engine DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 924 of 1200

INSTALL

CAUTION: Do not hammer on power steering

pump pulley or shaft to remove power steering

pump pulley. This will damage the pulley and the

power steering pump.

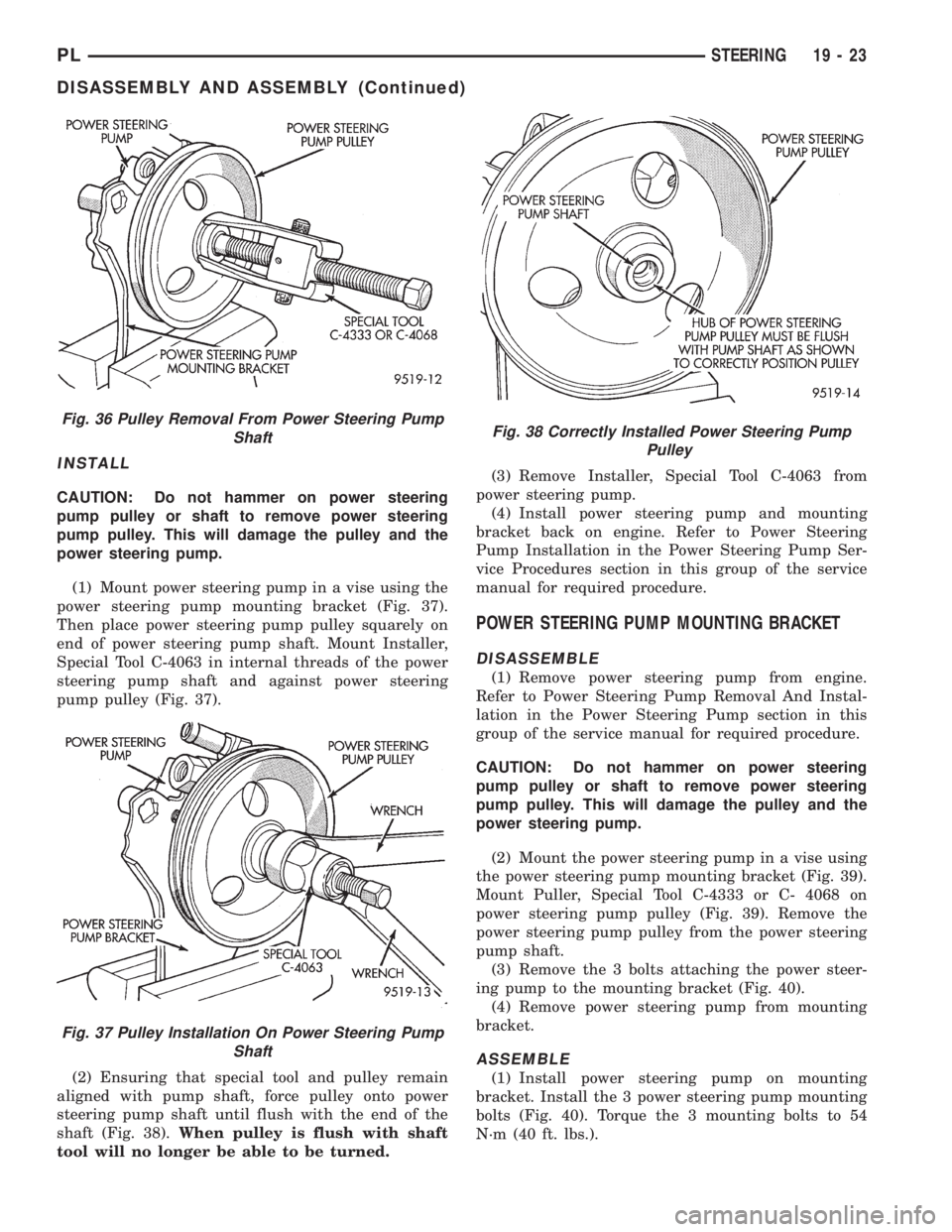

(1) Mount power steering pump in a vise using the

power steering pump mounting bracket (Fig. 37).

Then place power steering pump pulley squarely on

end of power steering pump shaft. Mount Installer,

Special Tool C-4063 in internal threads of the power

steering pump shaft and against power steering

pump pulley (Fig. 37).

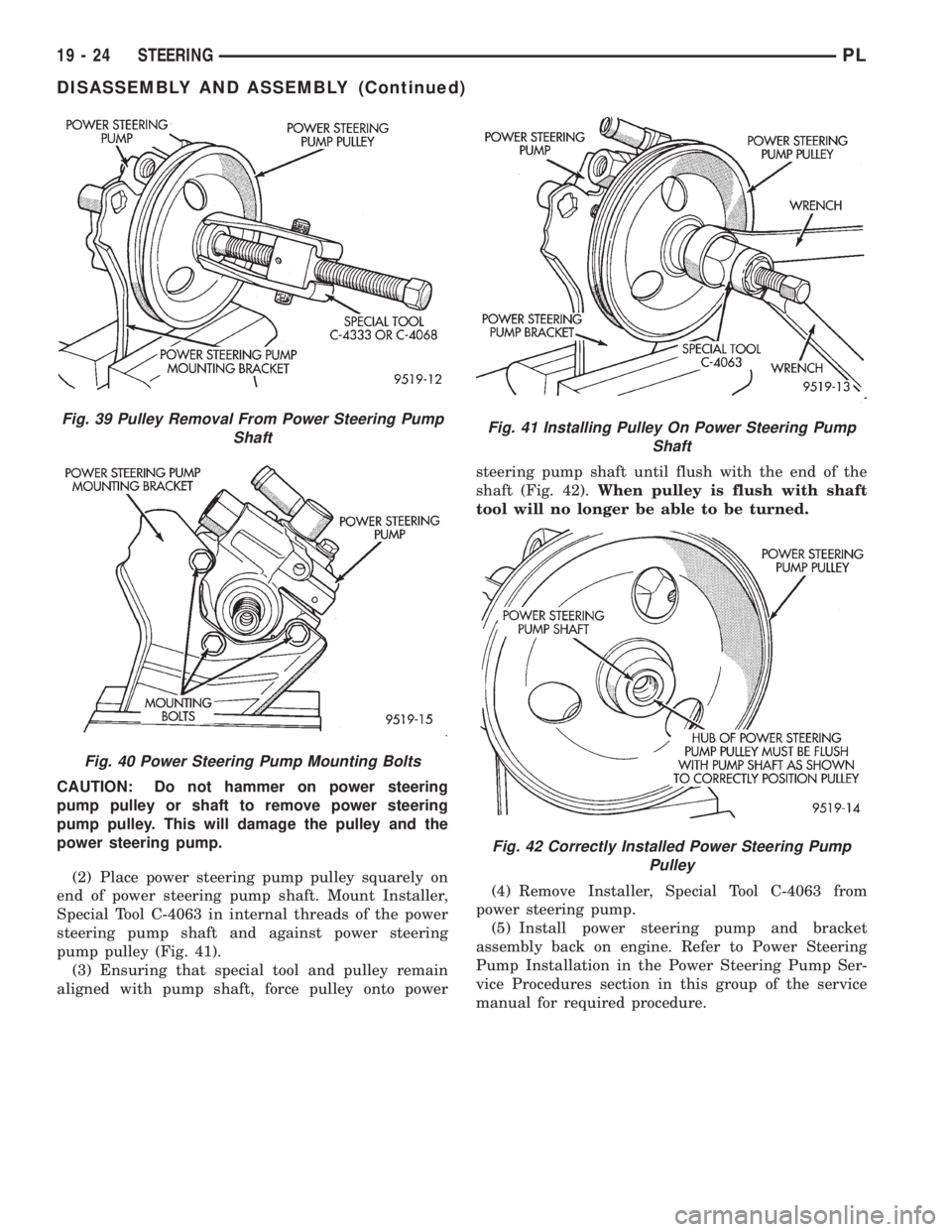

(2) Ensuring that special tool and pulley remain

aligned with pump shaft, force pulley onto power

steering pump shaft until flush with the end of the

shaft (Fig. 38).When pulley is flush with shaft

tool will no longer be able to be turned.(3) Remove Installer, Special Tool C-4063 from

power steering pump.

(4) Install power steering pump and mounting

bracket back on engine. Refer to Power Steering

Pump Installation in the Power Steering Pump Ser-

vice Procedures section in this group of the service

manual for required procedure.

POWER STEERING PUMP MOUNTING BRACKET

DISASSEMBLE

(1) Remove power steering pump from engine.

Refer to Power Steering Pump Removal And Instal-

lation in the Power Steering Pump section in this

group of the service manual for required procedure.

CAUTION: Do not hammer on power steering

pump pulley or shaft to remove power steering

pump pulley. This will damage the pulley and the

power steering pump.

(2) Mount the power steering pump in a vise using

the power steering pump mounting bracket (Fig. 39).

Mount Puller, Special Tool C-4333 or C- 4068 on

power steering pump pulley (Fig. 39). Remove the

power steering pump pulley from the power steering

pump shaft.

(3) Remove the 3 bolts attaching the power steer-

ing pump to the mounting bracket (Fig. 40).

(4) Remove power steering pump from mounting

bracket.

ASSEMBLE

(1) Install power steering pump on mounting

bracket. Install the 3 power steering pump mounting

bolts (Fig. 40). Torque the 3 mounting bolts to 54

N´m (40 ft. lbs.).

Fig. 36 Pulley Removal From Power Steering Pump

Shaft

Fig. 37 Pulley Installation On Power Steering Pump

Shaft

Fig. 38 Correctly Installed Power Steering Pump

Pulley

PLSTEERING 19 - 23

DISASSEMBLY AND ASSEMBLY (Continued)

Page 925 of 1200

CAUTION: Do not hammer on power steering

pump pulley or shaft to remove power steering

pump pulley. This will damage the pulley and the

power steering pump.

(2) Place power steering pump pulley squarely on

end of power steering pump shaft. Mount Installer,

Special Tool C-4063 in internal threads of the power

steering pump shaft and against power steering

pump pulley (Fig. 41).

(3) Ensuring that special tool and pulley remain

aligned with pump shaft, force pulley onto powersteering pump shaft until flush with the end of the

shaft (Fig. 42).When pulley is flush with shaft

tool will no longer be able to be turned.

(4) Remove Installer, Special Tool C-4063 from

power steering pump.

(5) Install power steering pump and bracket

assembly back on engine. Refer to Power Steering

Pump Installation in the Power Steering Pump Ser-

vice Procedures section in this group of the service

manual for required procedure.

Fig. 41 Installing Pulley On Power Steering Pump

Shaft

Fig. 42 Correctly Installed Power Steering Pump

Pulley

Fig. 39 Pulley Removal From Power Steering Pump

Shaft

Fig. 40 Power Steering Pump Mounting Bolts

19 - 24 STEERINGPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 926 of 1200

SPECIFICATIONS

POWER STEERING PUMP FLOW SPECIFICATIONS

Power Steering Pump Flow:

At 1500 RPM And

Minimum Pressure.........4.9 to 5.3 Liters/Min

(1.3 to 1.9 GPM)

Control Valve Pressure Relief....8240 to 8920 kPa

(1195 to 1293 psi)

POWER STEERING PUMP FASTENER TORQUE

SPECIFICATIONS

DESCRIPTION TORQUE

Power Steering Hose:

Tube Nuts Pressure And Return...........31N´m

(275 in. lbs.)

Bracket To Front Crossmember

Attaching Bolt.............23N´m(17ft.lbs.).

Power Steering Pump:

Pressure Hose Banjo Bolt......34N´m(25ft.lbs.).

Discharge Fitting.............75N´m(55ft.lbs.)

To Bracket Mounting Bolts.....54N´m(40. ft. lbs.)

Brackets To Engine Mounting Bolts.......54N´m

(40 ft. lbs.)

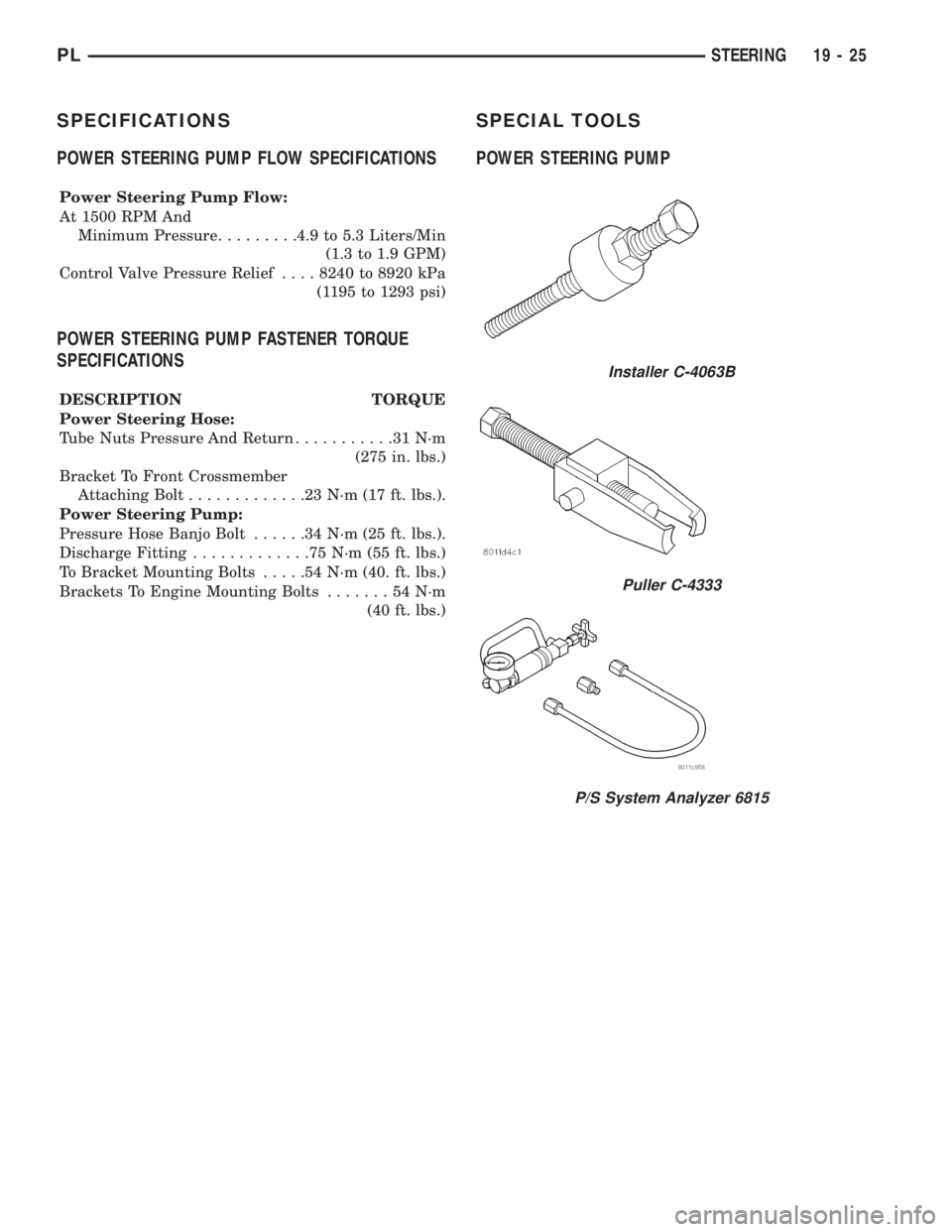

SPECIAL TOOLS

POWER STEERING PUMP

Installer C-4063B

Puller C-4333

P/S System Analyzer 6815

PLSTEERING 19 - 25

Page 928 of 1200

However, under these conditions, steering effort will

be increased.

NOTE: The power steering gear (Fig. 1) should NOT

be serviced or adjusted. If a malfunction or oil leak

occurs with the steering gear, the complete steering

gear needs to be replaced.

DIAGNOSIS AND TESTING

POWER STEERING SYSTEM TEST PROCEDURE

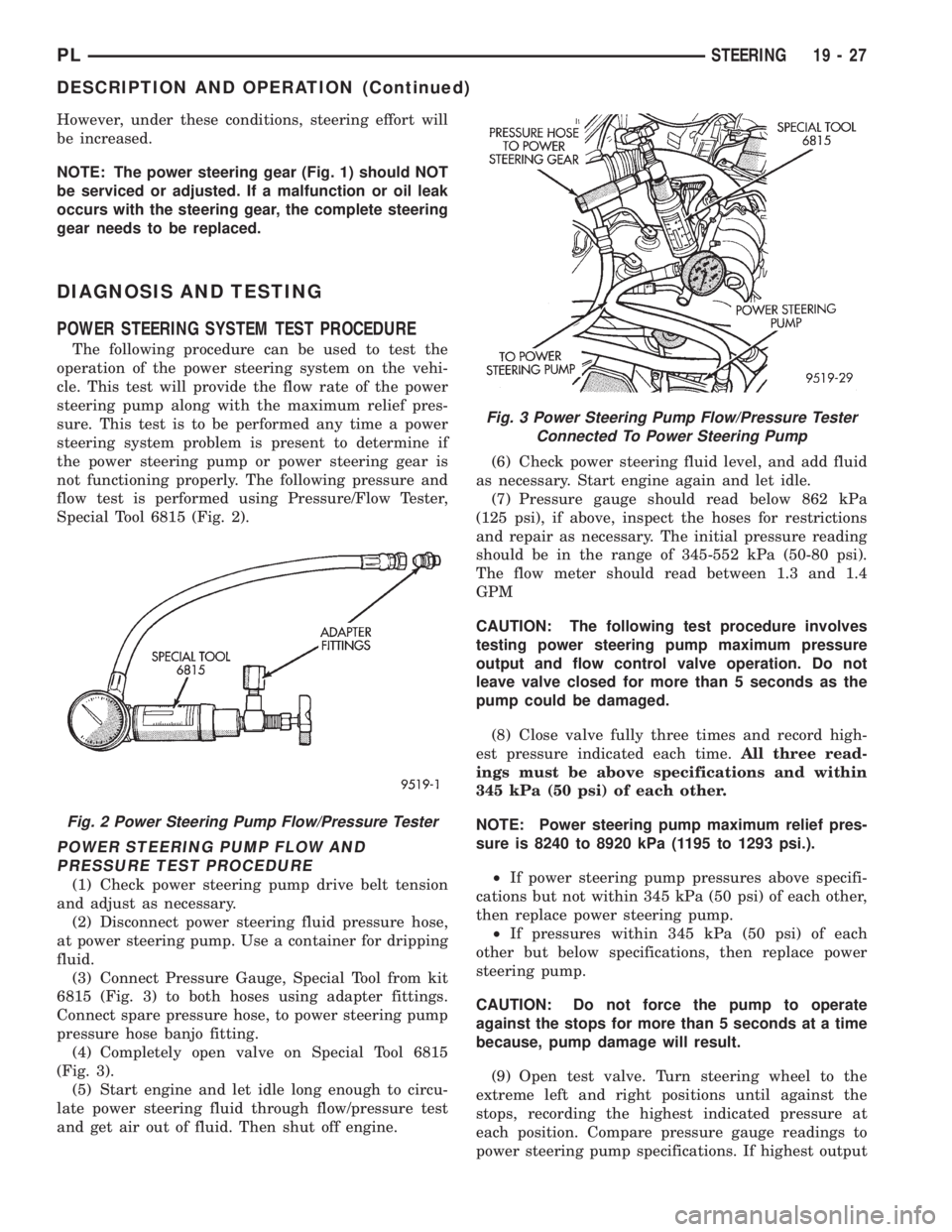

The following procedure can be used to test the

operation of the power steering system on the vehi-

cle. This test will provide the flow rate of the power

steering pump along with the maximum relief pres-

sure. This test is to be performed any time a power

steering system problem is present to determine if

the power steering pump or power steering gear is

not functioning properly. The following pressure and

flow test is performed using Pressure/Flow Tester,

Special Tool 6815 (Fig. 2).

POWER STEERING PUMP FLOW AND

PRESSURE TEST PROCEDURE

(1) Check power steering pump drive belt tension

and adjust as necessary.

(2) Disconnect power steering fluid pressure hose,

at power steering pump. Use a container for dripping

fluid.

(3) Connect Pressure Gauge, Special Tool from kit

6815 (Fig. 3) to both hoses using adapter fittings.

Connect spare pressure hose, to power steering pump

pressure hose banjo fitting.

(4) Completely open valve on Special Tool 6815

(Fig. 3).

(5) Start engine and let idle long enough to circu-

late power steering fluid through flow/pressure test

and get air out of fluid. Then shut off engine.(6) Check power steering fluid level, and add fluid

as necessary. Start engine again and let idle.

(7) Pressure gauge should read below 862 kPa

(125 psi), if above, inspect the hoses for restrictions

and repair as necessary. The initial pressure reading

should be in the range of 345-552 kPa (50-80 psi).

The flow meter should read between 1.3 and 1.4

GPM

CAUTION: The following test procedure involves

testing power steering pump maximum pressure

output and flow control valve operation. Do not

leave valve closed for more than 5 seconds as the

pump could be damaged.

(8) Close valve fully three times and record high-

est pressure indicated each time.All three read-

ings must be above specifications and within

345 kPa (50 psi) of each other.

NOTE: Power steering pump maximum relief pres-

sure is 8240 to 8920 kPa (1195 to 1293 psi.).

²If power steering pump pressures above specifi-

cations but not within 345 kPa (50 psi) of each other,

then replace power steering pump.

²If pressures within 345 kPa (50 psi) of each

other but below specifications, then replace power

steering pump.

CAUTION: Do not force the pump to operate

against the stops for more than 5 seconds at a time

because, pump damage will result.

(9) Open test valve. Turn steering wheel to the

extreme left and right positions until against the

stops, recording the highest indicated pressure at

each position. Compare pressure gauge readings to

power steering pump specifications. If highest output

Fig. 3 Power Steering Pump Flow/Pressure Tester

Connected To Power Steering Pump

Fig. 2 Power Steering Pump Flow/Pressure Tester

PLSTEERING 19 - 27

DESCRIPTION AND OPERATION (Continued)

Page 929 of 1200

pressures are not the same against either stop, the

steering gear is leaking internally and must be

replaced.

REMOVAL AND INSTALLATION

MANUAL AND POWER STEERING GEAR

The removal and replacement procedure for both

the manual and power steering gears is the same.

The only additional steps of the procedure for the

power steering gear, is the removal and replacement

of the power steering fluid lines at the steering gear.

REMOVE

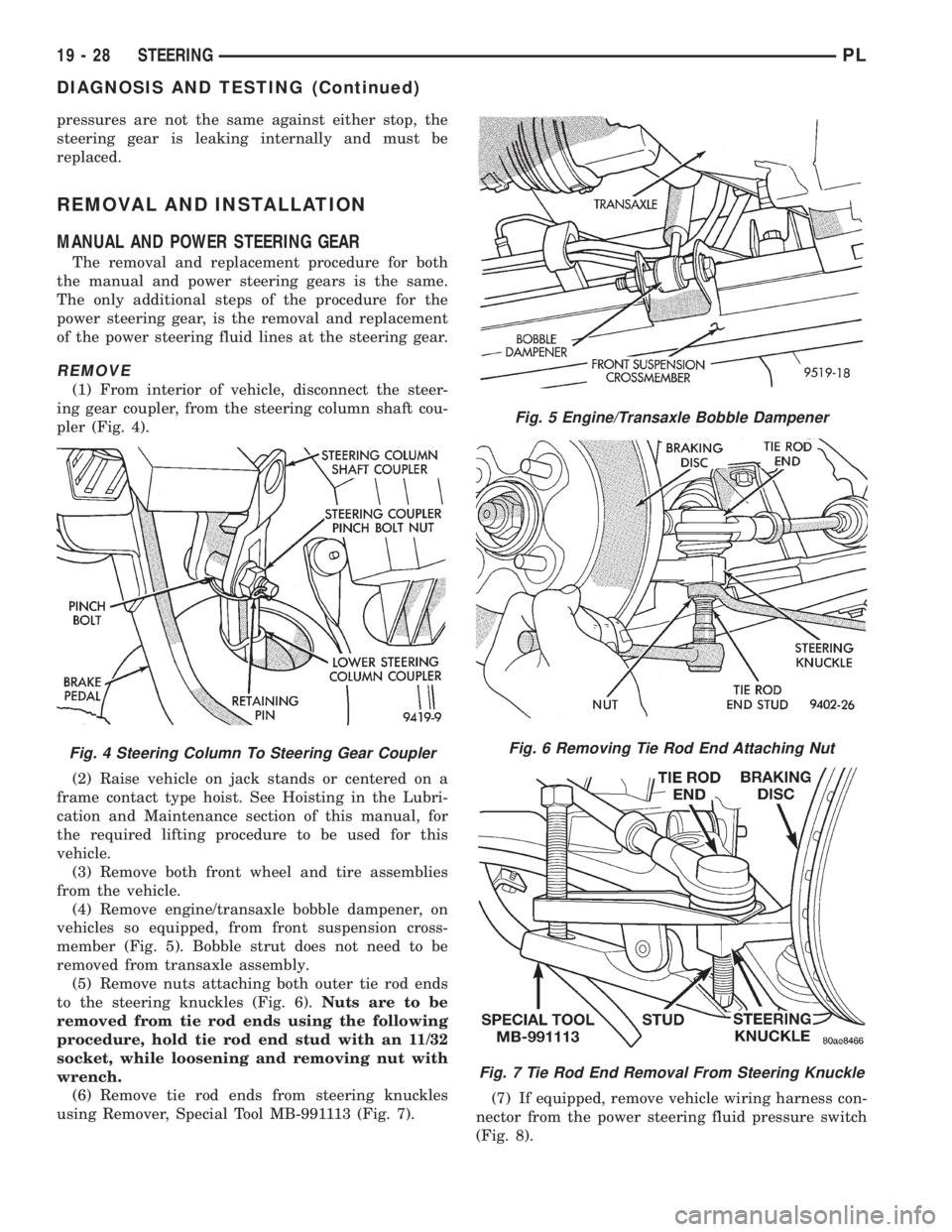

(1) From interior of vehicle, disconnect the steer-

ing gear coupler, from the steering column shaft cou-

pler (Fig. 4).

(2) Raise vehicle on jack stands or centered on a

frame contact type hoist. See Hoisting in the Lubri-

cation and Maintenance section of this manual, for

the required lifting procedure to be used for this

vehicle.

(3) Remove both front wheel and tire assemblies

from the vehicle.

(4) Remove engine/transaxle bobble dampener, on

vehicles so equipped, from front suspension cross-

member (Fig. 5). Bobble strut does not need to be

removed from transaxle assembly.

(5) Remove nuts attaching both outer tie rod ends

to the steering knuckles (Fig. 6).Nuts are to be

removed from tie rod ends using the following

procedure, hold tie rod end stud with an 11/32

socket, while loosening and removing nut with

wrench.

(6) Remove tie rod ends from steering knuckles

using Remover, Special Tool MB-991113 (Fig. 7).(7) If equipped, remove vehicle wiring harness con-

nector from the power steering fluid pressure switch

(Fig. 8).

Fig. 4 Steering Column To Steering Gear Coupler

Fig. 5 Engine/Transaxle Bobble Dampener

Fig. 6 Removing Tie Rod End Attaching Nut

Fig. 7 Tie Rod End Removal From Steering Knuckle

19 - 28 STEERINGPL

DIAGNOSIS AND TESTING (Continued)

Page 932 of 1200

Torque the 4 steering gear mounting bolts to 68 N´m

(50 ft. lbs.).

(2) Using the transmission jack, raise front sus-

pension crossmember and steering gear against body

and frame rails of vehicle. Start the 2 rear bolts into

tapping plates, attaching front suspension crossmem-

ber to body of vehicle (Fig. 13). Then install the 2

front bolts, attaching front suspension crossmember

to frame rails of vehicle (Fig. 13). Tighten the 4

mounting bolts, until front suspension crossmember

is against body of vehicle at the 4 mounting points.

Then torque the 4 mounting bolts to 2 N´m (20 in.

lbs.) to hold front suspension crossmember in posi-

tion.

CAUTION: When front suspension crossmember is

installed back in vehicle, crossmember MUST be

aligned with positioning marks previously scribbed

into body of vehicle (Fig. 16). This MUST be done to

maintain NET BUILD front suspension alignment

settings.

(3) Using a soft face hammer, tap front suspension

crossmember into position, until it is aligned with

the 2 previously scribbed positioning marks on body

of vehicle (Fig. 16). When front suspension cross-

member is correctly positioned, torque the 2 rear

crossmember/lower control arm mounting bolts to

163 N´m (120 ft. lbs.). Then torque the 2 front cross-

member to frame rail attaching bolts to 163 N´m (120

ft. lbs.) (Fig. 13).

(4) If vehicle is equipped with power steering,

install power steering fluid pressure and return

hoses into correct fluid ports on power steering gear

assembly (Fig. 10). Torque power steering fluid pres-

sure and return lines to steering gear tube nuts (Fig.

10) to 31 N´m (275 in. lbs.).(5) If vehicle is equipped with power steering,

install power steering pressure and return hose rout-

ing bracket and attaching screw on front suspension

crossmember (Fig. 9). Torque hose routing bracket to

crossmember attaching bolt (Fig. 9) to 23 N´m (17 ft,

lbs.).

(6) If the vehicle is equipped with power steering,

install vehicle wiring harness connector onto power

steering fluid pressure switch on steering gear

assembly (Fig. 8). Be sure locking tab on wiring har-

ness connector is securely latched to pressure switch.

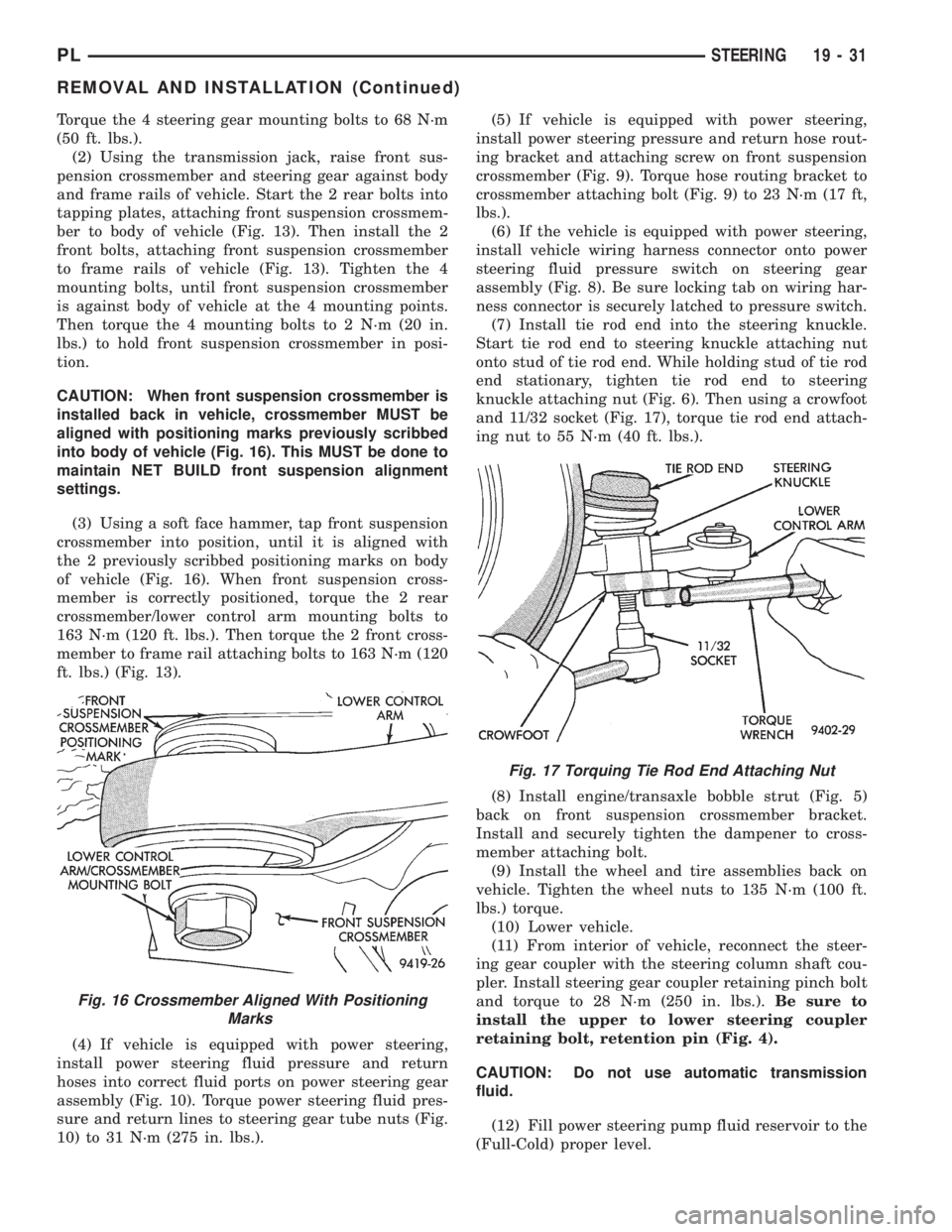

(7) Install tie rod end into the steering knuckle.

Start tie rod end to steering knuckle attaching nut

onto stud of tie rod end. While holding stud of tie rod

end stationary, tighten tie rod end to steering

knuckle attaching nut (Fig. 6). Then using a crowfoot

and 11/32 socket (Fig. 17), torque tie rod end attach-

ing nut to 55 N´m (40 ft. lbs.).

(8) Install engine/transaxle bobble strut (Fig. 5)

back on front suspension crossmember bracket.

Install and securely tighten the dampener to cross-

member attaching bolt.

(9) Install the wheel and tire assemblies back on

vehicle. Tighten the wheel nuts to 135 N´m (100 ft.

lbs.) torque.

(10) Lower vehicle.

(11) From interior of vehicle, reconnect the steer-

ing gear coupler with the steering column shaft cou-

pler. Install steering gear coupler retaining pinch bolt

and torque to 28 N´m (250 in. lbs.).Be sure to

install the upper to lower steering coupler

retaining bolt, retention pin (Fig. 4).

CAUTION: Do not use automatic transmission

fluid.

(12) Fill power steering pump fluid reservoir to the

(Full-Cold) proper level.

Fig. 16 Crossmember Aligned With Positioning

Marks

Fig. 17 Torquing Tie Rod End Attaching Nut

PLSTEERING 19 - 31

REMOVAL AND INSTALLATION (Continued)

Page 933 of 1200

(13) Start the engine and let run for a few seconds.

Then turn the engine off.

(14) Add fluid if necessary.

(15) Raise front wheels of vehicle off the ground.

(16) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks.Fill pump reservoir to correct

level with Mopart, Power Steering Fluid, or

equivalent.See Checking Fluid Level.

(17) Lower front wheels of vehicle back on the

ground.

CAUTION: During this procedure do not allow the

steering gear inner tie rod boots to become twisted.

(See Wheel Alignment in the suspension section of

this service manual).

(18) Adjust the front Toe setting on the vehicle.

Refer to the Toe Setting Procedure in Front Suspen-

sion Service Procedures in this group of the service

manual. Refer to the Specifications Section at the

end of this group for the desired front Toe specifica-

tion.

(19) Tighten tie rod jam nut (Fig. 18) to 61 N´m

(45 ft.lbs.) torque.

(20) Adjust steering gear to tie rod boots at tie

rods.

DISASSEMBLY AND ASSEMBLY

OUTER TIE ROD

DISASSEMBLE

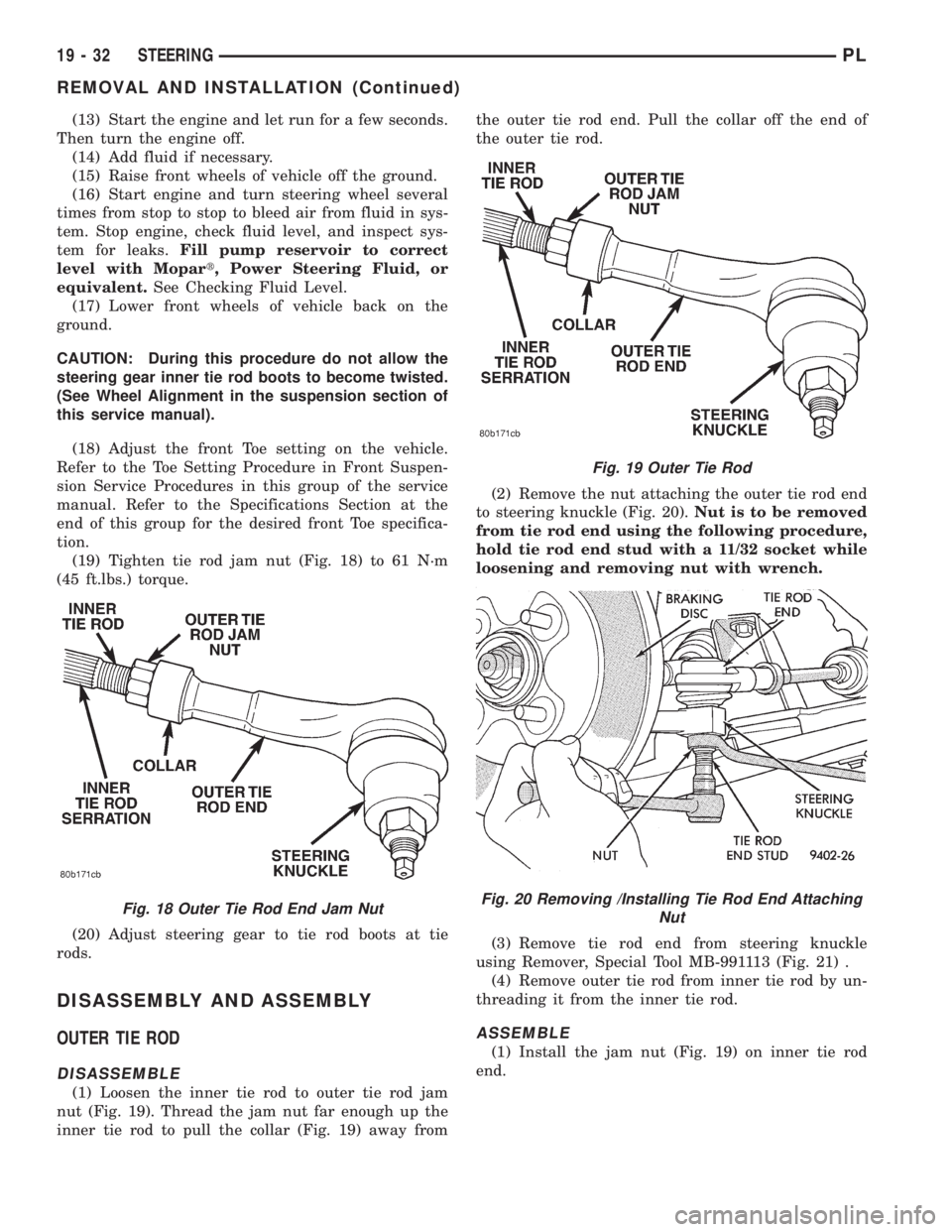

(1) Loosen the inner tie rod to outer tie rod jam

nut (Fig. 19). Thread the jam nut far enough up the

inner tie rod to pull the collar (Fig. 19) away fromthe outer tie rod end. Pull the collar off the end of

the outer tie rod.

(2) Remove the nut attaching the outer tie rod end

to steering knuckle (Fig. 20).Nut is to be removed

from tie rod end using the following procedure,

hold tie rod end stud with a 11/32 socket while

loosening and removing nut with wrench.

(3) Remove tie rod end from steering knuckle

using Remover, Special Tool MB-991113 (Fig. 21) .

(4) Remove outer tie rod from inner tie rod by un-

threading it from the inner tie rod.

ASSEMBLE

(1) Install the jam nut (Fig. 19) on inner tie rod

end.

Fig. 18 Outer Tie Rod End Jam Nut

Fig. 19 Outer Tie Rod

Fig. 20 Removing /Installing Tie Rod End Attaching

Nut

19 - 32 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 945 of 1200

CAUTION: The transaxle output shaft is serviced as

a unit. No disassembly and reassembly is possible.

Damage to the transaxle may result.

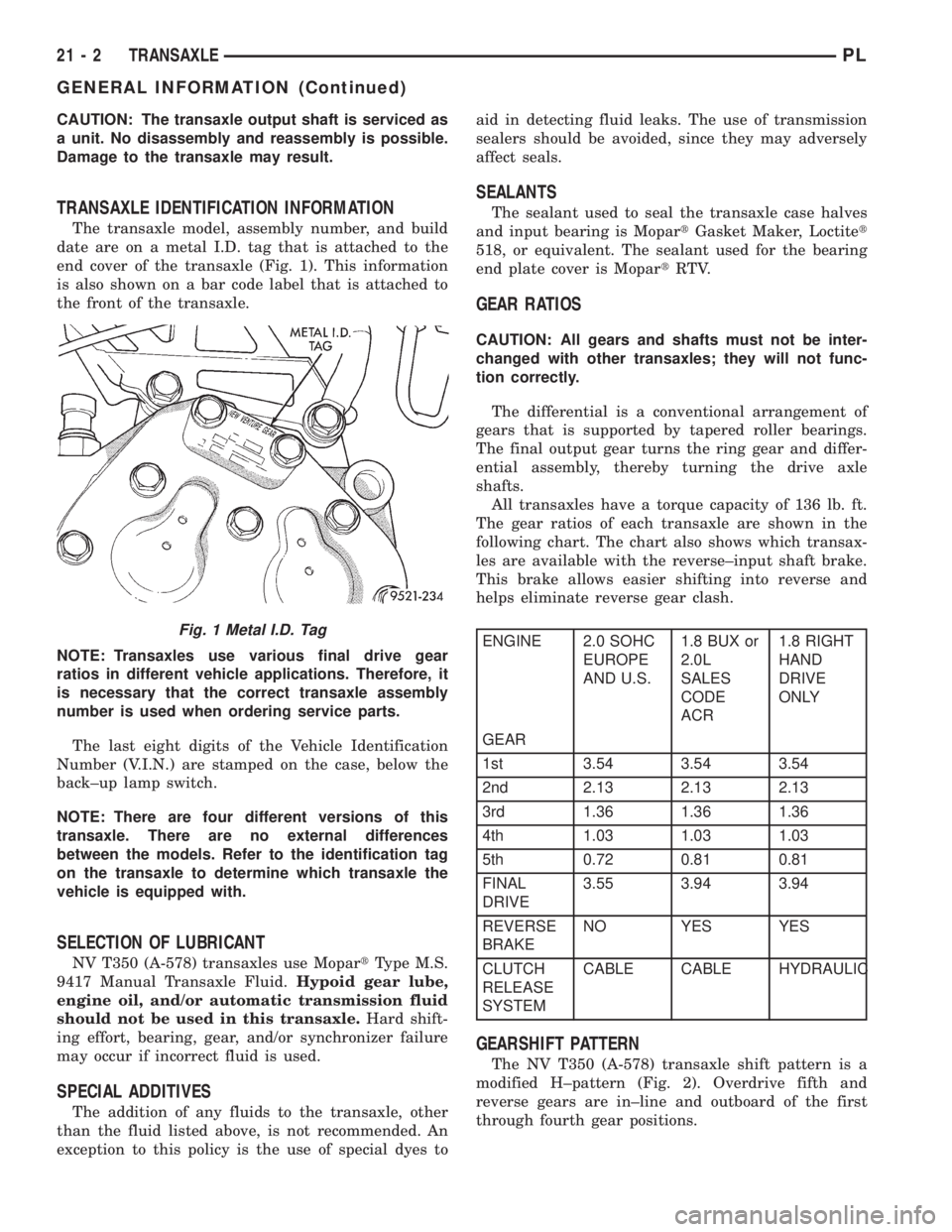

TRANSAXLE IDENTIFICATION INFORMATION

The transaxle model, assembly number, and build

date are on a metal I.D. tag that is attached to the

end cover of the transaxle (Fig. 1). This information

is also shown on a bar code label that is attached to

the front of the transaxle.

NOTE: Transaxles use various final drive gear

ratios in different vehicle applications. Therefore, it

is necessary that the correct transaxle assembly

number is used when ordering service parts.

The last eight digits of the Vehicle Identification

Number (V.I.N.) are stamped on the case, below the

back±up lamp switch.

NOTE: There are four different versions of this

transaxle. There are no external differences

between the models. Refer to the identification tag

on the transaxle to determine which transaxle the

vehicle is equipped with.

SELECTION OF LUBRICANT

NV T350 (A-578) transaxles use MopartType M.S.

9417 Manual Transaxle Fluid.Hypoid gear lube,

engine oil, and/or automatic transmission fluid

should not be used in this transaxle.Hard shift-

ing effort, bearing, gear, and/or synchronizer failure

may occur if incorrect fluid is used.

SPECIAL ADDITIVES

The addition of any fluids to the transaxle, other

than the fluid listed above, is not recommended. An

exception to this policy is the use of special dyes toaid in detecting fluid leaks. The use of transmission

sealers should be avoided, since they may adversely

affect seals.

SEALANTS

The sealant used to seal the transaxle case halves

and input bearing is MopartGasket Maker, Loctitet

518, or equivalent. The sealant used for the bearing

end plate cover is MopartRTV.

GEAR RATIOS

CAUTION: All gears and shafts must not be inter-

changed with other transaxles; they will not func-

tion correctly.

The differential is a conventional arrangement of

gears that is supported by tapered roller bearings.

The final output gear turns the ring gear and differ-

ential assembly, thereby turning the drive axle

shafts.

All transaxles have a torque capacity of 136 lb. ft.

The gear ratios of each transaxle are shown in the

following chart. The chart also shows which transax-

les are available with the reverse±input shaft brake.

This brake allows easier shifting into reverse and

helps eliminate reverse gear clash.

ENGINE 2.0 SOHC

EUROPE

AND U.S.1.8 BUX or

2.0L

SALES

CODE

ACR1.8 RIGHT

HAND

DRIVE

ONLY

GEAR

1st 3.54 3.54 3.54

2nd 2.13 2.13 2.13

3rd 1.36 1.36 1.36

4th 1.03 1.03 1.03

5th 0.72 0.81 0.81

FINAL

DRIVE3.55 3.94 3.94

REVERSE

BRAKENO YES YES

CLUTCH

RELEASE

SYSTEMCABLE CABLE HYDRAULIC

GEARSHIFT PATTERN

The NV T350 (A-578) transaxle shift pattern is a

modified H±pattern (Fig. 2). Overdrive fifth and

reverse gears are in±line and outboard of the first

through fourth gear positions.

Fig. 1 Metal I.D. Tag

21 - 2 TRANSAXLEPL

GENERAL INFORMATION (Continued)

Page 951 of 1200

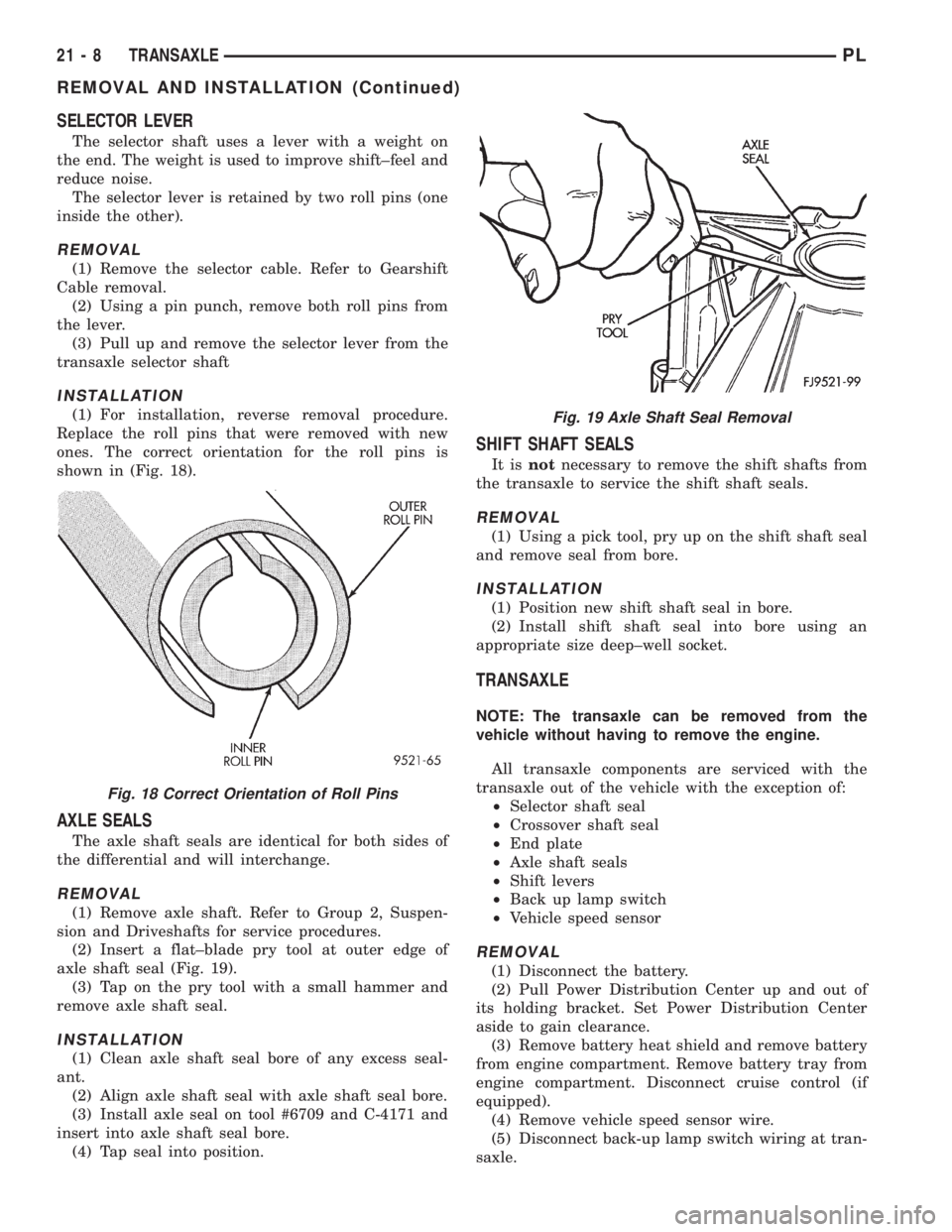

SELECTOR LEVER

The selector shaft uses a lever with a weight on

the end. The weight is used to improve shift±feel and

reduce noise.

The selector lever is retained by two roll pins (one

inside the other).

REMOVAL

(1) Remove the selector cable. Refer to Gearshift

Cable removal.

(2) Using a pin punch, remove both roll pins from

the lever.

(3) Pull up and remove the selector lever from the

transaxle selector shaft

INSTALLATION

(1) For installation, reverse removal procedure.

Replace the roll pins that were removed with new

ones. The correct orientation for the roll pins is

shown in (Fig. 18).

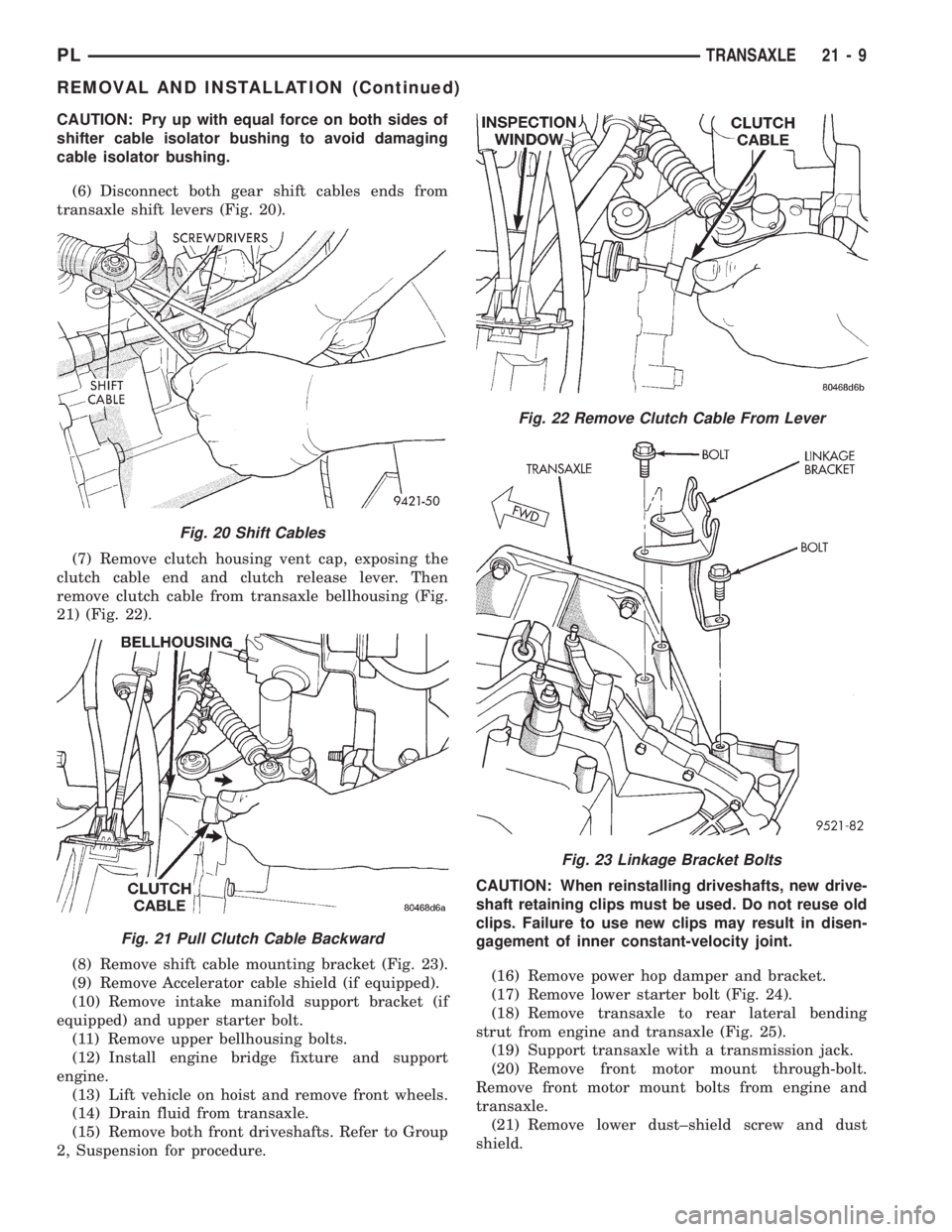

AXLE SEALS

The axle shaft seals are identical for both sides of

the differential and will interchange.

REMOVAL

(1) Remove axle shaft. Refer to Group 2, Suspen-

sion and Driveshafts for service procedures.

(2) Insert a flat±blade pry tool at outer edge of

axle shaft seal (Fig. 19).

(3) Tap on the pry tool with a small hammer and

remove axle shaft seal.

INSTALLATION

(1) Clean axle shaft seal bore of any excess seal-

ant.

(2) Align axle shaft seal with axle shaft seal bore.

(3) Install axle seal on tool #6709 and C-4171 and

insert into axle shaft seal bore.

(4) Tap seal into position.

SHIFT SHAFT SEALS

It isnotnecessary to remove the shift shafts from

the transaxle to service the shift shaft seals.

REMOVAL

(1) Using a pick tool, pry up on the shift shaft seal

and remove seal from bore.

INSTALLATION

(1) Position new shift shaft seal in bore.

(2) Install shift shaft seal into bore using an

appropriate size deep±well socket.

TRANSAXLE

NOTE: The transaxle can be removed from the

vehicle without having to remove the engine.

All transaxle components are serviced with the

transaxle out of the vehicle with the exception of:

²Selector shaft seal

²Crossover shaft seal

²End plate

²Axle shaft seals

²Shift levers

²Back up lamp switch

²Vehicle speed sensor

REMOVAL

(1) Disconnect the battery.

(2) Pull Power Distribution Center up and out of

its holding bracket. Set Power Distribution Center

aside to gain clearance.

(3) Remove battery heat shield and remove battery

from engine compartment. Remove battery tray from

engine compartment. Disconnect cruise control (if

equipped).

(4) Remove vehicle speed sensor wire.

(5) Disconnect back-up lamp switch wiring at tran-

saxle.

Fig. 18 Correct Orientation of Roll Pins

Fig. 19 Axle Shaft Seal Removal

21 - 8 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 952 of 1200

CAUTION: Pry up with equal force on both sides of

shifter cable isolator bushing to avoid damaging

cable isolator bushing.

(6) Disconnect both gear shift cables ends from

transaxle shift levers (Fig. 20).

(7) Remove clutch housing vent cap, exposing the

clutch cable end and clutch release lever. Then

remove clutch cable from transaxle bellhousing (Fig.

21) (Fig. 22).

(8) Remove shift cable mounting bracket (Fig. 23).

(9) Remove Accelerator cable shield (if equipped).

(10) Remove intake manifold support bracket (if

equipped) and upper starter bolt.

(11) Remove upper bellhousing bolts.

(12) Install engine bridge fixture and support

engine.

(13) Lift vehicle on hoist and remove front wheels.

(14) Drain fluid from transaxle.

(15) Remove both front driveshafts. Refer to Group

2, Suspension for procedure.CAUTION: When reinstalling driveshafts, new drive-

shaft retaining clips must be used. Do not reuse old

clips. Failure to use new clips may result in disen-

gagement of inner constant-velocity joint.

(16) Remove power hop damper and bracket.

(17) Remove lower starter bolt (Fig. 24).

(18) Remove transaxle to rear lateral bending

strut from engine and transaxle (Fig. 25).

(19) Support transaxle with a transmission jack.

(20) Remove front motor mount through-bolt.

Remove front motor mount bolts from engine and

transaxle.

(21) Remove lower dust±shield screw and dust

shield.

Fig. 20 Shift Cables

Fig. 21 Pull Clutch Cable Backward

Fig. 22 Remove Clutch Cable From Lever

Fig. 23 Linkage Bracket Bolts

PLTRANSAXLE 21 - 9

REMOVAL AND INSTALLATION (Continued)