Fuel line DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 9 of 1200

DISCONNECT CABLE CLAMPS AS FOLLOWS:

²Disconnect BLACK cable clamp from engine

ground on disabled vehicle.

²When using a Booster vehicle, disconnect

BLACK cable clamp from battery negative terminal.

Disconnect RED cable clamp from battery positive

terminal.

²Disconnect RED cable clamp from battery posi-

tive terminal on disabled vehicle.

TOWING RECOMMENDATIONS

WARNING: DO NOT ALLOW TOWING ATTACH-

MENT DEVICES TO CONTACT THE FUEL TANK OR

LINES, FUEL LEAK CAN RESULT. DO NOT LIFT OR

TOW VEHICLE BY FRONT OR REAR BUMPER, OR

BUMPER ENERGY ABSORBER UNITS. DO NOT

VENTURE UNDER A LIFTED VEHICLE IF NOT SUP-

PORTED PROPERLY ON SAFETY STANDS. DO NOT

ALLOW PASSENGERS TO RIDE IN A TOWED VEHI-

CLE. USE A SAFETY CHAIN THAT IS INDEPENDENT

FROM THE TOWING ATTACHMENT DEVICE.

CAUTION: Do not damage brake lines, exhaust

system, shock absorbers, sway bars, or any other

under vehicle components when attaching towing

device to vehicle. Do not attach towing device to

front or rear suspension components. Do not

secure vehicle to towing device by the use of front

or rear suspension or steering components.

Remove or secure loose or protruding objects from

a damaged vehicle before towing. Refer to state and

local rules and regulations before towing a vehicle.

Do not allow weight of towed vehicle to bear on

lower fascia, air dams, or spoilers.

RECOMMENDED TOWING EQUIPMENT

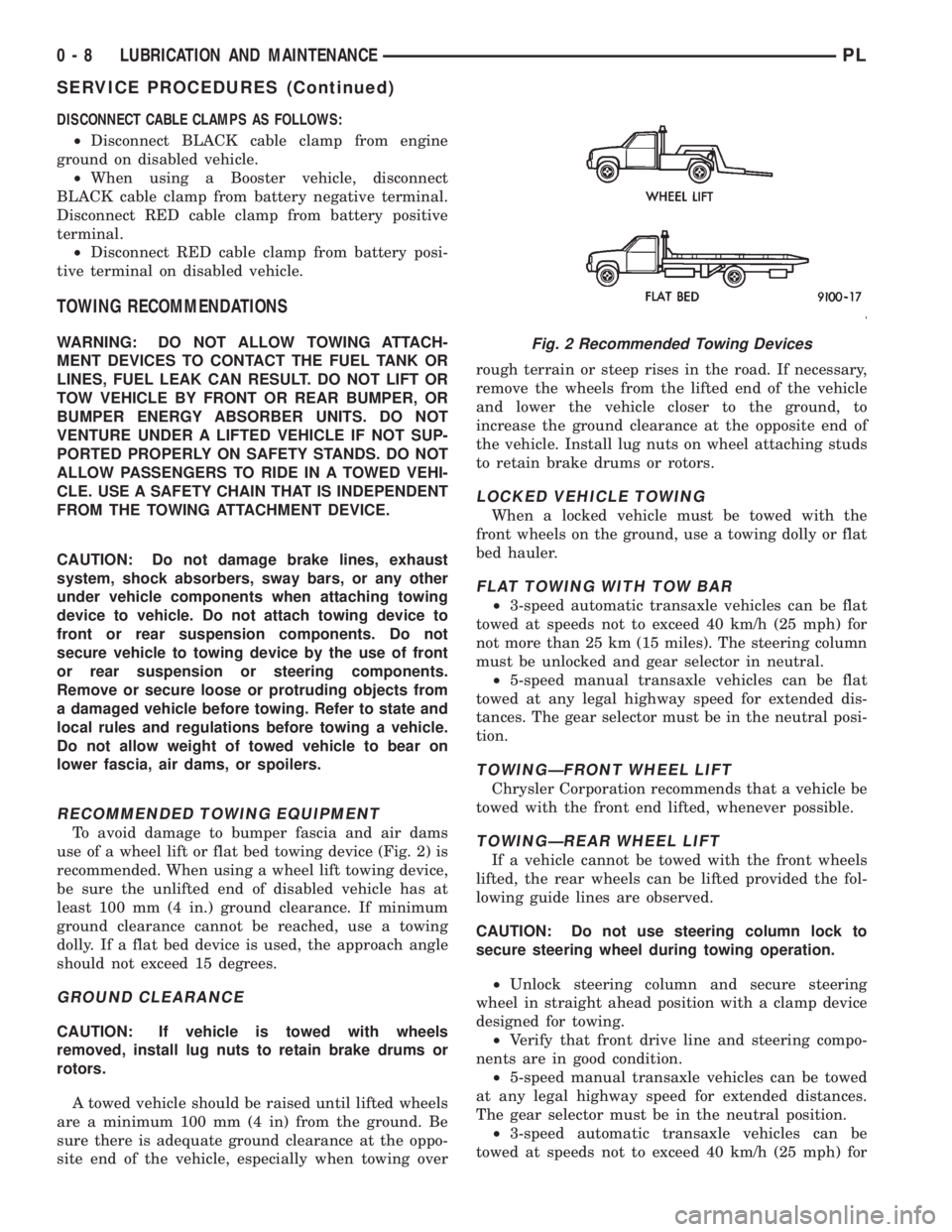

To avoid damage to bumper fascia and air dams

use of a wheel lift or flat bed towing device (Fig. 2) is

recommended. When using a wheel lift towing device,

be sure the unlifted end of disabled vehicle has at

least 100 mm (4 in.) ground clearance. If minimum

ground clearance cannot be reached, use a towing

dolly. If a flat bed device is used, the approach angle

should not exceed 15 degrees.

GROUND CLEARANCE

CAUTION: If vehicle is towed with wheels

removed, install lug nuts to retain brake drums or

rotors.

A towed vehicle should be raised until lifted wheels

are a minimum 100 mm (4 in) from the ground. Be

sure there is adequate ground clearance at the oppo-

site end of the vehicle, especially when towing overrough terrain or steep rises in the road. If necessary,

remove the wheels from the lifted end of the vehicle

and lower the vehicle closer to the ground, to

increase the ground clearance at the opposite end of

the vehicle. Install lug nuts on wheel attaching studs

to retain brake drums or rotors.

LOCKED VEHICLE TOWING

When a locked vehicle must be towed with the

front wheels on the ground, use a towing dolly or flat

bed hauler.

FLAT TOWING WITH TOW BAR

²3-speed automatic transaxle vehicles can be flat

towed at speeds not to exceed 40 km/h (25 mph) for

not more than 25 km (15 miles). The steering column

must be unlocked and gear selector in neutral.

²5-speed manual transaxle vehicles can be flat

towed at any legal highway speed for extended dis-

tances. The gear selector must be in the neutral posi-

tion.

TOWINGÐFRONT WHEEL LIFT

Chrysler Corporation recommends that a vehicle be

towed with the front end lifted, whenever possible.

TOWINGÐREAR WHEEL LIFT

If a vehicle cannot be towed with the front wheels

lifted, the rear wheels can be lifted provided the fol-

lowing guide lines are observed.

CAUTION: Do not use steering column lock to

secure steering wheel during towing operation.

²Unlock steering column and secure steering

wheel in straight ahead position with a clamp device

designed for towing.

²Verify that front drive line and steering compo-

nents are in good condition.

²5-speed manual transaxle vehicles can be towed

at any legal highway speed for extended distances.

The gear selector must be in the neutral position.

²3-speed automatic transaxle vehicles can be

towed at speeds not to exceed 40 km/h (25 mph) for

Fig. 2 Recommended Towing Devices

0 - 8 LUBRICATION AND MAINTENANCEPL

SERVICE PROCEDURES (Continued)

Page 259 of 1200

Connect the DVM between the center and sensor

ground terminal. Refer to Group 8W - Wiring Dia-

grams for correct pinout.

With the ignition switch in the ON position, check

the output voltage at the center terminal wire of the

connector. Check the output voltage at idle and at

Wide-Open-Throttle (WOT). At idle, TPS output volt-

age should be approximately 0.38 volts to 1.2 volts.

At wide open throttle, TPS output voltage should be

approximately 3.1 volts to 4.4 volts. The output volt-

age should gradually increase as the throttle plate

moves slowly from idle to WOT.

Check for spread terminals at the sensor and PCM

connections before replacing the TPS.

SPARK PLUG CONDITION

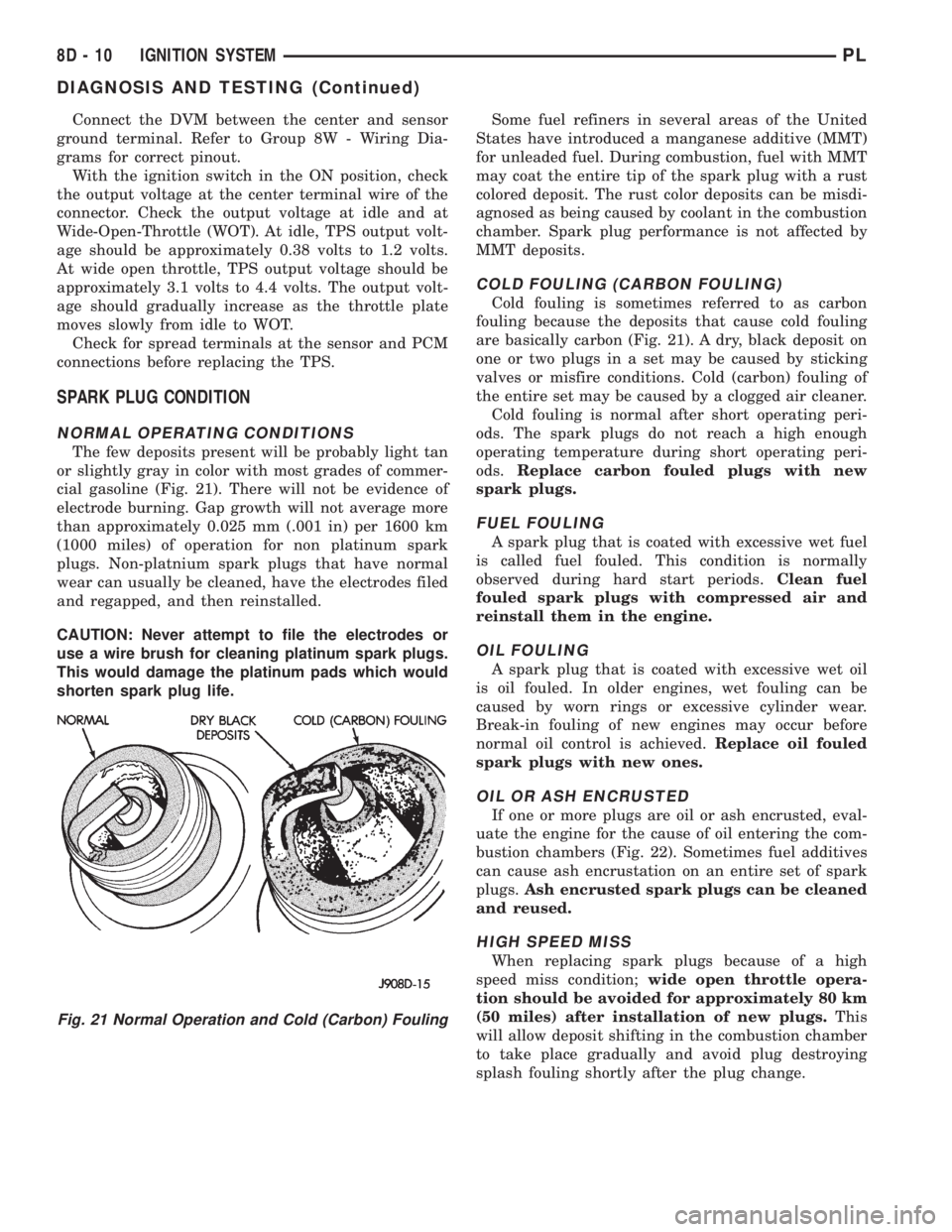

NORMAL OPERATING CONDITIONS

The few deposits present will be probably light tan

or slightly gray in color with most grades of commer-

cial gasoline (Fig. 21). There will not be evidence of

electrode burning. Gap growth will not average more

than approximately 0.025 mm (.001 in) per 1600 km

(1000 miles) of operation for non platinum spark

plugs. Non-platnium spark plugs that have normal

wear can usually be cleaned, have the electrodes filed

and regapped, and then reinstalled.

CAUTION: Never attempt to file the electrodes or

use a wire brush for cleaning platinum spark plugs.

This would damage the platinum pads which would

shorten spark plug life.Some fuel refiners in several areas of the United

States have introduced a manganese additive (MMT)

for unleaded fuel. During combustion, fuel with MMT

may coat the entire tip of the spark plug with a rust

colored deposit. The rust color deposits can be misdi-

agnosed as being caused by coolant in the combustion

chamber. Spark plug performance is not affected by

MMT deposits.

COLD FOULING (CARBON FOULING)

Cold fouling is sometimes referred to as carbon

fouling because the deposits that cause cold fouling

are basically carbon (Fig. 21). A dry, black deposit on

one or two plugs in a set may be caused by sticking

valves or misfire conditions. Cold (carbon) fouling of

the entire set may be caused by a clogged air cleaner.

Cold fouling is normal after short operating peri-

ods. The spark plugs do not reach a high enough

operating temperature during short operating peri-

ods.Replace carbon fouled plugs with new

spark plugs.

FUEL FOULING

A spark plug that is coated with excessive wet fuel

is called fuel fouled. This condition is normally

observed during hard start periods.Clean fuel

fouled spark plugs with compressed air and

reinstall them in the engine.

OIL FOULING

A spark plug that is coated with excessive wet oil

is oil fouled. In older engines, wet fouling can be

caused by worn rings or excessive cylinder wear.

Break-in fouling of new engines may occur before

normal oil control is achieved.Replace oil fouled

spark plugs with new ones.

OIL OR ASH ENCRUSTED

If one or more plugs are oil or ash encrusted, eval-

uate the engine for the cause of oil entering the com-

bustion chambers (Fig. 22). Sometimes fuel additives

can cause ash encrustation on an entire set of spark

plugs.Ash encrusted spark plugs can be cleaned

and reused.

HIGH SPEED MISS

When replacing spark plugs because of a high

speed miss condition;wide open throttle opera-

tion should be avoided for approximately 80 km

(50 miles) after installation of new plugs.This

will allow deposit shifting in the combustion chamber

to take place gradually and avoid plug destroying

splash fouling shortly after the plug change.

Fig. 21 Normal Operation and Cold (Carbon) Fouling

8D - 10 IGNITION SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 270 of 1200

INSTRUMENT PANEL AND SYSTEMS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

DOME LAMP............................ 1

ELECTRONIC DIGITAL CLOCK.............. 1

INSTRUMENT CLUSTER................... 2

WARNING AND INDICATOR LAMPS......... 2

DIAGNOSIS AND TESTING

AIRBAG WARNING SYSTEM............... 2

BRAKE SYSTEM WARNING LAMP TEST...... 2

FOG LAMP SWITCH TEST................. 2

FUEL TANK SENDING UNIT TEST........... 3

HEADLAMP SWITCH TEST................. 3

HEATER A/C BLOWER SWITCH TEST........ 3

HEATER BLOWER SWITCH TEST............ 3

INDIVIDUAL GAUGE INOPERATIVE.......... 4

INSTRUMENT PANEL AND COMPONENTS.... 4

LOW OIL PRESSURE WARNING LAMP TEST . . 4

MULTIPLE GAUGE INOPERATIVE TEST....... 4

SEAT BELT REMINDER SYSTEM TEST....... 6

SENDING UNIT......................... 6

SERVICE ENGINE SOON INDICATOR......... 6

VEHICLE SPEED SENSOR TEST............. 6

REMOVAL AND INSTALLATION

ASH RECEIVER RETAINER AND LAMP....... 6

CENTER BEZEL.......................... 6

CIGAR LIGHTER RECEPTACLE.............. 6

CLUSTER LAMP......................... 7

CLUSTER PRINTED CIRCUIT BOARD........ 7CLUSTER.............................. 7

DOME LENS/LAMP....................... 8

FLOOR CONSOLE........................ 8

GAUGE................................ 8

GLOVE BOX DOOR/BIN................... 8

GLOVE BOX SWITCH/LAMP................ 9

HEADLAMP SWITCH..................... 9

HEATER A/C CONTROL BLOWER SWITCH . . . 10

HEATER A/C CONTROL LAMP............ 10

HEATER A/C CONTROL................... 9

HEATER CONTROL BLOWER SWITCH....... 10

IGNITION KEY LAMP.................... 10

INSTRUMENT PANEL.................... 10

LEFT TRIM PANEL...................... 10

ODOMETER............................ 10

RADIO................................ 12

REAR WINDOW DEFOGGER AND/OR FOG

LAMP SWITCH....................... 12

RIGHT TRIM PANEL..................... 12

SHIFTER KNOB......................... 13

STEERING COLUMN COVER LINER......... 13

STEERING COLUMN COVER.............. 13

STEERING COLUMN SHROUDS............ 13

TOP COVER AND CLUSTER BEZEL

REMOVAL........................... 14

TRANSMISSION RANGE INDICATOR LAMP . . 14

TRUNK LAMP/LENS..................... 14

VEHICLE SPEED SENSOR................ 14

GENERAL INFORMATION

INTRODUCTION

The purpose of the dash gauges and indicator

lamps is to keep the driver informed about the oper-

ating condition of the vehicle. If an abnormal condi-

tion occurs, the driver is informed by indicator lamp.

The driver can seek service before damage occurs.

Indicator lamps use ON/OFF switch functions for

operation, while gauges use a sending unit or sensor.

DESCRIPTION AND OPERATION

DOME LAMP

The Dome Lamp operates when a door is open or

when the headlamp switch is placed in courtesy posi-

tion.

ELECTRONIC DIGITAL CLOCK

The electronic digital clock is in the radio. The

clock and radio each use the display panel built into

the radio. A digital readout indicates the time in

hours and minutes whenever the ignition switch is in

the ON or ACC position.

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 333 of 1200

HEADLAMP ALIGNMENT

INDEX

page page

GENERAL INFORMATION

HEADLAMP ALIGNMENT................... 4

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION....... 4ADJUSTMENTS

FOG LAMP ALIGNMENT................... 4

HEADLAMP ADJUSTMENT USING ALIGNMENT

SCREEN.............................. 4

GENERAL INFORMATION

HEADLAMP ALIGNMENT

Headlamps can be aligned using the screen method

provided in this section.

SERVICE PROCEDURES

HEADLAMP ALIGNMENT PREPARATION

(1) Verify headlamp dimmer switch and high beam

indicator operation.

(2) Inspect and correct damaged or defective com-

ponents that could interfere with proper headlamp

alignment.

(3) Verify proper tire inflation.

(4) Clean headlamp lenses.

(5) Verify that luggage area is not heavily loaded.

(6) Fuel tank should be FULL. Add 2.94 kg (6.5

lbs.) of weight over the fuel tank for each estimated

gallon of missing fuel.

ADJUSTMENTS

HEADLAMP ADJUSTMENT USING ALIGNMENT

SCREEN

ALIGNMENT SCREEN PREPARATION

(1) Position vehicle on a level surface perpendicu-

lar to a flat wall 7.62 meters (25 ft.) away from front

of headlamp lens (Fig. 1).

(2) If necessary, tape a line on the floor 7.62

meters (25 ft.) away from and parallel to the wall.

(3) From the floor up 1.27 meters (5 ft.), tape a

line on the wall at the center line of the vehicle.

Sight along the center line of the vehicle (from rear

of vehicle forward) to verify accuracy of the line

placement.

(4) Rock vehicle side-to-side three times to allow

suspension to stabilize.(5) Jounce front suspension three times by pushing

downward on front bumper and releasing.

(6) Measure the distance from the center of head-

lamp lens to the floor. Transfer measurement to the

alignment screen (with tape). Use this line for

up/down adjustment reference.

(7) Measure distance from the center line of the

vehicle to the center of each headlamp being aligned.

Transfer measurements to screen (with tape) to each

side of vehicle center line. Use these lines for left/

right adjustment reference.

HEADLAMP ADJUSTMENT

A properly aimed low beam headlamp will project

the center of the low beam hot spot on the alignment

screen from 178 mm (7 in.) below the headlamp cen-

ter line. The side- to-side left edge of low beam hot

spot should be 127 mm (5 in.) to the right of head-

lamp center line (Fig. 1). The high beams on a vehi-

cle with aero headlamps cannot be aligned. The high

beam pattern should be correct when the low beams

are aligned properly.

To adjust headlamp alignment, rotate alignment

screws to achieve the specified low beam hot spot

pattern.

FOG LAMP ALIGNMENT

Prepare an alignment screen. Refer to Alignment

Screen Preparation paragraph in this section. Disen-

gage the wire connectors from the back of the head-

lamp bulbs to disable the headlamps. This will allow

a more accurate projection reading of the fog lamps.

Turn on the headlamp switch and actuate the fog

lamp switch. A properly aligned fog lamp will project

a pattern on the alignment screen 100 mm (4 in.)

below the fog lamp centerline and straight ahead

(Fig. 2).

8L - 4 LAMPSPL

Page 715 of 1200

assure gasket rails are flat. Flatten rails with a ham-

mer on a heavy steel plate if required. Gasket sur-

faces must be free of oil and dirt. Make sure old

gasket material is removed from blind attaching

holes.

FORM-IN-PLACE GASKET APPLICATION

Assembling parts using a form-in-place gasket

requires care but it's easier then using precut gas-

kets.

MopartGasket Maker material should be applied

sparingly 1 mm (0.040 inch.) diameter or less of seal-

ant to one gasket surface. Be certain the material

surrounds each mounting hole. Excess material can

easily be wiped off. Components should be torqued in

place within 15 minutes. The use of a locating dowel

is recommended during assembly to prevent smear-

ing material off the location.

The MopartSilicone Rubber Adhesive Sealant gas-

ket material or equivalent should be applied in a con-

tinuous bead approximately 3 mm (0.120 inch) in

diameter. All mounting holes must be circled. For

corner sealing, a 3.17 or 6.35 mm (1/8 or 1/4 inch.)

drop is placed in the center of the gasket contact

area. Uncured sealant may be removed with a shop

towel. Components should be torqued in place while

the sealant is still wet to the touch (within 10 min-

utes). The usage of a locating dowel is recommended

during assembly to prevent smearing material off the

location.

CRANKSHAFT SPROCKET BOLT ACCESS PLUG

An Access plug is located in the right inner fender

shield. Remove the plug and insert the proper size

socket, extension and ratchet, when crankshaft rota-

tion is necessary.

ENGINE CORE PLUGS

REMOVAL

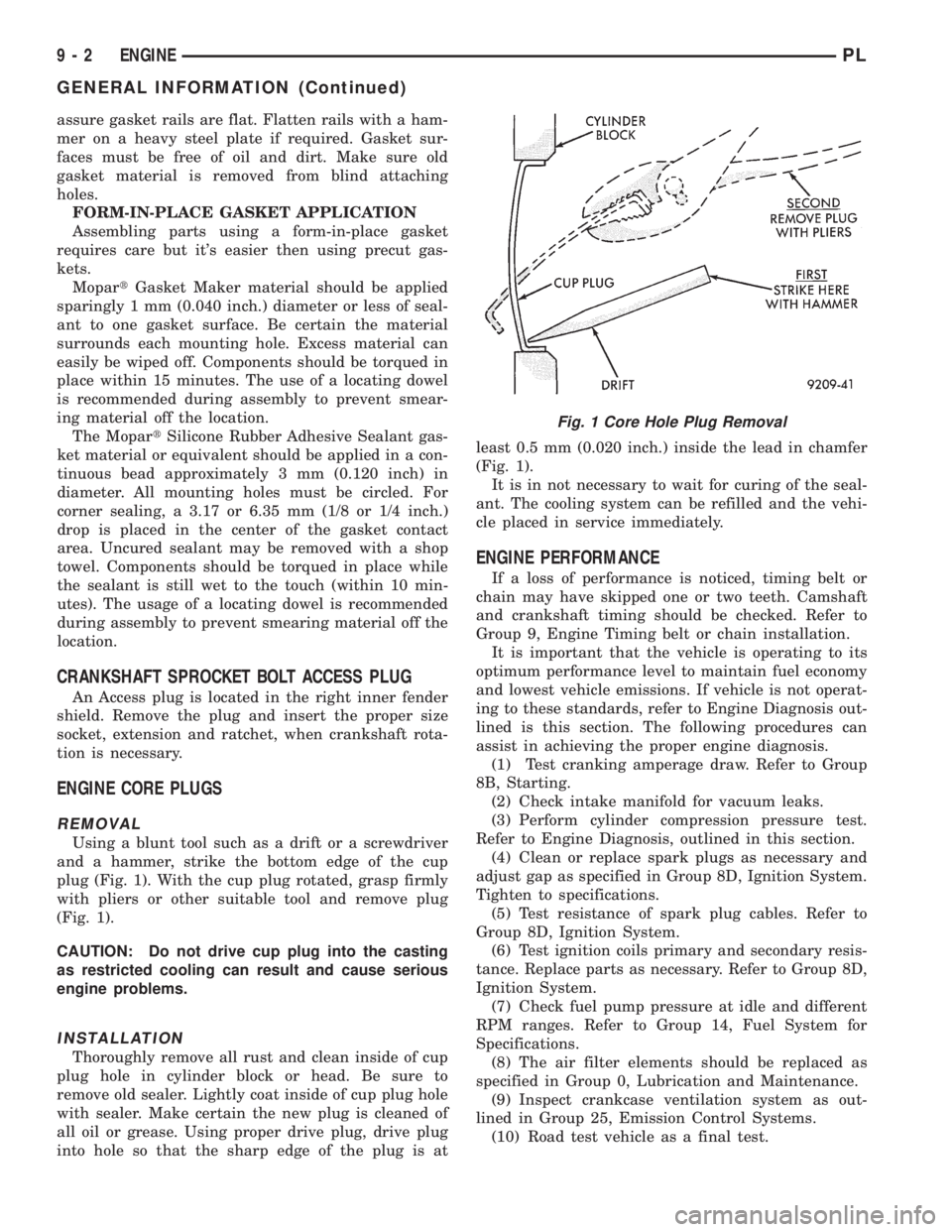

Using a blunt tool such as a drift or a screwdriver

and a hammer, strike the bottom edge of the cup

plug (Fig. 1). With the cup plug rotated, grasp firmly

with pliers or other suitable tool and remove plug

(Fig. 1).

CAUTION: Do not drive cup plug into the casting

as restricted cooling can result and cause serious

engine problems.

INSTALLATION

Thoroughly remove all rust and clean inside of cup

plug hole in cylinder block or head. Be sure to

remove old sealer. Lightly coat inside of cup plug hole

with sealer. Make certain the new plug is cleaned of

all oil or grease. Using proper drive plug, drive plug

into hole so that the sharp edge of the plug is atleast 0.5 mm (0.020 inch.) inside the lead in chamfer

(Fig. 1).

It is in not necessary to wait for curing of the seal-

ant. The cooling system can be refilled and the vehi-

cle placed in service immediately.

ENGINE PERFORMANCE

If a loss of performance is noticed, timing belt or

chain may have skipped one or two teeth. Camshaft

and crankshaft timing should be checked. Refer to

Group 9, Engine Timing belt or chain installation.

It is important that the vehicle is operating to its

optimum performance level to maintain fuel economy

and lowest vehicle emissions. If vehicle is not operat-

ing to these standards, refer to Engine Diagnosis out-

lined is this section. The following procedures can

assist in achieving the proper engine diagnosis.

(1) Test cranking amperage draw. Refer to Group

8B, Starting.

(2) Check intake manifold for vacuum leaks.

(3) Perform cylinder compression pressure test.

Refer to Engine Diagnosis, outlined in this section.

(4) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8D, Ignition System.

Tighten to specifications.

(5) Test resistance of spark plug cables. Refer to

Group 8D, Ignition System.

(6) Test ignition coils primary and secondary resis-

tance. Replace parts as necessary. Refer to Group 8D,

Ignition System.

(7) Check fuel pump pressure at idle and different

RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(8) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(9) Inspect crankcase ventilation system as out-

lined in Group 25, Emission Control Systems.

(10) Road test vehicle as a final test.

Fig. 1 Core Hole Plug Removal

9 - 2 ENGINEPL

GENERAL INFORMATION (Continued)

Page 718 of 1200

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., Connecting

Rods, Pistons, Valves etc.)

(7) Repair engine or components as necessary to

prevent this problem from occurring again.

CAUTION: Squirt approximately 1 teaspoon of oil

into cylinders, rotate engine to lubricate the cylin-

der walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Fill engine with specified amount of approved

oil and install new oil filter.

(11) Connect negative battery cable.

(12) Start engine and check for any leaks.

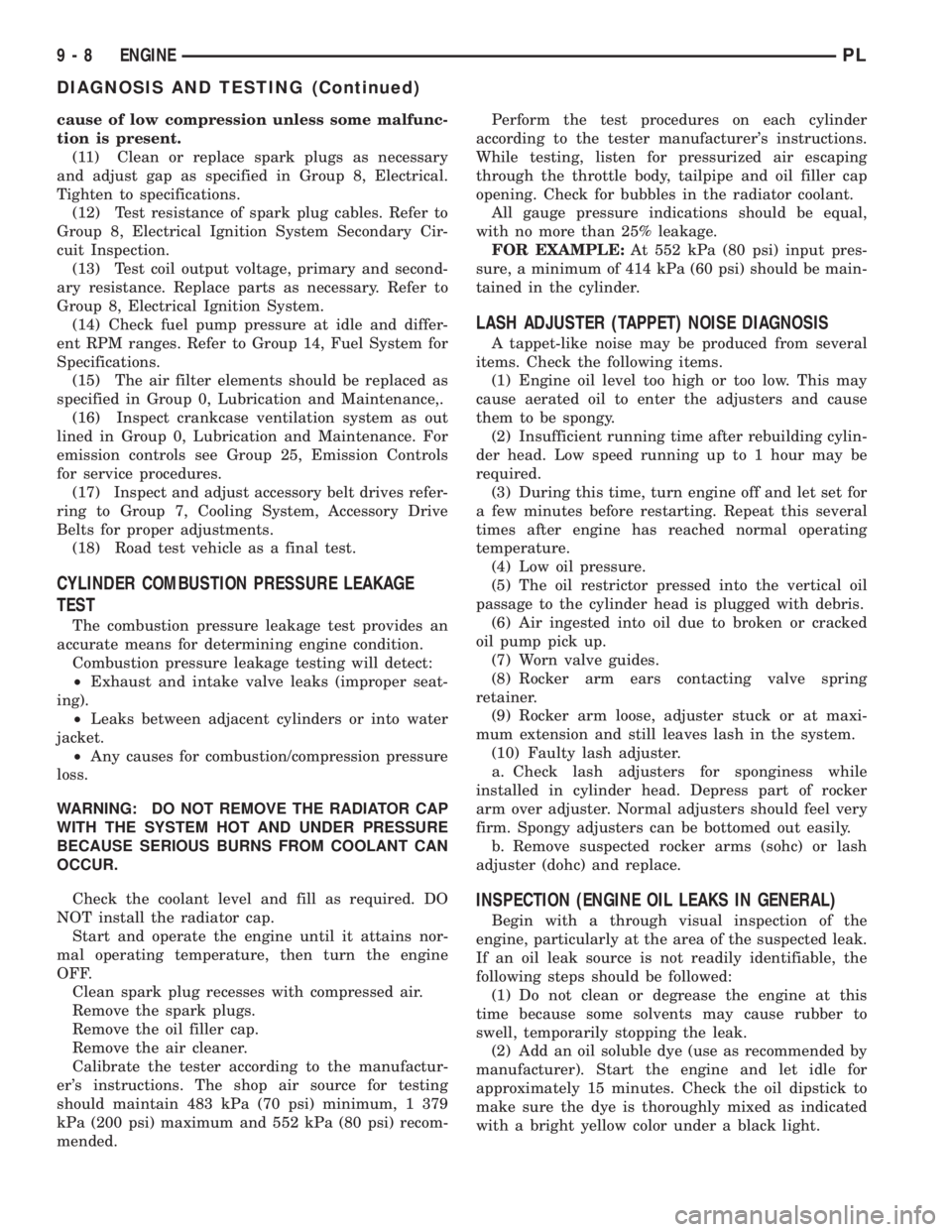

CHECKING ENGINE OIL LEVEL

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,

allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Add only when the level is at or below the

ADD mark (Fig. 5).

ENGINE OIL SERVICE

WARNING: NEW OR USED ENGINE OIL CAN BE

IRRITATING TO THE SKIN. AVOID PROLONGED OR

REPEATED SKIN CONTACT WITH ENGINE OIL.

CONTAMINANTS IN USED ENGINE OIL, CAUSED BY

INTERNAL COMBUSTION, CAN BE HAZARDOUS TO

YOUR HEALTH. THOROUGHLY WASH EXPOSED

SKIN WITH SOAP AND WATER. DO NOT WASH

SKIN WITH GASOLINE, DIESEL FUEL, THINNER, OR

SOLVENTS, HEALTH PROBLEMS CAN RESULT. DO

NOT POLLUTE, DISPOSE OF USED ENGINE OIL

PROPERLY. CONTACT YOUR DEALER OR GOVERN-MENT AGENCY FOR LOCATION OF COLLECTION

CENTER IN YOUR AREA.

ENGINE OIL SPECIFICATION

CAUTION: Do not use non-detergent or straight

mineral oil when adding or changing crankcase

lubricant. Engine failure can result.

API SERVICE GRADE CERTIFIED

Use an engine oil that is API Service Grade Certi-

fied. MOPARtprovides engine oils that conforms to

this service grade.

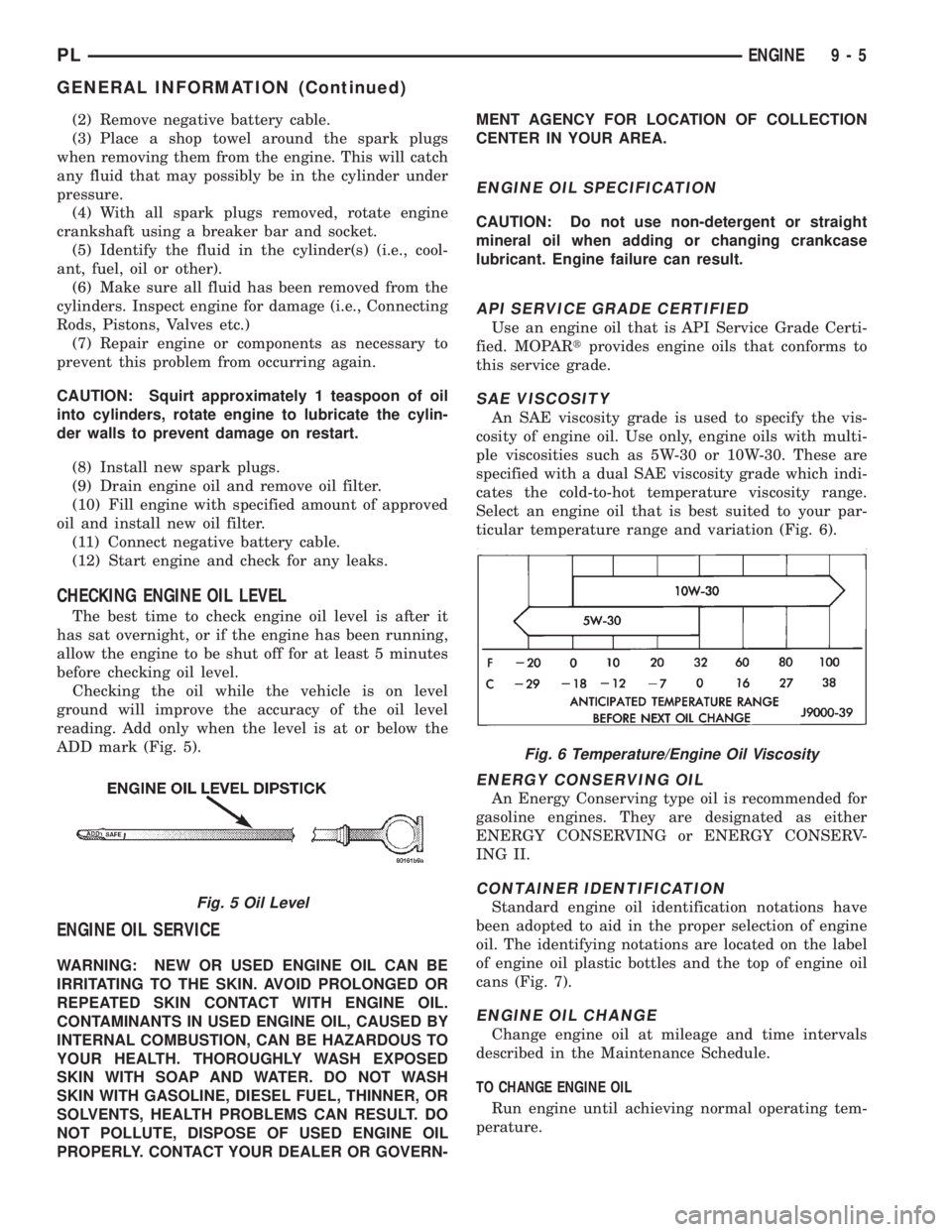

SAE VISCOSITY

An SAE viscosity grade is used to specify the vis-

cosity of engine oil. Use only, engine oils with multi-

ple viscosities such as 5W-30 or 10W-30. These are

specified with a dual SAE viscosity grade which indi-

cates the cold-to-hot temperature viscosity range.

Select an engine oil that is best suited to your par-

ticular temperature range and variation (Fig. 6).

ENERGY CONSERVING OIL

An Energy Conserving type oil is recommended for

gasoline engines. They are designated as either

ENERGY CONSERVING or ENERGY CONSERV-

ING II.

CONTAINER IDENTIFICATION

Standard engine oil identification notations have

been adopted to aid in the proper selection of engine

oil. The identifying notations are located on the label

of engine oil plastic bottles and the top of engine oil

cans (Fig. 7).

ENGINE OIL CHANGE

Change engine oil at mileage and time intervals

described in the Maintenance Schedule.

TO CHANGE ENGINE OIL

Run engine until achieving normal operating tem-

perature.

Fig. 5 Oil Level

Fig. 6 Temperature/Engine Oil Viscosity

PLENGINE 9 - 5

GENERAL INFORMATION (Continued)

Page 720 of 1200

ENGINE DIAGNOSIS

INDEX

page page

DIAGNOSIS AND TESTING

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST........................ 8

CYLINDER COMPRESSION PRESSURE TEST . . 7

ENGINE DIAGNOSISÐMECHANICAL......... 11

ENGINE DIAGNOSISÐPERFORMANCE...... 10GENERAL INFORMATION.................. 7

INSPECTION (ENGINE OIL LEAKS IN

GENERAL)............................ 8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS..... 7

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS.. 8

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If a change in RPM'S, the area of the suspected

leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

should not be disassembled to determine the

PLENGINE 9 - 7

Page 721 of 1200

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary

and adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance,.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1 379

kPa (200 psi) maximum and 552 kPa (80 psi) recom-

mended.Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

INSPECTION (ENGINE OIL LEAKS IN GENERAL)

Begin with a through visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

make sure the dye is thoroughly mixed as indicated

with a bright yellow color under a black light.

9 - 8 ENGINEPL

DIAGNOSIS AND TESTING (Continued)

Page 732 of 1200

(3) Remove the power hop damper bracket, if nec-

essary.

(4) Reverse removal procedure for installation.

Tighten all bolts and nuts to 54 N´m (40 ft. lbs.)

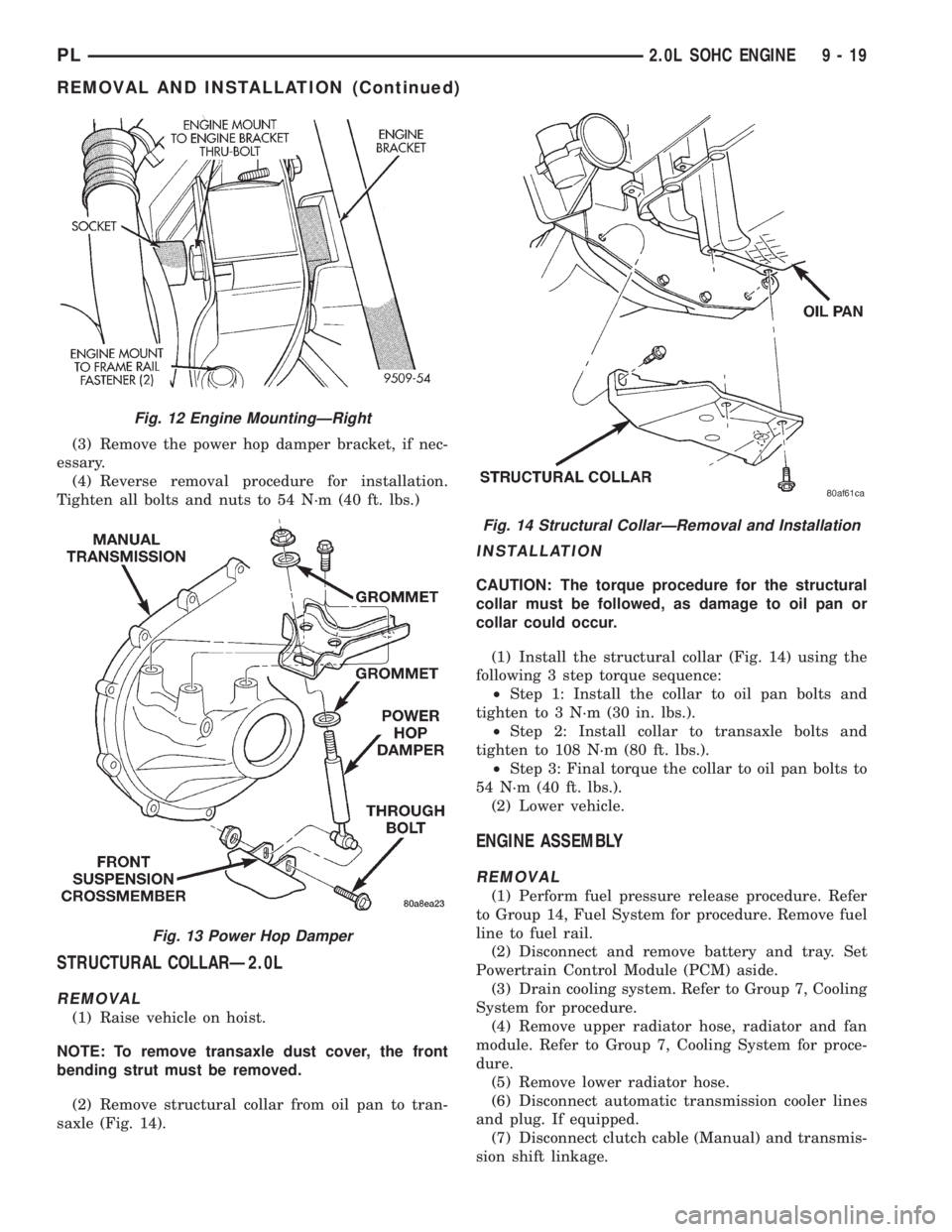

STRUCTURAL COLLARÐ2.0L

REMOVAL

(1) Raise vehicle on hoist.

NOTE: To remove transaxle dust cover, the front

bending strut must be removed.

(2) Remove structural collar from oil pan to tran-

saxle (Fig. 14).

INSTALLATION

CAUTION: The torque procedure for the structural

collar must be followed, as damage to oil pan or

collar could occur.

(1) Install the structural collar (Fig. 14) using the

following 3 step torque sequence:

²Step 1: Install the collar to oil pan bolts and

tighten to 3 N´m (30 in. lbs.).

²Step 2: Install collar to transaxle bolts and

tighten to 108 N´m (80 ft. lbs.).

²Step 3: Final torque the collar to oil pan bolts to

54 N´m (40 ft. lbs.).

(2) Lower vehicle.

ENGINE ASSEMBLY

REMOVAL

(1) Perform fuel pressure release procedure. Refer

to Group 14, Fuel System for procedure. Remove fuel

line to fuel rail.

(2) Disconnect and remove battery and tray. Set

Powertrain Control Module (PCM) aside.

(3) Drain cooling system. Refer to Group 7, Cooling

System for procedure.

(4) Remove upper radiator hose, radiator and fan

module. Refer to Group 7, Cooling System for proce-

dure.

(5) Remove lower radiator hose.

(6) Disconnect automatic transmission cooler lines

and plug. If equipped.

(7) Disconnect clutch cable (Manual) and transmis-

sion shift linkage.

Fig. 12 Engine MountingÐRight

Fig. 13 Power Hop Damper

Fig. 14 Structural CollarÐRemoval and Installation

PL2.0L SOHC ENGINE 9 - 19

REMOVAL AND INSTALLATION (Continued)

Page 734 of 1200

(8) Install A/C compressor and hoses. Refer to

Group 24, Heater and Air Conditioning for procedure.

(9) Install accessory drive belts. Refer to Group 7,

Cooling System Accessory Drive Section for belt ten-

sion adjustment.

(10) Install front engine mount. Refer to this sec-

tion for procedure.

(11) Manual transmission: Install power hop

damper.

(12) Install inner splash shield. Install wheels and

tires.

(13)Manual Transmission:Connect clutch cable

and linkages. Refer to Group 6, Manual Transaxle

Clutch.

(14)Automatic Transmission:Connect shifter

and kickdown linkage. Refer to Group 21, Transaxle

for procedures.

(15) Connect fuel line and heater hoses.

(16) Install ground straps. Connect engine and

throttle body connections and harnesses. Refer to

Group 8, Electrical for procedure.

(17) Connect throttle body linkage. Refer to Group

14, Fuel System for procedure.

(18) Install radiator and shroud assembly. Install

radiator hoses. Fill cooling system. Refer to Group 7,

Cooling System for filling procedure.

(19) Install battery tray and battery. Set Power-

train Control Module (PCM) into place.

(20) Install air cleaner and hoses.

(21) Install oil filter. Fill engine crankcase with

proper oil to correct level.

(22) Perform camshaft and crankshaft timing

relearn procedure as follows:

²Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located in

the passenger compartment; at the lower edge of

instrument panel; near the steering column.

²Turn the ignition switch on and access the ªmis-

cellaneousº screen.

²Select ªre-learn cam/crankº option and follow

directions on DRB screen.

(23) Start engine and run until operating temper-

ature is reached.

(24) Adjust transmission linkage, if necessary.

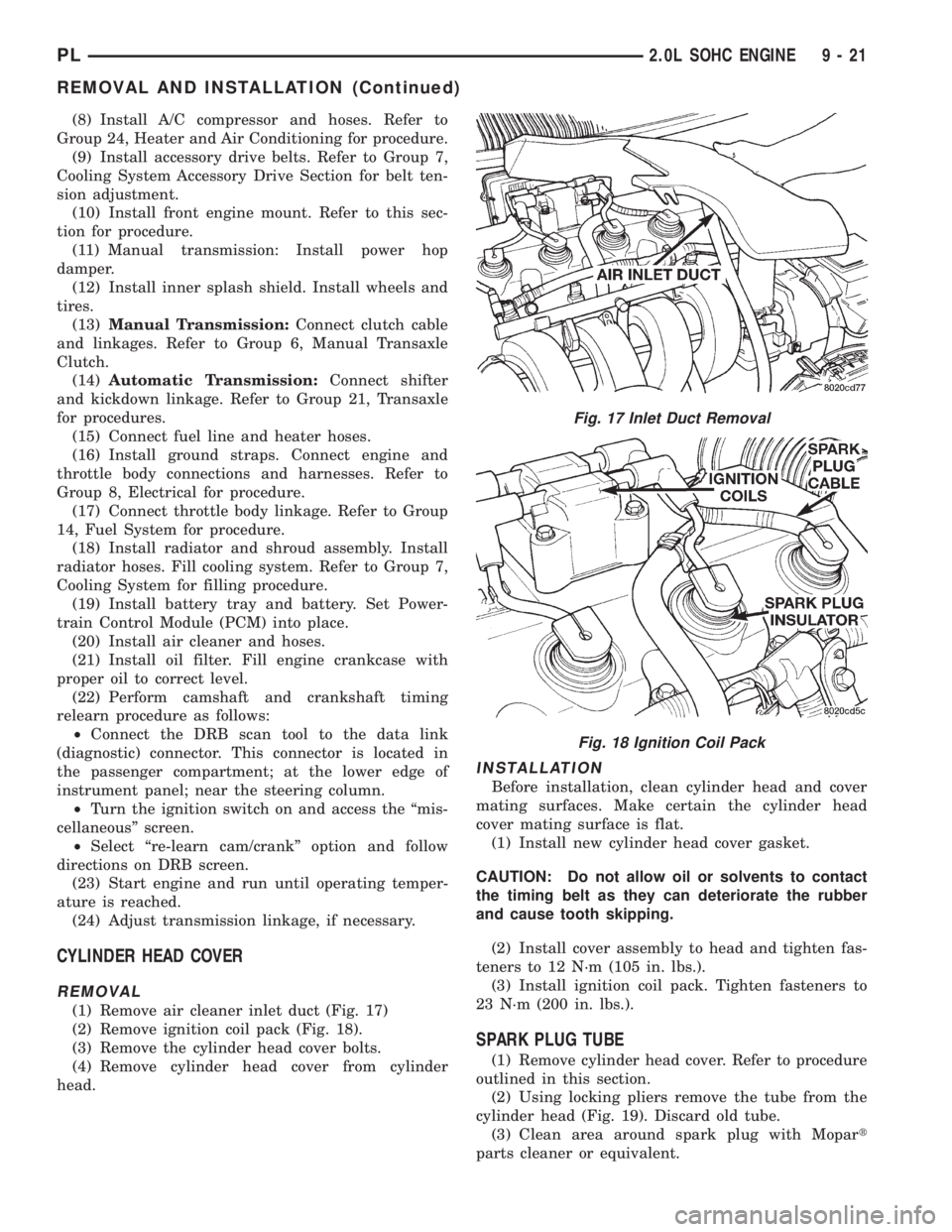

CYLINDER HEAD COVER

REMOVAL

(1) Remove air cleaner inlet duct (Fig. 17)

(2) Remove ignition coil pack (Fig. 18).

(3) Remove the cylinder head cover bolts.

(4) Remove cylinder head cover from cylinder

head.

INSTALLATION

Before installation, clean cylinder head and cover

mating surfaces. Make certain the cylinder head

cover mating surface is flat.

(1) Install new cylinder head cover gasket.

CAUTION: Do not allow oil or solvents to contact

the timing belt as they can deteriorate the rubber

and cause tooth skipping.

(2) Install cover assembly to head and tighten fas-

teners to 12 N´m (105 in. lbs.).

(3) Install ignition coil pack. Tighten fasteners to

23 N´m (200 in. lbs.).

SPARK PLUG TUBE

(1) Remove cylinder head cover. Refer to procedure

outlined in this section.

(2) Using locking pliers remove the tube from the

cylinder head (Fig. 19). Discard old tube.

(3) Clean area around spark plug with Mopart

parts cleaner or equivalent.

Fig. 17 Inlet Duct Removal

Fig. 18 Ignition Coil Pack

PL2.0L SOHC ENGINE 9 - 21

REMOVAL AND INSTALLATION (Continued)