turn signal bulb DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 310 of 1200

TURN SIGNAL AND FLASHERS

CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION......................... 1

DESCRIPTION AND OPERATION

COMBINATION FLASHER.................. 1

HAZARD WARNING SYSTEM............... 1DIAGNOSIS AND TESTING

MULTI-FUNCTION SWITCH................ 2

MULTI-FUNCTION SWITCH TEST............ 2

REMOVAL AND INSTALLATION

MULTI-FUNCTION SWITCH................ 4

GENERAL INFORMATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, RESTRAINT SYSTEMS FOR

AIRBAG REMOVAL PROCEDURES.

The turn signals are part of the multi-function

switch. Which contains:

²Electrical circuitry for turn signals

²Hazard warning switch

²Headlamp beam select switch

²Headlamp optical horn

The integrated switch assembly is mounted to the

left hand side of the steering column. When the

driver wishes to signal his intentions to change direc-

tion of travel, he moves the lever upward to cause

the right signals to flash and downward to cause the

left signals to flash. After completion of a turn the

system is deactivated automatically. As the steering

wheel returns to the straight ahead position, a can-

celing cam molded to the clockspring mechanism

comes in contact with the cancel actuator on the turn

signal multi-function switch assembly. The cam lobe,

pushing on the cancel actuator, returns the switch to

the off position.

If only momentary signaling such as indication of a

lane change is desired, the switch is actuated to a

left or right intermediate detent position. In this

position the signal lamps flash as described above,

but the switch returns to the OFF position as soon as

the lever is released.

When the system is activated, one of two indicator

lamps mounted in the instrument cluster flashes in

unison with the turn signal lamps, indicating to the

driver that the system is operating.

DESCRIPTION AND OPERATION

HAZARD WARNING SYSTEM

The hazard warning system is actuated by a slide

button located on the top of the steering column

between the steering wheel and the instrument

panel. The hazard switch is identified with a double

triangle on front of the button.

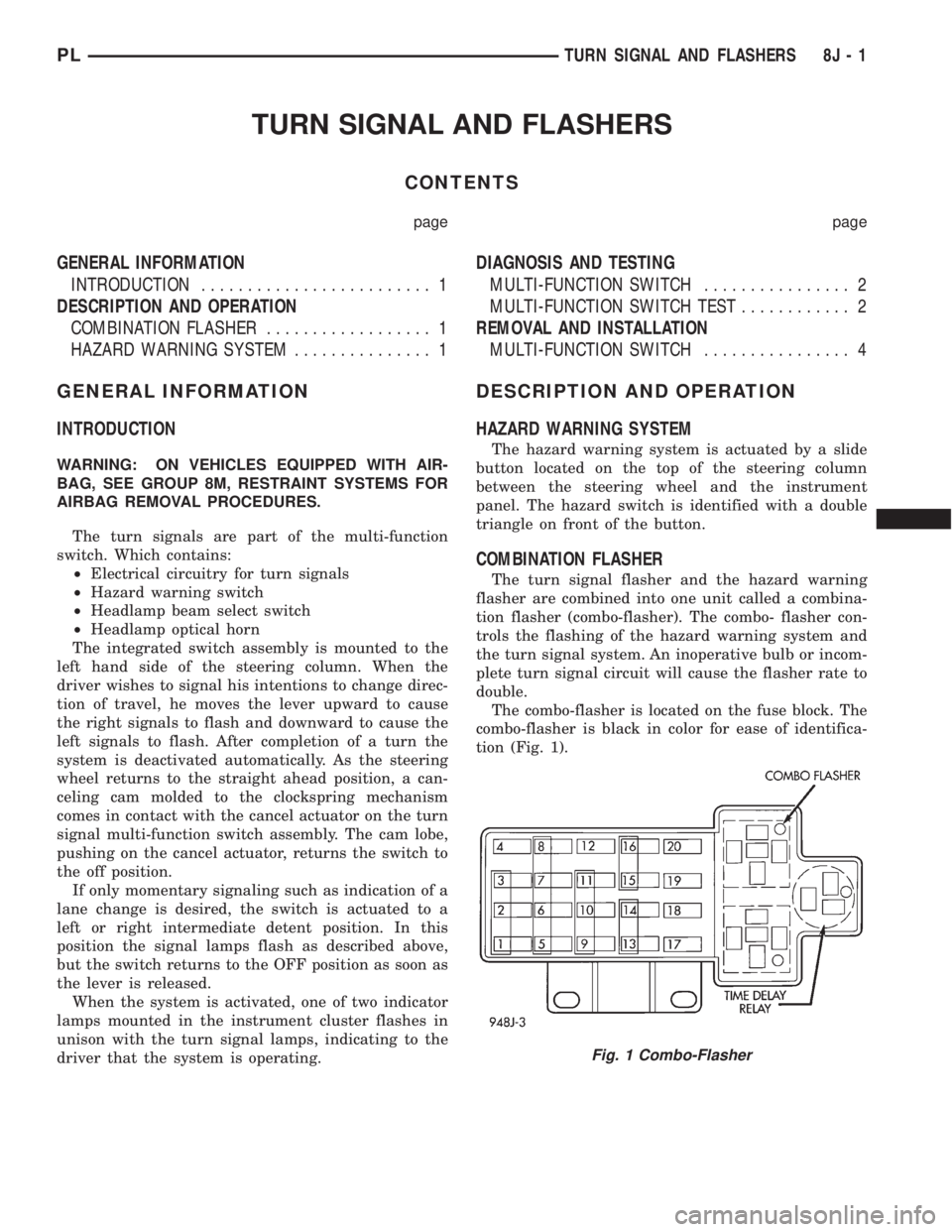

COMBINATION FLASHER

The turn signal flasher and the hazard warning

flasher are combined into one unit called a combina-

tion flasher (combo-flasher). The combo- flasher con-

trols the flashing of the hazard warning system and

the turn signal system. An inoperative bulb or incom-

plete turn signal circuit will cause the flasher rate to

double.

The combo-flasher is located on the fuse block. The

combo-flasher is black in color for ease of identifica-

tion (Fig. 1).

Fig. 1 Combo-Flasher

PLTURN SIGNAL AND FLASHERS 8J - 1

Page 335 of 1200

LAMP BULB SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP BULB . . . 7

DOME LAMP BULB....................... 8

FOG LAMP BULB......................... 6

FRONT SIDE MARKER LAMP BULB.......... 7

HEADLAMP BULB........................ 6

LICENSE PLATE LAMP BULB............... 8PARK AND TURN SIGNAL LAMP BULB........ 6

REAR CARGO LAMP BULB................. 8

TAIL, STOP, BACK-UP AND TURN SIGNAL

LAMP BULB........................... 7

UNDERHOOD LAMP BULB................. 8

VISOR VANITY LAMP BULB................. 8

REMOVAL AND INSTALLATION

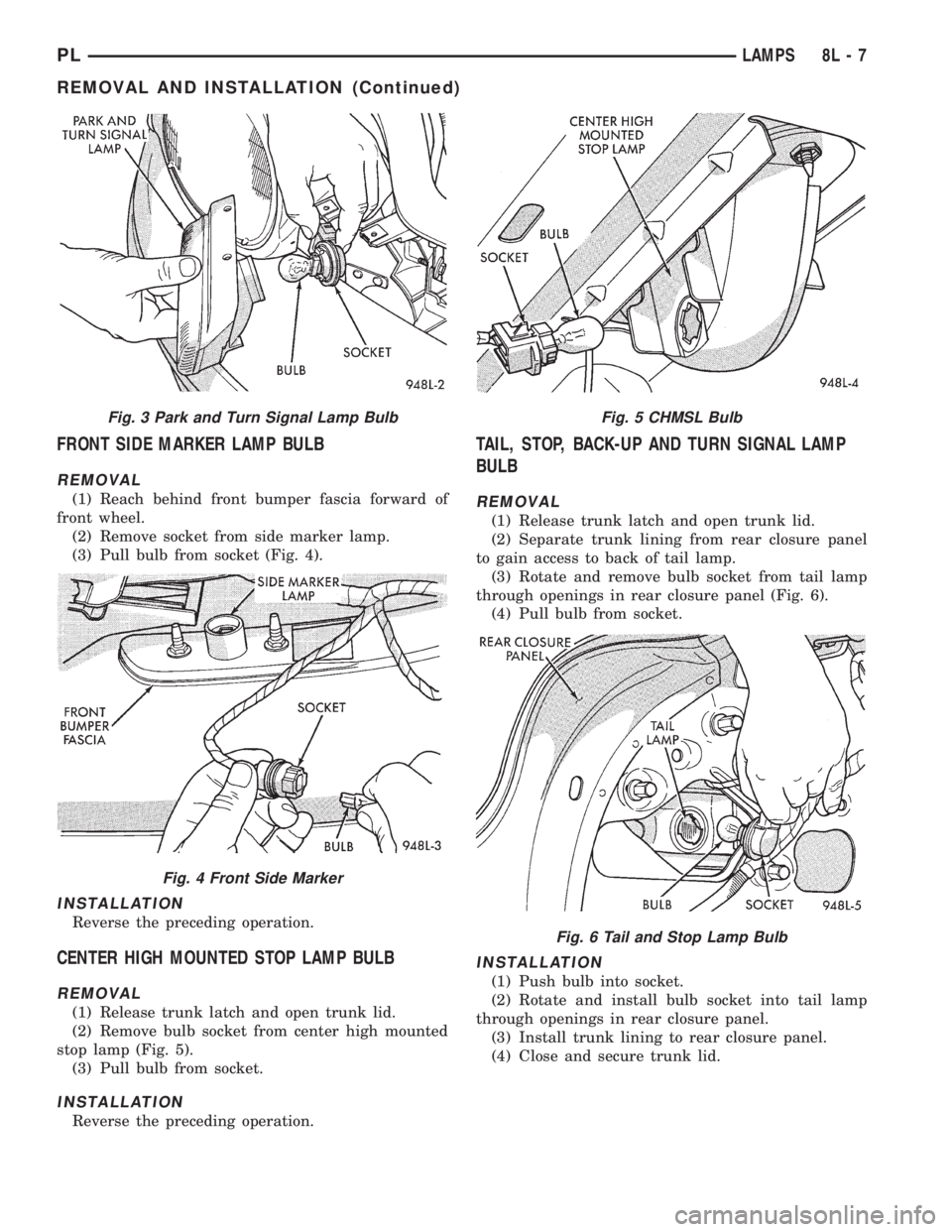

HEADLAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Disengage wire connector from headlamp bulb

connector.

(3) Remove retaining ring holding bulb to back of

headlamp module.

(4) Pull bulb from back of headlamp module (Fig.

1).

INSTALLATION

CAUTION: Do not touch the glass of halogen

bulbs with fingers or other possibly oily surface,

reduced bulb life will result.

Reverse the preceding operation.

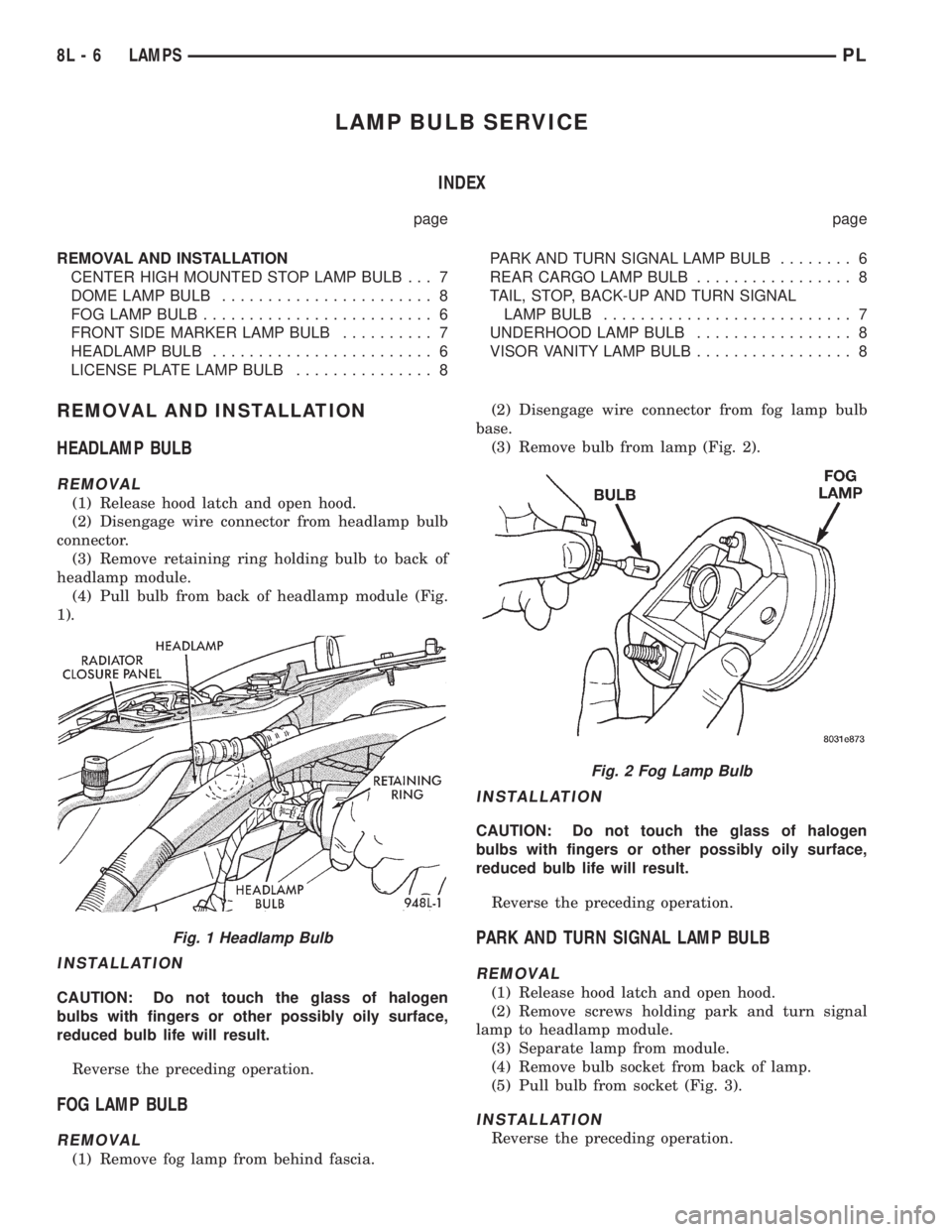

FOG LAMP BULB

REMOVAL

(1) Remove fog lamp from behind fascia.(2) Disengage wire connector from fog lamp bulb

base.

(3) Remove bulb from lamp (Fig. 2).

INSTALLATION

CAUTION: Do not touch the glass of halogen

bulbs with fingers or other possibly oily surface,

reduced bulb life will result.

Reverse the preceding operation.

PARK AND TURN SIGNAL LAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws holding park and turn signal

lamp to headlamp module.

(3) Separate lamp from module.

(4) Remove bulb socket from back of lamp.

(5) Pull bulb from socket (Fig. 3).

INSTALLATION

Reverse the preceding operation.

Fig. 1 Headlamp Bulb

Fig. 2 Fog Lamp Bulb

8L - 6 LAMPSPL

Page 336 of 1200

FRONT SIDE MARKER LAMP BULB

REMOVAL

(1) Reach behind front bumper fascia forward of

front wheel.

(2) Remove socket from side marker lamp.

(3) Pull bulb from socket (Fig. 4).

INSTALLATION

Reverse the preceding operation.

CENTER HIGH MOUNTED STOP LAMP BULB

REMOVAL

(1) Release trunk latch and open trunk lid.

(2) Remove bulb socket from center high mounted

stop lamp (Fig. 5).

(3) Pull bulb from socket.

INSTALLATION

Reverse the preceding operation.

TAIL, STOP, BACK-UP AND TURN SIGNAL LAMP

BULB

REMOVAL

(1) Release trunk latch and open trunk lid.

(2) Separate trunk lining from rear closure panel

to gain access to back of tail lamp.

(3) Rotate and remove bulb socket from tail lamp

through openings in rear closure panel (Fig. 6).

(4) Pull bulb from socket.

INSTALLATION

(1) Push bulb into socket.

(2) Rotate and install bulb socket into tail lamp

through openings in rear closure panel.

(3) Install trunk lining to rear closure panel.

(4) Close and secure trunk lid.

Fig. 3 Park and Turn Signal Lamp Bulb

Fig. 4 Front Side Marker

Fig. 5 CHMSL Bulb

Fig. 6 Tail and Stop Lamp Bulb

PLLAMPS 8L - 7

REMOVAL AND INSTALLATION (Continued)

Page 338 of 1200

LAMP SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

CENTER HIGH MOUNTED STOP LAMP

(CHMSL)............................. 10

DOME LAMP........................... 11

FOG LAMP.............................. 9

FRONT SIDE MARKER LAMP.............. 10

HEADLAMP MODULE..................... 9LICENSE PLATE LAMP................... 11

PARK AND TURN SIGNAL LAMP............. 9

REAR CARGO LAMP..................... 11

TAIL, STOP AND TURN SIGNAL LAMP........ 10

UNDERHOOD LAMP..................... 11

VISOR VANITY LAMP..................... 11

REMOVAL AND INSTALLATION

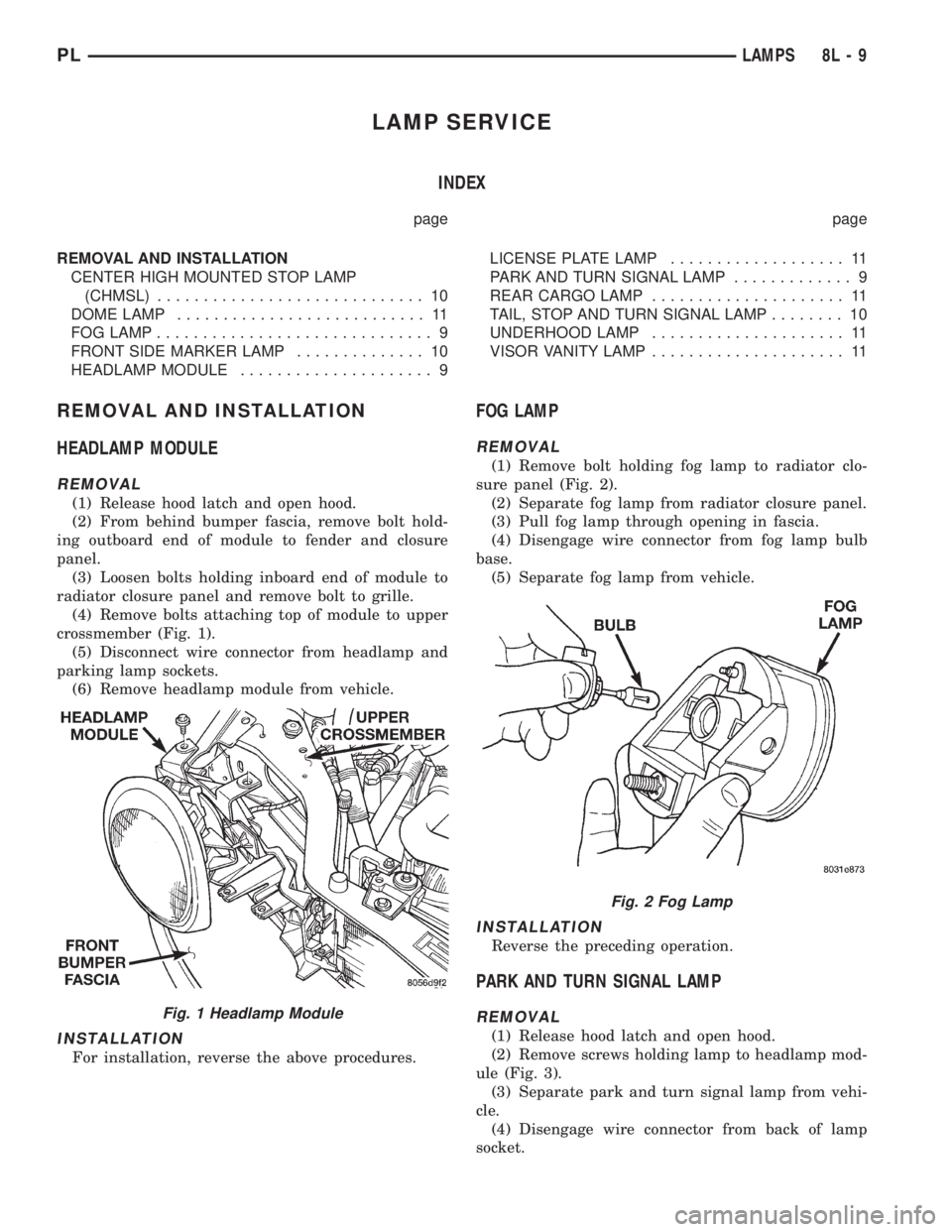

HEADLAMP MODULE

REMOVAL

(1) Release hood latch and open hood.

(2) From behind bumper fascia, remove bolt hold-

ing outboard end of module to fender and closure

panel.

(3) Loosen bolts holding inboard end of module to

radiator closure panel and remove bolt to grille.

(4) Remove bolts attaching top of module to upper

crossmember (Fig. 1).

(5) Disconnect wire connector from headlamp and

parking lamp sockets.

(6) Remove headlamp module from vehicle.

INSTALLATION

For installation, reverse the above procedures.

FOG LAMP

REMOVAL

(1) Remove bolt holding fog lamp to radiator clo-

sure panel (Fig. 2).

(2) Separate fog lamp from radiator closure panel.

(3) Pull fog lamp through opening in fascia.

(4) Disengage wire connector from fog lamp bulb

base.

(5) Separate fog lamp from vehicle.

INSTALLATION

Reverse the preceding operation.

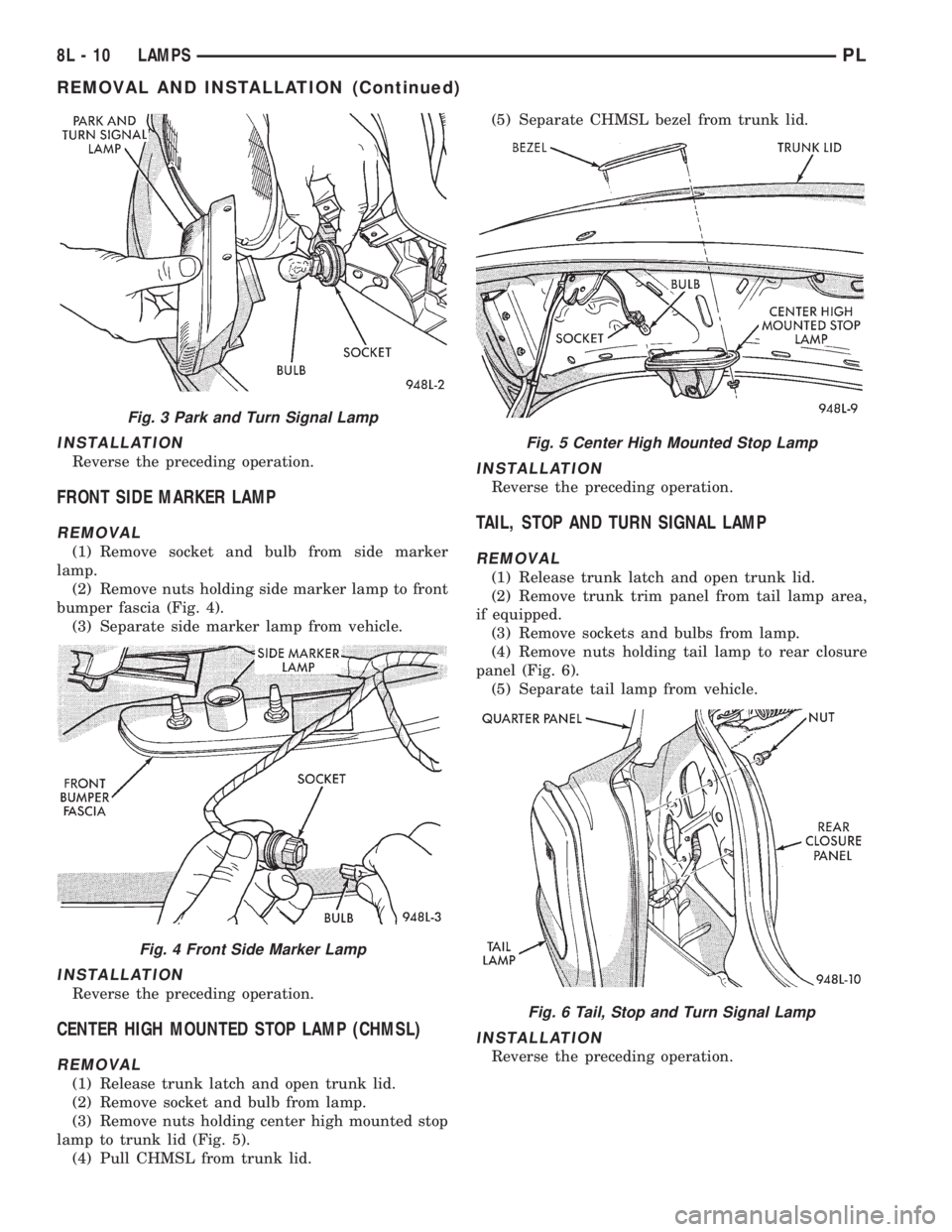

PARK AND TURN SIGNAL LAMP

REMOVAL

(1) Release hood latch and open hood.

(2) Remove screws holding lamp to headlamp mod-

ule (Fig. 3).

(3) Separate park and turn signal lamp from vehi-

cle.

(4) Disengage wire connector from back of lamp

socket.

Fig. 1 Headlamp Module

Fig. 2 Fog Lamp

PLLAMPS 8L - 9

Page 339 of 1200

INSTALLATION

Reverse the preceding operation.

FRONT SIDE MARKER LAMP

REMOVAL

(1) Remove socket and bulb from side marker

lamp.

(2) Remove nuts holding side marker lamp to front

bumper fascia (Fig. 4).

(3) Separate side marker lamp from vehicle.

INSTALLATION

Reverse the preceding operation.

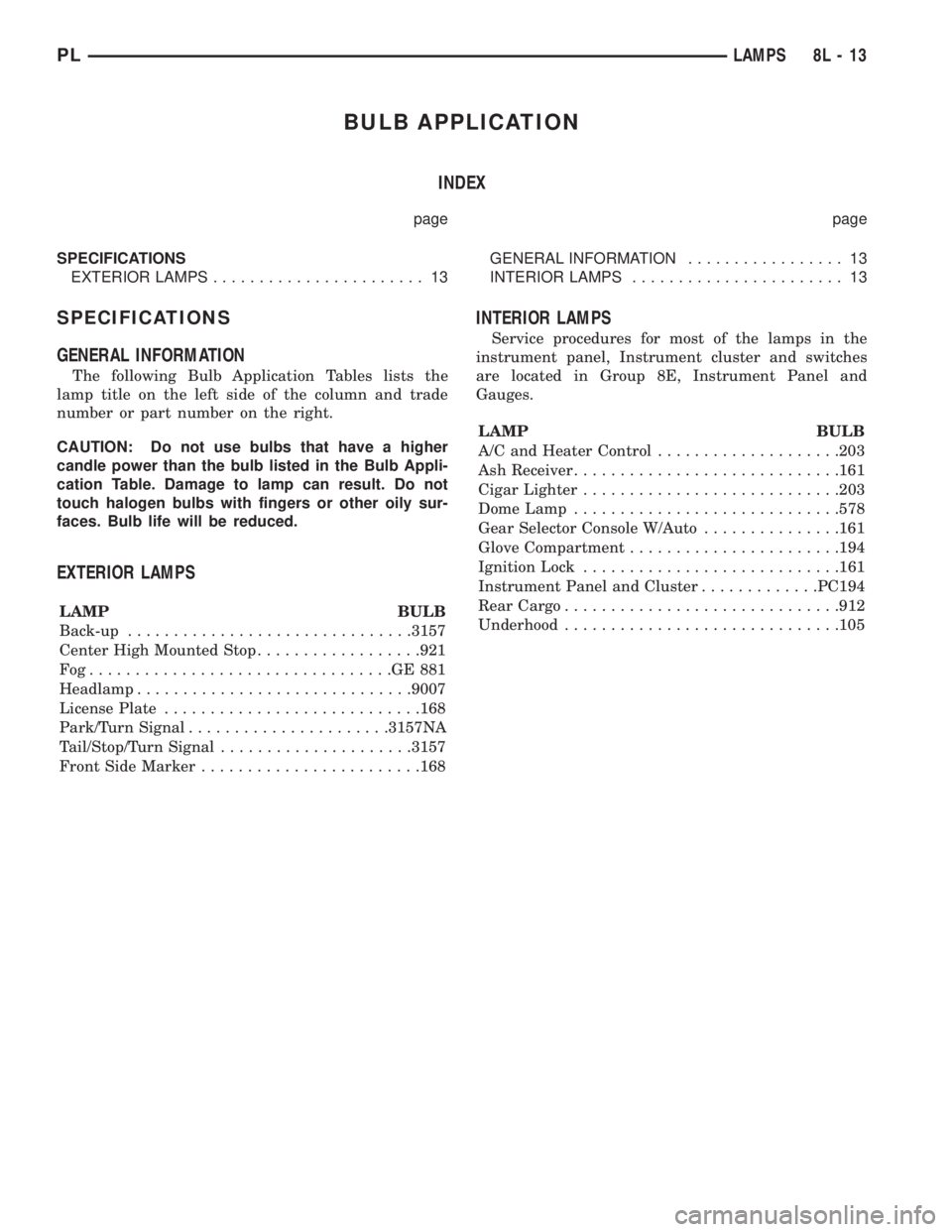

CENTER HIGH MOUNTED STOP LAMP (CHMSL)

REMOVAL

(1) Release trunk latch and open trunk lid.

(2) Remove socket and bulb from lamp.

(3) Remove nuts holding center high mounted stop

lamp to trunk lid (Fig. 5).

(4) Pull CHMSL from trunk lid.(5) Separate CHMSL bezel from trunk lid.

INSTALLATION

Reverse the preceding operation.

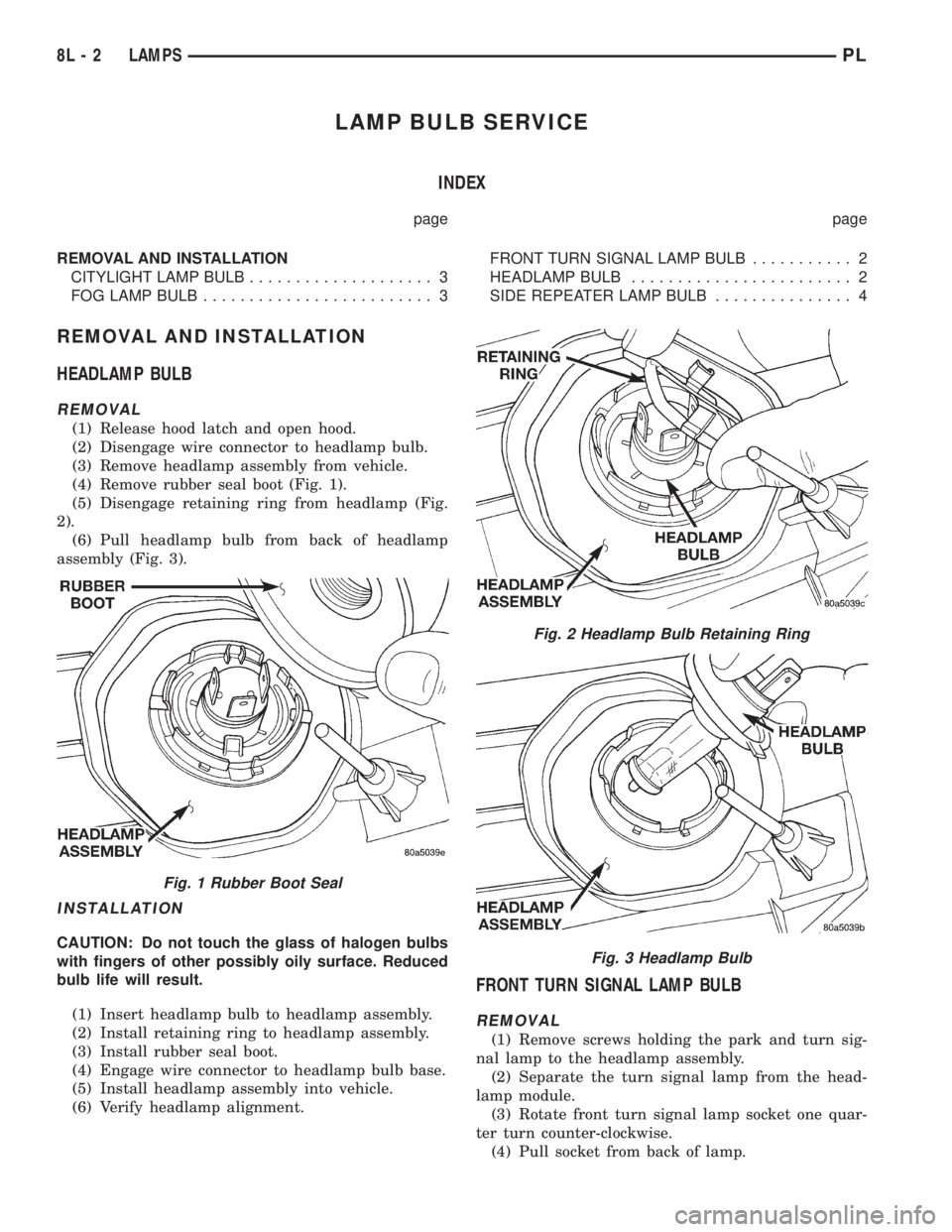

TAIL, STOP AND TURN SIGNAL LAMP

REMOVAL

(1) Release trunk latch and open trunk lid.

(2) Remove trunk trim panel from tail lamp area,

if equipped.

(3) Remove sockets and bulbs from lamp.

(4) Remove nuts holding tail lamp to rear closure

panel (Fig. 6).

(5) Separate tail lamp from vehicle.

INSTALLATION

Reverse the preceding operation.

Fig. 3 Park and Turn Signal Lamp

Fig. 4 Front Side Marker Lamp

Fig. 5 Center High Mounted Stop Lamp

Fig. 6 Tail, Stop and Turn Signal Lamp

8L - 10 LAMPSPL

REMOVAL AND INSTALLATION (Continued)

Page 342 of 1200

BULB APPLICATION

INDEX

page page

SPECIFICATIONS

EXTERIOR LAMPS....................... 13GENERAL INFORMATION................. 13

INTERIOR LAMPS....................... 13

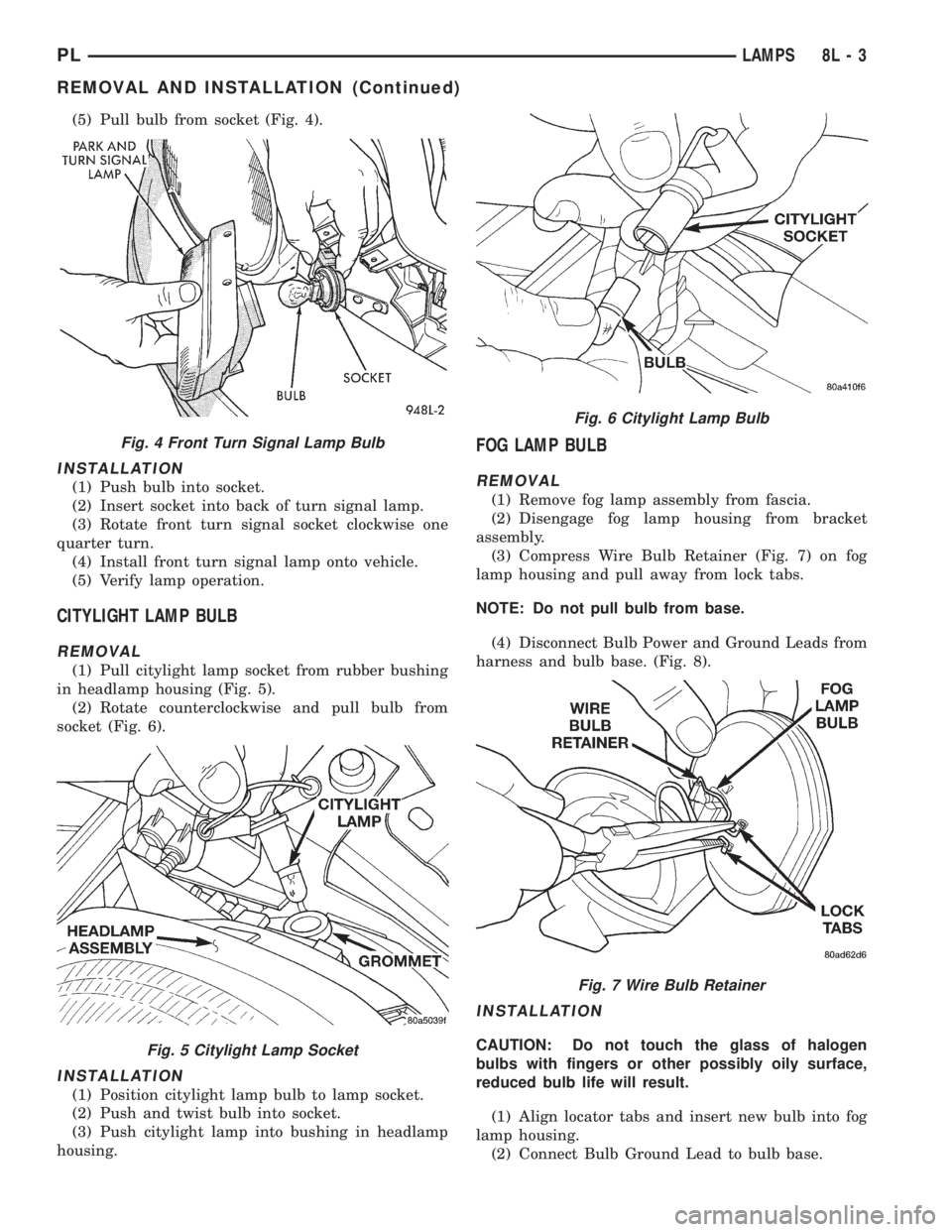

SPECIFICATIONS

GENERAL INFORMATION

The following Bulb Application Tables lists the

lamp title on the left side of the column and trade

number or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result. Do not

touch halogen bulbs with fingers or other oily sur-

faces. Bulb life will be reduced.

EXTERIOR LAMPS

LAMP BULB

Back-up...............................3157

Center High Mounted Stop..................921

Fog.................................GE881

Headlamp..............................9007

License Plate............................168

Park/Turn Signal......................3157NA

Tail/Stop/Turn Signal.....................3157

Front Side Marker........................168

INTERIOR LAMPS

Service procedures for most of the lamps in the

instrument panel, Instrument cluster and switches

are located in Group 8E, Instrument Panel and

Gauges.

LAMP BULB

A/C and Heater Control....................203

Ash Receiver.............................161

Cigar Lighter............................203

Dome Lamp.............................578

Gear Selector Console W/Auto...............161

Glove Compartment.......................194

Ignition Lock............................161

Instrument Panel and Cluster.............PC194

Rear Cargo..............................912

Underhood..............................105

PLLAMPS 8L - 13

Page 345 of 1200

LAMP BULB SERVICE

INDEX

page page

REMOVAL AND INSTALLATION

CITYLIGHT LAMP BULB.................... 3

FOG LAMP BULB......................... 3FRONT TURN SIGNAL LAMP BULB........... 2

HEADLAMP BULB........................ 2

SIDE REPEATER LAMP BULB............... 4

REMOVAL AND INSTALLATION

HEADLAMP BULB

REMOVAL

(1) Release hood latch and open hood.

(2) Disengage wire connector to headlamp bulb.

(3) Remove headlamp assembly from vehicle.

(4) Remove rubber seal boot (Fig. 1).

(5) Disengage retaining ring from headlamp (Fig.

2).

(6) Pull headlamp bulb from back of headlamp

assembly (Fig. 3).

INSTALLATION

CAUTION: Do not touch the glass of halogen bulbs

with fingers of other possibly oily surface. Reduced

bulb life will result.

(1) Insert headlamp bulb to headlamp assembly.

(2) Install retaining ring to headlamp assembly.

(3) Install rubber seal boot.

(4) Engage wire connector to headlamp bulb base.

(5) Install headlamp assembly into vehicle.

(6) Verify headlamp alignment.

FRONT TURN SIGNAL LAMP BULB

REMOVAL

(1) Remove screws holding the park and turn sig-

nal lamp to the headlamp assembly.

(2) Separate the turn signal lamp from the head-

lamp module.

(3) Rotate front turn signal lamp socket one quar-

ter turn counter-clockwise.

(4) Pull socket from back of lamp.

Fig. 1 Rubber Boot Seal

Fig. 2 Headlamp Bulb Retaining Ring

Fig. 3 Headlamp Bulb

8L - 2 LAMPSPL

Page 346 of 1200

(5) Pull bulb from socket (Fig. 4).

INSTALLATION

(1) Push bulb into socket.

(2) Insert socket into back of turn signal lamp.

(3) Rotate front turn signal socket clockwise one

quarter turn.

(4) Install front turn signal lamp onto vehicle.

(5) Verify lamp operation.

CITYLIGHT LAMP BULB

REMOVAL

(1) Pull citylight lamp socket from rubber bushing

in headlamp housing (Fig. 5).

(2) Rotate counterclockwise and pull bulb from

socket (Fig. 6).

INSTALLATION

(1) Position citylight lamp bulb to lamp socket.

(2) Push and twist bulb into socket.

(3) Push citylight lamp into bushing in headlamp

housing.

FOG LAMP BULB

REMOVAL

(1) Remove fog lamp assembly from fascia.

(2) Disengage fog lamp housing from bracket

assembly.

(3) Compress Wire Bulb Retainer (Fig. 7) on fog

lamp housing and pull away from lock tabs.

NOTE: Do not pull bulb from base.

(4) Disconnect Bulb Power and Ground Leads from

harness and bulb base. (Fig. 8).

INSTALLATION

CAUTION: Do not touch the glass of halogen

bulbs with fingers or other possibly oily surface,

reduced bulb life will result.

(1) Align locator tabs and insert new bulb into fog

lamp housing.

(2) Connect Bulb Ground Lead to bulb base.

Fig. 4 Front Turn Signal Lamp Bulb

Fig. 5 Citylight Lamp Socket

Fig. 6 Citylight Lamp Bulb

Fig. 7 Wire Bulb Retainer

PLLAMPS 8L - 3

REMOVAL AND INSTALLATION (Continued)

Page 351 of 1200

BULB APPLICATION

INDEX

page page

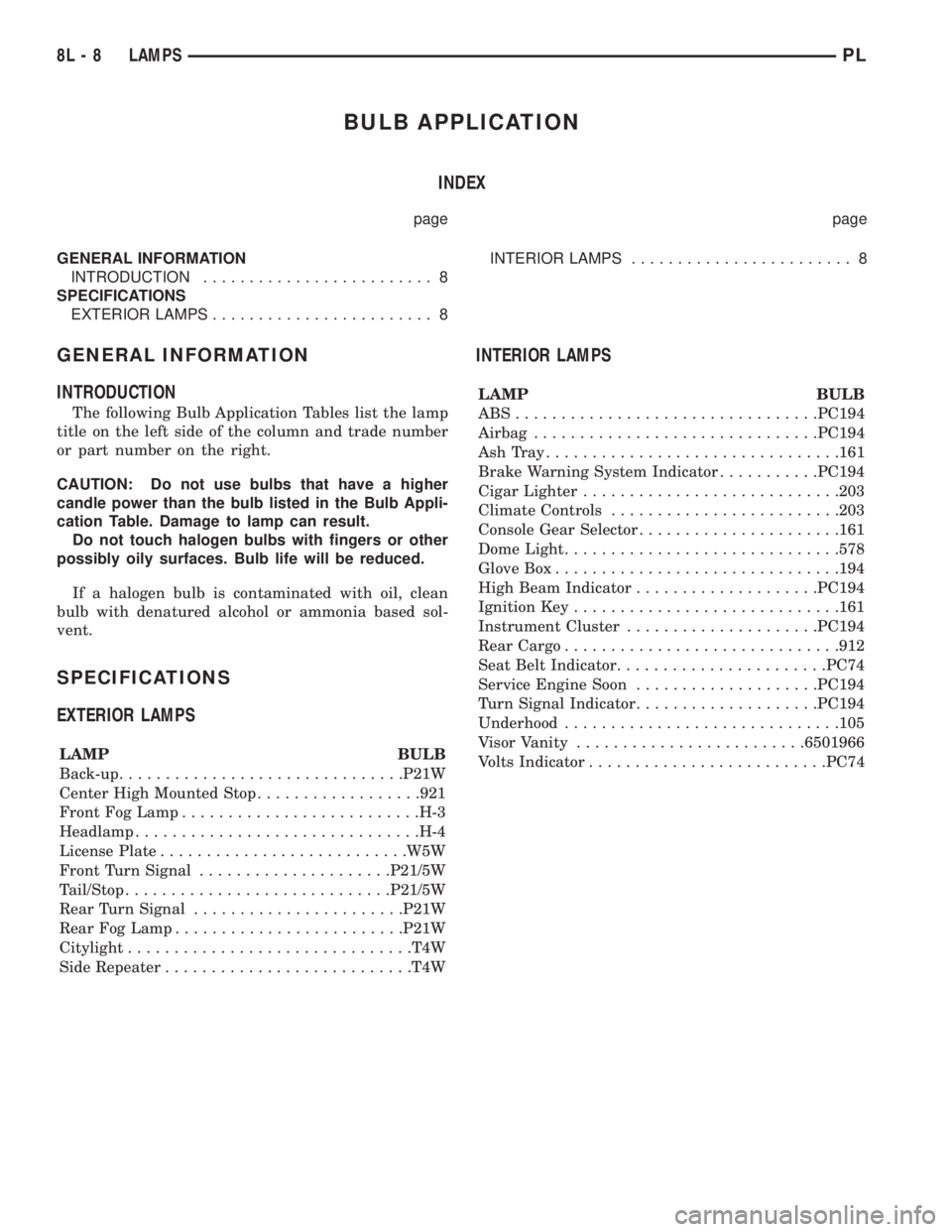

GENERAL INFORMATION

INTRODUCTION......................... 8

SPECIFICATIONS

EXTERIOR LAMPS........................ 8INTERIOR LAMPS........................ 8

GENERAL INFORMATION

INTRODUCTION

The following Bulb Application Tables list the lamp

title on the left side of the column and trade number

or part number on the right.

CAUTION: Do not use bulbs that have a higher

candle power than the bulb listed in the Bulb Appli-

cation Table. Damage to lamp can result.

Do not touch halogen bulbs with fingers or other

possibly oily surfaces. Bulb life will be reduced.

If a halogen bulb is contaminated with oil, clean

bulb with denatured alcohol or ammonia based sol-

vent.

SPECIFICATIONS

EXTERIOR LAMPS

LAMP BULB

Back-up...............................P21W

Center High Mounted Stop..................921

Front Fog Lamp..........................H-3

Headlamp...............................H-4

License Plate...........................W5W

Front Turn Signal.....................P21/5W

Tail/Stop.............................P21/5W

Rear Turn Signal.......................P21W

Rear Fog Lamp.........................P21W

Citylight...............................T4W

Side Repeater...........................T4W

INTERIOR LAMPS

LAMP BULB

ABS.................................PC194

Airbag...............................PC194

AshTray................................161

Brake Warning System Indicator...........PC194

Cigar Lighter............................203

Climate Controls.........................203

Console Gear Selector......................161

Dome Light..............................578

Glove Box...............................194

High Beam Indicator....................PC194

Ignition Key.............................161

Instrument Cluster.....................PC194

Rear Cargo..............................912

Seat Belt Indicator.......................PC74

Service Engine Soon....................PC194

Turn Signal Indicator....................PC194

Underhood..............................105

Visor Vanity.........................6501966

Volts Indicator..........................PC74

8L - 8 LAMPSPL

Page 875 of 1200

FUEL INJECTORSÐPCM OUTPUT

The 2.0L engine uses electrically operated top feed

fuel injectors (Fig. 26). The Automatic Shutdown

(ASD) relay supplies battery voltage to the fuel injec-

tors. The PCM controls the ground path for each

injector in sequence. By switching the ground paths

on and off, the PCM fine-tunes injector pulse width.

Injector pulse width refers to the amount of time an

injector operates.

The PCM determines injector synchronization from

the camshaft position sensor and crankshaft position

sensor inputs. The PCM grounds the ASD and fuel

pump relays after receiving the camshaft position

sensor and crankshaft position sensor inputs.

The PCM energizes the injectors in a sequential

order during all engine operating conditions except

start-up. For the first injector pulse width during

start-up, all injectors are energized at the same time.

Once the PCM determines crankshaft position, it

begins energizing the injectors in sequence.

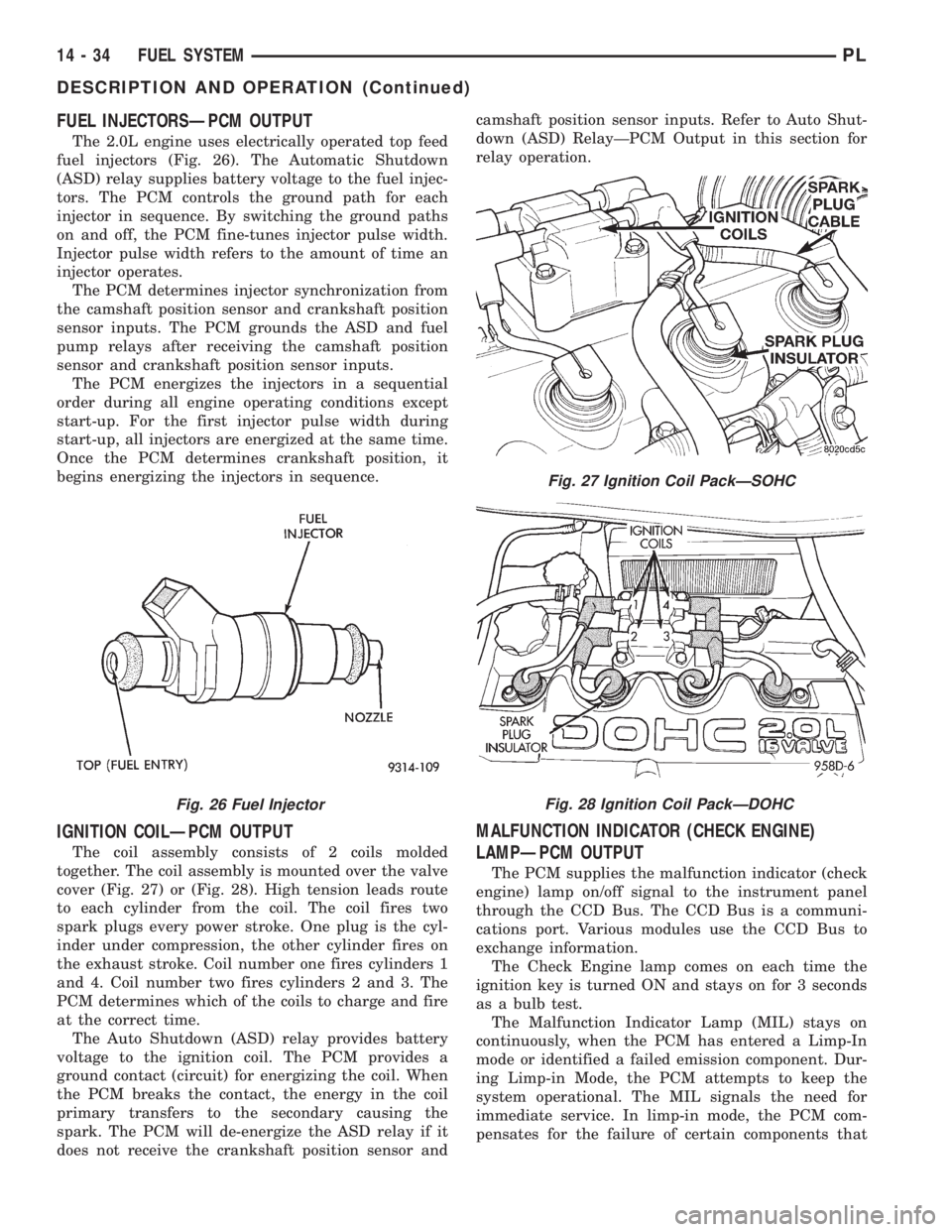

IGNITION COILÐPCM OUTPUT

The coil assembly consists of 2 coils molded

together. The coil assembly is mounted over the valve

cover (Fig. 27) or (Fig. 28). High tension leads route

to each cylinder from the coil. The coil fires two

spark plugs every power stroke. One plug is the cyl-

inder under compression, the other cylinder fires on

the exhaust stroke. Coil number one fires cylinders 1

and 4. Coil number two fires cylinders 2 and 3. The

PCM determines which of the coils to charge and fire

at the correct time.

The Auto Shutdown (ASD) relay provides battery

voltage to the ignition coil. The PCM provides a

ground contact (circuit) for energizing the coil. When

the PCM breaks the contact, the energy in the coil

primary transfers to the secondary causing the

spark. The PCM will de-energize the ASD relay if it

does not receive the crankshaft position sensor andcamshaft position sensor inputs. Refer to Auto Shut-

down (ASD) RelayÐPCM Output in this section for

relay operation.

MALFUNCTION INDICATOR (CHECK ENGINE)

LAMPÐPCM OUTPUT

The PCM supplies the malfunction indicator (check

engine) lamp on/off signal to the instrument panel

through the CCD Bus. The CCD Bus is a communi-

cations port. Various modules use the CCD Bus to

exchange information.

The Check Engine lamp comes on each time the

ignition key is turned ON and stays on for 3 seconds

as a bulb test.

The Malfunction Indicator Lamp (MIL) stays on

continuously, when the PCM has entered a Limp-In

mode or identified a failed emission component. Dur-

ing Limp-in Mode, the PCM attempts to keep the

system operational. The MIL signals the need for

immediate service. In limp-in mode, the PCM com-

pensates for the failure of certain components that

Fig. 26 Fuel Injector

Fig. 27 Ignition Coil PackÐSOHC

Fig. 28 Ignition Coil PackÐDOHC

14 - 34 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)