cooling DODGE NEON 1999 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 984 of 1200

NOTE: Transaxle operation requirements are differ-

ent for each vehicle and engine combination. Some

internal parts will be different to provide for this.

Therefore, when replacing parts, refer to the seven

digit part number stamped on rear of the transaxle

oil pan flange.

Within this transaxle, there are three primary

areas:

(1) Main center line plus valve body.

(2) Transfer shaft center line (includes governor

and parking sprag).

(3) Differential center line.

Center distances between the main rotating parts

in these three areas are held precise to maintain a

low noise level.

The torque converter, transaxle area, and differen-

tial are housed in an integral aluminum die casting.

The differential oil sump is common with the

transaxle sump. Separate filling of the differen-

tial is NOT necessary.

The torque converter is attached to the crankshaft

through a flexible driving plate. Cooling of the con-

verter is accomplished by circulating the transaxle

fluid through a remote cooler. There are two types of

coolers used. An oil-to-water type cooler located in

the radiator side tank and/or an oil-to-air heat

exchanger. The torque converter assembly is a sealed

unit that cannot be disassembled.

The transaxle fluid is filtered by an internal filter

attached to the lower side of the valve body assembly.

Engine torque is transmitted to the torque con-

verter and then through the input shaft to multiple-

disc clutches in the transaxle. The power flow

depends on the application of the clutches and bands.

Refer to Elements in Use Chart in Diagnosis and

Tests section.

The transaxle consists of:

²Two multiple-disc clutches

²An overrunning clutch

²Two servos

²A hydraulic accumulator

²Two bands

²Two planetary gear sets

This provides three forward ratios and a reverse

ratio. The common sun gear of the planetary gear

sets is connected to the front clutch by a driving

shell. The driving shell is splined to the sun gear and

front clutch retainer. The hydraulic system consists

of an oil pump and a single valve body which con-

tains all of the valves except the governor valves.

The transaxle sump and differential sump are both

vented through the dipstick. Output torque from the

main center line is delivered through helical gears to

the transfer shaft. This gear set is a factor in the

transaxle final drive (axle) ratio. The shaft also car-

ries the governor and parking sprag. An integral heli-cal gear on the transfer shaft drives the differential

ring gear. The final drive gearing is completed with

one of two gear ratios; 2.98 or 3.19 depending on

model and application.

FLUID LEVEL AND CONDITION

NOTE: The transmission and differential sump have

a common oil sump with a communicating opening

between the two.

The torque converter fills in both the P (Park) and

N (Neutral) positions. Place the selector lever in P

(Park) to be sure that the fluid level check is accu-

rate.The engine should be running at idle

speed for at least one minute, with the vehicle

on level ground. This will ensure complete oil

level stabilization between differential and

transmission.The fluid should be at normal operat-

ing temperature (approximately 82É C. or 180É F.).

The fluid level is correct if it is in the HOT region

(cross-hatched area) on the dipstick.

Low fluid level can cause a variety of conditions,

because it allows the pump to take in air along with

the fluid. As in any hydraulic system, air bubbles

make the fluid spongy therefore, pressures will be

low and will build up slowly.

Improper filling also can raise the fluid level too

high. When the transaxle has too much fluid, the

gears churn up foam and cause the same conditions

that occur with a low fluid level.

In either case, the air bubbles can cause overheat-

ing, fluid oxidation, and varnishing. This can inter-

fere with normal valve, clutch, and servo operation.

Foaming also can result in fluid escaping from the

transaxle dipstick, where it may be mistaken for a

leak.

Along with fluid level, it is important to check the

condition of the fluid. When the fluid smells burned,

or is contaminated with metal or friction material

particles, a complete transaxle overhaul is needed.

Be sure to examine the fluid on the dipstick closely.

If there is any doubt about its condition, drain out a

sample for a double check.

SELECTION OF LUBRICANT

It is important that the proper lubricant be used in

these transmissions. Mopar ATF PLUS 3 (Automatic

Transmission Fluid- type 7176) should be used to aid

in ensuring optimum transmission performance. It is

important that the transmission fluid be maintained

at the prescribed level using the recommended fluids.

SPECIAL ADDITIVES

Chrysler Corporation does not recommend the

addition of any fluids to the transmission, other than

that fluid listed above. An exception to this policy is

PLTRANSAXLE 21 - 41

GENERAL INFORMATION (Continued)

Page 1056 of 1200

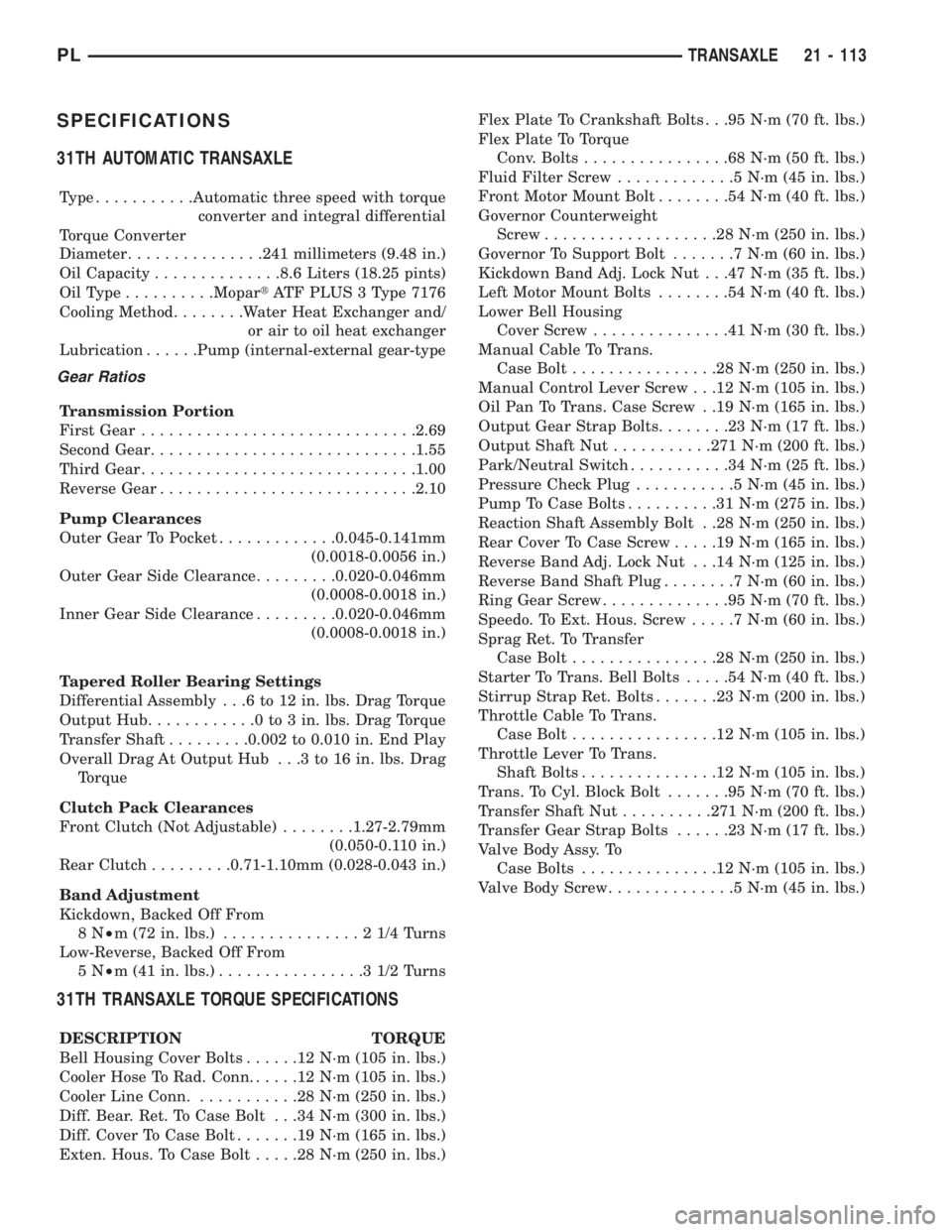

SPECIFICATIONS

31TH AUTOMATIC TRANSAXLE

Type...........Automatic three speed with torque

converter and integral differential

Torque Converter

Diameter...............241 millimeters (9.48 in.)

Oil Capacity..............8.6 Liters (18.25 pints)

OilType..........MopartATF PLUS 3 Type 7176

Cooling Method........Water Heat Exchanger and/

or air to oil heat exchanger

Lubrication......Pump (internal-external gear-type

Gear Ratios

Transmission Portion

First Gear..............................2.69

Second Gear.............................1.55

Third Gear..............................1.00

Reverse Gear............................2.10

Pump Clearances

Outer Gear To Pocket.............0.045-0.141mm

(0.0018-0.0056 in.)

Outer Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Inner Gear Side Clearance.........0.020-0.046mm

(0.0008-0.0018 in.)

Tapered Roller Bearing Settings

Differential Assembly . . .6 to 12 in. lbs. Drag Torque

Output Hub............0to3in.lbs. Drag Torque

Transfer Shaft.........0.002 to 0.010 in. End Play

Overall Drag At Output Hub . . .3 to 16 in. lbs. Drag

Torque

Clutch Pack Clearances

Front Clutch (Not Adjustable)........1.27-2.79mm

(0.050-0.110 in.)

Rear Clutch.........0.71-1.10mm (0.028-0.043 in.)

Band Adjustment

Kickdown, Backed Off From

8N²m (72 in. lbs.)...............21/4Turns

Low-Reverse, Backed Off From

5N²m (41 in. lbs.)................31/2Turns

31TH TRANSAXLE TORQUE SPECIFICATIONS

DESCRIPTION TORQUE

Bell Housing Cover Bolts......12N´m(105 in. lbs.)

Cooler Hose To Rad. Conn......12N´m(105 in. lbs.)

Cooler Line Conn............28N´m(250 in. lbs.)

Diff. Bear. Ret. To Case Bolt . . .34 N´m (300 in. lbs.)

Diff. Cover To Case Bolt.......19N´m(165 in. lbs.)

Exten. Hous. To Case Bolt.....28N´m(250 in. lbs.)Flex Plate To Crankshaft Bolts . . .95 N´m (70 ft. lbs.)

Flex Plate To Torque

Conv. Bolts................68N´m(50ft.lbs.)

Fluid Filter Screw.............5N´m(45in.lbs.)

Front Motor Mount Bolt........54N´m(40ft.lbs.)

Governor Counterweight

Screw...................28N´m(250 in. lbs.)

Governor To Support Bolt.......7N´m(60in.lbs.)

Kickdown Band Adj. Lock Nut . . .47 N´m (35 ft. lbs.)

Left Motor Mount Bolts........54N´m(40ft.lbs.)

Lower Bell Housing

Cover Screw...............41N´m(30ft.lbs.)

Manual Cable To Trans.

Case Bolt................28N´m(250 in. lbs.)

Manual Control Lever Screw . . .12 N´m (105 in. lbs.)

Oil Pan To Trans. Case Screw . .19 N´m (165 in. lbs.)

Output Gear Strap Bolts........23N´m(17ft.lbs.)

Output Shaft Nut...........271 N´m (200 ft. lbs.)

Park/Neutral Switch...........34N´m(25ft.lbs.)

Pressure Check Plug...........5N´m(45in.lbs.)

Pump To Case Bolts..........31N´m(275 in. lbs.)

Reaction Shaft Assembly Bolt . .28 N´m (250 in. lbs.)

Rear Cover To Case Screw.....19N´m(165 in. lbs.)

Reverse Band Adj. Lock Nut . . .14 N´m (125 in. lbs.)

Reverse Band Shaft Plug........7N´m(60in.lbs.)

Ring Gear Screw..............95N´m(70ft.lbs.)

Speedo. To Ext. Hous. Screw.....7N´m(60in.lbs.)

Sprag Ret. To Transfer

Case Bolt................28N´m(250 in. lbs.)

Starter To Trans. Bell Bolts.....54N´m(40ft.lbs.)

Stirrup Strap Ret. Bolts.......23N´m(200 in. lbs.)

Throttle Cable To Trans.

Case Bolt................12N´m(105 in. lbs.)

Throttle Lever To Trans.

Shaft Bolts...............12N´m(105 in. lbs.)

Trans. To Cyl. Block Bolt.......95N´m(70ft.lbs.)

Transfer Shaft Nut..........271 N´m (200 ft. lbs.)

Transfer Gear Strap Bolts......23N´m(17ft.lbs.)

Valve Body Assy. To

Case Bolts...............12N´m(105 in. lbs.)

Valve Body Screw..............5N´m(45in.lbs.)

PLTRANSAXLE 21 - 113

Page 1062 of 1200

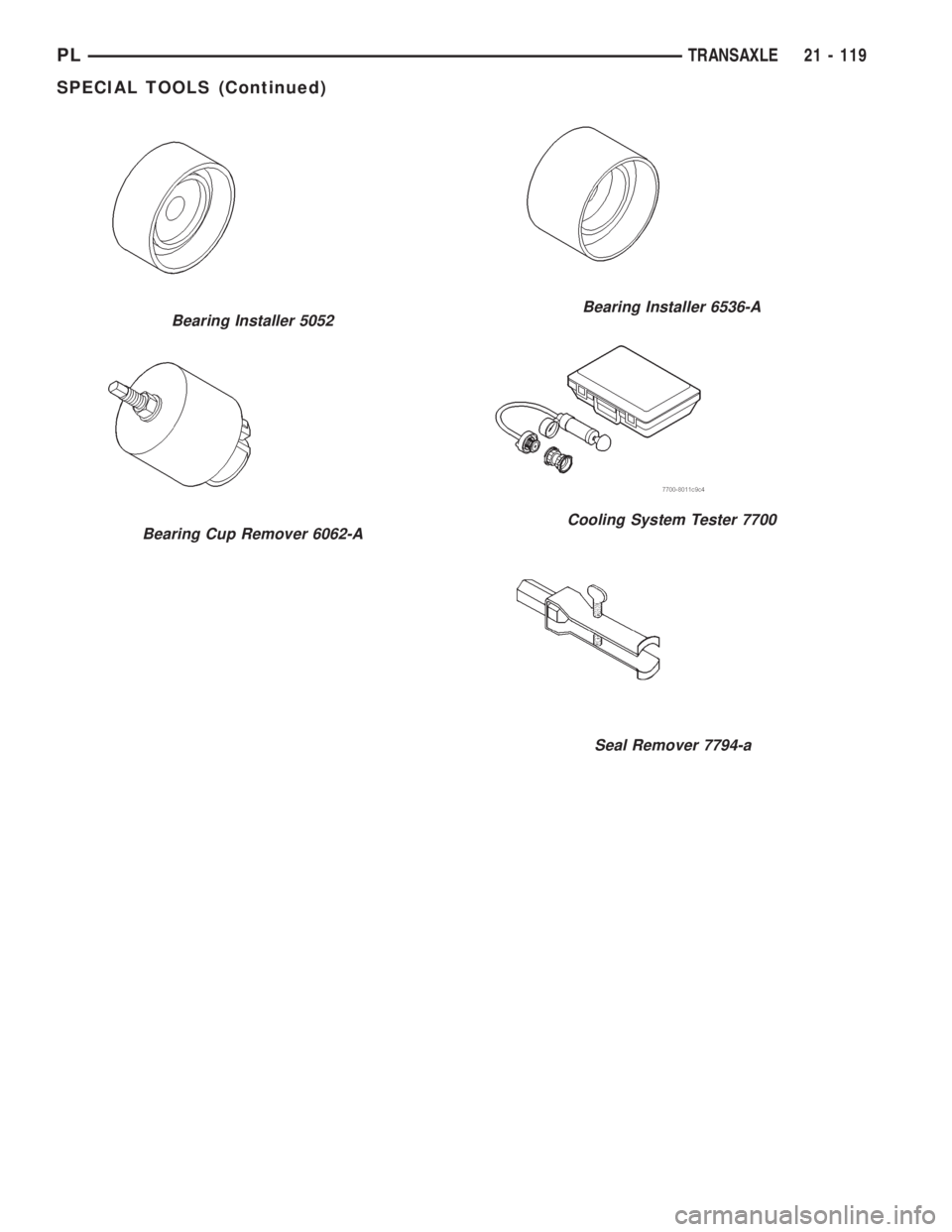

Seal Remover 7794-a

Bearing Installer 5052

Bearing Cup Remover 6062-A

Bearing Installer 6536-A

Cooling System Tester 7700

PLTRANSAXLE 21 - 119

SPECIAL TOOLS (Continued)

Page 1134 of 1200

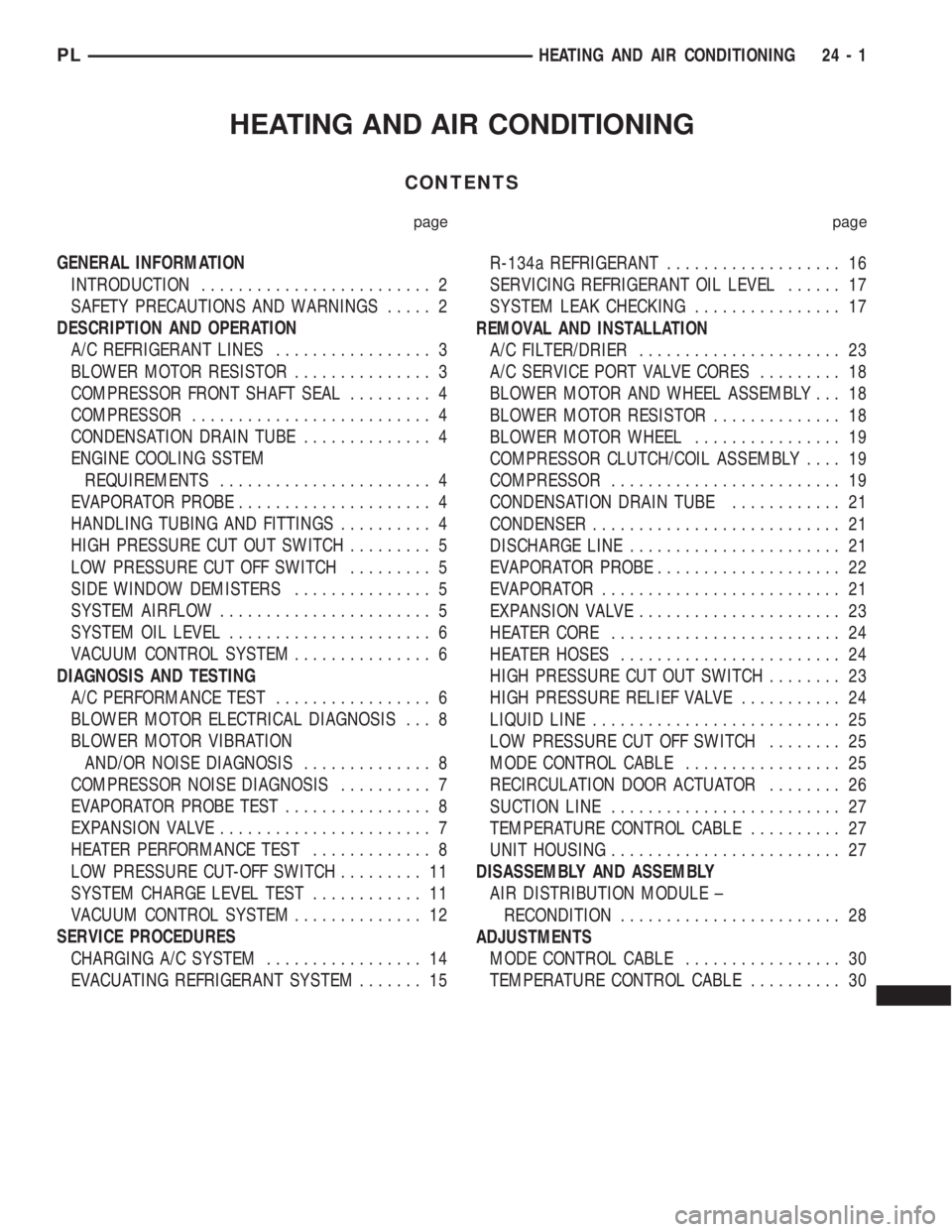

HEATING AND AIR CONDITIONING

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 2

SAFETY PRECAUTIONS AND WARNINGS..... 2

DESCRIPTION AND OPERATION

A/C REFRIGERANT LINES................. 3

BLOWER MOTOR RESISTOR............... 3

COMPRESSOR FRONT SHAFT SEAL......... 4

COMPRESSOR.......................... 4

CONDENSATION DRAIN TUBE.............. 4

ENGINE COOLING SSTEM

REQUIREMENTS....................... 4

EVAPORATOR PROBE..................... 4

HANDLING TUBING AND FITTINGS.......... 4

HIGH PRESSURE CUT OUT SWITCH......... 5

LOW PRESSURE CUT OFF SWITCH......... 5

SIDE WINDOW DEMISTERS............... 5

SYSTEM AIRFLOW....................... 5

SYSTEM OIL LEVEL...................... 6

VACUUM CONTROL SYSTEM............... 6

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST................. 6

BLOWER MOTOR ELECTRICAL DIAGNOSIS . . . 8

BLOWER MOTOR VIBRATION

AND/OR NOISE DIAGNOSIS.............. 8

COMPRESSOR NOISE DIAGNOSIS.......... 7

EVAPORATOR PROBE TEST................ 8

EXPANSION VALVE....................... 7

HEATER PERFORMANCE TEST............. 8

LOW PRESSURE CUT-OFF SWITCH......... 11

SYSTEM CHARGE LEVEL TEST............ 11

VACUUM CONTROL SYSTEM.............. 12

SERVICE PROCEDURES

CHARGING A/C SYSTEM................. 14

EVACUATING REFRIGERANT SYSTEM....... 15R-134a REFRIGERANT................... 16

SERVICING REFRIGERANT OIL LEVEL...... 17

SYSTEM LEAK CHECKING................ 17

REMOVAL AND INSTALLATION

A/C FILTER/DRIER...................... 23

A/C SERVICE PORT VALVE CORES......... 18

BLOWER MOTOR AND WHEEL ASSEMBLY . . . 18

BLOWER MOTOR RESISTOR.............. 18

BLOWER MOTOR WHEEL................ 19

COMPRESSOR CLUTCH/COIL ASSEMBLY.... 19

COMPRESSOR......................... 19

CONDENSATION DRAIN TUBE............ 21

CONDENSER........................... 21

DISCHARGE LINE....................... 21

EVAPORATOR PROBE.................... 22

EVAPORATOR.......................... 21

EXPANSION VALVE...................... 23

HEATER CORE......................... 24

HEATER HOSES........................ 24

HIGH PRESSURE CUT OUT SWITCH........ 23

HIGH PRESSURE RELIEF VALVE........... 24

LIQUID LINE........................... 25

LOW PRESSURE CUT OFF SWITCH........ 25

MODE CONTROL CABLE................. 25

RECIRCULATION DOOR ACTUATOR........ 26

SUCTION LINE......................... 27

TEMPERATURE CONTROL CABLE.......... 27

UNIT HOUSING......................... 27

DISASSEMBLY AND ASSEMBLY

AIR DISTRIBUTION MODULE ±

RECONDITION........................ 28

ADJUSTMENTS

MODE CONTROL CABLE................. 30

TEMPERATURE CONTROL CABLE.......... 30

PLHEATING AND AIR CONDITIONING 24 - 1

Page 1135 of 1200

GENERAL INFORMATION

INTRODUCTION

Both the heater and the heater/air conditioning

systems share many of the same functioning compo-

nents. This group will deal with both systems

together when component function is common, and

separately when they are not.

For proper operation of the instrument panel con-

trols, refer to the Owner's Manual provided with the

vehicle.

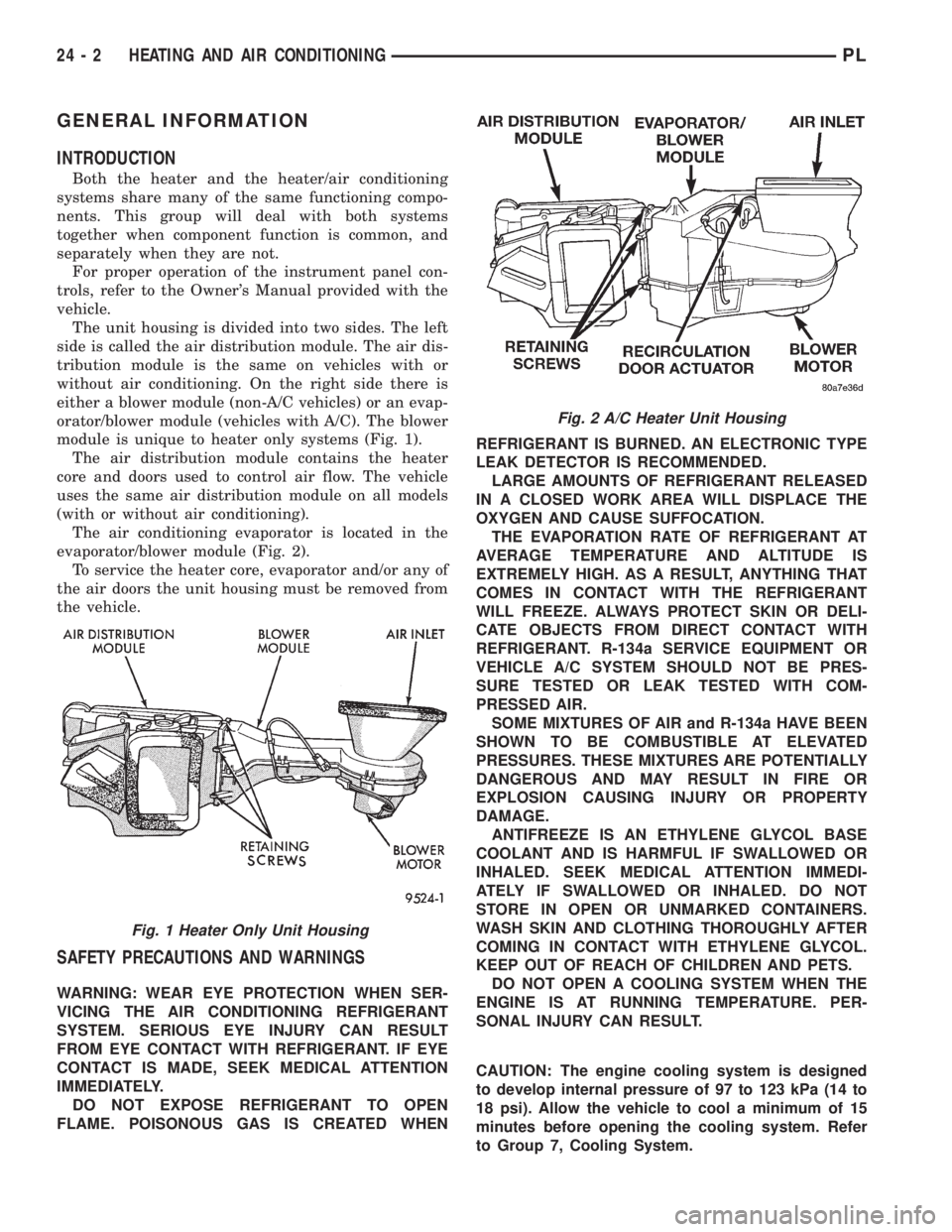

The unit housing is divided into two sides. The left

side is called the air distribution module. The air dis-

tribution module is the same on vehicles with or

without air conditioning. On the right side there is

either a blower module (non-A/C vehicles) or an evap-

orator/blower module (vehicles with A/C). The blower

module is unique to heater only systems (Fig. 1).

The air distribution module contains the heater

core and doors used to control air flow. The vehicle

uses the same air distribution module on all models

(with or without air conditioning).

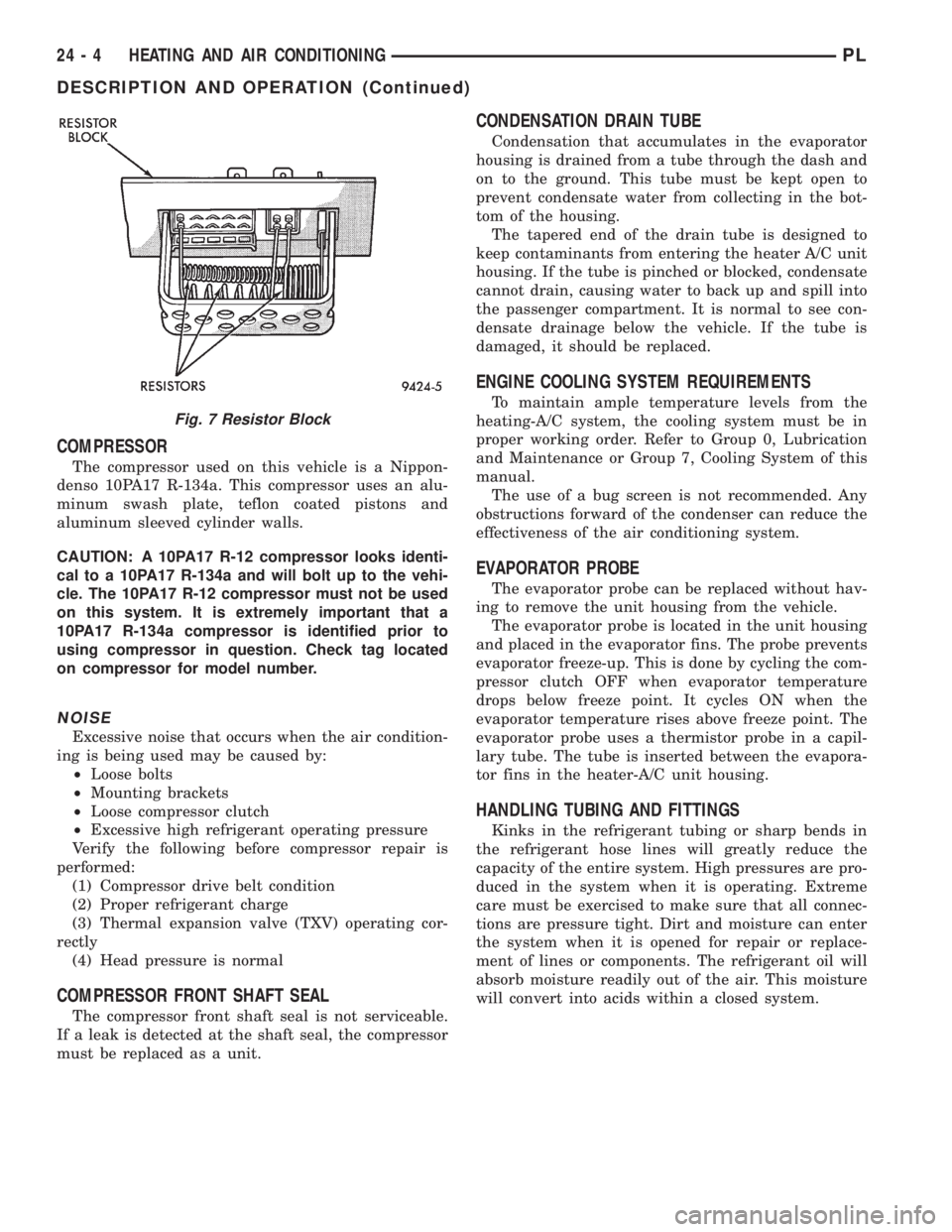

The air conditioning evaporator is located in the

evaporator/blower module (Fig. 2).

To service the heater core, evaporator and/or any of

the air doors the unit housing must be removed from

the vehicle.

SAFETY PRECAUTIONS AND WARNINGS

WARNING: WEAR EYE PROTECTION WHEN SER-

VICING THE AIR CONDITIONING REFRIGERANT

SYSTEM. SERIOUS EYE INJURY CAN RESULT

FROM EYE CONTACT WITH REFRIGERANT. IF EYE

CONTACT IS MADE, SEEK MEDICAL ATTENTION

IMMEDIATELY.

DO NOT EXPOSE REFRIGERANT TO OPEN

FLAME. POISONOUS GAS IS CREATED WHENREFRIGERANT IS BURNED. AN ELECTRONIC TYPE

LEAK DETECTOR IS RECOMMENDED.

LARGE AMOUNTS OF REFRIGERANT RELEASED

IN A CLOSED WORK AREA WILL DISPLACE THE

OXYGEN AND CAUSE SUFFOCATION.

THE EVAPORATION RATE OF REFRIGERANT AT

AVERAGE TEMPERATURE AND ALTITUDE IS

EXTREMELY HIGH. AS A RESULT, ANYTHING THAT

COMES IN CONTACT WITH THE REFRIGERANT

WILL FREEZE. ALWAYS PROTECT SKIN OR DELI-

CATE OBJECTS FROM DIRECT CONTACT WITH

REFRIGERANT. R-134a SERVICE EQUIPMENT OR

VEHICLE A/C SYSTEM SHOULD NOT BE PRES-

SURE TESTED OR LEAK TESTED WITH COM-

PRESSED AIR.

SOME MIXTURES OF AIR and R-134a HAVE BEEN

SHOWN TO BE COMBUSTIBLE AT ELEVATED

PRESSURES. THESE MIXTURES ARE POTENTIALLY

DANGEROUS AND MAY RESULT IN FIRE OR

EXPLOSION CAUSING INJURY OR PROPERTY

DAMAGE.

ANTIFREEZE IS AN ETHYLENE GLYCOL BASE

COOLANT AND IS HARMFUL IF SWALLOWED OR

INHALED. SEEK MEDICAL ATTENTION IMMEDI-

ATELY IF SWALLOWED OR INHALED. DO NOT

STORE IN OPEN OR UNMARKED CONTAINERS.

WASH SKIN AND CLOTHING THOROUGHLY AFTER

COMING IN CONTACT WITH ETHYLENE GLYCOL.

KEEP OUT OF REACH OF CHILDREN AND PETS.

DO NOT OPEN A COOLING SYSTEM WHEN THE

ENGINE IS AT RUNNING TEMPERATURE. PER-

SONAL INJURY CAN RESULT.

CAUTION: The engine cooling system is designed

to develop internal pressure of 97 to 123 kPa (14 to

18 psi). Allow the vehicle to cool a minimum of 15

minutes before opening the cooling system. Refer

to Group 7, Cooling System.

Fig. 2 A/C Heater Unit Housing

Fig. 1 Heater Only Unit Housing

24 - 2 HEATING AND AIR CONDITIONINGPL

Page 1137 of 1200

COMPRESSOR

The compressor used on this vehicle is a Nippon-

denso 10PA17 R-134a. This compressor uses an alu-

minum swash plate, teflon coated pistons and

aluminum sleeved cylinder walls.

CAUTION: A 10PA17 R-12 compressor looks identi-

cal to a 10PA17 R-134a and will bolt up to the vehi-

cle. The 10PA17 R-12 compressor must not be used

on this system. It is extremely important that a

10PA17 R-134a compressor is identified prior to

using compressor in question. Check tag located

on compressor for model number.

NOISE

Excessive noise that occurs when the air condition-

ing is being used may be caused by:

²Loose bolts

²Mounting brackets

²Loose compressor clutch

²Excessive high refrigerant operating pressure

Verify the following before compressor repair is

performed:

(1) Compressor drive belt condition

(2) Proper refrigerant charge

(3) Thermal expansion valve (TXV) operating cor-

rectly

(4) Head pressure is normal

COMPRESSOR FRONT SHAFT SEAL

The compressor front shaft seal is not serviceable.

If a leak is detected at the shaft seal, the compressor

must be replaced as a unit.

CONDENSATION DRAIN TUBE

Condensation that accumulates in the evaporator

housing is drained from a tube through the dash and

on to the ground. This tube must be kept open to

prevent condensate water from collecting in the bot-

tom of the housing.

The tapered end of the drain tube is designed to

keep contaminants from entering the heater A/C unit

housing. If the tube is pinched or blocked, condensate

cannot drain, causing water to back up and spill into

the passenger compartment. It is normal to see con-

densate drainage below the vehicle. If the tube is

damaged, it should be replaced.

ENGINE COOLING SYSTEM REQUIREMENTS

To maintain ample temperature levels from the

heating-A/C system, the cooling system must be in

proper working order. Refer to Group 0, Lubrication

and Maintenance or Group 7, Cooling System of this

manual.

The use of a bug screen is not recommended. Any

obstructions forward of the condenser can reduce the

effectiveness of the air conditioning system.

EVAPORATOR PROBE

The evaporator probe can be replaced without hav-

ing to remove the unit housing from the vehicle.

The evaporator probe is located in the unit housing

and placed in the evaporator fins. The probe prevents

evaporator freeze-up. This is done by cycling the com-

pressor clutch OFF when evaporator temperature

drops below freeze point. It cycles ON when the

evaporator temperature rises above freeze point. The

evaporator probe uses a thermistor probe in a capil-

lary tube. The tube is inserted between the evapora-

tor fins in the heater-A/C unit housing.

HANDLING TUBING AND FITTINGS

Kinks in the refrigerant tubing or sharp bends in

the refrigerant hose lines will greatly reduce the

capacity of the entire system. High pressures are pro-

duced in the system when it is operating. Extreme

care must be exercised to make sure that all connec-

tions are pressure tight. Dirt and moisture can enter

the system when it is opened for repair or replace-

ment of lines or components. The refrigerant oil will

absorb moisture readily out of the air. This moisture

will convert into acids within a closed system.

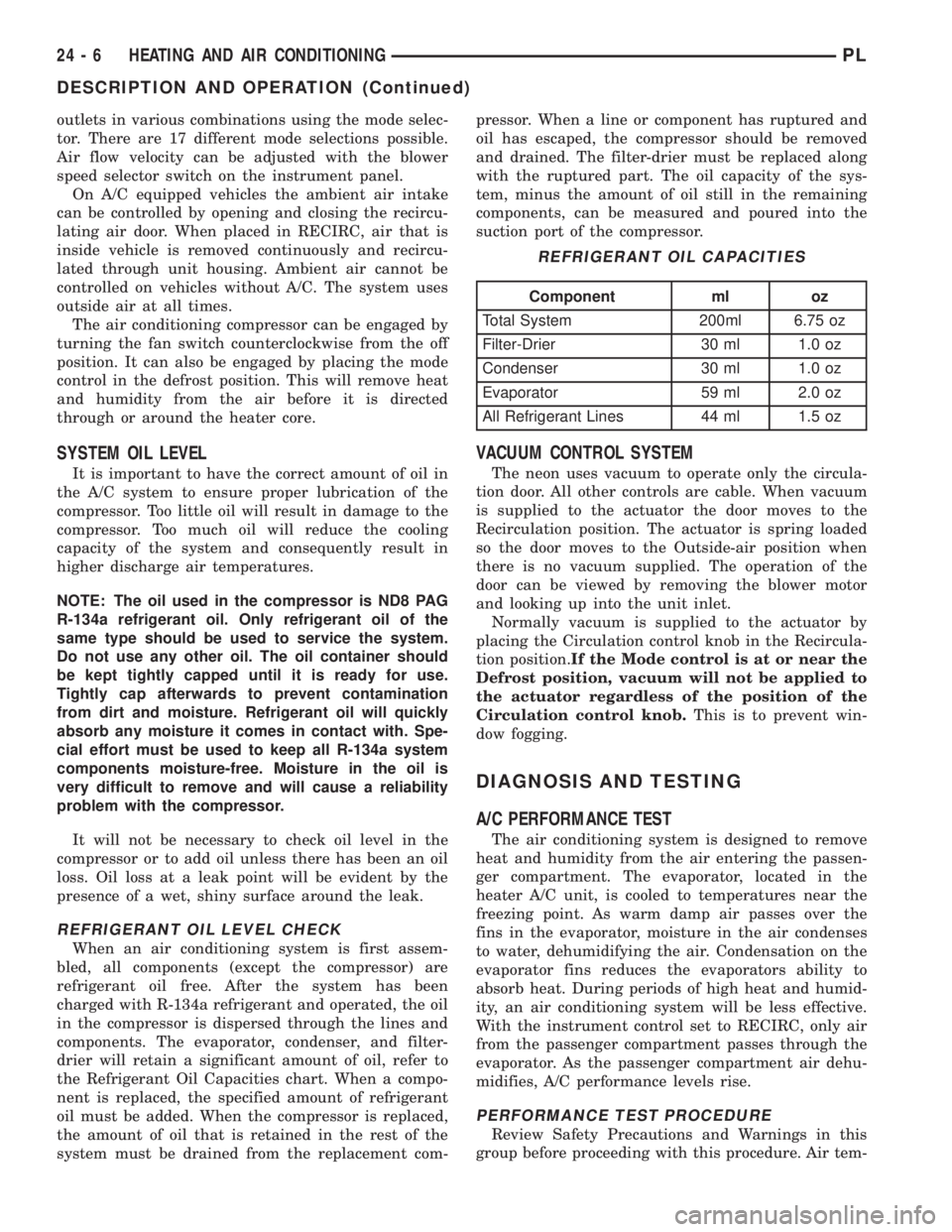

Fig. 7 Resistor Block

24 - 4 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)

Page 1139 of 1200

outlets in various combinations using the mode selec-

tor. There are 17 different mode selections possible.

Air flow velocity can be adjusted with the blower

speed selector switch on the instrument panel.

On A/C equipped vehicles the ambient air intake

can be controlled by opening and closing the recircu-

lating air door. When placed in RECIRC, air that is

inside vehicle is removed continuously and recircu-

lated through unit housing. Ambient air cannot be

controlled on vehicles without A/C. The system uses

outside air at all times.

The air conditioning compressor can be engaged by

turning the fan switch counterclockwise from the off

position. It can also be engaged by placing the mode

control in the defrost position. This will remove heat

and humidity from the air before it is directed

through or around the heater core.

SYSTEM OIL LEVEL

It is important to have the correct amount of oil in

the A/C system to ensure proper lubrication of the

compressor. Too little oil will result in damage to the

compressor. Too much oil will reduce the cooling

capacity of the system and consequently result in

higher discharge air temperatures.

NOTE: The oil used in the compressor is ND8 PAG

R-134a refrigerant oil. Only refrigerant oil of the

same type should be used to service the system.

Do not use any other oil. The oil container should

be kept tightly capped until it is ready for use.

Tightly cap afterwards to prevent contamination

from dirt and moisture. Refrigerant oil will quickly

absorb any moisture it comes in contact with. Spe-

cial effort must be used to keep all R-134a system

components moisture-free. Moisture in the oil is

very difficult to remove and will cause a reliability

problem with the compressor.

It will not be necessary to check oil level in the

compressor or to add oil unless there has been an oil

loss. Oil loss at a leak point will be evident by the

presence of a wet, shiny surface around the leak.

REFRIGERANT OIL LEVEL CHECK

When an air conditioning system is first assem-

bled, all components (except the compressor) are

refrigerant oil free. After the system has been

charged with R-134a refrigerant and operated, the oil

in the compressor is dispersed through the lines and

components. The evaporator, condenser, and filter-

drier will retain a significant amount of oil, refer to

the Refrigerant Oil Capacities chart. When a compo-

nent is replaced, the specified amount of refrigerant

oil must be added. When the compressor is replaced,

the amount of oil that is retained in the rest of the

system must be drained from the replacement com-pressor. When a line or component has ruptured and

oil has escaped, the compressor should be removed

and drained. The filter-drier must be replaced along

with the ruptured part. The oil capacity of the sys-

tem, minus the amount of oil still in the remaining

components, can be measured and poured into the

suction port of the compressor.

VACUUM CONTROL SYSTEM

The neon uses vacuum to operate only the circula-

tion door. All other controls are cable. When vacuum

is supplied to the actuator the door moves to the

Recirculation position. The actuator is spring loaded

so the door moves to the Outside-air position when

there is no vacuum supplied. The operation of the

door can be viewed by removing the blower motor

and looking up into the unit inlet.

Normally vacuum is supplied to the actuator by

placing the Circulation control knob in the Recircula-

tion position.If the Mode control is at or near the

Defrost position, vacuum will not be applied to

the actuator regardless of the position of the

Circulation control knob.This is to prevent win-

dow fogging.

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to RECIRC, only air

from the passenger compartment passes through the

evaporator. As the passenger compartment air dehu-

midifies, A/C performance levels rise.

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings in this

group before proceeding with this procedure. Air tem-

REFRIGERANT OIL CAPACITIES

Component ml oz

Total System 200ml 6.75 oz

Filter-Drier 30 ml 1.0 oz

Condenser 30 ml 1.0 oz

Evaporator 59 ml 2.0 oz

All Refrigerant Lines 44 ml 1.5 oz

24 - 6 HEATING AND AIR CONDITIONINGPL

DESCRIPTION AND OPERATION (Continued)

Page 1144 of 1200

MAXIMUM HEATER OUTPUT: TEST AND

ACTION

Engine coolant is provided to the heater system by

two 16 mm (5/8 inch inside diameter) heater hoses.

With engine idling at normal running temperature,

set the control to maximum heat, floor, and high

blower setting. Using a test thermometer, check the

air temperature coming from the floor outlets, refer

to Temperature Reference Table.

If the floor outlet air temperature is insufficient,

refer to Group 7, Cooling Systems for specifications.

Both heater hoses should be HOT to the touch (cool-

ant return hose should be slightly cooler than the

supply hose). If coolant return hose is much cooler

than the supply hose, locate and repair engine cool-

ant flow obstruction in heater system.

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF

INSUFFICIENT HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door cable.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

LOW PRESSURE CUT-OFF SWITCH

The work area must not be below 21ÉC (70ÉF) to

test the compressor clutch circuit.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Raise hood and disconnect low pressure cut off

switch connector boot.

(3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot.

(4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams.

(5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, low pressure out off switch will

complete the clutch circuit. If the low pressure gauge

reads below 140 kPa (20 psi), the system is low on

refrigerant charge or empty due to a leak. Refer to

Service±Procedures, System Leak Checking in this

section.

(6) Install connector boot on switch and repeat

Step 3. If the clutch does not engage, replace the low

pressure cut off switch.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

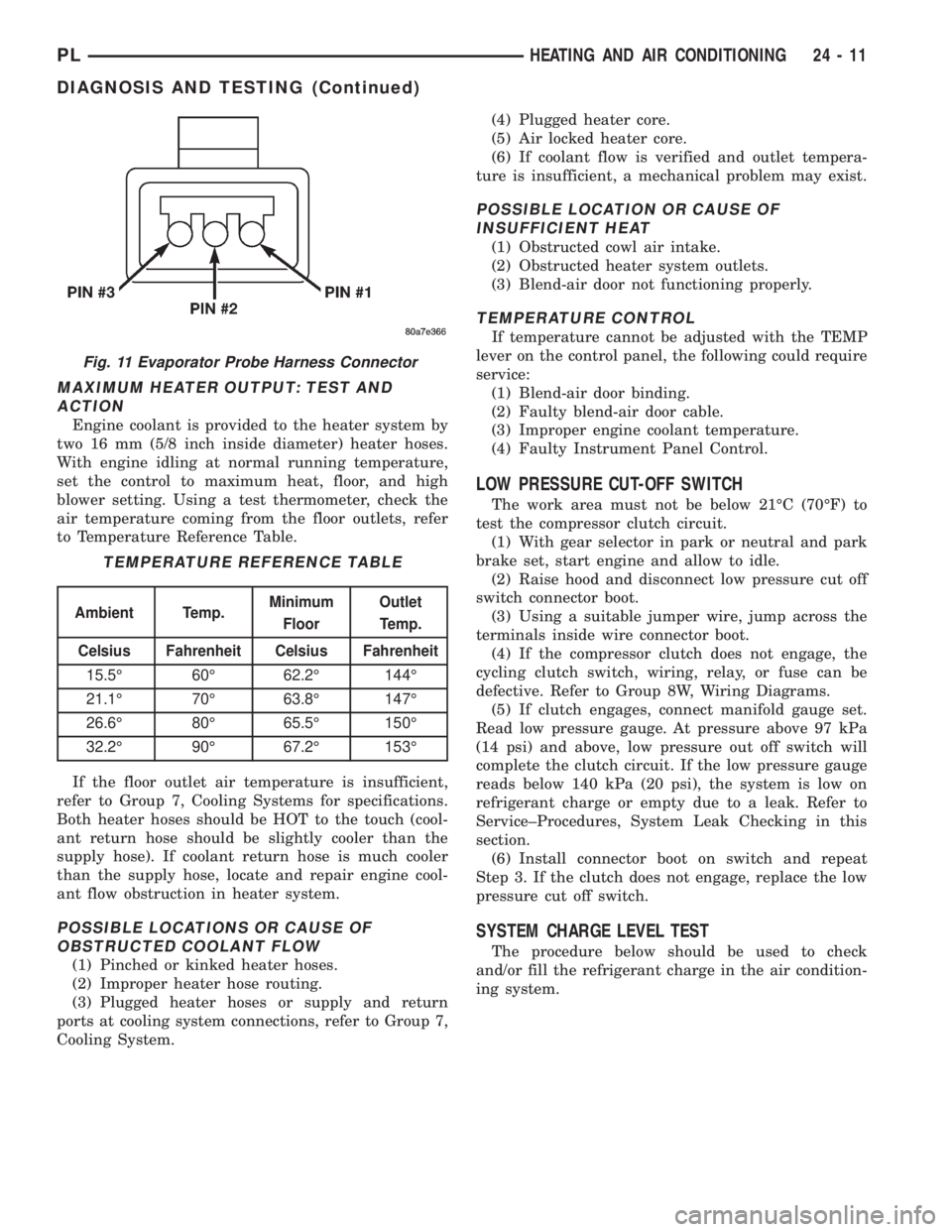

Fig. 11 Evaporator Probe Harness Connector

TEMPERATURE REFERENCE TABLE

Ambient Temp.Minimum

FloorOutlet

Temp.

Celsius Fahrenheit Celsius Fahrenheit

15.5É 60É 62.2É 144É

21.1É 70É 63.8É 147É

26.6É 80É 65.5É 150É

32.2É 90É 67.2É 153É

PLHEATING AND AIR CONDITIONING 24 - 11

DIAGNOSIS AND TESTING (Continued)

Page 1150 of 1200

SERVICING REFRIGERANT OIL LEVEL

CAUTION: The refrigerant oil used in a R-134a A/C

system is unique. Use only oils which were

designed to work with R-134a refrigerant. The oil

designated for this vehicle is ND8 PAG (polyalka-

lene glycol).

Recovery/recycling equipment will measure the

lubricant being removed. This is the amount of lubri-

cant to be added back to the system. If a new com-

pressor is being installed, drain lubricant from old

compressor, measure the amount drained and discard

old lubricant. Drain the lubricant from the new com-

pressor into a clean container. Return the amount of

lubricant measured from the old compressor, plus the

amount reclaimed from the system back into the new

compressor.

(1) Discharge refrigerant system using recovery/re-

cycling equipment if charge is present.

(2) Disconnect refrigerant lines from A/C compres-

sor. Cap the open lines to prevent moisture from

entering system.

(3) Remove compressor from vehicle.

(4) From suction port on top of compressor, drain

lubricant from compressor.

(5) Add system capacity minus the capacity of

components that have not been replaced. Refer to the

Lubricant Capacity Chart. Add lubricant through the

suction port on compressor. This is not to exceed 200

ml (6.75 oz.) in total.

(6) Install compressor and connect refrigerant

lines. Then evacuate and charge refrigerant system.

SYSTEM LEAK CHECKING

WARNING: R-134a SERVICE EQUIPMENT OR VEHI-

CLE A/C SYSTEM SHOULD NOT BE PRESSURE

TESTED OR LEAK TESTED WITH COMPRESSED

AIR. MIXTURE OF AIR and R-134a CAN BE COM-

BUSTIBLE AT ELEVATED PRESSURES. THESE MIX-

TURES ARE POTENTIALLY DANGEROUS AND MAY

RESULT IN FIRE OR EXPLOSION CAUSING INJURY

OR PROPERTY DAMAGE.

AVOID BREATHING A/C REFRIGERANT AND

LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

If the A/C system is not cooling properly, determine

if the refrigerant system is fully charged with

R-134a. This is accomplished by performing a system

Charge Level-Check or Fill. If while performing thistest A/C liquid line pressure is less than 345 kPa (50

psi) proceed to Empty Refrigerant System Leak Test.

If liquid line pressure is greater than 345 kPa (50

psi) proceed to low refrigerant level leak test. If the

refrigerant system is empty or low in refrigerant

charge, a leak at any line fitting or component seal is

likely. A review of the fittings, lines and components

for oily residue is an indication of the leak location.

To detect a leak in the refrigerant system, perform

one of the following procedures as indicated by the

symptoms.

EMPTY REFRIGERANT SYSTEM LEAK TEST

(1) Evacuate the refrigerant system to the lowest

degree of vacuum possible (approx. 28 in Hg.). Deter-

mine if the system holds a vacuum for 15 minutes. If

vacuum is held, a leak is probably not present. If sys-

tem will not maintain vacuum level, proceed with

this procedure.

(2) Prepare a .284 Kg. (10 oz.) refrigerant charge

to be injected into the system.

(3) Connect and dispense .284 Kg. (10 oz.) of

refrigerant into the evacuated refrigerant system.

(4) Proceed to Step 2 of Low Refrigerant Level

Leak Test.

LOW REFRIGERANT LEVEL LEAK TEST

(1) Determine if there is any (R-134a) refrigerant

in the system.

(2) Position the vehicle in a wind free work area.

This will aid in detecting small leaks.

(3) Bring the refrigerant system up to operating

temperature and pressure. This is done by allowing

the engine to run for five minutes with the system

set to the following:

²Transaxle in Park

²Engine Idling at 700 rpm

²A/C Controls Set in 100 percent outside air

²Blower switch in the high A/C position

²A/C in the ON position

²Open all windows

CAUTION: A leak detector designed for R-12 refrig-

erant (only) will not detect leaks in a R-134a refrig-

erant system.

(4) Shut off the vehicle and wait 2 to 7 minutes.

Then use an Electronic Leak Detector that is

designed to detect R-134a type refrigerant and search

for leaks. Fittings, lines, or components that appear

to be oily usually indicates a refrigerant leak. To

inspect the evaporator core for leaks, insert the leak

detector probe into the drain tube opening or a heat

duct. A R-134a dye is available to aid in leak detec-

tion, use only Chrysler approved refrigerant dye.

PLHEATING AND AIR CONDITIONING 24 - 17

SERVICE PROCEDURES (Continued)

Page 1152 of 1200

(4) Remove two resistor block retaining screws.

The screw threads attaching the resistor block are

not full length. It is necessary to gently pry out the

resistor block while turning the screws counterclock-

wise enabling the threads to engages.

(5) Remove resistor block from vehicle.

INSTALLATION

For installation, reverse the above procedures.

BLOWER MOTOR WHEEL

The blower motor wheel is only serviced with the

blower motor. The wheel and the motor are balanced

as an assembly. If the blower motor wheel requires

replacement, the blower motor must also be replaced.

Refer to blower motor for replacement procedure.

COMPRESSOR

CAUTION: Add only new lubricant when system

requires additional lubricant. Do not use old

reclaimed lubricant.

REMOVAL

The A/C compressor may be unbolted and reposi-

tioned without discharging the refrigerant system.

Discharging is not necessary if removing the com-

pressor clutch/coil assembly, engine, cylinder head, or

alternator.

WARNING: REFRIGERANT PRESSURES REMAIN

HIGH EVEN THOUGH THE ENGINE MAY BE

TURNED OFF. DO NOT TWIST OR KINK THE

REFRIGERANT LINES WHEN REMOVING A FULLY

CHARGED COMPRESSOR. SAFETY GLASSES

MUST BE WORN.

(1) Disconnect battery negative cable.

(2) Loosen and remove drive belts, refer to Group

7, Engine Cooling.

(3) Using a R-134a refrigerant recovery machine,

remove the refrigerant from A/C system. If the com-

pressor is being replaced.

(4) Disconnect compressor clutch wire lead.

(5) Remove refrigerant lines from compressor, if

necessary.

(6) If system is left open place plug/cap over open

lines.

(7) Remove compressor attaching bolt.

(8) Remove compressor. If refrigerant lines were

not removed, lift compressor/clutch assembly and tie

it to a suitable component.

INSTALLATION

For installation, reverse the above procedures.

COMPRESSOR CLUTCH/COIL ASSEMBLY

Compressor assembly must be removed from mount-

ing. Although, refrigerant discharge is not necessary.

REMOVAL

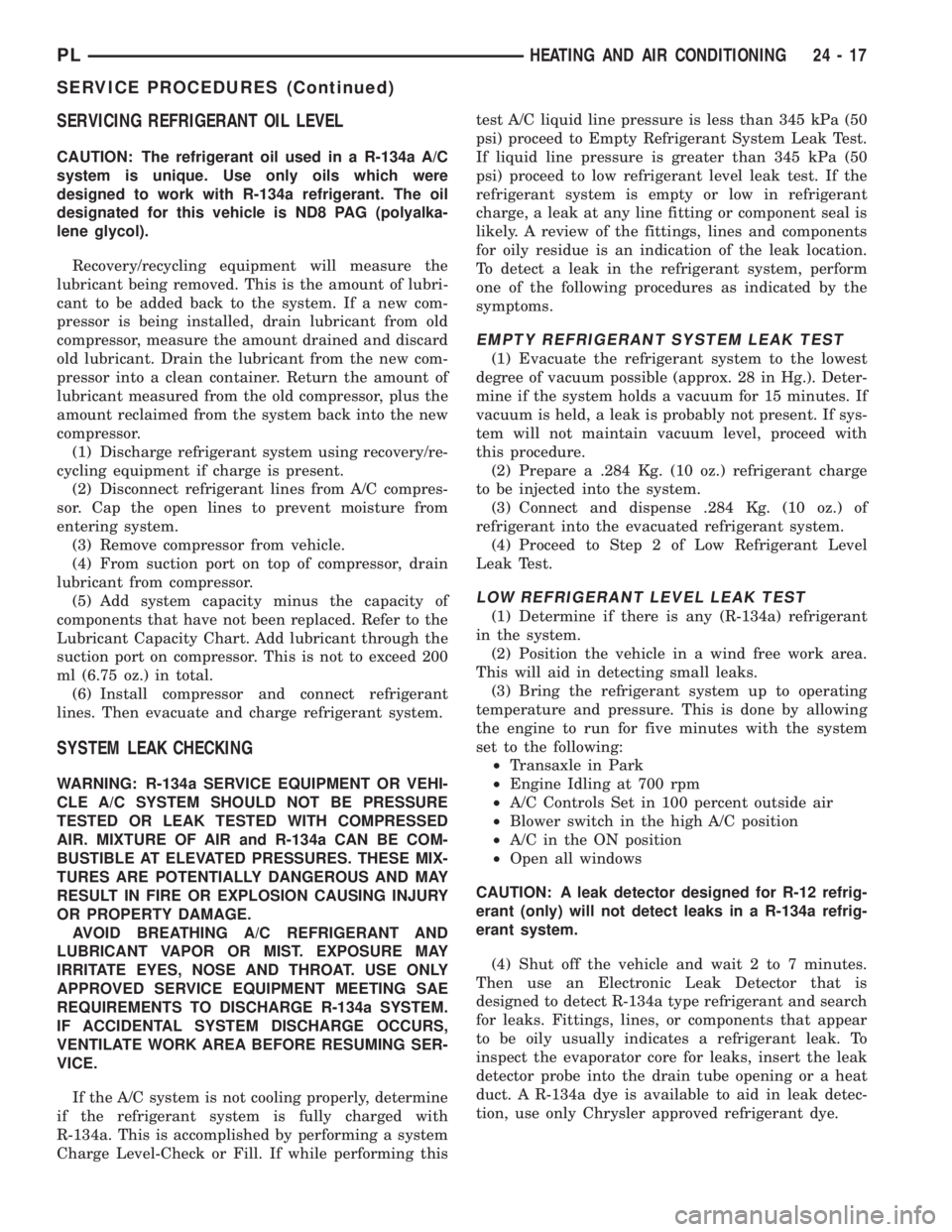

(1) Remove the compressor shaft bolt (Fig. 20). A

band type oil filter removal tool can be placed around

the clutch plate to aid in bolt removal.

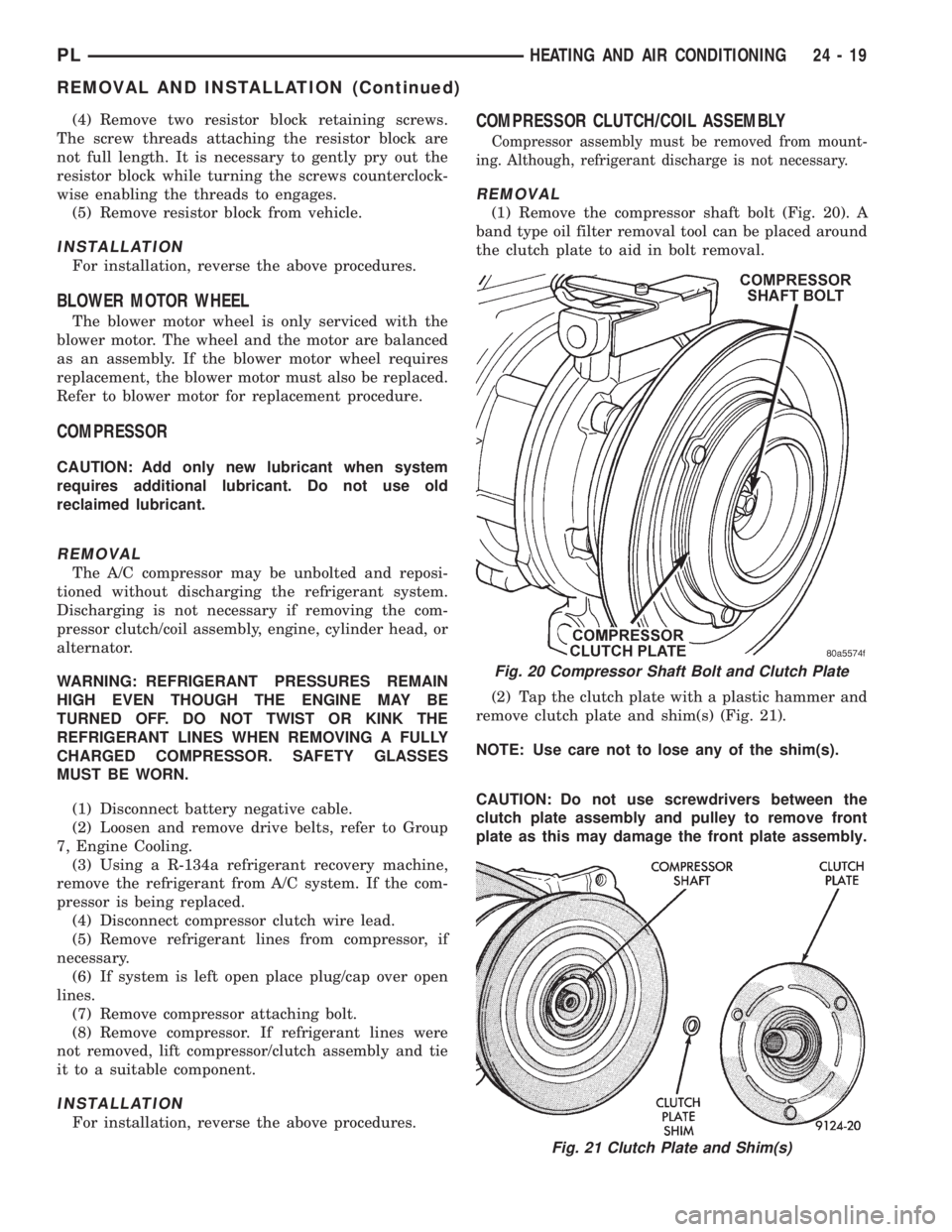

(2) Tap the clutch plate with a plastic hammer and

remove clutch plate and shim(s) (Fig. 21).

NOTE: Use care not to lose any of the shim(s).

CAUTION: Do not use screwdrivers between the

clutch plate assembly and pulley to remove front

plate as this may damage the front plate assembly.

Fig. 20 Compressor Shaft Bolt and Clutch Plate

Fig. 21 Clutch Plate and Shim(s)

PLHEATING AND AIR CONDITIONING 24 - 19

REMOVAL AND INSTALLATION (Continued)