boot DODGE NEON 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 257 of 1200

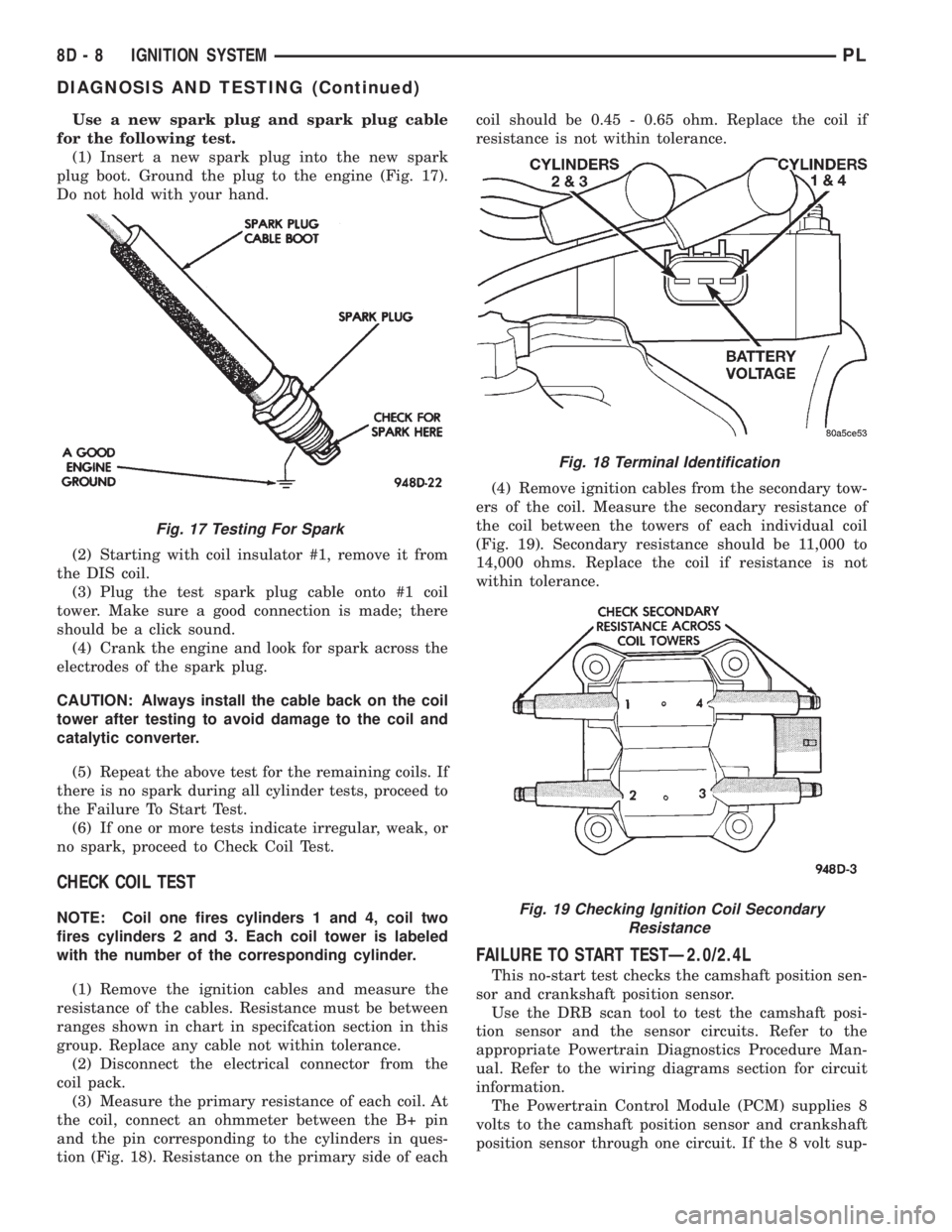

Use a new spark plug and spark plug cable

for the following test.

(1) Insert a new spark plug into the new spark

plug boot. Ground the plug to the engine (Fig. 17).

Do not hold with your hand.

(2) Starting with coil insulator #1, remove it from

the DIS coil.

(3) Plug the test spark plug cable onto #1 coil

tower. Make sure a good connection is made; there

should be a click sound.

(4) Crank the engine and look for spark across the

electrodes of the spark plug.

CAUTION: Always install the cable back on the coil

tower after testing to avoid damage to the coil and

catalytic converter.

(5) Repeat the above test for the remaining coils. If

there is no spark during all cylinder tests, proceed to

the Failure To Start Test.

(6) If one or more tests indicate irregular, weak, or

no spark, proceed to Check Coil Test.

CHECK COIL TEST

NOTE: Coil one fires cylinders 1 and 4, coil two

fires cylinders 2 and 3. Each coil tower is labeled

with the number of the corresponding cylinder.

(1) Remove the ignition cables and measure the

resistance of the cables. Resistance must be between

ranges shown in chart in specifcation section in this

group. Replace any cable not within tolerance.

(2) Disconnect the electrical connector from the

coil pack.

(3) Measure the primary resistance of each coil. At

the coil, connect an ohmmeter between the B+ pin

and the pin corresponding to the cylinders in ques-

tion (Fig. 18). Resistance on the primary side of eachcoil should be 0.45 - 0.65 ohm. Replace the coil if

resistance is not within tolerance.

(4) Remove ignition cables from the secondary tow-

ers of the coil. Measure the secondary resistance of

the coil between the towers of each individual coil

(Fig. 19). Secondary resistance should be 11,000 to

14,000 ohms. Replace the coil if resistance is not

within tolerance.

FAILURE TO START TESTÐ2.0/2.4L

This no-start test checks the camshaft position sen-

sor and crankshaft position sensor.

Use the DRB scan tool to test the camshaft posi-

tion sensor and the sensor circuits. Refer to the

appropriate Powertrain Diagnostics Procedure Man-

ual. Refer to the wiring diagrams section for circuit

information.

The Powertrain Control Module (PCM) supplies 8

volts to the camshaft position sensor and crankshaft

position sensor through one circuit. If the 8 volt sup-

Fig. 17 Testing For Spark

Fig. 18 Terminal Identification

Fig. 19 Checking Ignition Coil Secondary

Resistance

8D - 8 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 261 of 1200

other operating conditions are causing engine over-

heating.

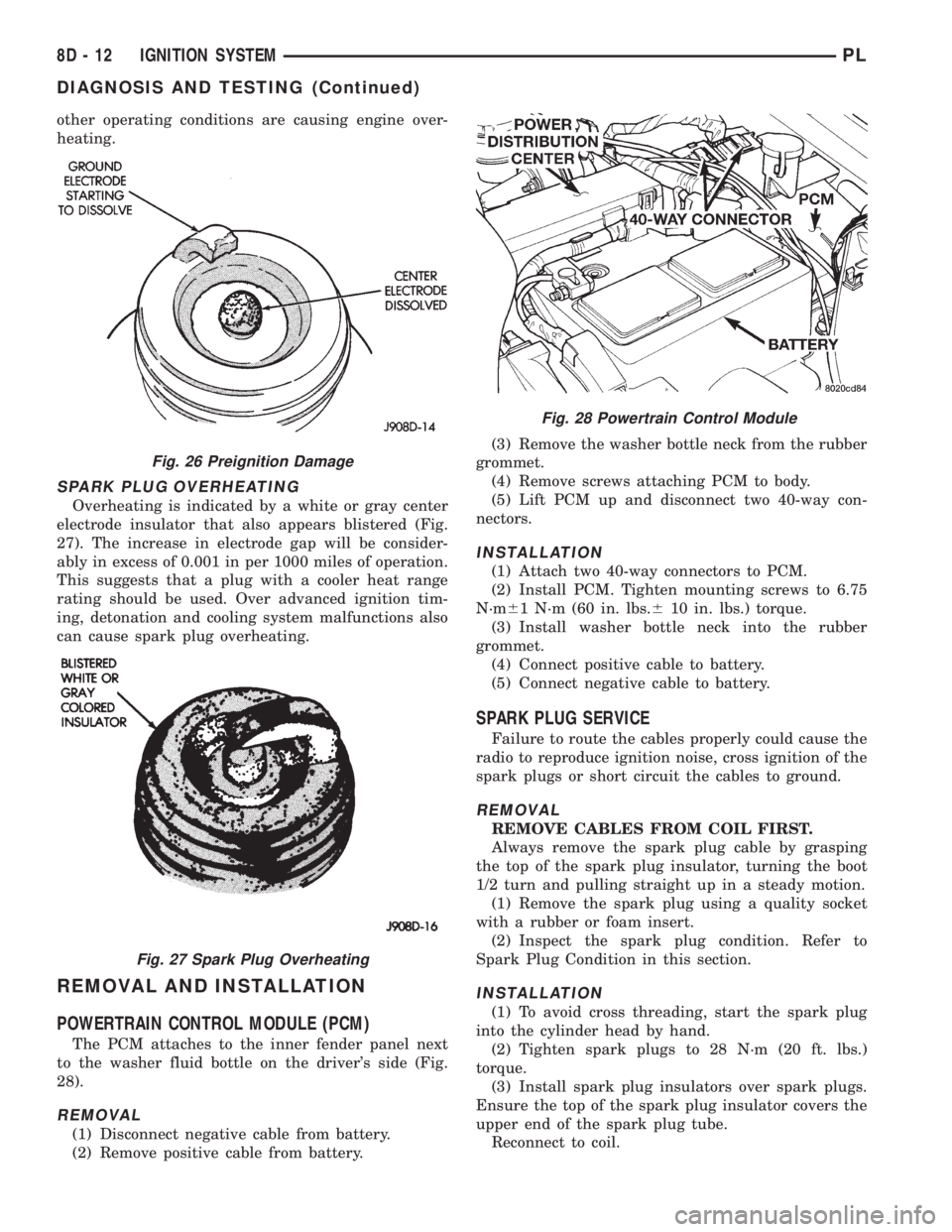

SPARK PLUG OVERHEATING

Overheating is indicated by a white or gray center

electrode insulator that also appears blistered (Fig.

27). The increase in electrode gap will be consider-

ably in excess of 0.001 in per 1000 miles of operation.

This suggests that a plug with a cooler heat range

rating should be used. Over advanced ignition tim-

ing, detonation and cooling system malfunctions also

can cause spark plug overheating.

REMOVAL AND INSTALLATION

POWERTRAIN CONTROL MODULE (PCM)

The PCM attaches to the inner fender panel next

to the washer fluid bottle on the driver's side (Fig.

28).

REMOVAL

(1) Disconnect negative cable from battery.

(2) Remove positive cable from battery.(3) Remove the washer bottle neck from the rubber

grommet.

(4) Remove screws attaching PCM to body.

(5) Lift PCM up and disconnect two 40-way con-

nectors.

INSTALLATION

(1) Attach two 40-way connectors to PCM.

(2) Install PCM. Tighten mounting screws to 6.75

N´m61 N´m (60 in. lbs.610 in. lbs.) torque.

(3) Install washer bottle neck into the rubber

grommet.

(4) Connect positive cable to battery.

(5) Connect negative cable to battery.

SPARK PLUG SERVICE

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

REMOVAL

REMOVE CABLES FROM COIL FIRST.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

(1) Remove the spark plug using a quality socket

with a rubber or foam insert.

(2) Inspect the spark plug condition. Refer to

Spark Plug Condition in this section.

INSTALLATION

(1) To avoid cross threading, start the spark plug

into the cylinder head by hand.

(2) Tighten spark plugs to 28 N´m (20 ft. lbs.)

torque.

(3) Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube.

Reconnect to coil.

Fig. 26 Preignition Damage

Fig. 27 Spark Plug Overheating

Fig. 28 Powertrain Control Module

8D - 12 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 262 of 1200

SPARK PLUG CABLE SERVICE

Failure to route the cables properly could cause the

radio to reproduce ignition noise, cross ignition of the

spark plugs or short circuit the cables to ground.

REMOVAL

Remove spark plug cable from coil frist.

Always remove the spark plug cable by grasping

the top of the spark plug insulator, turning the boot

1/2 turn and pulling straight up in a steady motion.

INSTALLATION

Install spark plug insulators over spark plugs.

Ensure the top of the spark plug insulator covers the

upper end of the spark plug tube.The connect the

other end to coil pack. OnSOHCengines, be sure

that dual plastic clip holds #1,#2 cables off of valve

cover and that PCV hose plastic clip holds #3 cable

away from metal PCV clamp and edge of air duct. On

DOHC, be sure that the plastic clip on PCV hose is

positioned so that cable clip is beneath hose, and that

#1 cable is snapped into this clip to protect it from

metal PCV clamp.

SPARK PLUG TUBES

The spark plugs tubes are pressed into the cylinder

head. Sealant is applied to the end of the tube before

installation. For engine information, refer to Group

9, Engines.

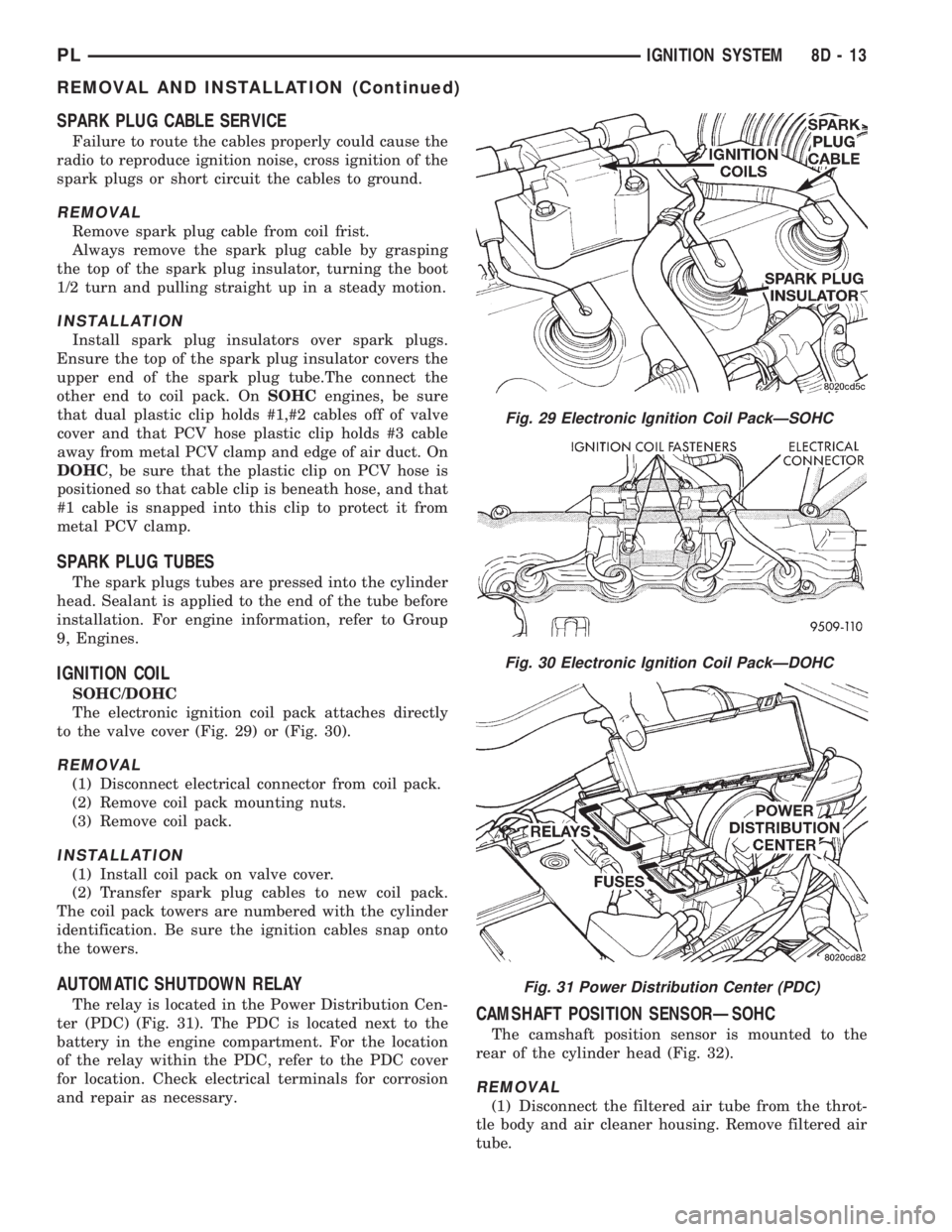

IGNITION COIL

SOHC/DOHC

The electronic ignition coil pack attaches directly

to the valve cover (Fig. 29) or (Fig. 30).

REMOVAL

(1) Disconnect electrical connector from coil pack.

(2) Remove coil pack mounting nuts.

(3) Remove coil pack.

INSTALLATION

(1) Install coil pack on valve cover.

(2) Transfer spark plug cables to new coil pack.

The coil pack towers are numbered with the cylinder

identification. Be sure the ignition cables snap onto

the towers.

AUTOMATIC SHUTDOWN RELAY

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 31). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.CAMSHAFT POSITION SENSORÐSOHC

The camshaft position sensor is mounted to the

rear of the cylinder head (Fig. 32).

REMOVAL

(1) Disconnect the filtered air tube from the throt-

tle body and air cleaner housing. Remove filtered air

tube.

Fig. 29 Electronic Ignition Coil PackÐSOHC

Fig. 30 Electronic Ignition Coil PackÐDOHC

Fig. 31 Power Distribution Center (PDC)

PLIGNITION SYSTEM 8D - 13

REMOVAL AND INSTALLATION (Continued)

Page 282 of 1200

the panel rearward to disengage the three locator

pins and remove.

(6) Reach in and disconnect the wiring connector(s)

for the rear window defogger and/or fog lamp

switch(s) as required.

INSTALLATION

For installation, reverse the above procedures.

SHIFTER KNOB

AUTOMATIC TRANSMISSION SHIFTER

REMOVAL

(1) Loosen the set screw at the left side under the

button area.

(2) Pull up until the knob slides off the shifter

shaft.

INSTALLATION

For installation, reverse the above procedures.

MANUAL TRANSMISSION SHIFTER

REMOVAL

(1) Pull the top part of the boot down until the two

tabs at the bottom of the knob are exposed.

(2) Release the locking tabs from the pins on the

shifter shaft.

(3) Pull up until the knob slides off the shifter

shaft.INSTALLATION

For installation, reverse the above procedures.

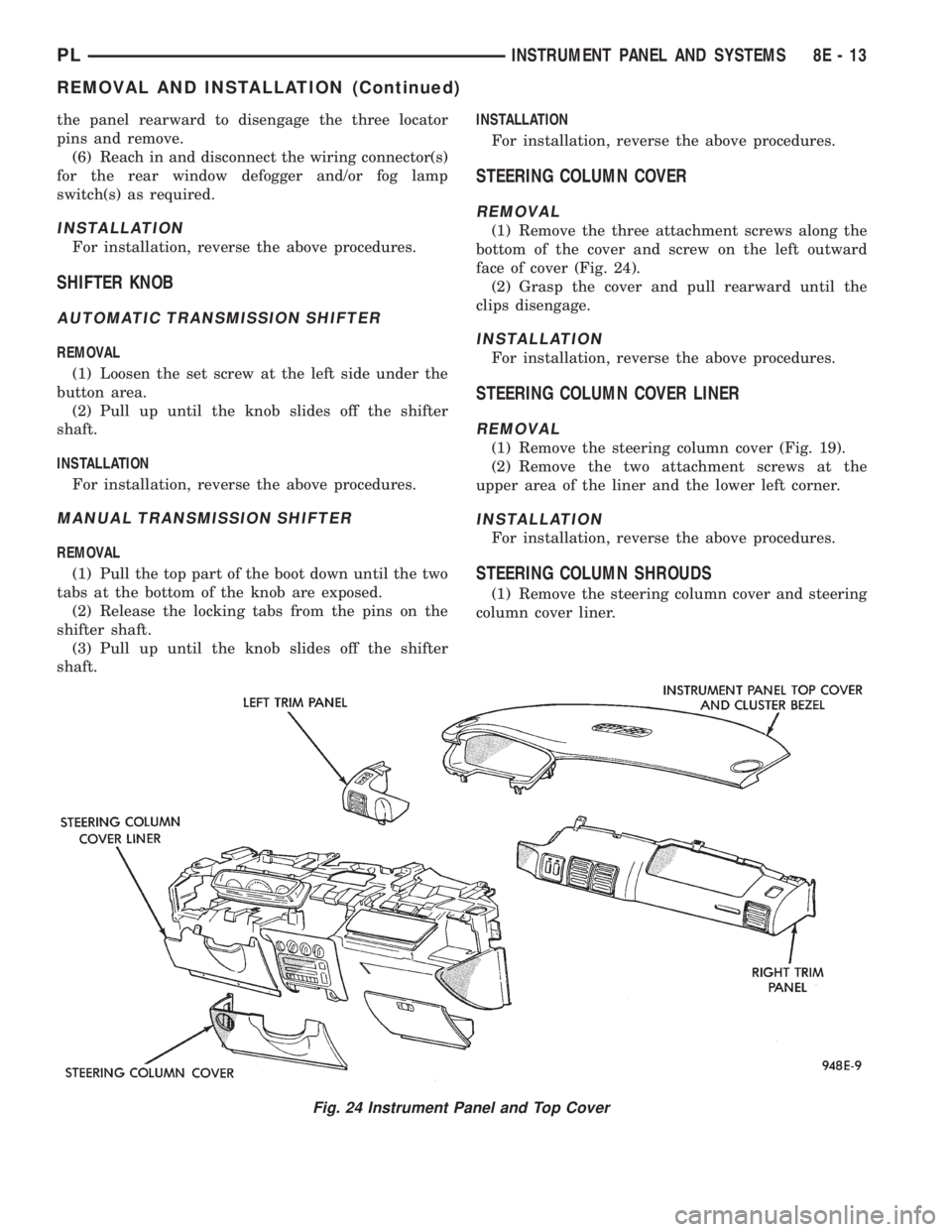

STEERING COLUMN COVER

REMOVAL

(1) Remove the three attachment screws along the

bottom of the cover and screw on the left outward

face of cover (Fig. 24).

(2) Grasp the cover and pull rearward until the

clips disengage.

INSTALLATION

For installation, reverse the above procedures.

STEERING COLUMN COVER LINER

REMOVAL

(1) Remove the steering column cover (Fig. 19).

(2) Remove the two attachment screws at the

upper area of the liner and the lower left corner.

INSTALLATION

For installation, reverse the above procedures.

STEERING COLUMN SHROUDS

(1) Remove the steering column cover and steering

column cover liner.

Fig. 24 Instrument Panel and Top Cover

PLINSTRUMENT PANEL AND SYSTEMS 8E - 13

REMOVAL AND INSTALLATION (Continued)

Page 345 of 1200

LAMP BULB SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

CITYLIGHT LAMP BULB.................... 3

FOG LAMP BULB......................... 3FRONT TURN SIGNAL LAMP BULB........... 2

HEADLAMP BULB........................ 2

SIDE REPEATER LAMP BULB............... 4

REMOVAL AND INSTALLATION

HEADLAMP BULB

REMOVAL

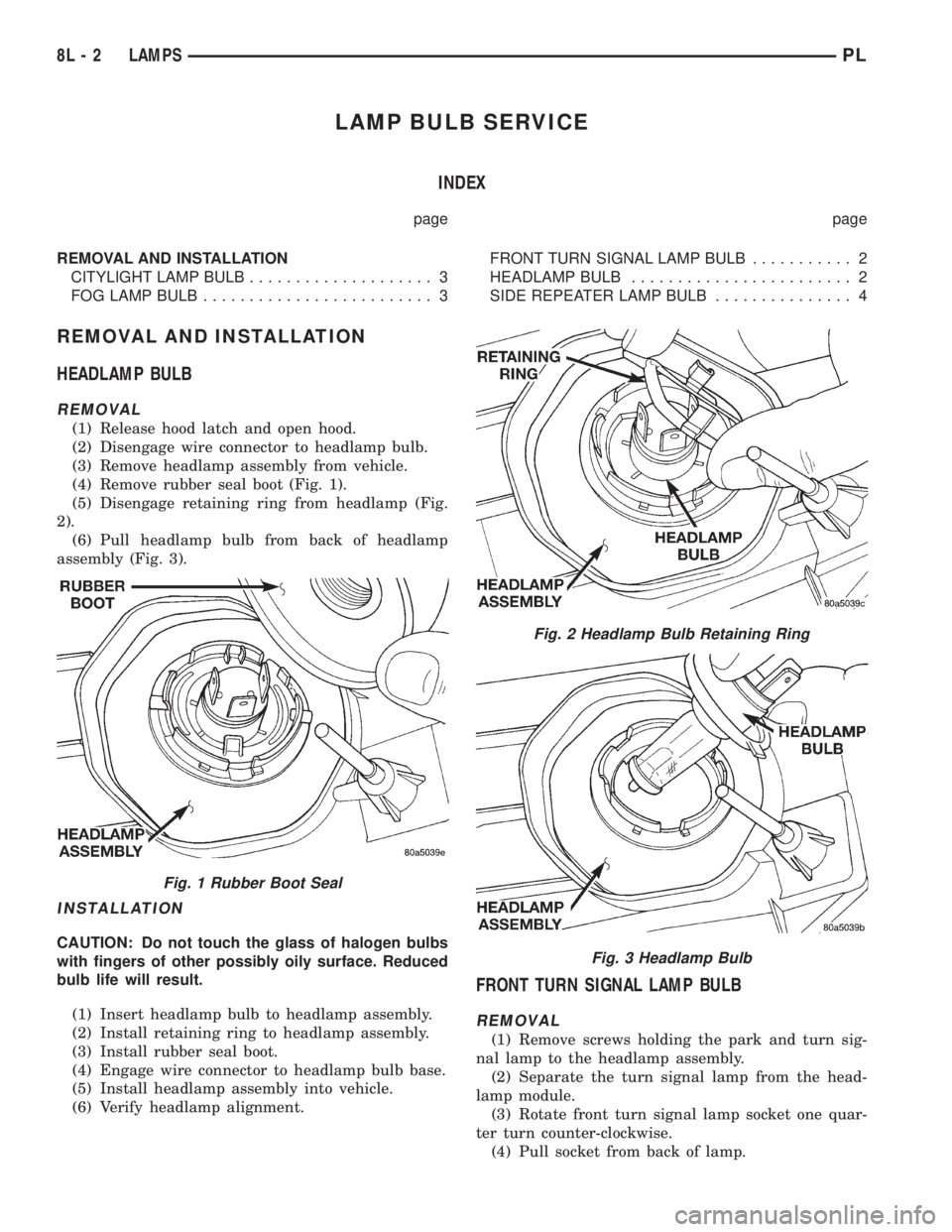

(1) Release hood latch and open hood.

(2) Disengage wire connector to headlamp bulb.

(3) Remove headlamp assembly from vehicle.

(4) Remove rubber seal boot (Fig. 1).

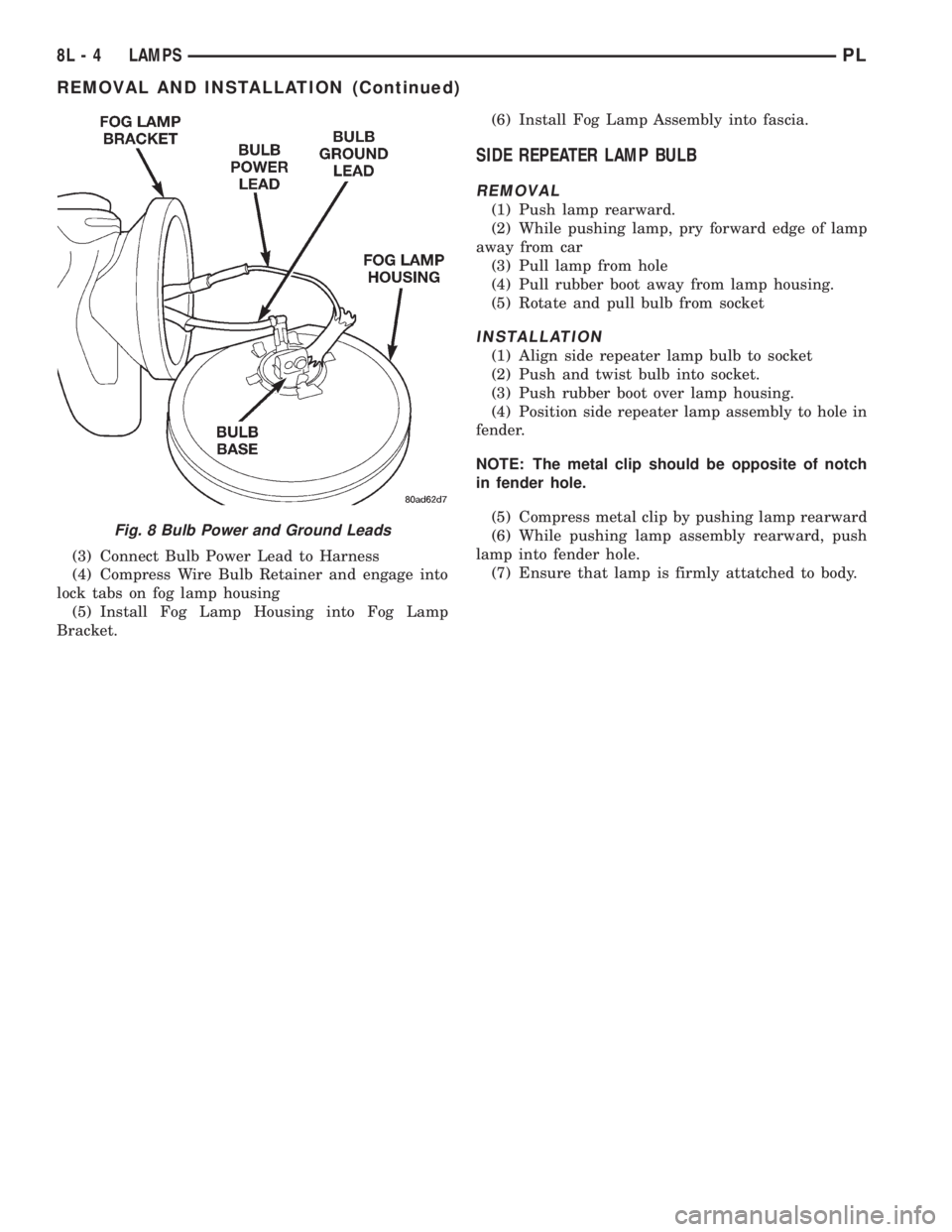

(5) Disengage retaining ring from headlamp (Fig.

2).

(6) Pull headlamp bulb from back of headlamp

assembly (Fig. 3).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers of other possibly oily surface. Reduced

bulb life will result.

(1) Insert headlamp bulb to headlamp assembly.

(2) Install retaining ring to headlamp assembly.

(3) Install rubber seal boot.

(4) Engage wire connector to headlamp bulb base.

(5) Install headlamp assembly into vehicle.

(6) Verify headlamp alignment.

FRONT TURN SIGNAL LAMP BULB

REMOVAL

(1) Remove screws holding the park and turn sig-

nal lamp to the headlamp assembly.

(2) Separate the turn signal lamp from the head-

lamp module.

(3) Rotate front turn signal lamp socket one quar-

ter turn counter-clockwise.

(4) Pull socket from back of lamp.

Fig. 1 Rubber Boot Seal

Fig. 2 Headlamp Bulb Retaining Ring

Fig. 3 Headlamp Bulb

8L - 2 LAMPSPL

Page 347 of 1200

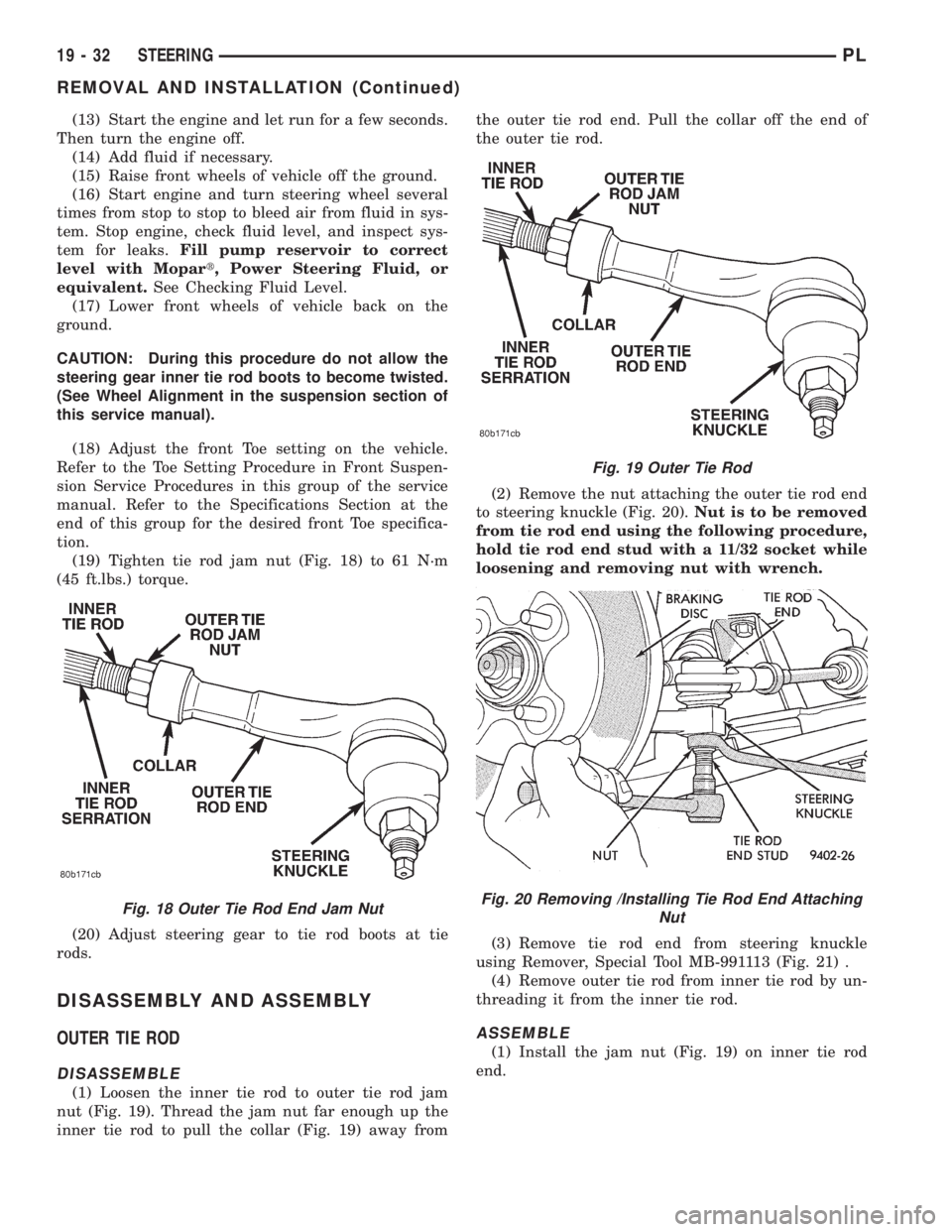

(3) Connect Bulb Power Lead to Harness

(4) Compress Wire Bulb Retainer and engage into

lock tabs on fog lamp housing

(5) Install Fog Lamp Housing into Fog Lamp

Bracket.(6) Install Fog Lamp Assembly into fascia.

SIDE REPEATER LAMP BULB

REMOVAL

(1) Push lamp rearward.

(2) While pushing lamp, pry forward edge of lamp

away from car

(3) Pull lamp from hole

(4) Pull rubber boot away from lamp housing.

(5) Rotate and pull bulb from socket

INSTALLATION

(1) Align side repeater lamp bulb to socket

(2) Push and twist bulb into socket.

(3) Push rubber boot over lamp housing.

(4) Position side repeater lamp assembly to hole in

fender.

NOTE: The metal clip should be opposite of notch

in fender hole.

(5) Compress metal clip by pushing lamp rearward

(6) While pushing lamp assembly rearward, push

lamp into fender hole.

(7) Ensure that lamp is firmly attatched to body.

Fig. 8 Bulb Power and Ground Leads

8L - 4 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 933 of 1200

(13) Start the engine and let run for a few seconds.

Then turn the engine off.

(14) Add fluid if necessary.

(15) Raise front wheels of vehicle off the ground.

(16) Start engine and turn steering wheel several

times from stop to stop to bleed air from fluid in sys-

tem. Stop engine, check fluid level, and inspect sys-

tem for leaks.Fill pump reservoir to correct

level with Mopart, Power Steering Fluid, or

equivalent.See Checking Fluid Level.

(17) Lower front wheels of vehicle back on the

ground.

CAUTION: During this procedure do not allow the

steering gear inner tie rod boots to become twisted.

(See Wheel Alignment in the suspension section of

this service manual).

(18) Adjust the front Toe setting on the vehicle.

Refer to the Toe Setting Procedure in Front Suspen-

sion Service Procedures in this group of the service

manual. Refer to the Specifications Section at the

end of this group for the desired front Toe specifica-

tion.

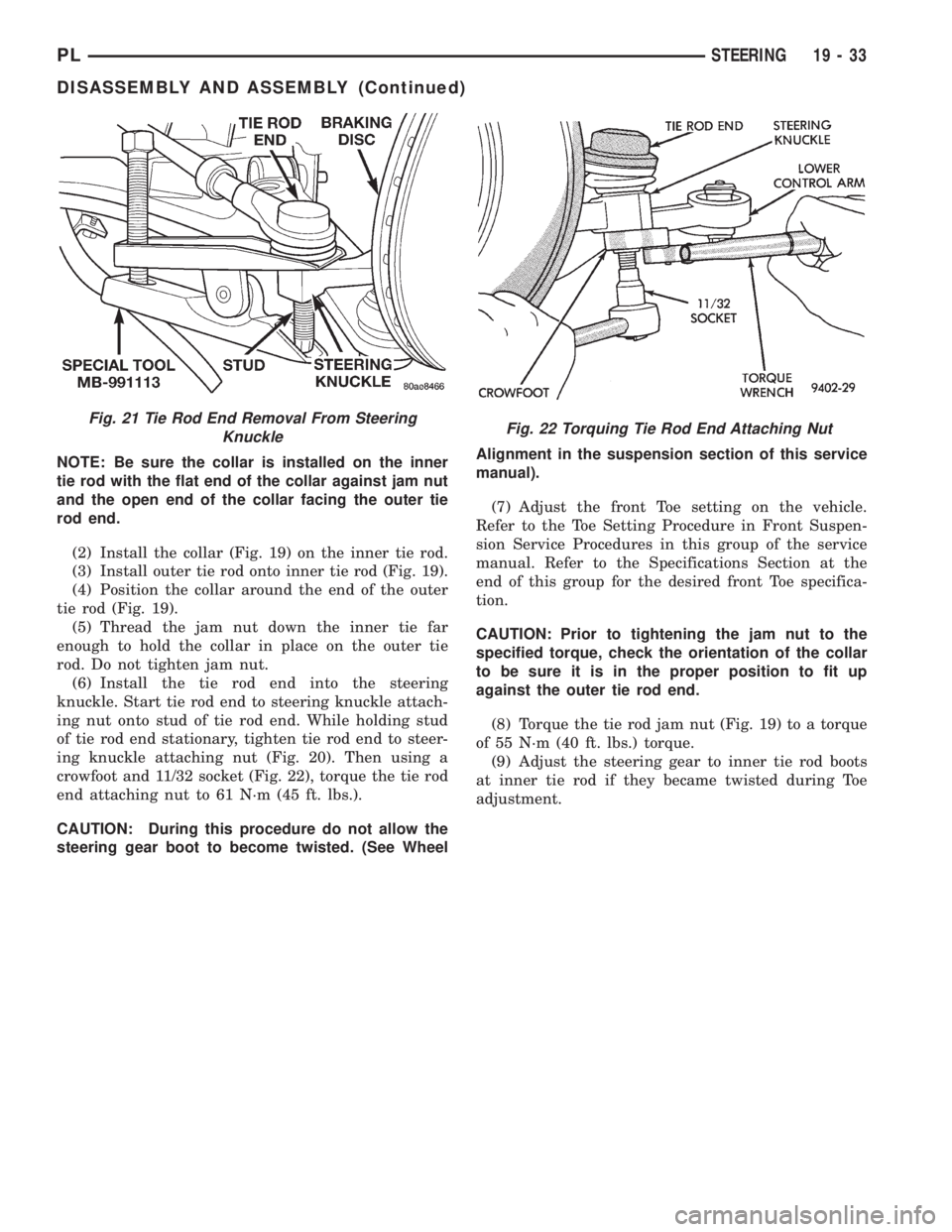

(19) Tighten tie rod jam nut (Fig. 18) to 61 N´m

(45 ft.lbs.) torque.

(20) Adjust steering gear to tie rod boots at tie

rods.

DISASSEMBLY AND ASSEMBLY

OUTER TIE ROD

DISASSEMBLE

(1) Loosen the inner tie rod to outer tie rod jam

nut (Fig. 19). Thread the jam nut far enough up the

inner tie rod to pull the collar (Fig. 19) away fromthe outer tie rod end. Pull the collar off the end of

the outer tie rod.

(2) Remove the nut attaching the outer tie rod end

to steering knuckle (Fig. 20).Nut is to be removed

from tie rod end using the following procedure,

hold tie rod end stud with a 11/32 socket while

loosening and removing nut with wrench.

(3) Remove tie rod end from steering knuckle

using Remover, Special Tool MB-991113 (Fig. 21) .

(4) Remove outer tie rod from inner tie rod by un-

threading it from the inner tie rod.

ASSEMBLE

(1) Install the jam nut (Fig. 19) on inner tie rod

end.

Fig. 18 Outer Tie Rod End Jam Nut

Fig. 19 Outer Tie Rod

Fig. 20 Removing /Installing Tie Rod End Attaching

Nut

19 - 32 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 934 of 1200

NOTE: Be sure the collar is installed on the inner

tie rod with the flat end of the collar against jam nut

and the open end of the collar facing the outer tie

rod end.

(2) Install the collar (Fig. 19) on the inner tie rod.

(3) Install outer tie rod onto inner tie rod (Fig. 19).

(4) Position the collar around the end of the outer

tie rod (Fig. 19).

(5) Thread the jam nut down the inner tie far

enough to hold the collar in place on the outer tie

rod. Do not tighten jam nut.

(6) Install the tie rod end into the steering

knuckle. Start tie rod end to steering knuckle attach-

ing nut onto stud of tie rod end. While holding stud

of tie rod end stationary, tighten tie rod end to steer-

ing knuckle attaching nut (Fig. 20). Then using a

crowfoot and 11/32 socket (Fig. 22), torque the tie rod

end attaching nut to 61 N´m (45 ft. lbs.).

CAUTION: During this procedure do not allow the

steering gear boot to become twisted. (See WheelAlignment in the suspension section of this service

manual).

(7) Adjust the front Toe setting on the vehicle.

Refer to the Toe Setting Procedure in Front Suspen-

sion Service Procedures in this group of the service

manual. Refer to the Specifications Section at the

end of this group for the desired front Toe specifica-

tion.

CAUTION: Prior to tightening the jam nut to the

specified torque, check the orientation of the collar

to be sure it is in the proper position to fit up

against the outer tie rod end.

(8) Torque the tie rod jam nut (Fig. 19) to a torque

of 55 N´m (40 ft. lbs.) torque.

(9) Adjust the steering gear to inner tie rod boots

at inner tie rod if they became twisted during Toe

adjustment.

Fig. 22 Torquing Tie Rod End Attaching NutFig. 21 Tie Rod End Removal From Steering

Knuckle

PLSTEERING 19 - 33

DISASSEMBLY AND ASSEMBLY (Continued)

Page 944 of 1200

TRANSAXLE

CONTENTS

page page

31TH AUTOMATIC TRANSAXLE............. 40 NVT350 (A-578) MANUAL TRANSAXLE....... 1

NV T350 (A-578) MANUAL TRANSAXLE

INDEX

page page

GENERAL INFORMATION

GEAR RATIOS........................... 2

GEARSHIFT PATTERN..................... 2

NV T350 MANUAL TRANSAXLE.............. 1

SEALANTS.............................. 2

SELECTION OF LUBRICANT................ 2

SPECIAL ADDITIVES...................... 2

TRANSAXLE IDENTIFICATION INFORMATION . . . 2

DESCRIPTION AND OPERATION

AXLE SEALS............................ 3

SHIFT LEVERS.......................... 3

DIAGNOSIS AND TESTING

CLUTCH PROBLEMS...................... 3

COMMON PROBLEM CAUSES.............. 3

HARD SHIFTING......................... 3

LOW LUBRICANT LEVEL................... 3

NOISY OPERATION....................... 3

SLIPS OUT OF GEAR..................... 3

SERVICE PROCEDURES

FLUID DRAIN AND FILL.................... 3

REMOVAL AND INSTALLATION

AXLE SEALS............................ 8

BACK-UP LAMP SWITCH................... 7

CROSSOVER LEVER...................... 7

GEARSHIFT BOOT....................... 4

GEARSHIFT CABLES...................... 4GEARSHIFT KNOB....................... 4

GEARSHIFT MECHANISM REPLACEMENT..... 6

SELECTOR LEVER....................... 8

SHIFT SHAFT SEALS...................... 8

TRANSAXLE............................ 8

VEHICLE SPEED SENSOR DRIVE GEAR...... 7

DISASSEMBLY AND ASSEMBLY

DIFFERENTIAL......................... 24

INPUT SHAFT.......................... 20

OUTPUT SHAFT........................ 24

SHIFT RAILS OVERHAUL................. 29

SYNCHRONIZER........................ 29

TRANSAXLE CASE OVERHAUL............. 30

TRANSAXLE........................... 10

CLEANING AND INSPECTION

SYNCHRONIZER........................ 35

TRANSAXLE........................... 35

ADJUSTMENTS

BEARING ADJUSTMENT PROCEDURE....... 35

DIFFERENTIAL BEARING PRELOAD

ADJUSTMENT......................... 36

GEARSHIFT CROSSOVER CABLE........... 35

SPECIFICATIONS

NV T350 (A-578) SPECIFICATIONS.......... 37

SPECIAL TOOLS

NV T350 (A-578) MANUAL TRANSAXLE....... 37

GENERAL INFORMATION

NV T350 MANUAL TRANSAXLE

NOTE: Safety goggles should be worn at all times

when working on these transaxles.

This five speed is a constant-mesh manual tran-

saxle. All gear ranges, except reverse, are synchro-

nized. The reverse gear utilizes a brake and blockingring for shifting ease. The reverse idler gear is sup-

ported on a sliding spindle idler shaft. The transaxle

case is aluminum with a steel end±plate bearing

cover. It is housed in a die-cast aluminum case fea-

turing a two±piece, middle split design.

The NV T350 (A-578) transaxle internal compo-

nents can be serviced only by separating the gear

case from the bellhousing case.

PLTRANSAXLE 21 - 1

Page 947 of 1200

REMOVAL AND INSTALLATION

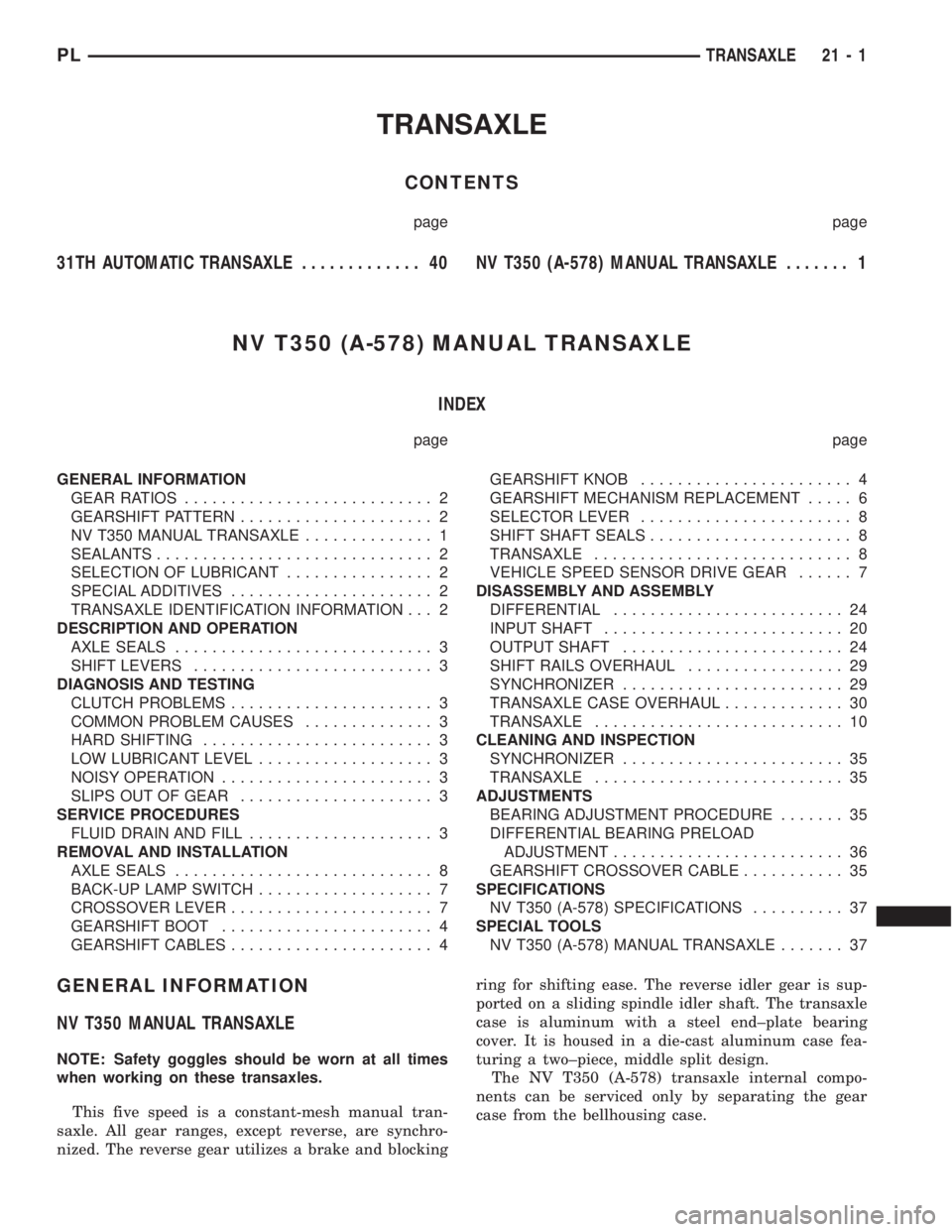

GEARSHIFT KNOB

REMOVAL

(1) Pull shifter boot down and away from shifter

roll pin.

(2) Pry legs of shift knob away from shift lever roll

pin using a flat blade pry tool.

(3) Remove knob from shifter handle (Fig. 5).

INSTALLATION

(1) For installation, reverse removal procedure.

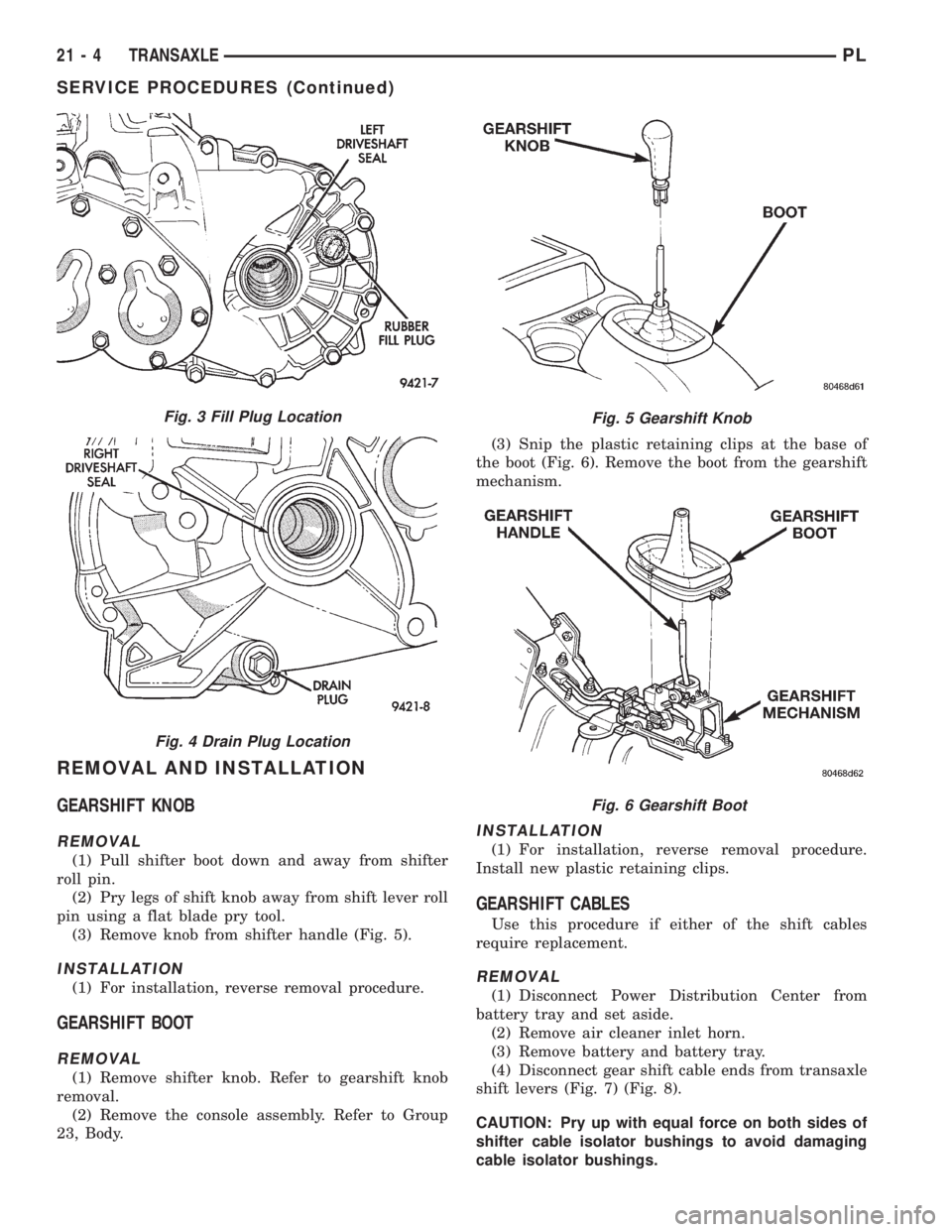

GEARSHIFT BOOT

REMOVAL

(1) Remove shifter knob. Refer to gearshift knob

removal.

(2) Remove the console assembly. Refer to Group

23, Body.(3) Snip the plastic retaining clips at the base of

the boot (Fig. 6). Remove the boot from the gearshift

mechanism.

INSTALLATION

(1) For installation, reverse removal procedure.

Install new plastic retaining clips.

GEARSHIFT CABLES

Use this procedure if either of the shift cables

require replacement.

REMOVAL

(1) Disconnect Power Distribution Center from

battery tray and set aside.

(2) Remove air cleaner inlet horn.

(3) Remove battery and battery tray.

(4) Disconnect gear shift cable ends from transaxle

shift levers (Fig. 7) (Fig. 8).

CAUTION: Pry up with equal force on both sides of

shifter cable isolator bushings to avoid damaging

cable isolator bushings.

Fig. 5 Gearshift Knob

Fig. 6 Gearshift Boot

Fig. 3 Fill Plug Location

Fig. 4 Drain Plug Location

21 - 4 TRANSAXLEPL

SERVICE PROCEDURES (Continued)