cooling DODGE NEON 1999 Service Owner's Guide

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 715 of 1200

assure gasket rails are flat. Flatten rails with a ham-

mer on a heavy steel plate if required. Gasket sur-

faces must be free of oil and dirt. Make sure old

gasket material is removed from blind attaching

holes.

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 inch.) diameter or less of seal-

ant to one gasket surface. Be certain the material

surrounds each mounting hole. Excess material can

easily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

The MopartSilicone Rubber Adhesive Sealant gas-

ket material or equivalent should be applied in a con-

tinuous bead approximately 3 mm (0.120 inch) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 inch.)

drop is placed in the center of the gasket contact

area. Uncured sealant may be removed with a shop

towel. Components should be torqued in place while

the sealant is still wet to the touch (within 10 min-

utes). The usage of a locating dowel is recommended

during assembly to prevent smearing material off the

location.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

ENGINE CORE PLUGS

REMOVAL

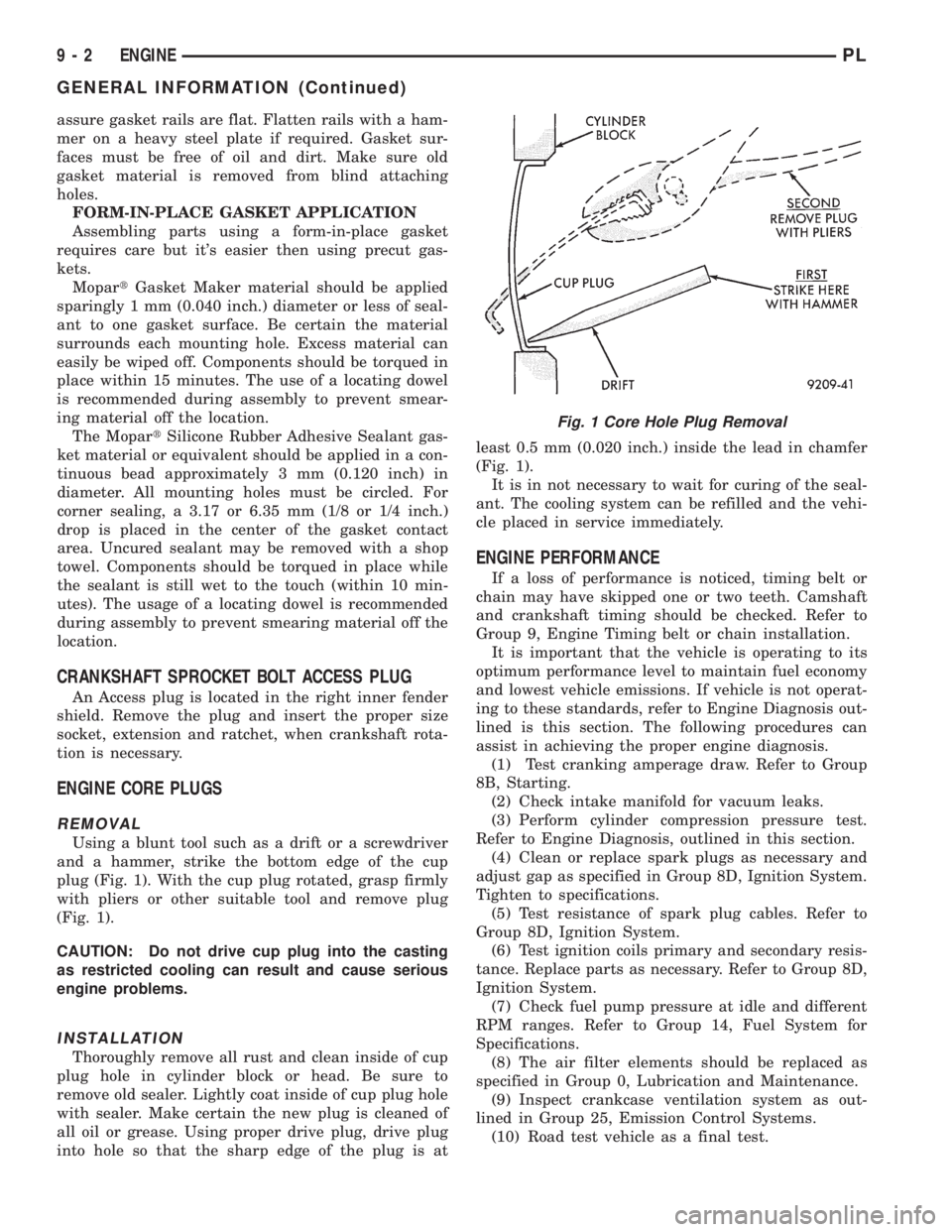

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 1). With the cup plug rotated, grasp firmly

with pliers or other suitable tool and remove plug

(Fig. 1).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly remove all rust and clean inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with sealer. Make certain the new plug is cleaned of

all oil or grease. Using proper drive plug, drive plug

into hole so that the sharp edge of the plug is atleast 0.5 mm (0.020 inch.) inside the lead in chamfer

(Fig. 1).

It is in not necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-

ing to these standards, refer to Engine Diagnosis out-

lined is this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis, outlined in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system as out-

lined in Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.

Fig. 1 Core Hole Plug Removal

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)

Page 721 of 1200

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary

and adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance,.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

9 - 8 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 727 of 1200

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up into the cylin-

der head. The rocker shafts route oil to the rocker

arms/hydraulic lash adjuster assemblies.

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEM-

B LY:A partial open deck is used for cooling and

weight reduction with water pump molded into the

block. Nominal wall thickness is 4 mm. The bedplate

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFT:A nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket trans-

mits crankshaft movement, via timing belt to the

camshaft sprocket providing timed valve actuation.

PISTONS:The SOHC EngineDOES NOThave

provision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hex

head cap screw are used to provide alignment and

durability in the assembly. Pistons And Connecting

rods are serviced as an assembly.

PISTON RINGS:The piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package consist of 2 steel rails and a expander

spacer.

CYLINDER HEADÐSOHC:It features a Single

Over Head Camshaft, four-valves per cylinder cross

flow design. The valves are arranged in two inlinebanks, with the two intake per cylinder facing

toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFTÐSOHC:The nodular iron camshaft

has five bearing journals and 3 cam lobes per cylin-

der. Provision for cam position sensor on the cam at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVESÐSOHC:Four valves per cylinder are

actuated by roller rocker arms/hydraulic lash adjust-

ers assemblies which pivot on rocker arm shafts. All

valves have 6 mm diameter chrome plated valve

stems. The valve train has 33 mm (1.299 inch) diam-

eter intake valves and 28 mm (1.10 inch) diameter

exhaust valves. Viton rubber valve stem seals are

integral with spring seats. Valve springs, spring

retainers, and locks are conventional design.

INTAKE MANIFOLD:The intake manifold is a

molded plastic composition, attached to the cylinder

head with ten fasteners. This long branch design

enhances low and mid-range torque.

EXHAUST MANIFOLD:The exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 3). The cylin-

der bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

9 - 14 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 732 of 1200

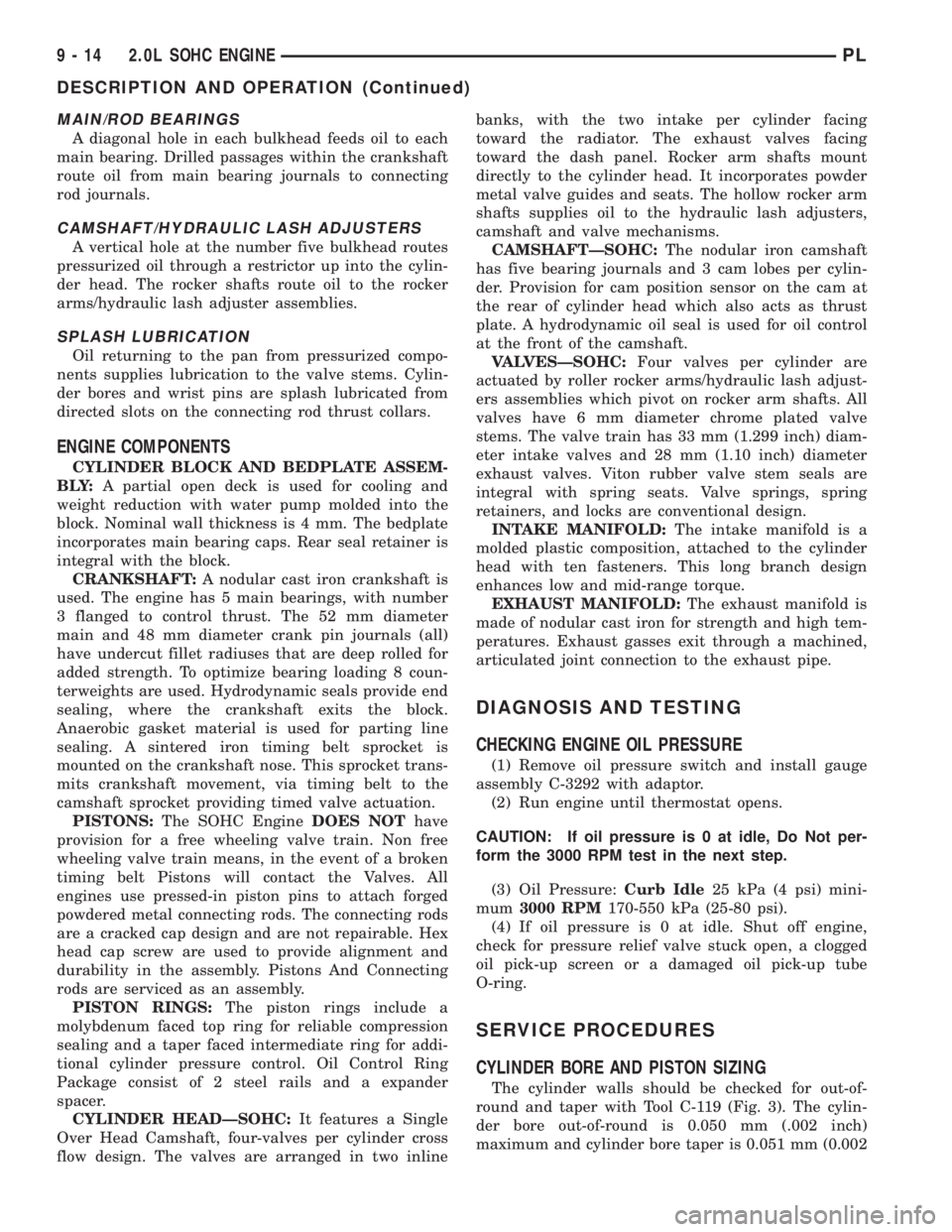

(3) Remove the power hop damper bracket, if nec-

essary.

(4) Reverse removal procedure for installation.

Tighten all bolts and nuts to 54 N´m (40 ft. lbs.)

STRUCTURAL COLLARÐ2.0L

REMOVAL

(1) Raise vehicle on hoist.

NOTE: To remove transaxle dust cover, the front

bending strut must be removed.

(2) Remove structural collar from oil pan to tran-

saxle (Fig. 14).

INSTALLATION

CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(1) Install the structural collar (Fig. 14) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(2) Lower vehicle.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect and remove battery and tray. Set

Powertrain Control Module (PCM) aside.

(3) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(4) Remove upper radiator hose, radiator and fan

module. Refer to Group 7, Cooling System for proce-

dure.

(5) Remove lower radiator hose.

(6) Disconnect automatic transmission cooler lines

and plug. If equipped.

(7) Disconnect clutch cable (Manual) and transmis-

sion shift linkage.

Fig. 12 Engine MountingÐRight

Fig. 13 Power Hop Damper

Fig. 14 Structural CollarÐRemoval and Installation

PL2.0L SOHC ENGINE 9 - 19

REMOVAL AND INSTALLATION (Continued)

Page 733 of 1200

(8) Disconnect throttle body linkage.

(9) Disconnect engine wiring harness.

(10) Disconnect heater hoses.

(11) Discharge Air Conditioning System. Refer to

Group 24, Air Conditioning for procedure.

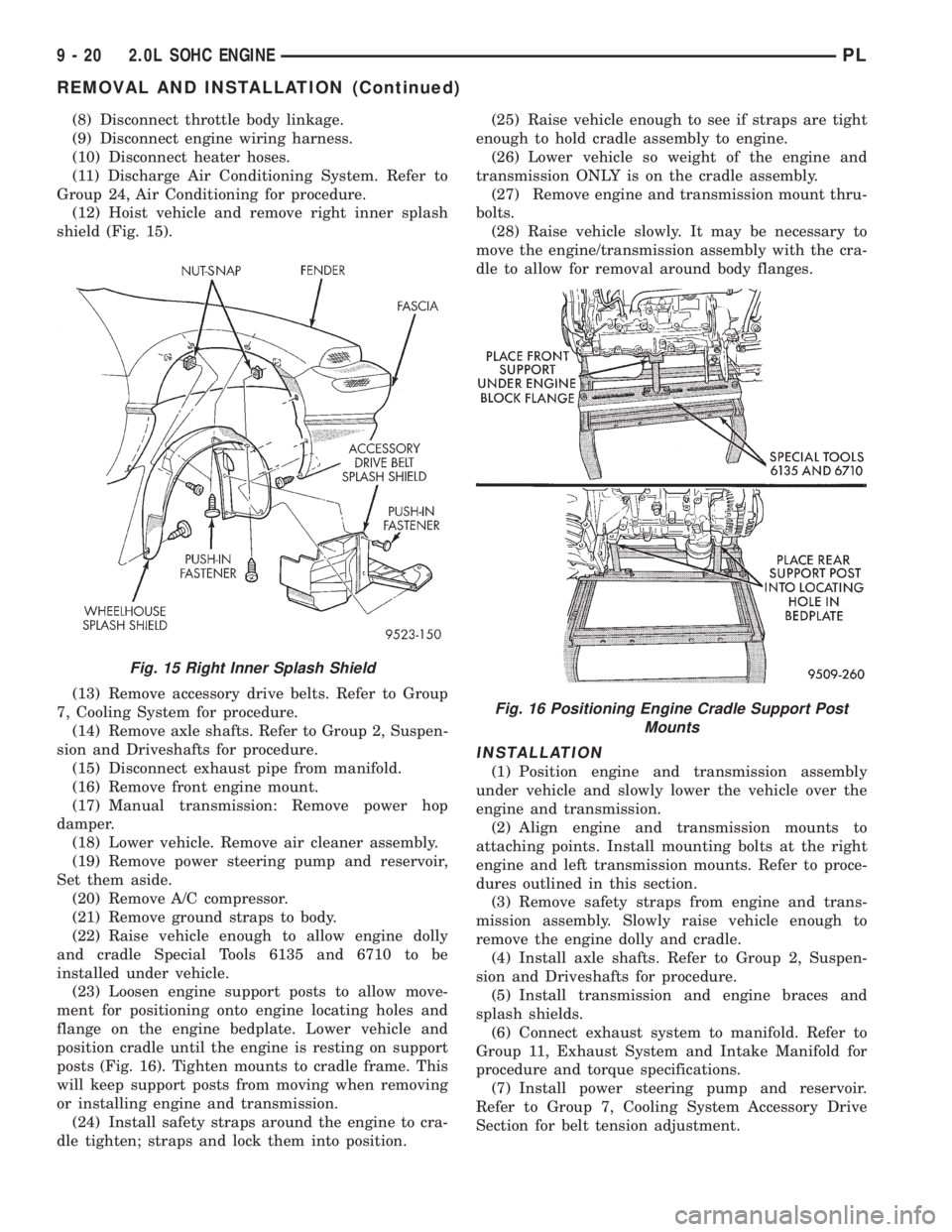

(12) Hoist vehicle and remove right inner splash

shield (Fig. 15).

(13) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(14) Remove axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(15) Disconnect exhaust pipe from manifold.

(16) Remove front engine mount.

(17) Manual transmission: Remove power hop

damper.

(18) Lower vehicle. Remove air cleaner assembly.

(19) Remove power steering pump and reservoir,

Set them aside.

(20) Remove A/C compressor.

(21) Remove ground straps to body.

(22) Raise vehicle enough to allow engine dolly

and cradle Special Tools 6135 and 6710 to be

installed under vehicle.

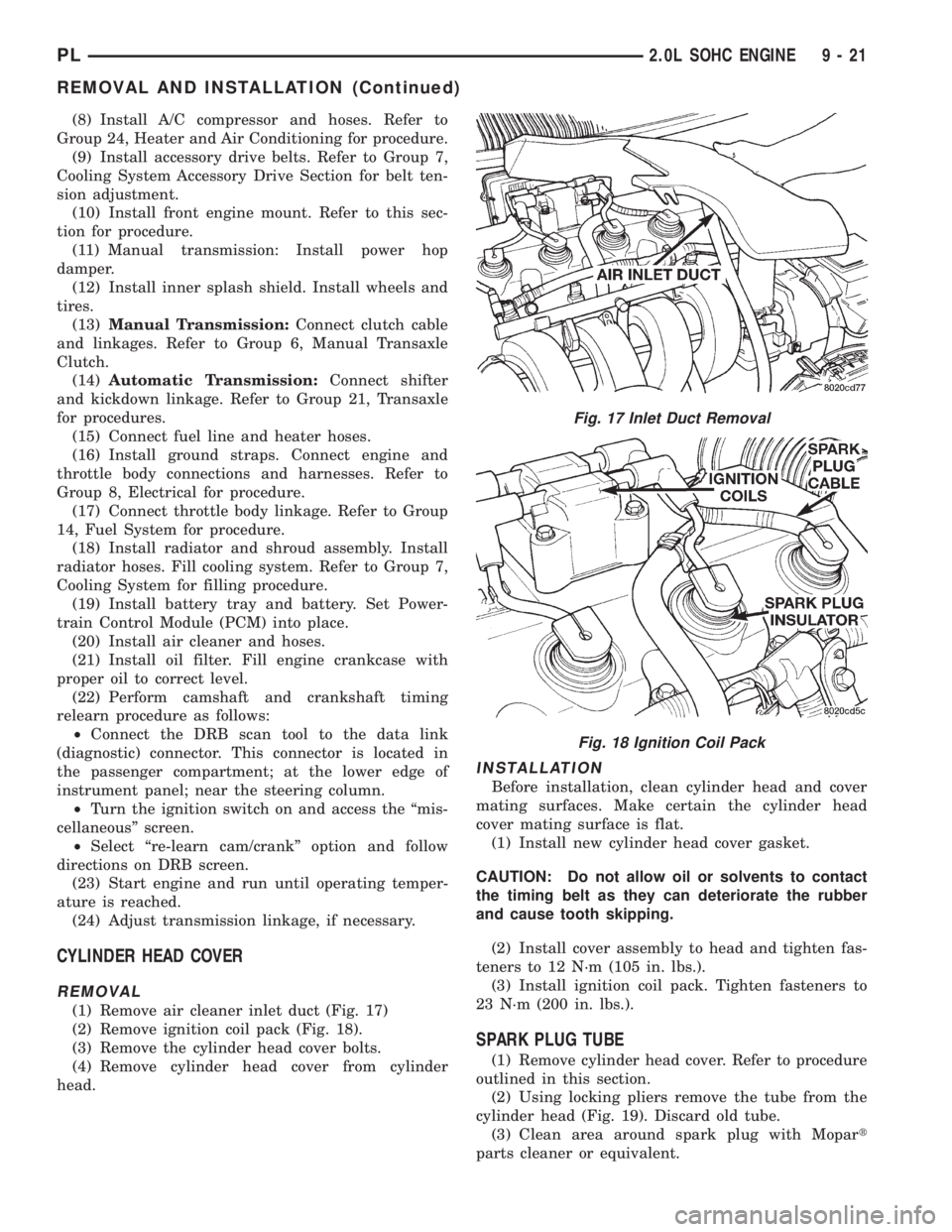

(23) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 16). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(24) Install safety straps around the engine to cra-

dle tighten; straps and lock them into position.(25) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(26) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

(27) Remove engine and transmission mount thru-

bolts.

(28) Raise vehicle slowly. It may be necessary to

move the engine/transmission assembly with the cra-

dle to allow for removal around body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine and transmission.

(2) Align engine and transmission mounts to

attaching points. Install mounting bolts at the right

engine and left transmission mounts. Refer to proce-

dures outlined in this section.

(3) Remove safety straps from engine and trans-

mission assembly. Slowly raise vehicle enough to

remove the engine dolly and cradle.

(4) Install axle shafts. Refer to Group 2, Suspen-

sion and Driveshafts for procedure.

(5) Install transmission and engine braces and

splash shields.

(6) Connect exhaust system to manifold. Refer to

Group 11, Exhaust System and Intake Manifold for

procedure and torque specifications.

(7) Install power steering pump and reservoir.

Refer to Group 7, Cooling System Accessory Drive

Section for belt tension adjustment.

Fig. 15 Right Inner Splash Shield

Fig. 16 Positioning Engine Cradle Support Post

Mounts

9 - 20 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 734 of 1200

(8) Install A/C compressor and hoses. Refer to

Group 24, Heater and Air Conditioning for procedure.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(10) Install front engine mount. Refer to this sec-

tion for procedure.

(11) Manual transmission: Install power hop

damper.

(12) Install inner splash shield. Install wheels and

tires.

(13)Manual Transmission:Connect clutch cable

and linkages. Refer to Group 6, Manual Transaxle

Clutch.

(14)Automatic Transmission:Connect shifter

and kickdown linkage. Refer to Group 21, Transaxle

for procedures.

(15) Connect fuel line and heater hoses.

(16) Install ground straps. Connect engine and

throttle body connections and harnesses. Refer to

Group 8, Electrical for procedure.

(17) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(18) Install radiator and shroud assembly. Install

radiator hoses. Fill cooling system. Refer to Group 7,

Cooling System for filling procedure.

(19) Install battery tray and battery. Set Power-

train Control Module (PCM) into place.

(20) Install air cleaner and hoses.

(21) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(22) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

(23) Start engine and run until operating temper-

ature is reached.

(24) Adjust transmission linkage, if necessary.

CYLINDER HEAD COVER

REMOVAL

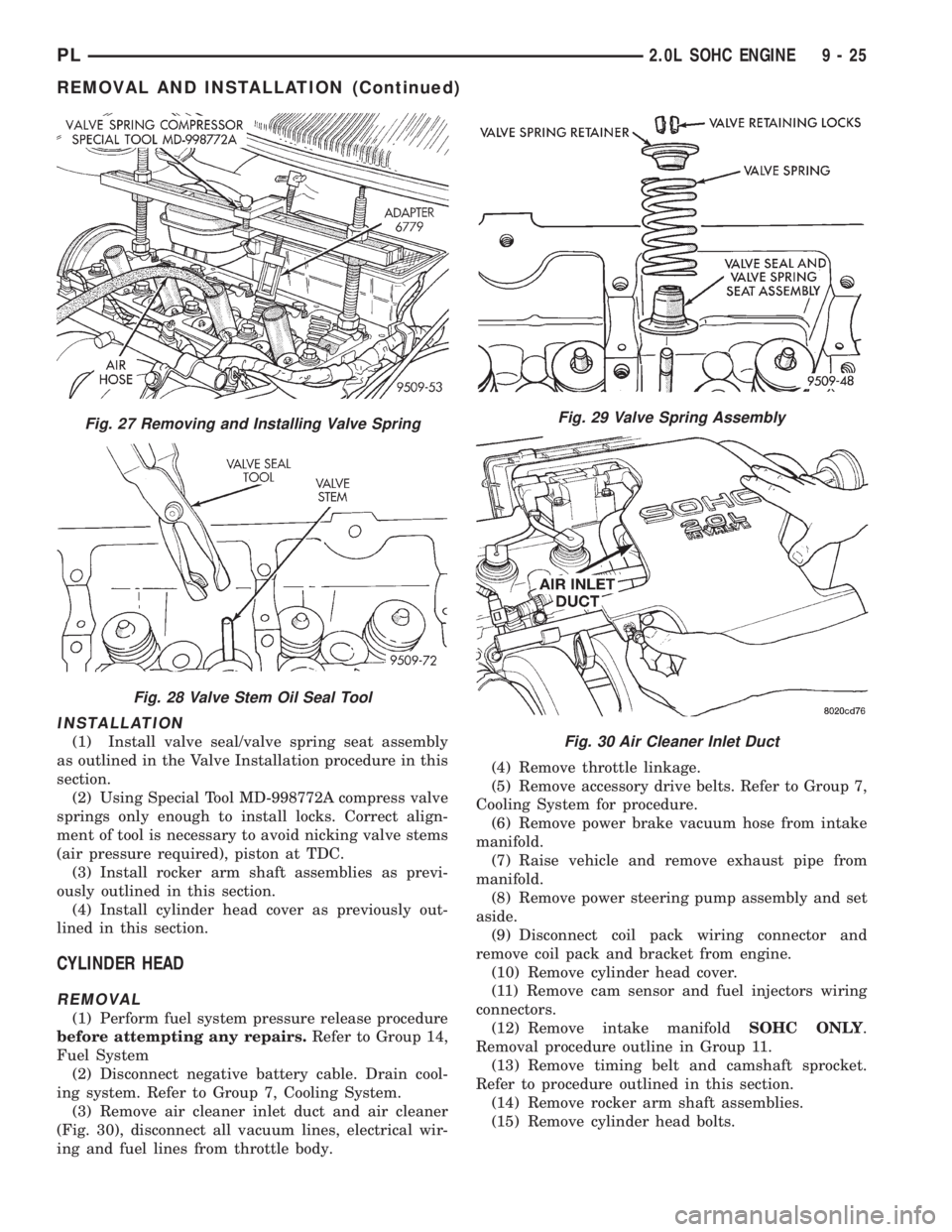

(1) Remove air cleaner inlet duct (Fig. 17)

(2) Remove ignition coil pack (Fig. 18).

(3) Remove the cylinder head cover bolts.

(4) Remove cylinder head cover from cylinder

head.

INSTALLATION

Before installation, clean cylinder head and cover

mating surfaces. Make certain the cylinder head

cover mating surface is flat.

(1) Install new cylinder head cover gasket.

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.

(2) Install cover assembly to head and tighten fas-

teners to 12 N´m (105 in. lbs.).

(3) Install ignition coil pack. Tighten fasteners to

23 N´m (200 in. lbs.).

SPARK PLUG TUBE

(1) Remove cylinder head cover. Refer to procedure

outlined in this section.

(2) Using locking pliers remove the tube from the

cylinder head (Fig. 19). Discard old tube.

(3) Clean area around spark plug with Mopart

parts cleaner or equivalent.

Fig. 17 Inlet Duct Removal

Fig. 18 Ignition Coil Pack

PL2.0L SOHC ENGINE 9 - 21

REMOVAL AND INSTALLATION (Continued)

Page 738 of 1200

INSTALLATION

(1) Install valve seal/valve spring seat assembly

as outlined in the Valve Installation procedure in this

section.

(2) Using Special Tool MD-998772A compress valve

springs only enough to install locks. Correct align-

ment of tool is necessary to avoid nicking valve stems

(air pressure required), piston at TDC.

(3) Install rocker arm shaft assemblies as previ-

ously outlined in this section.

(4) Install cylinder head cover as previously out-

lined in this section.

CYLINDER HEAD

REMOVAL

(1) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System

(2) Disconnect negative battery cable. Drain cool-

ing system. Refer to Group 7, Cooling System.

(3) Remove air cleaner inlet duct and air cleaner

(Fig. 30), disconnect all vacuum lines, electrical wir-

ing and fuel lines from throttle body.(4) Remove throttle linkage.

(5) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure.

(6) Remove power brake vacuum hose from intake

manifold.

(7) Raise vehicle and remove exhaust pipe from

manifold.

(8) Remove power steering pump assembly and set

aside.

(9) Disconnect coil pack wiring connector and

remove coil pack and bracket from engine.

(10) Remove cylinder head cover.

(11) Remove cam sensor and fuel injectors wiring

connectors.

(12) Remove intake manifoldSOHC ONLY.

Removal procedure outline in Group 11.

(13) Remove timing belt and camshaft sprocket.

Refer to procedure outlined in this section.

(14) Remove rocker arm shaft assemblies.

(15) Remove cylinder head bolts.

Fig. 27 Removing and Installing Valve Spring

Fig. 28 Valve Stem Oil Seal Tool

Fig. 29 Valve Spring Assembly

Fig. 30 Air Cleaner Inlet Duct

PL2.0L SOHC ENGINE 9 - 25

REMOVAL AND INSTALLATION (Continued)

Page 740 of 1200

For the rest of installation, reverse removal proce-

dure.

(3) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

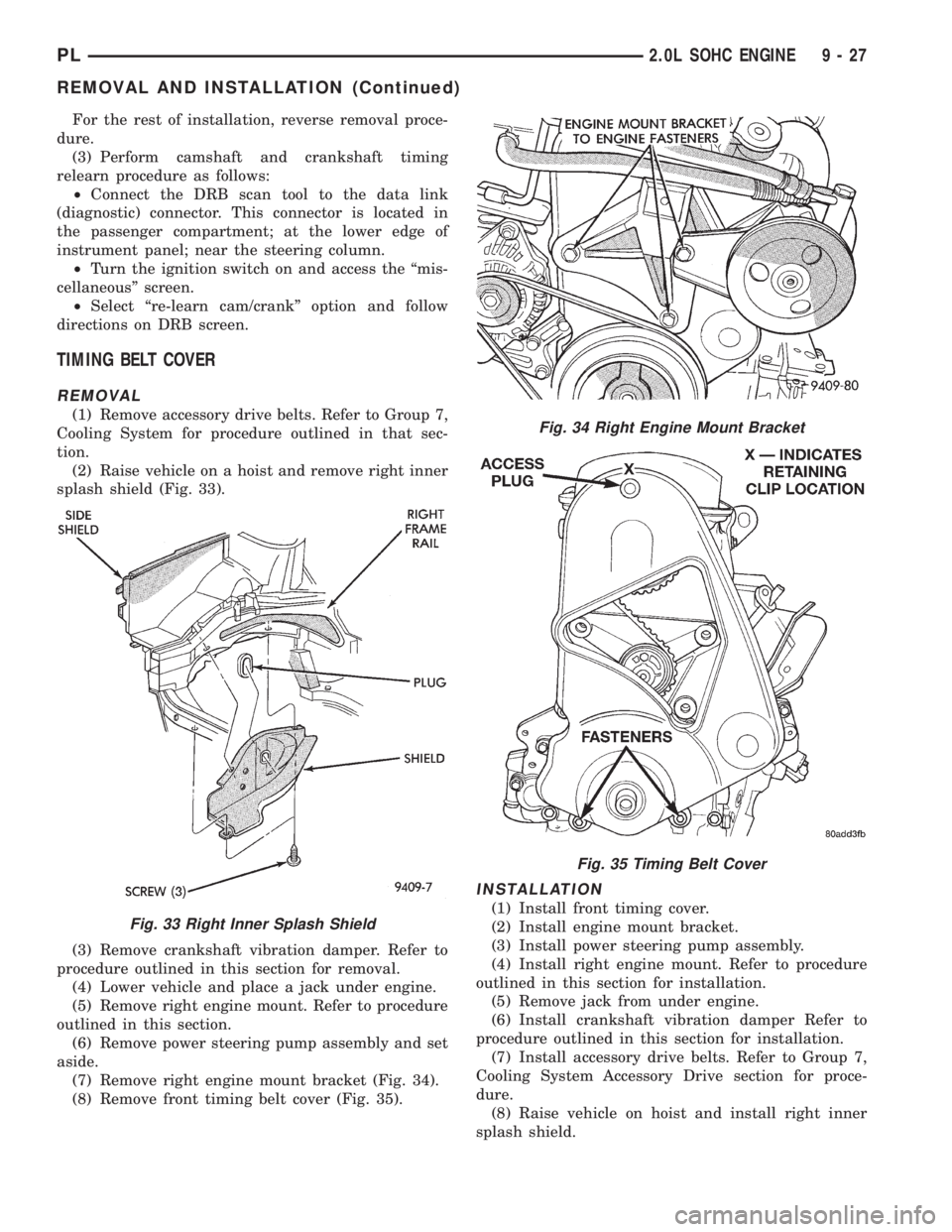

TIMING BELT COVER

REMOVAL

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure outlined in that sec-

tion.

(2) Raise vehicle on a hoist and remove right inner

splash shield (Fig. 33).

(3) Remove crankshaft vibration damper. Refer to

procedure outlined in this section for removal.

(4) Lower vehicle and place a jack under engine.

(5) Remove right engine mount. Refer to procedure

outlined in this section.

(6) Remove power steering pump assembly and set

aside.

(7) Remove right engine mount bracket (Fig. 34).

(8) Remove front timing belt cover (Fig. 35).

INSTALLATION

(1) Install front timing cover.

(2) Install engine mount bracket.

(3) Install power steering pump assembly.

(4) Install right engine mount. Refer to procedure

outlined in this section for installation.

(5) Remove jack from under engine.

(6) Install crankshaft vibration damper Refer to

procedure outlined in this section for installation.

(7) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive section for proce-

dure.

(8) Raise vehicle on hoist and install right inner

splash shield.

Fig. 33 Right Inner Splash Shield

Fig. 34 Right Engine Mount Bracket

Fig. 35 Timing Belt Cover

PL2.0L SOHC ENGINE 9 - 27

REMOVAL AND INSTALLATION (Continued)

Page 742 of 1200

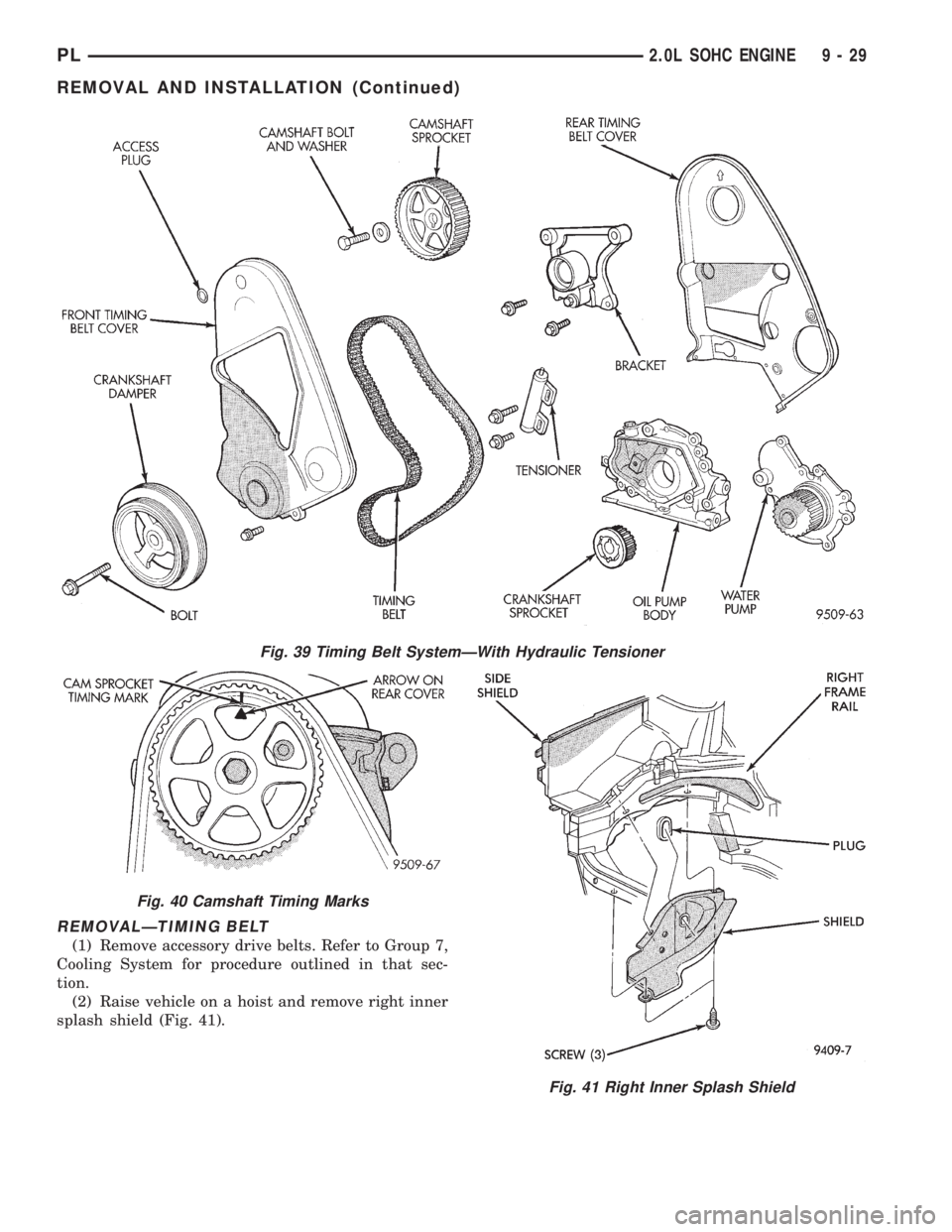

REMOVALÐTIMING BELT

(1) Remove accessory drive belts. Refer to Group 7,

Cooling System for procedure outlined in that sec-

tion.

(2) Raise vehicle on a hoist and remove right inner

splash shield (Fig. 41).

Fig. 39 Timing Belt SystemÐWith Hydraulic Tensioner

Fig. 40 Camshaft Timing Marks

Fig. 41 Right Inner Splash Shield

PL2.0L SOHC ENGINE 9 - 29

REMOVAL AND INSTALLATION (Continued)

Page 745 of 1200

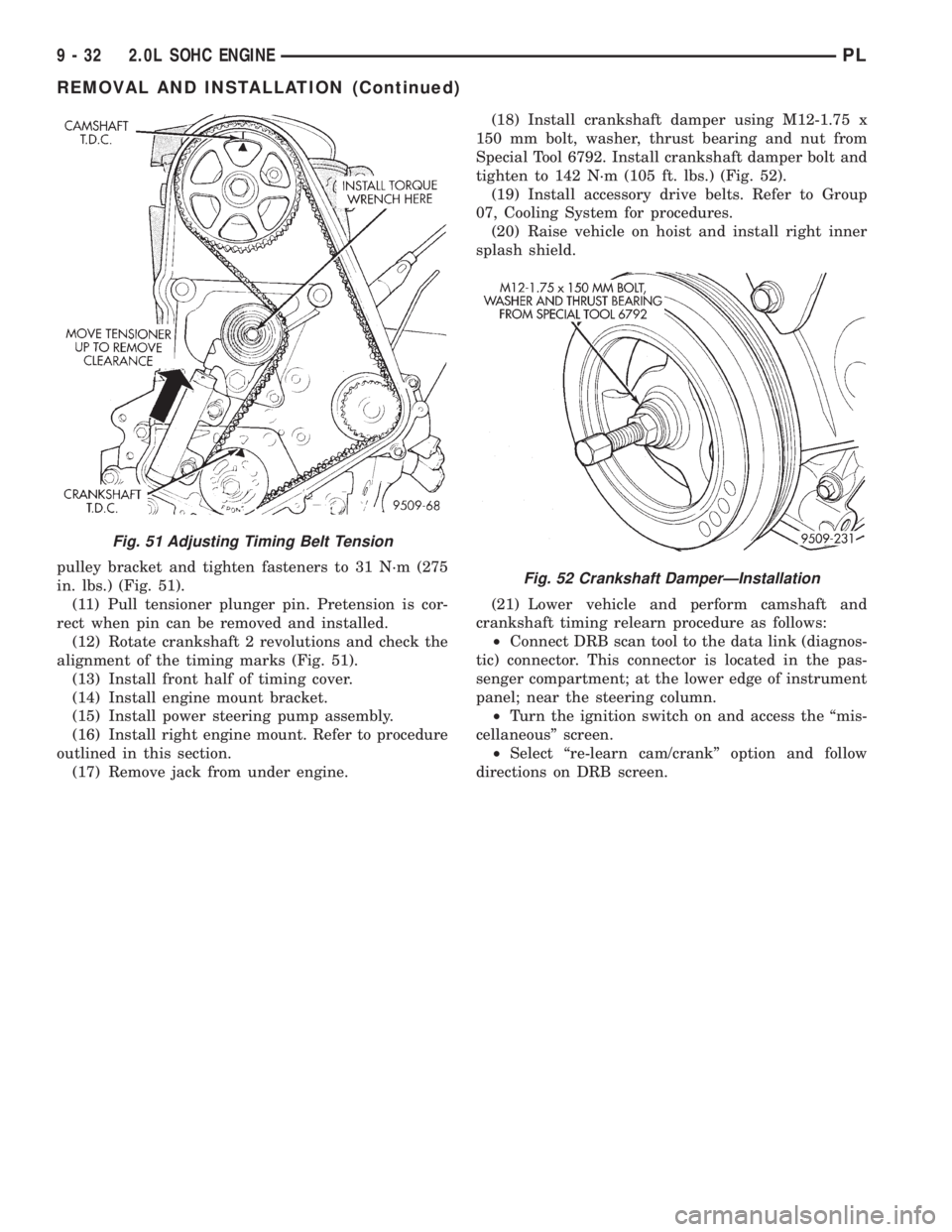

pulley bracket and tighten fasteners to 31 N´m (275

in. lbs.) (Fig. 51).

(11) Pull tensioner plunger pin. Pretension is cor-

rect when pin can be removed and installed.

(12) Rotate crankshaft 2 revolutions and check the

alignment of the timing marks (Fig. 51).

(13) Install front half of timing cover.

(14) Install engine mount bracket.

(15) Install power steering pump assembly.

(16) Install right engine mount. Refer to procedure

outlined in this section.

(17) Remove jack from under engine.(18) Install crankshaft damper using M12-1.75 x

150 mm bolt, washer, thrust bearing and nut from

Special Tool 6792. Install crankshaft damper bolt and

tighten to 142 N´m (105 ft. lbs.) (Fig. 52).

(19) Install accessory drive belts. Refer to Group

07, Cooling System for procedures.

(20) Raise vehicle on hoist and install right inner

splash shield.

(21) Lower vehicle and perform camshaft and

crankshaft timing relearn procedure as follows:

²Connect DRB scan tool to the data link (diagnos-

tic) connector. This connector is located in the pas-

senger compartment; at the lower edge of instrument

panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

Fig. 51 Adjusting Timing Belt Tension

Fig. 52 Crankshaft DamperÐInstallation

9 - 32 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)