sensor DODGE NEON 1999 Service Owner's Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 168 of 1200

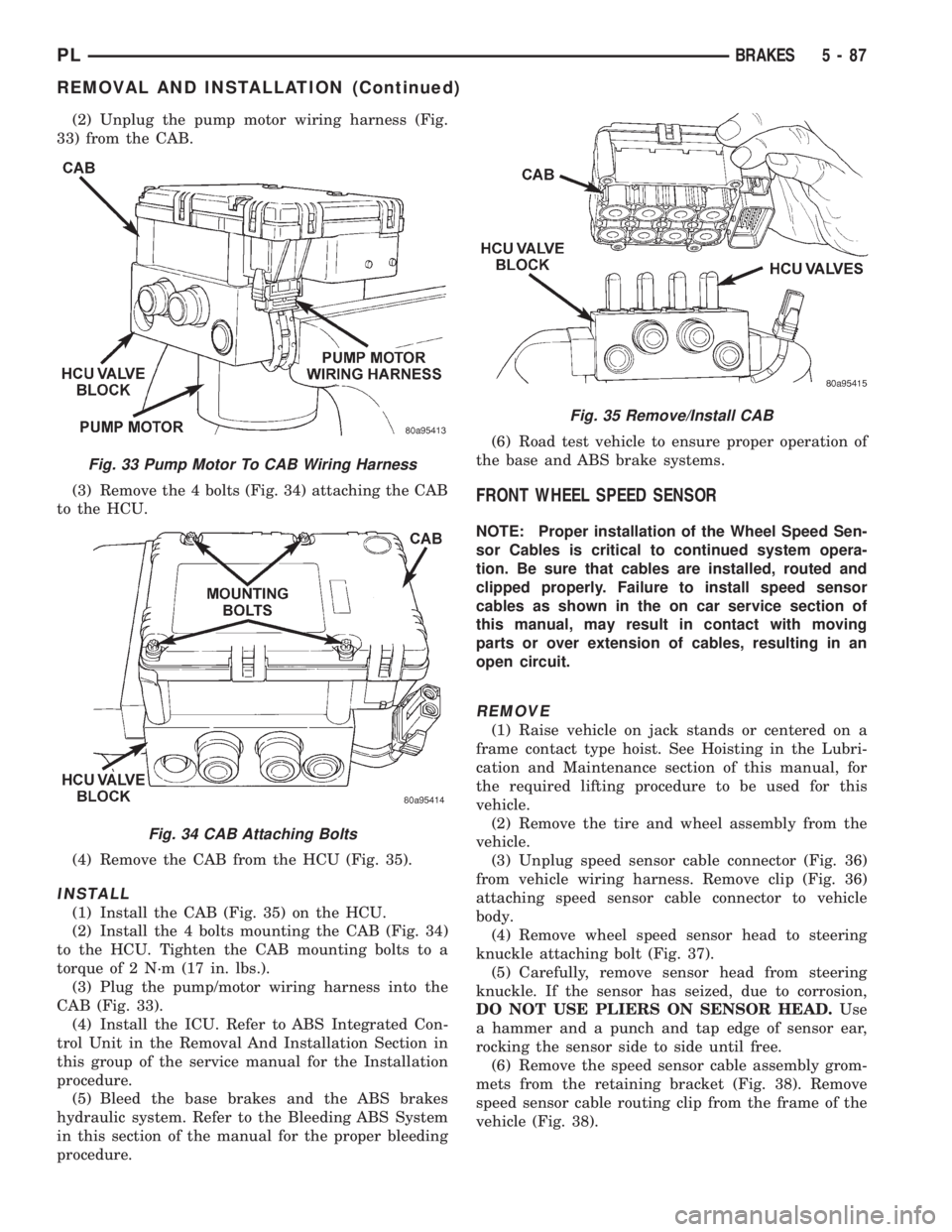

(2) Unplug the pump motor wiring harness (Fig.

33) from the CAB.

(3) Remove the 4 bolts (Fig. 34) attaching the CAB

to the HCU.

(4) Remove the CAB from the HCU (Fig. 35).

INSTALL

(1) Install the CAB (Fig. 35) on the HCU.

(2) Install the 4 bolts mounting the CAB (Fig. 34)

to the HCU. Tighten the CAB mounting bolts to a

torque of 2 N´m (17 in. lbs.).

(3) Plug the pump/motor wiring harness into the

CAB (Fig. 33).

(4) Install the ICU. Refer to ABS Integrated Con-

trol Unit in the Removal And Installation Section in

this group of the service manual for the Installation

procedure.

(5) Bleed the base brakes and the ABS brakes

hydraulic system. Refer to the Bleeding ABS System

in this section of the manual for the proper bleeding

procedure.(6) Road test vehicle to ensure proper operation of

the base and ABS brake systems.

FRONT WHEEL SPEED SENSOR

NOTE: Proper installation of the Wheel Speed Sen-

sor Cables is critical to continued system opera-

tion. Be sure that cables are installed, routed and

clipped properly. Failure to install speed sensor

cables as shown in the on car service section of

this manual, may result in contact with moving

parts or over extension of cables, resulting in an

open circuit.

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the tire and wheel assembly from the

vehicle.

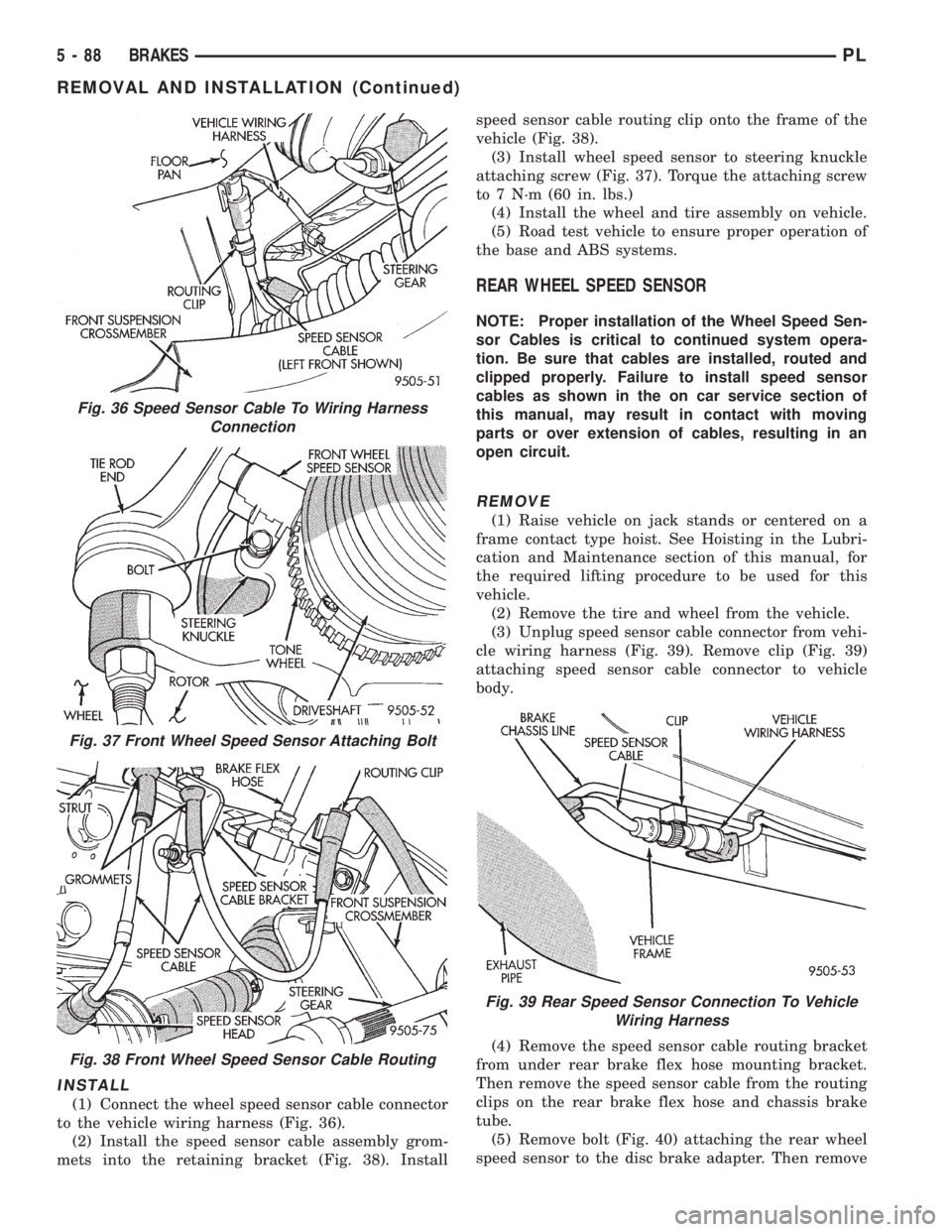

(3) Unplug speed sensor cable connector (Fig. 36)

from vehicle wiring harness. Remove clip (Fig. 36)

attaching speed sensor cable connector to vehicle

body.

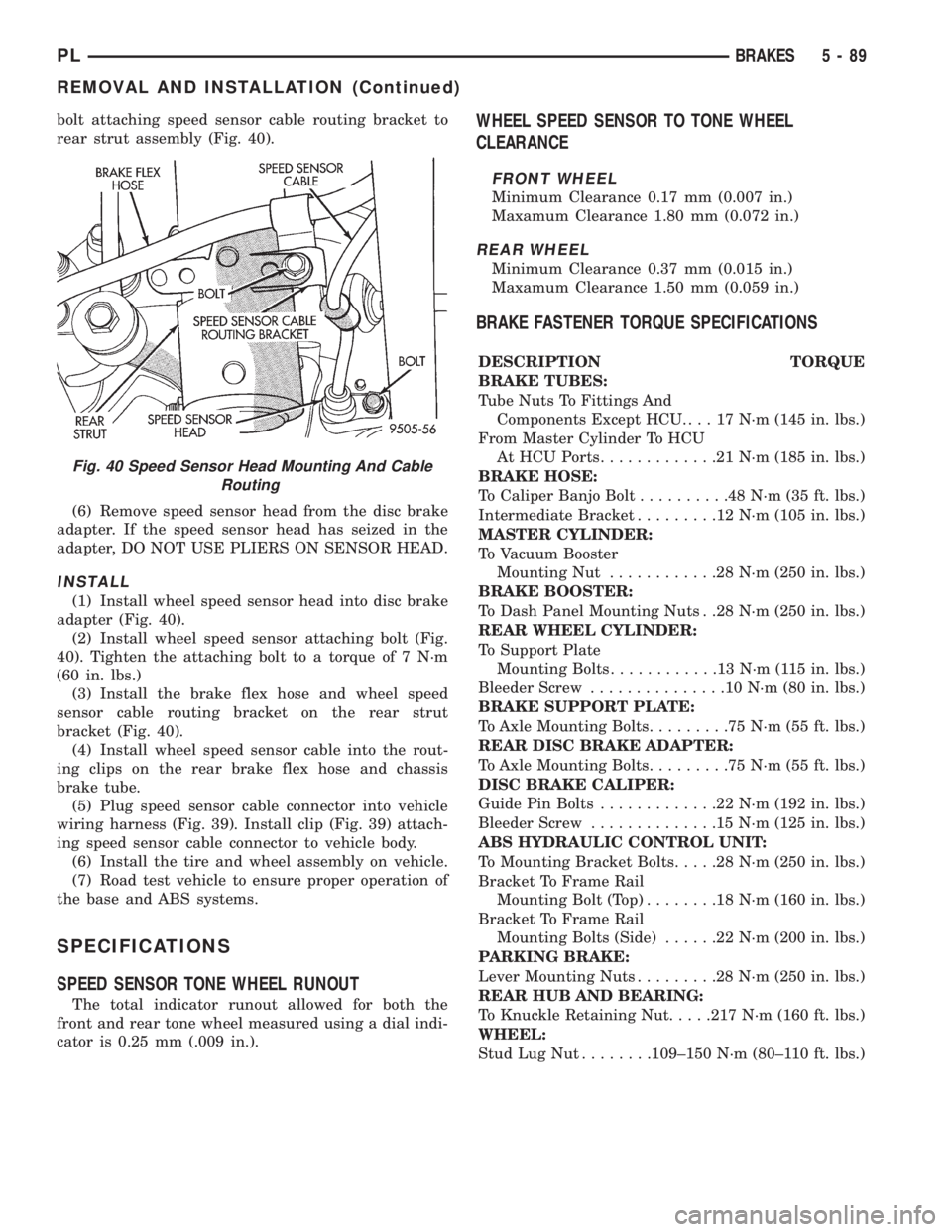

(4) Remove wheel speed sensor head to steering

knuckle attaching bolt (Fig. 37).

(5) Carefully, remove sensor head from steering

knuckle. If the sensor has seized, due to corrosion,

DO NOT USE PLIERS ON SENSOR HEAD.Use

a hammer and a punch and tap edge of sensor ear,

rocking the sensor side to side until free.

(6) Remove the speed sensor cable assembly grom-

mets from the retaining bracket (Fig. 38). Remove

speed sensor cable routing clip from the frame of the

vehicle (Fig. 38).

Fig. 33 Pump Motor To CAB Wiring Harness

Fig. 34 CAB Attaching Bolts

Fig. 35 Remove/Install CAB

PLBRAKES 5 - 87

REMOVAL AND INSTALLATION (Continued)

Page 169 of 1200

INSTALL

(1) Connect the wheel speed sensor cable connector

to the vehicle wiring harness (Fig. 36).

(2) Install the speed sensor cable assembly grom-

mets into the retaining bracket (Fig. 38). Installspeed sensor cable routing clip onto the frame of the

vehicle (Fig. 38).

(3) Install wheel speed sensor to steering knuckle

attaching screw (Fig. 37). Torque the attaching screw

to 7 N´m (60 in. lbs.)

(4) Install the wheel and tire assembly on vehicle.

(5) Road test vehicle to ensure proper operation of

the base and ABS systems.

REAR WHEEL SPEED SENSOR

NOTE: Proper installation of the Wheel Speed Sen-

sor Cables is critical to continued system opera-

tion. Be sure that cables are installed, routed and

clipped properly. Failure to install speed sensor

cables as shown in the on car service section of

this manual, may result in contact with moving

parts or over extension of cables, resulting in an

open circuit.

REMOVE

(1) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(2) Remove the tire and wheel from the vehicle.

(3) Unplug speed sensor cable connector from vehi-

cle wiring harness (Fig. 39). Remove clip (Fig. 39)

attaching speed sensor cable connector to vehicle

body.

(4) Remove the speed sensor cable routing bracket

from under rear brake flex hose mounting bracket.

Then remove the speed sensor cable from the routing

clips on the rear brake flex hose and chassis brake

tube.

(5) Remove bolt (Fig. 40) attaching the rear wheel

speed sensor to the disc brake adapter. Then remove

Fig. 36 Speed Sensor Cable To Wiring Harness

Connection

Fig. 37 Front Wheel Speed Sensor Attaching Bolt

Fig. 38 Front Wheel Speed Sensor Cable Routing

Fig. 39 Rear Speed Sensor Connection To Vehicle

Wiring Harness

5 - 88 BRAKESPL

REMOVAL AND INSTALLATION (Continued)

Page 170 of 1200

bolt attaching speed sensor cable routing bracket to

rear strut assembly (Fig. 40).

(6) Remove speed sensor head from the disc brake

adapter. If the speed sensor head has seized in the

adapter, DO NOT USE PLIERS ON SENSOR HEAD.

INSTALL

(1) Install wheel speed sensor head into disc brake

adapter (Fig. 40).

(2) Install wheel speed sensor attaching bolt (Fig.

40). Tighten the attaching bolt to a torque of 7 N´m

(60 in. lbs.)

(3) Install the brake flex hose and wheel speed

sensor cable routing bracket on the rear strut

bracket (Fig. 40).

(4) Install wheel speed sensor cable into the rout-

ing clips on the rear brake flex hose and chassis

brake tube.

(5) Plug speed sensor cable connector into vehicle

wiring harness (Fig. 39). Install clip (Fig. 39) attach-

ing speed sensor cable connector to vehicle body.

(6) Install the tire and wheel assembly on vehicle.

(7) Road test vehicle to ensure proper operation of

the base and ABS systems.

SPECIFICATIONS

SPEED SENSOR TONE WHEEL RUNOUT

The total indicator runout allowed for both the

front and rear tone wheel measured using a dial indi-

cator is 0.25 mm (.009 in.).

WHEEL SPEED SENSOR TO TONE WHEEL

CLEARANCE

FRONT WHEEL

Minimum Clearance 0.17 mm (0.007 in.)

Maxamum Clearance 1.80 mm (0.072 in.)

REAR WHEEL

Minimum Clearance 0.37 mm (0.015 in.)

Maxamum Clearance 1.50 mm (0.059 in.)

BRAKE FASTENER TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

BRAKE TUBES:

Tube Nuts To Fittings And

Components Except HCU. . . . 17 N´m (145 in. lbs.)

From Master Cylinder To HCU

At HCU Ports.............21N´m(185 in. lbs.)

BRAKE HOSE:

To Caliper Banjo Bolt..........48N´m(35ft.lbs.)

Intermediate Bracket.........12N´m(105 in. lbs.)

MASTER CYLINDER:

To Vacuum Booster

Mounting Nut............28N´m(250 in. lbs.)

BRAKE BOOSTER:

To Dash Panel Mounting Nuts . .28 N´m (250 in. lbs.)

REAR WHEEL CYLINDER:

To Support Plate

Mounting Bolts............13N´m(115in.lbs.)

Bleeder Screw...............10N´m(80in.lbs.)

BRAKE SUPPORT PLATE:

To Axle Mounting Bolts.........75N´m(55ft.lbs.)

REAR DISC BRAKE ADAPTER:

To Axle Mounting Bolts.........75N´m(55ft.lbs.)

DISC BRAKE CALIPER:

Guide Pin Bolts.............22N´m(192 in. lbs.)

Bleeder Screw..............15N´m(125 in. lbs.)

ABS HYDRAULIC CONTROL UNIT:

To Mounting Bracket Bolts.....28N´m(250 in. lbs.)

Bracket To Frame Rail

Mounting Bolt (Top)........18N´m(160 in. lbs.)

Bracket To Frame Rail

Mounting Bolts (Side)......22N´m(200 in. lbs.)

PARKING BRAKE:

Lever Mounting Nuts.........28N´m(250 in. lbs.)

REAR HUB AND BEARING:

To Knuckle Retaining Nut.....217 N´m (160 ft. lbs.)

WHEEL:

Stud Lug Nut........109±150 N´m (80±110 ft. lbs.)

Fig. 40 Speed Sensor Head Mounting And Cable

Routing

PLBRAKES 5 - 89

REMOVAL AND INSTALLATION (Continued)

Page 200 of 1200

DIAGNOSIS AND TESTING

COOLING SYSTEM DIAGNOSIS

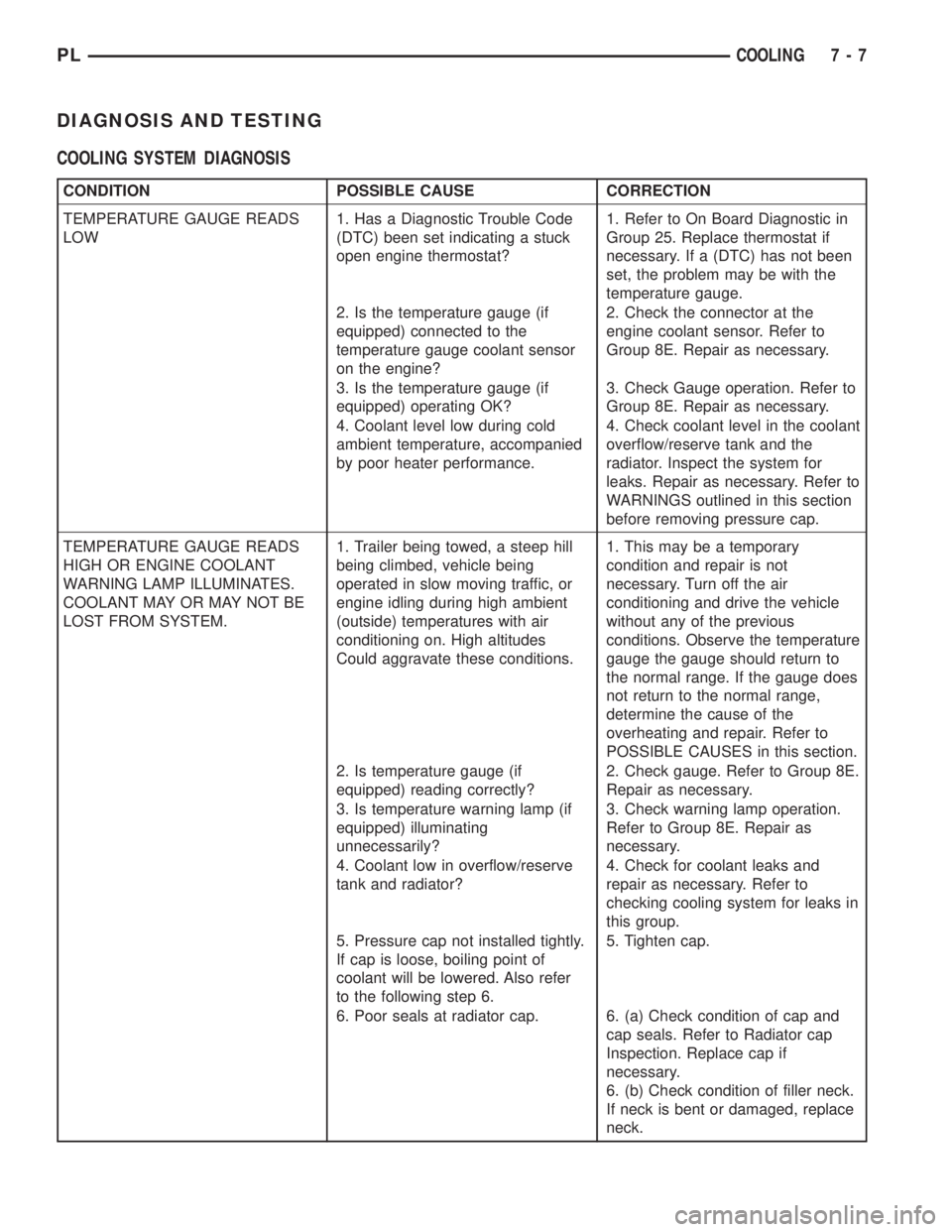

CONDITION POSSIBLE CAUSE CORRECTION

TEMPERATURE GAUGE READS

LOW1. Has a Diagnostic Trouble Code

(DTC) been set indicating a stuck

open engine thermostat?1. Refer to On Board Diagnostic in

Group 25. Replace thermostat if

necessary. If a (DTC) has not been

set, the problem may be with the

temperature gauge.

2. Is the temperature gauge (if

equipped) connected to the

temperature gauge coolant sensor

on the engine?2. Check the connector at the

engine coolant sensor. Refer to

Group 8E. Repair as necessary.

3. Is the temperature gauge (if

equipped) operating OK?3. Check Gauge operation. Refer to

Group 8E. Repair as necessary.

4. Coolant level low during cold

ambient temperature, accompanied

by poor heater performance.4. Check coolant level in the coolant

overflow/reserve tank and the

radiator. Inspect the system for

leaks. Repair as necessary. Refer to

WARNINGS outlined in this section

before removing pressure cap.

TEMPERATURE GAUGE READS

HIGH OR ENGINE COOLANT

WARNING LAMP ILLUMINATES.

COOLANT MAY OR MAY NOT BE

LOST FROM SYSTEM.1. Trailer being towed, a steep hill

being climbed, vehicle being

operated in slow moving traffic, or

engine idling during high ambient

(outside) temperatures with air

conditioning on. High altitudes

Could aggravate these conditions.1. This may be a temporary

condition and repair is not

necessary. Turn off the air

conditioning and drive the vehicle

without any of the previous

conditions. Observe the temperature

gauge the gauge should return to

the normal range. If the gauge does

not return to the normal range,

determine the cause of the

overheating and repair. Refer to

POSSIBLE CAUSES in this section.

2. Is temperature gauge (if

equipped) reading correctly?2. Check gauge. Refer to Group 8E.

Repair as necessary.

3. Is temperature warning lamp (if

equipped) illuminating

unnecessarily?3. Check warning lamp operation.

Refer to Group 8E. Repair as

necessary.

4. Coolant low in overflow/reserve

tank and radiator?4. Check for coolant leaks and

repair as necessary. Refer to

checking cooling system for leaks in

this group.

5. Pressure cap not installed tightly.

If cap is loose, boiling point of

coolant will be lowered. Also refer

to the following step 6.5. Tighten cap.

6. Poor seals at radiator cap. 6. (a) Check condition of cap and

cap seals. Refer to Radiator cap

Inspection. Replace cap if

necessary.

6. (b) Check condition of filler neck.

If neck is bent or damaged, replace

neck.

PLCOOLING 7 - 7

Page 207 of 1200

WATER PUMP DIAGNOSIS

A quick flow test to tell whether or not the pump is

working is to see if the heater warms properly. A

defective pump will not be able to circulate heated

coolant through the long heater hose.

Another flow test to help determine pump opera-

tion.

WARNING: DO NOT remove radiator cap if the cool-

ing system is hot or under pressure.

(1) Remove radiator cap.

(2) Remove a small amount of coolant from the

system, start the engine and warm up until thermo-

stat opens. With the thermostat open and coolant

level low you will see if the water pump is pumping

coolant through the system.

COOLING SYSTEM FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use the following procedures:

(1) If engine is cold, idle engine until normal oper-

ating temperature is reached. Then feel the upper

radiator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE THE COOLING SYS-

TEM PRESSURE CAP WITH THE SYSTEM HOT AND

UNDER PRESSURE BECAUSE SERIOUS BURNS

FROM COOLANT CAN OCCUR.

(2) Remove pressure cap when engine is cold,

remove small amount of coolant Idle engine until

thermostat opens, you should observe coolant flow

while looking down the filler neck. Once flow is

detected install the pressure cap.

RADIATOR FAN CONTROL

Fan control is accomplished two ways. The fan

always runs when the air conditioning compressor

clutch is engaged. In addition to this control, the fan

is turned on by the temperature of the coolant which

is sensed by the coolant temperature sensor which

sends the message to the Powertrain Control Module

(PCM). The (PCM) turns on the fan through the

Solid State Fan Relay. The Solid State Fan Relay is

located on the left front inner frame just behind the

radiator. See Wiring Diagrams Manual for circuity

and diagnostics provided.

Switching through the (PCM) provides fan control

for the following conditions.

²The fan will not run during cranking until the

engine starts no matter what the coolant tempera-

ture is.

²Fan will run when the air conditioning clutch is

engaged and low pressure cutout switch is closed.

²Fan will run at vehicle speeds above about 40

mph only if coolant temperature reaches 110ÉC(230ÉF). It will turn off when the temperature drops

to 104ÉC (220ÉF). At speeds below 40 mph the fan

switches on at 102ÉC (215ÉF) and off at 93ÉC (200ÉF).

Refer to Radiator Fan Control Module Group 14,

Fuel Injection for more information.

ELECTRIC FAN MOTOR TEST

Refer to Powertrain Diagnostic Manual for procedure.

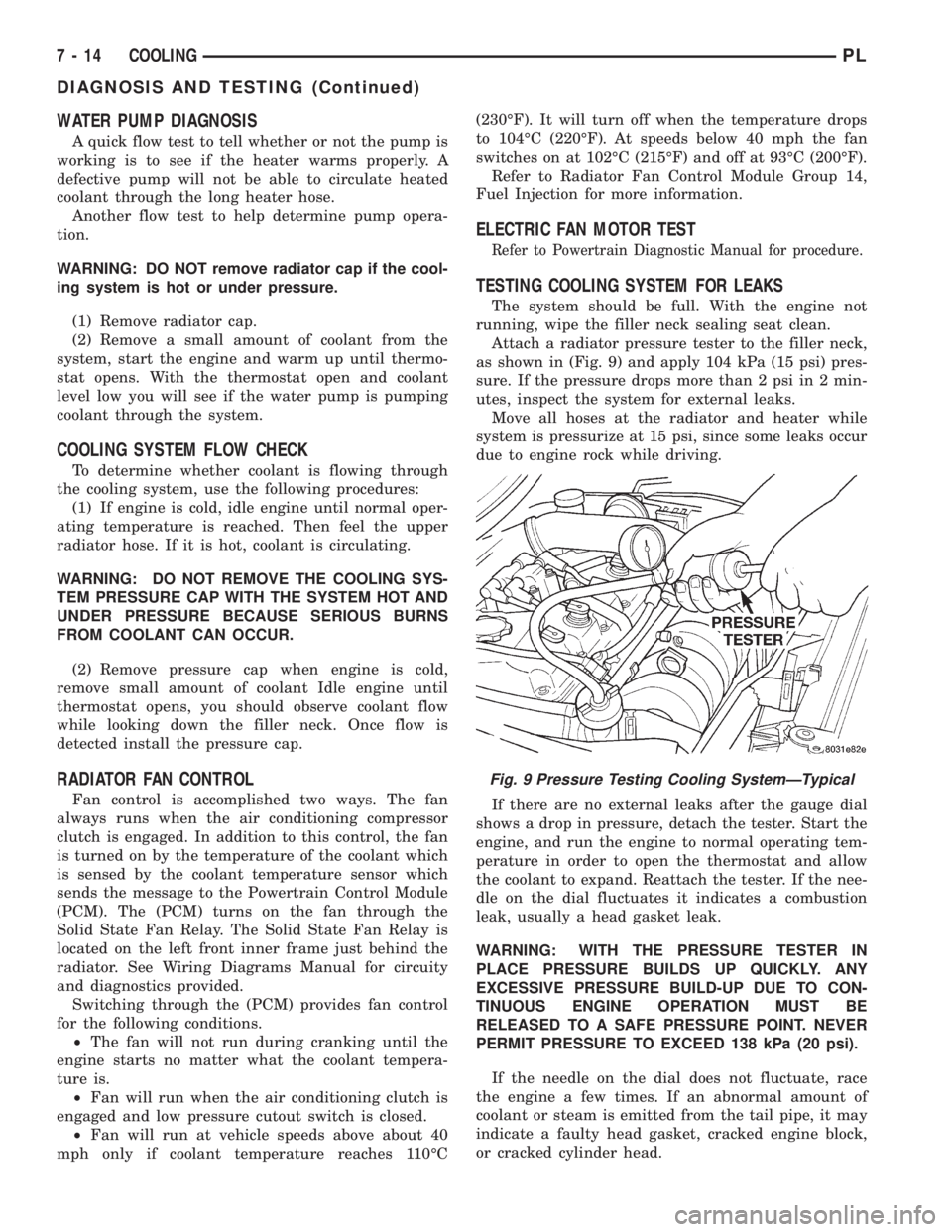

TESTING COOLING SYSTEM FOR LEAKS

The system should be full. With the engine not

running, wipe the filler neck sealing seat clean.

Attach a radiator pressure tester to the filler neck,

as shown in (Fig. 9) and apply 104 kPa (15 psi) pres-

sure. If the pressure drops more than 2 psi in 2 min-

utes, inspect the system for external leaks.

Move all hoses at the radiator and heater while

system is pressurize at 15 psi, since some leaks occur

due to engine rock while driving.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start the

engine, and run the engine to normal operating tem-

perature in order to open the thermostat and allow

the coolant to expand. Reattach the tester. If the nee-

dle on the dial fluctuates it indicates a combustion

leak, usually a head gasket leak.

WARNING: WITH THE PRESSURE TESTER IN

PLACE PRESSURE BUILDS UP QUICKLY. ANY

EXCESSIVE PRESSURE BUILD-UP DUE TO CON-

TINUOUS ENGINE OPERATION MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block,

or cracked cylinder head.

Fig. 9 Pressure Testing Cooling SystemÐTypical

7 - 14 COOLINGPL

DIAGNOSIS AND TESTING (Continued)

Page 218 of 1200

BATTERY

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)........ 1

CHARGING TIME REQUIRED............... 1

DIAGNOSIS AND TESTING

BATTERY BUILT-IN TEST INDICATOR........ 2

BATTERY IGNITION OFF DRAW (IOD)........ 3

BATTERY LOAD TEST..................... 5

BATTERY OPEN CIRCUIT VOLTAGE TEST..... 6

BATTERY TEMPERATURE SENSOR.......... 6

SERVICE PROCEDURES

BATTERY CHARGING..................... 6CHARGING COMPLETELY DISCHARGED

BATTERY............................. 7

VISUAL INSPECTION..................... 7

REMOVAL AND INSTALLATION

BATTERY TRAY.......................... 9

BATTERY............................... 8

FRESH AIR INLET TUBE REMOVAL.......... 9

SPECIFICATIONS

BATTERY SPECIFICATIONS............... 10

TORQUE.............................. 10

GENERAL INFORMATION

INTRODUCTION

The battery stores, stabilizes, and delivers electri-

cal current to operate various electrical systems in

the vehicle. The determination of whether a battery

is good or bad is made by its ability to accept a

charge. It also must supply high-amperage current

for a long enough period to be able to start the vehi-

cle. The capability of the battery to store electrical

current comes from a chemical reaction. This reac-

tion takes place between the sulfuric acid solution

(electrolyte) and the lead +/- plates in each cell of the

battery. As the battery discharges, the plates react

with the acid from the electrolyte. When the charging

system charges the battery, the water is converted to

sulfuric acid in the battery. The concentration of acid

in the electrolyte is measured as specific gravity

using a hydrometer. The original equipment (OE)

battery is equipped with a hydrometer (test indica-

tor) built into the battery cover. The specific gravity

indicates the battery's state-of-charge. The OE bat-

tery is sealed and water cannot be added.

The battery is vented to release gases that are cre-

ated when the battery is being charged and dis-

charged. The battery top, posts, and terminals should

be cleaned when other under hood maintenance is

performed.

When the electrolyte level is below the top of the

plates, Yellow/Clear in the test Indicator, the battery

must be replaced. The battery must be completely

charged, and the battery top, posts, and cable clampsmust be cleaned before diagnostic procedures are per-

formed.DESCRIPTION AND OPERATION

BATTERY IGNITION OFF DRAW (IOD)

A completely normal vehicle will have a small

amount of current drain on the battery with the key

out of the ignition. It can range from 4 to 10 milli-

amperes after all the modules time out. If a vehicle

will not be operated for approximately a 20 days, the

IOD fuse should be disconnected to minimize the

vehicle electrical drain on the battery. The IOD fuse

is located in the Power Distribution Center (PDC).

Refer to the PDC to locate the cover proper fuse.

CHARGING TIME REQUIRED

WARNING: NEVER EXCEED 20 AMPS WHEN

CHARGING A COLD -1ÉC (30ÉF) BATTERY. PER-

SONAL INJURY MAY RESULT.

The time required to charge a battery will vary

depending upon the following factors.

SIZE OF BATTERY

A completely discharged large heavy-duty battery

may require more recharging time than a completely

discharged small capacity battery. Refer to Battery

Charging Timetable for proper charging times.

PLBATTERY 8A - 1

Page 223 of 1200

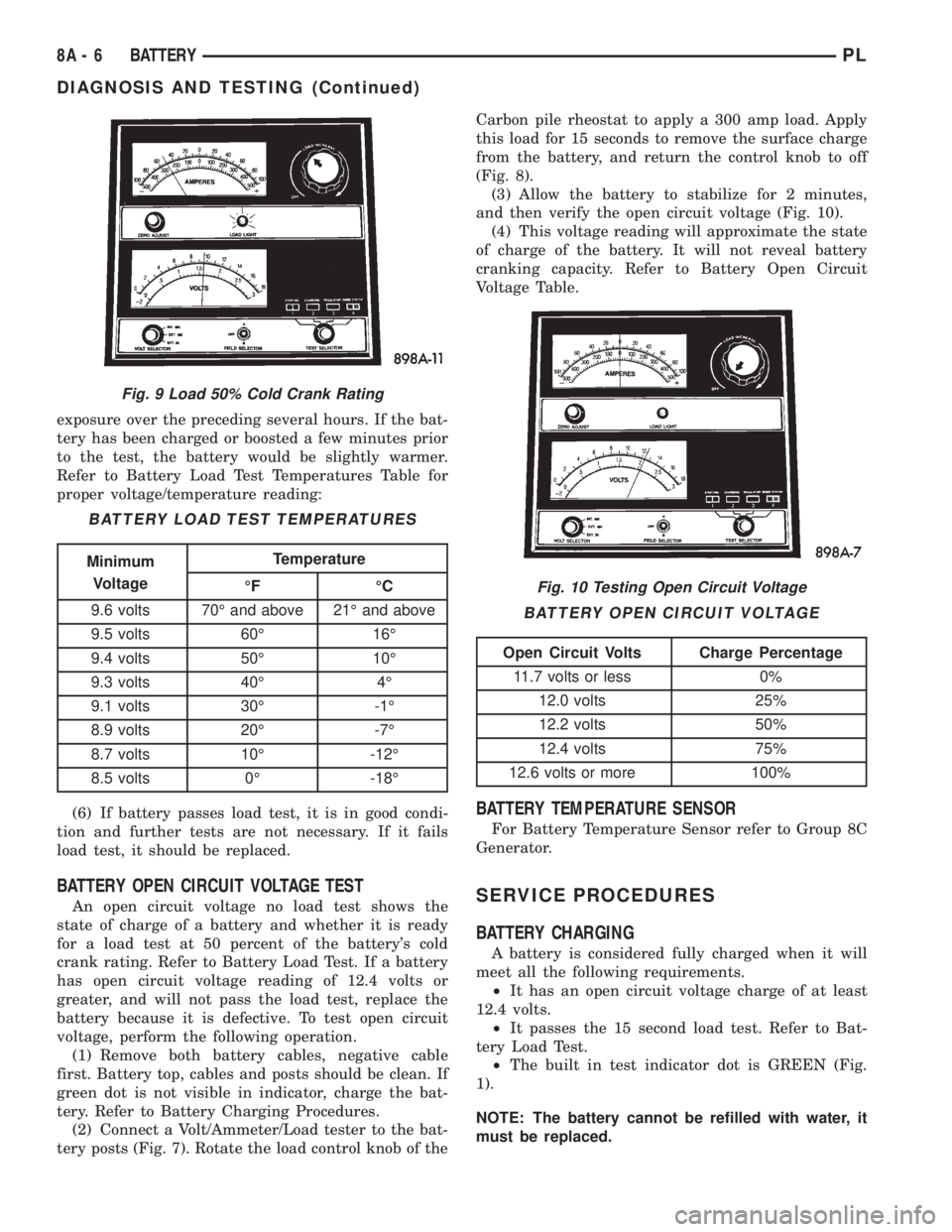

exposure over the preceding several hours. If the bat-

tery has been charged or boosted a few minutes prior

to the test, the battery would be slightly warmer.

Refer to Battery Load Test Temperatures Table for

proper voltage/temperature reading:

(6) If battery passes load test, it is in good condi-

tion and further tests are not necessary. If it fails

load test, it should be replaced.

BATTERY OPEN CIRCUIT VOLTAGE TEST

An open circuit voltage no load test shows the

state of charge of a battery and whether it is ready

for a load test at 50 percent of the battery's cold

crank rating. Refer to Battery Load Test. If a battery

has open circuit voltage reading of 12.4 volts or

greater, and will not pass the load test, replace the

battery because it is defective. To test open circuit

voltage, perform the following operation.

(1) Remove both battery cables, negative cable

first. Battery top, cables and posts should be clean. If

green dot is not visible in indicator, charge the bat-

tery. Refer to Battery Charging Procedures.

(2) Connect a Volt/Ammeter/Load tester to the bat-

tery posts (Fig. 7). Rotate the load control knob of theCarbon pile rheostat to apply a 300 amp load. Apply

this load for 15 seconds to remove the surface charge

from the battery, and return the control knob to off

(Fig. 8).

(3) Allow the battery to stabilize for 2 minutes,

and then verify the open circuit voltage (Fig. 10).

(4) This voltage reading will approximate the state

of charge of the battery. It will not reveal battery

cranking capacity. Refer to Battery Open Circuit

Voltage Table.

BATTERY TEMPERATURE SENSOR

For Battery Temperature Sensor refer to Group 8C

Generator.

SERVICE PROCEDURES

BATTERY CHARGING

A battery is considered fully charged when it will

meet all the following requirements.

²It has an open circuit voltage charge of at least

12.4 volts.

²It passes the 15 second load test. Refer to Bat-

tery Load Test.

²The built in test indicator dot is GREEN (Fig.

1).

NOTE: The battery cannot be refilled with water, it

must be replaced.

Fig. 9 Load 50% Cold Crank Rating

BATTERY LOAD TEST TEMPERATURES

Minimum

VoltageTemperature

ÉF ÉC

9.6 volts 70É and above 21É and above

9.5 volts 60É 16É

9.4 volts 50É 10É

9.3 volts 40É 4É

9.1 volts 30É -1É

8.9 volts 20É -7É

8.7 volts 10É -12É

8.5 volts 0É -18É

Fig. 10 Testing Open Circuit Voltage

BATTERY OPEN CIRCUIT VOLTAGE

Open Circuit Volts Charge Percentage

11.7 volts or less 0%

12.0 volts 25%

12.2 volts 50%

12.4 volts 75%

12.6 volts or more 100%

8A - 6 BATTERYPL

DIAGNOSIS AND TESTING (Continued)

Page 224 of 1200

WARNING: DO NOT CHARGE A BATTERY THAT

HAS EXCESSIVELY LOW ELECTROLYTE LEVEL.

BATTERY MAY SPARK INTERNALLY AND

EXPLODE. EXPLOSIVE GASES FORM OVER THE

BATTERY. DO NOT SMOKE, USE FLAME, OR CRE-

ATE SPARKS NEAR BATTERY. DO NOT ASSIST

BOOST OR CHARGE A FROZEN BATTERY. BAT-

TERY CASING MAY FRACTURE. BATTERY ACID IS

POISON, AND MAY CAUSE SEVERE BURNS. BAT-

TERIES CONTAIN SULFURIC ACID. AVOID CON-

TACT WITH SKIN, EYES, OR CLOTHING. IN THE

EVENT OF CONTACT, FLUSH WITH WATER AND

CALL PHYSICIAN IMMEDIATELY. KEEP OUT OF

REACH OF CHILDREN.

CAUTION: Disconnect the battery NEGATIVE cable

first, before charging battery to avoid damage to

electrical systems. Lift the red battery boot cover

from the positive cable clamp. Do not exceed 16.0

volts while charging battery. Refer to the instruc-

tions supplied with charging equipment

Battery electrolyte may bubble inside of battery

case while being charged properly. If the electrolyte

boils violently, or is discharged from the vent holes

while charging, immediately reduce charging rate or

turn off charger. Evaluate battery condition. Battery

damage may occur if charging is excessive.

Some battery chargers are equipped with polarity

sensing devices to protect the charger or battery from

being damaged if improperly connected. If the bat-

tery state of charge is too low for the polarity sensor

to detect, the sensor must be bypassed for charger to

operate. Refer to operating instructions provided

with battery charger being used.

CAUTION: Charge battery until test indicator

appears green. Do not overcharge.

It may be necessary to jiggle the battery or vehicle

to bring the green dot in the test indicator into view.

After the battery has been charged to 12.4 volts or

greater, perform a load test to determine cranking

capacity. Refer to Battery Load Test in this Group. If

the battery passes the load test, the battery is OK to

use. If battery will not pass the load test, it must be

replaced. Properly clean and inspect battery hold

downs, tray, terminals, cables, posts, and top before

completing service.

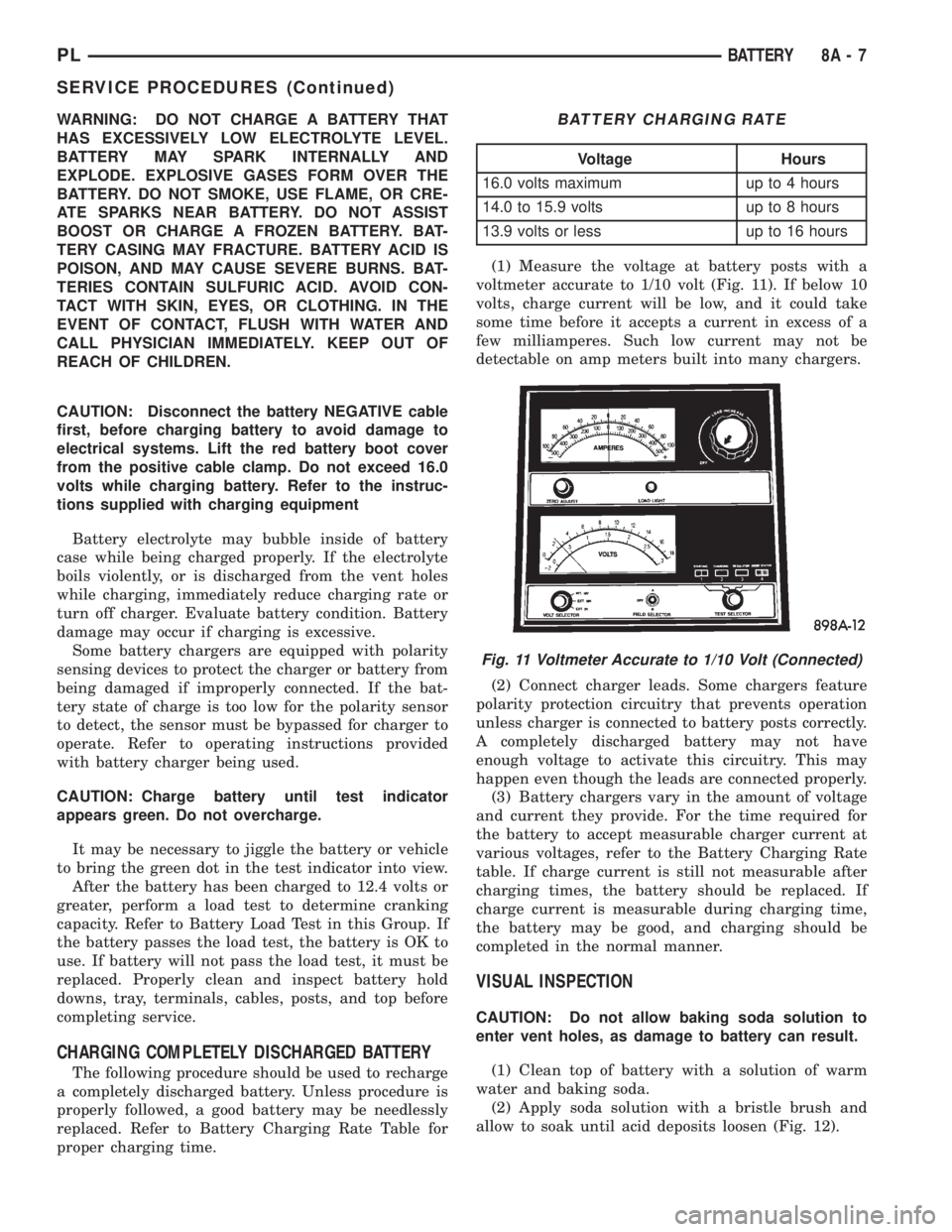

CHARGING COMPLETELY DISCHARGED BATTERY

The following procedure should be used to recharge

a completely discharged battery. Unless procedure is

properly followed, a good battery may be needlessly

replaced. Refer to Battery Charging Rate Table for

proper charging time.(1) Measure the voltage at battery posts with a

voltmeter accurate to 1/10 volt (Fig. 11). If below 10

volts, charge current will be low, and it could take

some time before it accepts a current in excess of a

few milliamperes. Such low current may not be

detectable on amp meters built into many chargers.

(2) Connect charger leads. Some chargers feature

polarity protection circuitry that prevents operation

unless charger is connected to battery posts correctly.

A completely discharged battery may not have

enough voltage to activate this circuitry. This may

happen even though the leads are connected properly.

(3) Battery chargers vary in the amount of voltage

and current they provide. For the time required for

the battery to accept measurable charger current at

various voltages, refer to the Battery Charging Rate

table. If charge current is still not measurable after

charging times, the battery should be replaced. If

charge current is measurable during charging time,

the battery may be good, and charging should be

completed in the normal manner.

VISUAL INSPECTION

CAUTION: Do not allow baking soda solution to

enter vent holes, as damage to battery can result.

(1) Clean top of battery with a solution of warm

water and baking soda.

(2) Apply soda solution with a bristle brush and

allow to soak until acid deposits loosen (Fig. 12).

BATTERY CHARGING RATE

Voltage Hours

16.0 volts maximum up to 4 hours

14.0 to 15.9 volts up to 8 hours

13.9 volts or less up to 16 hours

Fig. 11 Voltmeter Accurate to 1/10 Volt (Connected)

PLBATTERY 8A - 7

SERVICE PROCEDURES (Continued)

Page 236 of 1200

CHARGING SYSTEM

CONTENTS

page page

GENERAL INFORMATION

OVERVIEW............................. 1

DESCRIPTION AND OPERATION

BATTERY TEMPERATURE SENSOR.......... 2

CHARGING SYSTEM OPERATION........... 1

ELECTRONIC VOLTAGE REGULATOR......... 2

GENERATOR............................ 2

DIAGNOSIS AND TESTING

BATTERY TEMPERATURE SENSOR.......... 8

CHARGING SYSTEM RESISTANCE TESTS..... 5CHARGING SYSTEM...................... 2

CURRENT OUTPUT TEST.................. 8

ON-BOARD DIAGNOSTIC SYSTEM TEST..... 10

REMOVAL AND INSTALLATION

BATTERY TEMPERATURE SENSOR......... 11

GENERATOR........................... 10

SPECIFICATIONS

GENERATOR RATINGS................... 12

TORQUE.............................. 12

GENERAL INFORMATION

OVERVIEW

The battery, starting, and charging systems oper-

ate with one another, and must be tested as a com-

plete system. In order for the vehicle to start and

charge properly, all of the components involved in

these systems must perform within specifications.

Group 8A covers the battery, Group 8B covers the

starting system, and Group 8C covers the charging

system. Refer to Group 8W - Wiring Diagrams for

complete circuit descriptions and diagrams. We have

separated these systems to make it easier to locate

the information you are seeking within this Service

Manual. However, when attempting to diagnose any

of these systems, it is important that you keep their

interdependency in mind.

The diagnostic procedures used in these groups

include the most basic conventional diagnostic meth-

ods to the more sophisticated On-Board Diagnostics

(OBD) built into the Powertrain Control Module

(PCM). Use of an induction ammeter, volt/ohmmeter,

battery charger, carbon pile rheostat (load tester),

and 12-volt test lamp may be required.

All OBD-sensed systems are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See the

On-Board Diagnostics Test in Group 8C - Charging

System for more information.

DESCRIPTION AND OPERATION

CHARGING SYSTEM OPERATION

The charging system consists of:

²Generator

²Electronic Voltage Regulator (EVR) circuitry

within the Powertrain Control Module (PCM)

²Ignition switch (refer to Group 8D, Ignition Sys-

tem for information)

²Battery (refer to Group 8A, Battery for informa-

tion)

²Battery temperature sensor

²Voltmeter (refer to Group 8E, Instrument Panel

and Gauges for information)

²Wiring harness and connections (refer to Group

8W, Wiring for information)

The charging system is turned on and off with the

ignition switch. When the ignition switch is turned to

the ON position, battery voltage is applied to the

generator rotor through one of the two field termi-

nals to produce a magnetic field. The generator is

driven by the engine through a serpentine belt and

pulley arrangement.

The amount of DC current produced by the gener-

ator is controlled by the EVR (field control) circuitry,

contained within the PCM. This circuitry is con-

nected in series with the second rotor field terminal

and ground.

PLCHARGING SYSTEM 8C - 1

Page 237 of 1200

A battery temperature sensor located on the front

bumper beam is used to sense battery temperature.

This temperature data, along with data from moni-

tored line voltage, is used by the PCM to vary the

battery charging rate. This is done by cycling the

ground path to control the strength of the rotor mag-

netic field. The PCM then compensates and regulates

generator current output accordingly and to maintain

the proper voltage depending on battery tempera-

ture.

All vehicles are equipped with On-Board Diagnos-

tics (OBD). All OBD-sensed systems, including the

EVR (field control) circuitry, are monitored by the

PCM. Each monitored circuit is assigned a Diagnos-

tic Trouble Code (DTC). The PCM will store a DTC in

electronic memory for any failure it detects. See On-

Board Diagnostic System Test in this group for more

information.

GENERATOR

The generator is belt-driven by the engine. It is

serviced only as a complete assembly. If the genera-

tor fails for any reason, the entire assembly must be

replaced.

As the energized rotor begins to rotate within the

generator, the spinning magnetic field induces a cur-

rent into the windings of the stator coil. Once the

generator begins producing sufficient current, it also

provides the current needed to energize the rotor.

The Y type stator winding connections deliver the

induced AC current to 3 positive and 3 negative

diodes for rectification. From the diodes, rectified DC

current is delivered to the vehicle electrical system

through the generator, battery, and ground terminals.

Noise emitting from the generator may be caused

by:

²Worn, loose or defective bearings

²Loose or defective drive pulley

²Incorrect, worn, damaged or misadjusted drive

belt

²Loose mounting bolts

²Misaligned drive pulley

²Defective stator or diode

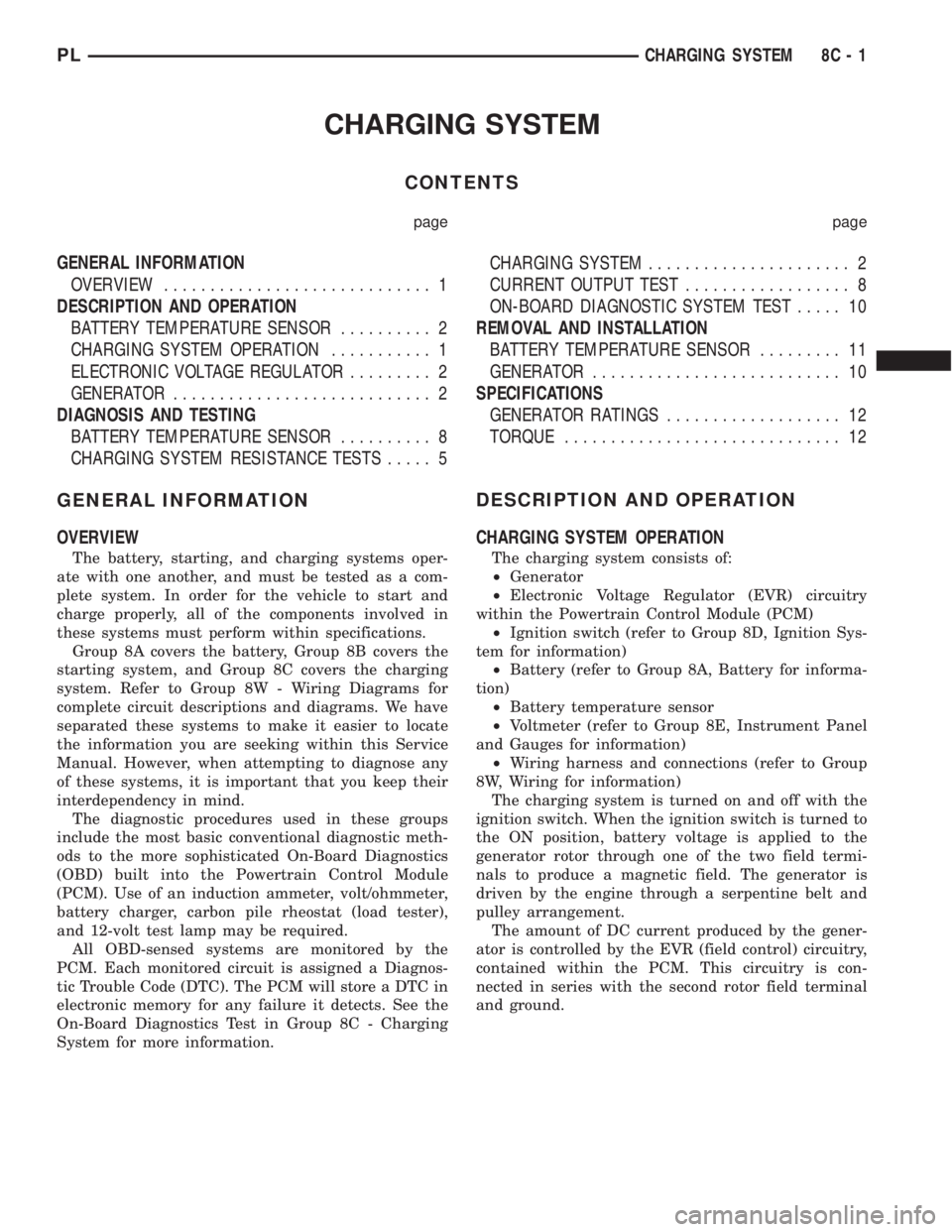

BATTERY TEMPERATURE SENSOR

The battery temperature sensor is used to deter-

mine the battery temperature. This temperature

data, along with data from monitored line voltage, is

used by the PCM to vary the battery charging rate.

System voltage will be higher at colder temperatures

and is gradually reduced at warmer temperatures.

The sensor is located on the bottom of the battery

tray (Fig. 1).

ELECTRONIC VOLTAGE REGULATOR

The Electronic Voltage Regulator (EVR) is not a

separate component. It is actually a voltage regulat-

ing circuit located within the Powertrain Control

Module (PCM). The EVR is not serviced separately. If

replacement is necessary, the PCM must be replaced.

Operation:The amount of DC current produced

by the generator is controlled by EVR circuitry con-

tained within the PCM. This circuitry is connected in

series with the generators second rotor field terminal

and its ground.

Voltage is regulated by cycling the ground path to

control the strength of the rotor magnetic field. The

EVR circuitry monitors system line voltage and bat-

tery temperature (refer to Battery Temperature Sen-

sor for more information). It then compensates and

regulates generator current output accordingly. Also

refer to Charging System Operation for additional

information.

DIAGNOSIS AND TESTING

CHARGING SYSTEM

When the ignition switch is turned to the ON posi-

tion, battery potential will register on the voltmeter.

During engine cranking a lower voltage will appear

on the meter. With the engine running, a voltage

reading higher than the first reading (ignition in ON)

should register.

The following are possible symptoms of a charging

system fault:

²The voltmeter does not operate properly

²An undercharged or overcharged battery condi-

tion occurs.

Fig. 1 Battery Temperature Sensor

8C - 2 CHARGING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)