Timing DODGE NEON 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 791 of 1200

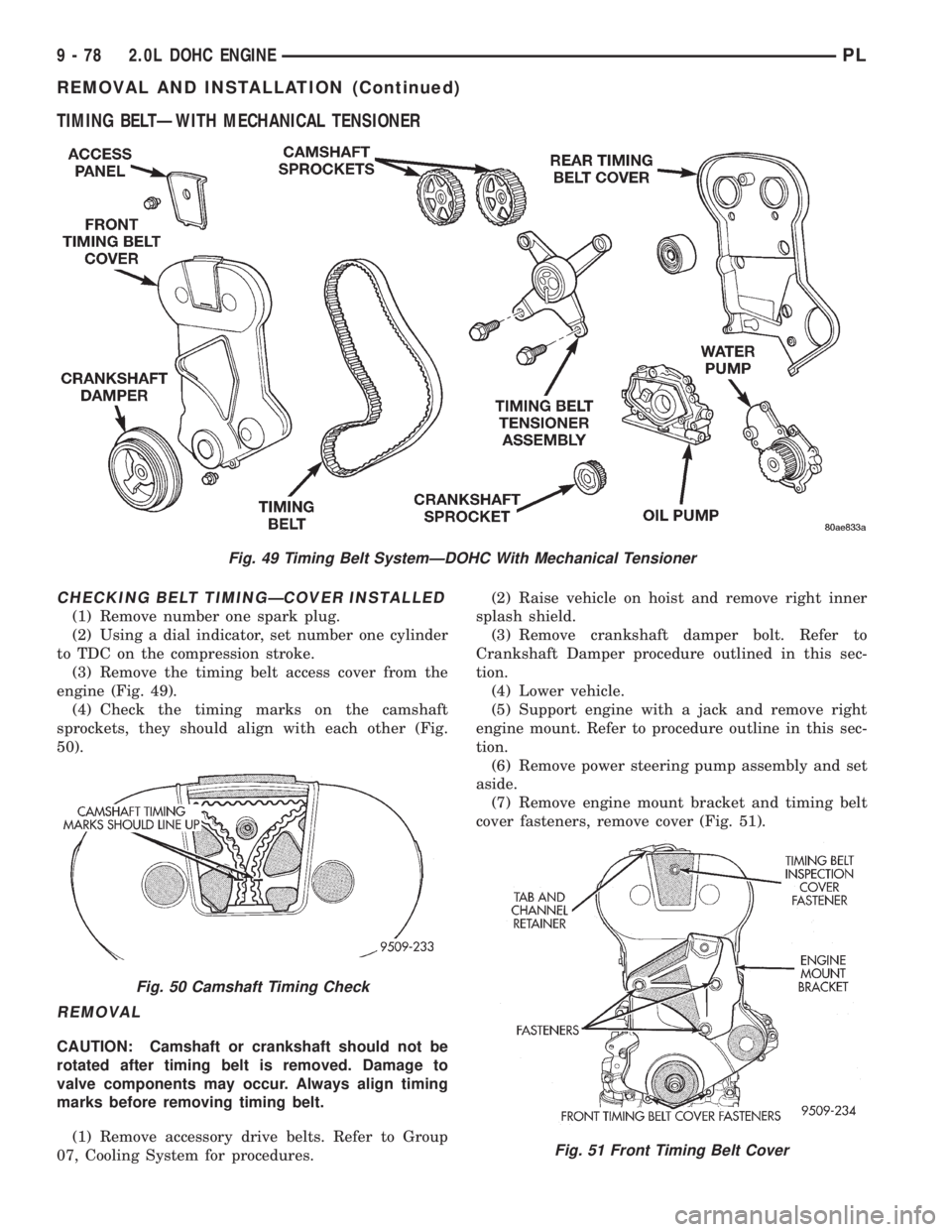

TIMING BELTÐWITH MECHANICAL TENSIONER

CHECKING BELT TIMINGÐCOVER INSTALLED

(1) Remove number one spark plug.

(2) Using a dial indicator, set number one cylinder

to TDC on the compression stroke.

(3) Remove the timing belt access cover from the

engine (Fig. 49).

(4) Check the timing marks on the camshaft

sprockets, they should align with each other (Fig.

50).

REMOVAL

CAUTION: Camshaft or crankshaft should not be

rotated after timing belt is removed. Damage to

valve components may occur. Always align timing

marks before removing timing belt.

(1) Remove accessory drive belts. Refer to Group

07, Cooling System for procedures.(2) Raise vehicle on hoist and remove right inner

splash shield.

(3) Remove crankshaft damper bolt. Refer to

Crankshaft Damper procedure outlined in this sec-

tion.

(4) Lower vehicle.

(5) Support engine with a jack and remove right

engine mount. Refer to procedure outline in this sec-

tion.

(6) Remove power steering pump assembly and set

aside.

(7) Remove engine mount bracket and timing belt

cover fasteners, remove cover (Fig. 51).

Fig. 49 Timing Belt SystemÐDOHC With Mechanical Tensioner

Fig. 50 Camshaft Timing Check

Fig. 51 Front Timing Belt Cover

9 - 78 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 792 of 1200

CAUTION: Align camshaft and crankshaft timing

marks before removing the timing belt by rotating

the engine with the crankshaft. Do not rotate the

camshaft once the timing belt has been removed as

damage to valve components may occur.

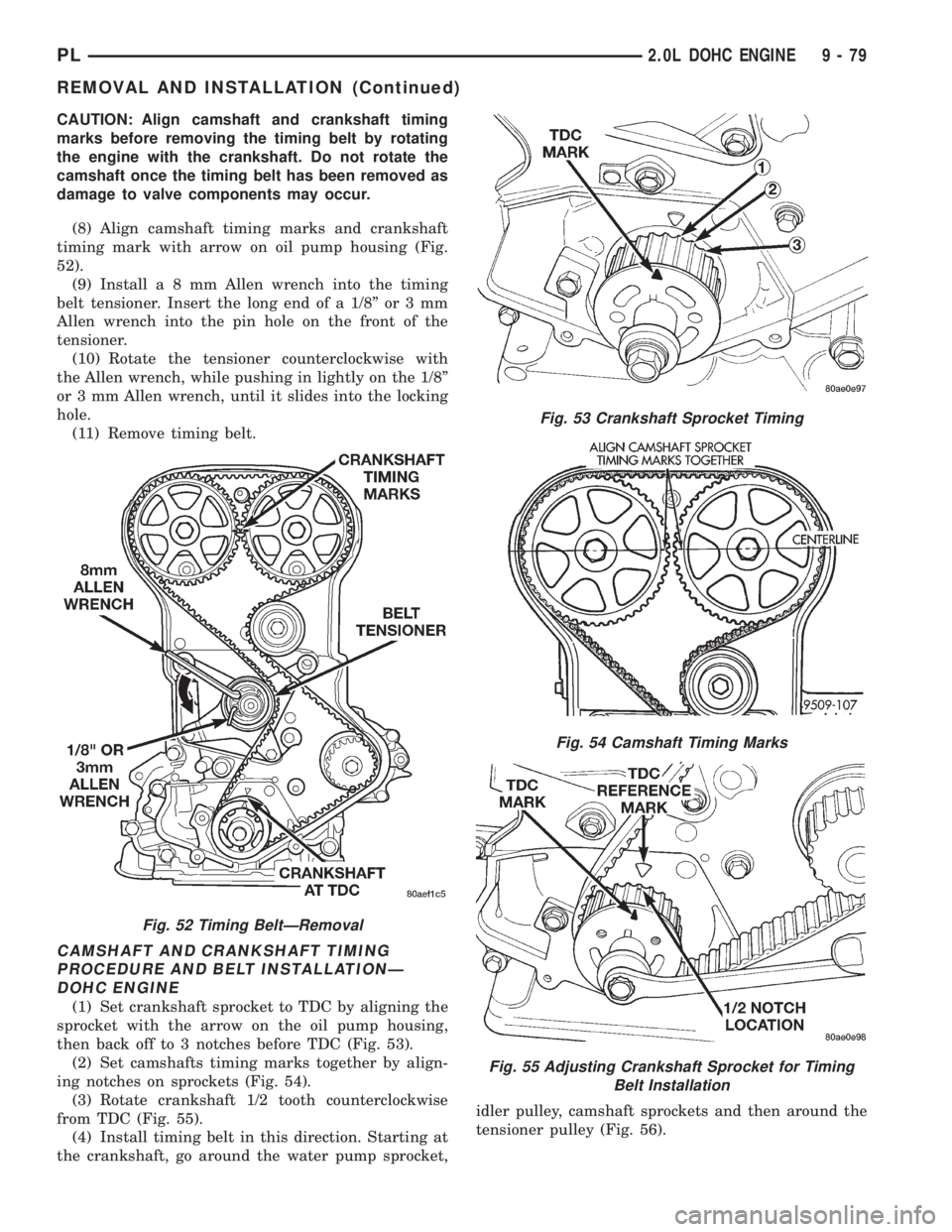

(8) Align camshaft timing marks and crankshaft

timing mark with arrow on oil pump housing (Fig.

52).

(9) Installa8mmAllen wrench into the timing

belt tensioner. Insert the long end of a 1/8º or 3 mm

Allen wrench into the pin hole on the front of the

tensioner.

(10) Rotate the tensioner counterclockwise with

the Allen wrench, while pushing in lightly on the 1/8º

or 3 mm Allen wrench, until it slides into the locking

hole.

(11) Remove timing belt.

CAMSHAFT AND CRANKSHAFT TIMING

PROCEDURE AND BELT INSTALLATIONÐ

DOHC ENGINE

(1) Set crankshaft sprocket to TDC by aligning the

sprocket with the arrow on the oil pump housing,

then back off to 3 notches before TDC (Fig. 53).

(2) Set camshafts timing marks together by align-

ing notches on sprockets (Fig. 54).

(3) Rotate crankshaft 1/2 tooth counterclockwise

from TDC (Fig. 55).

(4) Install timing belt in this direction. Starting at

the crankshaft, go around the water pump sprocket,idler pulley, camshaft sprockets and then around the

tensioner pulley (Fig. 56).

Fig. 52 Timing BeltÐRemoval

Fig. 53 Crankshaft Sprocket Timing

Fig. 54 Camshaft Timing Marks

Fig. 55 Adjusting Crankshaft Sprocket for Timing

Belt Installation

PL2.0L DOHC ENGINE 9 - 79

REMOVAL AND INSTALLATION (Continued)

Page 793 of 1200

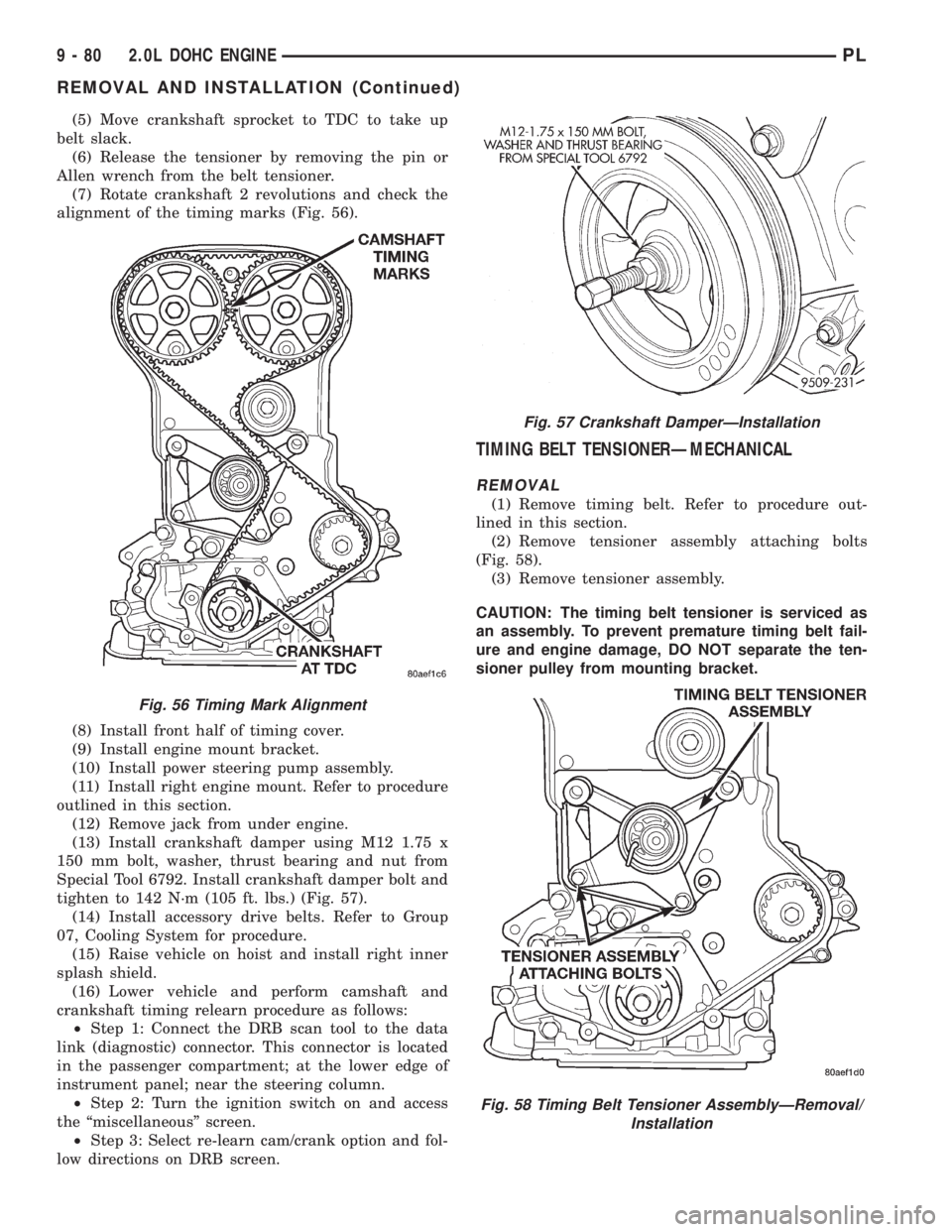

(5) Move crankshaft sprocket to TDC to take up

belt slack.

(6) Release the tensioner by removing the pin or

Allen wrench from the belt tensioner.

(7) Rotate crankshaft 2 revolutions and check the

alignment of the timing marks (Fig. 56).

(8) Install front half of timing cover.

(9) Install engine mount bracket.

(10) Install power steering pump assembly.

(11) Install right engine mount. Refer to procedure

outlined in this section.

(12) Remove jack from under engine.

(13) Install crankshaft damper using M12 1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (105 ft. lbs.) (Fig. 57).

(14) Install accessory drive belts. Refer to Group

07, Cooling System for procedure.

(15) Raise vehicle on hoist and install right inner

splash shield.

(16) Lower vehicle and perform camshaft and

crankshaft timing relearn procedure as follows:

²Step 1: Connect the DRB scan tool to the data

link (diagnostic) connector. This connector is located

in the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Step 2: Turn the ignition switch on and access

the ªmiscellaneousº screen.

²Step 3: Select re-learn cam/crank option and fol-

low directions on DRB screen.

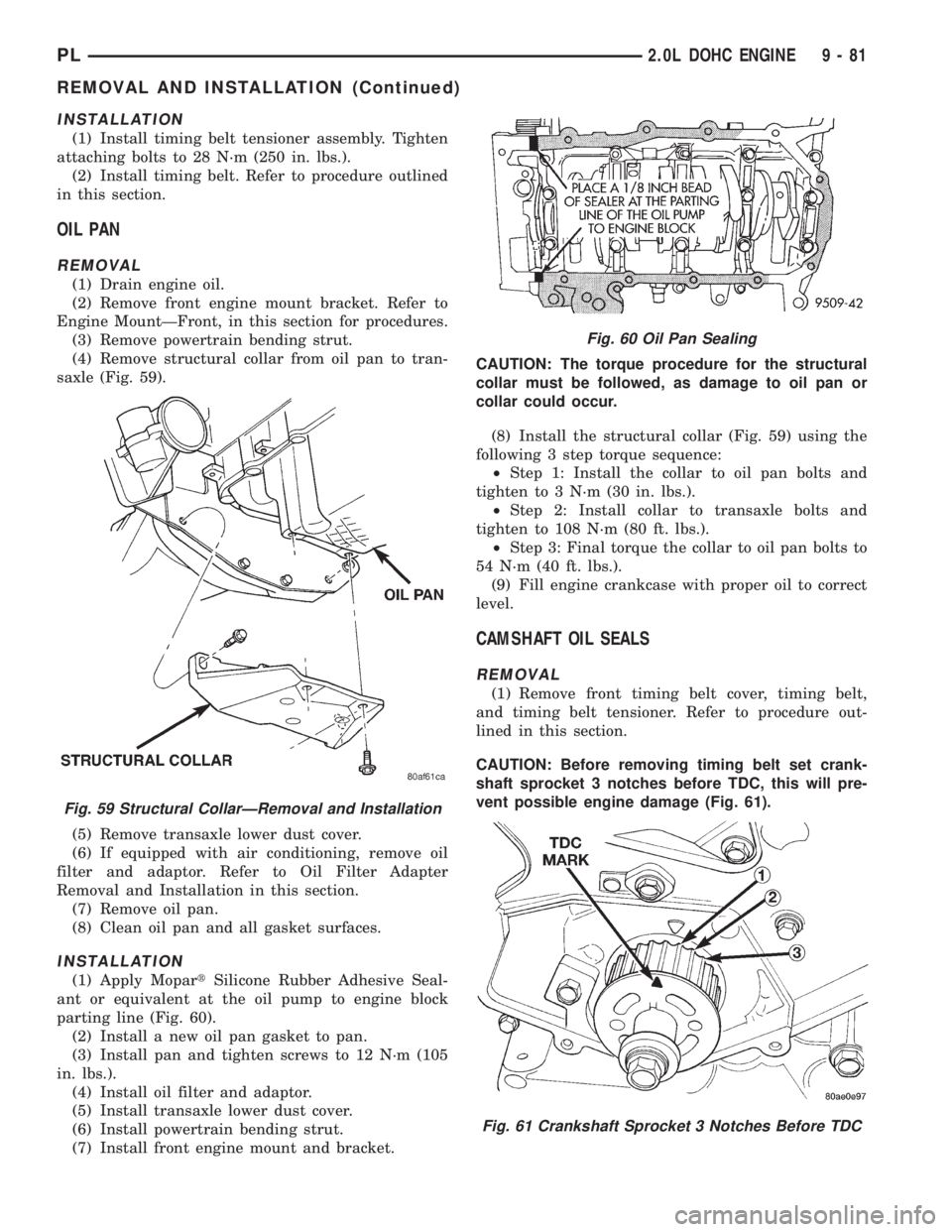

TIMING BELT TENSIONERÐMECHANICAL

REMOVAL

(1) Remove timing belt. Refer to procedure out-

lined in this section.

(2) Remove tensioner assembly attaching bolts

(Fig. 58).

(3) Remove tensioner assembly.

CAUTION: The timing belt tensioner is serviced as

an assembly. To prevent premature timing belt fail-

ure and engine damage, DO NOT separate the ten-

sioner pulley from mounting bracket.

Fig. 56 Timing Mark Alignment

Fig. 57 Crankshaft DamperÐInstallation

Fig. 58 Timing Belt Tensioner AssemblyÐRemoval/

Installation

9 - 80 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 794 of 1200

INSTALLATION

(1) Install timing belt tensioner assembly. Tighten

attaching bolts to 28 N´m (250 in. lbs.).

(2) Install timing belt. Refer to procedure outlined

in this section.

OIL PAN

REMOVAL

(1) Drain engine oil.

(2) Remove front engine mount bracket. Refer to

Engine MountÐFront, in this section for procedures.

(3) Remove powertrain bending strut.

(4) Remove structural collar from oil pan to tran-

saxle (Fig. 59).

(5) Remove transaxle lower dust cover.

(6) If equipped with air conditioning, remove oil

filter and adaptor. Refer to Oil Filter Adapter

Removal and Installation in this section.

(7) Remove oil pan.

(8) Clean oil pan and all gasket surfaces.

INSTALLATION

(1) Apply MopartSilicone Rubber Adhesive Seal-

ant or equivalent at the oil pump to engine block

parting line (Fig. 60).

(2) Install a new oil pan gasket to pan.

(3) Install pan and tighten screws to 12 N´m (105

in. lbs.).

(4) Install oil filter and adaptor.

(5) Install transaxle lower dust cover.

(6) Install powertrain bending strut.

(7) Install front engine mount and bracket.CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(8) Install the structural collar (Fig. 59) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(9) Fill engine crankcase with proper oil to correct

level.

CAMSHAFT OIL SEALS

REMOVAL

(1) Remove front timing belt cover, timing belt,

and timing belt tensioner. Refer to procedure out-

lined in this section.

CAUTION: Before removing timing belt set crank-

shaft sprocket 3 notches before TDC, this will pre-

vent possible engine damage (Fig. 61).

Fig. 59 Structural CollarÐRemoval and Installation

Fig. 60 Oil Pan Sealing

Fig. 61 Crankshaft Sprocket 3 Notches Before TDC

PL2.0L DOHC ENGINE 9 - 81

REMOVAL AND INSTALLATION (Continued)

Page 795 of 1200

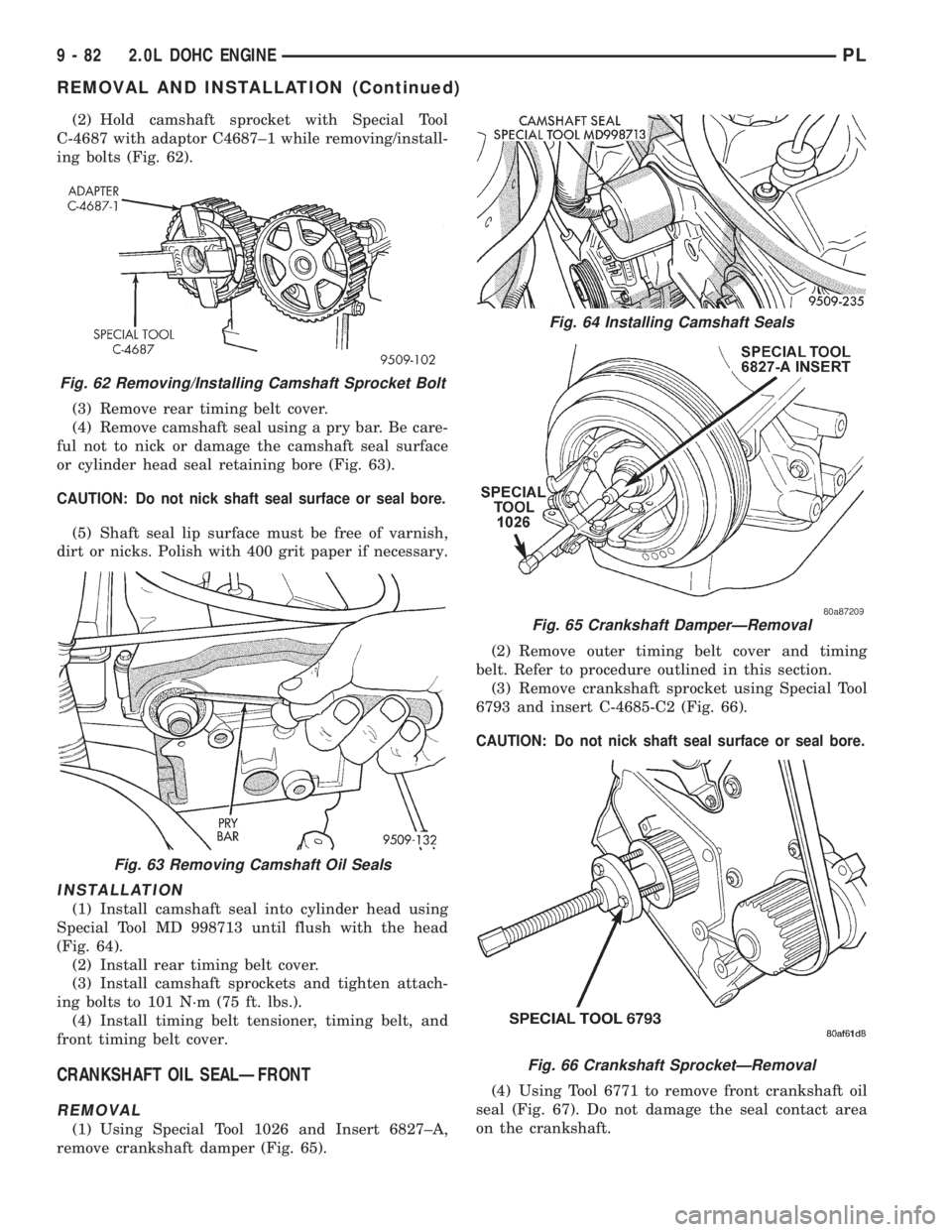

(2) Hold camshaft sprocket with Special Tool

C-4687 with adaptor C4687±1 while removing/install-

ing bolts (Fig. 62).

(3) Remove rear timing belt cover.

(4) Remove camshaft seal using a pry bar. Be care-

ful not to nick or damage the camshaft seal surface

or cylinder head seal retaining bore (Fig. 63).

CAUTION: Do not nick shaft seal surface or seal bore.

(5) Shaft seal lip surface must be free of varnish,

dirt or nicks. Polish with 400 grit paper if necessary.

INSTALLATION

(1) Install camshaft seal into cylinder head using

Special Tool MD 998713 until flush with the head

(Fig. 64).

(2) Install rear timing belt cover.

(3) Install camshaft sprockets and tighten attach-

ing bolts to 101 N´m (75 ft. lbs.).

(4) Install timing belt tensioner, timing belt, and

front timing belt cover.

CRANKSHAFT OIL SEALÐFRONT

REMOVAL

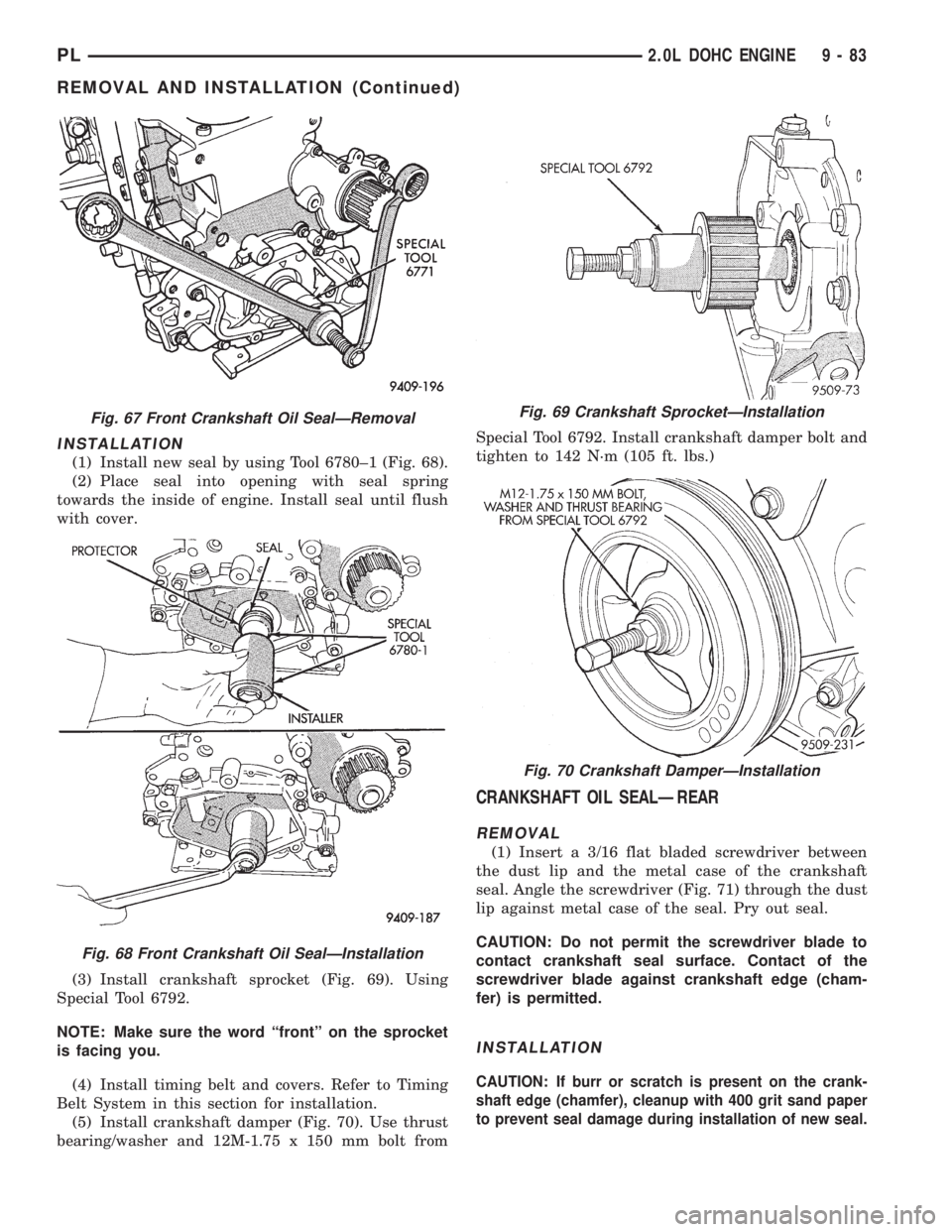

(1) Using Special Tool 1026 and Insert 6827±A,

remove crankshaft damper (Fig. 65).(2) Remove outer timing belt cover and timing

belt. Refer to procedure outlined in this section.

(3) Remove crankshaft sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 66).

CAUTION: Do not nick shaft seal surface or seal bore.

(4) Using Tool 6771 to remove front crankshaft oil

seal (Fig. 67). Do not damage the seal contact area

on the crankshaft.

Fig. 62 Removing/Installing Camshaft Sprocket Bolt

Fig. 63 Removing Camshaft Oil Seals

Fig. 64 Installing Camshaft Seals

Fig. 65 Crankshaft DamperÐRemoval

Fig. 66 Crankshaft SprocketÐRemoval

9 - 82 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 796 of 1200

INSTALLATION

(1) Install new seal by using Tool 6780±1 (Fig. 68).

(2) Place seal into opening with seal spring

towards the inside of engine. Install seal until flush

with cover.

(3) Install crankshaft sprocket (Fig. 69). Using

Special Tool 6792.

NOTE: Make sure the word ªfrontº on the sprocket

is facing you.

(4) Install timing belt and covers. Refer to Timing

Belt System in this section for installation.

(5) Install crankshaft damper (Fig. 70). Use thrust

bearing/washer and 12M-1.75 x 150 mm bolt fromSpecial Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (105 ft. lbs.)

CRANKSHAFT OIL SEALÐREAR

REMOVAL

(1) Insert a 3/16 flat bladed screwdriver between

the dust lip and the metal case of the crankshaft

seal. Angle the screwdriver (Fig. 71) through the dust

lip against metal case of the seal. Pry out seal.

CAUTION: Do not permit the screwdriver blade to

contact crankshaft seal surface. Contact of the

screwdriver blade against crankshaft edge (cham-

fer) is permitted.

INSTALLATION

CAUTION: If burr or scratch is present on the crank-

shaft edge (chamfer), cleanup with 400 grit sand paper

to prevent seal damage during installation of new seal.

Fig. 67 Front Crankshaft Oil SealÐRemoval

Fig. 68 Front Crankshaft Oil SealÐInstallation

Fig. 69 Crankshaft SprocketÐInstallation

Fig. 70 Crankshaft DamperÐInstallation

PL2.0L DOHC ENGINE 9 - 83

REMOVAL AND INSTALLATION (Continued)

Page 800 of 1200

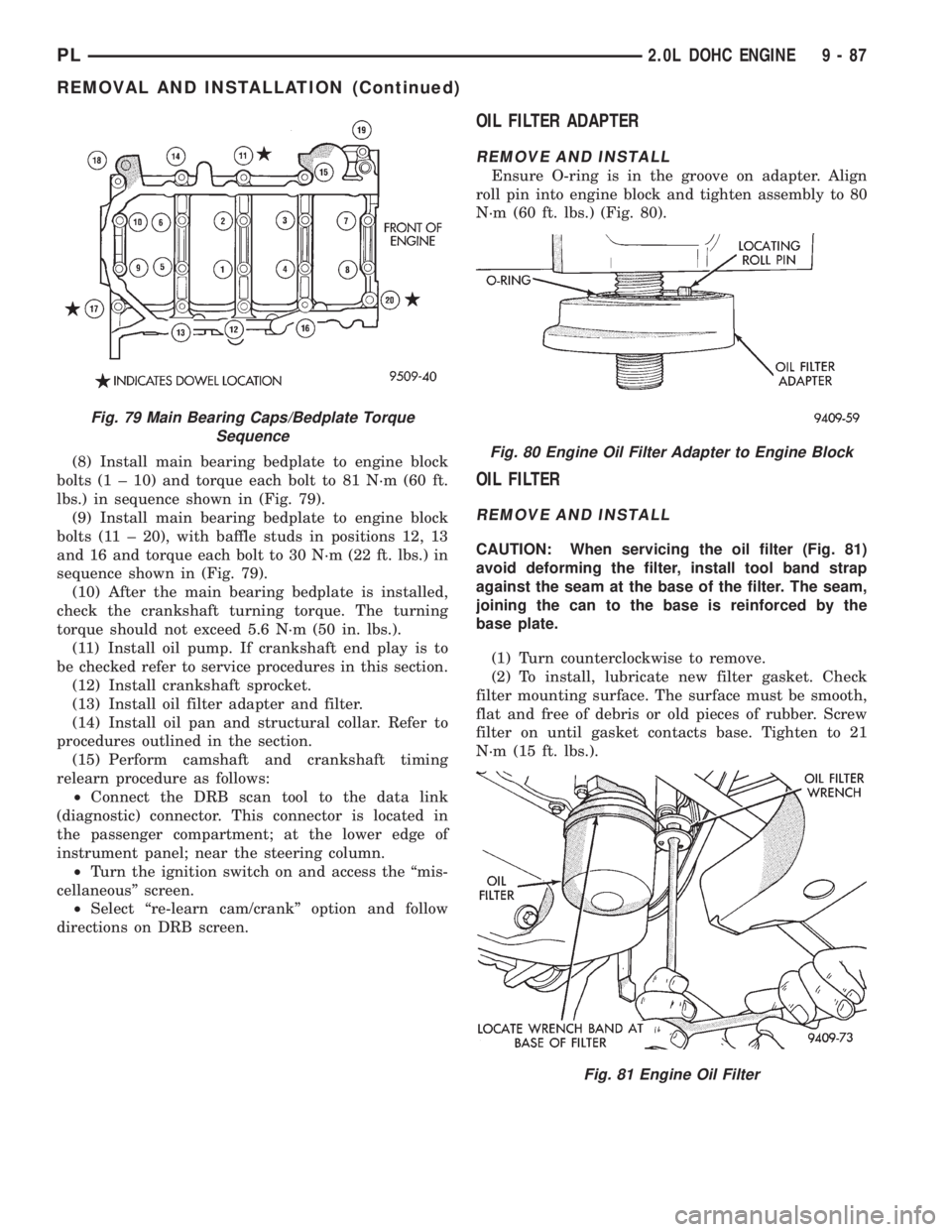

(8) Install main bearing bedplate to engine block

bolts (1 ± 10) and torque each bolt to 81 N´m (60 ft.

lbs.) in sequence shown in (Fig. 79).

(9) Install main bearing bedplate to engine block

bolts (11 ± 20), with baffle studs in positions 12, 13

and 16 and torque each bolt to 30 N´m (22 ft. lbs.) in

sequence shown in (Fig. 79).

(10) After the main bearing bedplate is installed,

check the crankshaft turning torque. The turning

torque should not exceed 5.6 N´m (50 in. lbs.).

(11) Install oil pump. If crankshaft end play is to

be checked refer to service procedures in this section.

(12) Install crankshaft sprocket.

(13) Install oil filter adapter and filter.

(14) Install oil pan and structural collar. Refer to

procedures outlined in the section.

(15) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

OIL FILTER ADAPTER

REMOVE AND INSTALL

Ensure O-ring is in the groove on adapter. Align

roll pin into engine block and tighten assembly to 80

N´m (60 ft. lbs.) (Fig. 80).

OIL FILTER

REMOVE AND INSTALL

CAUTION: When servicing the oil filter (Fig. 81)

avoid deforming the filter, install tool band strap

against the seam at the base of the filter. The seam,

joining the can to the base is reinforced by the

base plate.

(1) Turn counterclockwise to remove.

(2) To install, lubricate new filter gasket. Check

filter mounting surface. The surface must be smooth,

flat and free of debris or old pieces of rubber. Screw

filter on until gasket contacts base. Tighten to 21

N´m (15 ft. lbs.).

Fig. 79 Main Bearing Caps/Bedplate Torque

Sequence

Fig. 80 Engine Oil Filter Adapter to Engine Block

Fig. 81 Engine Oil Filter

PL2.0L DOHC ENGINE 9 - 87

REMOVAL AND INSTALLATION (Continued)

Page 801 of 1200

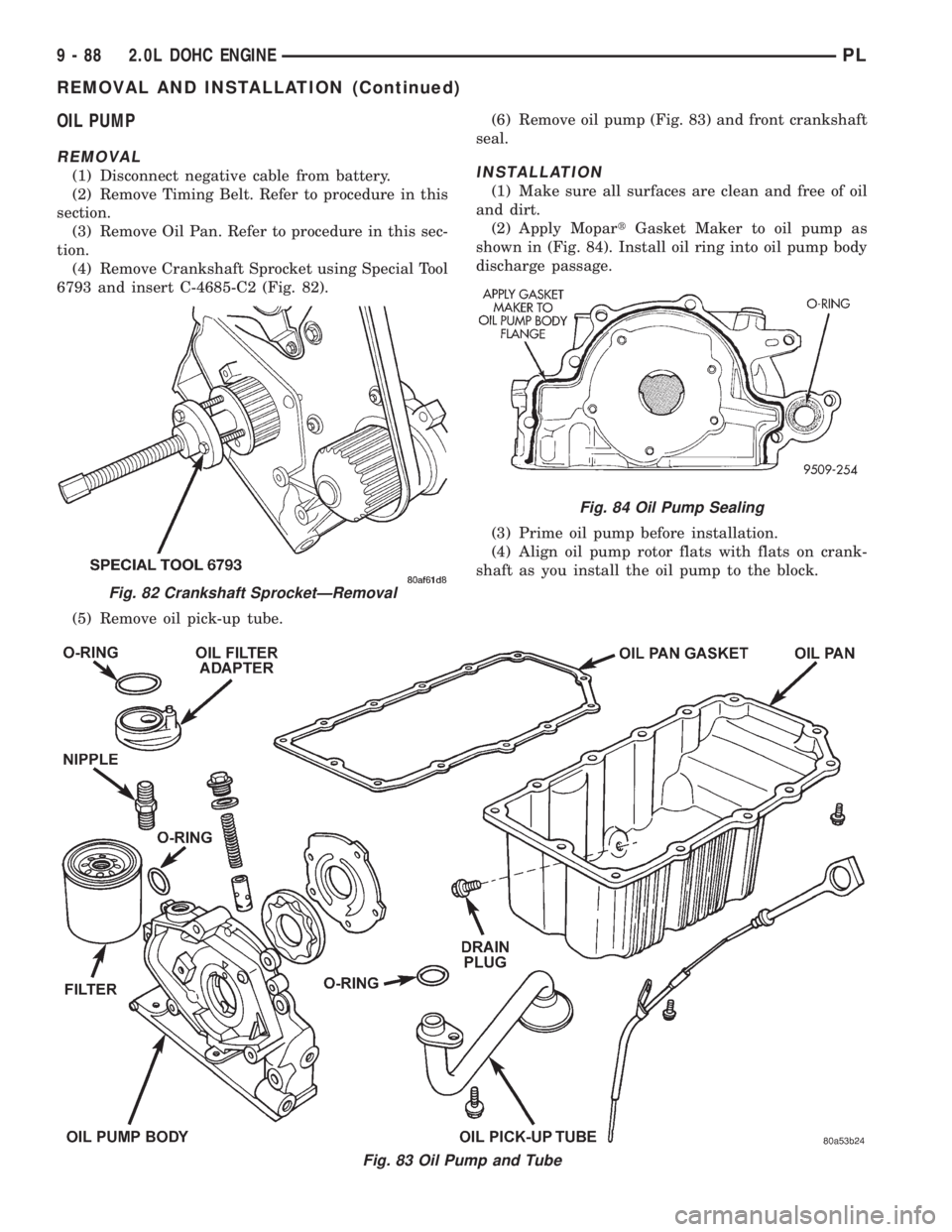

OIL PUMP

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove Timing Belt. Refer to procedure in this

section.

(3) Remove Oil Pan. Refer to procedure in this sec-

tion.

(4) Remove Crankshaft Sprocket using Special Tool

6793 and insert C-4685-C2 (Fig. 82).

(5) Remove oil pick-up tube.(6) Remove oil pump (Fig. 83) and front crankshaft

seal.INSTALLATION

(1) Make sure all surfaces are clean and free of oil

and dirt.

(2) Apply MopartGasket Maker to oil pump as

shown in (Fig. 84). Install oil ring into oil pump body

discharge passage.

(3) Prime oil pump before installation.

(4) Align oil pump rotor flats with flats on crank-

shaft as you install the oil pump to the block.

Fig. 83 Oil Pump and Tube

Fig. 82 Crankshaft SprocketÐRemoval

Fig. 84 Oil Pump Sealing

9 - 88 2.0L DOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 802 of 1200

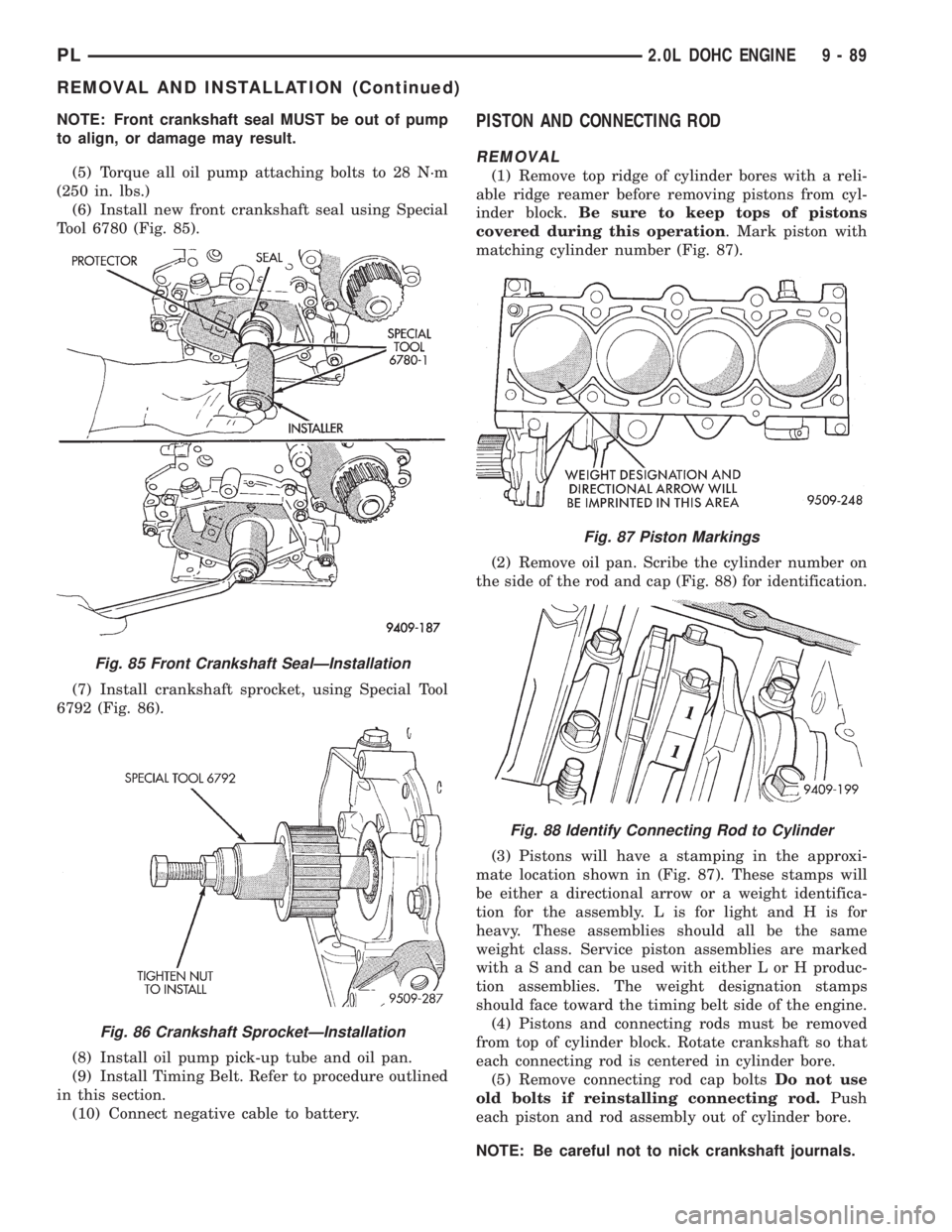

NOTE: Front crankshaft seal MUST be out of pump

to align, or damage may result.

(5) Torque all oil pump attaching bolts to 28 N´m

(250 in. lbs.)

(6) Install new front crankshaft seal using Special

Tool 6780 (Fig. 85).

(7) Install crankshaft sprocket, using Special Tool

6792 (Fig. 86).

(8) Install oil pump pick-up tube and oil pan.

(9) Install Timing Belt. Refer to procedure outlined

in this section.

(10) Connect negative cable to battery.PISTON AND CONNECTING ROD

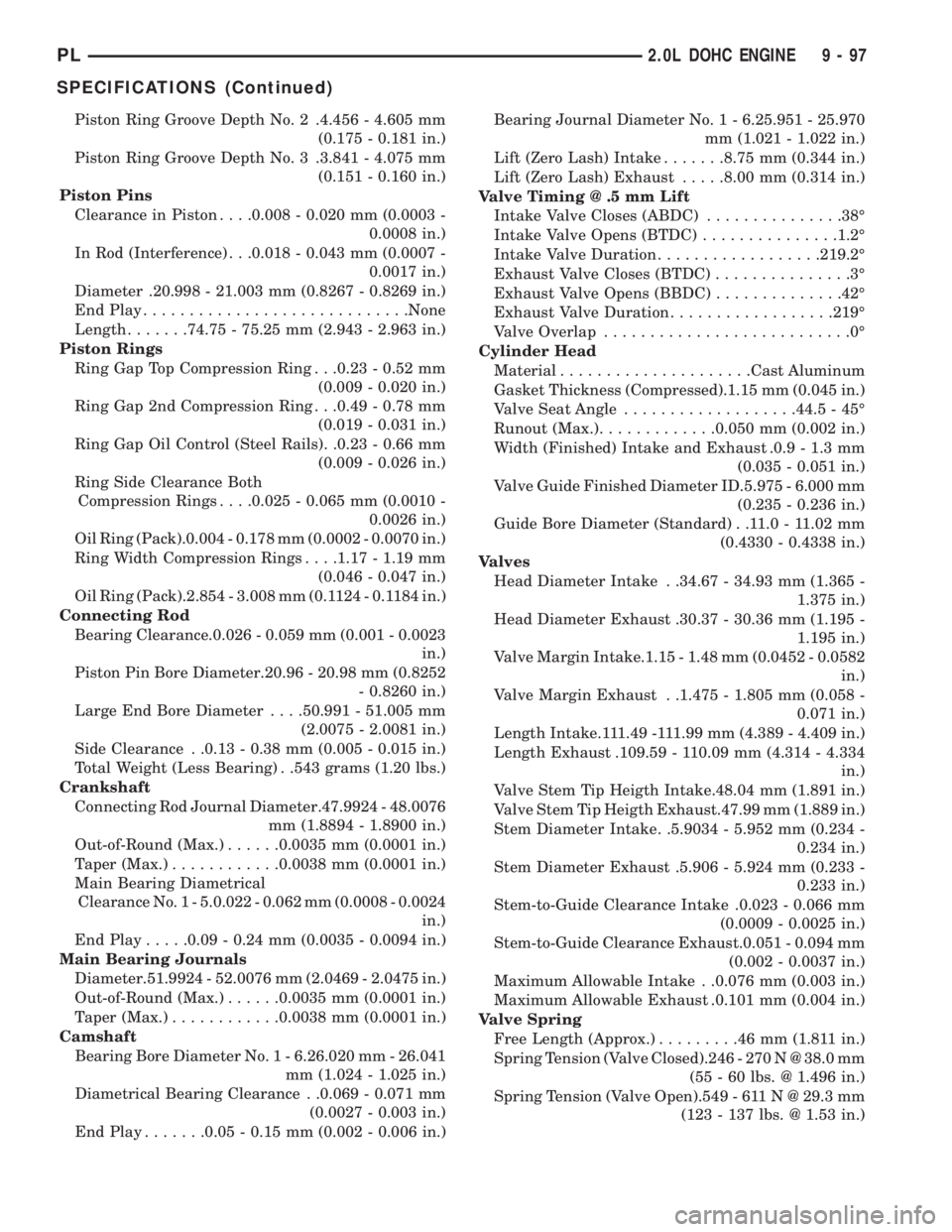

REMOVAL

(1) Remove top ridge of cylinder bores with a reli-

able ridge reamer before removing pistons from cyl-

inder block.Be sure to keep tops of pistons

covered during this operation. Mark piston with

matching cylinder number (Fig. 87).

(2) Remove oil pan. Scribe the cylinder number on

the side of the rod and cap (Fig. 88) for identification.

(3) Pistons will have a stamping in the approxi-

mate location shown in (Fig. 87). These stamps will

be either a directional arrow or a weight identifica-

tion for the assembly. L is for light and H is for

heavy. These assemblies should all be the same

weight class. Service piston assemblies are marked

with a S and can be used with either L or H produc-

tion assemblies. The weight designation stamps

should face toward the timing belt side of the engine.

(4) Pistons and connecting rods must be removed

from top of cylinder block. Rotate crankshaft so that

each connecting rod is centered in cylinder bore.

(5) Remove connecting rod cap boltsDo not use

old bolts if reinstalling connecting rod.Push

each piston and rod assembly out of cylinder bore.

NOTE: Be careful not to nick crankshaft journals.

Fig. 85 Front Crankshaft SealÐInstallation

Fig. 86 Crankshaft SprocketÐInstallation

Fig. 87 Piston Markings

Fig. 88 Identify Connecting Rod to Cylinder

PL2.0L DOHC ENGINE 9 - 89

REMOVAL AND INSTALLATION (Continued)

Page 810 of 1200

Piston Ring Groove Depth No. 2 .4.456 - 4.605 mm

(0.175 - 0.181 in.)

Piston Ring Groove Depth No. 3 .3.841 - 4.075 mm

(0.151 - 0.160 in.)

Piston Pins

Clearance in Piston. . . .0.008 - 0.020 mm (0.0003 -

0.0008 in.)

In Rod (Interference) . . .0.018 - 0.043 mm (0.0007 -

0.0017 in.)

Diameter .20.998 - 21.003 mm (0.8267 - 0.8269 in.)

End Play.............................None

Length.......74.75 - 75.25 mm (2.943 - 2.963 in.)

Piston Rings

Ring Gap Top Compression Ring . . .0.23 - 0.52 mm

(0.009 - 0.020 in.)

Ring Gap 2nd Compression Ring . . .0.49 - 0.78 mm

(0.019 - 0.031 in.)

Ring Gap Oil Control (Steel Rails). .0.23 - 0.66 mm

(0.009 - 0.026 in.)

Ring Side Clearance Both

Compression Rings. . . .0.025 - 0.065 mm (0.0010 -

0.0026 in.)

Oil Ring (Pack).0.004 - 0.178 mm (0.0002 - 0.0070 in.)

Ring Width Compression Rings. . . .1.17 - 1.19 mm

(0.046 - 0.047 in.)

Oil Ring (Pack).2.854 - 3.008 mm (0.1124 - 0.1184 in.)

Connecting Rod

Bearing Clearance.0.026 - 0.059 mm (0.001 - 0.0023

in.)

Piston Pin Bore Diameter.20.96 - 20.98 mm (0.8252

- 0.8260 in.)

Large End Bore Diameter. . . .50.991 - 51.005 mm

(2.0075 - 2.0081 in.)

Side Clearance . .0.13 - 0.38 mm (0.005 - 0.015 in.)

Total Weight (Less Bearing) . .543 grams (1.20 lbs.)

Crankshaft

Connecting Rod Journal Diameter.47.9924 - 48.0076

mm (1.8894 - 1.8900 in.)

Out-of-Round (Max.)......0.0035 mm (0.0001 in.)

Taper (Max.)............0.0038 mm (0.0001 in.)

Main Bearing Diametrical

Clearance No. 1 - 5.0.022 - 0.062 mm (0.0008 - 0.0024

in.)

End Play.....0.09 - 0.24 mm (0.0035 - 0.0094 in.)

Main Bearing Journals

Diameter.51.9924 - 52.0076 mm (2.0469 - 2.0475 in.)

Out-of-Round (Max.)......0.0035 mm (0.0001 in.)

Taper (Max.)............0.0038 mm (0.0001 in.)

Camshaft

Bearing Bore Diameter No. 1 - 6.26.020 mm - 26.041

mm (1.024 - 1.025 in.)

Diametrical Bearing Clearance . .0.069 - 0.071 mm

(0.0027 - 0.003 in.)

End Play.......0.05 - 0.15 mm (0.002 - 0.006 in.)Bearing Journal Diameter No. 1 - 6.25.951 - 25.970

mm (1.021 - 1.022 in.)

Lift (Zero Lash) Intake.......8.75 mm (0.344 in.)

Lift (Zero Lash) Exhaust.....8.00 mm (0.314 in.)

Valve Timing @ .5 mm Lift

Intake Valve Closes (ABDC)...............38É

Intake Valve Opens (BTDC)...............1.2É

Intake Valve Duration..................219.2É

Exhaust Valve Closes (BTDC)...............3É

Exhaust Valve Opens (BBDC)..............42É

Exhaust Valve Duration..................219É

Valve Overlap...........................0É

Cylinder Head

Material.....................Cast Aluminum

Gasket Thickness (Compressed).1.15 mm (0.045 in.)

Valve Seat Angle...................44.5 - 45É

Runout (Max.).............0.050 mm (0.002 in.)

Width (Finished) Intake and Exhaust .0.9 - 1.3 mm

(0.035 - 0.051 in.)

Valve Guide Finished Diameter ID.5.975 - 6.000 mm

(0.235 - 0.236 in.)

Guide Bore Diameter (Standard) . .11.0 - 11.02 mm

(0.4330 - 0.4338 in.)

Valves

Head Diameter Intake . .34.67 - 34.93 mm (1.365 -

1.375 in.)

Head Diameter Exhaust .30.37 - 30.36 mm (1.195 -

1.195 in.)

Valve Margin Intake.1.15 - 1.48 mm (0.0452 - 0.0582

in.)

Valve Margin Exhaust . .1.475 - 1.805 mm (0.058 -

0.071 in.)

Length Intake.111.49 -111.99 mm (4.389 - 4.409 in.)

Length Exhaust .109.59 - 110.09 mm (4.314 - 4.334

in.)

Valve Stem Tip Heigth Intake.48.04 mm (1.891 in.)

Valve Stem Tip Heigth Exhaust.47.99 mm (1.889 in.)

Stem Diameter Intake. .5.9034 - 5.952 mm (0.234 -

0.234 in.)

Stem Diameter Exhaust .5.906 - 5.924 mm (0.233 -

0.233 in.)

Stem-to-Guide Clearance Intake .0.023 - 0.066 mm

(0.0009 - 0.0025 in.)

Stem-to-Guide Clearance Exhaust.0.051 - 0.094 mm

(0.002 - 0.0037 in.)

Maximum Allowable Intake . .0.076 mm (0.003 in.)

Maximum Allowable Exhaust .0.101 mm (0.004 in.)

Valve Spring

Free Length (Approx.).........46mm(1.811 in.)

Spring Tension (Valve Closed).246 - 270 N @ 38.0 mm

(55 - 60 lbs. @ 1.496 in.)

Spring Tension (Valve Open).549 - 611 N @ 29.3 mm

(123 - 137 lbs. @ 1.53 in.)

PL2.0L DOHC ENGINE 9 - 97

SPECIFICATIONS (Continued)