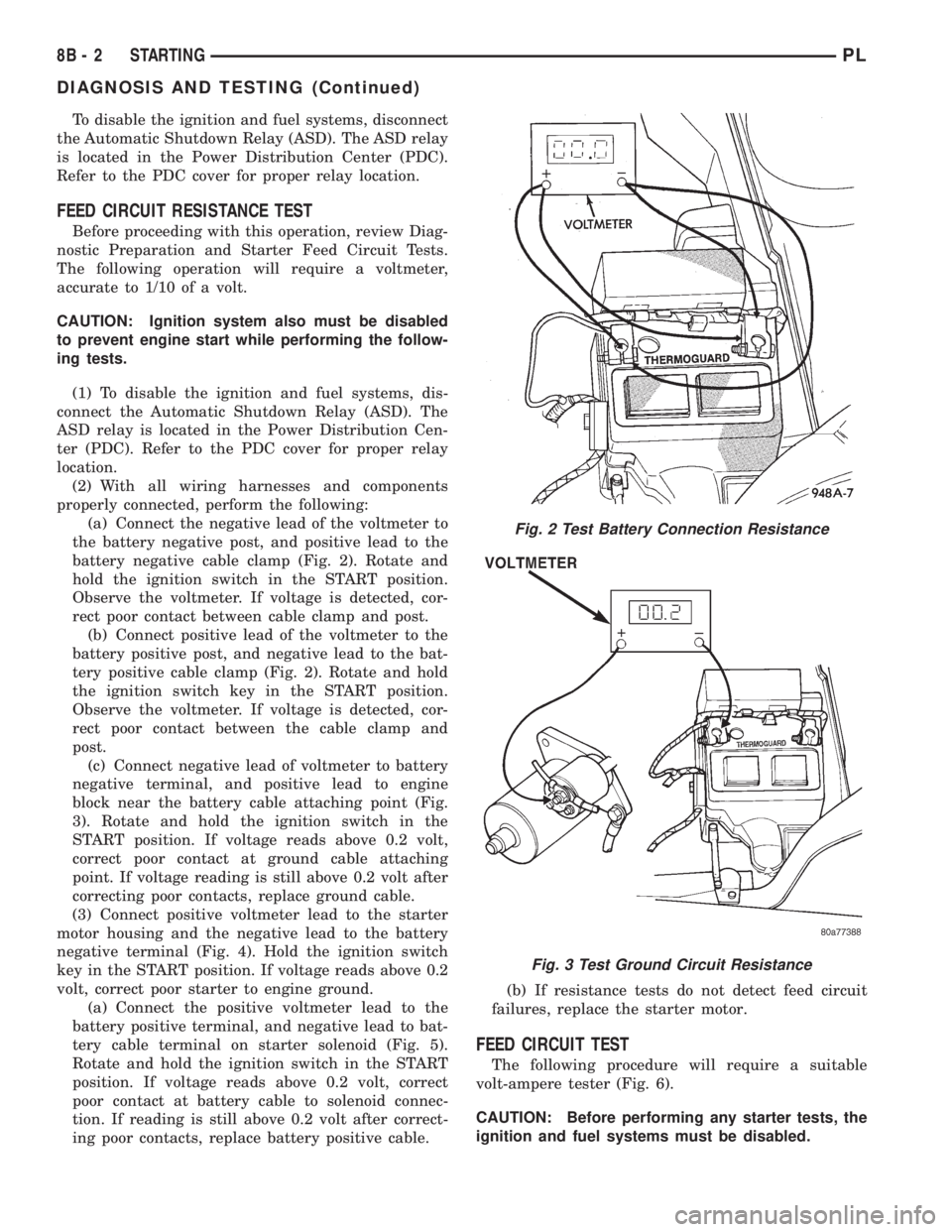

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp (Fig. 2). Rotate and

hold the ignition switch in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp (Fig. 2). Rotate and hold

the ignition switch key in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between the cable clamp and

post.

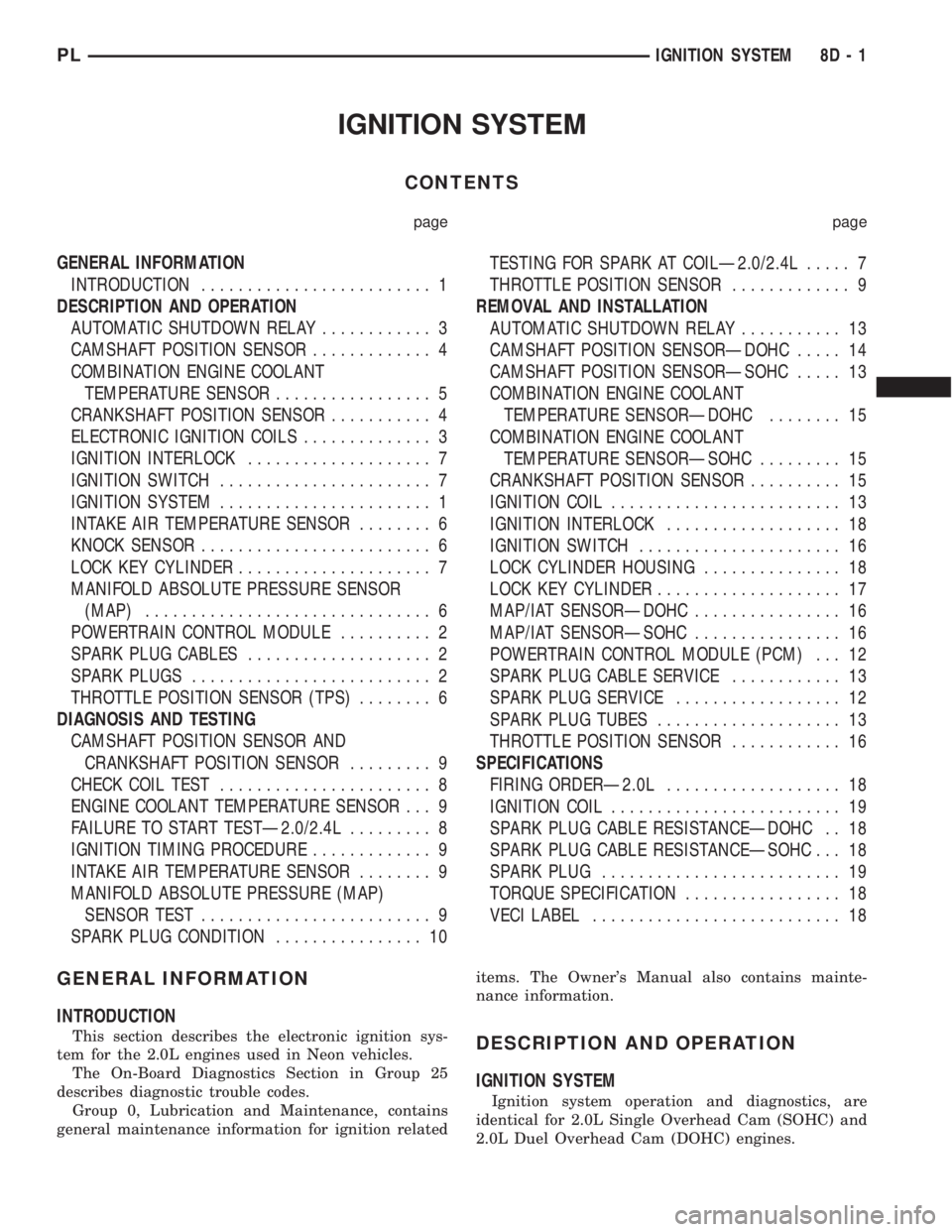

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point (Fig.

3). Rotate and hold the ignition switch in the

START position. If voltage reads above 0.2 volt,

correct poor contact at ground cable attaching

point. If voltage reading is still above 0.2 volt after

correcting poor contacts, replace ground cable.

(3) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal (Fig. 4). Hold the ignition switch

key in the START position. If voltage reads above 0.2

volt, correct poor starter to engine ground.

(a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid (Fig. 5).

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at battery cable to solenoid connec-

tion. If reading is still above 0.2 volt after correct-

ing poor contacts, replace battery positive cable.(b) If resistance tests do not detect feed circuit

failures, replace the starter motor.

FEED CIRCUIT TEST

The following procedure will require a suitable

volt-ampere tester (Fig. 6).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

Fig. 2 Test Battery Connection Resistance

Fig. 3 Test Ground Circuit Resistance

8B - 2 STARTINGPL

DIAGNOSIS AND TESTING (Continued)

Page 250 of 1200

IGNITION SYSTEM

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

AUTOMATIC SHUTDOWN RELAY............ 3

CAMSHAFT POSITION SENSOR............. 4

COMBINATION ENGINE COOLANT

TEMPERATURE SENSOR................. 5

CRANKSHAFT POSITION SENSOR........... 4

ELECTRONIC IGNITION COILS.............. 3

IGNITION INTERLOCK.................... 7

IGNITION SWITCH....................... 7

IGNITION SYSTEM....................... 1

INTAKE AIR TEMPERATURE SENSOR........ 6

KNOCK SENSOR......................... 6

LOCK KEY CYLINDER..................... 7

MANIFOLD ABSOLUTE PRESSURE SENSOR

(MAP)............................... 6

POWERTRAIN CONTROL MODULE.......... 2

SPARK PLUG CABLES.................... 2

SPARK PLUGS.......................... 2

THROTTLE POSITION SENSOR (TPS)........ 6

DIAGNOSIS AND TESTING

CAMSHAFT POSITION SENSOR AND

CRANKSHAFT POSITION SENSOR......... 9

CHECK COIL TEST....................... 8

ENGINE COOLANT TEMPERATURE SENSOR . . . 9

FAILURE TO START TESTÐ2.0/2.4L......... 8

IGNITION TIMING PROCEDURE............. 9

INTAKE AIR TEMPERATURE SENSOR........ 9

MANIFOLD ABSOLUTE PRESSURE (MAP)

SENSOR TEST......................... 9

SPARK PLUG CONDITION................ 10TESTING FOR SPARK AT COILÐ2.0/2.4L..... 7

THROTTLE POSITION SENSOR............. 9

REMOVAL AND INSTALLATION

AUTOMATIC SHUTDOWN RELAY........... 13

CAMSHAFT POSITION SENSORÐDOHC..... 14

CAMSHAFT POSITION SENSORÐSOHC..... 13

COMBINATION ENGINE COOLANT

TEMPERATURE SENSORÐDOHC........ 15

COMBINATION ENGINE COOLANT

TEMPERATURE SENSORÐSOHC......... 15

CRANKSHAFT POSITION SENSOR.......... 15

IGNITION COIL......................... 13

IGNITION INTERLOCK................... 18

IGNITION SWITCH...................... 16

LOCK CYLINDER HOUSING............... 18

LOCK KEY CYLINDER.................... 17

MAP/IAT SENSORÐDOHC................ 16

MAP/IAT SENSORÐSOHC................ 16

POWERTRAIN CONTROL MODULE (PCM) . . . 12

SPARK PLUG CABLE SERVICE............ 13

SPARK PLUG SERVICE.................. 12

SPARK PLUG TUBES.................... 13

THROTTLE POSITION SENSOR............ 16

SPECIFICATIONS

FIRING ORDERÐ2.0L................... 18

IGNITION COIL......................... 19

SPARK PLUG CABLE RESISTANCEÐDOHC . . 18

SPARK PLUG CABLE RESISTANCEÐSOHC . . . 18

SPARK PLUG.......................... 19

TORQUE SPECIFICATION................. 18

VECI LABEL........................... 18

GENERAL INFORMATION

INTRODUCTION

This section describes the electronic ignition sys-

tem for the 2.0L engines used in Neon vehicles.

The On-Board Diagnostics Section in Group 25

describes diagnostic trouble codes.

Group 0, Lubrication and Maintenance, contains

general maintenance information for ignition relateditems. The Owner's Manual also contains mainte-

nance information.DESCRIPTION AND OPERATION

IGNITION SYSTEM

Ignition system operation and diagnostics, are

identical for 2.0L Single Overhead Cam (SOHC) and

2.0L Duel Overhead Cam (DOHC) engines.

PLIGNITION SYSTEM 8D - 1

Page 255 of 1200

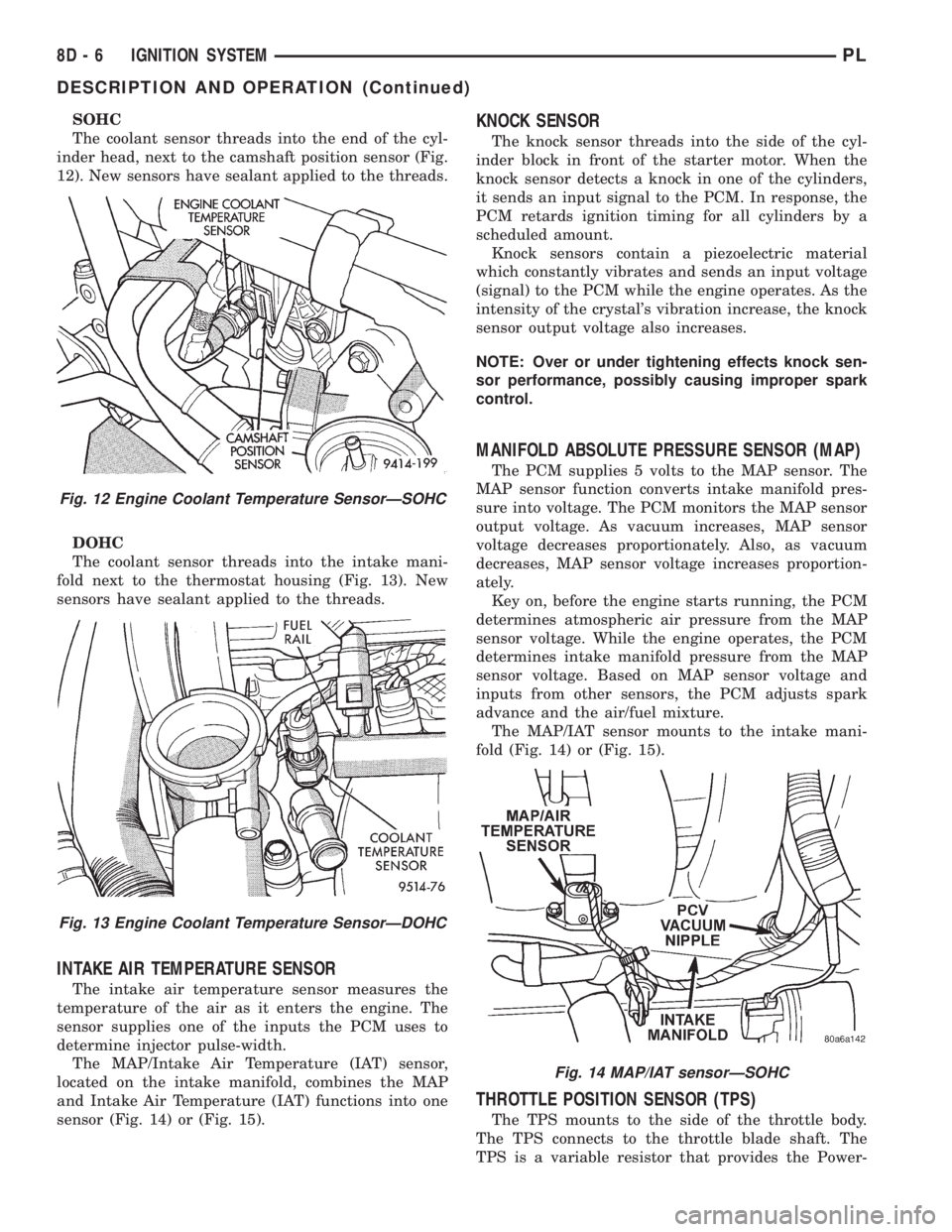

SOHC

The coolant sensor threads into the end of the cyl-

inder head, next to the camshaft position sensor (Fig.

12). New sensors have sealant applied to the threads.

DOHC

The coolant sensor threads into the intake mani-

fold next to the thermostat housing (Fig. 13). New

sensors have sealant applied to the threads.

INTAKE AIR TEMPERATURE SENSOR

The intake air temperature sensor measures the

temperature of the air as it enters the engine. The

sensor supplies one of the inputs the PCM uses to

determine injector pulse-width.

The MAP/Intake Air Temperature (IAT) sensor,

located on the intake manifold, combines the MAP

and Intake Air Temperature (IAT) functions into one

sensor (Fig. 14) or (Fig. 15).

KNOCK SENSOR

The knock sensor threads into the side of the cyl-

inder block in front of the starter motor. When the

knock sensor detects a knock in one of the cylinders,

it sends an input signal to the PCM. In response, the

PCM retards ignition timing for all cylinders by a

scheduled amount.

Knock sensors contain a piezoelectric material

which constantly vibrates and sends an input voltage

(signal) to the PCM while the engine operates. As the

intensity of the crystal's vibration increase, the knock

sensor output voltage also increases.

NOTE: Over or under tightening effects knock sen-

sor performance, possibly causing improper spark

control.

MANIFOLD ABSOLUTE PRESSURE SENSOR (MAP)

The PCM supplies 5 volts to the MAP sensor. The

MAP sensor function converts intake manifold pres-

sure into voltage. The PCM monitors the MAP sensor

output voltage. As vacuum increases, MAP sensor

voltage decreases proportionately. Also, as vacuum

decreases, MAP sensor voltage increases proportion-

ately.

Key on, before the engine starts running, the PCM

determines atmospheric air pressure from the MAP

sensor voltage. While the engine operates, the PCM

determines intake manifold pressure from the MAP

sensor voltage. Based on MAP sensor voltage and

inputs from other sensors, the PCM adjusts spark

advance and the air/fuel mixture.

The MAP/IAT sensor mounts to the intake mani-

fold (Fig. 14) or (Fig. 15).

THROTTLE POSITION SENSOR (TPS)

The TPS mounts to the side of the throttle body.

The TPS connects to the throttle blade shaft. The

TPS is a variable resistor that provides the Power-

Fig. 12 Engine Coolant Temperature SensorÐSOHC

Fig. 13 Engine Coolant Temperature SensorÐDOHC

Fig. 14 MAP/IAT sensorÐSOHC

8D - 6 IGNITION SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 256 of 1200

train Control Module (PCM) with an input signal

(voltage). The signal represents throttle blade posi-

tion. As the position of the throttle blade changes,

the resistance of the TPS changes.

The PCM supplies approximately 5 volts to the

TPS. The TPS output voltage (input signal to the

powertrain control module) represents throttle blade

position. The TPS output voltage to the PCM varies

from approximately 0.38 volts to 1.2 volts at mini-

mum throttle opening (idle) to a maximum of 3.1

volts to 4.4 volts at wide open throttle.

Along with inputs from other sensors, the PCM

uses the TPS input to determine current engine oper-

ating conditions. The PCM also adjusts fuel injector

pulse width and ignition timing based on these

inputs.

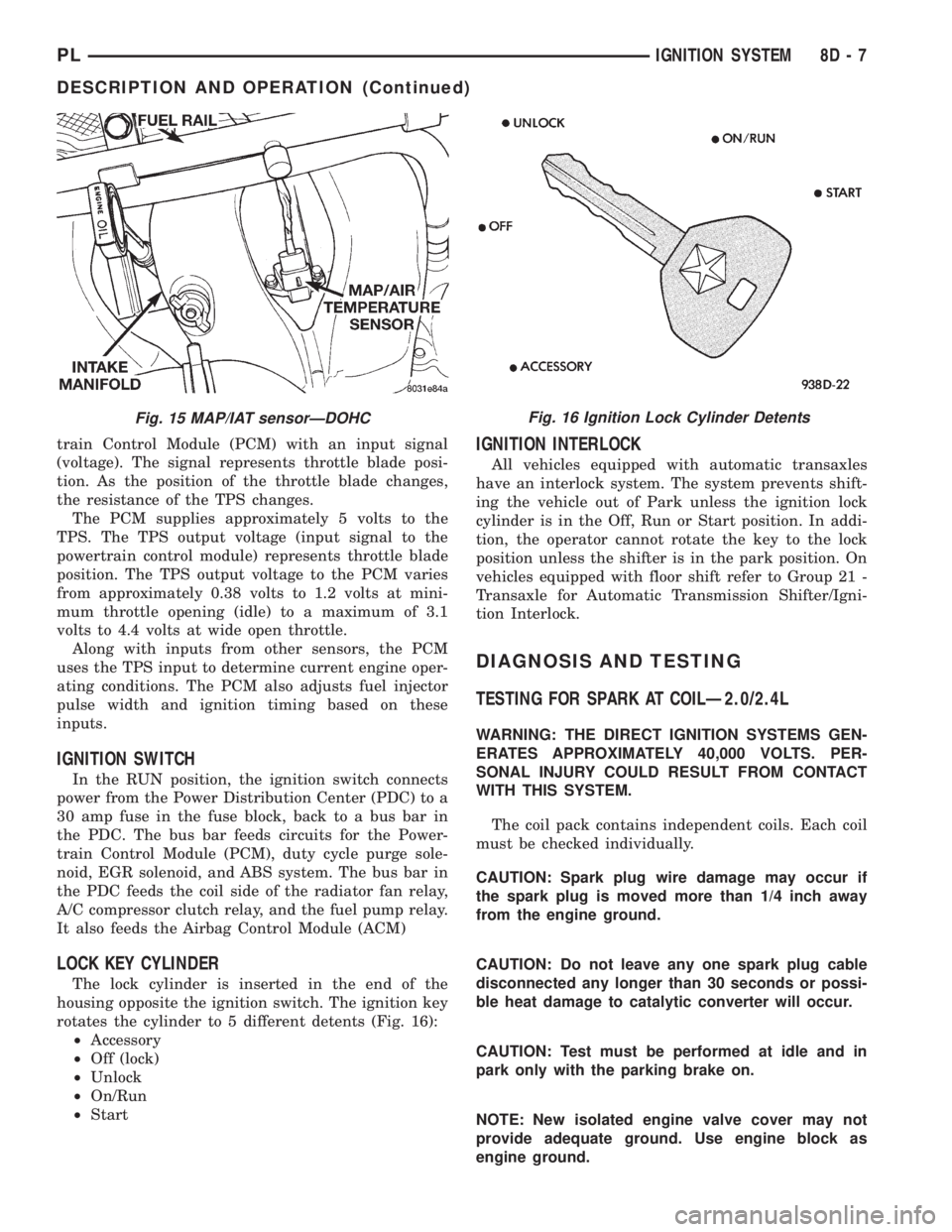

IGNITION SWITCH

In the RUN position, the ignition switch connects

power from the Power Distribution Center (PDC) to a

30 amp fuse in the fuse block, back to a bus bar in

the PDC. The bus bar feeds circuits for the Power-

train Control Module (PCM), duty cycle purge sole-

noid, EGR solenoid, and ABS system. The bus bar in

the PDC feeds the coil side of the radiator fan relay,

A/C compressor clutch relay, and the fuel pump relay.

It also feeds the Airbag Control Module (ACM)

LOCK KEY CYLINDER

The lock cylinder is inserted in the end of the

housing opposite the ignition switch. The ignition key

rotates the cylinder to 5 different detents (Fig. 16):

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

IGNITION INTERLOCK

All vehicles equipped with automatic transaxles

have an interlock system. The system prevents shift-

ing the vehicle out of Park unless the ignition lock

cylinder is in the Off, Run or Start position. In addi-

tion, the operator cannot rotate the key to the lock

position unless the shifter is in the park position. On

vehicles equipped with floor shift refer to Group 21 -

Transaxle for Automatic Transmission Shifter/Igni-

tion Interlock.

DIAGNOSIS AND TESTING

TESTING FOR SPARK AT COILÐ2.0/2.4L

WARNING: THE DIRECT IGNITION SYSTEMS GEN-

ERATES APPROXIMATELY 40,000 VOLTS. PER-

SONAL INJURY COULD RESULT FROM CONTACT

WITH THIS SYSTEM.

The coil pack contains independent coils. Each coil

must be checked individually.

CAUTION: Spark plug wire damage may occur if

the spark plug is moved more than 1/4 inch away

from the engine ground.

CAUTION: Do not leave any one spark plug cable

disconnected any longer than 30 seconds or possi-

ble heat damage to catalytic converter will occur.

CAUTION: Test must be performed at idle and in

park only with the parking brake on.

NOTE: New isolated engine valve cover may not

provide adequate ground. Use engine block as

engine ground.

Fig. 15 MAP/IAT sensorÐDOHCFig. 16 Ignition Lock Cylinder Detents

PLIGNITION SYSTEM 8D - 7

DESCRIPTION AND OPERATION (Continued)

Page 258 of 1200

ply circuit shorts to ground, neither sensor will pro-

duce a signal (output voltage to the PCM).

When the ignition key is turned and left in the On

position, the PCM automatically energizes the Auto

Shutdown (ASD) relay. However, the controller de-en-

ergizes the relay within one second because it has

not received a camshaft position sensor signal indi-

cating engine rotation.

During cranking, the ASD relay will not energize

until the PCM receives a camshaft position sensor

signal. Secondly, the ASD relay remains energized

only if the controller senses a crankshaft position

sensor signal immediately after detecting the cam-

shaft position sensor signal.

(1) Check battery voltage. Voltage should approxi-

mately 12.66 volts or higher to perform failure to

start test.

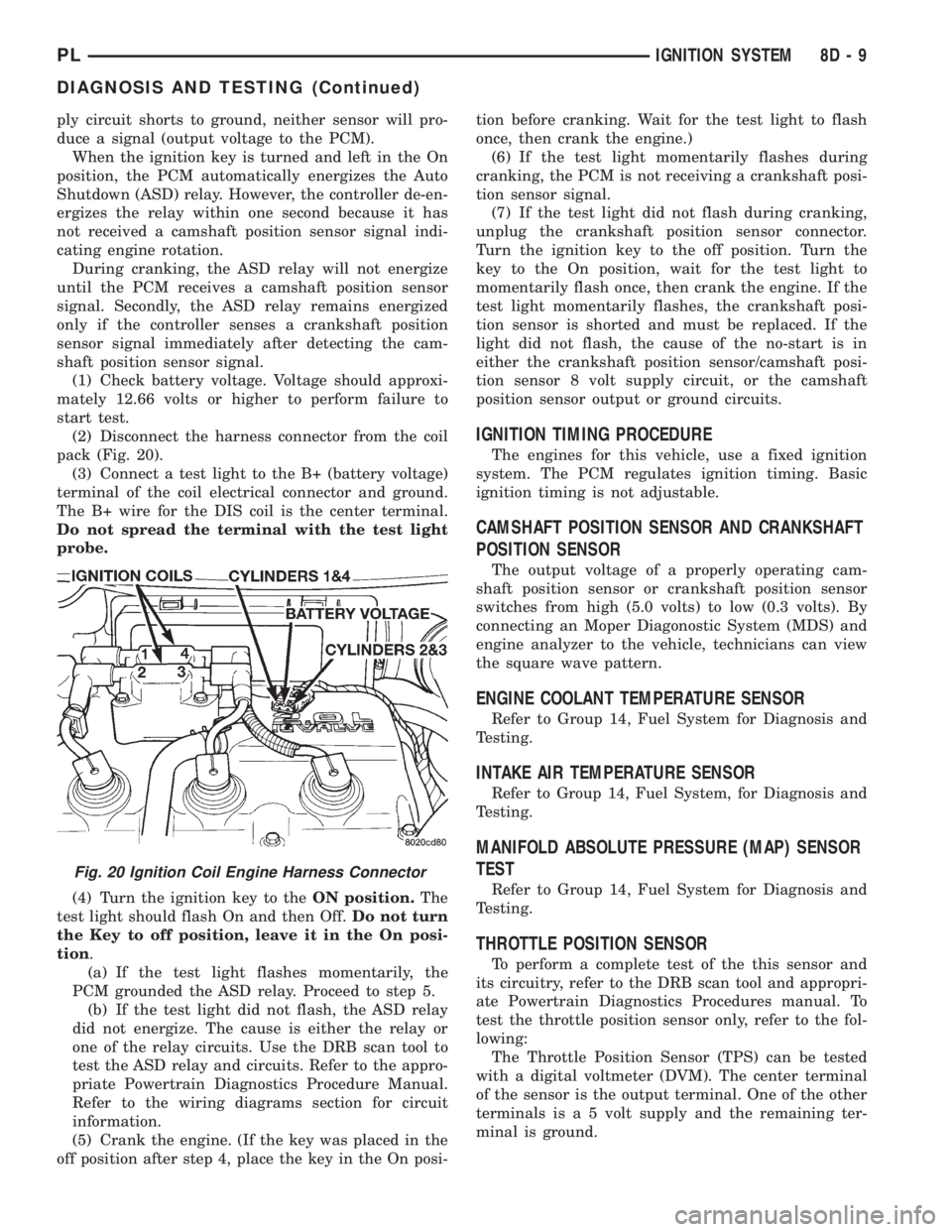

(2) Disconnect the harness connector from the coil

pack (Fig. 20).

(3) Connect a test light to the B+ (battery voltage)

terminal of the coil electrical connector and ground.

The B+ wire for the DIS coil is the center terminal.

Do not spread the terminal with the test light

probe.

(4) Turn the ignition key to theON position.The

test light should flash On and then Off.Do not turn

the Key to off position, leave it in the On posi-

tion.

(a) If the test light flashes momentarily, the

PCM grounded the ASD relay. Proceed to step 5.

(b) If the test light did not flash, the ASD relay

did not energize. The cause is either the relay or

one of the relay circuits. Use the DRB scan tool to

test the ASD relay and circuits. Refer to the appro-

priate Powertrain Diagnostics Procedure Manual.

Refer to the wiring diagrams section for circuit

information.

(5) Crank the engine. (If the key was placed in the

off position after step 4, place the key in the On posi-tion before cranking. Wait for the test light to flash

once, then crank the engine.)

(6) If the test light momentarily flashes during

cranking, the PCM is not receiving a crankshaft posi-

tion sensor signal.

(7) If the test light did not flash during cranking,

unplug the crankshaft position sensor connector.

Turn the ignition key to the off position. Turn the

key to the On position, wait for the test light to

momentarily flash once, then crank the engine. If the

test light momentarily flashes, the crankshaft posi-

tion sensor is shorted and must be replaced. If the

light did not flash, the cause of the no-start is in

either the crankshaft position sensor/camshaft posi-

tion sensor 8 volt supply circuit, or the camshaft

position sensor output or ground circuits.

IGNITION TIMING PROCEDURE

The engines for this vehicle, use a fixed ignition

system. The PCM regulates ignition timing. Basic

ignition timing is not adjustable.

CAMSHAFT POSITION SENSOR AND CRANKSHAFT

POSITION SENSOR

The output voltage of a properly operating cam-

shaft position sensor or crankshaft position sensor

switches from high (5.0 volts) to low (0.3 volts). By

connecting an Moper Diagonostic System (MDS) and

engine analyzer to the vehicle, technicians can view

the square wave pattern.

ENGINE COOLANT TEMPERATURE SENSOR

Refer to Group 14, Fuel System for Diagnosis and

Testing.

INTAKE AIR TEMPERATURE SENSOR

Refer to Group 14, Fuel System, for Diagnosis and

Testing.

MANIFOLD ABSOLUTE PRESSURE (MAP) SENSOR

TEST

Refer to Group 14, Fuel System for Diagnosis and

Testing.

THROTTLE POSITION SENSOR

To perform a complete test of the this sensor and

its circuitry, refer to the DRB scan tool and appropri-

ate Powertrain Diagnostics Procedures manual. To

test the throttle position sensor only, refer to the fol-

lowing:

The Throttle Position Sensor (TPS) can be tested

with a digital voltmeter (DVM). The center terminal

of the sensor is the output terminal. One of the other

terminals is a 5 volt supply and the remaining ter-

minal is ground.

Fig. 20 Ignition Coil Engine Harness Connector

PLIGNITION SYSTEM 8D - 9

DIAGNOSIS AND TESTING (Continued)

Page 265 of 1200

MAP/IAT SENSORÐSOHC

Refer to Group 14, Fuel Injection Section for

Removal/Installation.

MAP/IAT SENSORÐDOHC

Refer to Group 14, Fuel Injection Section for

Removal/Installation..

THROTTLE POSITION SENSOR

Refer to Group 14, Fuel Injection Section, for

Removal/Installation.

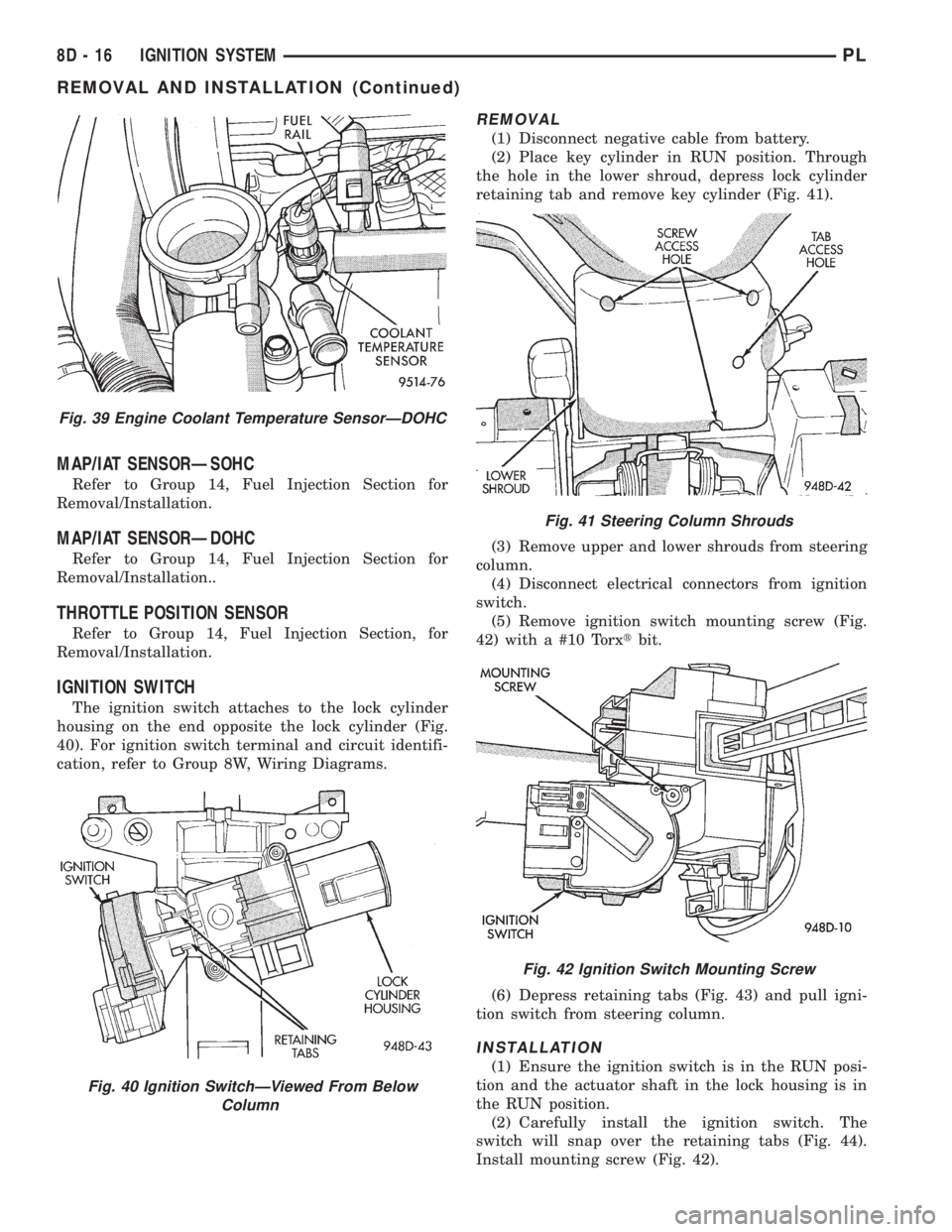

IGNITION SWITCH

The ignition switch attaches to the lock cylinder

housing on the end opposite the lock cylinder (Fig.

40). For ignition switch terminal and circuit identifi-

cation, refer to Group 8W, Wiring Diagrams.

REMOVAL

(1) Disconnect negative cable from battery.

(2) Place key cylinder in RUN position. Through

the hole in the lower shroud, depress lock cylinder

retaining tab and remove key cylinder (Fig. 41).

(3) Remove upper and lower shrouds from steering

column.

(4) Disconnect electrical connectors from ignition

switch.

(5) Remove ignition switch mounting screw (Fig.

42) with a #10 Torxtbit.

(6) Depress retaining tabs (Fig. 43) and pull igni-

tion switch from steering column.

INSTALLATION

(1) Ensure the ignition switch is in the RUN posi-

tion and the actuator shaft in the lock housing is in

the RUN position.

(2) Carefully install the ignition switch. The

switch will snap over the retaining tabs (Fig. 44).

Install mounting screw (Fig. 42).

Fig. 39 Engine Coolant Temperature SensorÐDOHC

Fig. 40 Ignition SwitchÐViewed From Below

Column

Fig. 41 Steering Column Shrouds

Fig. 42 Ignition Switch Mounting Screw

8D - 16 IGNITION SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 266 of 1200

(3) Install electrical connectors to ignition switch.

(4) Install upper and lower shrouds.

(5) Install key cylinder (cylinder retaining tab will

depress only in the RUN position).

(6) Connect negative cable to battery.

(7) Check for proper operation of ignition switch

and key-in warning switch.

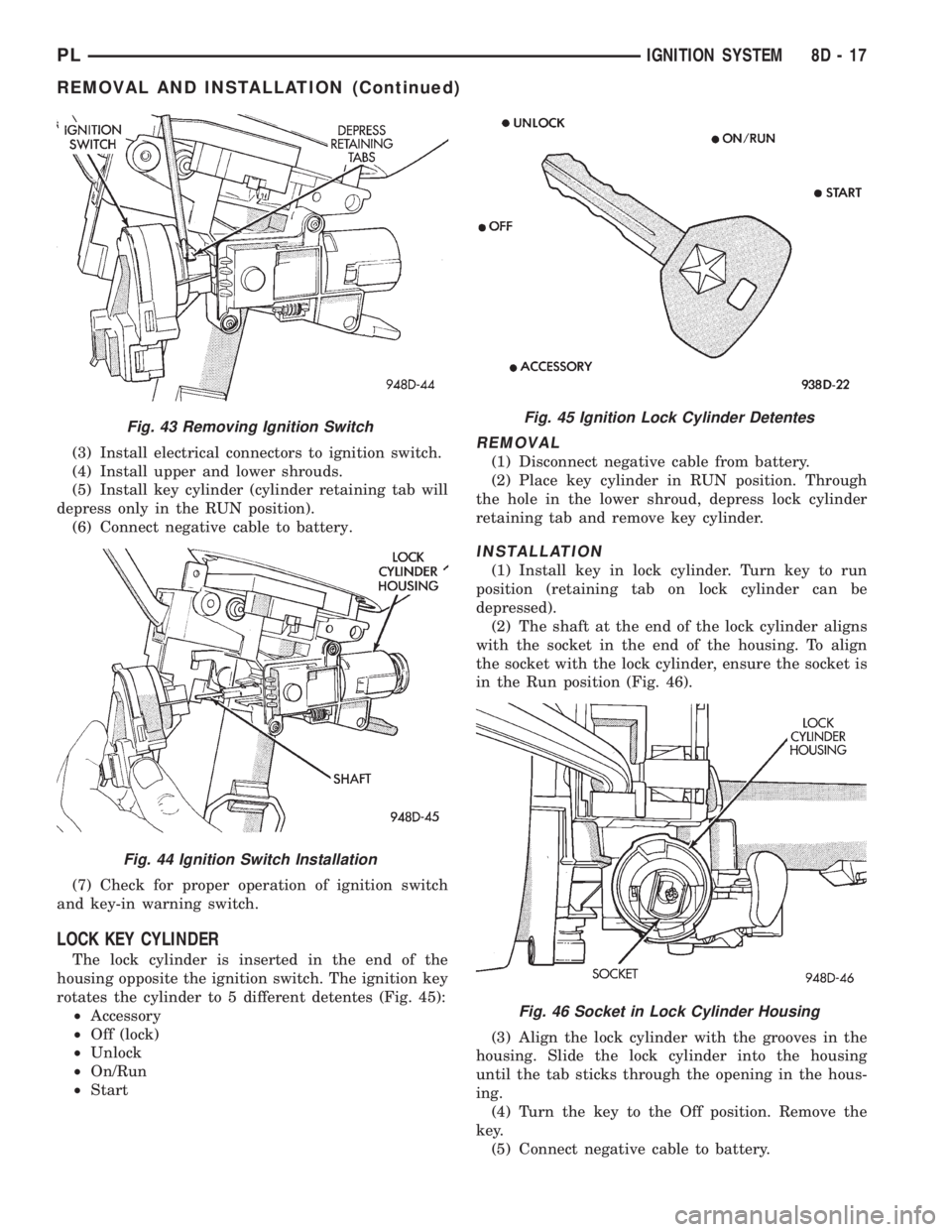

LOCK KEY CYLINDER

The lock cylinder is inserted in the end of the

housing opposite the ignition switch. The ignition key

rotates the cylinder to 5 different detentes (Fig. 45):

²Accessory

²Off (lock)

²Unlock

²On/Run

²Start

REMOVAL

(1) Disconnect negative cable from battery.

(2) Place key cylinder in RUN position. Through

the hole in the lower shroud, depress lock cylinder

retaining tab and remove key cylinder.

INSTALLATION

(1) Install key in lock cylinder. Turn key to run

position (retaining tab on lock cylinder can be

depressed).

(2) The shaft at the end of the lock cylinder aligns

with the socket in the end of the housing. To align

the socket with the lock cylinder, ensure the socket is

in the Run position (Fig. 46).

(3) Align the lock cylinder with the grooves in the

housing. Slide the lock cylinder into the housing

until the tab sticks through the opening in the hous-

ing.

(4) Turn the key to the Off position. Remove the

key.

(5) Connect negative cable to battery.

Fig. 43 Removing Ignition Switch

Fig. 44 Ignition Switch Installation

Fig. 45 Ignition Lock Cylinder Detentes

Fig. 46 Socket in Lock Cylinder Housing

PLIGNITION SYSTEM 8D - 17

REMOVAL AND INSTALLATION (Continued)

Page 270 of 1200

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

DOME LAMP............................ 1

ELECTRONIC DIGITAL CLOCK.............. 1

INSTRUMENT CLUSTER................... 2

WARNING AND INDICATOR LAMPS......... 2

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM............... 2

BRAKE SYSTEM WARNING LAMP TEST...... 2

FOG LAMP SWITCH TEST................. 2

FUEL TANK SENDING UNIT TEST........... 3

HEADLAMP SWITCH TEST................. 3

HEATER A/C BLOWER SWITCH TEST........ 3

HEATER BLOWER SWITCH TEST............ 3

INDIVIDUAL GAUGE INOPERATIVE.......... 4

INSTRUMENT PANEL AND COMPONENTS.... 4

LOW OIL PRESSURE WARNING LAMP TEST . . 4

MULTIPLE GAUGE INOPERATIVE TEST....... 4

SEAT BELT REMINDER SYSTEM TEST....... 6

SENDING UNIT......................... 6

SERVICE ENGINE SOON INDICATOR......... 6

VEHICLE SPEED SENSOR TEST............. 6

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP....... 6

CENTER BEZEL.......................... 6

CIGAR LIGHTER RECEPTACLE.............. 6

CLUSTER LAMP......................... 7

CLUSTER PRINTED CIRCUIT BOARD........ 7CLUSTER.............................. 7

DOME LENS/LAMP....................... 8

FLOOR CONSOLE........................ 8

GAUGE................................ 8

GLOVE BOX DOOR/BIN................... 8

GLOVE BOX SWITCH/LAMP................ 9

HEADLAMP SWITCH..................... 9

HEATER A/C CONTROL BLOWER SWITCH . . . 10

HEATER A/C CONTROL LAMP............ 10

HEATER A/C CONTROL................... 9

HEATER CONTROL BLOWER SWITCH....... 10

IGNITION KEY LAMP.................... 10

INSTRUMENT PANEL.................... 10

LEFT TRIM PANEL...................... 10

ODOMETER............................ 10

RADIO................................ 12

REAR WINDOW DEFOGGER AND/OR FOG

LAMP SWITCH....................... 12

RIGHT TRIM PANEL..................... 12

SHIFTER KNOB......................... 13

STEERING COLUMN COVER LINER......... 13

STEERING COLUMN COVER.............. 13

STEERING COLUMN SHROUDS............ 13

TOP COVER AND CLUSTER BEZEL

REMOVAL........................... 14

TRANSMISSION RANGE INDICATOR LAMP . . 14

TRUNK LAMP/LENS..................... 14

VEHICLE SPEED SENSOR................ 14

GENERAL INFORMATION

INTRODUCTION

The purpose of the dash gauges and indicator

lamps is to keep the driver informed about the oper-

ating condition of the vehicle. If an abnormal condi-

tion occurs, the driver is informed by indicator lamp.

The driver can seek service before damage occurs.

Indicator lamps use ON/OFF switch functions for

operation, while gauges use a sending unit or sensor.

DESCRIPTION AND OPERATION

DOME LAMP

The Dome Lamp operates when a door is open or

when the headlamp switch is placed in courtesy posi-

tion.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position.

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 279 of 1200

HEATER A/C CONTROL BLOWER SWITCH

The switch is not serviced, replace heater A/C con-

trol. Refer to the Heater A/C Control Removal and

Installation.

HEATER A/C CONTROL LAMP

REMOVAL

(1) Remove the Heater A/C Control. Refer to the

Heater A/C Control Removal.

(2) Remove the two center knobs by pulling the

knob rearward.

(3) Replace the lamp.

INSTALLATION

For installation, reverse the above procedures.

HEATER CONTROL BLOWER SWITCH

The switch is not serviced, replace the heater con-

trol. Refer to the A/C Heater Control Removal and

Installation.

IGNITION KEY LAMP

REMOVAL

(1) Remove the steering column cover. Refer to

Steering Column Cover Removal.

(2) Disconnect the lamp hood from the base panel.

(3) Remove the lamp socket from hood and replace

the lamp.

INSTALLATION

For installation, reverse the above procedures.

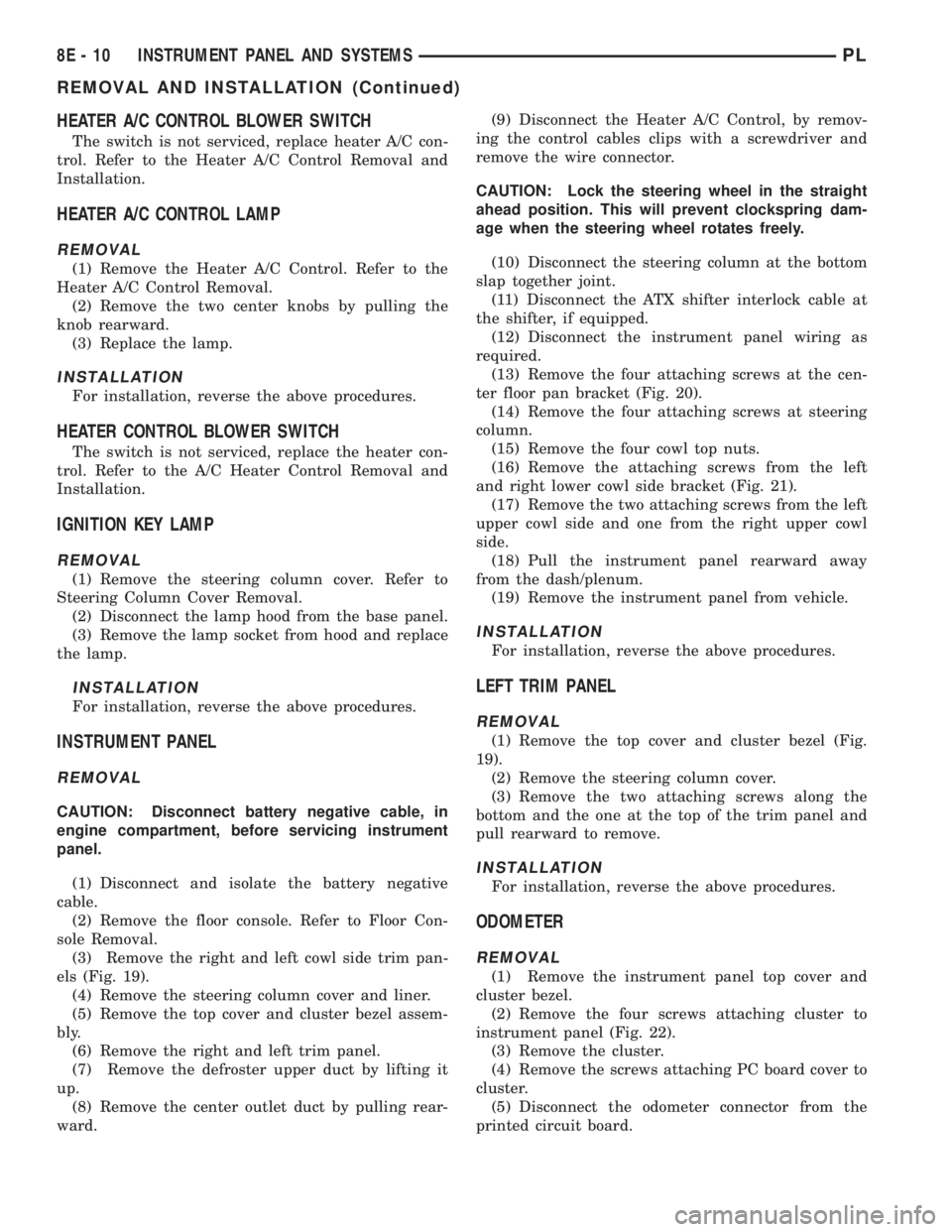

INSTRUMENT PANEL

REMOVAL

CAUTION: Disconnect battery negative cable, in

engine compartment, before servicing instrument

panel.

(1) Disconnect and isolate the battery negative

cable.

(2) Remove the floor console. Refer to Floor Con-

sole Removal.

(3) Remove the right and left cowl side trim pan-

els (Fig. 19).

(4) Remove the steering column cover and liner.

(5) Remove the top cover and cluster bezel assem-

bly.

(6) Remove the right and left trim panel.

(7) Remove the defroster upper duct by lifting it

up.

(8) Remove the center outlet duct by pulling rear-

ward.(9) Disconnect the Heater A/C Control, by remov-

ing the control cables clips with a screwdriver and

remove the wire connector.

CAUTION: Lock the steering wheel in the straight

ahead position. This will prevent clockspring dam-

age when the steering wheel rotates freely.

(10) Disconnect the steering column at the bottom

slap together joint.

(11) Disconnect the ATX shifter interlock cable at

the shifter, if equipped.

(12) Disconnect the instrument panel wiring as

required.

(13) Remove the four attaching screws at the cen-

ter floor pan bracket (Fig. 20).

(14) Remove the four attaching screws at steering

column.

(15) Remove the four cowl top nuts.

(16) Remove the attaching screws from the left

and right lower cowl side bracket (Fig. 21).

(17) Remove the two attaching screws from the left

upper cowl side and one from the right upper cowl

side.

(18) Pull the instrument panel rearward away

from the dash/plenum.

(19) Remove the instrument panel from vehicle.

INSTALLATION

For installation, reverse the above procedures.

LEFT TRIM PANEL

REMOVAL

(1) Remove the top cover and cluster bezel (Fig.

19).

(2) Remove the steering column cover.

(3) Remove the two attaching screws along the

bottom and the one at the top of the trim panel and

pull rearward to remove.

INSTALLATION

For installation, reverse the above procedures.

ODOMETER

REMOVAL

(1) Remove the instrument panel top cover and

cluster bezel.

(2) Remove the four screws attaching cluster to

instrument panel (Fig. 22).

(3) Remove the cluster.

(4) Remove the screws attaching PC board cover to

cluster.

(5) Disconnect the odometer connector from the

printed circuit board.

8E - 10 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 283 of 1200

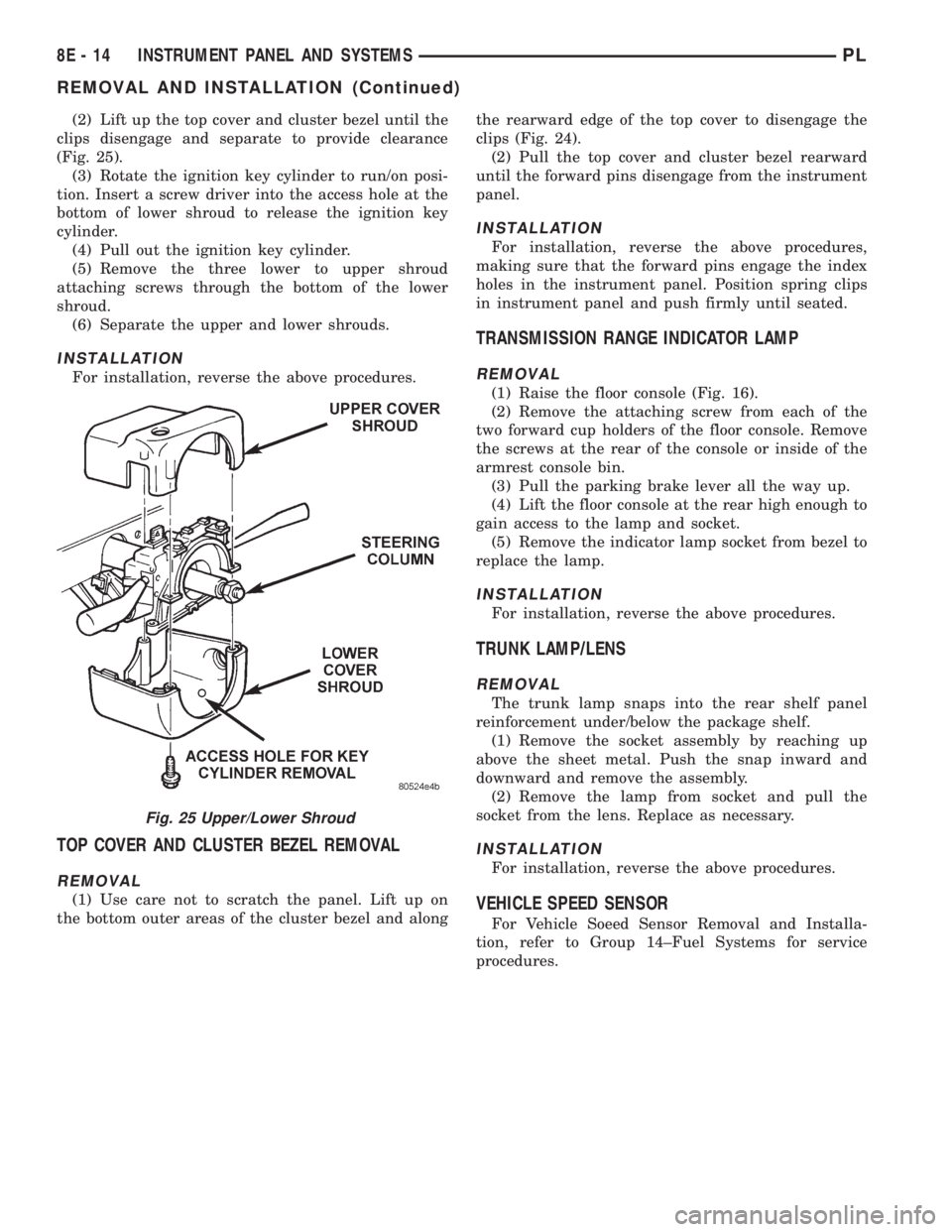

(2) Lift up the top cover and cluster bezel until the

clips disengage and separate to provide clearance

(Fig. 25).

(3) Rotate the ignition key cylinder to run/on posi-

tion. Insert a screw driver into the access hole at the

bottom of lower shroud to release the ignition key

cylinder.

(4) Pull out the ignition key cylinder.

(5) Remove the three lower to upper shroud

attaching screws through the bottom of the lower

shroud.

(6) Separate the upper and lower shrouds.

INSTALLATION

For installation, reverse the above procedures.

TOP COVER AND CLUSTER BEZEL REMOVAL

REMOVAL

(1) Use care not to scratch the panel. Lift up on

the bottom outer areas of the cluster bezel and alongthe rearward edge of the top cover to disengage the

clips (Fig. 24).

(2) Pull the top cover and cluster bezel rearward

until the forward pins disengage from the instrument

panel.

INSTALLATION

For installation, reverse the above procedures,

making sure that the forward pins engage the index

holes in the instrument panel. Position spring clips

in instrument panel and push firmly until seated.

TRANSMISSION RANGE INDICATOR LAMP

REMOVAL

(1) Raise the floor console (Fig. 16).

(2) Remove the attaching screw from each of the

two forward cup holders of the floor console. Remove

the screws at the rear of the console or inside of the

armrest console bin.

(3) Pull the parking brake lever all the way up.

(4) Lift the floor console at the rear high enough to

gain access to the lamp and socket.

(5) Remove the indicator lamp socket from bezel to

replace the lamp.

INSTALLATION

For installation, reverse the above procedures.

TRUNK LAMP/LENS

REMOVAL

The trunk lamp snaps into the rear shelf panel

reinforcement under/below the package shelf.

(1) Remove the socket assembly by reaching up

above the sheet metal. Push the snap inward and

downward and remove the assembly.

(2) Remove the lamp from socket and pull the

socket from the lens. Replace as necessary.

INSTALLATION

For installation, reverse the above procedures.

VEHICLE SPEED SENSOR

For Vehicle Soeed Sensor Removal and Installa-

tion, refer to Group 14±Fuel Systems for service

procedures.

Fig. 25 Upper/Lower Shroud

8E - 14 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)