relay DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 150 of 1200

ANTILOCK BRAKE SYSTEM±TEVES MARK 20

INDEX

page page

DESCRIPTION AND OPERATION

ABS BRAKE SYSTEM COMPONENTS........ 71

ABS BRAKES OPERATION AND VEHICLE

PERFORMANCE....................... 69

ABS COMPONENT ABBREVIATION LIST...... 69

ABS FLUID ACCUMULATORS.............. 72

ABS FUSES............................ 73

ABS MASTER CYLINDER AND POWER BRAKE

BOOSTER............................ 71

ABS RELAYS........................... 73

ABS WARNING LAMP (YELLOW)............ 75

ANTILOCK BRAKES OPERATION

DESCRIPTION........................ 69

CONTROLLER ANTILOCK BRAKES (CAB)..... 74

HCU PUMP/MOTOR..................... 72

HYDRAULIC CIRCUITS AND VALVE

OPERATION.......................... 75

INLET VALVES AND SOLENOIDS............ 72

INTEGRATED CONTROL UNIT (ICU)......... 71

OUTLET VALVES AND SOLENOIDS.......... 72

PROPORTIONING VALVE................. 73

WHEEL SPEED SENSORS................. 73

DIAGNOSIS AND TESTING

ABS DIAGNOSTIC TROUBLE CODES........ 78

ABS DIAGNOSTICS MANUAL.............. 76

ABS GENERAL DIAGNOSTICS INFORMATION . 75

ABS SERVICE PRECAUTIONS.............. 76

ABS SYSTEM SELF DIAGNOSTICS.......... 77ABS WIRING DIAGRAM INFORMATION....... 76

BRAKE FLUID CONTAMINATION............ 80

DRB DIAGNOSTIC CONNECTOR............ 77

DRB DIAGNOSTIC SCAN TOOL USAGE...... 77

INTERMITTENT DIAGNOSTIC TROUBLE

CODES.............................. 78

PROPORTIONING VALVE................. 79

TEST DRIVING ABS COMPLAINT VEHICLE.... 80

TONEWHEEL INSPECTION................ 79

SERVICE PROCEDURES

BLEEDING TEVES MARK 20 HYDRAULIC

SYSTEM............................. 81

BRAKE FLUID LEVEL INSPECTION.......... 80

REMOVAL AND INSTALLATION

ABS GENERAL SERVICE PRECAUTIONS..... 81

ABS HYDRAULIC CONTROL UNIT........... 82

CONTROLLER ANTILOCK BRAKES (CAB)..... 86

FRONT WHEEL SPEED SENSOR........... 87

MASTER CYLINDER AND POWER BRAKE

BOOSTER............................ 86

PROPORTIONING VALVES................ 86

REAR WHEEL SPEED SENSOR............ 88

SPECIFICATIONS

BRAKE FASTENER TORQUE SPECIFICATIONS . 89

SPEED SENSOR TONE WHEEL RUNOUT..... 89

WHEEL SPEED SENSOR TO TONE WHEEL

CLEARANCE.......................... 89

DESCRIPTION AND OPERATION

ANTILOCK BRAKES OPERATION DESCRIPTION

The purpose of an Antilock Brake System (ABS) is

to prevent wheel lock-up under braking conditions on

virtually any type of road surface. Antilock Braking

is desirable because a vehicle which is stopped with-

out locking the wheels will retain directional stability

and some steering capability. This allows the driver

to retain greater control of the vehicle during brak-

ing.

This section of the service manual covers the

description and on car service for the ITT Teves

Mark 20 ABS Brake System. If other service is

required on the non ABS related components of the

brake system, refer to the appropriate section in this

group of the service manual for the specific service

procedure required.

ABS COMPONENT ABBREVIATION LIST

In this section of the service manual, several

abbreviations are used for the components of the

Teves Mark 20 ABS Brake System. They are listed

below for your reference.

²CAB±Controller Antilock Brake

²ICU±Integrated Control Unit

²HCU±Hydraulic Control Unit

²ABS±Antilock Brake System

²PSI±Pounds Per Square Inch (pressure)

²WSS±Wheel Speed Sensor

²FWD±Front Wheel Drive

²DTC±Diagnostic Trouble Code

ABS BRAKES OPERATION AND VEHICLE

PERFORMANCE

This ABS System represents the current state-of-

the-art in vehicle braking systems and offers the

driver increased safety and control during braking.

PLBRAKES 5 - 69

Page 154 of 1200

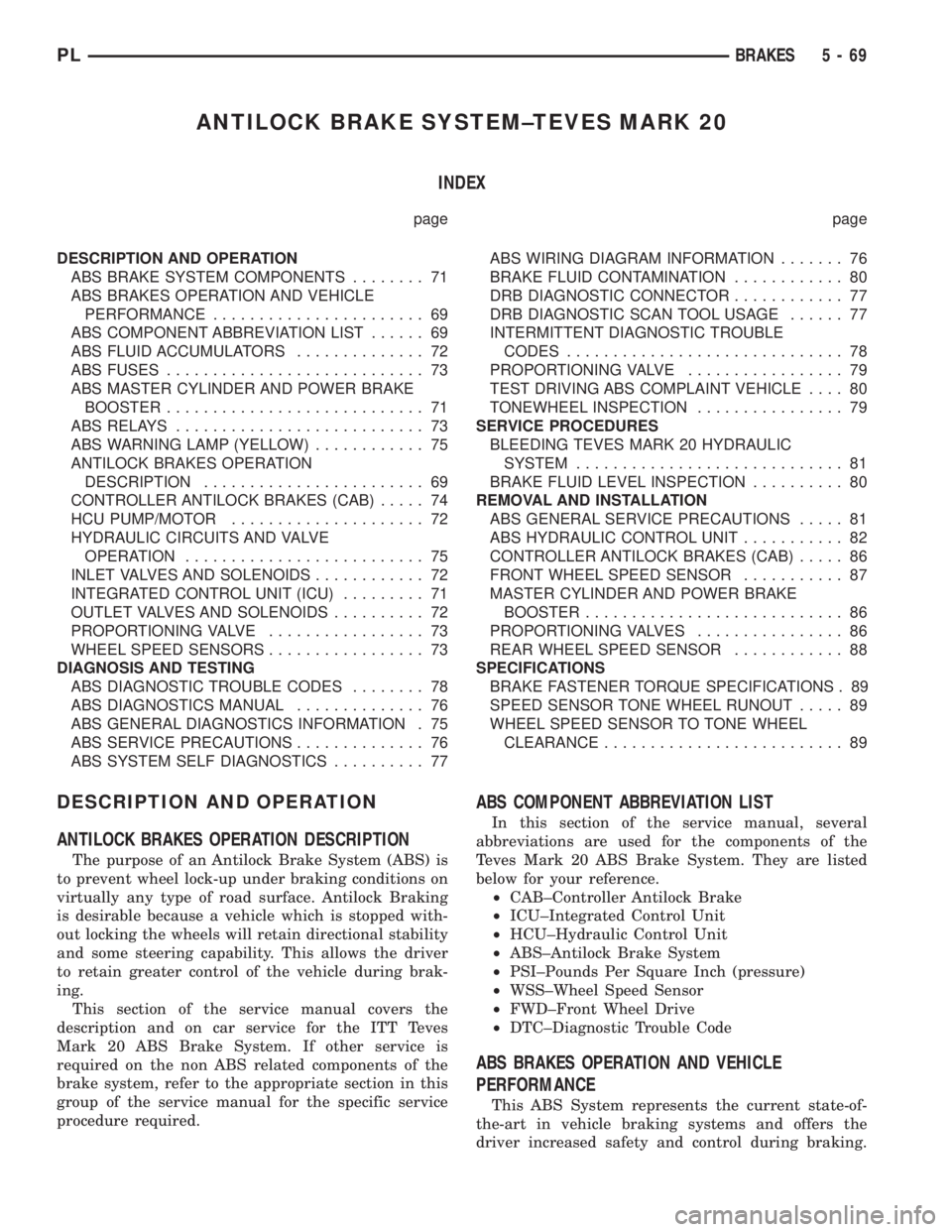

ABS FUSES

The fuse for the ABS pump motor and the ABS

system are located in the power distribution center

(PDC) (Fig. 5). Refer to the sticker on the inside of

the PDC cover for the location of the ABS pump

motor and the ABS system fuse in the PDC. The

PDC is located on the drivers side of the engine com-

partment between the back of the battery and the

strut tower (Fig. 5).

ABS RELAYS

On this vehicle three relays are used to control the

Teves Mark 20 Antilock Brake System. The three

relays are the pump motor relay, the system relay,

and the ABS yellow warning lamp relay. The pump

motor relay and the system relay are located in the

CAB and the ABS yellow warning lamp relay is

located in the PDC. If either the pump motor relay or

the system relay is diagnosed as not functioning

properly the CAB will need to be replaced. Refer to

Controller Antilock Brakes in the Removal And

Installation Section in this group of the service man-

ual for the procedure. If the ABS yellow warning

lamp relay is diagnosed as not functioning properly it

can be replaced as a seperated relay in the PDC.

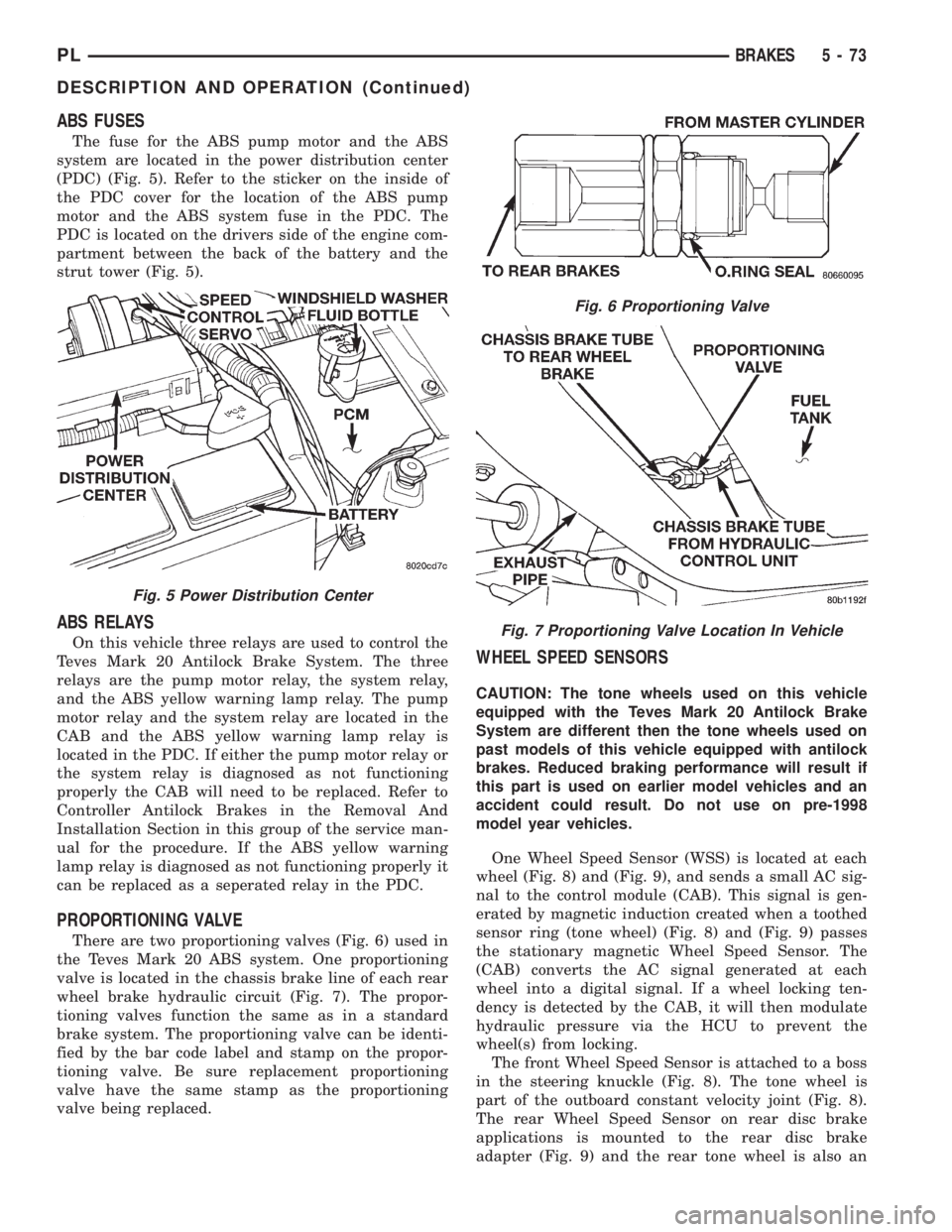

PROPORTIONING VALVE

There are two proportioning valves (Fig. 6) used in

the Teves Mark 20 ABS system. One proportioning

valve is located in the chassis brake line of each rear

wheel brake hydraulic circuit (Fig. 7). The propor-

tioning valves function the same as in a standard

brake system. The proportioning valve can be identi-

fied by the bar code label and stamp on the propor-

tioning valve. Be sure replacement proportioning

valve have the same stamp as the proportioning

valve being replaced.

WHEEL SPEED SENSORS

CAUTION: The tone wheels used on this vehicle

equipped with the Teves Mark 20 Antilock Brake

System are different then the tone wheels used on

past models of this vehicle equipped with antilock

brakes. Reduced braking performance will result if

this part is used on earlier model vehicles and an

accident could result. Do not use on pre-1998

model year vehicles.

One Wheel Speed Sensor (WSS) is located at each

wheel (Fig. 8) and (Fig. 9), and sends a small AC sig-

nal to the control module (CAB). This signal is gen-

erated by magnetic induction created when a toothed

sensor ring (tone wheel) (Fig. 8) and (Fig. 9) passes

the stationary magnetic Wheel Speed Sensor. The

(CAB) converts the AC signal generated at each

wheel into a digital signal. If a wheel locking ten-

dency is detected by the CAB, it will then modulate

hydraulic pressure via the HCU to prevent the

wheel(s) from locking.

The front Wheel Speed Sensor is attached to a boss

in the steering knuckle (Fig. 8). The tone wheel is

part of the outboard constant velocity joint (Fig. 8).

The rear Wheel Speed Sensor on rear disc brake

applications is mounted to the rear disc brake

adapter (Fig. 9) and the rear tone wheel is also an

Fig. 5 Power Distribution Center

Fig. 6 Proportioning Valve

Fig. 7 Proportioning Valve Location In Vehicle

PLBRAKES 5 - 73

DESCRIPTION AND OPERATION (Continued)

Page 156 of 1200

cally cleared from the CAB memory after the identi-

cal fault has not been seen during the next 255 key

cycles of vehicle operation.

CONTROLLER ANTILOCK BRAKE INPUTS

²Four wheel speed sensors.

²Stop lamp switch.

²Ignition switch.

²System relay voltage.

²Ground.

²Diagnostics Communications (CCD)

CONTROLLER ANTILOCK BRAKE OUTPUTS

²ABS warning lamp actuation.

²Diagnostic communication. (CCD)

ABS WARNING LAMP (YELLOW)

The ABS system uses a yellow colored ABS Warn-

ing Lamp. The ABS warning lamp is located on the

lower left side of the instrument pane. The purpose

of the warning lamp is discussed in detail below.

The ABS warning lamp will turn on when the CAB

detects a condition which results in a shutdown of

ABS function. When the ignition key is turned to the

on position, the ABS Warning Lamp is on until the

CAB completes its self tests and turns the lamp off

(approximately 4 seconds after the ignition switch is

turned on). Under most conditions, when the ABS

warning lamp is on, only the ABS function of the

brake system is affected. The standard brake system

and the ability to stop the car will not be affected

when only the ABS warning lamp is on.

The ABS warning lamp is controlled by the CAB.

The CAB turns on the yellow ABS warning lamp by

grounding the circuit.

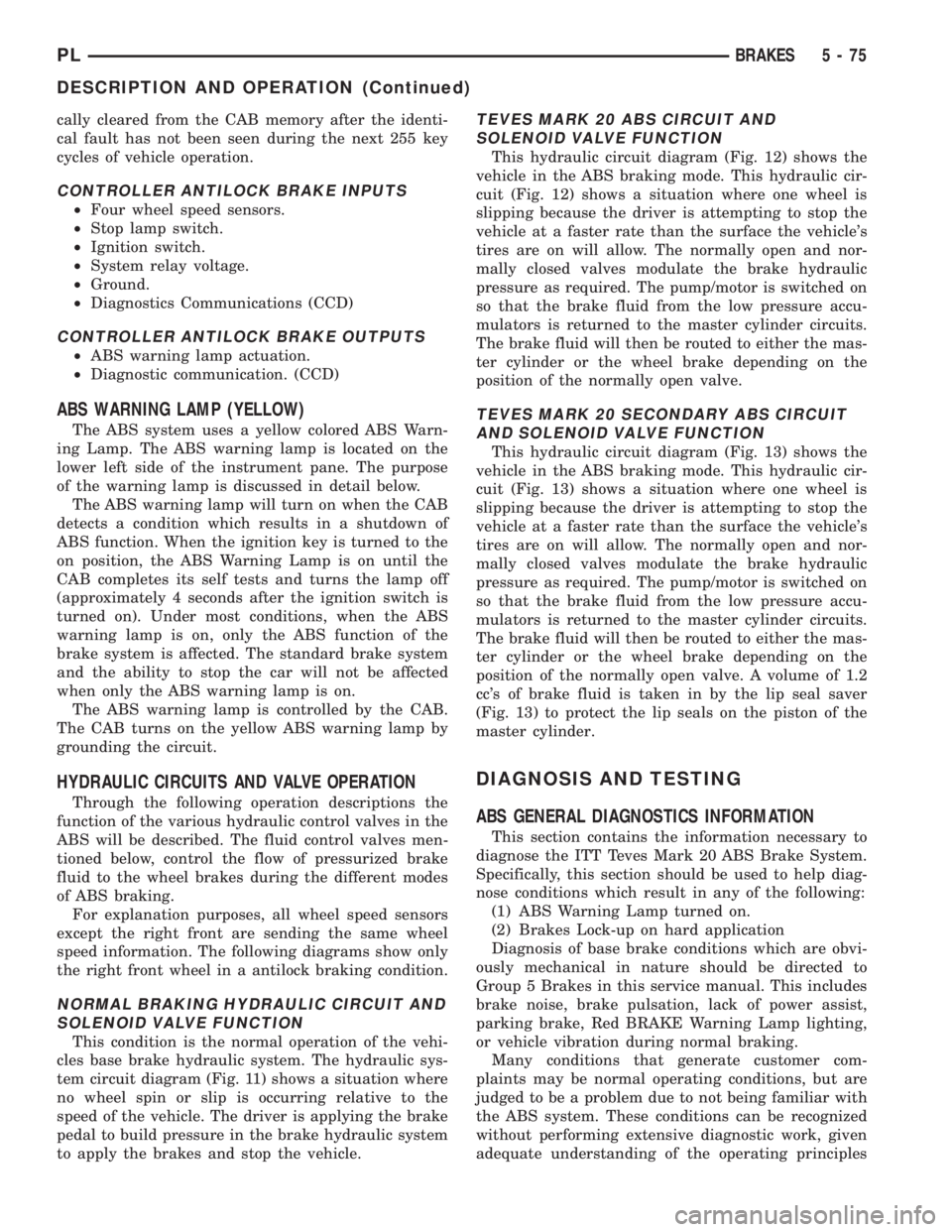

HYDRAULIC CIRCUITS AND VALVE OPERATION

Through the following operation descriptions the

function of the various hydraulic control valves in the

ABS will be described. The fluid control valves men-

tioned below, control the flow of pressurized brake

fluid to the wheel brakes during the different modes

of ABS braking.

For explanation purposes, all wheel speed sensors

except the right front are sending the same wheel

speed information. The following diagrams show only

the right front wheel in a antilock braking condition.

NORMAL BRAKING HYDRAULIC CIRCUIT AND

SOLENOID VALVE FUNCTION

This condition is the normal operation of the vehi-

cles base brake hydraulic system. The hydraulic sys-

tem circuit diagram (Fig. 11) shows a situation where

no wheel spin or slip is occurring relative to the

speed of the vehicle. The driver is applying the brake

pedal to build pressure in the brake hydraulic system

to apply the brakes and stop the vehicle.

TEVES MARK 20 ABS CIRCUIT AND

SOLENOID VALVE FUNCTION

This hydraulic circuit diagram (Fig. 12) shows the

vehicle in the ABS braking mode. This hydraulic cir-

cuit (Fig. 12) shows a situation where one wheel is

slipping because the driver is attempting to stop the

vehicle at a faster rate than the surface the vehicle's

tires are on will allow. The normally open and nor-

mally closed valves modulate the brake hydraulic

pressure as required. The pump/motor is switched on

so that the brake fluid from the low pressure accu-

mulators is returned to the master cylinder circuits.

The brake fluid will then be routed to either the mas-

ter cylinder or the wheel brake depending on the

position of the normally open valve.

TEVES MARK 20 SECONDARY ABS CIRCUIT

AND SOLENOID VALVE FUNCTION

This hydraulic circuit diagram (Fig. 13) shows the

vehicle in the ABS braking mode. This hydraulic cir-

cuit (Fig. 13) shows a situation where one wheel is

slipping because the driver is attempting to stop the

vehicle at a faster rate than the surface the vehicle's

tires are on will allow. The normally open and nor-

mally closed valves modulate the brake hydraulic

pressure as required. The pump/motor is switched on

so that the brake fluid from the low pressure accu-

mulators is returned to the master cylinder circuits.

The brake fluid will then be routed to either the mas-

ter cylinder or the wheel brake depending on the

position of the normally open valve. A volume of 1.2

cc's of brake fluid is taken in by the lip seal saver

(Fig. 13) to protect the lip seals on the piston of the

master cylinder.

DIAGNOSIS AND TESTING

ABS GENERAL DIAGNOSTICS INFORMATION

This section contains the information necessary to

diagnose the ITT Teves Mark 20 ABS Brake System.

Specifically, this section should be used to help diag-

nose conditions which result in any of the following:

(1) ABS Warning Lamp turned on.

(2) Brakes Lock-up on hard application

Diagnosis of base brake conditions which are obvi-

ously mechanical in nature should be directed to

Group 5 Brakes in this service manual. This includes

brake noise, brake pulsation, lack of power assist,

parking brake, Red BRAKE Warning Lamp lighting,

or vehicle vibration during normal braking.

Many conditions that generate customer com-

plaints may be normal operating conditions, but are

judged to be a problem due to not being familiar with

the ABS system. These conditions can be recognized

without performing extensive diagnostic work, given

adequate understanding of the operating principles

PLBRAKES 5 - 75

DESCRIPTION AND OPERATION (Continued)

Page 158 of 1200

DRB DIAGNOSTIC SCAN TOOL USAGE

The diagnostics of the ITT Teves Mark 20 ABS sys-

tem used on this vehicle is performed using the DRB

scan tool. Refer to the diagnostics manual covering

the ITT Teves Mark 20 ABS system for the required

diagnostics ans testing procedures and the DRB oper-

ators manual for its proper operational information.

DRB DIAGNOSTIC CONNECTOR

On this vehicle, the diagnostics connector used for

diagnosing the Teves Mark 20 ABS system is located

under the steering column lower cover, to the left

side of the steering column (Fig. 14). The Teves Mark

20 ABS system uses the CCD connector which is

shared by other vehicle diagnostic systems such as

the powertrain control module and air bag.

ABS SYSTEM SELF DIAGNOSTICS

The ITT Teves Mark 20 ABS system is equipped

with a self diagnostic capability which may be used

to assist in the isolation of ABS faults. The features

of the self diagnostics system are described below.

START-UP CYCLE

The self diagnostic ABS start up cycle begins when

the ignition switch is turned to the on position. Elec-

trical checks are completed on ABS components, suchas the Controller, solenoid continuity, and the system

relay operation. During this check the Amber ABS

Warning Light is turned on for approximately 5 sec-

onds and the brake pedal may emit a popping sound

and move slightly when the solenoid valves are

checked.

DRIVE-OFF CYCLE

Further Functional testing is accomplished once

the vehicle is set in motion and reaches a speed of

about 20 kph (12 mph.). This cycle is performed only

once after each ignition on/off cycle.

²The pump/motor is activated briefly to verify

function. When the pump/motor is activated a whirl-

ing or buzzing sound may be heard by the driver,

which is normal when the pump/motor is running.

²The wheel speed sensor output is verified to be

within the correct operating range.

ONGOING TESTS

Other tests are performed on a continuous basis.

These include checks for solenoid continuity, wheel

speed sensor continuity and wheel speed sensor out-

put.

Fig. 12 ABS Mode Hydraulic Circuit

PLBRAKES 5 - 77

DIAGNOSIS AND TESTING (Continued)

Page 160 of 1200

A visual inspection for loose, disconnected, or mis-

routed wires should be done before attempting to

diagnose or service the ITT Teves Mark 20 antilock

brake system. A visual inspection will eliminate

unnecessary testing and diagnostics time. A thorough

visual inspection will include the following compo-

nents and areas of the vehicle.

(1) Inspect fuses in the power distribution center

(PDC) and the wiring junction block. Verify that all

fuses are fully inserted into the PDC and wring junc-

tion block. A label on the underside of the PDC cover

identifies the locations of the ABS fuses in the PDC.

(2) Inspect the 25-way electrical connector at the

CAB for damage, spread or backed-out wiring termi-

nals. Verify that the 25-way connector is fully

inserted in the socket on the CAB. Be sure that wires

are not stretched tight or pulled out of the connector.

(3) Verify that all the wheel speed sensor connec-

tions are secure.

(4) Poor mating of connector halves or terminals

not fully seated in the connector body.

(5) Improperly formed or damaged terminals. All

connector terminals in a suspect circuit should be

carefully reformed to increase contact tension.

(6) Poor terminal to wire connection. This requires

removing the terminal from the connector body to

inspect.

(7) Pin presence in the connector assembly

(8) Proper ground connections. Check all ground

connections for signs of corrosion, tight fasteners, or

other potential defects. Refer to wiring diagram man-

ual for ground locations.

(9) Problems with main power sources of the vehi-

cle. Inspect battery, generator, ignition circuits and

other related relays and fuses.

(10) If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record the trouble code.

(11) Most failures of the ABS system will disable

ABS function for the entire ignition cycle even if the

fault clears before key-off. There are some failure

conditions, however, which will allow ABS operation

to resume during the ignition cycle in which a failure

occurred if the failure conditions are no longer

present. The following conditions may result in inter-

mittent illumination of the ABS Warning Lamp. All

other failures will cause the lamp to remain on until

the ignition switch is turned off. Circuits involving

these inputs to the CAB should be investigated if a

complaint of intermittent warning system operation

is encountered.

(12) Low system voltage. If Low System Voltage is

detected by the CAB, the CAB will turn on the ABS

Warning Lamp until normal system voltage is

achieved. Once normal voltage is seen at the CAB,

normal operation resumes.(13) High system voltage. If high system voltage is

detected by the CAB, the CAB will turn on the

Amber ABS Warning Lamp until normal system volt-

age is achieved. Once normal voltage is again

detected by the CAB, normal ABS operation resumes.

(14) Additionally, any condition which results in

interruption of electrical current to the CAB or mod-

ulator assembly may cause the ABS Warning Lamp

to turn on intermittently.

(15) The body controller can turn on the (yellow)

ABS warning lamp if CCD communication between

the body controller and the CAB is interupted.

TONEWHEEL INSPECTION

CAUTION: The tone wheels used on this vehicle

equipped with the Teves Mark 20 Antilock Brake

System are different then those used on past mod-

els of this vehicle equipped with antilock brakes.

Reduced braking performance will result if this part

is used on earlier model vehicles and an accident

could result. Do not use on pre-1998 model year

vehicles.

Carefully inspect tonewheel at the suspected faulty

wheel speed sensor for missing, chipped or broken

teeth, this can cause erratic speed sensor signals.

Tonewheels should show no evidence of contact

with the wheel speed sensors. If contact was made,

determine cause and correct before replacing the

wheel speed sensor.

Excessive runout of the tonewheel can cause

erratic wheel speed sensor signals. Refer to Tone-

wheel Runout in the Specification Section in this sec-

tion of the service manual for the tonewheel runout

specification. Replace drive shaft assembly or rear

hub/bearing assembly if tonewheel runout exceeds

the specification.

Inspect tonewheels for looseness on their mounting

surfaces. Tonewheels are pressed onto their mounting

surfaces and should not rotate independently from

the mounting surface.

Check the wheel speed sensor head alignment to

the tone wheel. Also check the gap between the speed

sensor head and the tone wheel to ensure it is at

specification. Refer to Wheel Speed Sensor Clearance

in the Specification Section in this section of the ser-

vice manual.

PROPORTIONING VALVE

CAUTION: Proportioning valves should never be

disassembled.

If premature rear wheel skid occurs on a hard

brake application, it could be an indication that a

PLBRAKES 5 - 79

DIAGNOSIS AND TESTING (Continued)

Page 173 of 1200

The clutch cable has a unique self-adjuster mecha-

nism built into the cable which compensates for

clutch disc wear. The cable requires no maintenance

or lubrication. There are no serviceable components

on the cable assembly.

The clutch pedal is connected to the cable through

a plastic spacer. The upper end of the clutch pedal

pivots in the pedal bracket on two nylon bushings

and a shaft. These bushings are greased at assembly

and do not require periodic lubrication.

CLUTCH DISC AND COVER APPLICATION

The 2.0 single overhead cam engine uses a 216 mm

(8.5 in.) clutch disc. The manual transaxle is avail-

able only with the 2.0 liter engine.

CLUTCH REPLACEMENT

The transaxle must be removed to service the

clutch disc, pressure plate, flywheel/drive plate,

and/or clutch release bearing and lever.

DESCRIPTION AND OPERATION

CLUTCH CABLE

The manual transaxle clutch release system has a

unique self-adjusting mechanism to compensate for

clutch disc wear. This adjuster mechanism is located

within the clutch cable assembly. The preload spring

maintains tension on the cable. This tension keeps

the clutch release bearing continuously loaded

against the fingers of the clutch cover assembly.

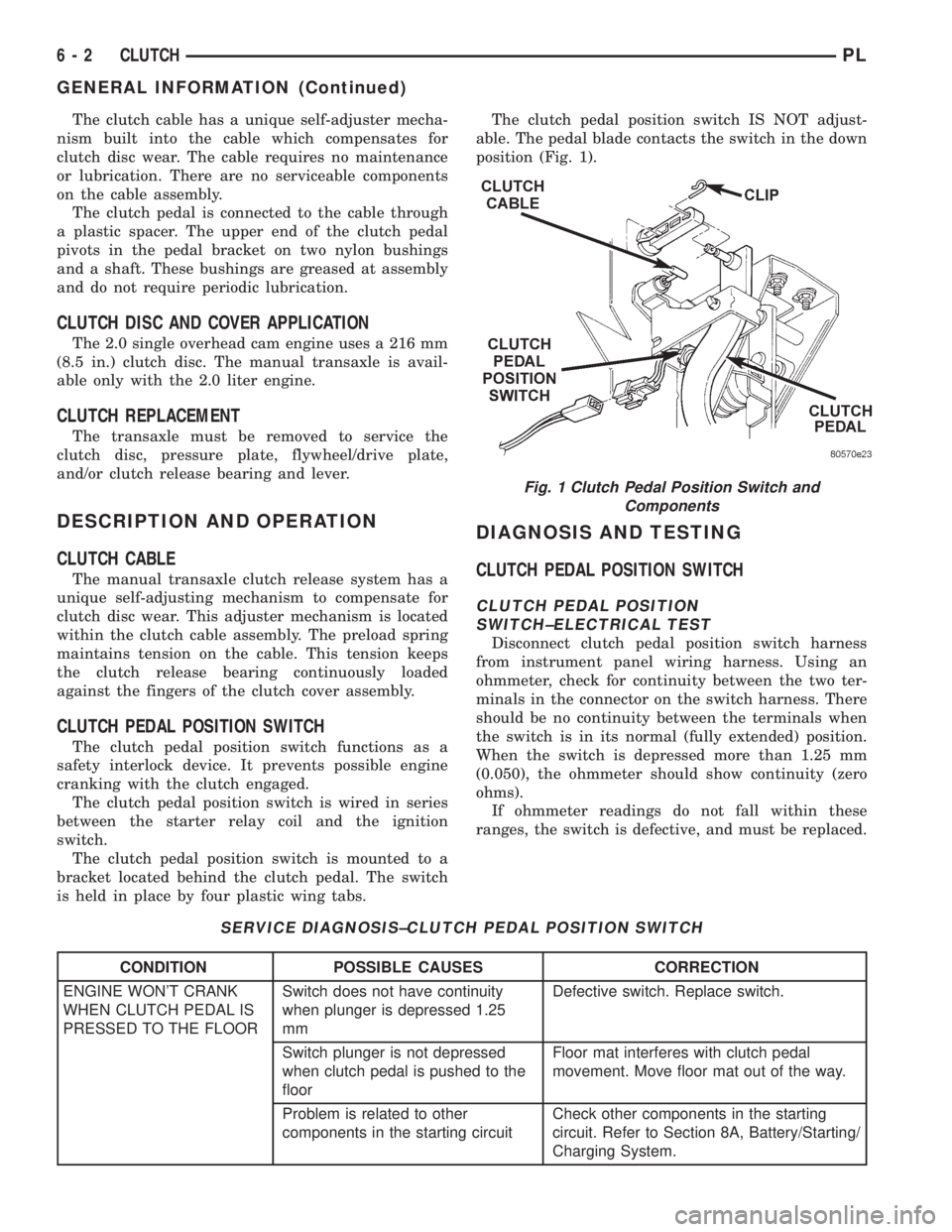

CLUTCH PEDAL POSITION SWITCH

The clutch pedal position switch functions as a

safety interlock device. It prevents possible engine

cranking with the clutch engaged.

The clutch pedal position switch is wired in series

between the starter relay coil and the ignition

switch.

The clutch pedal position switch is mounted to a

bracket located behind the clutch pedal. The switch

is held in place by four plastic wing tabs.The clutch pedal position switch IS NOT adjust-

able. The pedal blade contacts the switch in the down

position (Fig. 1).

DIAGNOSIS AND TESTING

CLUTCH PEDAL POSITION SWITCH

CLUTCH PEDAL POSITION

SWITCH±ELECTRICAL TEST

Disconnect clutch pedal position switch harness

from instrument panel wiring harness. Using an

ohmmeter, check for continuity between the two ter-

minals in the connector on the switch harness. There

should be no continuity between the terminals when

the switch is in its normal (fully extended) position.

When the switch is depressed more than 1.25 mm

(0.050), the ohmmeter should show continuity (zero

ohms).

If ohmmeter readings do not fall within these

ranges, the switch is defective, and must be replaced.

SERVICE DIAGNOSIS±CLUTCH PEDAL POSITION SWITCH

CONDITION POSSIBLE CAUSES CORRECTION

ENGINE WON'T CRANK

WHEN CLUTCH PEDAL IS

PRESSED TO THE FLOORSwitch does not have continuity

when plunger is depressed 1.25

mmDefective switch. Replace switch.

Switch plunger is not depressed

when clutch pedal is pushed to the

floorFloor mat interferes with clutch pedal

movement. Move floor mat out of the way.

Problem is related to other

components in the starting circuitCheck other components in the starting

circuit. Refer to Section 8A, Battery/Starting/

Charging System.

Fig. 1 Clutch Pedal Position Switch and

Components

6 - 2 CLUTCHPL

GENERAL INFORMATION (Continued)

Page 207 of 1200

WATER PUMP DIAGNOSIS

A quick flow test to tell whether or not the pump is

working is to see if the heater warms properly. A

defective pump will not be able to circulate heated

coolant through the long heater hose.

Another flow test to help determine pump opera-

tion.

WARNING: DO NOT remove radiator cap if the cool-

ing system is hot or under pressure.

(1) Remove radiator cap.

(2) Remove a small amount of coolant from the

system, start the engine and warm up until thermo-

stat opens. With the thermostat open and coolant

level low you will see if the water pump is pumping

coolant through the system.

COOLING SYSTEM FLOW CHECK

To determine whether coolant is flowing through

the cooling system, use the following procedures:

(1) If engine is cold, idle engine until normal oper-

ating temperature is reached. Then feel the upper

radiator hose. If it is hot, coolant is circulating.

WARNING: DO NOT REMOVE THE COOLING SYS-

TEM PRESSURE CAP WITH THE SYSTEM HOT AND

UNDER PRESSURE BECAUSE SERIOUS BURNS

FROM COOLANT CAN OCCUR.

(2) Remove pressure cap when engine is cold,

remove small amount of coolant Idle engine until

thermostat opens, you should observe coolant flow

while looking down the filler neck. Once flow is

detected install the pressure cap.

RADIATOR FAN CONTROL

Fan control is accomplished two ways. The fan

always runs when the air conditioning compressor

clutch is engaged. In addition to this control, the fan

is turned on by the temperature of the coolant which

is sensed by the coolant temperature sensor which

sends the message to the Powertrain Control Module

(PCM). The (PCM) turns on the fan through the

Solid State Fan Relay. The Solid State Fan Relay is

located on the left front inner frame just behind the

radiator. See Wiring Diagrams Manual for circuity

and diagnostics provided.

Switching through the (PCM) provides fan control

for the following conditions.

²The fan will not run during cranking until the

engine starts no matter what the coolant tempera-

ture is.

²Fan will run when the air conditioning clutch is

engaged and low pressure cutout switch is closed.

²Fan will run at vehicle speeds above about 40

mph only if coolant temperature reaches 110ÉC(230ÉF). It will turn off when the temperature drops

to 104ÉC (220ÉF). At speeds below 40 mph the fan

switches on at 102ÉC (215ÉF) and off at 93ÉC (200ÉF).

Refer to Radiator Fan Control Module Group 14,

Fuel Injection for more information.

ELECTRIC FAN MOTOR TEST

Refer to Powertrain Diagnostic Manual for procedure.

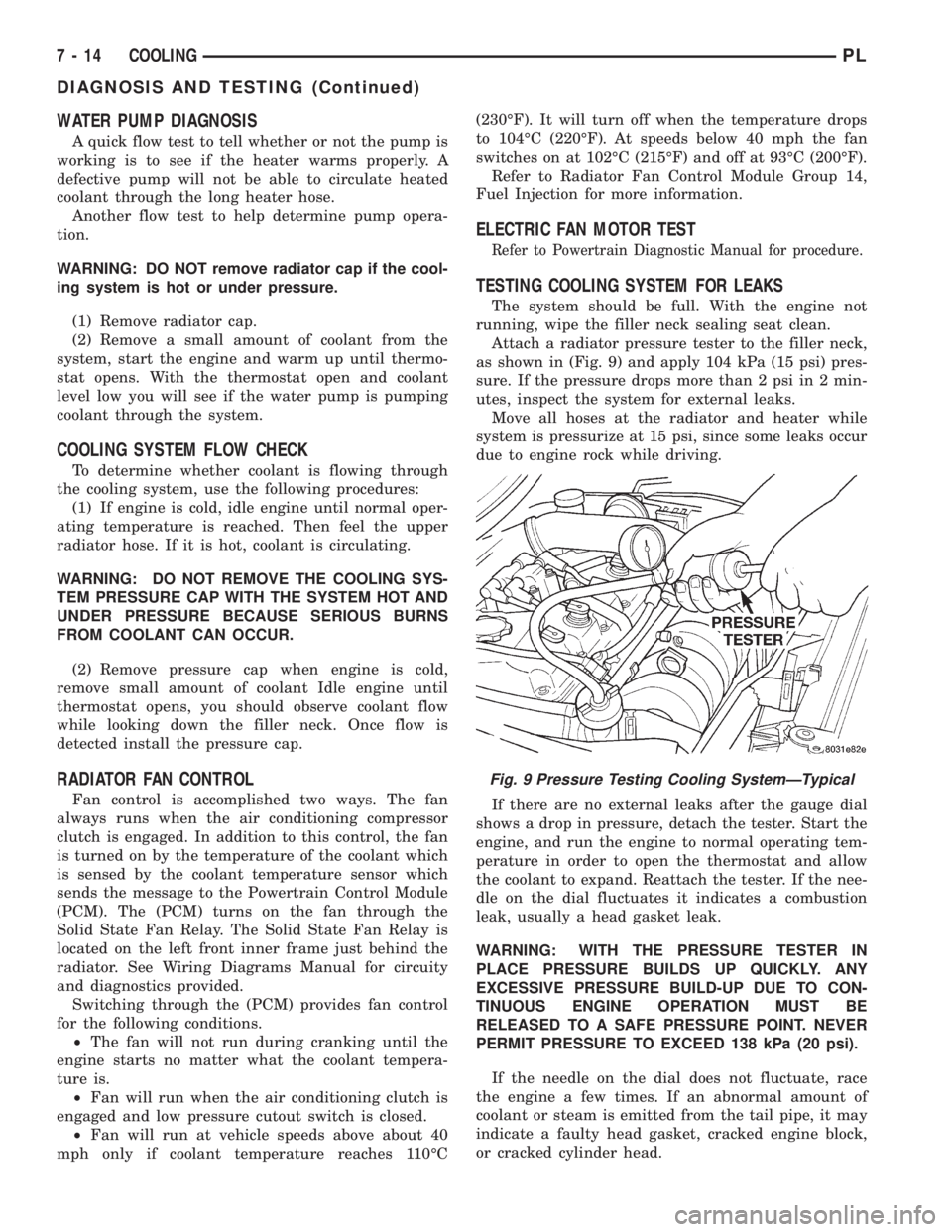

TESTING COOLING SYSTEM FOR LEAKS

The system should be full. With the engine not

running, wipe the filler neck sealing seat clean.

Attach a radiator pressure tester to the filler neck,

as shown in (Fig. 9) and apply 104 kPa (15 psi) pres-

sure. If the pressure drops more than 2 psi in 2 min-

utes, inspect the system for external leaks.

Move all hoses at the radiator and heater while

system is pressurize at 15 psi, since some leaks occur

due to engine rock while driving.

If there are no external leaks after the gauge dial

shows a drop in pressure, detach the tester. Start the

engine, and run the engine to normal operating tem-

perature in order to open the thermostat and allow

the coolant to expand. Reattach the tester. If the nee-

dle on the dial fluctuates it indicates a combustion

leak, usually a head gasket leak.

WARNING: WITH THE PRESSURE TESTER IN

PLACE PRESSURE BUILDS UP QUICKLY. ANY

EXCESSIVE PRESSURE BUILD-UP DUE TO CON-

TINUOUS ENGINE OPERATION MUST BE

RELEASED TO A SAFE PRESSURE POINT. NEVER

PERMIT PRESSURE TO EXCEED 138 kPa (20 psi).

If the needle on the dial does not fluctuate, race

the engine a few times. If an abnormal amount of

coolant or steam is emitted from the tail pipe, it may

indicate a faulty head gasket, cracked engine block,

or cracked cylinder head.

Fig. 9 Pressure Testing Cooling SystemÐTypical

7 - 14 COOLINGPL

DIAGNOSIS AND TESTING (Continued)

Page 228 of 1200

STARTING

CONTENTS

page page

GENERAL INFORMATION

BOSCH STARTER........................ 1

INTRODUCTION......................... 1

SUPPLY CIRCUIT AND CONTROL CIRCUIT.... 1

DIAGNOSIS AND TESTING

FEED CIRCUIT RESISTANCE TEST........... 2

FEED CIRCUIT TEST...................... 2

STARTER CONTROL CIRCUIT.............. 1STARTING SYSTEM TEST................. 4

REMOVAL AND INSTALLATION

SAFETY SWITCHES...................... 6

STARTER RELAY........................ 7

STARTER .............................. 6

SPECIFICATIONS

STARTER .............................. 7

TORQUE............................... 7

GENERAL INFORMATION

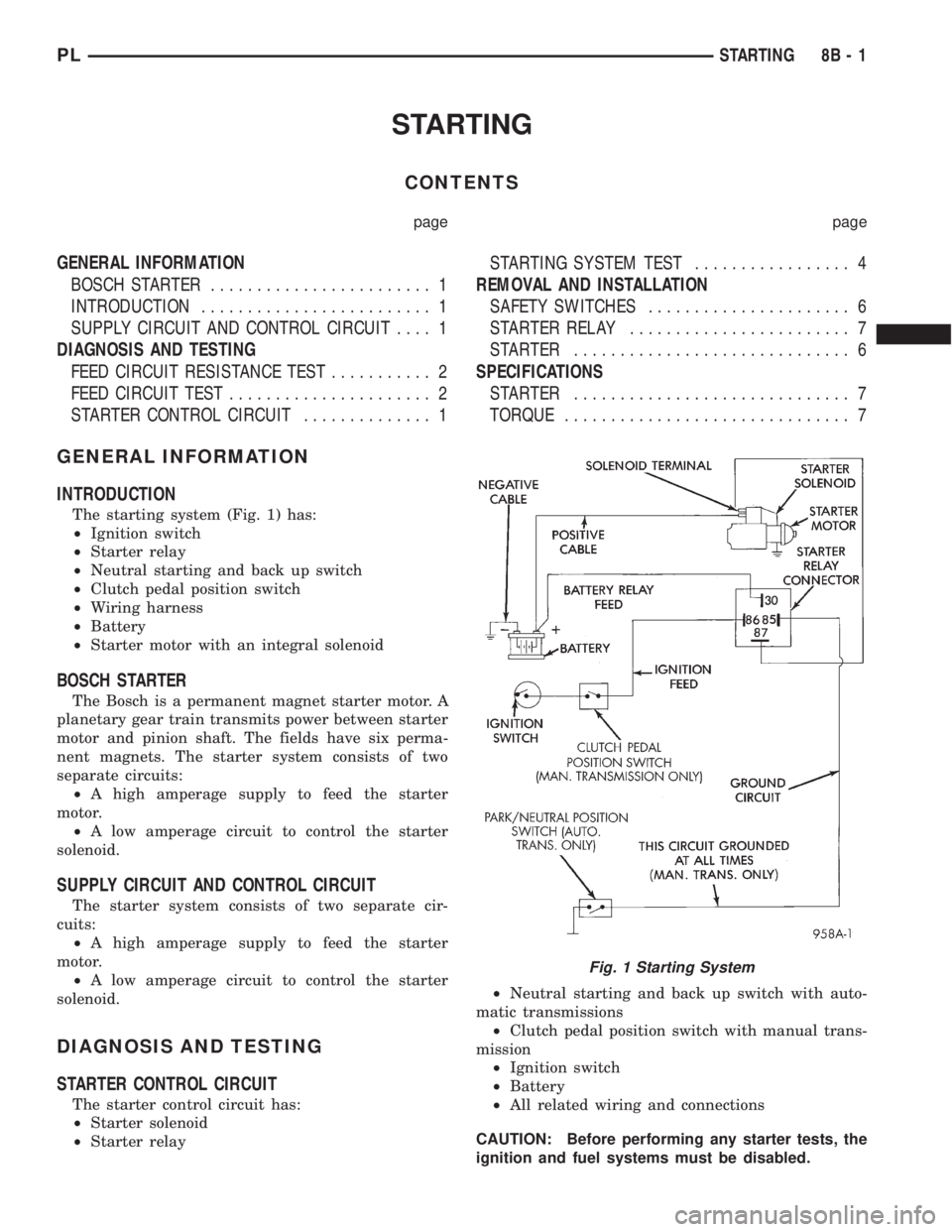

INTRODUCTION

The starting system (Fig. 1) has:

²Ignition switch

²Starter relay

²Neutral starting and back up switch

²Clutch pedal position switch

²Wiring harness

²Battery

²Starter motor with an integral solenoid

BOSCH STARTER

The Bosch is a permanent magnet starter motor. A

planetary gear train transmits power between starter

motor and pinion shaft. The fields have six perma-

nent magnets. The starter system consists of two

separate circuits:

²A high amperage supply to feed the starter

motor.

²A low amperage circuit to control the starter

solenoid.

SUPPLY CIRCUIT AND CONTROL CIRCUIT

The starter system consists of two separate cir-

cuits:

²A high amperage supply to feed the starter

motor.

²A low amperage circuit to control the starter

solenoid.

DIAGNOSIS AND TESTING

STARTER CONTROL CIRCUIT

The starter control circuit has:

²Starter solenoid

²Starter relay²Neutral starting and back up switch with auto-

matic transmissions

²Clutch pedal position switch with manual trans-

mission

²Ignition switch

²Battery

²All related wiring and connections

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

Fig. 1 Starting System

PLSTARTING 8B - 1

Page 229 of 1200

To disable the ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the Power Distribution Center (PDC).

Refer to the PDC cover for proper relay location.

FEED CIRCUIT RESISTANCE TEST

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition system also must be disabled

to prevent engine start while performing the follow-

ing tests.

(1) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) With all wiring harnesses and components

properly connected, perform the following:

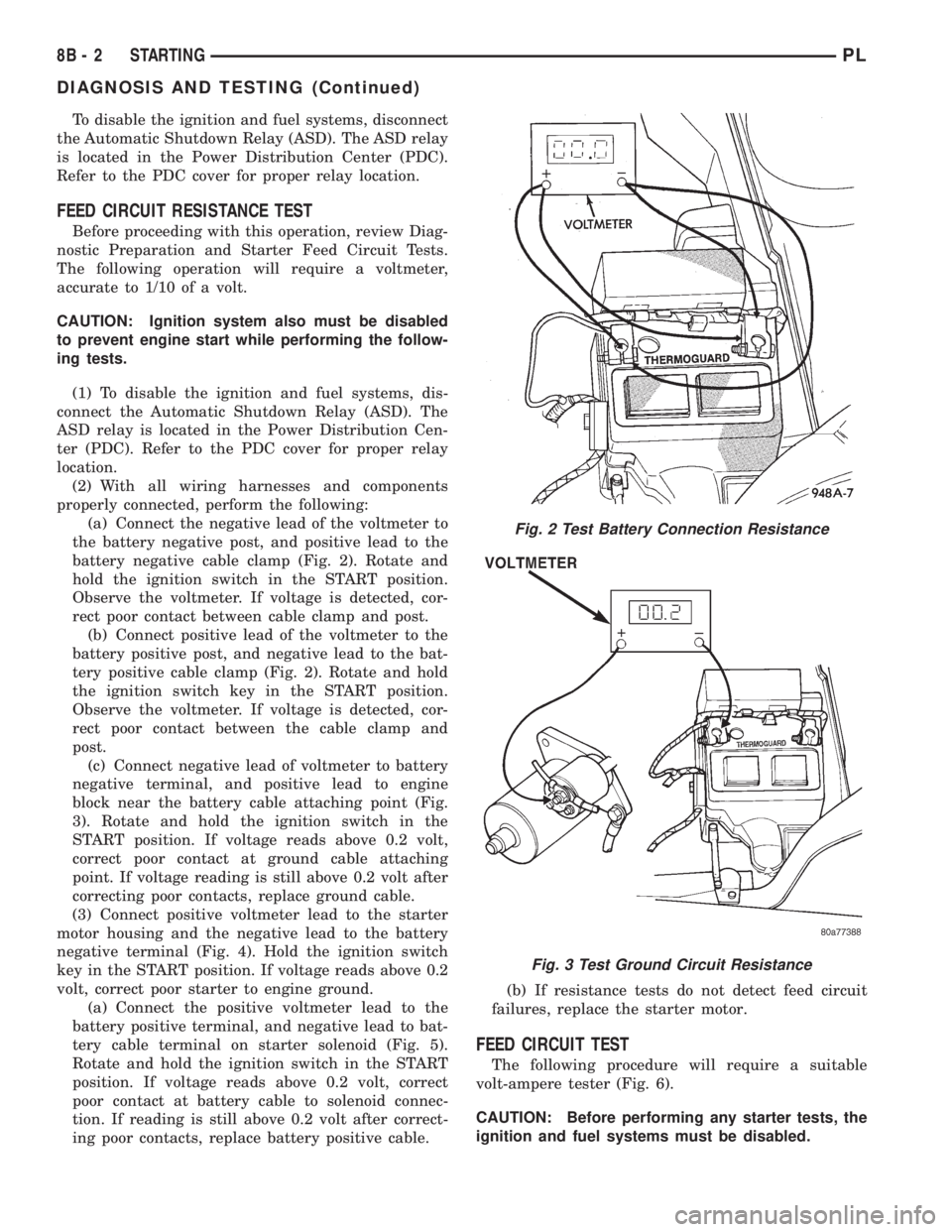

(a) Connect the negative lead of the voltmeter to

the battery negative post, and positive lead to the

battery negative cable clamp (Fig. 2). Rotate and

hold the ignition switch in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between cable clamp and post.

(b) Connect positive lead of the voltmeter to the

battery positive post, and negative lead to the bat-

tery positive cable clamp (Fig. 2). Rotate and hold

the ignition switch key in the START position.

Observe the voltmeter. If voltage is detected, cor-

rect poor contact between the cable clamp and

post.

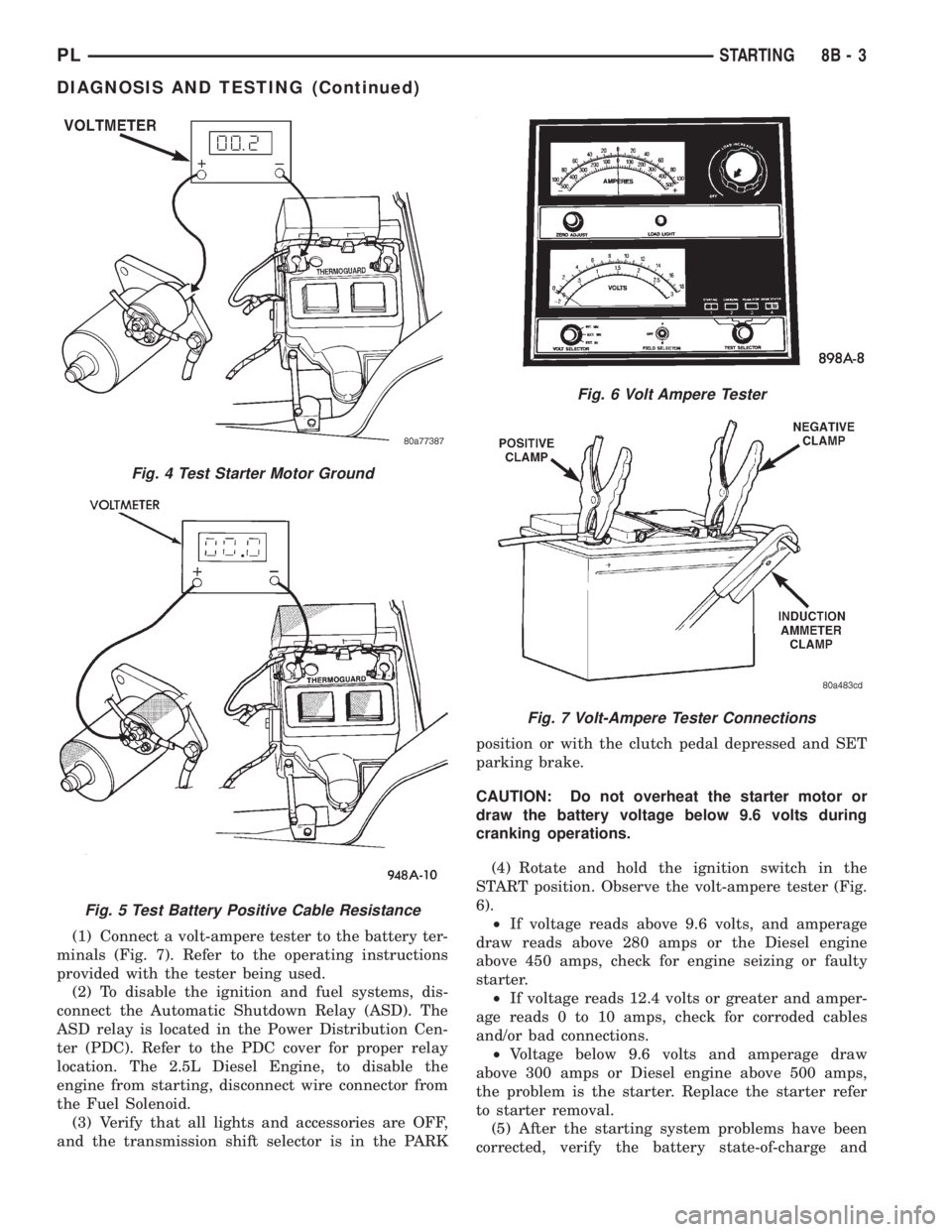

(c) Connect negative lead of voltmeter to battery

negative terminal, and positive lead to engine

block near the battery cable attaching point (Fig.

3). Rotate and hold the ignition switch in the

START position. If voltage reads above 0.2 volt,

correct poor contact at ground cable attaching

point. If voltage reading is still above 0.2 volt after

correcting poor contacts, replace ground cable.

(3) Connect positive voltmeter lead to the starter

motor housing and the negative lead to the battery

negative terminal (Fig. 4). Hold the ignition switch

key in the START position. If voltage reads above 0.2

volt, correct poor starter to engine ground.

(a) Connect the positive voltmeter lead to the

battery positive terminal, and negative lead to bat-

tery cable terminal on starter solenoid (Fig. 5).

Rotate and hold the ignition switch in the START

position. If voltage reads above 0.2 volt, correct

poor contact at battery cable to solenoid connec-

tion. If reading is still above 0.2 volt after correct-

ing poor contacts, replace battery positive cable.(b) If resistance tests do not detect feed circuit

failures, replace the starter motor.

FEED CIRCUIT TEST

The following procedure will require a suitable

volt-ampere tester (Fig. 6).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

Fig. 2 Test Battery Connection Resistance

Fig. 3 Test Ground Circuit Resistance

8B - 2 STARTINGPL

DIAGNOSIS AND TESTING (Continued)

Page 230 of 1200

(1) Connect a volt-ampere tester to the battery ter-

minals (Fig. 7). Refer to the operating instructions

provided with the tester being used.

(2) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown Relay (ASD). The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location. The 2.5L Diesel Engine, to disable the

engine from starting, disconnect wire connector from

the Fuel Solenoid.

(3) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARKposition or with the clutch pedal depressed and SET

parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(4) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

6).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps or the Diesel engine

above 450 amps, check for engine seizing or faulty

starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²Voltage below 9.6 volts and amperage draw

above 300 amps or Diesel engine above 500 amps,

the problem is the starter. Replace the starter refer

to starter removal.

(5) After the starting system problems have been

corrected, verify the battery state-of-charge and

Fig. 6 Volt Ampere Tester

Fig. 7 Volt-Ampere Tester Connections

Fig. 4 Test Starter Motor Ground

Fig. 5 Test Battery Positive Cable Resistance

PLSTARTING 8B - 3

DIAGNOSIS AND TESTING (Continued)