key DODGE NEON 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 306 of 1200

the plunger reaches the end of its travel. A ratchet-

ing sound will be heard during this procedure.

Connect the wiring harness to the switch. Mount

the switch into the bracket by holding the switch

with the plunger facing forward in car. There is an

index key on the switch that mates with the bracket

slot at the top of the square hole. Align key and push

switch into square hole in bracket while depressing

the brake pedal. Once the switch is seated in the

hole, rotate clockwise approximately 30 degrees to

lock into place. The switch will automatically adjust

when the pedal is released. Pull back on the pedal to

assure correct adjustment.

SPEED CONTROL SERVO CABLE

REMOVAL

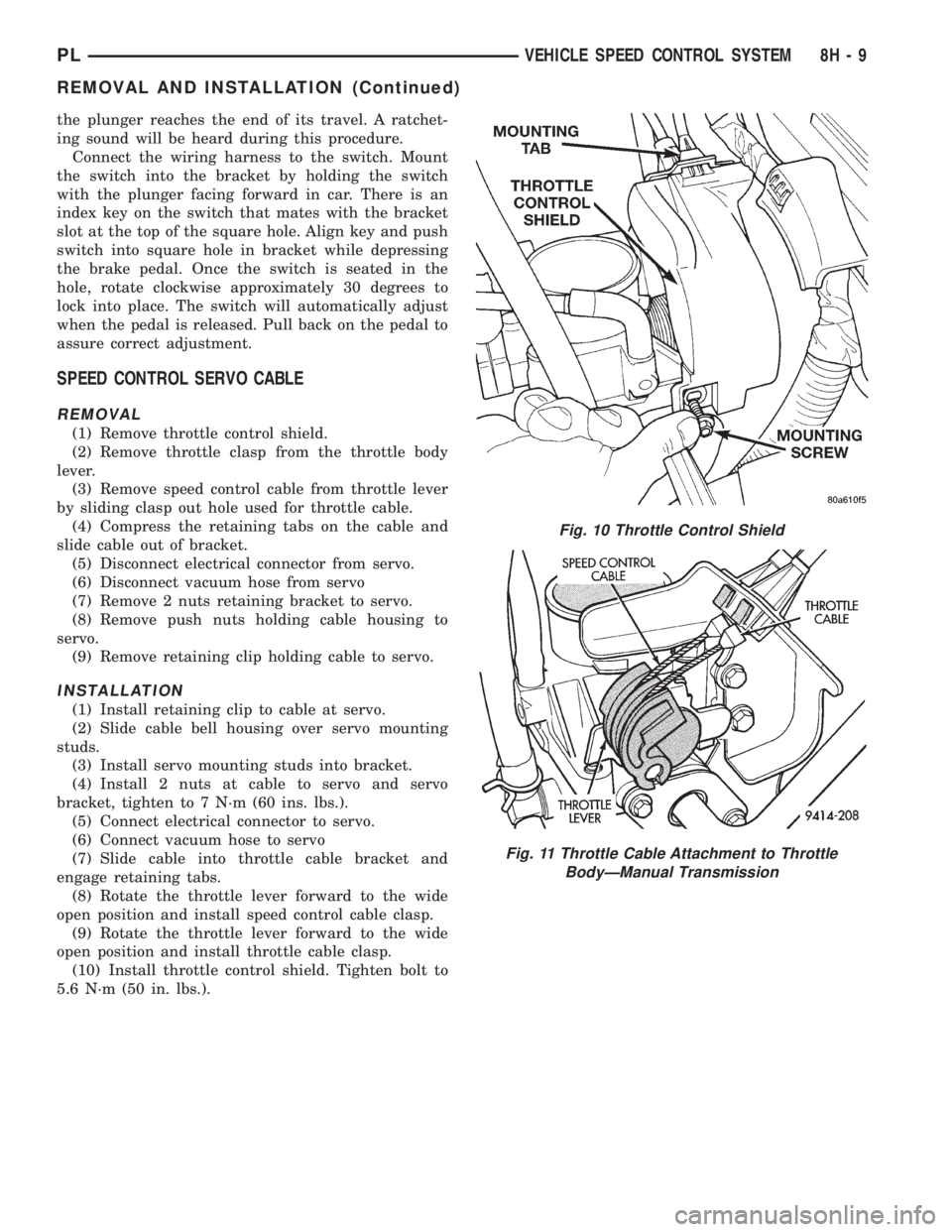

(1) Remove throttle control shield.

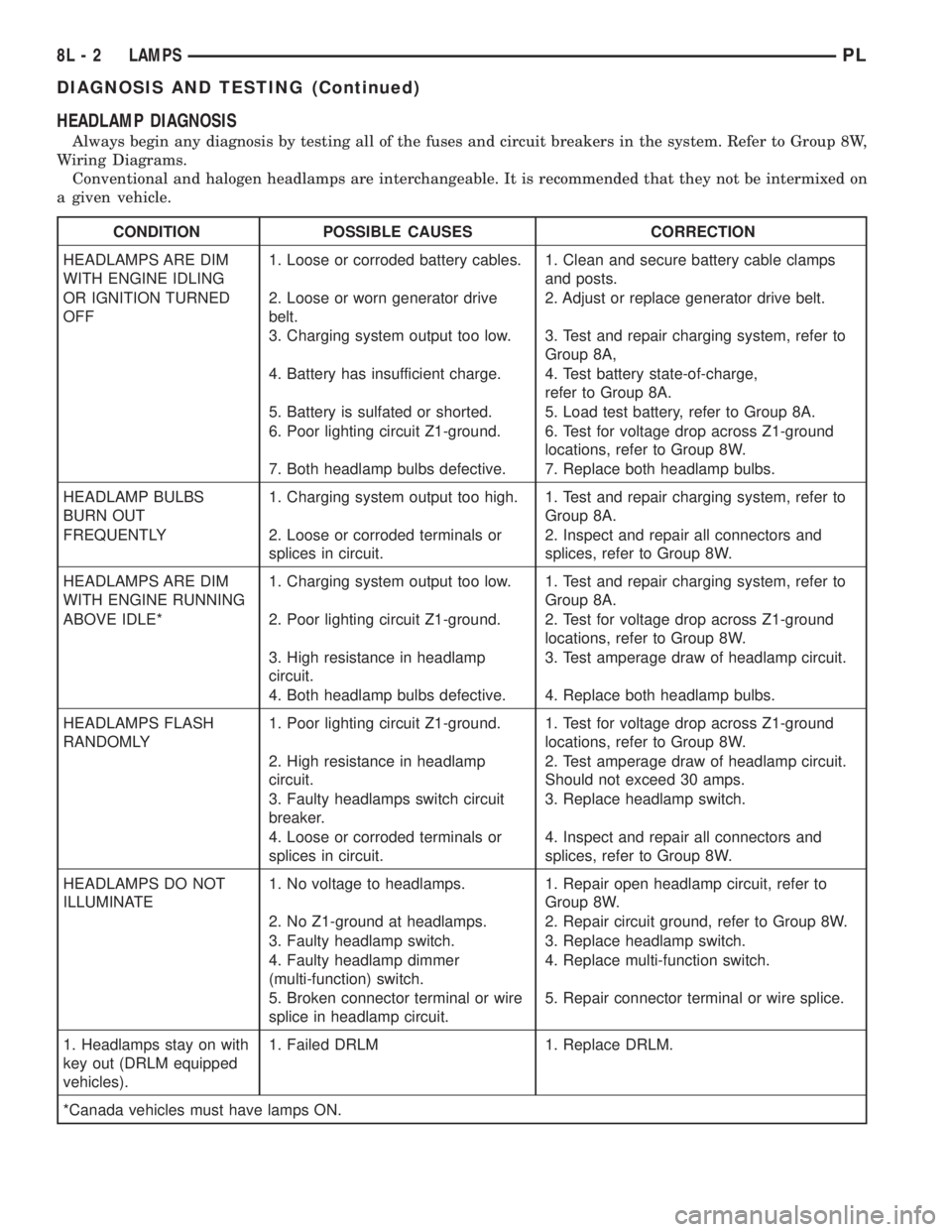

(2) Remove throttle clasp from the throttle body

lever.

(3) Remove speed control cable from throttle lever

by sliding clasp out hole used for throttle cable.

(4) Compress the retaining tabs on the cable and

slide cable out of bracket.

(5) Disconnect electrical connector from servo.

(6) Disconnect vacuum hose from servo

(7) Remove 2 nuts retaining bracket to servo.

(8) Remove push nuts holding cable housing to

servo.

(9) Remove retaining clip holding cable to servo.

INSTALLATION

(1) Install retaining clip to cable at servo.

(2) Slide cable bell housing over servo mounting

studs.

(3) Install servo mounting studs into bracket.

(4) Install 2 nuts at cable to servo and servo

bracket, tighten to 7 N´m (60 ins. lbs.).

(5) Connect electrical connector to servo.

(6) Connect vacuum hose to servo

(7) Slide cable into throttle cable bracket and

engage retaining tabs.

(8) Rotate the throttle lever forward to the wide

open position and install speed control cable clasp.

(9) Rotate the throttle lever forward to the wide

open position and install throttle cable clasp.

(10) Install throttle control shield. Tighten bolt to

5.6 N´m (50 in. lbs.).

Fig. 10 Throttle Control Shield

Fig. 11 Throttle Cable Attachment to Throttle

BodyÐManual Transmission

PLVEHICLE SPEED CONTROL SYSTEM 8H - 9

REMOVAL AND INSTALLATION (Continued)

Page 331 of 1200

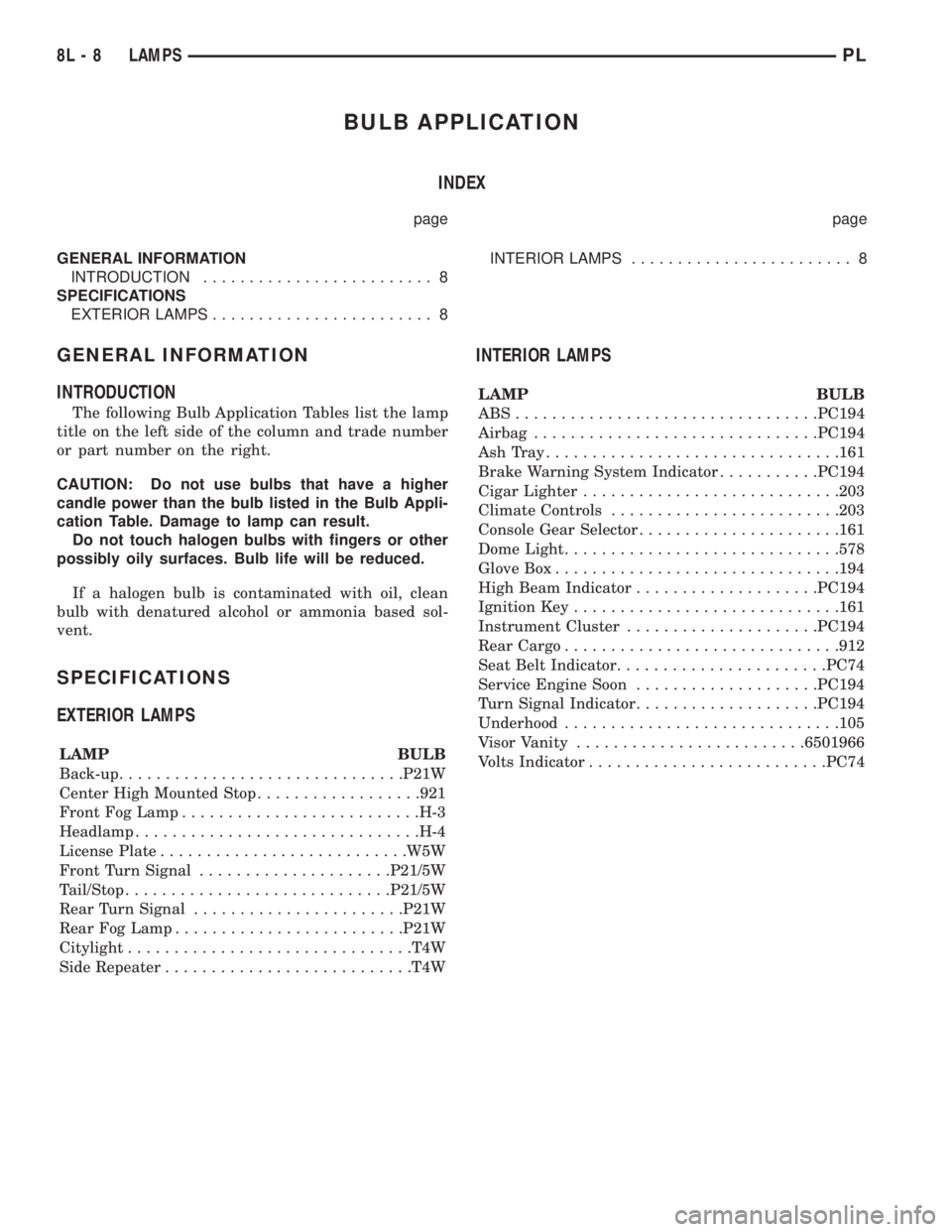

HEADLAMP DIAGNOSIS

Always begin any diagnosis by testing all of the fuses and circuit breakers in the system. Refer to Group 8W,

Wiring Diagrams.

Conventional and halogen headlamps are interchangeable. It is recommended that they not be intermixed on

a given vehicle.

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

OR IGNITION TURNED

OFF2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer to

Group 8A,

4. Battery has insufficient charge. 4. Test battery state-of-charge,

refer to Group 8A.

5. Battery is sulfated or shorted. 5. Load test battery, refer to Group 8A.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS

BURN OUT1. Charging system output too high. 1. Test and repair charging system, refer to

Group 8A.

FREQUENTLY 2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices, refer to Group 8W.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING1. Charging system output too low. 1. Test and repair charging system, refer to

Group 8A.

ABOVE IDLE* 2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations, refer to Group 8W.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp circuit.

Should not exceed 30 amps.

3. Faulty headlamps switch circuit

breaker.3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices, refer to Group 8W.

HEADLAMPS DO NOT

ILLUMINATE1. No voltage to headlamps. 1. Repair open headlamp circuit, refer to

Group 8W.

2. No Z1-ground at headlamps. 2. Repair circuit ground, refer to Group 8W.

3. Faulty headlamp switch. 3. Replace headlamp switch.

4. Faulty headlamp dimmer

(multi-function) switch.4. Replace multi-function switch.

5. Broken connector terminal or wire

splice in headlamp circuit.5. Repair connector terminal or wire splice.

1. Headlamps stay on with

key out (DRLM equipped

vehicles).1. Failed DRLM 1. Replace DRLM.

*Canada vehicles must have lamps ON.

8L - 2 LAMPSPL

DIAGNOSIS AND TESTING (Continued)

Page 351 of 1200

BULB APPLICATION

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 8

SPECIFICATIONS

EXTERIOR LAMPS........................ 8INTERIOR LAMPS........................ 8

GENERAL INFORMATION

INTRODUCTION

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

SPECIFICATIONS

EXTERIOR LAMPS

LAMP BULB

Back-up...............................P21W

Center High Mounted Stop..................921

Front Fog Lamp..........................H-3

Headlamp...............................H-4

License Plate...........................W5W

Front Turn Signal.....................P21/5W

Tail/Stop.............................P21/5W

Rear Turn Signal.......................P21W

Rear Fog Lamp.........................P21W

Citylight...............................T4W

Side Repeater...........................T4W

INTERIOR LAMPS

LAMP BULB

ABS.................................PC194

Airbag...............................PC194

AshTray................................161

Brake Warning System Indicator...........PC194

Cigar Lighter............................203

Climate Controls.........................203

Console Gear Selector......................161

Dome Light..............................578

Glove Box...............................194

High Beam Indicator....................PC194

Ignition Key.............................161

Instrument Cluster.....................PC194

Rear Cargo..............................912

Seat Belt Indicator.......................PC74

Service Engine Soon....................PC194

Turn Signal Indicator....................PC194

Underhood..............................105

Visor Vanity.........................6501966

Volts Indicator..........................PC74

8L - 8 LAMPSPL

Page 354 of 1200

DIAGNOSIS AND TESTING

AIRBAG SYSTEM TEST

(1) Disconnect and isolate the negative battery

cable.

(2) Connect scan tool (DRB) to Data Link connec-

tor, located at right side of the steering column and

at the lower edge of the lower instrument panel.

(3) Turn the ignition key to ON position. Exit vehi-

cle with scan tool. Use the latest version of the

proper cartridge.

(4) After checking that no one is inside the vehicle,

connect the battery negative terminal.

(5) Using the scan tool, read and record active

diagnostic code data.

(6) Read and record any stored diagnostic codes.

(7) Refer to the Passive Restraint Diagnostic Test

Manual if any diagnostic codes are found in Step 5 or

Step 6.

(8) Erase stored diagnostic codes if there are no

active diagnostic codes. If problems remain, diagnos-

tic codes will not erase. Refer to the Passive

Restraint Diagnostic Test Manual to diagnose the

problem.If the airbag warning lamp either fails

to light with the ignition switch on, or the light

goes on and stays on, there is a system malfunc-

tion. Refer to the Passive Restraint Diagnostic

Test Manual to diagnose the problem.

SERVICE PROCEDURES

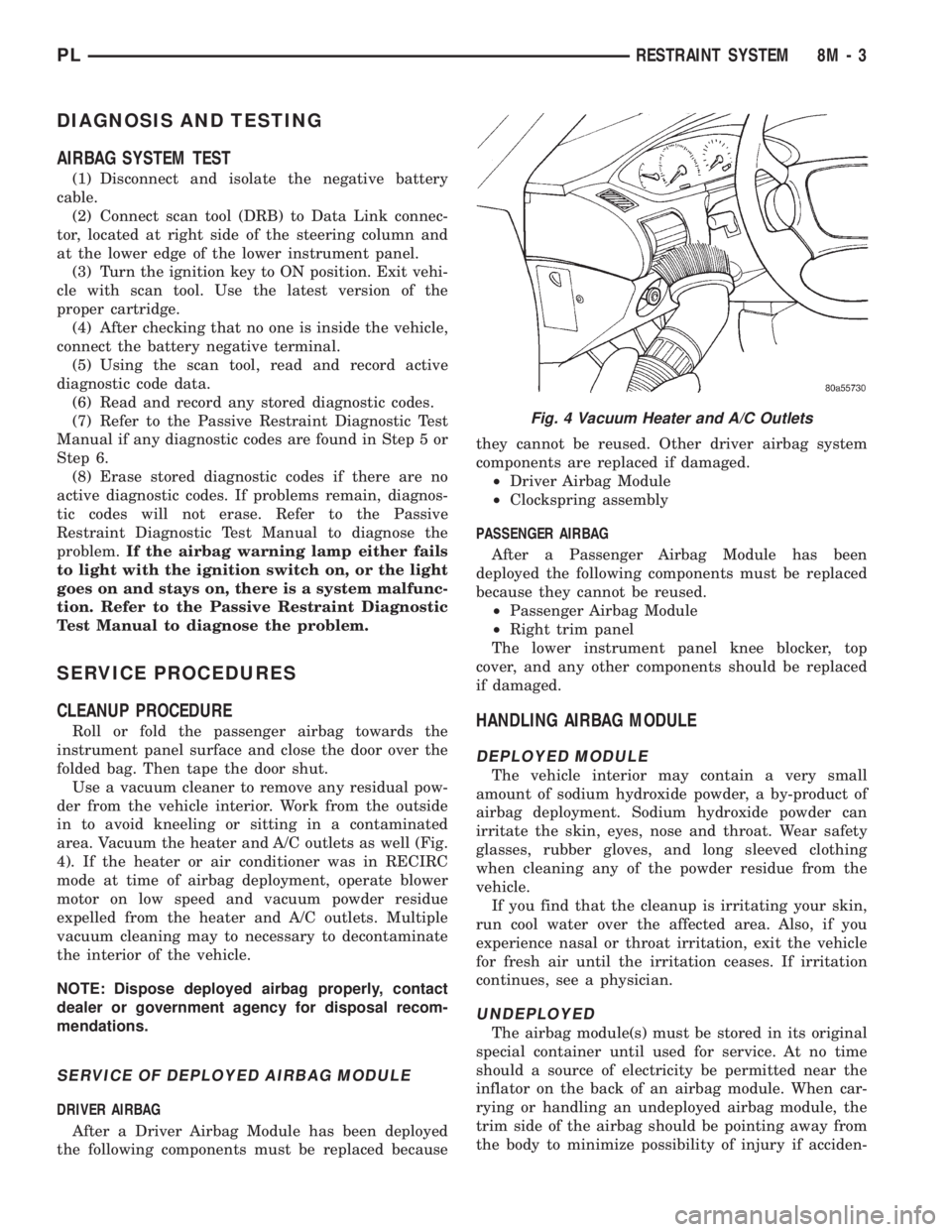

CLEANUP PROCEDURE

Roll or fold the passenger airbag towards the

instrument panel surface and close the door over the

folded bag. Then tape the door shut.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well (Fig.

4). If the heater or air conditioner was in RECIRC

mode at time of airbag deployment, operate blower

motor on low speed and vacuum powder residue

expelled from the heater and A/C outlets. Multiple

vacuum cleaning may to necessary to decontaminate

the interior of the vehicle.

NOTE: Dispose deployed airbag properly, contact

dealer or government agency for disposal recom-

mendations.

SERVICE OF DEPLOYED AIRBAG MODULE

DRIVER AIRBAG

After a Driver Airbag Module has been deployed

the following components must be replaced becausethey cannot be reused. Other driver airbag system

components are replaced if damaged.

²Driver Airbag Module

²Clockspring assembly

PASSENGER AIRBAG

After a Passenger Airbag Module has been

deployed the following components must be replaced

because they cannot be reused.

²Passenger Airbag Module

²Right trim panel

The lower instrument panel knee blocker, top

cover, and any other components should be replaced

if damaged.

HANDLING AIRBAG MODULE

DEPLOYED MODULE

The vehicle interior may contain a very small

amount of sodium hydroxide powder, a by-product of

airbag deployment. Sodium hydroxide powder can

irritate the skin, eyes, nose and throat. Wear safety

glasses, rubber gloves, and long sleeved clothing

when cleaning any of the powder residue from the

vehicle.

If you find that the cleanup is irritating your skin,

run cool water over the affected area. Also, if you

experience nasal or throat irritation, exit the vehicle

for fresh air until the irritation ceases. If irritation

continues, see a physician.

UNDEPLOYED

The airbag module(s) must be stored in its original

special container until used for service. At no time

should a source of electricity be permitted near the

inflator on the back of an airbag module. When car-

rying or handling an undeployed airbag module, the

trim side of the airbag should be pointing away from

the body to minimize possibility of injury if acciden-

Fig. 4 Vacuum Heater and A/C Outlets

PLRESTRAINT SYSTEM 8M - 3

Page 370 of 1200

POWER DOOR LOCKS

CONTENTS

page page

POWER DOOR LOCKS..................... 1REMOTE KEYLESS ENTRY.................. 3

POWER DOOR LOCKS

INDEX

page page

DESCRIPTION AND OPERATION

INTRODUCTION......................... 1

DIAGNOSIS AND TESTING

DOOR LOCK MOTOR..................... 1

DOOR LOCK SWITCH..................... 1WIRING................................ 1

REMOVAL AND INSTALLATION

DOOR LOCK MOTOR..................... 2

DOOR LOCK SWITCH..................... 2

DESCRIPTION AND OPERATION

INTRODUCTION

All doors can be locked or unlocked electrically by

operating the switch on either front door panels.

The rear doors can be locked or unlocked by actu-

ation of the front door switch, or can be locked or

unlocked mechanically and independently with their

respective locking knobs.

The front doors can be locked or unlocked mechan-

ically with the locking knob regardless of electrical

locking and unlocking actuation with the front door

knobs.

The right and left front door can be locked or

unlocked mechanically from the outside with the key

or electrically as described above.

CHILD PROTECTION LOCK

The child protection lock is on the rear door only.

The lock will disable the inside door handle from

opening the door when engaged. The lock is part of

the latch/lock assembly. The lock is engaged by mov-

ing a lever that is located on the rearward inside

edge of the door.

DIAGNOSIS AND TESTING

DOOR LOCK MOTOR

Make certain battery is in normal condition before

circuits are tested.To determine which motor is faulty, check each

individual door for electrical lock and unlock or dis-

connect the motor connectors one at a time, while

operating the door lock switch. In the event that

none of the motors work, the problem maybe caused

by a shorted motor, or a bad switch. Disconnecting

the defective motor will allow the others to work.

To test an individual door lock motor, disconnect

the electrical connector from the motor. To lock the

door, connect a 12 volt power source to the positive

pin of the lock motor and a ground wire to the other

pin (Fig. 1) To unlock the door reverse the wire con-

nections at the motor pin terminals. If these results

are NOT obtained, replace the door latch assembly.

DOOR LOCK SWITCH

Remove the switch from its mounting location.

Using an ohmmeter, refer to (Fig. 2) to determine if

continuity is correct in the Lock and Unlock switch

positions. If these results are not obtained, replace

the switch.

WIRING

The following wiring test sequence determines

whether or not voltage is continuous through the

body harness to switch.

(1) Remove left side switch from door trim panel.

(2) Carefully separate multiple terminal block on

wiring harness from switch body.

PLPOWER DOOR LOCKS 8P - 1

Page 372 of 1200

REMOTE KEYLESS ENTRY

INDEX

page page

GENERAL INFORMATION

INTRODUCTION......................... 3

DESCRIPTION AND OPERATION

VEHICLE ACCESS CODE (VAC)

PROGRAMMING........................ 3

DIAGNOSIS AND TESTING

REMOTE KEYLESS ENTRY CONDITION....... 4

REMOTE KEYLESS ENTRY SYSTEM......... 5

SERVICE PROCEDURES

HORN CHIRP CANCELLATION.............. 5PANIC FUNCTION CANCELLATION........... 5

PROGRAM REMOTE KEYLESS ENTRY

MODULE.............................. 5

REMOVAL AND INSTALLATION

REMOTE KEYLESS ENTRY MODULE......... 6

SPECIFICATIONS

RKE TRANSMITTER BATTERY.............. 6

RKE TRANSMITTER RANGE................ 6

GENERAL INFORMATION

INTRODUCTION

The key fob transmitter has three buttons to actu-

ate and program the Remote Keyless Entry (RKE)

system (Fig. 1).

²UNLOCK: Actuating the UNLOCK button once

will unlock the driver door and activate the illumi-

nated entry system. Actuating the UNLOCK button

twice within five seconds will unlock all doors.

²LOCK: Actuating the LOCK button locks all

doors and sounds horn (chirp). The chirp verifies the

door lock operation.

²PANIC: Actuating the PANIC button sounds the

horns and alternately flashes the headlamps and

parking lamps. The panic alarm will remain on for

one minute, until the PANIC button is actuated

again or the ignition is switched to the RUN position.

²The Remote Keyless Entry Module is capable of

retaining the transmitter Vehicle Access Code (VAC)

in memory even after vehicle power has been inter-

rupted.

DESCRIPTION AND OPERATION

VEHICLE ACCESS CODE (VAC) PROGRAMMING

The system allows locking and unlocking of vehicle

door(s) by remote control using a hand held radio fre-

quency transmitter. The ignition switch must be OFF

before the panic function can be activated with the

transmitter.

The receiver may receive VAC signals from two

transmitters. Each transmitter has its own VehicleAccess Code and the code is programmed and stored

into receiver memory. If the transmitter is replaced

or a second transmitter is added, the codes of both

units have to be reprogrammed into the receiver

memory. If a receiver module is replaced, both the

transmitter codes must be stored in the new receiver

memory.

OPERATION

The transmitter has three buttons for operation

(Fig. 1). They are LOCK, UNLOCK and PANIC.

The receiver is capable of retaining all Vehicle

Access Codes (VAC) even when power is removed.

Each remote keyless entry module (RKE) must

have at least one and no more than two transmitters.

Fig. 1 Key Fob Transmitter

PLPOWER DOOR LOCKS 8P - 3

Page 373 of 1200

DIAGNOSIS AND TESTING

REMOTE KEYLESS ENTRY CONDITION

Use an analog voltmeter for the following test.

REMOTE KEYLESS ENTRY GENERAL CHECKS

BEFORE OTHER CHECKS.

(1) Check if door locks operate properly. If not OK,

repair as necessary.

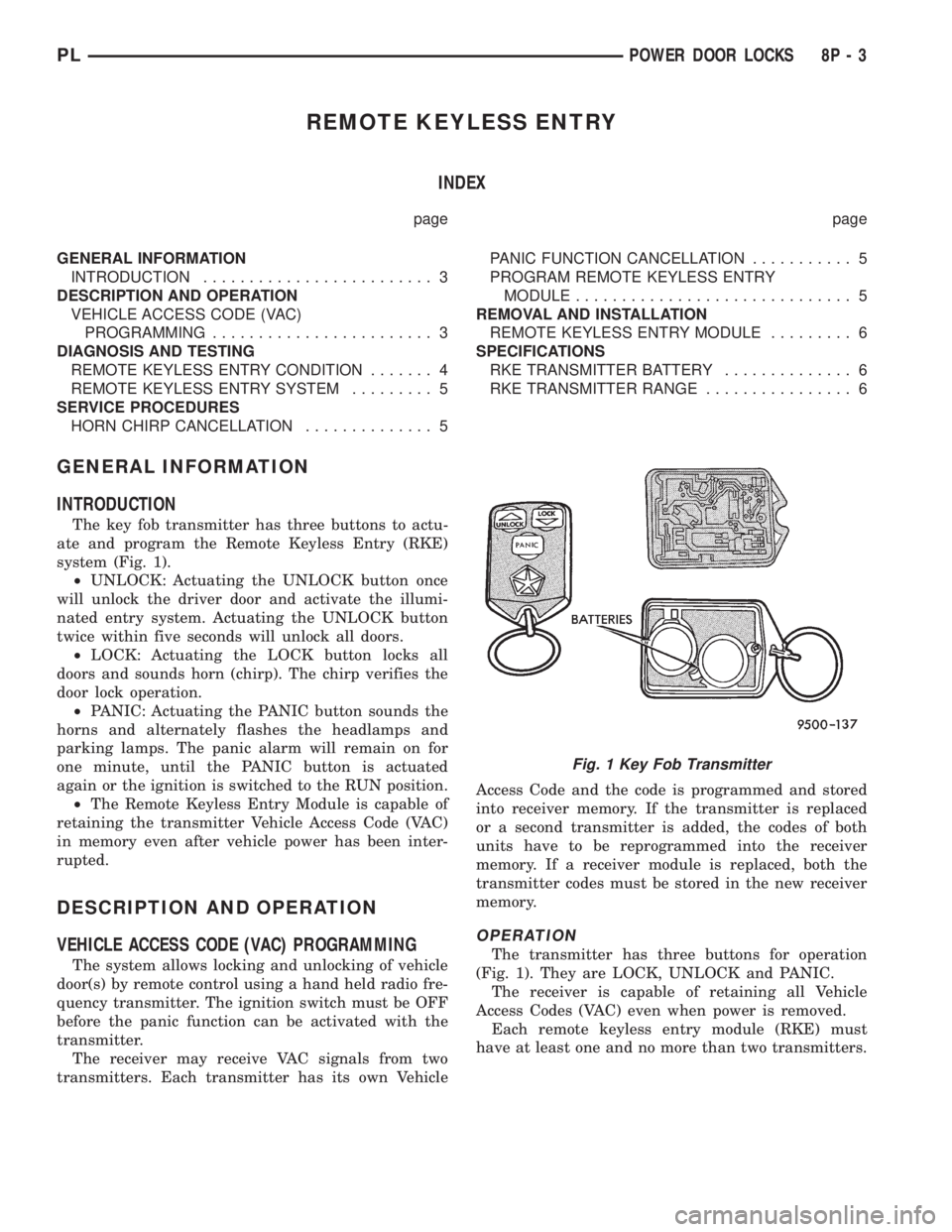

(2) Disconnect the wire connectors at the RKE

module Using a ohmmeter check for continuity

between the Pins of the wire connectors (Fig. 2):

²Pin 1 to Pin 4 of the gray connector.

²Pin 2 to Pin 3 of the gray connector.

²Pin 1 of the black connector to Pin 3 of the gray

connector.

If no continuity repair as necessary. Refer to Group

8W, Wiring Diagrams.

(3) Using a voltmeter, check the wire connectors

for battery feed and ignition feed (Fig. 2):

²Check Pin 2 of the black connector for battery

feed.

²Check Pin 8 of the black connector for ignition

feed with the ignition key in the ON position.

If not OK, check and repair as necessary.

(4) Using a ohmmeter, check the Pin 8 of the black

connector for continuity to ground. If not OK, check

and repair as necessary (Fig. 2).

(5) Test transmitter batteries for at least six volts.

If not OK, replace batteries as necessary.

(6) Check if module is programmed properly. Refer

to Program Remote Keyless Entry Module. If module

will not program check for continuity between Pin 4

of the black connector to the programming line con-

nector (Fig. 2). If no continuity repair as necessary,

refer to Group 8W, Wiring Diagrams.

(7) Check if horn operates properly. If not OK,

repair as necessary.

DRIVER DOOR WILL NOT UNLOCK WITH THE

TRANSMITTER

(1) Using an analog voltmeter, connect the meter

to Pin 1 of the black connector and to ground. Press

the unlock button once and check for a voltage pulse

(Fig. 2).

(2) If no voltage pulse is measured, replace the

receiver. If voltage pulse is measured, check the wir-

ing to the driver door and repair as necessary.

DRIVER DOOR WILL UNLOCK WITH THE

TRANSMITTER, BUT ALL OTHER DOORS WILL

NOT UNLOCK

(1) Using an analog voltmeter, connect the meter

to Pin 3 of the gray connector and to ground (Fig. 2).

Press the unlock button twice within five seconds

and check for a voltage pulse.

(2) If no voltage pulse is measured, replace the

receiver. If voltage pulse is measured, check the wir-

ing to the passenger door lock motors and repair as

necessary.

ALL DOORS WILL NOT LOCK WITH THE

TRANSMITTER

(1) Using an analog voltmeter, connect the meter

to Pin 1 of the gray connector and to ground. Press

the lock button and check for a voltage pulse (Fig. 2).

(2) If no voltage pulse is measured, replace the

receiver. If voltage pulse is measured, check the wir-

ing to the door lock motors and repair as necessary.

DOORS WILL LOCK USING THE

TRANSMITTER BUT THERE IS NO HORN

CHIRP

(1) Using an analog voltmeter, connect the meter

to Pin 6 of the gray connector and to ground. Press

the lock button and check for a voltage pulse

decrease (Fig. 2).

(2) If no voltage pulse decrease is measured,

replace the receiver. If voltage OK, repair circuit to

the horn relay as necessary.

ILLUMINATED ENTRY FAILS TO WORK IN

INITIAL UNLOCKING WITH TRANSMITTER

(1) Using an analog voltmeter, connect the meter

to Pin 6 of the black connector and to ground. Press

the lock button and check for a voltage pulse

decrease (Fig. 2).

(2) If no voltage pulse decrease is measured,

replace the receiver. If voltage OK, repair circuit to

the dome as necessary.

PARKING LAMPS AND/OR HEAD LAMPS FAIL

TO FLASH WITH PANIC BUTTON

(1) Using an analog voltmeter, connect the meter

to Pin 5 of the gray connector and to ground to test

Fig. 2 Remote Keyless Entry Module

8P - 4 POWER DOOR LOCKSPL

Page 374 of 1200

parking lamps out put. Press the panic button and

check for a voltage pulse (Fig. 2).

(2) If no voltage pulse is measured, replace the

receiver. If voltage OK, repair circuit to the parking

lamps as necessary.

(3) Connect the meter to Pin 5 of the black connec-

tor and to ground to test head lamps out put. Press

the panic button and check for a voltage pulse (Fig.

2).

(4) If no voltage pulse is measured, replace the

receiver. If voltage OK, repair circuit to the head

lamps as necessary.

REMOTE KEYLESS ENTRY SYSTEM

When trouble shooting problems with the Remote

Keyless Entry System, always verify that the power

door lock/unlock switches are functional. If the doors

do not lock/unlock refer to Group 8W, Wiring Dia-

gram for Pin and wiring locations.

If the following items do not work:

²Remote keyless entry system

²Radio/clock

²Door lock switches

A blown fuse is the probable cause. Check fuses 2,

3 and 11 in the fuse block. To check for a blown fuse,

pull the fuse out slightly, but maintain contact

between the fuse terminals and the terminals in fuse

block. Using the voltmeter probe, check both termi-

nals for 12 volts. If only one terminal measures bat-

tery voltage, the circuit breaker is defective and must

be replaced. If neither terminal measures battery

voltage, check the high current fuses 3 and 11 in the

Power Distribution Center (PDC). The PDC is located

in the engine compartment. If fuse(s) are NOT OK,

replace fuse(s) or repair as necessary. If fuses are

OK, check for an open or shorted circuit to the Power

Distribution Center, repair as needed.

SERVICE PROCEDURES

HORN CHIRP CANCELLATION

During the programming operation the horn chirp

can be disabled or enable using the following proce-

dure. One or both transmitters can be program to be

disabled or enable.

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel upper

edge. The RKE Programming Line is a green wire

with a red bullet connector.

(2) Using a jumper wire, ground the RKE pro-

gramming line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter. The locks

will cycle to confirm programming,

(5) To disable or enable horn chirp press the lock

button on the transmitter four times and the hornwill sound to confirm programming. Press the lock

button on the second transmitter four times and the

horn will sound to confirm programming.

(6) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(7) Replace any removed components. Return pro-

gramming line chirpto its original position. Check for

system operation.

PANIC FUNCTION CANCELLATION

During the programming operation the panic func-

tion can be disabled or enable using the following

procedure. One or both transmitters can be program

to be disabled or enable.

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel. The RKE

Program Line is a green wire with a red bullet con-

nector.

(2) Using a jumper wire, ground the RKE Pro-

gramming Line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter. The locks

will cycle to confirm programming,

(5) To disable or enable panic function press the

panic button on the transmitter four times and the

horn will sound to confirm programming. Press the

panic button on the second transmitter four times

and the horn will sound to confirm programming.

(6) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(7) Replace any removed components. Return the

programming line to its original position. Check for

system operation.

PROGRAM REMOTE KEYLESS ENTRY MODULE

(1) Retrieve the programming line from the upper

edge of the passenger side cowl trim panel. The RKE

Programming Line is a green wire with a red bullet

connector.

(2) Using a jumper wire, ground the RKE pro-

gramming line.

(3) Turn ignition switch to the ON position.

(4) Press any button on the transmitter to set

code. The locks will cycle to confirm programming. If

there is a second transmitter it must be set at this

time. Press any button on the second transmitter and

wait for the locks to cycle to confirm programming.

(5) Disconnect the programming line from ground.

This returns the system to its normal operation

mode.

(6) Replace all removed components. Return pro-

gramming line to its original position. Check for sys-

tem operation.

PLPOWER DOOR LOCKS 8P - 5

DIAGNOSIS AND TESTING (Continued)

Page 375 of 1200

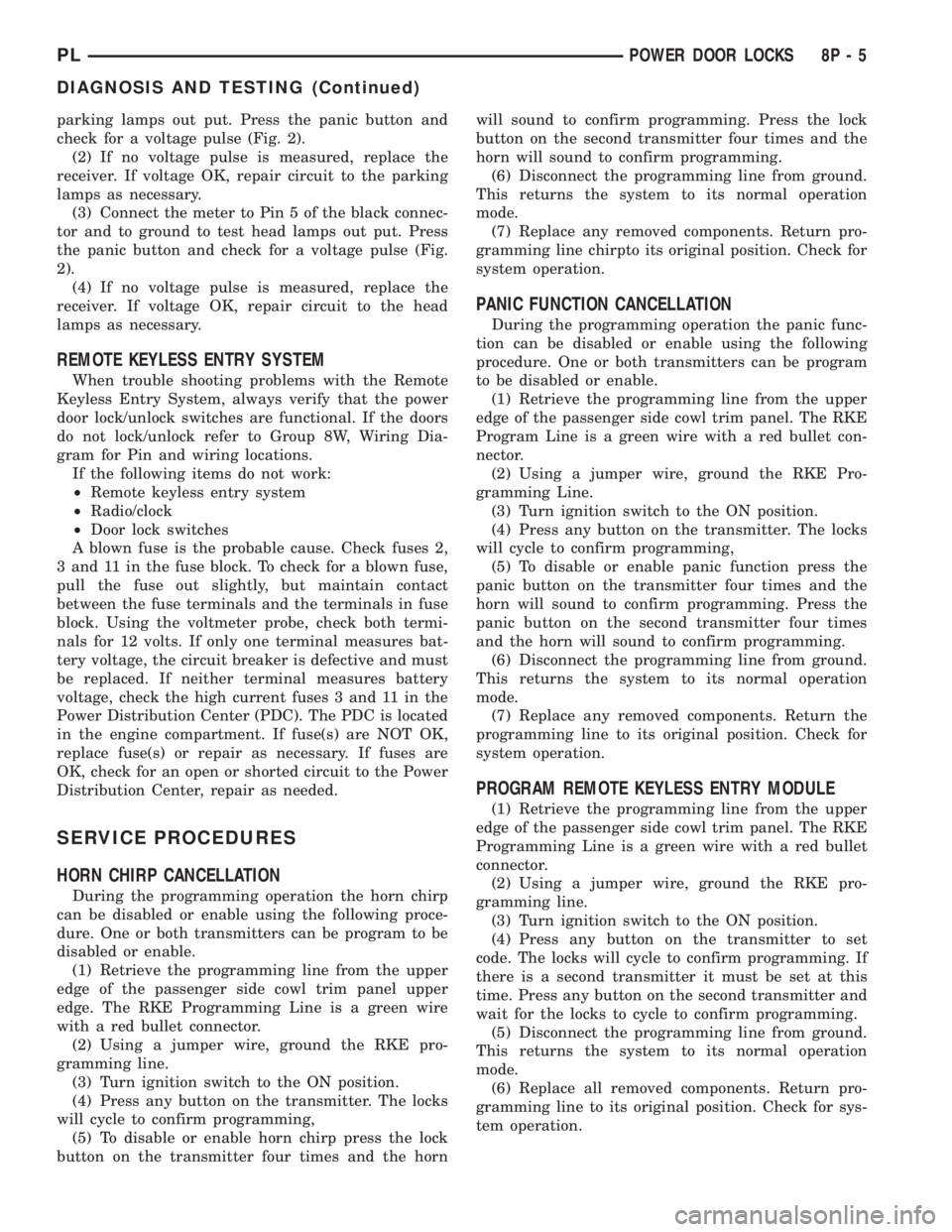

REMOVAL AND INSTALLATION

REMOTE KEYLESS ENTRY MODULE

REMOVAL

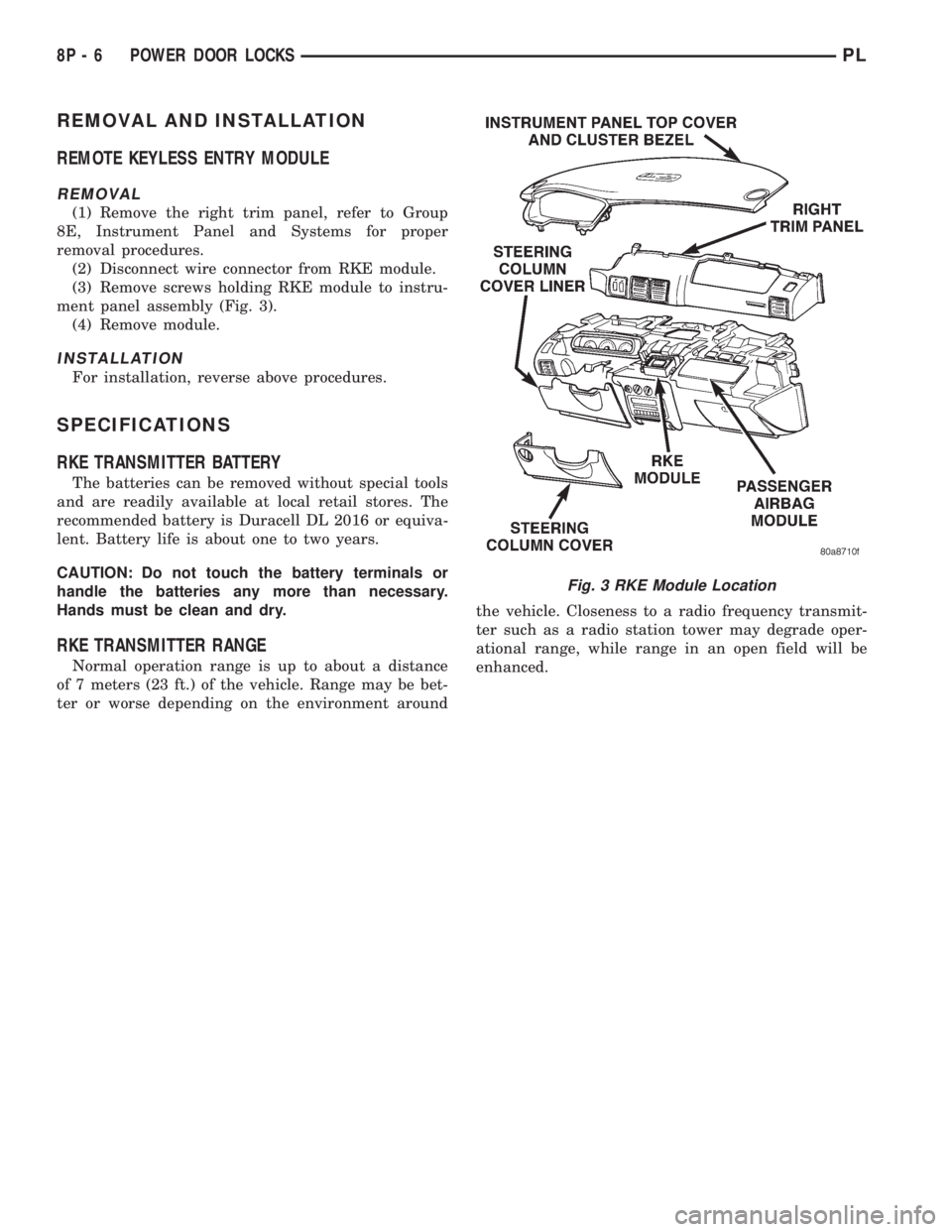

(1) Remove the right trim panel, refer to Group

8E, Instrument Panel and Systems for proper

removal procedures.

(2) Disconnect wire connector from RKE module.

(3) Remove screws holding RKE module to instru-

ment panel assembly (Fig. 3).

(4) Remove module.

INSTALLATION

For installation, reverse above procedures.

SPECIFICATIONS

RKE TRANSMITTER BATTERY

The batteries can be removed without special tools

and are readily available at local retail stores. The

recommended battery is Duracell DL 2016 or equiva-

lent. Battery life is about one to two years.

CAUTION: Do not touch the battery terminals or

handle the batteries any more than necessary.

Hands must be clean and dry.

RKE TRANSMITTER RANGE

Normal operation range is up to about a distance

of 7 meters (23 ft.) of the vehicle. Range may be bet-

ter or worse depending on the environment aroundthe vehicle. Closeness to a radio frequency transmit-

ter such as a radio station tower may degrade oper-

ational range, while range in an open field will be

enhanced.

Fig. 3 RKE Module Location

8P - 6 POWER DOOR LOCKSPL

Page 376 of 1200

IMMOBILIZER SYSTEM

CONTENTS

page page

DESCRIPTION AND OPERATION

IMMOBILIZER RECEIVER................ 1

IMMOBILIZER SYSTEM.................. 1

IMMOBILIZER TRANSMITTER............. 2

POWER-UP MODE...................... 2

DIAGNOSIS AND TESTING

IMMOBILIZER DIAGNOSIS............... 2SERVICE PROCEDURES

VEHICLE IMMOBILIZER SYSTEM.......... 3

REMOVAL AND INSTALLATION

IMMOBILIZER RECEIVER................ 3

DESCRIPTION AND OPERATION

IMMOBILIZER SYSTEM

The Immobilizer system includes the following

unique items:

²An immobilizer module receiver that controls

system operation and also controls the RKE and Illu-

minated entry systems, if equipped.

²An encoded Crankshaft Position Sensor for the

ignition system. The Immobilizer module decodes the

signal from the crankshaft so the PCM can recognize

it as a valid Crankshaft Position Sensor signal, and

allow the engine to run.

²A wiring harness that interconnects the crank-

shaft sensor, the immobilizer receiver, and the PCM.

²Two key fob transmitters.

The Immobilizer System prevents unauthorized

operation of the vehicle by disabling the engine and

starter. The system will NOT allow the vehicle to

start unless the UNLOCK button on the RKE trans-

mitter is pressed. The system will be activated after

turning the ignition switch to the OFF position and

using one of the following methods.

(1) Press the LOCK button on the RKE transmit-

ter.

(2) LOCK the doors by pressing a power lock but-

ton switch.

(3) LOCK the driver or passenger door using the

key.

²The Security light will flash, for about 16 sec-

onds, indicating that the engine and starter will be

disabled.

²The Security light remaining on, indicates the

system is not operational.

²The Immobilizer will activate automatically

within 10 minutes of the ignition switch being in the

OFF position, whether the vehicle has been locked or

unlocked.²An attempt to start the vehicle without pressing

the UNLOCK button on the RKE transmitter will

result in a warning chime and the Security light

flashing.

NOTE: The ignition switch must be in the OFF posi-

tion in order for the system to be activated, whether

the doors are closed or not.

IMMOBILIZER RECEIVER

The immobilizer receiver is programmed to

respond to the Lock and Unlock radio signals issued

by the immobilizer transmitters. The receiver will

only respond to the radio signals of transmitters (up

to four) whose vehicle access codes have been stored

in the receiver's electronic memory. The receiver is

programmed at the assembly plant with the vehicle

access codes of the two transmitters that are shipped

with the vehicle.

The immobilizer receiver also has a central pro-

cessing unit, which contains the immobilizer system

logic. The programming in the immobilizer receiver

allows the system to learn and retain transmitter

vehicle access codes, as well as to communicate with

the Powertrain Control Module (PCM) and/or the

DRB scan tool on the Chrysler Collision Detection

(CCD) data bus network.

The CCD data bus network allows the sharing of

sensor information. This helps to reduce wiring har-

ness complexity, reduce internal controller hardware,

and reduce component sensor current loads. At the

same time, the CCD data bus network provides

increased reliability and enhanced diagnostic capabil-

ities.

Each immobilizer transmitter has a different vehi-

cle access code, which must be programmed into the

memory of the immobilizer receiver in the vehicle in

order to operate the immobilizer system. A DRB scan

tool must be used to program new or additional

PLIMMOBILIZER SYSTEM 8Q - 1