window DODGE NEON 1999 Service Workshop Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 645 of 1200

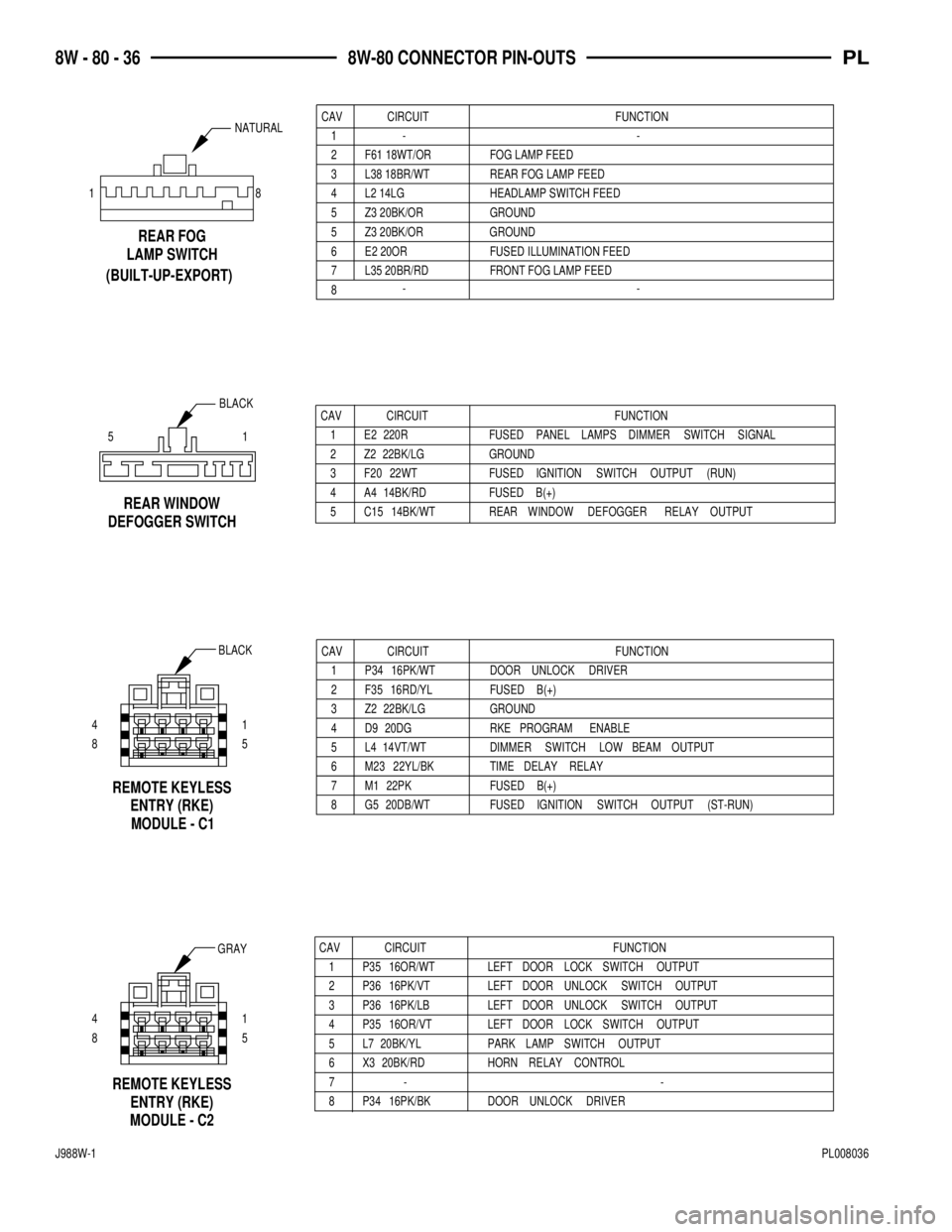

CAV CIRCUIT FUNCTION

1 E2 220R FUSED PANEL LAMPS DIMMER SWITCH SIGNAL

2 Z2 22BK/LG GROUND

3 F20 22WT FUSED IGNITION SWITCH OUTPUT (RUN)

4 A4 14BK/RD FUSED B(+)

5 C15 14BK/WT REAR WINDOW DEFOGGER RELAY OUTPUT

BLACK

51

41

85

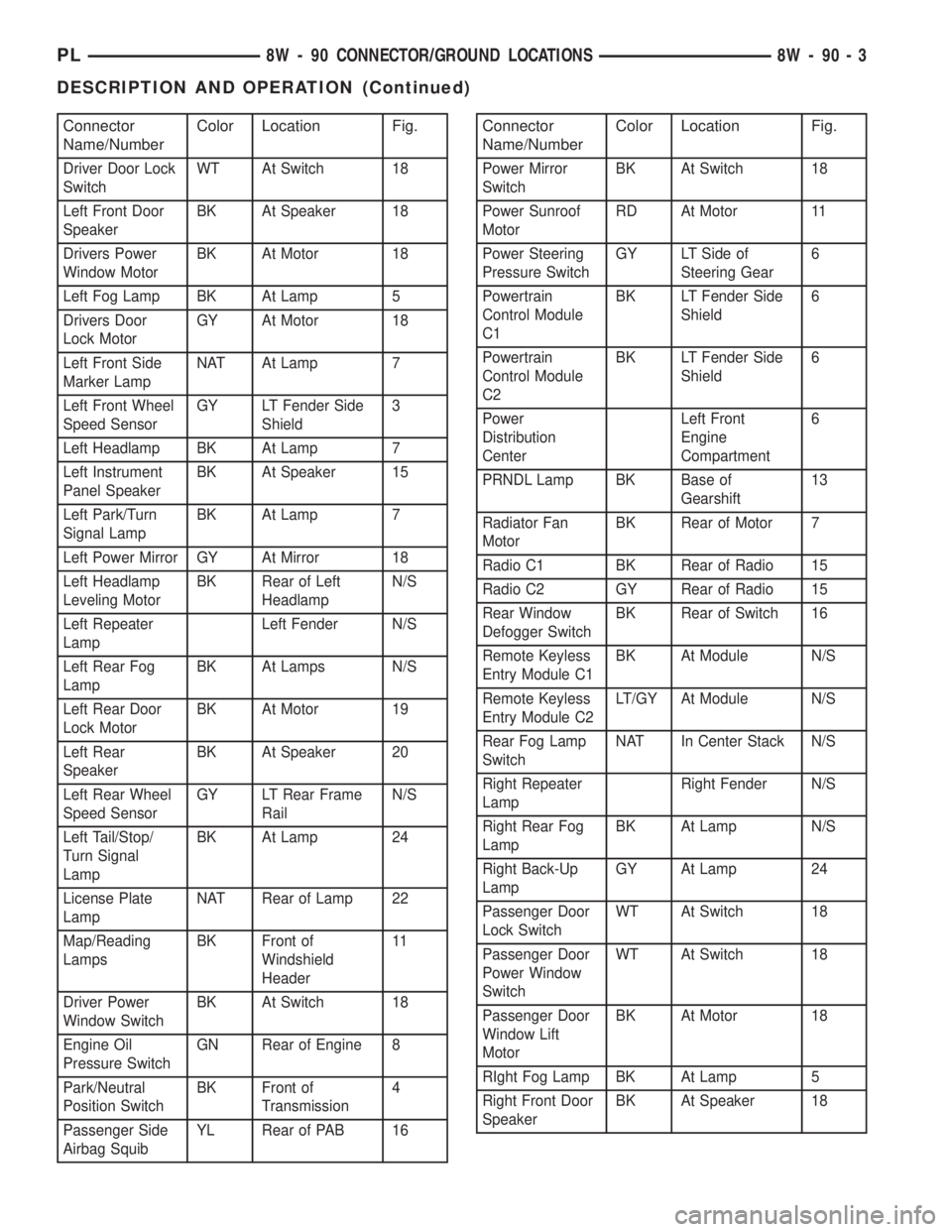

CAV CIRCUIT FUNCTION

1 P34 16PK/WT DOOR UNLOCK DRIVER

2 F35 16RD/YL FUSED B(+)

3 Z2 22BK/LG GROUND

4 D9 20DG RKE PROGRAM ENABLE

5 L4 14VT/WT DIMMER SWITCH LOW BEAM OUTPUT

6 M23 22YL/BK TIME DELAY RELAY

7 M1 22PK FUSED B(+)

8 G5 20DB/WT FUSED IGNITION SWITCH OUTPUT (ST-RUN)

BLACK

41

85

CAV CIRCUIT FUNCTION

1 P35 16OR/WT LEFT DOOR LOCK SWITCH OUTPUT

2 P36 16PK/VT LEFT DOOR UNLOCK SWITCH OUTPUT

3 P36 16PK/LB LEFT DOOR UNLOCK SWITCH OUTPUT

4 P35 16OR/VT LEFT DOOR LOCK SWITCH OUTPUT

5 L7 20BK/YL PARK LAMP SWITCH OUTPUT

6 X3 20BK/RD HORN RELAY CONTROL

7- -

8 P34 16PK/BK DOOR UNLOCK DRIVER

GRAY

8FRONT FOG LAMP FEED L35 20BR/RD 7

FUSED ILLUMINATION FEED E2 20OR 6

GROUND Z3 20BK/OR 5

HEADLAMP SWITCH FEED L2 14LG 4

REAR FOG LAMP FEED L38 18BR/WT 3

FOG LAMP FEED F61 18WT/OR 2

- - 1

FUNCTION CIRCUIT CAV

- - Z3 20BK/OR GROUND

5

8 1

NATURAL

REAR FOG

LAMP SWITCH

REAR WINDOW

DEFOGGER SWITCH

REMOTE KEYLESS

ENTRY (RKE)

MODULE - C1

REMOTE KEYLESS

ENTRY (RKE)

MODULE - C2 (BUILT-UP-EXPORT)

8W - 80 - 36 8W-80 CONNECTOR PIN-OUTSPL

J988W-1PL008036

Page 656 of 1200

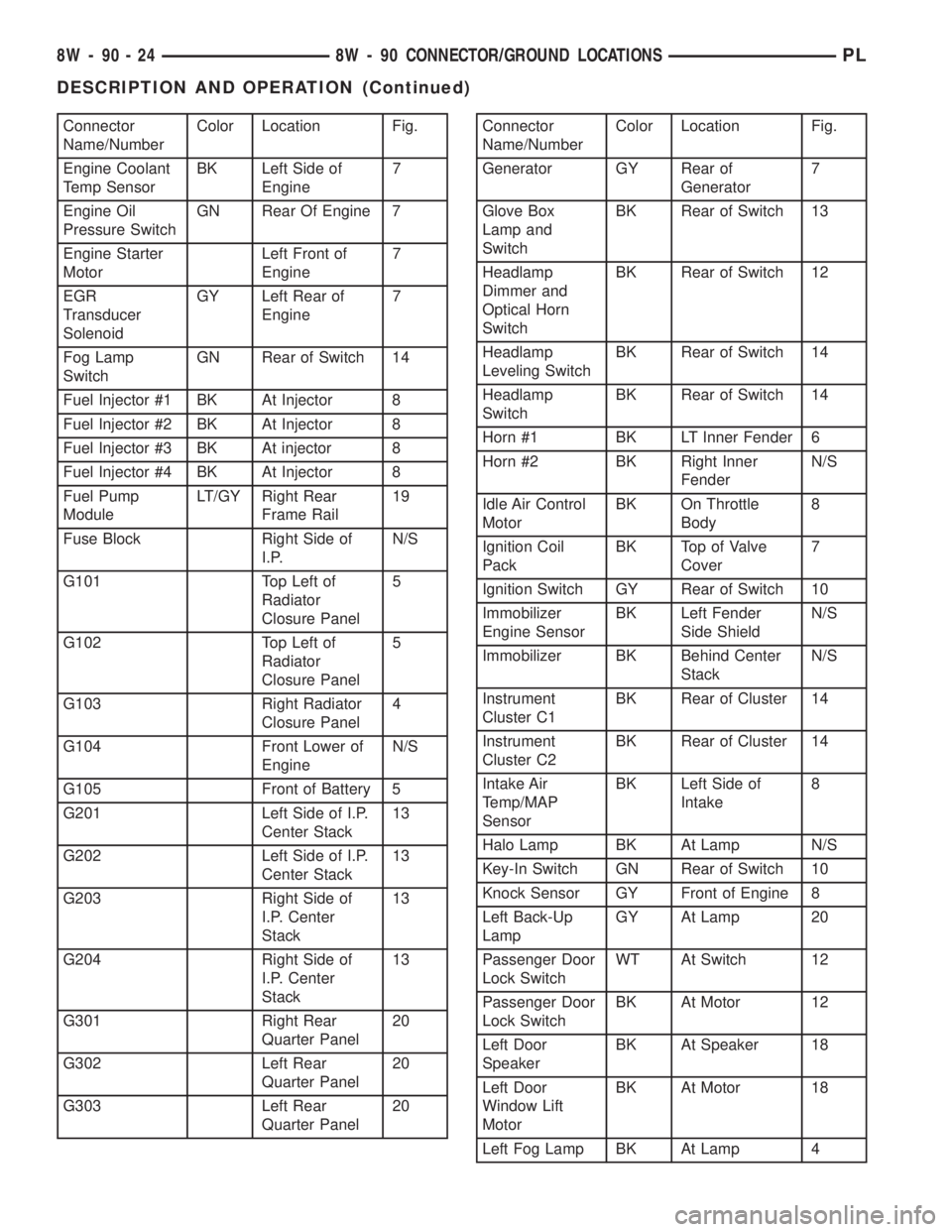

Connector

Name/NumberColor Location Fig.

Driver Door Lock

SwitchWT At Switch 18

Left Front Door

SpeakerBK At Speaker 18

Drivers Power

Window MotorBK At Motor 18

Left Fog Lamp BK At Lamp 5

Drivers Door

Lock MotorGY At Motor 18

Left Front Side

Marker LampNAT At Lamp 7

Left Front Wheel

Speed SensorGY LT Fender Side

Shield3

Left Headlamp BK At Lamp 7

Left Instrument

Panel SpeakerBK At Speaker 15

Left Park/Turn

Signal LampBK At Lamp 7

Left Power Mirror GY At Mirror 18

Left Headlamp

Leveling MotorBK Rear of Left

HeadlampN/S

Left Repeater

LampLeft Fender N/S

Left Rear Fog

LampBK At Lamps N/S

Left Rear Door

Lock MotorBK At Motor 19

Left Rear

SpeakerBK At Speaker 20

Left Rear Wheel

Speed SensorGY LT Rear Frame

RailN/S

Left Tail/Stop/

Turn Signal

LampBK At Lamp 24

License Plate

LampNAT Rear of Lamp 22

Map/Reading

LampsBK Front of

Windshield

Header11

Driver Power

Window SwitchBK At Switch 18

Engine Oil

Pressure SwitchGN Rear of Engine 8

Park/Neutral

Position SwitchBK Front of

Transmission4

Passenger Side

Airbag SquibYL Rear of PAB 16

Connector

Name/NumberColor Location Fig.

Power Mirror

SwitchBK At Switch 18

Power Sunroof

MotorRD At Motor 11

Power Steering

Pressure SwitchGY LT Side of

Steering Gear6

Powertrain

Control Module

C1BK LT Fender Side

Shield6

Powertrain

Control Module

C2BK LT Fender Side

Shield6

Power

Distribution

CenterLeft Front

Engine

Compartment6

PRNDL Lamp BK Base of

Gearshift13

Radiator Fan

MotorBK Rear of Motor 7

Radio C1 BK Rear of Radio 15

Radio C2 GY Rear of Radio 15

Rear Window

Defogger SwitchBK Rear of Switch 16

Remote Keyless

Entry Module C1BK At Module N/S

Remote Keyless

Entry Module C2LT/GY At Module N/S

Rear Fog Lamp

SwitchNAT In Center Stack N/S

Right Repeater

LampRight Fender N/S

Right Rear Fog

LampBK At Lamp N/S

Right Back-Up

LampGY At Lamp 24

Passenger Door

Lock SwitchWT At Switch 18

Passenger Door

Power Window

SwitchWT At Switch 18

Passenger Door

Window Lift

MotorBK At Motor 18

RIght Fog Lamp BK At Lamp 5

Right Front Door

SpeakerBK At Speaker 18

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 3

DESCRIPTION AND OPERATION (Continued)

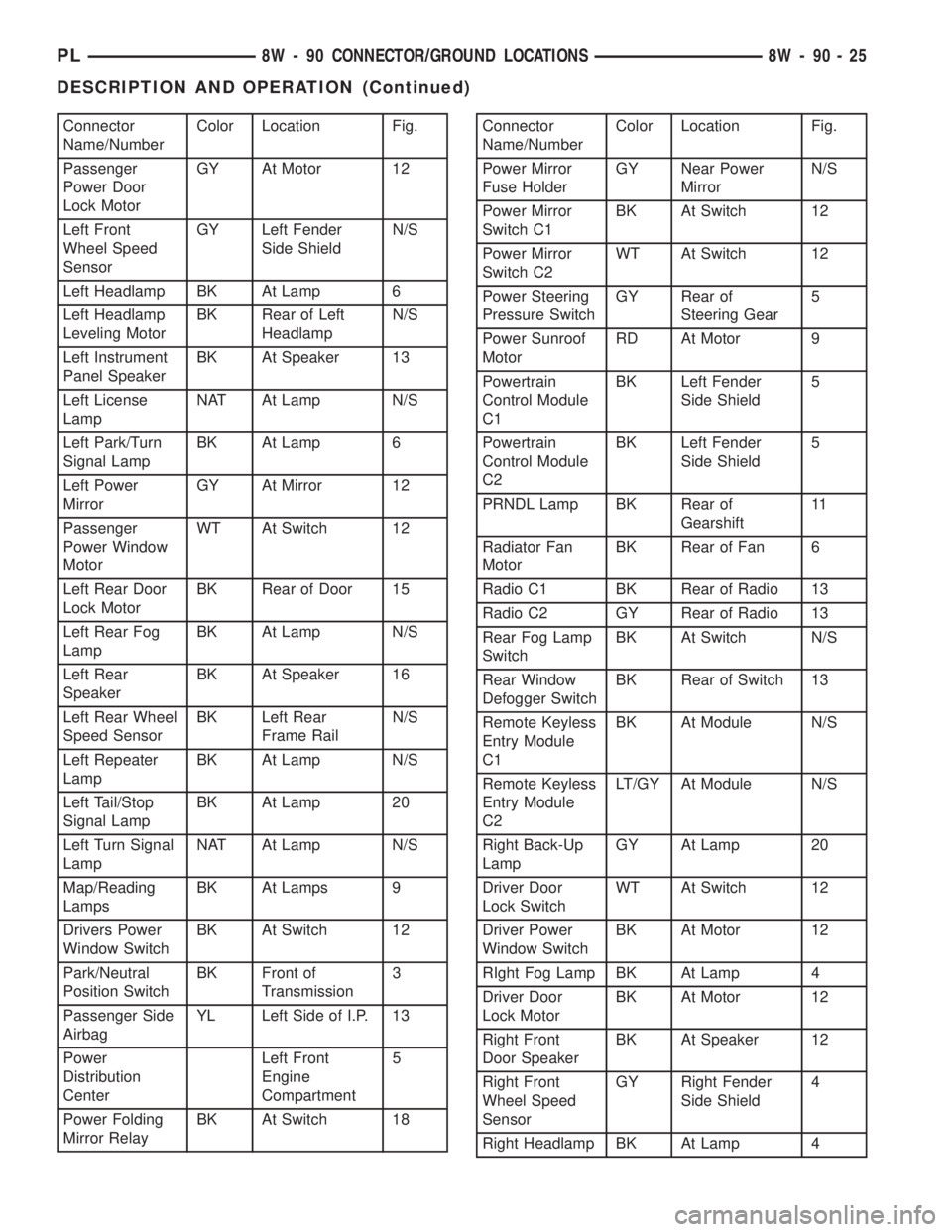

Page 677 of 1200

Connector

Name/NumberColor Location Fig.

Engine Coolant

Temp SensorBK Left Side of

Engine7

Engine Oil

Pressure SwitchGN Rear Of Engine 7

Engine Starter

MotorLeft Front of

Engine7

EGR

Transducer

SolenoidGY Left Rear of

Engine7

Fog Lamp

SwitchGN Rear of Switch 14

Fuel Injector #1 BK At Injector 8

Fuel Injector #2 BK At Injector 8

Fuel Injector #3 BK At injector 8

Fuel Injector #4 BK At Injector 8

Fuel Pump

ModuleLT/GY Right Rear

Frame Rail19

Fuse Block Right Side of

I.P.N/S

G101 Top Left of

Radiator

Closure Panel5

G102 Top Left of

Radiator

Closure Panel5

G103 Right Radiator

Closure Panel4

G104 Front Lower of

EngineN/S

G105 Front of Battery 5

G201 Left Side of I.P.

Center Stack13

G202 Left Side of I.P.

Center Stack13

G203 Right Side of

I.P. Center

Stack13

G204 Right Side of

I.P. Center

Stack13

G301 Right Rear

Quarter Panel20

G302 Left Rear

Quarter Panel20

G303 Left Rear

Quarter Panel20Connector

Name/NumberColor Location Fig.

Generator GY Rear of

Generator7

Glove Box

Lamp and

SwitchBK Rear of Switch 13

Headlamp

Dimmer and

Optical Horn

SwitchBK Rear of Switch 12

Headlamp

Leveling SwitchBK Rear of Switch 14

Headlamp

SwitchBK Rear of Switch 14

Horn #1 BK LT Inner Fender 6

Horn #2 BK Right Inner

FenderN/S

Idle Air Control

MotorBK On Throttle

Body8

Ignition Coil

PackBK Top of Valve

Cover7

Ignition Switch GY Rear of Switch 10

Immobilizer

Engine SensorBK Left Fender

Side ShieldN/S

Immobilizer BK Behind Center

StackN/S

Instrument

Cluster C1BK Rear of Cluster 14

Instrument

Cluster C2BK Rear of Cluster 14

Intake Air

Temp/MAP

SensorBK Left Side of

Intake8

Halo Lamp BK At Lamp N/S

Key-In Switch GN Rear of Switch 10

Knock Sensor GY Front of Engine 8

Left Back-Up

LampGY At Lamp 20

Passenger Door

Lock SwitchWT At Switch 12

Passenger Door

Lock SwitchBK At Motor 12

Left Door

SpeakerBK At Speaker 18

Left Door

Window Lift

MotorBK At Motor 18

Left Fog Lamp BK At Lamp 4

8W - 90 - 24 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 678 of 1200

Connector

Name/NumberColor Location Fig.

Passenger

Power Door

Lock MotorGY At Motor 12

Left Front

Wheel Speed

SensorGY Left Fender

Side ShieldN/S

Left Headlamp BK At Lamp 6

Left Headlamp

Leveling MotorBK Rear of Left

HeadlampN/S

Left Instrument

Panel SpeakerBK At Speaker 13

Left License

LampNAT At Lamp N/S

Left Park/Turn

Signal LampBK At Lamp 6

Left Power

MirrorGY At Mirror 12

Passenger

Power Window

MotorWT At Switch 12

Left Rear Door

Lock MotorBK Rear of Door 15

Left Rear Fog

LampBK At Lamp N/S

Left Rear

SpeakerBK At Speaker 16

Left Rear Wheel

Speed SensorBK Left Rear

Frame RailN/S

Left Repeater

LampBK At Lamp N/S

Left Tail/Stop

Signal LampBK At Lamp 20

Left Turn Signal

LampNAT At Lamp N/S

Map/Reading

LampsBK At Lamps 9

Drivers Power

Window SwitchBK At Switch 12

Park/Neutral

Position SwitchBK Front of

Transmission3

Passenger Side

AirbagYL Left Side of I.P. 13

Power

Distribution

CenterLeft Front

Engine

Compartment5

Power Folding

Mirror RelayBK At Switch 18Connector

Name/NumberColor Location Fig.

Power Mirror

Fuse HolderGY Near Power

MirrorN/S

Power Mirror

Switch C1BK At Switch 12

Power Mirror

Switch C2WT At Switch 12

Power Steering

Pressure SwitchGY Rear of

Steering Gear5

Power Sunroof

MotorRD At Motor 9

Powertrain

Control Module

C1BK Left Fender

Side Shield5

Powertrain

Control Module

C2BK Left Fender

Side Shield5

PRNDL Lamp BK Rear of

Gearshift11

Radiator Fan

MotorBK Rear of Fan 6

Radio C1 BK Rear of Radio 13

Radio C2 GY Rear of Radio 13

Rear Fog Lamp

SwitchBK At Switch N/S

Rear Window

Defogger SwitchBK Rear of Switch 13

Remote Keyless

Entry Module

C1BK At Module N/S

Remote Keyless

Entry Module

C2LT/GY At Module N/S

Right Back-Up

LampGY At Lamp 20

Driver Door

Lock SwitchWT At Switch 12

Driver Power

Window SwitchBK At Motor 12

RIght Fog Lamp BK At Lamp 4

Driver Door

Lock MotorBK At Motor 12

Right Front

Door SpeakerBK At Speaker 12

Right Front

Wheel Speed

SensorGY Right Fender

Side Shield4

Right Headlamp BK At Lamp 4

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 25

DESCRIPTION AND OPERATION (Continued)

Page 839 of 1200

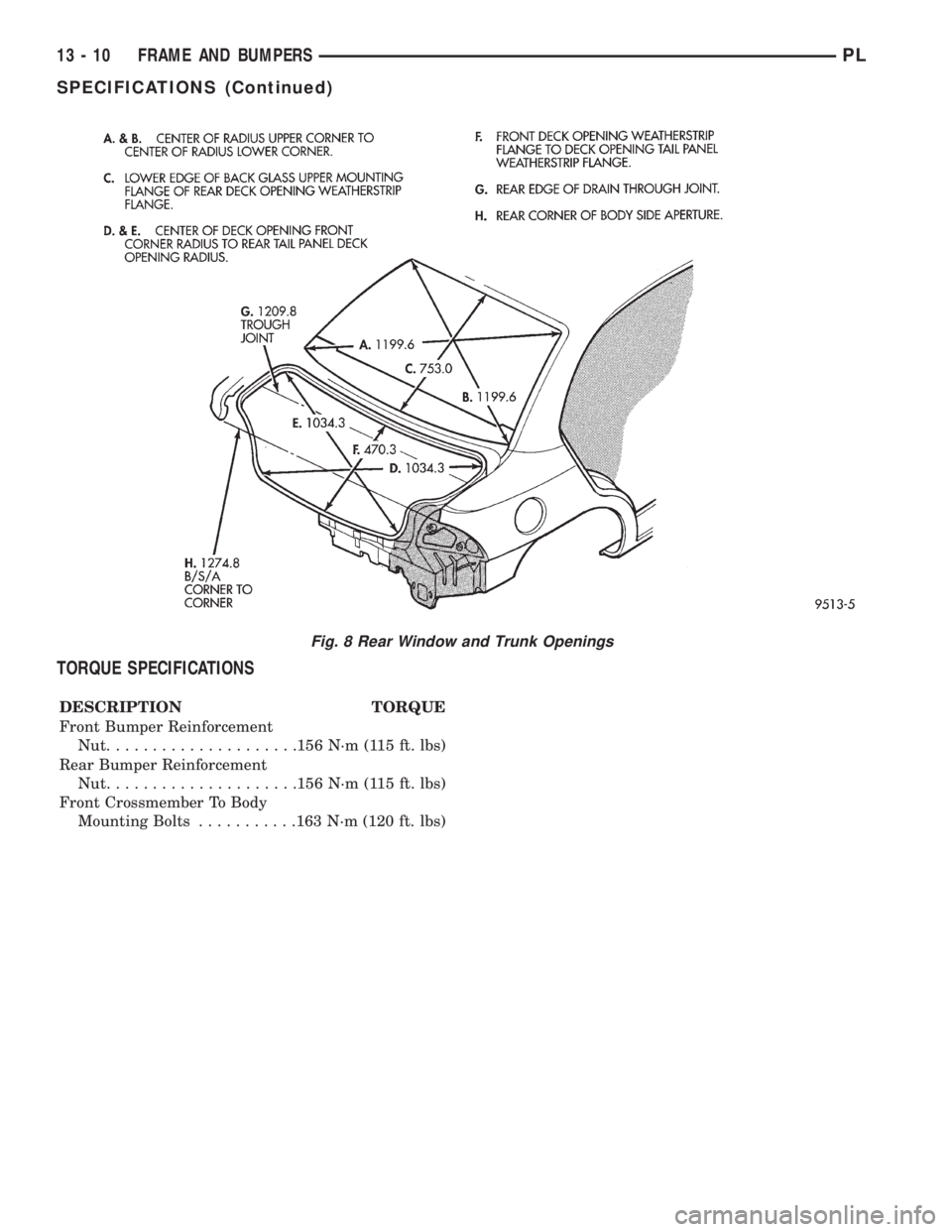

TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Front Bumper Reinforcement

Nut.....................156 N´m (115 ft. lbs)

Rear Bumper Reinforcement

Nut.....................156 N´m (115 ft. lbs)

Front Crossmember To Body

Mounting Bolts...........163 N´m (120 ft. lbs)

Fig. 8 Rear Window and Trunk Openings

13 - 10 FRAME AND BUMPERSPL

SPECIFICATIONS (Continued)

Page 852 of 1200

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

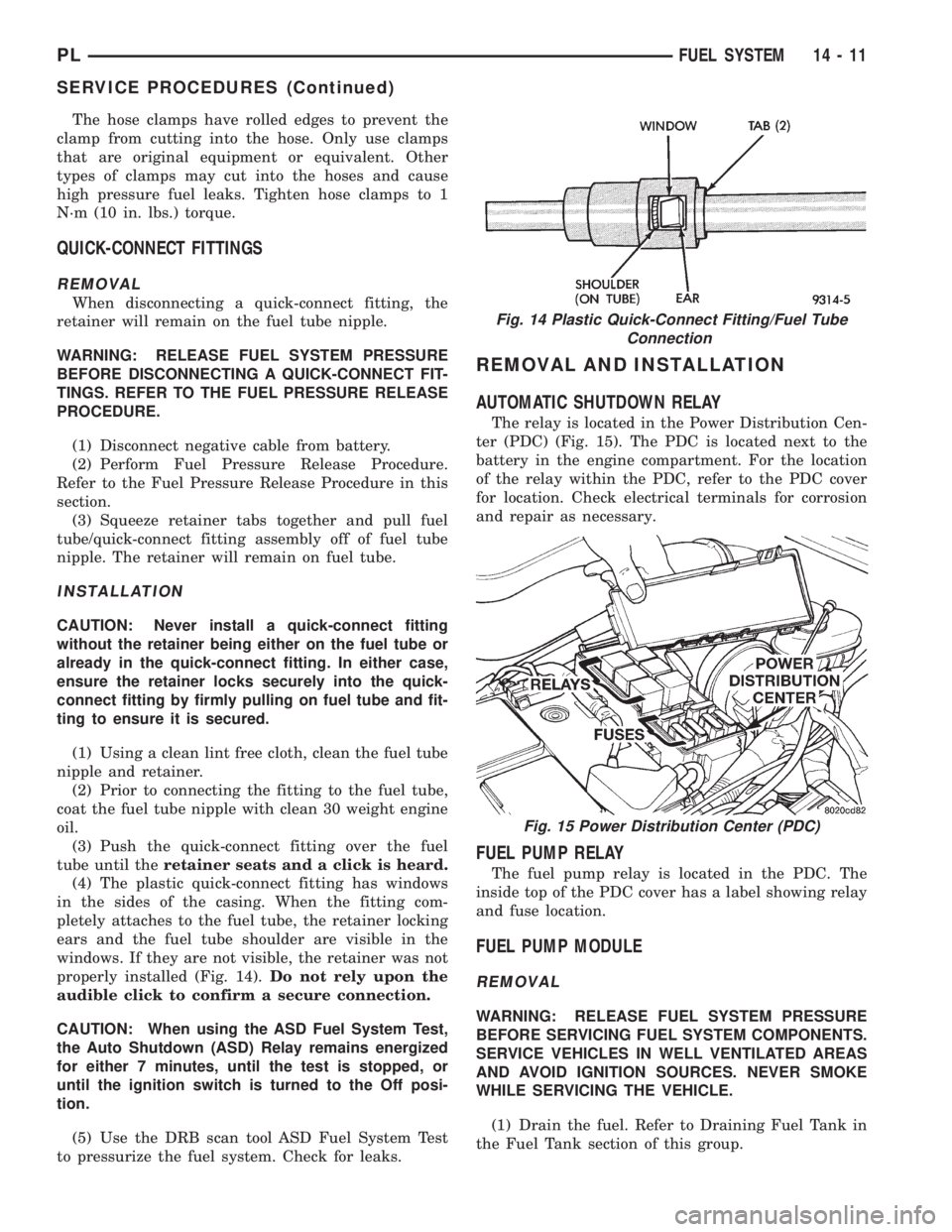

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 14).Do not rely upon the

audible click to confirm a secure connection.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.

(5) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

REMOVAL AND INSTALLATION

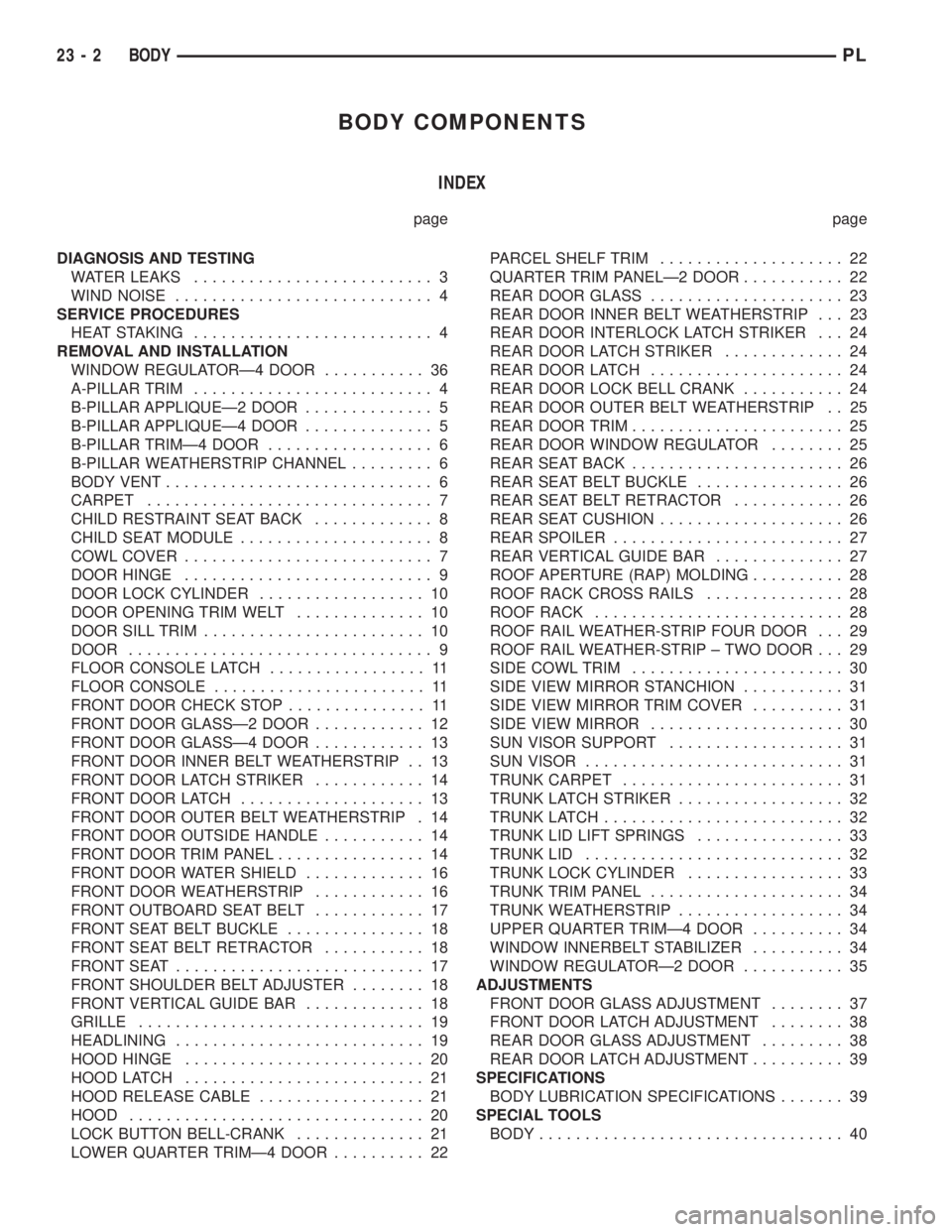

AUTOMATIC SHUTDOWN RELAY

The relay is located in the Power Distribution Cen-

ter (PDC) (Fig. 15). The PDC is located next to the

battery in the engine compartment. For the location

of the relay within the PDC, refer to the PDC cover

for location. Check electrical terminals for corrosion

and repair as necessary.

FUEL PUMP RELAY

The fuel pump relay is located in the PDC. The

inside top of the PDC cover has a label showing relay

and fuse location.

FUEL PUMP MODULE

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Drain the fuel. Refer to Draining Fuel Tank in

the Fuel Tank section of this group.

Fig. 14 Plastic Quick-Connect Fitting/Fuel Tube

Connection

Fig. 15 Power Distribution Center (PDC)

PLFUEL SYSTEM 14 - 11

SERVICE PROCEDURES (Continued)

Page 1083 of 1200

BODY COMPONENTS

INDEX

page page

DIAGNOSIS AND TESTING

WATER LEAKS.......................... 3

WIND NOISE............................ 4

SERVICE PROCEDURES

HEAT STAKING.......................... 4

REMOVAL AND INSTALLATION

WINDOW REGULATORÐ4 DOOR........... 36

A-PILLAR TRIM.......................... 4

B-PILLAR APPLIQUEÐ2 DOOR.............. 5

B-PILLAR APPLIQUEÐ4 DOOR.............. 5

B-PILLAR TRIMÐ4 DOOR.................. 6

B-PILLAR WEATHERSTRIP CHANNEL......... 6

BODY VENT............................. 6

CARPET............................... 7

CHILD RESTRAINT SEAT BACK............. 8

CHILD SEAT MODULE..................... 8

COWL COVER........................... 7

DOOR HINGE........................... 9

DOOR LOCK CYLINDER.................. 10

DOOR OPENING TRIM WELT.............. 10

DOOR SILL TRIM........................ 10

DOOR................................. 9

FLOOR CONSOLE LATCH................. 11

FLOOR CONSOLE....................... 11

FRONT DOOR CHECK STOP............... 11

FRONT DOOR GLASSÐ2 DOOR............ 12

FRONT DOOR GLASSÐ4 DOOR............ 13

FRONT DOOR INNER BELT WEATHERSTRIP . . 13

FRONT DOOR LATCH STRIKER............ 14

FRONT DOOR LATCH.................... 13

FRONT DOOR OUTER BELT WEATHERSTRIP . 14

FRONT DOOR OUTSIDE HANDLE........... 14

FRONT DOOR TRIM PANEL................ 14

FRONT DOOR WATER SHIELD............. 16

FRONT DOOR WEATHERSTRIP............ 16

FRONT OUTBOARD SEAT BELT............ 17

FRONT SEAT BELT BUCKLE............... 18

FRONT SEAT BELT RETRACTOR........... 18

FRONT SEAT........................... 17

FRONT SHOULDER BELT ADJUSTER........ 18

FRONT VERTICAL GUIDE BAR............. 18

GRILLE............................... 19

HEADLINING........................... 19

HOOD HINGE.......................... 20

HOOD LATCH.......................... 21

HOOD RELEASE CABLE.................. 21

HOOD................................ 20

LOCK BUTTON BELL-CRANK.............. 21

LOWER QUARTER TRIMÐ4 DOOR.......... 22PARCEL SHELF TRIM.................... 22

QUARTER TRIM PANELÐ2 DOOR........... 22

REAR DOOR GLASS..................... 23

REAR DOOR INNER BELT WEATHERSTRIP . . . 23

REAR DOOR INTERLOCK LATCH STRIKER . . . 24

REAR DOOR LATCH STRIKER............. 24

REAR DOOR LATCH..................... 24

REAR DOOR LOCK BELL CRANK........... 24

REAR DOOR OUTER BELT WEATHERSTRIP . . 25

REAR DOOR TRIM....................... 25

REAR DOOR WINDOW REGULATOR........ 25

REAR SEAT BACK....................... 26

REAR SEAT BELT BUCKLE................ 26

REAR SEAT BELT RETRACTOR............ 26

REAR SEAT CUSHION.................... 26

REAR SPOILER......................... 27

REAR VERTICAL GUIDE BAR.............. 27

ROOF APERTURE (RAP) MOLDING.......... 28

ROOF RACK CROSS RAILS............... 28

ROOF RACK........................... 28

ROOF RAIL WEATHER-STRIP FOUR DOOR . . . 29

ROOF RAIL WEATHER-STRIP ± TWO DOOR . . . 29

SIDE COWL TRIM....................... 30

SIDE VIEW MIRROR STANCHION........... 31

SIDE VIEW MIRROR TRIM COVER.......... 31

SIDE VIEW MIRROR..................... 30

SUN VISOR SUPPORT................... 31

SUN VISOR............................ 31

TRUNK CARPET........................ 31

TRUNK LATCH STRIKER.................. 32

TRUNK LATCH.......................... 32

TRUNK LID LIFT SPRINGS................ 33

TRUNK LID............................ 32

TRUNK LOCK CYLINDER................. 33

TRUNK TRIM PANEL..................... 34

TRUNK WEATHERSTRIP.................. 34

UPPER QUARTER TRIMÐ4 DOOR.......... 34

WINDOW INNERBELT STABILIZER.......... 34

WINDOW REGULATORÐ2 DOOR........... 35

ADJUSTMENTS

FRONT DOOR GLASS ADJUSTMENT........ 37

FRONT DOOR LATCH ADJUSTMENT........ 38

REAR DOOR GLASS ADJUSTMENT......... 38

REAR DOOR LATCH ADJUSTMENT.......... 39

SPECIFICATIONS

BODY LUBRICATION SPECIFICATIONS....... 39

SPECIAL TOOLS

BODY................................. 40

23 - 2 BODYPL

Page 1084 of 1200

DIAGNOSIS AND TESTING

WATER LEAKS

Water leaks can be caused by poor sealing,

improper body component alignment, body seam

porosity, missing plugs, or blocked drain holes. Cen-

trifugal and gravitational force can cause water to

drip from a location away from the actual leak point,

making leak detection difficult. All body sealing

points should be water tight in normal wet-driving

conditions. Water flowing downward from the front of

the vehicle should not enter the passenger or luggage

compartment. Moving sealing surfaces will not

always seal water tight under all conditions. At

times, side glass or door seals will allow water to

enter the passenger compartment during high pres-

sure washing or hard driving rain (severe) condi-

tions. Overcompensating on door or glass

adjustments to stop a water leak that occurs under

severe conditions can cause premature seal wear and

excessive closing or latching effort. After completing

a repair, water-test vehicle to verify leak has stopped

before returning vehicle to use.

VISUAL INSPECTION BEFORE WATER LEAK

TESTS

Verify that floor and body plugs are in place, body

drains are clear, and body components are properly

aligned and sealed. If component alignment or seal-

ing is necessary, refer to the appropriate section of

this group for proper procedures.

WATER LEAK TESTS

WARNING: DO NOT USE ELECTRIC SHOP LIGHTS

OR TOOLS IN WATER TEST AREA. PERSONAL

INJURY CAN RESULT.

When the conditions causing a water leak have

been determined, simulate the conditions as closely

as possible.

²If a leak occurs with the vehicle parked in a

steady light rain, flood the leak area with an open-

ended garden hose.

²If a leak occurs while driving at highway speeds

in a steady rain, test the leak area with a reasonable

velocity stream or fan spray of water. Direct the

spray in a direction comparable to actual conditions.

²If a leak occurs when the vehicle is parked on an

incline, hoist the end or side of the vehicle to simu-

late this condition. This method can be used when

the leak occurs when the vehicle accelerates, stops or

turns. If the leak occurs on acceleration, hoist the

front of the vehicle. If the leak occurs when braking,

hoist the back of the vehicle. If the leak occurs on left

turns, hoist the left side of the vehicle. If the leak

occurs on right turns, hoist the right side of the vehi-cle. For hoisting recommendations refer to Group 0,

Lubrication and Maintenance, General Information

section.

WATER LEAK DETECTION

To detect a water leak point-of-entry, do a water

test and watch for water tracks or droplets forming

on the inside of the vehicle. If necessary, remove inte-

rior trim covers or panels to gain visual access to the

leak area. If the hose cannot be positioned without

being held, have someone help do the water test.

Some water leaks must be tested for a considerable

length of time to become apparent. When a leak

appears, find the highest point of the water track or

drop. The highest point usually will show the point of

entry. After leak point has been found, repair the

leak and water test to verify that the leak has

stopped.

Locating the entry point of water that is leaking

into a cavity between panels can be difficult. The

trapped water may splash or run from the cavity,

often at a distance from the entry point. Most water

leaks of this type become apparent after accelerating,

stopping, turning, or when on an incline.

MIRROR INSPECTION METHOD

When a leak point area is visually obstructed, use

a suitable mirror to gain visual access. A mirror can

also be used to deflect light to a limited-access area

to assist in locating a leak point.

BRIGHT LIGHT LEAK TEST METHOD

Some water leaks in the luggage compartment can

be detected without water testing. Position the vehi-

cle in a brightly lit area. From inside the darkened

luggage compartment inspect around seals and body

seams. If necessary, have a helper direct a drop light

over the suspected leak areas around the luggage

compartment. If light is visible through a normally

sealed location, water could enter through the open-

ing.

PRESSURIZED LEAK TEST METHOD

When a water leak into the passenger compart-

ment cannot be detected by water testing, pressurize

the passenger compartment and soap test exterior of

the vehicle. To pressurize the passenger compart-

ment, close all doors and windows, start engine, and

set heater control to high blower in HEAT position. If

engine can not be started, connect a charger to the

battery to ensure adequate voltage to the blower.

With interior pressurized, apply dish detergent solu-

tion to suspected leak area on the exterior of the

vehicle. Apply detergent solution with spray device or

soft bristle brush. If soap bubbles occur at a body

seam, joint, seal or gasket, the leak entry point could

be at that location.

PLBODY 23 - 3

Page 1093 of 1200

INSTALLATION

(1) Position door check on vehicle and install bolts

attaching stop to door end frame.

(2) Install door speaker, if so equipped.

(3) Install bolt holding door check stop to hinge

pillar.

(4) Install door trim panel and water shield.

FRONT DOOR GLASSÐ2 DOOR

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove inner and outer door belt weather-

strips.

(3) Loosen inner belt stabilizer.

(4) Lower door glass to bottom of travel to access

glass attachment bolts.

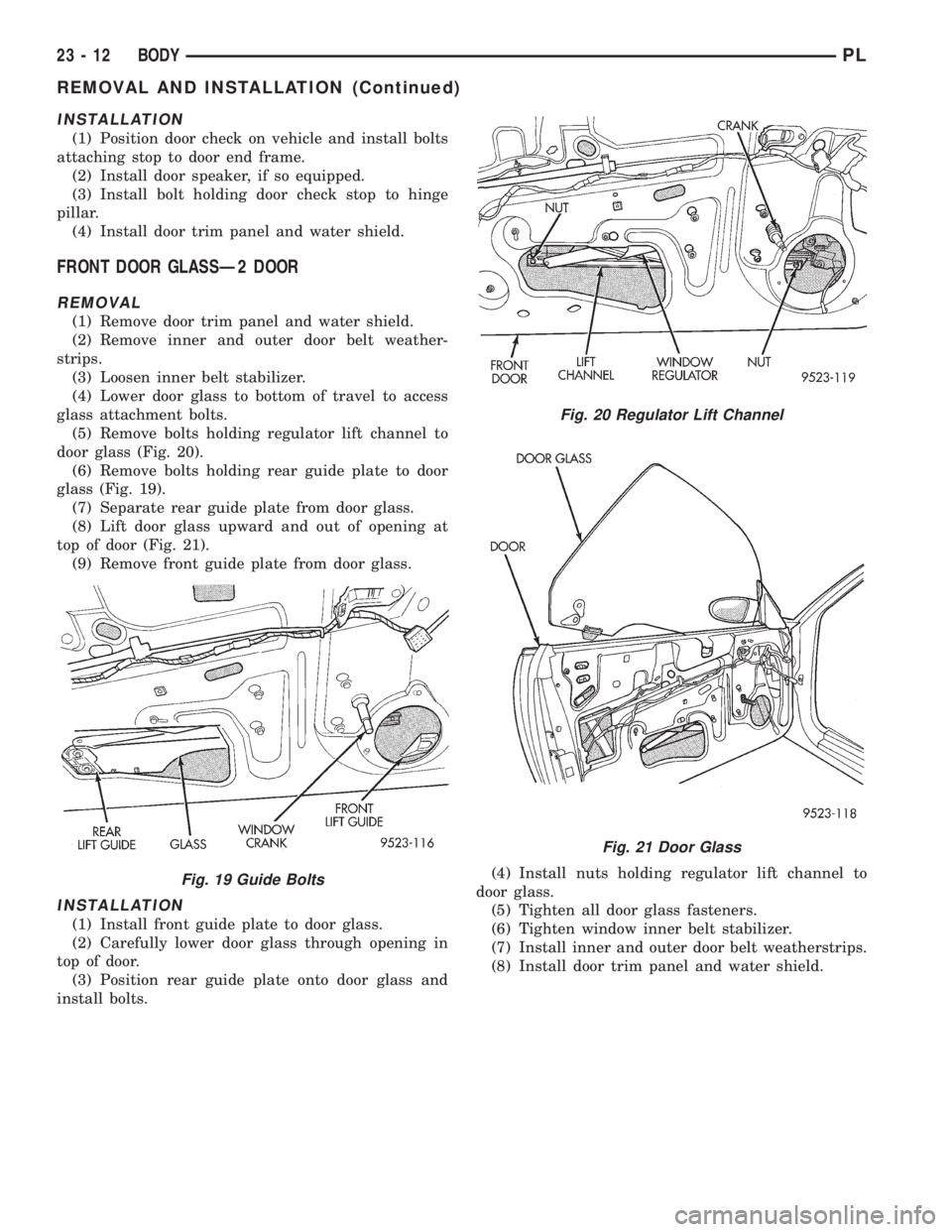

(5) Remove bolts holding regulator lift channel to

door glass (Fig. 20).

(6) Remove bolts holding rear guide plate to door

glass (Fig. 19).

(7) Separate rear guide plate from door glass.

(8) Lift door glass upward and out of opening at

top of door (Fig. 21).

(9) Remove front guide plate from door glass.

INSTALLATION

(1) Install front guide plate to door glass.

(2) Carefully lower door glass through opening in

top of door.

(3) Position rear guide plate onto door glass and

install bolts.(4) Install nuts holding regulator lift channel to

door glass.

(5) Tighten all door glass fasteners.

(6) Tighten window inner belt stabilizer.

(7) Install inner and outer door belt weatherstrips.

(8) Install door trim panel and water shield.

Fig. 19 Guide Bolts

Fig. 20 Regulator Lift Channel

Fig. 21 Door Glass

23 - 12 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1094 of 1200

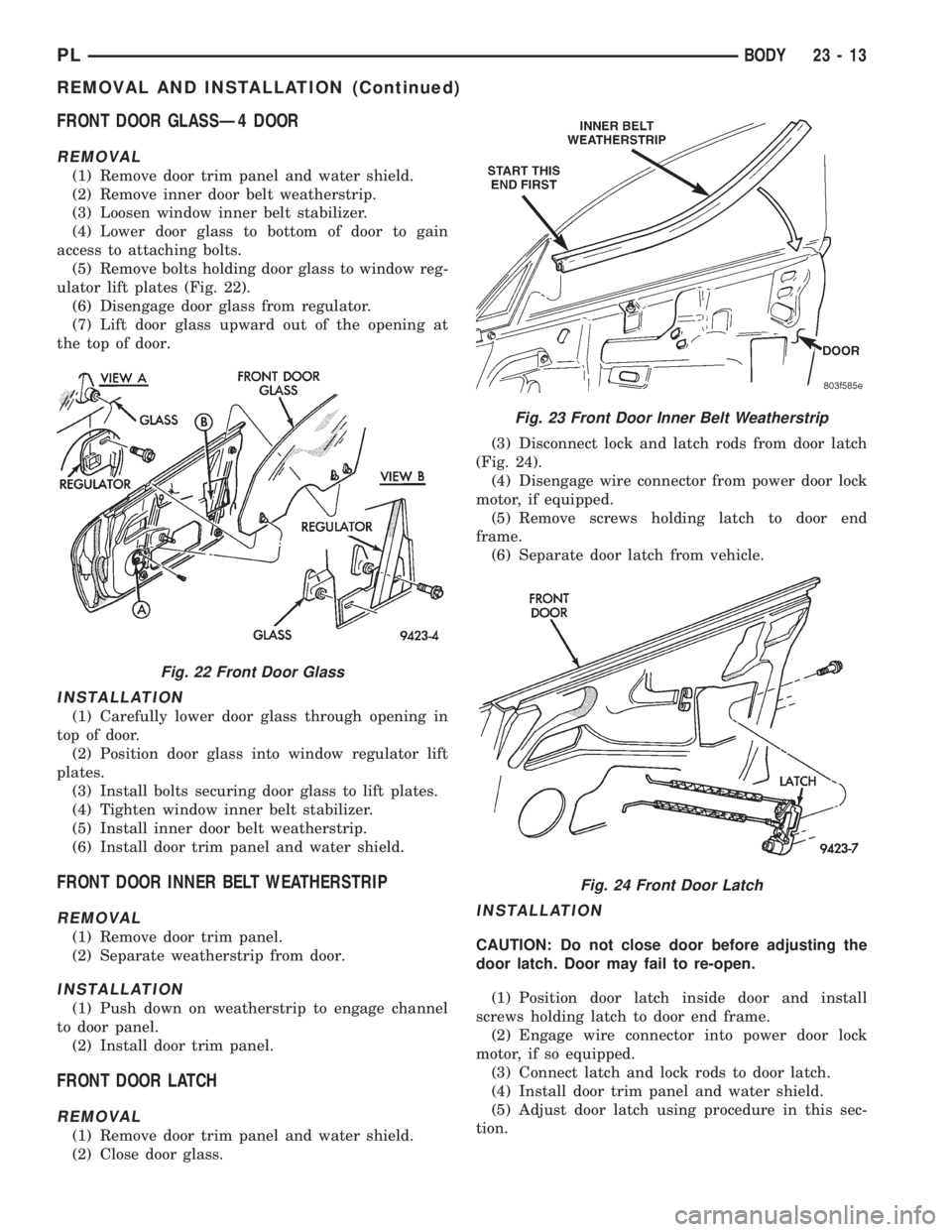

FRONT DOOR GLASSÐ4 DOOR

REMOVAL

(1) Remove door trim panel and water shield.

(2) Remove inner door belt weatherstrip.

(3) Loosen window inner belt stabilizer.

(4) Lower door glass to bottom of door to gain

access to attaching bolts.

(5) Remove bolts holding door glass to window reg-

ulator lift plates (Fig. 22).

(6) Disengage door glass from regulator.

(7) Lift door glass upward out of the opening at

the top of door.

INSTALLATION

(1) Carefully lower door glass through opening in

top of door.

(2) Position door glass into window regulator lift

plates.

(3) Install bolts securing door glass to lift plates.

(4) Tighten window inner belt stabilizer.

(5) Install inner door belt weatherstrip.

(6) Install door trim panel and water shield.

FRONT DOOR INNER BELT WEATHERSTRIP

REMOVAL

(1) Remove door trim panel.

(2) Separate weatherstrip from door.

INSTALLATION

(1) Push down on weatherstrip to engage channel

to door panel.

(2) Install door trim panel.

FRONT DOOR LATCH

REMOVAL

(1) Remove door trim panel and water shield.

(2) Close door glass.(3) Disconnect lock and latch rods from door latch

(Fig. 24).

(4) Disengage wire connector from power door lock

motor, if equipped.

(5) Remove screws holding latch to door end

frame.

(6) Separate door latch from vehicle.

INSTALLATION

CAUTION: Do not close door before adjusting the

door latch. Door may fail to re-open.

(1) Position door latch inside door and install

screws holding latch to door end frame.

(2) Engage wire connector into power door lock

motor, if so equipped.

(3) Connect latch and lock rods to door latch.

(4) Install door trim panel and water shield.

(5) Adjust door latch using procedure in this sec-

tion.

Fig. 22 Front Door Glass

Fig. 23 Front Door Inner Belt Weatherstrip

Fig. 24 Front Door Latch

PLBODY 23 - 13

REMOVAL AND INSTALLATION (Continued)