Timing DODGE NEON 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 748 of 1200

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE AND BELT INSTALLATIONÐ

SOHC ENGINE

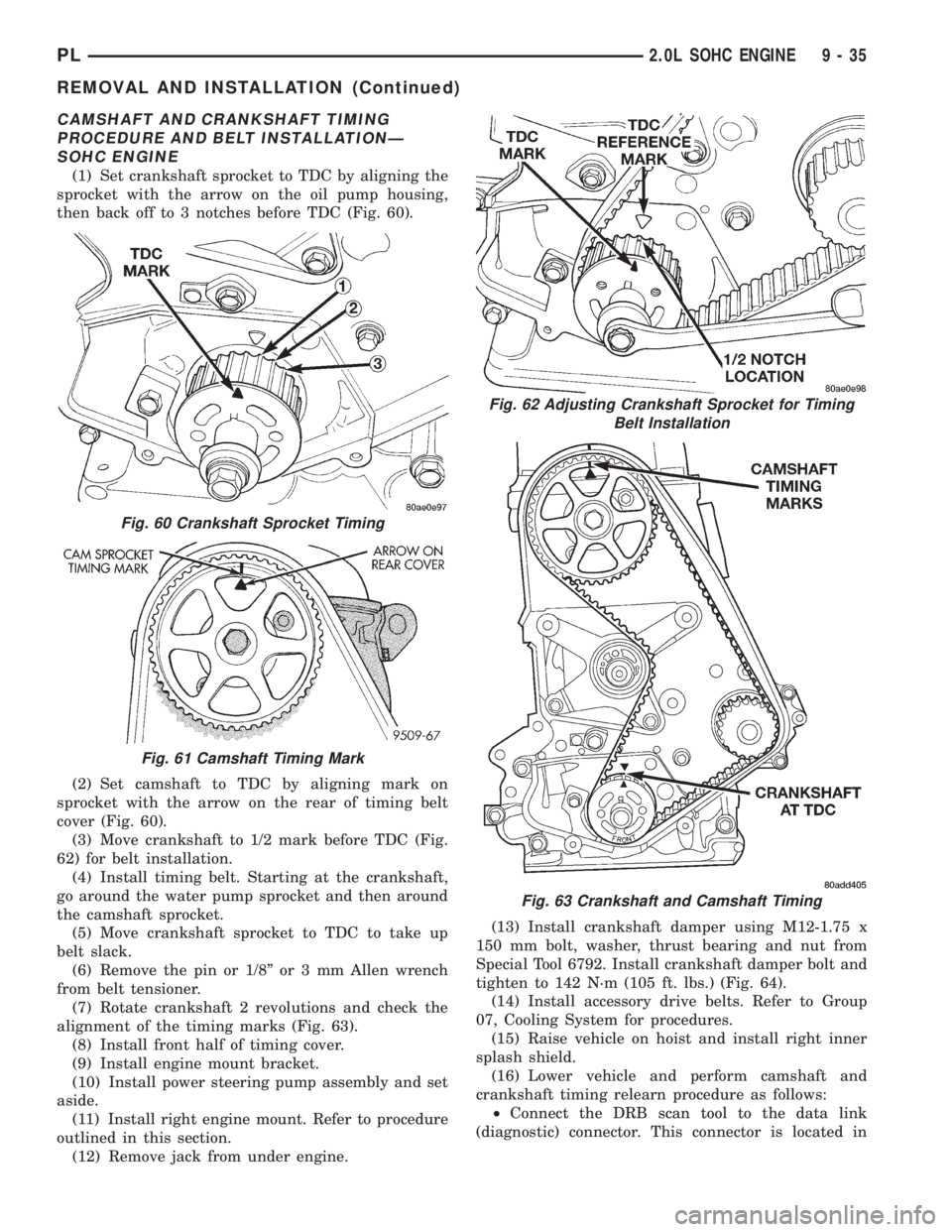

(1) Set crankshaft sprocket to TDC by aligning the

sprocket with the arrow on the oil pump housing,

then back off to 3 notches before TDC (Fig. 60).

(2) Set camshaft to TDC by aligning mark on

sprocket with the arrow on the rear of timing belt

cover (Fig. 60).

(3) Move crankshaft to 1/2 mark before TDC (Fig.

62) for belt installation.

(4) Install timing belt. Starting at the crankshaft,

go around the water pump sprocket and then around

the camshaft sprocket.

(5) Move crankshaft sprocket to TDC to take up

belt slack.

(6) Remove the pin or 1/8º or 3 mm Allen wrench

from belt tensioner.

(7) Rotate crankshaft 2 revolutions and check the

alignment of the timing marks (Fig. 63).

(8) Install front half of timing cover.

(9) Install engine mount bracket.

(10) Install power steering pump assembly and set

aside.

(11) Install right engine mount. Refer to procedure

outlined in this section.

(12) Remove jack from under engine.(13) Install crankshaft damper using M12-1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (105 ft. lbs.) (Fig. 64).

(14) Install accessory drive belts. Refer to Group

07, Cooling System for procedures.

(15) Raise vehicle on hoist and install right inner

splash shield.

(16) Lower vehicle and perform camshaft and

crankshaft timing relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

Fig. 60 Crankshaft Sprocket Timing

Fig. 61 Camshaft Timing Mark

Fig. 62 Adjusting Crankshaft Sprocket for Timing

Belt Installation

Fig. 63 Crankshaft and Camshaft Timing

PL2.0L SOHC ENGINE 9 - 35

REMOVAL AND INSTALLATION (Continued)

Page 749 of 1200

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

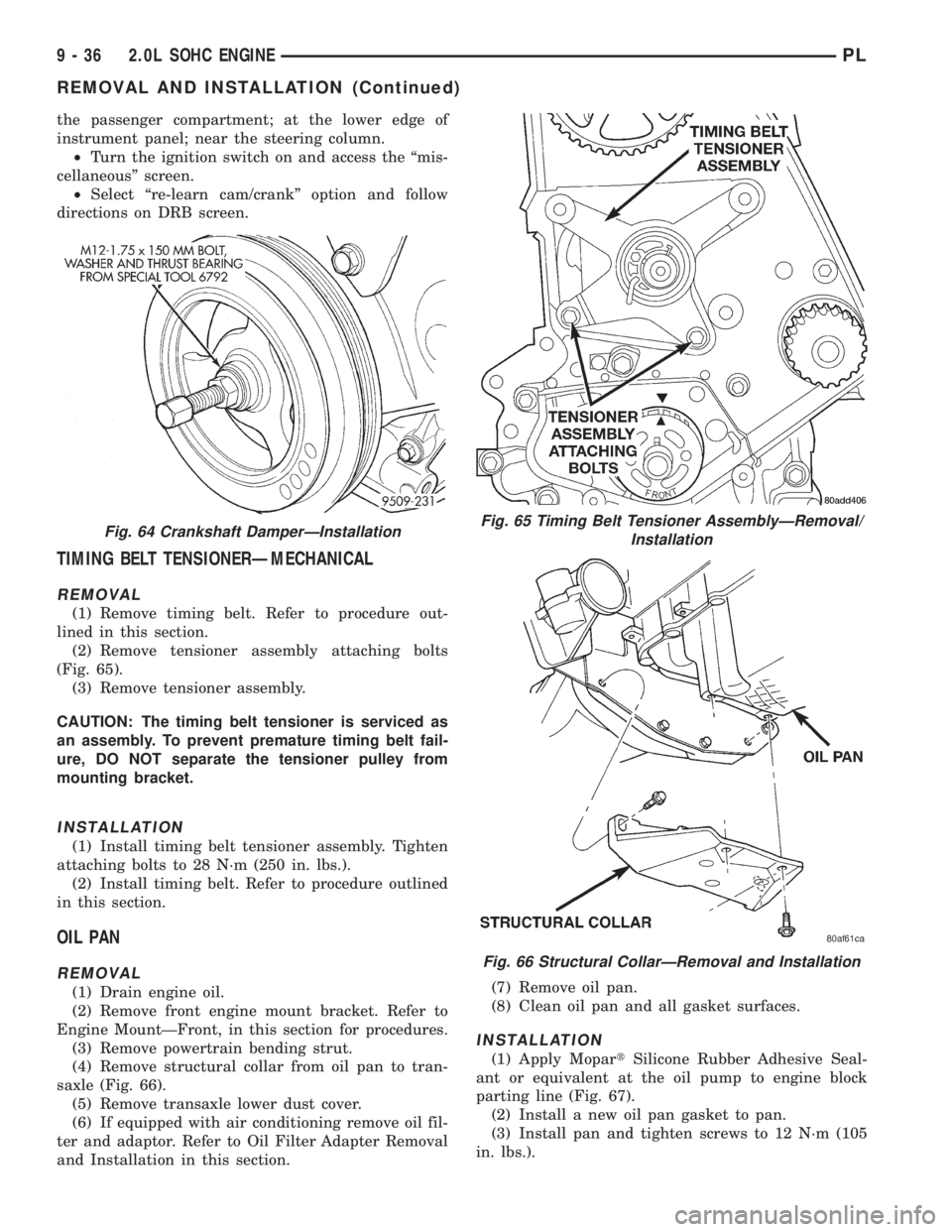

TIMING BELT TENSIONERÐMECHANICAL

REMOVAL

(1) Remove timing belt. Refer to procedure out-

lined in this section.

(2) Remove tensioner assembly attaching bolts

(Fig. 65).

(3) Remove tensioner assembly.

CAUTION: The timing belt tensioner is serviced as

an assembly. To prevent premature timing belt fail-

ure, DO NOT separate the tensioner pulley from

mounting bracket.

INSTALLATION

(1) Install timing belt tensioner assembly. Tighten

attaching bolts to 28 N´m (250 in. lbs.).

(2) Install timing belt. Refer to procedure outlined

in this section.

OIL PAN

REMOVAL

(1) Drain engine oil.

(2) Remove front engine mount bracket. Refer to

Engine MountÐFront, in this section for procedures.

(3) Remove powertrain bending strut.

(4) Remove structural collar from oil pan to tran-

saxle (Fig. 66).

(5) Remove transaxle lower dust cover.

(6) If equipped with air conditioning remove oil fil-

ter and adaptor. Refer to Oil Filter Adapter Removal

and Installation in this section.(7) Remove oil pan.

(8) Clean oil pan and all gasket surfaces.

INSTALLATION

(1) Apply MopartSilicone Rubber Adhesive Seal-

ant or equivalent at the oil pump to engine block

parting line (Fig. 67).

(2) Install a new oil pan gasket to pan.

(3) Install pan and tighten screws to 12 N´m (105

in. lbs.).

Fig. 64 Crankshaft DamperÐInstallationFig. 65 Timing Belt Tensioner AssemblyÐRemoval/

Installation

Fig. 66 Structural CollarÐRemoval and Installation

9 - 36 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 750 of 1200

(4) Install oil filter and adaptor.

(5) Install transaxle lower dust cover.

(6) Install powertrain bending strut.

(7) Install front engine mount and bracket.

CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(8) Install the structural collar (Fig. 66) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(9) Fill engine crankcase with proper oil to correct

level.

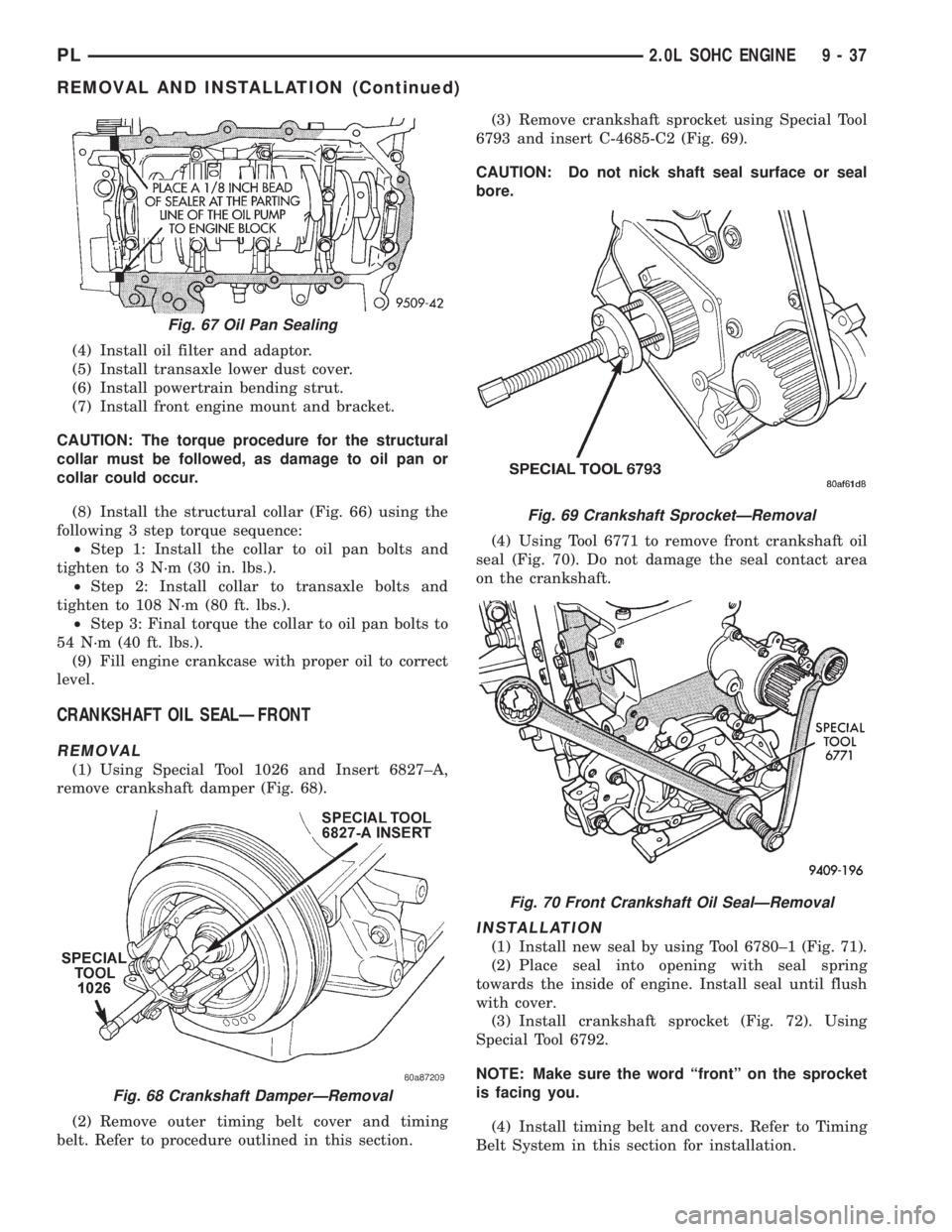

CRANKSHAFT OIL SEALÐFRONT

REMOVAL

(1) Using Special Tool 1026 and Insert 6827±A,

remove crankshaft damper (Fig. 68).

(2) Remove outer timing belt cover and timing

belt. Refer to procedure outlined in this section.(3) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 69).

CAUTION: Do not nick shaft seal surface or seal

bore.

(4) Using Tool 6771 to remove front crankshaft oil

seal (Fig. 70). Do not damage the seal contact area

on the crankshaft.

INSTALLATION

(1) Install new seal by using Tool 6780±1 (Fig. 71).

(2) Place seal into opening with seal spring

towards the inside of engine. Install seal until flush

with cover.

(3) Install crankshaft sprocket (Fig. 72). Using

Special Tool 6792.

NOTE: Make sure the word ªfrontº on the sprocket

is facing you.

(4) Install timing belt and covers. Refer to Timing

Belt System in this section for installation.

Fig. 67 Oil Pan Sealing

Fig. 68 Crankshaft DamperÐRemoval

Fig. 69 Crankshaft SprocketÐRemoval

Fig. 70 Front Crankshaft Oil SealÐRemoval

PL2.0L SOHC ENGINE 9 - 37

REMOVAL AND INSTALLATION (Continued)

Page 755 of 1200

(11) Install oil pump. If crankshaft end play is to

be checked refer to service procedures in this section.

(12) Install crankshaft sprocket.

(13) Install oil filter adapter and filter.

(14) Install oil pan and structural collar. Refer to

procedures outlined in the section.

(15) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

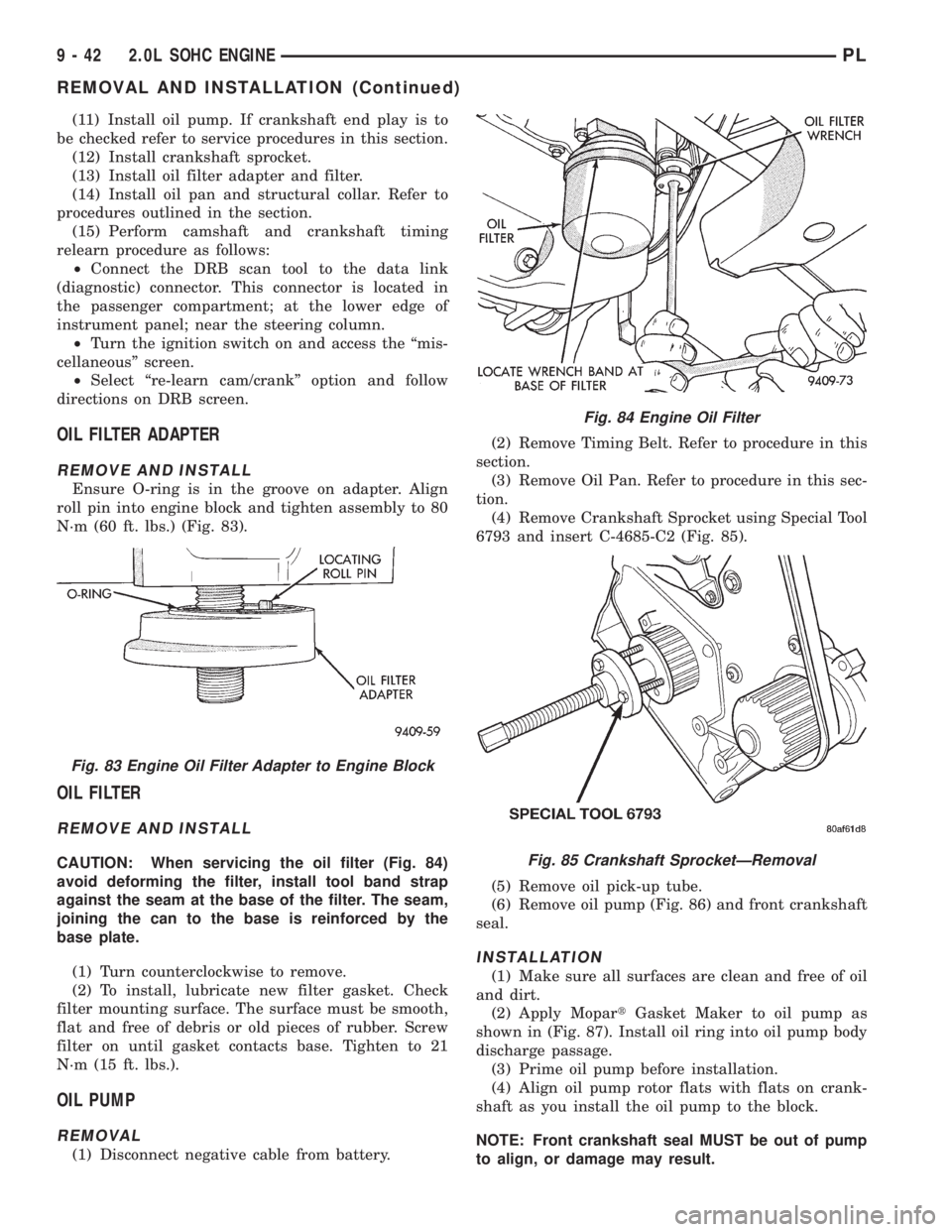

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 83).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 84)

avoid deforming the filter, install tool band strap

against the seam at the base of the filter. The seam,

joining the can to the base is reinforced by the

base plate.

(1) Turn counterclockwise to remove.

(2) To install, lubricate new filter gasket. Check

filter mounting surface. The surface must be smooth,

flat and free of debris or old pieces of rubber. Screw

filter on until gasket contacts base. Tighten to 21

N´m (15 ft. lbs.).

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.(2) Remove Timing Belt. Refer to procedure in this

section.

(3) Remove Oil Pan. Refer to procedure in this sec-

tion.

(4) Remove Crankshaft Sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 85).

(5) Remove oil pick-up tube.

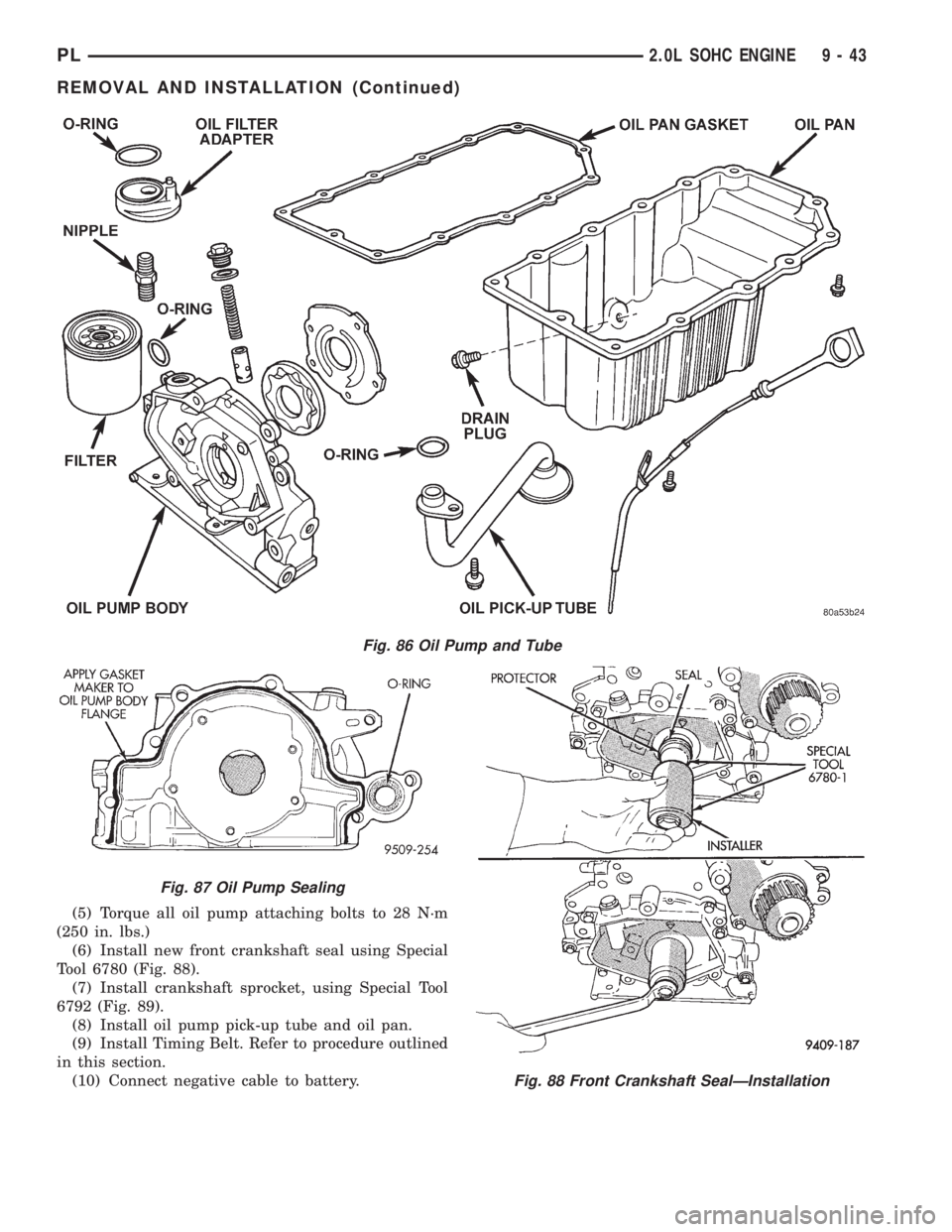

(6) Remove oil pump (Fig. 86) and front crankshaft

seal.

INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.

(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 87). Install oil ring into oil pump body

discharge passage.

(3) Prime oil pump before installation.

(4) Align oil pump rotor flats with flats on crank-

shaft as you install the oil pump to the block.

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

Fig. 83 Engine Oil Filter Adapter to Engine Block

Fig. 84 Engine Oil Filter

Fig. 85 Crankshaft SprocketÐRemoval

9 - 42 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 756 of 1200

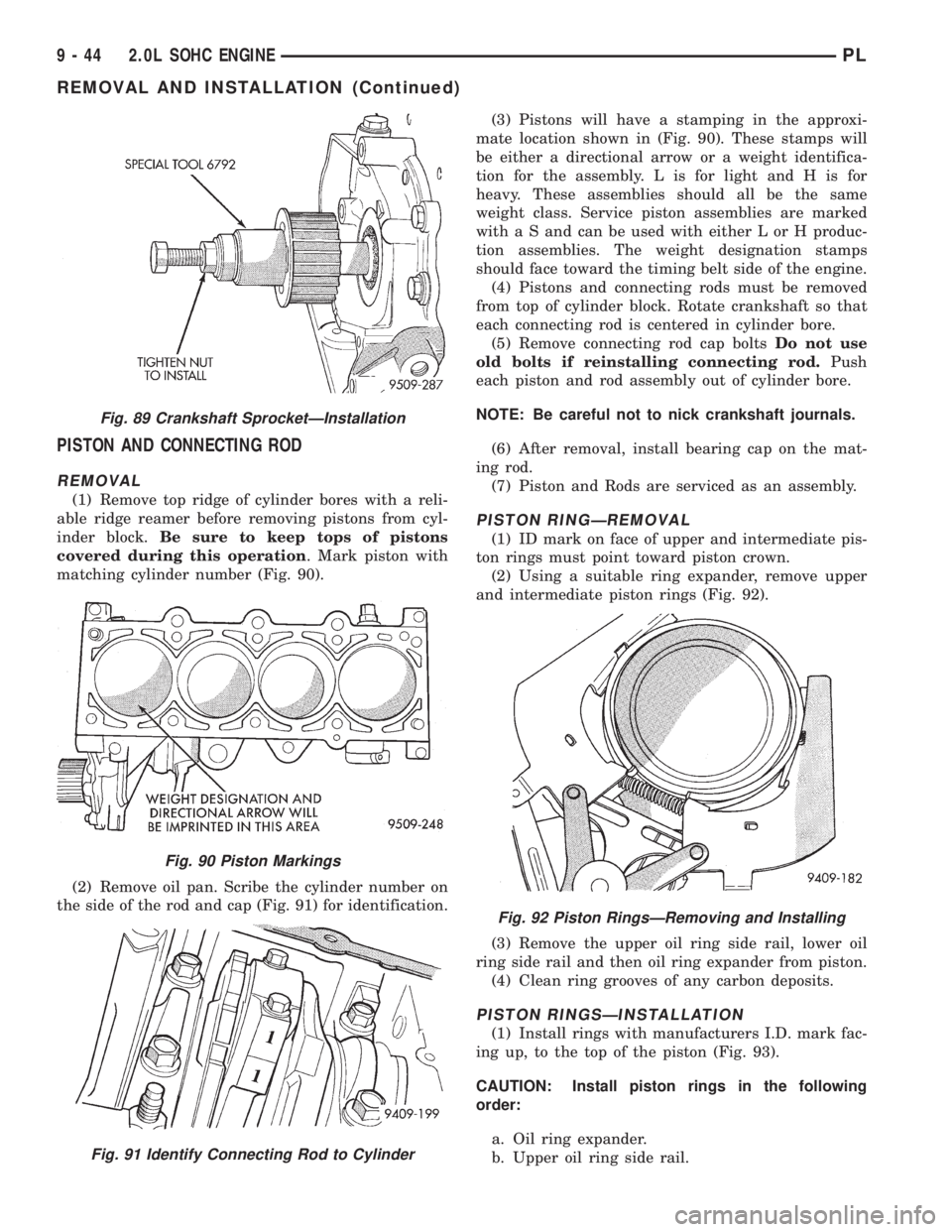

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.)

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 88).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 89).

(8) Install oil pump pick-up tube and oil pan.

(9) Install Timing Belt. Refer to procedure outlined

in this section.

(10) Connect negative cable to battery.

Fig. 86 Oil Pump and Tube

Fig. 87 Oil Pump Sealing

Fig. 88 Front Crankshaft SealÐInstallation

PL2.0L SOHC ENGINE 9 - 43

REMOVAL AND INSTALLATION (Continued)

Page 757 of 1200

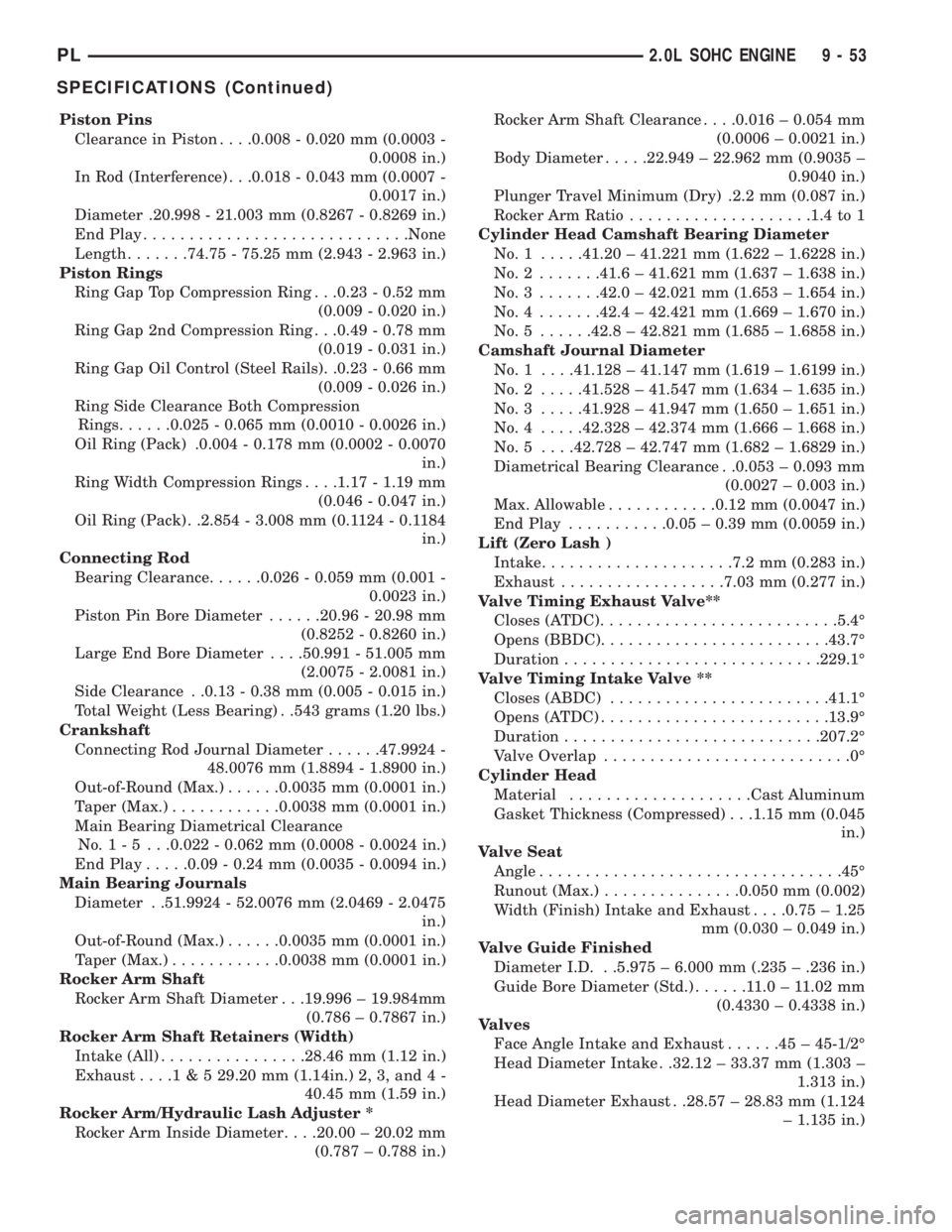

PISTON AND CONNECTING ROD

REMOVAL

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 90).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 91) for identification.(3) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 90). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove connecting rod cap boltsDo not use

old bolts if reinstalling connecting rod.Push

each piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

(6) After removal, install bearing cap on the mat-

ing rod.

(7) Piston and Rods are serviced as an assembly.

PISTON RINGÐREMOVAL

(1) ID mark on face of upper and intermediate pis-

ton rings must point toward piston crown.

(2) Using a suitable ring expander, remove upper

and intermediate piston rings (Fig. 92).

(3) Remove the upper oil ring side rail, lower oil

ring side rail and then oil ring expander from piston.

(4) Clean ring grooves of any carbon deposits.

PISTON RINGSÐINSTALLATION

(1) Install rings with manufacturers I.D. mark fac-

ing up, to the top of the piston (Fig. 93).

CAUTION: Install piston rings in the following

order:

a. Oil ring expander.

b. Upper oil ring side rail.

Fig. 89 Crankshaft SprocketÐInstallation

Fig. 90 Piston Markings

Fig. 91 Identify Connecting Rod to Cylinder

Fig. 92 Piston RingsÐRemoving and Installing

9 - 44 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 766 of 1200

Piston Pins

Clearance in Piston. . . .0.008 - 0.020 mm (0.0003 -

0.0008 in.)

In Rod (Interference) . . .0.018 - 0.043 mm (0.0007 -

0.0017 in.)

Diameter .20.998 - 21.003 mm (0.8267 - 0.8269 in.)

End Play.............................None

Length.......74.75 - 75.25 mm (2.943 - 2.963 in.)

Piston Rings

Ring Gap Top Compression Ring . . .0.23 - 0.52 mm

(0.009 - 0.020 in.)

Ring Gap 2nd Compression Ring . . .0.49 - 0.78 mm

(0.019 - 0.031 in.)

Ring Gap Oil Control (Steel Rails). .0.23 - 0.66 mm

(0.009 - 0.026 in.)

Ring Side Clearance Both Compression

Rings......0.025 - 0.065 mm (0.0010 - 0.0026 in.)

Oil Ring (Pack) .0.004 - 0.178 mm (0.0002 - 0.0070

in.)

Ring Width Compression Rings. . . .1.17 - 1.19 mm

(0.046 - 0.047 in.)

Oil Ring (Pack) . .2.854 - 3.008 mm (0.1124 - 0.1184

in.)

Connecting Rod

Bearing Clearance......0.026 - 0.059 mm (0.001 -

0.0023 in.)

Piston Pin Bore Diameter......20.96 - 20.98 mm

(0.8252 - 0.8260 in.)

Large End Bore Diameter. . . .50.991 - 51.005 mm

(2.0075 - 2.0081 in.)

Side Clearance . .0.13 - 0.38 mm (0.005 - 0.015 in.)

Total Weight (Less Bearing) . .543 grams (1.20 lbs.)

Crankshaft

Connecting Rod Journal Diameter......47.9924 -

48.0076 mm (1.8894 - 1.8900 in.)

Out-of-Round (Max.)......0.0035 mm (0.0001 in.)

Taper (Max.)............0.0038 mm (0.0001 in.)

Main Bearing Diametrical Clearance

No.1-5 ...0.022 - 0.062 mm (0.0008 - 0.0024 in.)

End Play.....0.09 - 0.24 mm (0.0035 - 0.0094 in.)

Main Bearing Journals

Diameter . .51.9924 - 52.0076 mm (2.0469 - 2.0475

in.)

Out-of-Round (Max.)......0.0035 mm (0.0001 in.)

Taper (Max.)............0.0038 mm (0.0001 in.)

Rocker Arm Shaft

Rocker Arm Shaft Diameter . . .19.996 ± 19.984mm

(0.786 ± 0.7867 in.)

Rocker Arm Shaft Retainers (Width)

Intake (All)................28.46 mm (1.12 in.)

Exhaust....1 & 5 29.20 mm (1.14in.) 2, 3, and 4 -

40.45 mm (1.59 in.)

Rocker Arm/Hydraulic Lash Adjuster *

Rocker Arm Inside Diameter. . . .20.00 ± 20.02 mm

(0.787 ± 0.788 in.)Rocker Arm Shaft Clearance. . . .0.016 ± 0.054 mm

(0.0006 ± 0.0021 in.)

Body Diameter.....22.949 ± 22.962 mm (0.9035 ±

0.9040 in.)

Plunger Travel Minimum (Dry) .2.2 mm (0.087 in.)

Rocker Arm Ratio....................1.4 to 1

Cylinder Head Camshaft Bearing Diameter

No.1 .....41.20 ± 41.221 mm (1.622 ± 1.6228 in.)

No.2 .......41.6 ± 41.621 mm (1.637 ± 1.638 in.)

No.3 .......42.0 ± 42.021 mm (1.653 ± 1.654 in.)

No.4 .......42.4 ± 42.421 mm (1.669 ± 1.670 in.)

No.5 ......42.8 ± 42.821 mm (1.685 ± 1.6858 in.)

Camshaft Journal Diameter

No. 1 . . . .41.128 ± 41.147 mm (1.619 ± 1.6199 in.)

No.2 .....41.528 ± 41.547 mm (1.634 ± 1.635 in.)

No.3 .....41.928 ± 41.947 mm (1.650 ± 1.651 in.)

No.4 .....42.328 ± 42.374 mm (1.666 ± 1.668 in.)

No. 5 . . . .42.728 ± 42.747 mm (1.682 ± 1.6829 in.)

Diametrical Bearing Clearance . .0.053 ± 0.093 mm

(0.0027 ± 0.003 in.)

Max. Allowable............0.12 mm (0.0047 in.)

End Play...........0.05 ± 0.39 mm (0.0059 in.)

Lift (Zero Lash )

Intake.....................7.2 mm (0.283 in.)

Exhaust..................7.03 mm (0.277 in.)

Valve Timing Exhaust Valve**

Closes (ATDC)..........................5.4É

Opens (BBDC).........................43.7É

Duration............................229.1É

Valve Timing Intake Valve **

Closes (ABDC)........................41.1É

Opens (ATDC).........................13.9É

Duration............................207.2É

Valve Overlap...........................0É

Cylinder Head

Material....................Cast Aluminum

Gasket Thickness (Compressed) . . .1.15 mm (0.045

in.)

Valve Seat

Angle.................................45É

Runout (Max.)...............0.050 mm (0.002)

Width (Finish) Intake and Exhaust. . . .0.75 ± 1.25

mm (0.030 ± 0.049 in.)

Valve Guide Finished

Diameter I.D. . .5.975 ± 6.000 mm (.235 ± .236 in.)

Guide Bore Diameter (Std.)......11.0±11.02 mm

(0.4330 ± 0.4338 in.)

Valves

Face Angle Intake and Exhaust......45±45-1/2É

Head Diameter Intake . .32.12 ± 33.37 mm (1.303 ±

1.313 in.)

Head Diameter Exhaust . .28.57 ± 28.83 mm (1.124

± 1.135 in.)

PL2.0L SOHC ENGINE 9 - 53

SPECIFICATIONS (Continued)

Page 767 of 1200

Valve Margin

Intake......1.15 ± 1.48 mm (0.0452 ± 0.0582 in.)

Exhaust.....1.475 ± 1.805 mm (0.058 ± 0.071 in.)

Valve Length (Overall)

Intake.....114.69 ± 115.19 mm (4.515 ± 4.535 in.)

Exhaust . . .109.59 ± 110.09 mm (4.603 ± 4.623 in.)

Valve Stem Tip Height

Intake........45.01 ± 46.07 mm (1.77 ± 1.81 in.)

Exhaust.......43.51 ± 44.57 mm (1.71 ± 1.75 in.)

Stem Diameter

Intake......5.934 ± 5.952 mm (0.234 ± 0.234 in.)

Exhaust.....5.906 ± 5.924 mm (0.233 ± 0.233 in.)

Stem to Guide Clearance

Intake. . . .0.048 ± 0.066 mm (0.0018 ± 0.0025 in.)

Exhaust . .0.0736 ± 0.094 mm (0.0029 ± 0.0037 in.)

Max. Allowable Intake......0.076 mm (0.003 in.)

Max. Allowable Exhaust.....0.101 mm (0.004 in.)

Valve Springs

Free Length (Approx.).......44.4 mm (1.747 in.)

Nominal Force (Valve closed) . .91 N´m @ 39.8 mm

(67 ft. lbs. @ 1.57 in.)

Nominal Force (Valve open). . .239 N´m @ 32.6 mm

(176 lbs. @ 1.28 in.)

Installed Height...........40.18 mm (1.580 in.)

* SERVICE AS AN ASSEMBLY WITH ROCKER

ARM.

** ALL READINGS IN CRANKSHAFT DEGREES,

AT 0.5 mm (0.019 in.) OF VALVE LIFT.

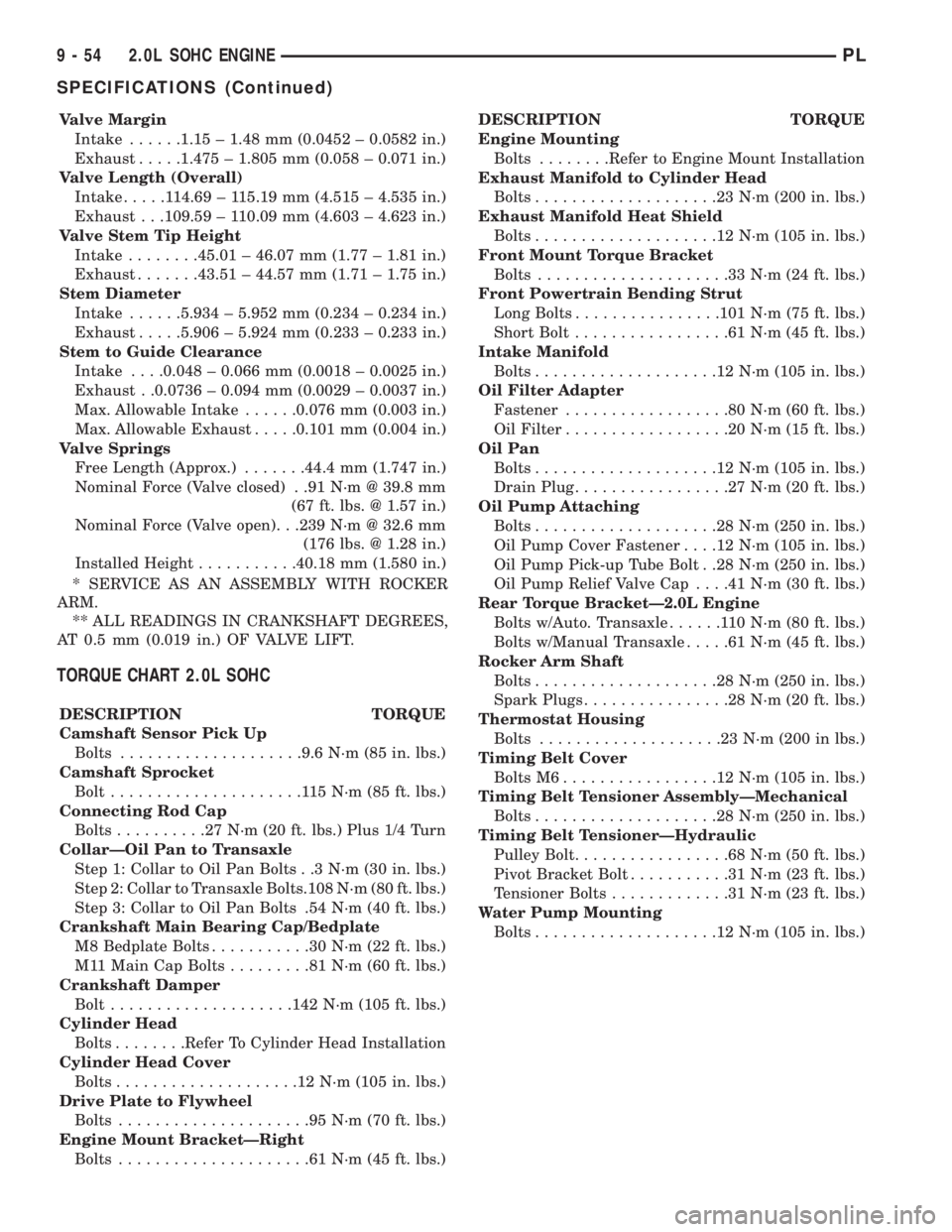

TORQUE CHART 2.0L SOHC

DESCRIPTION TORQUE

Camshaft Sensor Pick Up

Bolts....................9.6 N´m (85 in. lbs.)

Camshaft Sprocket

Bolt.....................115N´m(85ft.lbs.)

Connecting Rod Cap

Bolts..........27N´m(20ft.lbs.) Plus 1/4 Turn

CollarÐOil Pan to Transaxle

Step 1: Collar to Oil Pan Bolts . .3 N´m (30 in. lbs.)

Step 2: Collar to Transaxle Bolts.108 N´m (80 ft. lbs.)

Step 3: Collar to Oil Pan Bolts .54 N´m (40 ft. lbs.)

Crankshaft Main Bearing Cap/Bedplate

M8 Bedplate Bolts...........30N´m(22ft.lbs.)

M11 Main Cap Bolts.........81N´m(60ft.lbs.)

Crankshaft Damper

Bolt....................142 N´m (105 ft. lbs.)

Cylinder Head

Bolts........Refer To Cylinder Head Installation

Cylinder Head Cover

Bolts....................12N´m(105 in. lbs.)

Drive Plate to Flywheel

Bolts.....................95N´m(70ft.lbs.)

Engine Mount BracketÐRight

Bolts.....................61N´m(45ft.lbs.)DESCRIPTION TORQUE

Engine Mounting

Bolts........Refer to Engine Mount Installation

Exhaust Manifold to Cylinder Head

Bolts....................23N´m(200 in. lbs.)

Exhaust Manifold Heat Shield

Bolts....................12N´m(105 in. lbs.)

Front Mount Torque Bracket

Bolts.....................33N´m(24ft.lbs.)

Front Powertrain Bending Strut

Long Bolts................101 N´m (75 ft. lbs.)

Short Bolt.................61N´m(45ft.lbs.)

Intake Manifold

Bolts....................12N´m(105 in. lbs.)

Oil Filter Adapter

Fastener..................80N´m(60ft.lbs.)

Oil Filter..................20N´m(15ft.lbs.)

Oil Pan

Bolts....................12N´m(105 in. lbs.)

Drain Plug.................27N´m(20ft.lbs.)

Oil Pump Attaching

Bolts....................28N´m(250 in. lbs.)

Oil Pump Cover Fastener. . . .12 N´m (105 in. lbs.)

Oil Pump Pick-up Tube Bolt . .28 N´m (250 in. lbs.)

Oil Pump Relief Valve Cap. . . .41 N´m (30 ft. lbs.)

Rear Torque BracketÐ2.0L Engine

Bolts w/Auto. Transaxle......110N´m(80ft.lbs.)

Bolts w/Manual Transaxle.....61N´m(45ft.lbs.)

Rocker Arm Shaft

Bolts....................28N´m(250 in. lbs.)

Spark Plugs................28N´m(20ft.lbs.)

Thermostat Housing

Bolts....................23N´m(200 in lbs.)

Timing Belt Cover

Bolts M6.................12N´m(105 in. lbs.)

Timing Belt Tensioner AssemblyÐMechanical

Bolts....................28N´m(250 in. lbs.)

Timing Belt TensionerÐHydraulic

Pulley Bolt.................68N´m(50ft.lbs.)

Pivot Bracket Bolt...........31N´m(23ft.lbs.)

Tensioner Bolts.............31N´m(23ft.lbs.)

Water Pump Mounting

Bolts....................12N´m(105 in. lbs.)

9 - 54 2.0L SOHC ENGINEPL

SPECIFICATIONS (Continued)

Page 771 of 1200

2.0L DOHC ENGINE

INDEX

page page

DESCRIPTION AND OPERATION

ENGINE COMPONENTS.................. 59

ENGINE IDENTIFICATION NUMBER......... 58

ENGINE LUBRICATION SYSTEM............ 58

GENERAL SPECIFICATION................ 58

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE......... 60

SERVICE PROCEDURES

CRANKSHAFT END PLAY................. 63

CYLINDER BORE AND PISTON SIZING....... 60

FITTING CONNECTING RODS.............. 62

FITTING CRANKSHAFT BEARINGS.......... 62

FITTING PISTON RINGS.................. 61

REMOVAL AND INSTALLATION

CAMSHAFT OIL SEALS................... 81

CAM FOLLOWER AND HYDRAULIC LASH

ADJUSTER ASSEMBLY.................. 69

CAMSHAFT............................ 67

CRANKSHAFT DAMPER.................. 73

CRANKSHAFT OIL SEALÐFRONT........... 82

CRANKSHAFT OIL SEALÐREAR............ 83

CRANKSHAFT.......................... 85

CYLINDER HEAD COVER................. 67

CYLINDER HEAD........................ 71

ENGINE ASSEMBLY...................... 65

ENGINE MOUNTÐFRONT................. 63

ENGINE MOUNTÐLEFT................... 63

ENGINE MOUNTÐRIGHT................. 64OIL FILTER ADAPTER.................... 87

OILFILTER ............................ 87

OILPAN ............................... 81

OIL PUMP............................. 88

PISTON AND CONNECTING ROD........... 89

POWER HOP DAMPER................... 64

STRUCTURAL COLLARÐ2.0L.............. 64

TIMING BELT COVER.................... 74

TIMING BELT TENSIONERÐMECHANICAL.... 80

TIMING BELTÐWITH HYDRAULIC TENSIONER . 75

TIMING BELTÐWITH MECHANICAL

TENSIONER.......................... 78

VALVE SPRING AND SEALSÐ

CYLINDER HEAD NOT REMOVED......... 69

DISASSEMBLY AND ASSEMBLY

OIL PUMP............................. 91

VALVE SERVICE WITH CYLINDER HEAD

REMOVED........................... 91

CLEANING AND INSPECTION

CYLINDER BLOCK AND BORE............. 96

CYLINDER HEAD AND CAMSHAFT JOURNALS . 94

OIL PUMP............................. 94

SPECIFICATIONS

2.0L DOHC............................. 96

TORQUE CHART 2.0L DOHC............... 98

SPECIAL TOOLS

2.0L DOHC............................. 98

DESCRIPTION AND OPERATION

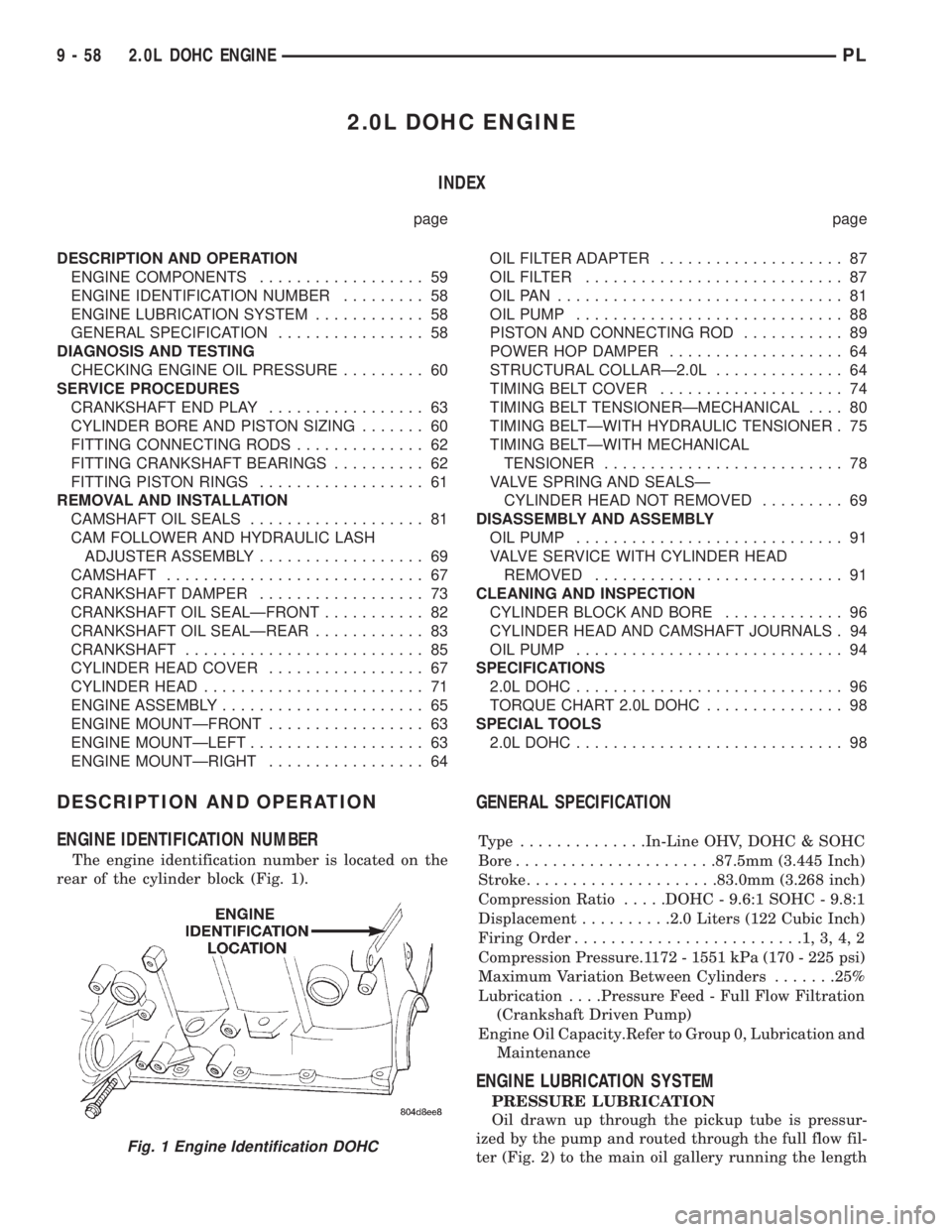

ENGINE IDENTIFICATION NUMBER

The engine identification number is located on the

rear of the cylinder block (Fig. 1).

GENERAL SPECIFICATION

Type ..............In-Line OHV, DOHC & SOHC

Bore......................87.5mm (3.445 Inch)

Stroke.....................83.0mm (3.268 inch)

Compression Ratio.....DOHC - 9.6:1 SOHC - 9.8:1

Displacement..........2.0 Liters (122 Cubic Inch)

Firing Order.........................1,3,4,2

Compression Pressure.1172 - 1551 kPa (170 - 225 psi)

Maximum Variation Between Cylinders.......25%

Lubrication. . . .Pressure Feed - Full Flow Filtration

(Crankshaft Driven Pump)

Engine Oil Capacity.Refer to Group 0, Lubrication and

Maintenance

ENGINE LUBRICATION SYSTEM

PRESSURE LUBRICATION

Oil drawn up through the pickup tube is pressur-

ized by the pump and routed through the full flow fil-

ter (Fig. 2) to the main oil gallery running the length

Fig. 1 Engine Identification DOHC

9 - 58 2.0L DOHC ENGINEPL

Page 773 of 1200

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFTA nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket pro-

vides motive power; via timing belt to the camshaft

sprocket providing timed valve actuation.

PISTONSThe DOHC EngineDO NOThave pro-

vision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hex

head cap screw are used to provide alignment and

durability in the assembly.

PISTON RINGSThe piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package contains of 2 steel rails and a expander

spacer.

CYLINDER HEADFeatures a Dual Over Head

Camshaft (DOHC), 4 valves per cylinder cross flow

design. The valves are arranged in two in-line banks,

with the ports of the bank of two intake valves per

cylinder facing toward the radiator side of engine

and ports of the bank of two exhaust valves per cyl-

inder facing toward the dash panel. Incorporates

powder metal valve guides and seats. Integral oil gal-

leys within the cylinder head supplies oil to the

hydraulic lash adjusters, camshaft and valve mecha-

nisms.

CAMSHAFTSThe nodular iron camshafts have

six bearing journals and 2 cam lobes per cylinder.

Flanges at the rear journals control camshaft end

play. Provision for cam position sensor is located on

the intake camshaft at the rear of cylinder head. A

hydrodynamic oil seal is used for oil control at the

front of the camshaft.

VA LV E SFour valves per cylinder are actuated by

roller cam followers which pivot on stationary

hydraulic lash adjusters. All valves have 6 mm diam-

eter chrome plated valve stems. The valve sizes are

34.8 mm (1.370 inch.) diameter intake valves and

30.5 mm (1.20 inch.) diameter exhaust valves. Viton

rubber valve stem seals are integral with the springseats. Valve springs, spring retainers, and locks are

conventional.

INTAKE MANIFOLDThe intake manifold is a

two piece aluminum casting, attached to the cylinder

head with ten fasteners. This long branch fan design

enhances low and mid-speed torque.

EXHAUST MANIFOLDThe exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

COMPONENT REPLACEMENT

If any of the following parts have been changed or

replaced:

²Camshaft

²Camshaft Position Sensor

²Camshaft Position Sensor Target Magnet

²Cylinder Block

²Cylinder Head

²Water Pump

²Powertrain Control Module (PCM)

²Timing Belt and Timing Belt Tensioner

The camshaft and crankshaft timing relearn proce-

dure must be performed. Refer to the component

Removal and Installation procedure outlined in this

Group.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 4). The cylin-

der bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

inch) maximum. If the cylinder walls are badly

scuffed or scored, the cylinder block should be

rebored and honed, and new pistons and rings fitted.

Whatever type of boring equipment is used, boring

and honing operation should be closely coordinated

9 - 60 2.0L DOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)