roof DODGE NEON 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 1082 of 1200

BODY

CONTENTS

page page

BODY COMPONENTS...................... 2

GENERAL SERVICE INFORMATION........... 1

PAINT................................. 41STATIONARY GLASS...................... 43

SUNROOF.............................. 47

GENERAL SERVICE INFORMATION

INDEX

page

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS...... 1

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use

when welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body. Most of these fasteners can be

reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

PLBODY 23 - 1

Page 1083 of 1200

BODY COMPONENTS

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 3

WIND NOISE............................ 4

SERVICE PROCEDURES

HEAT STAKING.......................... 4

REMOVAL AND INSTALLATION

WINDOW REGULATORÐ4 DOOR........... 36

A-PILLAR TRIM.......................... 4

B-PILLAR APPLIQUEÐ2 DOOR.............. 5

B-PILLAR APPLIQUEÐ4 DOOR.............. 5

B-PILLAR TRIMÐ4 DOOR.................. 6

B-PILLAR WEATHERSTRIP CHANNEL......... 6

BODY VENT............................. 6

CARPET............................... 7

CHILD RESTRAINT SEAT BACK............. 8

CHILD SEAT MODULE..................... 8

COWL COVER........................... 7

DOOR HINGE........................... 9

DOOR LOCK CYLINDER.................. 10

DOOR OPENING TRIM WELT.............. 10

DOOR SILL TRIM........................ 10

DOOR................................. 9

FLOOR CONSOLE LATCH................. 11

FLOOR CONSOLE....................... 11

FRONT DOOR CHECK STOP............... 11

FRONT DOOR GLASSÐ2 DOOR............ 12

FRONT DOOR GLASSÐ4 DOOR............ 13

FRONT DOOR INNER BELT WEATHERSTRIP . . 13

FRONT DOOR LATCH STRIKER............ 14

FRONT DOOR LATCH.................... 13

FRONT DOOR OUTER BELT WEATHERSTRIP . 14

FRONT DOOR OUTSIDE HANDLE........... 14

FRONT DOOR TRIM PANEL................ 14

FRONT DOOR WATER SHIELD............. 16

FRONT DOOR WEATHERSTRIP............ 16

FRONT OUTBOARD SEAT BELT............ 17

FRONT SEAT BELT BUCKLE............... 18

FRONT SEAT BELT RETRACTOR........... 18

FRONT SEAT........................... 17

FRONT SHOULDER BELT ADJUSTER........ 18

FRONT VERTICAL GUIDE BAR............. 18

GRILLE............................... 19

HEADLINING........................... 19

HOOD HINGE.......................... 20

HOOD LATCH.......................... 21

HOOD RELEASE CABLE.................. 21

HOOD................................ 20

LOCK BUTTON BELL-CRANK.............. 21

LOWER QUARTER TRIMÐ4 DOOR.......... 22PARCEL SHELF TRIM.................... 22

QUARTER TRIM PANELÐ2 DOOR........... 22

REAR DOOR GLASS..................... 23

REAR DOOR INNER BELT WEATHERSTRIP . . . 23

REAR DOOR INTERLOCK LATCH STRIKER . . . 24

REAR DOOR LATCH STRIKER............. 24

REAR DOOR LATCH..................... 24

REAR DOOR LOCK BELL CRANK........... 24

REAR DOOR OUTER BELT WEATHERSTRIP . . 25

REAR DOOR TRIM....................... 25

REAR DOOR WINDOW REGULATOR........ 25

REAR SEAT BACK....................... 26

REAR SEAT BELT BUCKLE................ 26

REAR SEAT BELT RETRACTOR............ 26

REAR SEAT CUSHION.................... 26

REAR SPOILER......................... 27

REAR VERTICAL GUIDE BAR.............. 27

ROOF APERTURE (RAP) MOLDING.......... 28

ROOF RACK CROSS RAILS............... 28

ROOF RACK........................... 28

ROOF RAIL WEATHER-STRIP FOUR DOOR . . . 29

ROOF RAIL WEATHER-STRIP ± TWO DOOR . . . 29

SIDE COWL TRIM....................... 30

SIDE VIEW MIRROR STANCHION........... 31

SIDE VIEW MIRROR TRIM COVER.......... 31

SIDE VIEW MIRROR..................... 30

SUN VISOR SUPPORT................... 31

SUN VISOR............................ 31

TRUNK CARPET........................ 31

TRUNK LATCH STRIKER.................. 32

TRUNK LATCH.......................... 32

TRUNK LID LIFT SPRINGS................ 33

TRUNK LID............................ 32

TRUNK LOCK CYLINDER................. 33

TRUNK TRIM PANEL..................... 34

TRUNK WEATHERSTRIP.................. 34

UPPER QUARTER TRIMÐ4 DOOR.......... 34

WINDOW INNERBELT STABILIZER.......... 34

WINDOW REGULATORÐ2 DOOR........... 35

ADJUSTMENTS

FRONT DOOR GLASS ADJUSTMENT........ 37

FRONT DOOR LATCH ADJUSTMENT........ 38

REAR DOOR GLASS ADJUSTMENT......... 38

REAR DOOR LATCH ADJUSTMENT.......... 39

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS....... 39

SPECIAL TOOLS

BODY................................. 40

23 - 2 BODYPL

Page 1100 of 1200

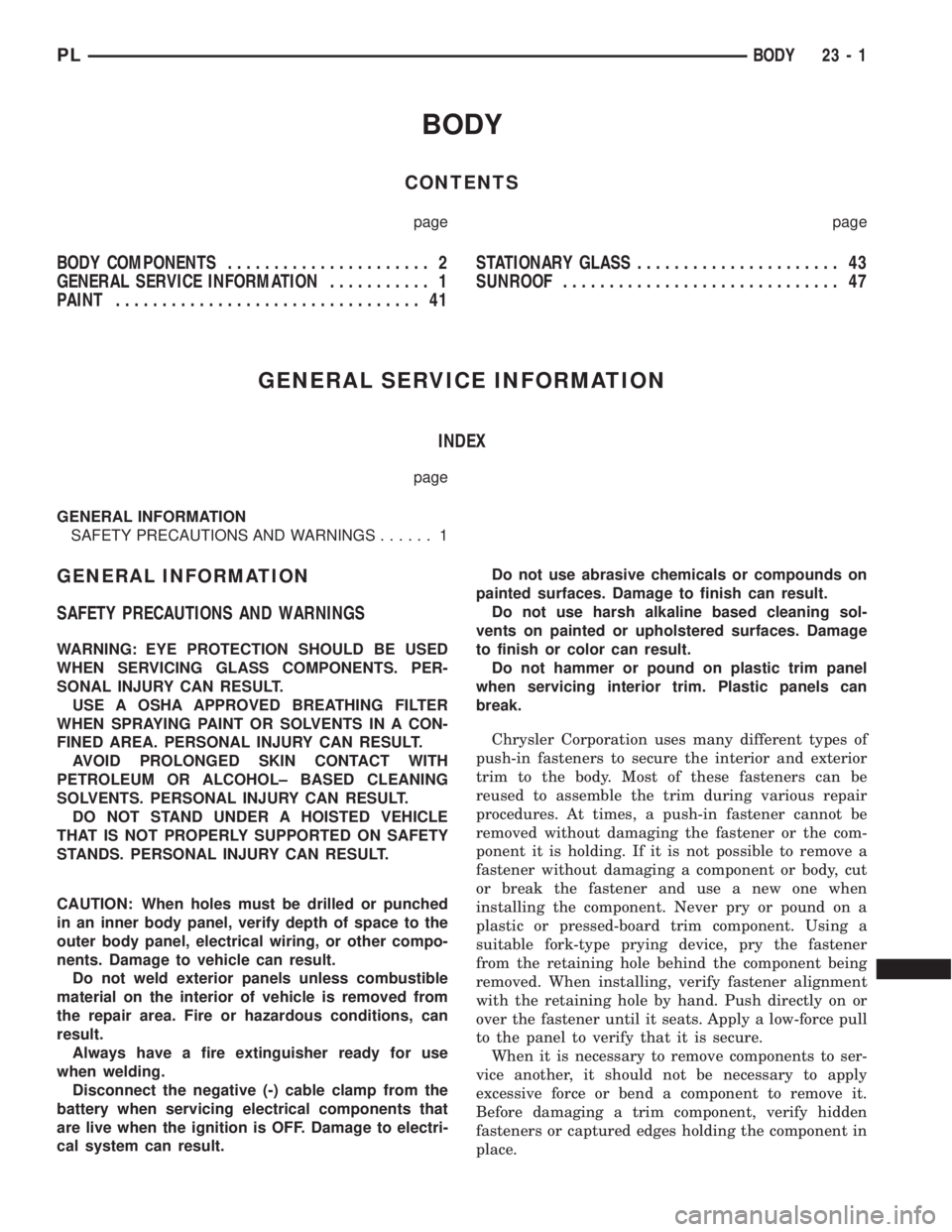

(6) Remove front vertical guide bar through

speaker hole in inner door panel (Fig. 42).

INSTALLATION

Reverse the preceding operation. Verify door glass

alignment, adjust if necessary.

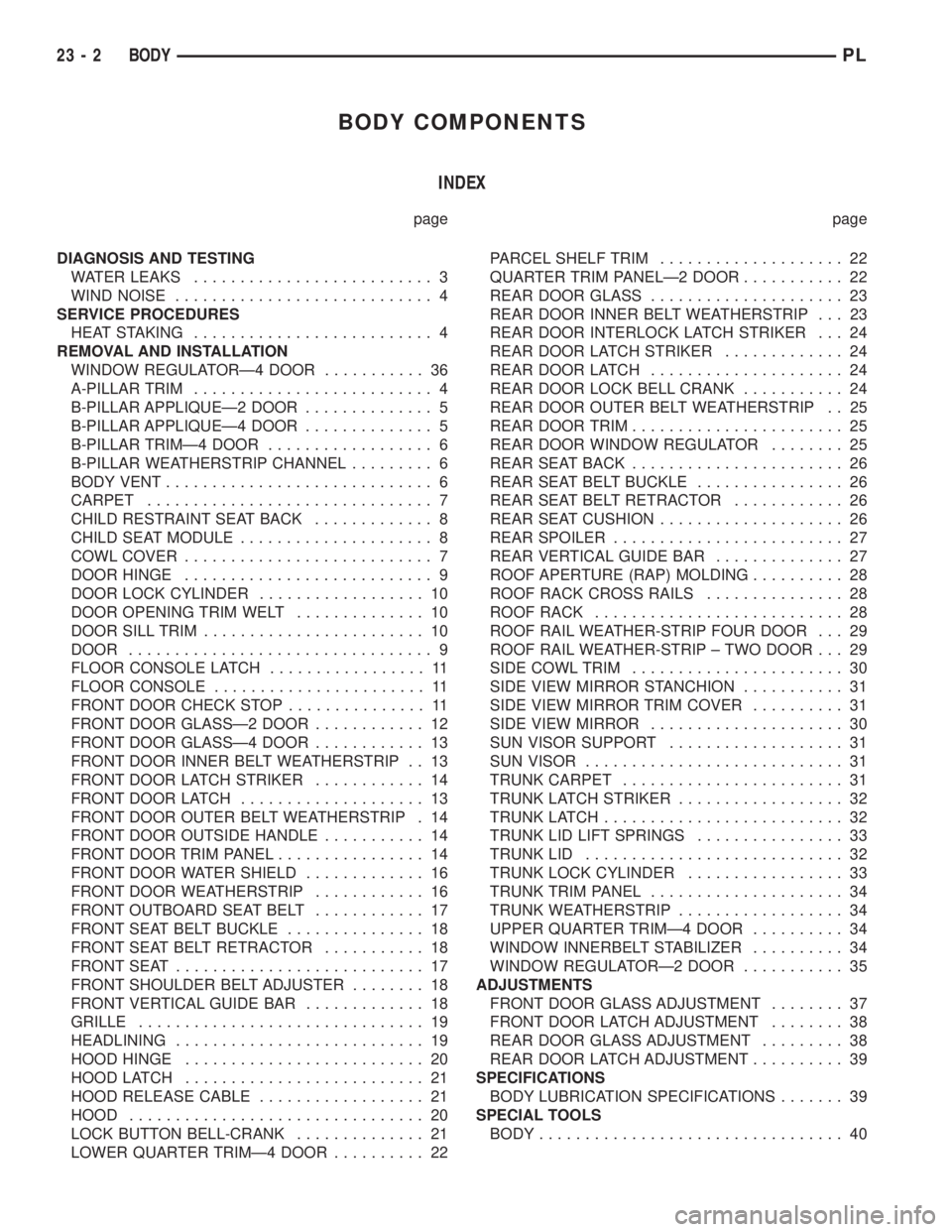

GRILLE

REMOVAL

(1) Release hood latch, open and support hood on

prop rod.

(2) Remove screws holding grille to parking lamps

(Fig. 43).

(3) Remove screw holding grille to radiator closure

panel.

(4) Separate grille from vehicle.

INSTALLATION

(1) Place grille into position on vehicle.

(2) Install screw holding grille to radiator closure

panel.

(3) Install screws holding grille to parking lamps.

HEADLINING

REMOVAL

(1) Remove screws holding sun visors to roof

header panel.

(2) Disengage wire connector from lighted vanity

mirror, if so equipped.

(3) Separate sun visors from vehicle.

(4) Remove A-pillar trim covers.

(5) Remove B-pillar trim panels, if vehicle is a 4

door.

(6) Remove (upper) quarter panel trim panels.

(7) Remove assist handles, if so equipped.

(8) Remove sun visor hooks.

(9) Remove coat hooks, if vehicle is a 4 door.

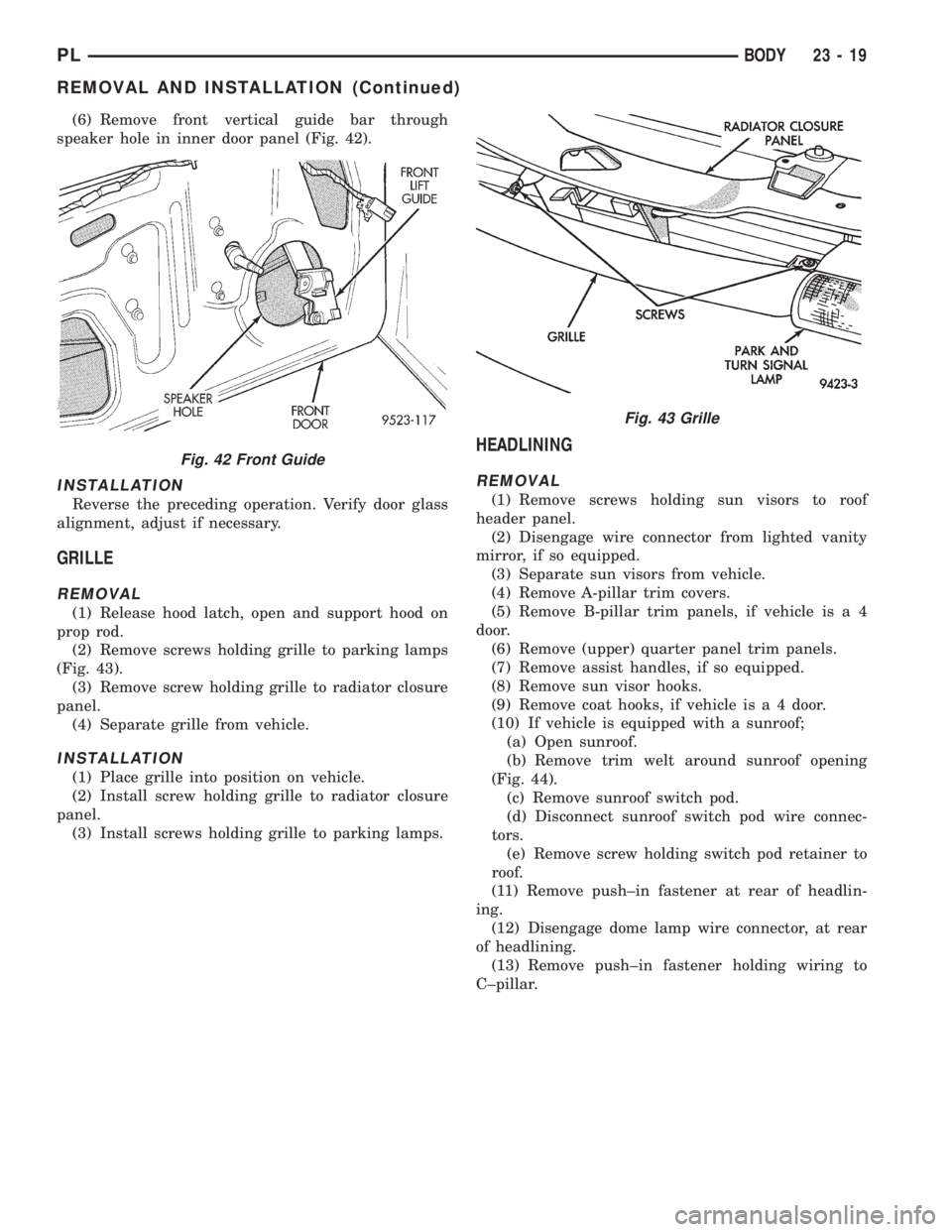

(10) If vehicle is equipped with a sunroof;

(a) Open sunroof.

(b) Remove trim welt around sunroof opening

(Fig. 44).

(c) Remove sunroof switch pod.

(d) Disconnect sunroof switch pod wire connec-

tors.

(e) Remove screw holding switch pod retainer to

roof.

(11) Remove push±in fastener at rear of headlin-

ing.

(12) Disengage dome lamp wire connector, at rear

of headlining.

(13) Remove push±in fastener holding wiring to

C±pillar.

Fig. 42 Front Guide

Fig. 43 Grille

PLBODY 23 - 19

REMOVAL AND INSTALLATION (Continued)

Page 1101 of 1200

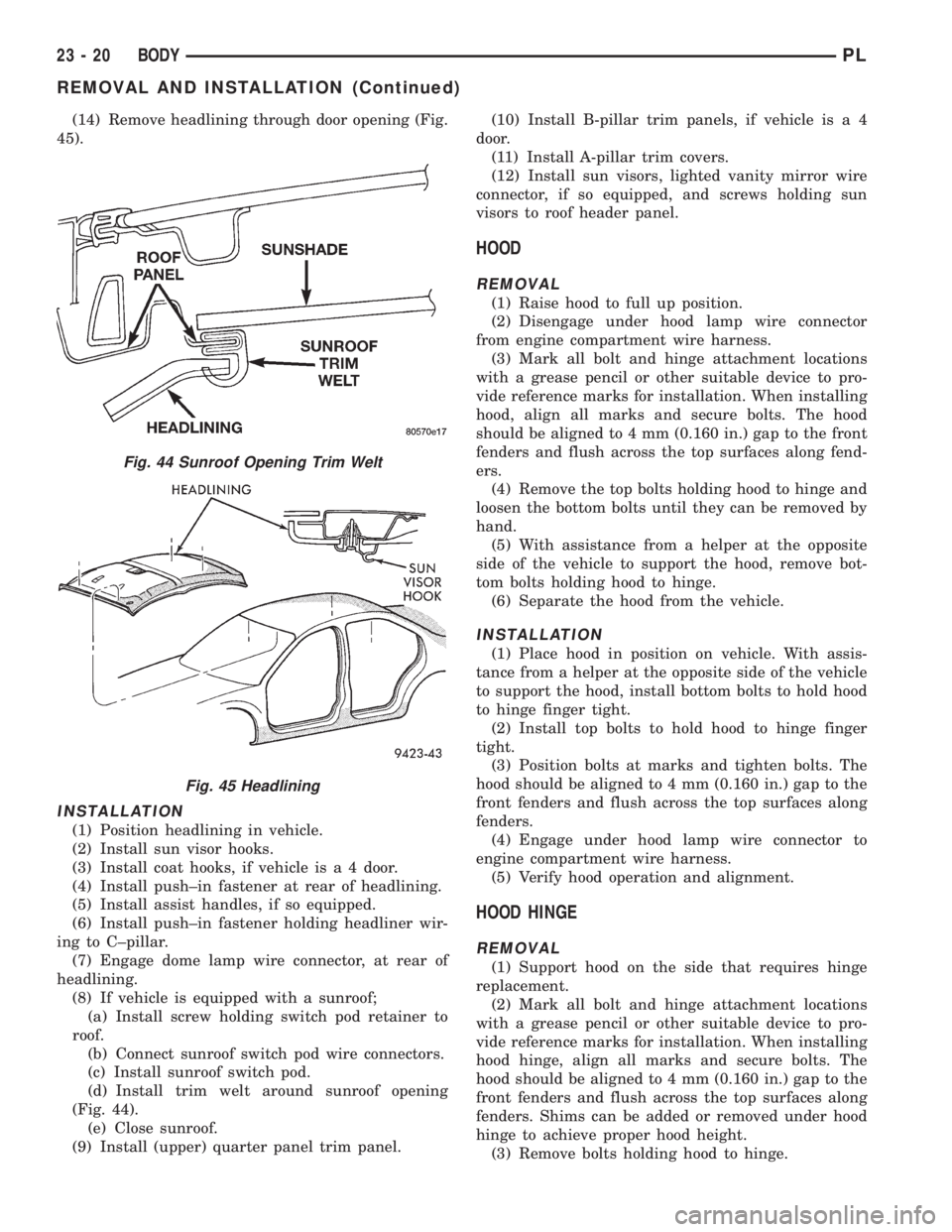

(14) Remove headlining through door opening (Fig.

45).

INSTALLATION

(1) Position headlining in vehicle.

(2) Install sun visor hooks.

(3) Install coat hooks, if vehicle is a 4 door.

(4) Install push±in fastener at rear of headlining.

(5) Install assist handles, if so equipped.

(6) Install push±in fastener holding headliner wir-

ing to C±pillar.

(7) Engage dome lamp wire connector, at rear of

headlining.

(8) If vehicle is equipped with a sunroof;

(a) Install screw holding switch pod retainer to

roof.

(b) Connect sunroof switch pod wire connectors.

(c) Install sunroof switch pod.

(d) Install trim welt around sunroof opening

(Fig. 44).

(e) Close sunroof.

(9) Install (upper) quarter panel trim panel.(10) Install B-pillar trim panels, if vehicle is a 4

door.

(11) Install A-pillar trim covers.

(12) Install sun visors, lighted vanity mirror wire

connector, if so equipped, and screws holding sun

visors to roof header panel.

HOOD

REMOVAL

(1) Raise hood to full up position.

(2) Disengage under hood lamp wire connector

from engine compartment wire harness.

(3) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When installing

hood, align all marks and secure bolts. The hood

should be aligned to 4 mm (0.160 in.) gap to the front

fenders and flush across the top surfaces along fend-

ers.

(4) Remove the top bolts holding hood to hinge and

loosen the bottom bolts until they can be removed by

hand.

(5) With assistance from a helper at the opposite

side of the vehicle to support the hood, remove bot-

tom bolts holding hood to hinge.

(6) Separate the hood from the vehicle.

INSTALLATION

(1) Place hood in position on vehicle. With assis-

tance from a helper at the opposite side of the vehicle

to support the hood, install bottom bolts to hold hood

to hinge finger tight.

(2) Install top bolts to hold hood to hinge finger

tight.

(3) Position bolts at marks and tighten bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders.

(4) Engage under hood lamp wire connector to

engine compartment wire harness.

(5) Verify hood operation and alignment.

HOOD HINGE

REMOVAL

(1) Support hood on the side that requires hinge

replacement.

(2) Mark all bolt and hinge attachment locations

with a grease pencil or other suitable device to pro-

vide reference marks for installation. When installing

hood hinge, align all marks and secure bolts. The

hood should be aligned to 4 mm (0.160 in.) gap to the

front fenders and flush across the top surfaces along

fenders. Shims can be added or removed under hood

hinge to achieve proper hood height.

(3) Remove bolts holding hood to hinge.

Fig. 44 Sunroof Opening Trim Welt

Fig. 45 Headlining

23 - 20 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1109 of 1200

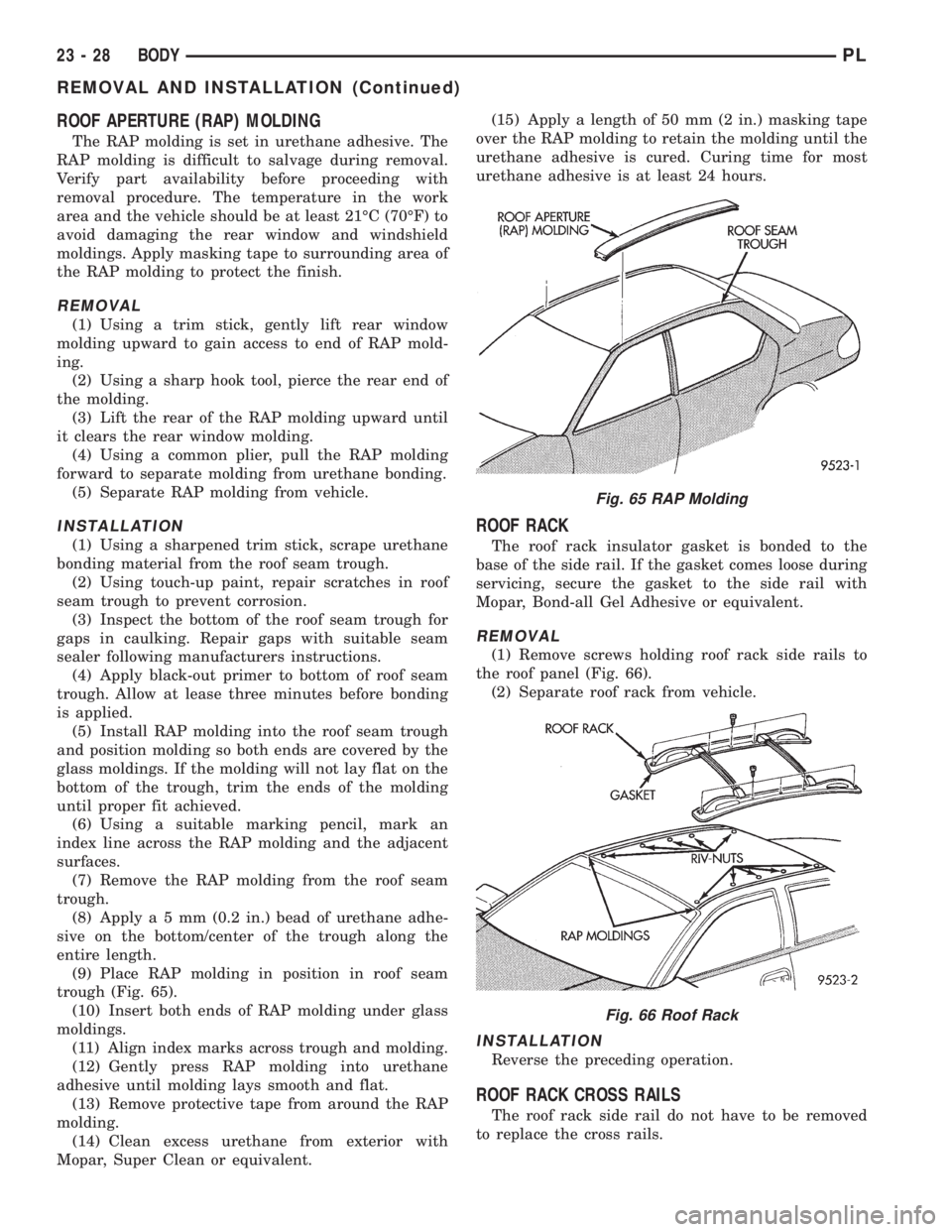

ROOF APERTURE (RAP) MOLDING

The RAP molding is set in urethane adhesive. The

RAP molding is difficult to salvage during removal.

Verify part availability before proceeding with

removal procedure. The temperature in the work

area and the vehicle should be at least 21ÉC (70ÉF) to

avoid damaging the rear window and windshield

moldings. Apply masking tape to surrounding area of

the RAP molding to protect the finish.

REMOVAL

(1) Using a trim stick, gently lift rear window

molding upward to gain access to end of RAP mold-

ing.

(2) Using a sharp hook tool, pierce the rear end of

the molding.

(3) Lift the rear of the RAP molding upward until

it clears the rear window molding.

(4) Using a common plier, pull the RAP molding

forward to separate molding from urethane bonding.

(5) Separate RAP molding from vehicle.

INSTALLATION

(1) Using a sharpened trim stick, scrape urethane

bonding material from the roof seam trough.

(2) Using touch-up paint, repair scratches in roof

seam trough to prevent corrosion.

(3) Inspect the bottom of the roof seam trough for

gaps in caulking. Repair gaps with suitable seam

sealer following manufacturers instructions.

(4) Apply black-out primer to bottom of roof seam

trough. Allow at lease three minutes before bonding

is applied.

(5) Install RAP molding into the roof seam trough

and position molding so both ends are covered by the

glass moldings. If the molding will not lay flat on the

bottom of the trough, trim the ends of the molding

until proper fit achieved.

(6) Using a suitable marking pencil, mark an

index line across the RAP molding and the adjacent

surfaces.

(7) Remove the RAP molding from the roof seam

trough.

(8) Applya5mm(0.2 in.) bead of urethane adhe-

sive on the bottom/center of the trough along the

entire length.

(9) Place RAP molding in position in roof seam

trough (Fig. 65).

(10) Insert both ends of RAP molding under glass

moldings.

(11) Align index marks across trough and molding.

(12) Gently press RAP molding into urethane

adhesive until molding lays smooth and flat.

(13) Remove protective tape from around the RAP

molding.

(14) Clean excess urethane from exterior with

Mopar, Super Clean or equivalent.(15) Apply a length of 50 mm (2 in.) masking tape

over the RAP molding to retain the molding until the

urethane adhesive is cured. Curing time for most

urethane adhesive is at least 24 hours.

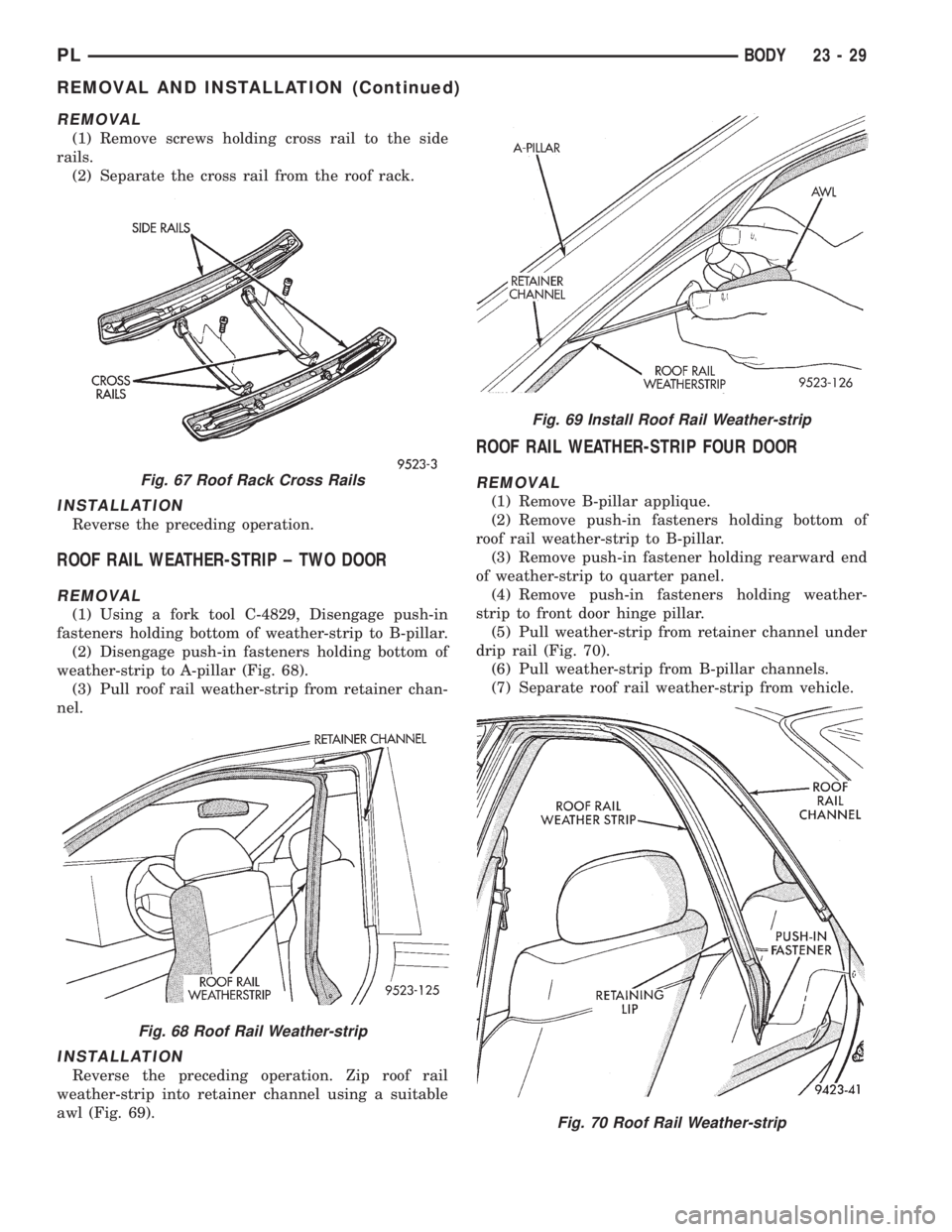

ROOF RACK

The roof rack insulator gasket is bonded to the

base of the side rail. If the gasket comes loose during

servicing, secure the gasket to the side rail with

Mopar, Bond-all Gel Adhesive or equivalent.

REMOVAL

(1) Remove screws holding roof rack side rails to

the roof panel (Fig. 66).

(2) Separate roof rack from vehicle.

INSTALLATION

Reverse the preceding operation.

ROOF RACK CROSS RAILS

The roof rack side rail do not have to be removed

to replace the cross rails.

Fig. 65 RAP Molding

Fig. 66 Roof Rack

23 - 28 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1110 of 1200

REMOVAL

(1) Remove screws holding cross rail to the side

rails.

(2) Separate the cross rail from the roof rack.

INSTALLATION

Reverse the preceding operation.

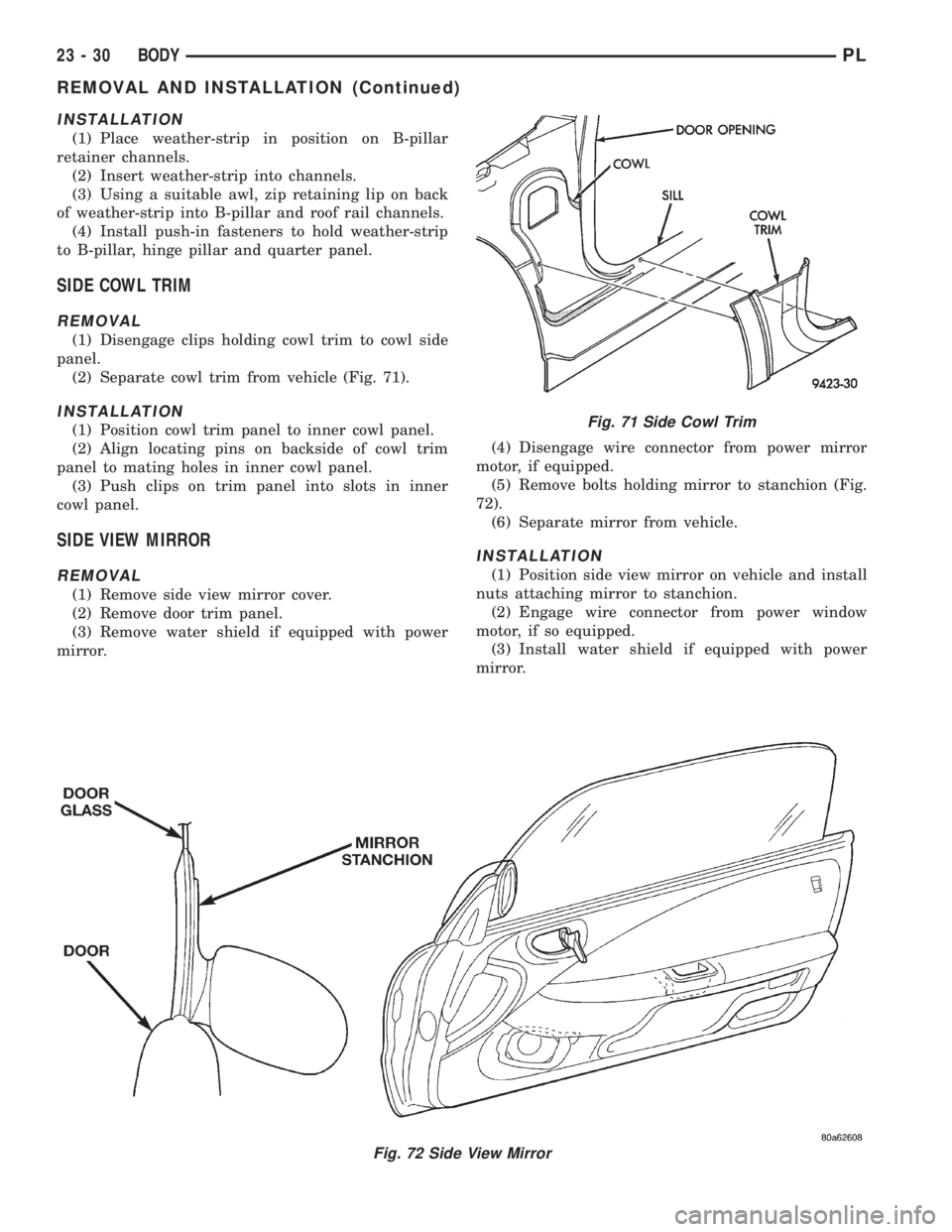

ROOF RAIL WEATHER-STRIP ± TWO DOOR

REMOVAL

(1) Using a fork tool C-4829, Disengage push-in

fasteners holding bottom of weather-strip to B-pillar.

(2) Disengage push-in fasteners holding bottom of

weather-strip to A-pillar (Fig. 68).

(3) Pull roof rail weather-strip from retainer chan-

nel.

INSTALLATION

Reverse the preceding operation. Zip roof rail

weather-strip into retainer channel using a suitable

awl (Fig. 69).

ROOF RAIL WEATHER-STRIP FOUR DOOR

REMOVAL

(1) Remove B-pillar applique.

(2) Remove push-in fasteners holding bottom of

roof rail weather-strip to B-pillar.

(3) Remove push-in fastener holding rearward end

of weather-strip to quarter panel.

(4) Remove push-in fasteners holding weather-

strip to front door hinge pillar.

(5) Pull weather-strip from retainer channel under

drip rail (Fig. 70).

(6) Pull weather-strip from B-pillar channels.

(7) Separate roof rail weather-strip from vehicle.

Fig. 67 Roof Rack Cross Rails

Fig. 68 Roof Rail Weather-strip

Fig. 69 Install Roof Rail Weather-strip

Fig. 70 Roof Rail Weather-strip

PLBODY 23 - 29

REMOVAL AND INSTALLATION (Continued)

Page 1111 of 1200

INSTALLATION

(1) Place weather-strip in position on B-pillar

retainer channels.

(2) Insert weather-strip into channels.

(3) Using a suitable awl, zip retaining lip on back

of weather-strip into B-pillar and roof rail channels.

(4) Install push-in fasteners to hold weather-strip

to B-pillar, hinge pillar and quarter panel.

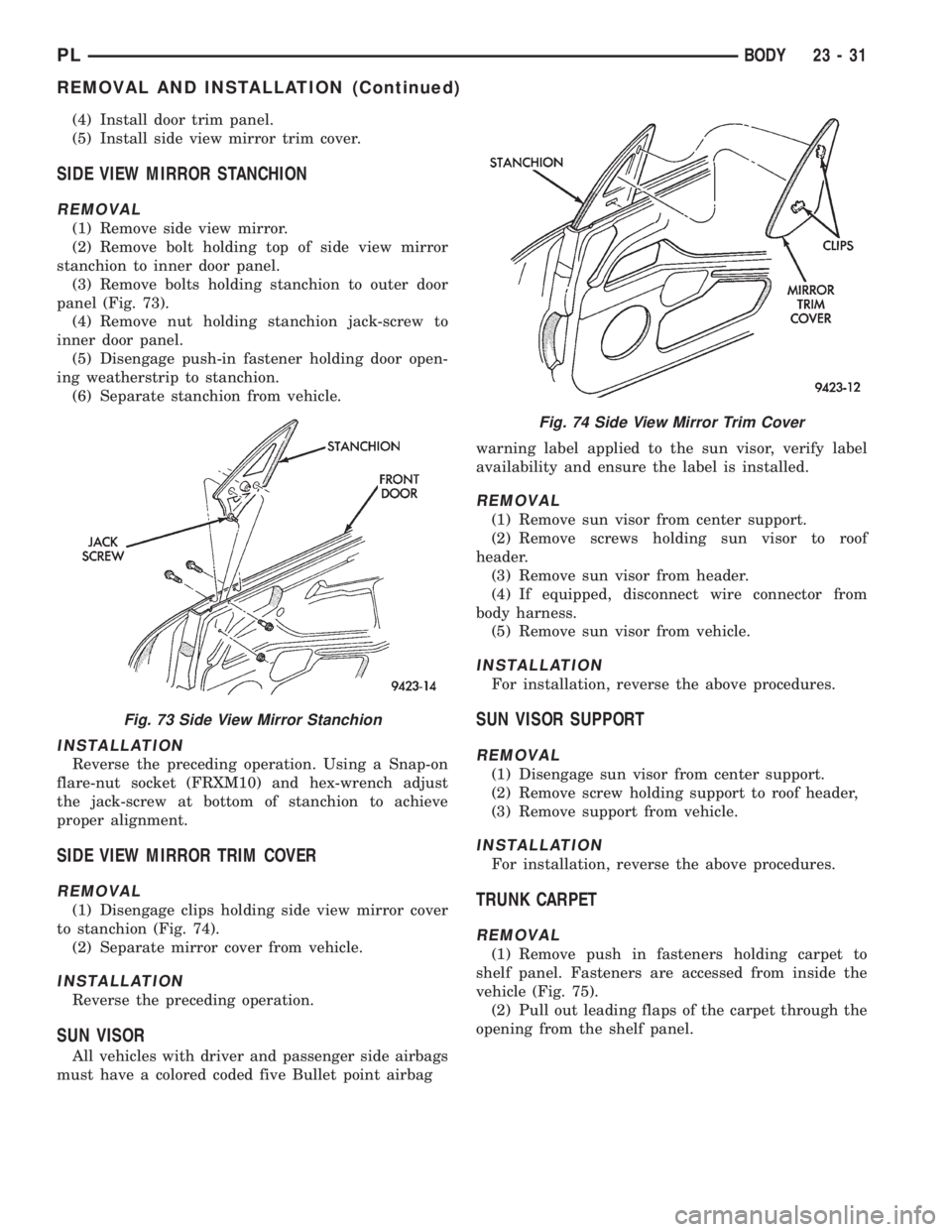

SIDE COWL TRIM

REMOVAL

(1) Disengage clips holding cowl trim to cowl side

panel.

(2) Separate cowl trim from vehicle (Fig. 71).

INSTALLATION

(1) Position cowl trim panel to inner cowl panel.

(2) Align locating pins on backside of cowl trim

panel to mating holes in inner cowl panel.

(3) Push clips on trim panel into slots in inner

cowl panel.

SIDE VIEW MIRROR

REMOVAL

(1) Remove side view mirror cover.

(2) Remove door trim panel.

(3) Remove water shield if equipped with power

mirror.(4) Disengage wire connector from power mirror

motor, if equipped.

(5) Remove bolts holding mirror to stanchion (Fig.

72).

(6) Separate mirror from vehicle.

INSTALLATION

(1) Position side view mirror on vehicle and install

nuts attaching mirror to stanchion.

(2) Engage wire connector from power window

motor, if so equipped.

(3) Install water shield if equipped with power

mirror.

Fig. 72 Side View Mirror

Fig. 71 Side Cowl Trim

23 - 30 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1112 of 1200

(4) Install door trim panel.

(5) Install side view mirror trim cover.

SIDE VIEW MIRROR STANCHION

REMOVAL

(1) Remove side view mirror.

(2) Remove bolt holding top of side view mirror

stanchion to inner door panel.

(3) Remove bolts holding stanchion to outer door

panel (Fig. 73).

(4) Remove nut holding stanchion jack-screw to

inner door panel.

(5) Disengage push-in fastener holding door open-

ing weatherstrip to stanchion.

(6) Separate stanchion from vehicle.

INSTALLATION

Reverse the preceding operation. Using a Snap-on

flare-nut socket (FRXM10) and hex-wrench adjust

the jack-screw at bottom of stanchion to achieve

proper alignment.

SIDE VIEW MIRROR TRIM COVER

REMOVAL

(1) Disengage clips holding side view mirror cover

to stanchion (Fig. 74).

(2) Separate mirror cover from vehicle.

INSTALLATION

Reverse the preceding operation.

SUN VISOR

All vehicles with driver and passenger side airbags

must have a colored coded five Bullet point airbagwarning label applied to the sun visor, verify label

availability and ensure the label is installed.

REMOVAL

(1) Remove sun visor from center support.

(2) Remove screws holding sun visor to roof

header.

(3) Remove sun visor from header.

(4) If equipped, disconnect wire connector from

body harness.

(5) Remove sun visor from vehicle.

INSTALLATION

For installation, reverse the above procedures.

SUN VISOR SUPPORT

REMOVAL

(1) Disengage sun visor from center support.

(2) Remove screw holding support to roof header,

(3) Remove support from vehicle.

INSTALLATION

For installation, reverse the above procedures.

TRUNK CARPET

REMOVAL

(1) Remove push in fasteners holding carpet to

shelf panel. Fasteners are accessed from inside the

vehicle (Fig. 75).

(2) Pull out leading flaps of the carpet through the

opening from the shelf panel.

Fig. 73 Side View Mirror Stanchion

Fig. 74 Side View Mirror Trim Cover

PLBODY 23 - 31

REMOVAL AND INSTALLATION (Continued)

Page 1115 of 1200

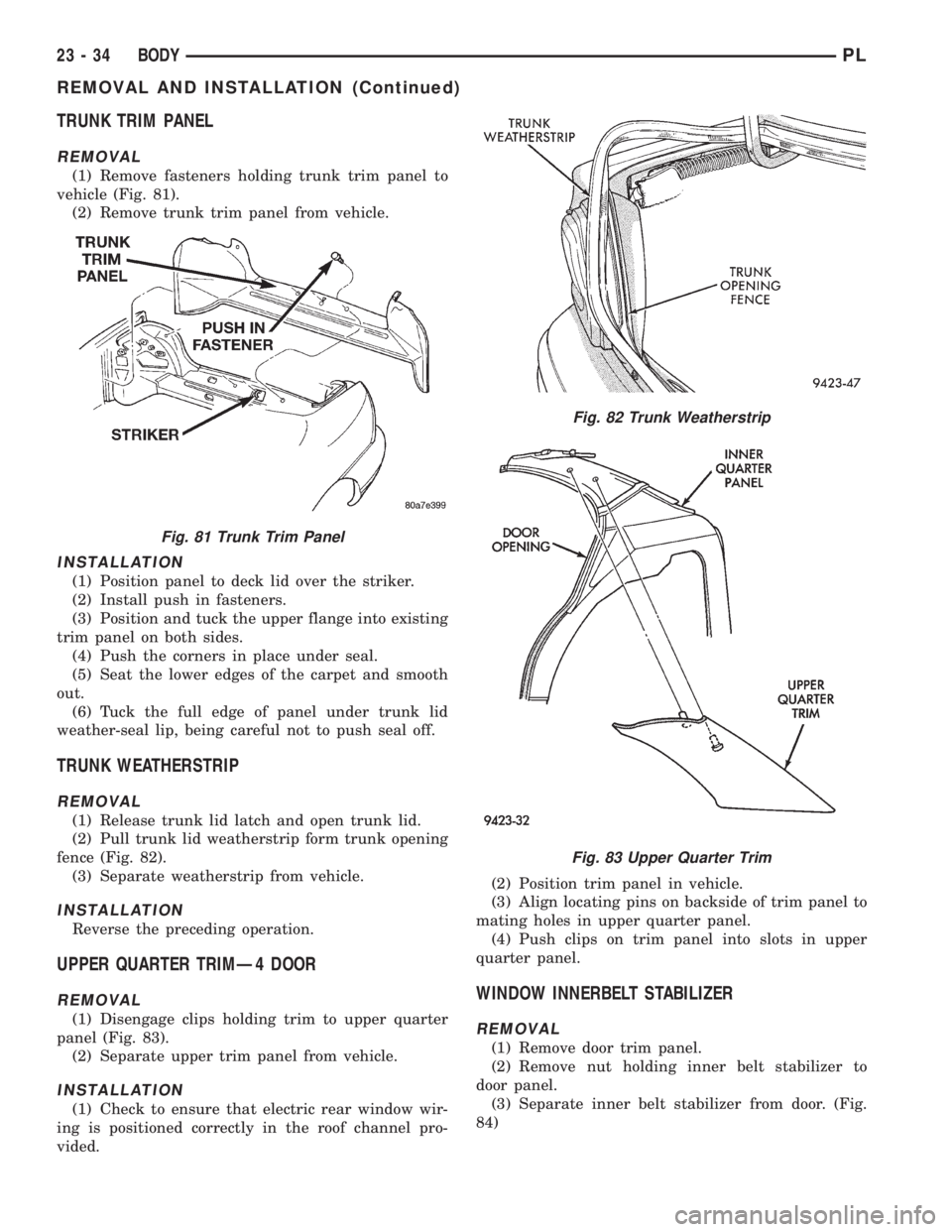

TRUNK TRIM PANEL

REMOVAL

(1) Remove fasteners holding trunk trim panel to

vehicle (Fig. 81).

(2) Remove trunk trim panel from vehicle.

INSTALLATION

(1) Position panel to deck lid over the striker.

(2) Install push in fasteners.

(3) Position and tuck the upper flange into existing

trim panel on both sides.

(4) Push the corners in place under seal.

(5) Seat the lower edges of the carpet and smooth

out.

(6) Tuck the full edge of panel under trunk lid

weather-seal lip, being careful not to push seal off.

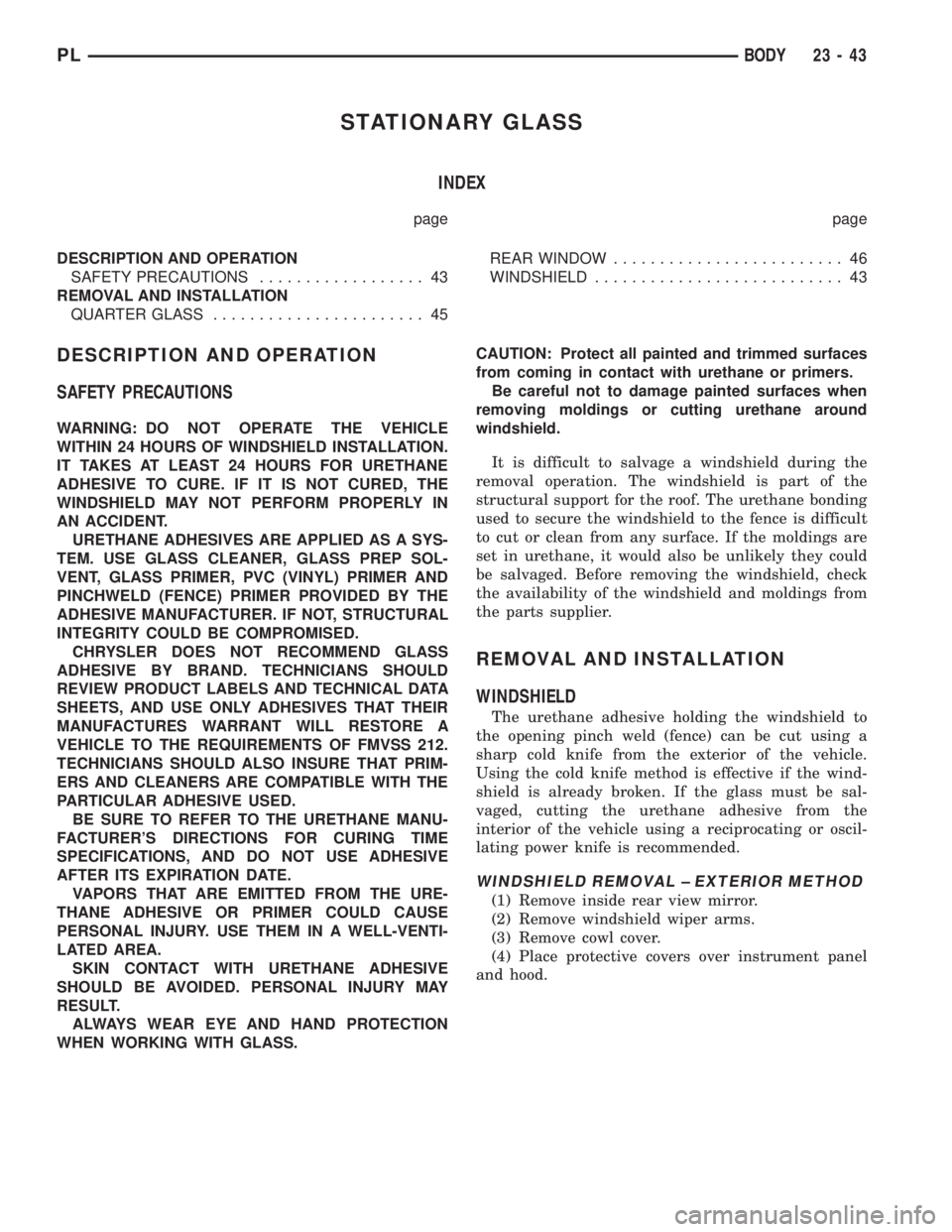

TRUNK WEATHERSTRIP

REMOVAL

(1) Release trunk lid latch and open trunk lid.

(2) Pull trunk lid weatherstrip form trunk opening

fence (Fig. 82).

(3) Separate weatherstrip from vehicle.

INSTALLATION

Reverse the preceding operation.

UPPER QUARTER TRIMÐ4 DOOR

REMOVAL

(1) Disengage clips holding trim to upper quarter

panel (Fig. 83).

(2) Separate upper trim panel from vehicle.

INSTALLATION

(1) Check to ensure that electric rear window wir-

ing is positioned correctly in the roof channel pro-

vided.(2) Position trim panel in vehicle.

(3) Align locating pins on backside of trim panel to

mating holes in upper quarter panel.

(4) Push clips on trim panel into slots in upper

quarter panel.

WINDOW INNERBELT STABILIZER

REMOVAL

(1) Remove door trim panel.

(2) Remove nut holding inner belt stabilizer to

door panel.

(3) Separate inner belt stabilizer from door. (Fig.

84)

Fig. 81 Trunk Trim Panel

Fig. 82 Trunk Weatherstrip

Fig. 83 Upper Quarter Trim

23 - 34 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1124 of 1200

STATIONARY GLASS

INDEX

page page

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS.................. 43

REMOVAL AND INSTALLATION

QUARTER GLASS....................... 45REAR WINDOW......................... 46

WINDSHIELD........................... 43

DESCRIPTION AND OPERATION

SAFETY PRECAUTIONS

WARNING: DO NOT OPERATE THE VEHICLE

WITHIN 24 HOURS OF WINDSHIELD INSTALLATION.

IT TAKES AT LEAST 24 HOURS FOR URETHANE

ADHESIVE TO CURE. IF IT IS NOT CURED, THE

WINDSHIELD MAY NOT PERFORM PROPERLY IN

AN ACCIDENT.

URETHANE ADHESIVES ARE APPLIED AS A SYS-

TEM. USE GLASS CLEANER, GLASS PREP SOL-

VENT, GLASS PRIMER, PVC (VINYL) PRIMER AND

PINCHWELD (FENCE) PRIMER PROVIDED BY THE

ADHESIVE MANUFACTURER. IF NOT, STRUCTURAL

INTEGRITY COULD BE COMPROMISED.

CHRYSLER DOES NOT RECOMMEND GLASS

ADHESIVE BY BRAND. TECHNICIANS SHOULD

REVIEW PRODUCT LABELS AND TECHNICAL DATA

SHEETS, AND USE ONLY ADHESIVES THAT THEIR

MANUFACTURES WARRANT WILL RESTORE A

VEHICLE TO THE REQUIREMENTS OF FMVSS 212.

TECHNICIANS SHOULD ALSO INSURE THAT PRIM-

ERS AND CLEANERS ARE COMPATIBLE WITH THE

PARTICULAR ADHESIVE USED.

BE SURE TO REFER TO THE URETHANE MANU-

FACTURER'S DIRECTIONS FOR CURING TIME

SPECIFICATIONS, AND DO NOT USE ADHESIVE

AFTER ITS EXPIRATION DATE.

VAPORS THAT ARE EMITTED FROM THE URE-

THANE ADHESIVE OR PRIMER COULD CAUSE

PERSONAL INJURY. USE THEM IN A WELL-VENTI-

LATED AREA.

SKIN CONTACT WITH URETHANE ADHESIVE

SHOULD BE AVOIDED. PERSONAL INJURY MAY

RESULT.

ALWAYS WEAR EYE AND HAND PROTECTION

WHEN WORKING WITH GLASS.CAUTION: Protect all painted and trimmed surfaces

from coming in contact with urethane or primers.

Be careful not to damage painted surfaces when

removing moldings or cutting urethane around

windshield.

It is difficult to salvage a windshield during the

removal operation. The windshield is part of the

structural support for the roof. The urethane bonding

used to secure the windshield to the fence is difficult

to cut or clean from any surface. If the moldings are

set in urethane, it would also be unlikely they could

be salvaged. Before removing the windshield, check

the availability of the windshield and moldings from

the parts supplier.

REMOVAL AND INSTALLATION

WINDSHIELD

The urethane adhesive holding the windshield to

the opening pinch weld (fence) can be cut using a

sharp cold knife from the exterior of the vehicle.

Using the cold knife method is effective if the wind-

shield is already broken. If the glass must be sal-

vaged, cutting the urethane adhesive from the

interior of the vehicle using a reciprocating or oscil-

lating power knife is recommended.

WINDSHIELD REMOVAL ± EXTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove windshield wiper arms.

(3) Remove cowl cover.

(4) Place protective covers over instrument panel

and hood.

PLBODY 23 - 43