remove seats DODGE NEON 1999 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 1999, Model line: NEON, Model: DODGE NEON 1999Pages: 1200, PDF Size: 35.29 MB

Page 43 of 1200

²Binding strut assembly pivot bearing. If pivot

bearing is replaced it is to be installed with the white

side of bearing facing up (Fig. 74).

²Inspect dust shield for rips and/or deterioration.

²Inspect jounce bumper for cracks and signs of

deterioration.

(11) Replace any components of the strut assembly

found to be worn or defective during the inspection,

before assembling the strut.

ASSEMBLE

(1) Clamp the strut assembly in a vise, with the

strut in a vertical position.When clamping the

strut assembly in the vise, do not clamp strut

using the body of the strut only by strut clevis

bracket (Fig. 67).

(2) Install the compressed coil spring onto the

strut. Coil spring is to be installed with smaller coil

down, so spring correctly seats on strut assembly

(Fig. 73).

(3) Install jounce bumper on the strut shaft (Fig.

72).

(4) Install dust shield, pivot bearing and upper

spring seat as an assembly on the strut (Fig. 71).

(5) Position upper spring seat alignment notch

with clevis bracket on strut assembly.

(6) Install strut mount on strut assembly (Fig. 70)

and the strut mount retaining nut on the shaft of the

strut assembly.

WARNING: THE FOLLOWING 2 STEPS MUST BE

COMPLETELY DONE BEFORE SPRING COMPRES-

SOR, SPECIAL TOOL C-4838 IS RELEASED FROM

THE COIL SPRING.

(7) Install Socket, Strut Nut, Special Tool L-4558A

(or L-4558) on the strut shaft retaining nut (Fig. 69).

Then install a 10 mm socket through the center of

the socket and on the hex of the strut shaft (Fig. 69).

While holding strut shaft from turning, torque strut

shaft retaining nut to 75 N´m (55 ft. lbs.).

(8) Equally loosen both Spring Compressors, Spe-

cial Tool C-4838 until top coil of spring is fully seated

against upper spring seat and strut mount. Then

relieve all tension from spring compressors and

remove spring compressors from strut assembly

spring.

BALL JOINT

DISASSEMBLE

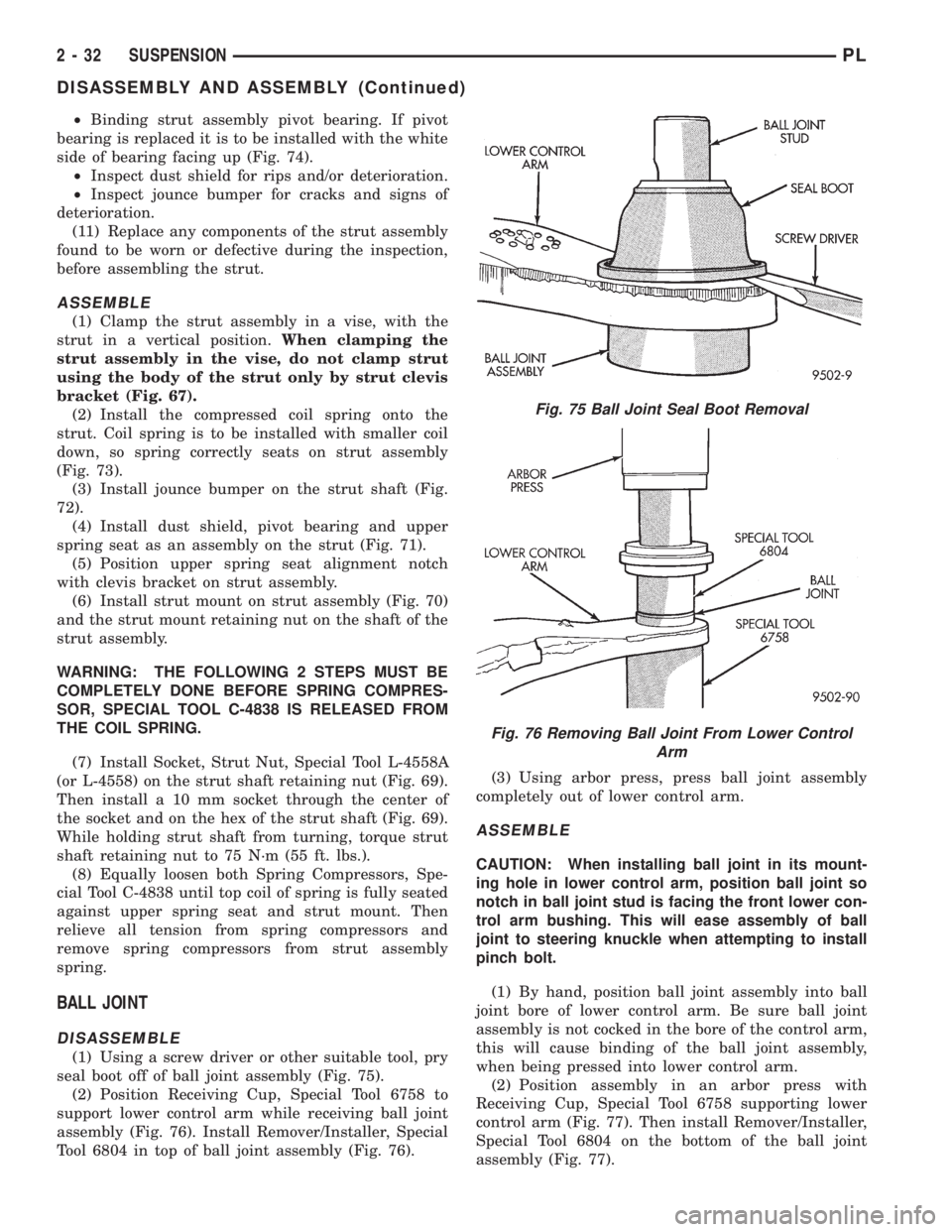

(1) Using a screw driver or other suitable tool, pry

seal boot off of ball joint assembly (Fig. 75).

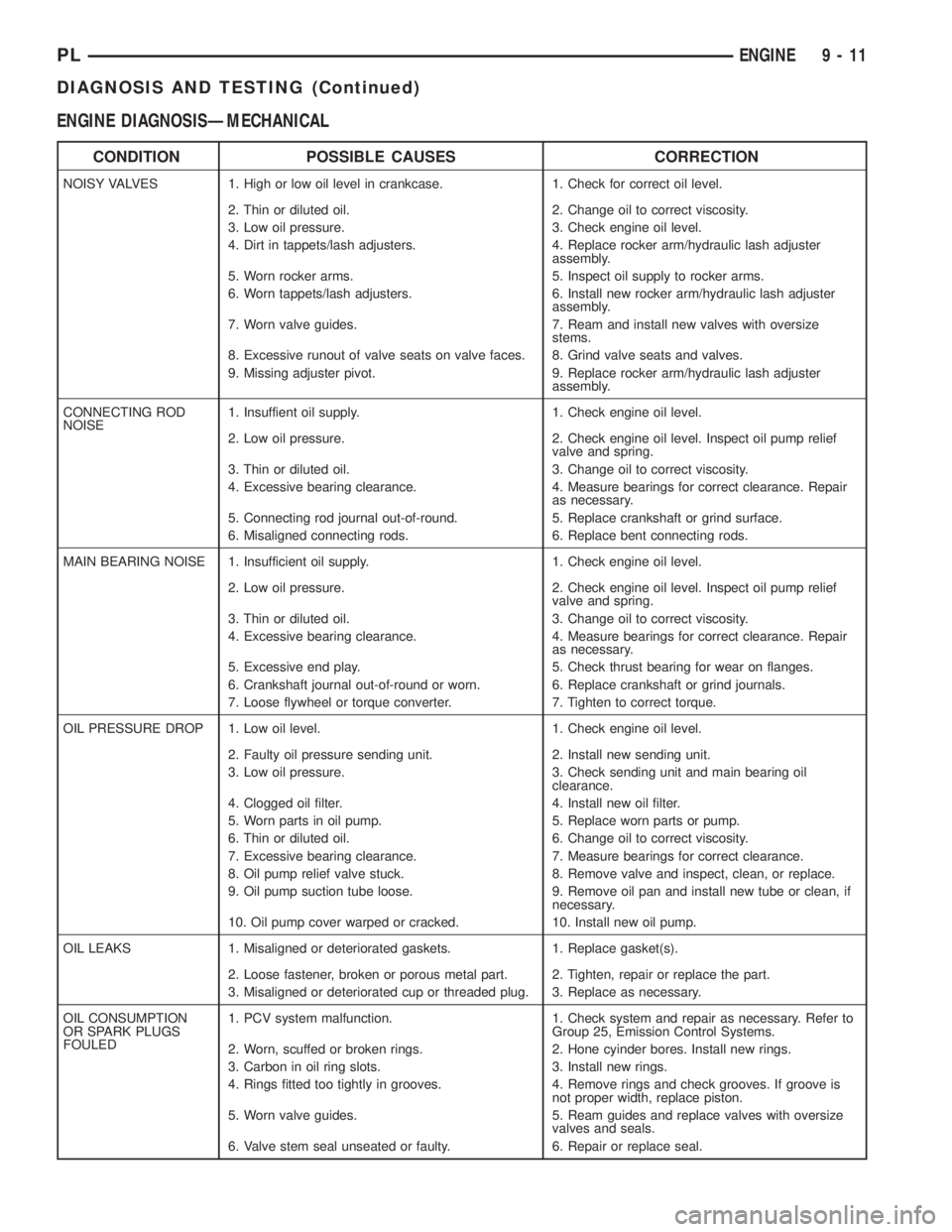

(2) Position Receiving Cup, Special Tool 6758 to

support lower control arm while receiving ball joint

assembly (Fig. 76). Install Remover/Installer, Special

Tool 6804 in top of ball joint assembly (Fig. 76).(3) Using arbor press, press ball joint assembly

completely out of lower control arm.

ASSEMBLE

CAUTION: When installing ball joint in its mount-

ing hole in lower control arm, position ball joint so

notch in ball joint stud is facing the front lower con-

trol arm bushing. This will ease assembly of ball

joint to steering knuckle when attempting to install

pinch bolt.

(1) By hand, position ball joint assembly into ball

joint bore of lower control arm. Be sure ball joint

assembly is not cocked in the bore of the control arm,

this will cause binding of the ball joint assembly,

when being pressed into lower control arm.

(2) Position assembly in an arbor press with

Receiving Cup, Special Tool 6758 supporting lower

control arm (Fig. 77). Then install Remover/Installer,

Special Tool 6804 on the bottom of the ball joint

assembly (Fig. 77).

Fig. 75 Ball Joint Seal Boot Removal

Fig. 76 Removing Ball Joint From Lower Control

Arm

2 - 32 SUSPENSIONPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 724 of 1200

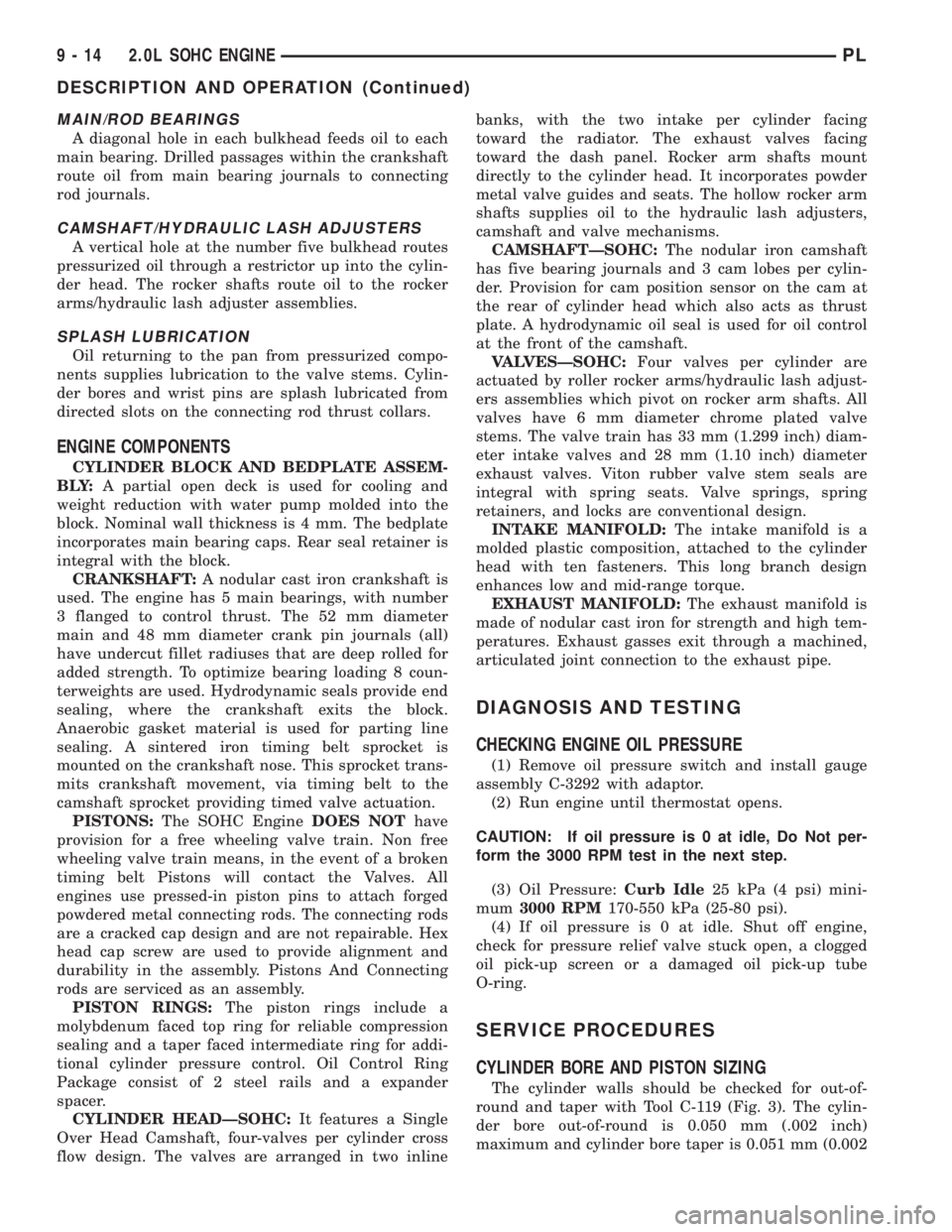

ENGINE DIAGNOSISÐMECHANICAL

CONDITION POSSIBLE CAUSES CORRECTION

NOISY VALVES 1. High or low oil level in crankcase. 1. Check for correct oil level.

2. Thin or diluted oil. 2. Change oil to correct viscosity.

3. Low oil pressure. 3. Check engine oil level.

4. Dirt in tappets/lash adjusters. 4. Replace rocker arm/hydraulic lash adjuster

assembly.

5. Worn rocker arms. 5. Inspect oil supply to rocker arms.

6. Worn tappets/lash adjusters. 6. Install new rocker arm/hydraulic lash adjuster

assembly.

7. Worn valve guides. 7. Ream and install new valves with oversize

stems.

8. Excessive runout of valve seats on valve faces. 8. Grind valve seats and valves.

9. Missing adjuster pivot. 9. Replace rocker arm/hydraulic lash adjuster

assembly.

CONNECTING ROD

NOISE1. Insuffient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil pump relief

valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct clearance. Repair

as necessary.

5. Connecting rod journal out-of-round. 5. Replace crankshaft or grind surface.

6. Misaligned connecting rods. 6. Replace bent connecting rods.

MAIN BEARING NOISE 1. Insufficient oil supply. 1. Check engine oil level.

2. Low oil pressure. 2. Check engine oil level. Inspect oil pump relief

valve and spring.

3. Thin or diluted oil. 3. Change oil to correct viscosity.

4. Excessive bearing clearance. 4. Measure bearings for correct clearance. Repair

as necessary.

5. Excessive end play. 5. Check thrust bearing for wear on flanges.

6. Crankshaft journal out-of-round or worn. 6. Replace crankshaft or grind journals.

7. Loose flywheel or torque converter. 7. Tighten to correct torque.

OIL PRESSURE DROP 1. Low oil level. 1. Check engine oil level.

2. Faulty oil pressure sending unit. 2. Install new sending unit.

3. Low oil pressure. 3. Check sending unit and main bearing oil

clearance.

4. Clogged oil filter. 4. Install new oil filter.

5. Worn parts in oil pump. 5. Replace worn parts or pump.

6. Thin or diluted oil. 6. Change oil to correct viscosity.

7. Excessive bearing clearance. 7. Measure bearings for correct clearance.

8. Oil pump relief valve stuck. 8. Remove valve and inspect, clean, or replace.

9. Oil pump suction tube loose. 9. Remove oil pan and install new tube or clean, if

necessary.

10. Oil pump cover warped or cracked. 10. Install new oil pump.

OIL LEAKS 1. Misaligned or deteriorated gaskets. 1. Replace gasket(s).

2. Loose fastener, broken or porous metal part. 2. Tighten, repair or replace the part.

3. Misaligned or deteriorated cup or threaded plug. 3. Replace as necessary.

OIL CONSUMPTION

OR SPARK PLUGS

FOULED1. PCV system malfunction. 1. Check system and repair as necessary. Refer to

Group 25, Emission Control Systems.

2. Worn, scuffed or broken rings. 2. Hone cyinder bores. Install new rings.

3. Carbon in oil ring slots. 3. Install new rings.

4. Rings fitted too tightly in grooves. 4. Remove rings and check grooves. If groove is

not proper width, replace piston.

5. Worn valve guides. 5. Ream guides and replace valves with oversize

valves and seals.

6. Valve stem seal unseated or faulty. 6. Repair or replace seal.

PLENGINE 9 - 11

DIAGNOSIS AND TESTING (Continued)

Page 727 of 1200

MAIN/ROD BEARINGS

A diagonal hole in each bulkhead feeds oil to each

main bearing. Drilled passages within the crankshaft

route oil from main bearing journals to connecting

rod journals.

CAMSHAFT/HYDRAULIC LASH ADJUSTERS

A vertical hole at the number five bulkhead routes

pressurized oil through a restrictor up into the cylin-

der head. The rocker shafts route oil to the rocker

arms/hydraulic lash adjuster assemblies.

SPLASH LUBRICATION

Oil returning to the pan from pressurized compo-

nents supplies lubrication to the valve stems. Cylin-

der bores and wrist pins are splash lubricated from

directed slots on the connecting rod thrust collars.

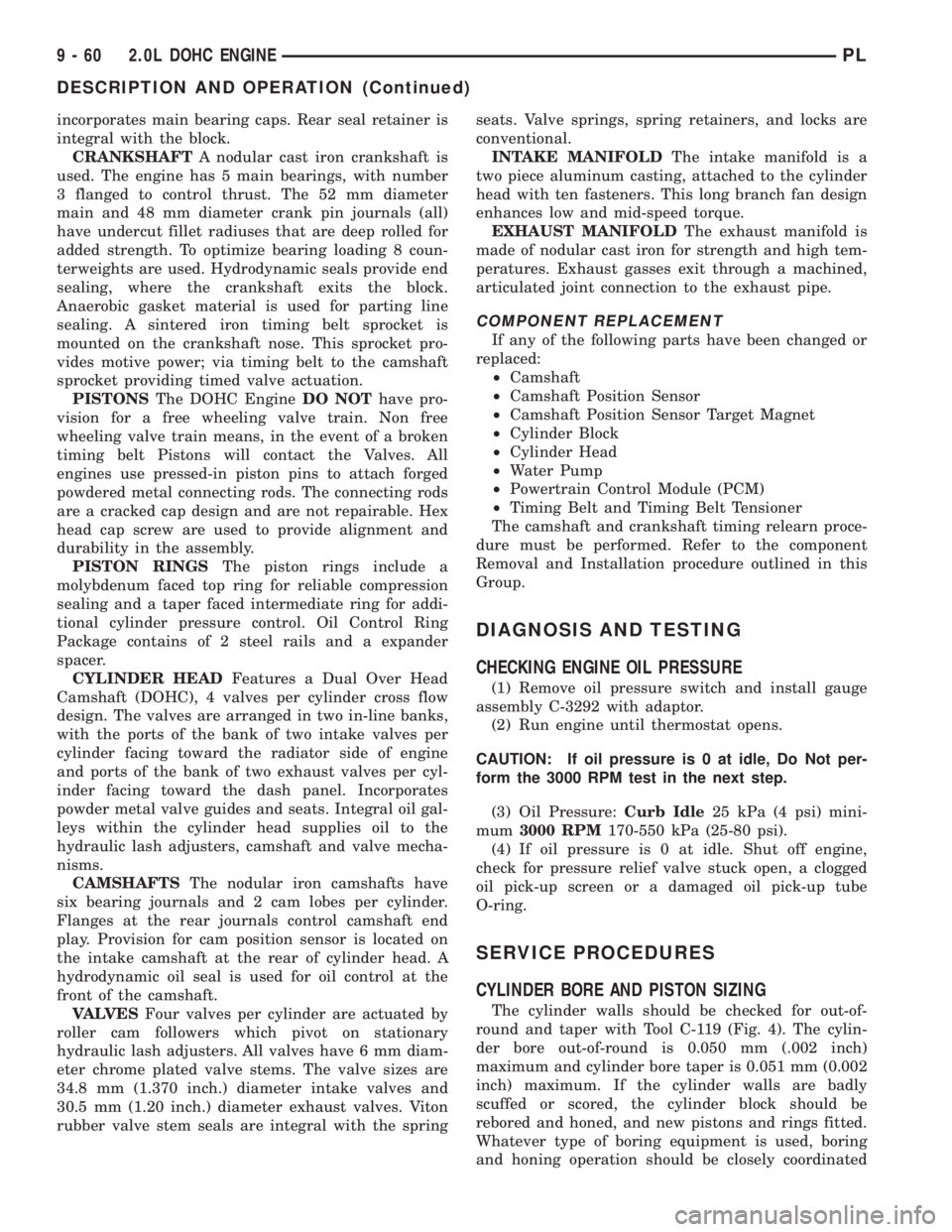

ENGINE COMPONENTS

CYLINDER BLOCK AND BEDPLATE ASSEM-

B LY:A partial open deck is used for cooling and

weight reduction with water pump molded into the

block. Nominal wall thickness is 4 mm. The bedplate

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFT:A nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket trans-

mits crankshaft movement, via timing belt to the

camshaft sprocket providing timed valve actuation.

PISTONS:The SOHC EngineDOES NOThave

provision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hex

head cap screw are used to provide alignment and

durability in the assembly. Pistons And Connecting

rods are serviced as an assembly.

PISTON RINGS:The piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package consist of 2 steel rails and a expander

spacer.

CYLINDER HEADÐSOHC:It features a Single

Over Head Camshaft, four-valves per cylinder cross

flow design. The valves are arranged in two inlinebanks, with the two intake per cylinder facing

toward the radiator. The exhaust valves facing

toward the dash panel. Rocker arm shafts mount

directly to the cylinder head. It incorporates powder

metal valve guides and seats. The hollow rocker arm

shafts supplies oil to the hydraulic lash adjusters,

camshaft and valve mechanisms.

CAMSHAFTÐSOHC:The nodular iron camshaft

has five bearing journals and 3 cam lobes per cylin-

der. Provision for cam position sensor on the cam at

the rear of cylinder head which also acts as thrust

plate. A hydrodynamic oil seal is used for oil control

at the front of the camshaft.

VALVESÐSOHC:Four valves per cylinder are

actuated by roller rocker arms/hydraulic lash adjust-

ers assemblies which pivot on rocker arm shafts. All

valves have 6 mm diameter chrome plated valve

stems. The valve train has 33 mm (1.299 inch) diam-

eter intake valves and 28 mm (1.10 inch) diameter

exhaust valves. Viton rubber valve stem seals are

integral with spring seats. Valve springs, spring

retainers, and locks are conventional design.

INTAKE MANIFOLD:The intake manifold is a

molded plastic composition, attached to the cylinder

head with ten fasteners. This long branch design

enhances low and mid-range torque.

EXHAUST MANIFOLD:The exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 3). The cylin-

der bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

9 - 14 2.0L SOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 773 of 1200

incorporates main bearing caps. Rear seal retainer is

integral with the block.

CRANKSHAFTA nodular cast iron crankshaft is

used. The engine has 5 main bearings, with number

3 flanged to control thrust. The 52 mm diameter

main and 48 mm diameter crank pin journals (all)

have undercut fillet radiuses that are deep rolled for

added strength. To optimize bearing loading 8 coun-

terweights are used. Hydrodynamic seals provide end

sealing, where the crankshaft exits the block.

Anaerobic gasket material is used for parting line

sealing. A sintered iron timing belt sprocket is

mounted on the crankshaft nose. This sprocket pro-

vides motive power; via timing belt to the camshaft

sprocket providing timed valve actuation.

PISTONSThe DOHC EngineDO NOThave pro-

vision for a free wheeling valve train. Non free

wheeling valve train means, in the event of a broken

timing belt Pistons will contact the Valves. All

engines use pressed-in piston pins to attach forged

powdered metal connecting rods. The connecting rods

are a cracked cap design and are not repairable. Hex

head cap screw are used to provide alignment and

durability in the assembly.

PISTON RINGSThe piston rings include a

molybdenum faced top ring for reliable compression

sealing and a taper faced intermediate ring for addi-

tional cylinder pressure control. Oil Control Ring

Package contains of 2 steel rails and a expander

spacer.

CYLINDER HEADFeatures a Dual Over Head

Camshaft (DOHC), 4 valves per cylinder cross flow

design. The valves are arranged in two in-line banks,

with the ports of the bank of two intake valves per

cylinder facing toward the radiator side of engine

and ports of the bank of two exhaust valves per cyl-

inder facing toward the dash panel. Incorporates

powder metal valve guides and seats. Integral oil gal-

leys within the cylinder head supplies oil to the

hydraulic lash adjusters, camshaft and valve mecha-

nisms.

CAMSHAFTSThe nodular iron camshafts have

six bearing journals and 2 cam lobes per cylinder.

Flanges at the rear journals control camshaft end

play. Provision for cam position sensor is located on

the intake camshaft at the rear of cylinder head. A

hydrodynamic oil seal is used for oil control at the

front of the camshaft.

VA LV E SFour valves per cylinder are actuated by

roller cam followers which pivot on stationary

hydraulic lash adjusters. All valves have 6 mm diam-

eter chrome plated valve stems. The valve sizes are

34.8 mm (1.370 inch.) diameter intake valves and

30.5 mm (1.20 inch.) diameter exhaust valves. Viton

rubber valve stem seals are integral with the springseats. Valve springs, spring retainers, and locks are

conventional.

INTAKE MANIFOLDThe intake manifold is a

two piece aluminum casting, attached to the cylinder

head with ten fasteners. This long branch fan design

enhances low and mid-speed torque.

EXHAUST MANIFOLDThe exhaust manifold is

made of nodular cast iron for strength and high tem-

peratures. Exhaust gasses exit through a machined,

articulated joint connection to the exhaust pipe.

COMPONENT REPLACEMENT

If any of the following parts have been changed or

replaced:

²Camshaft

²Camshaft Position Sensor

²Camshaft Position Sensor Target Magnet

²Cylinder Block

²Cylinder Head

²Water Pump

²Powertrain Control Module (PCM)

²Timing Belt and Timing Belt Tensioner

The camshaft and crankshaft timing relearn proce-

dure must be performed. Refer to the component

Removal and Installation procedure outlined in this

Group.

DIAGNOSIS AND TESTING

CHECKING ENGINE OIL PRESSURE

(1) Remove oil pressure switch and install gauge

assembly C-3292 with adaptor.

(2) Run engine until thermostat opens.

CAUTION: If oil pressure is 0 at idle, Do Not per-

form the 3000 RPM test in the next step.

(3) Oil Pressure:Curb Idle25 kPa (4 psi) mini-

mum3000 RPM170-550 kPa (25-80 psi).

(4) If oil pressure is 0 at idle. Shut off engine,

check for pressure relief valve stuck open, a clogged

oil pick-up screen or a damaged oil pick-up tube

O-ring.

SERVICE PROCEDURES

CYLINDER BORE AND PISTON SIZING

The cylinder walls should be checked for out-of-

round and taper with Tool C-119 (Fig. 4). The cylin-

der bore out-of-round is 0.050 mm (.002 inch)

maximum and cylinder bore taper is 0.051 mm (0.002

inch) maximum. If the cylinder walls are badly

scuffed or scored, the cylinder block should be

rebored and honed, and new pistons and rings fitted.

Whatever type of boring equipment is used, boring

and honing operation should be closely coordinated

9 - 60 2.0L DOHC ENGINEPL

DESCRIPTION AND OPERATION (Continued)

Page 805 of 1200

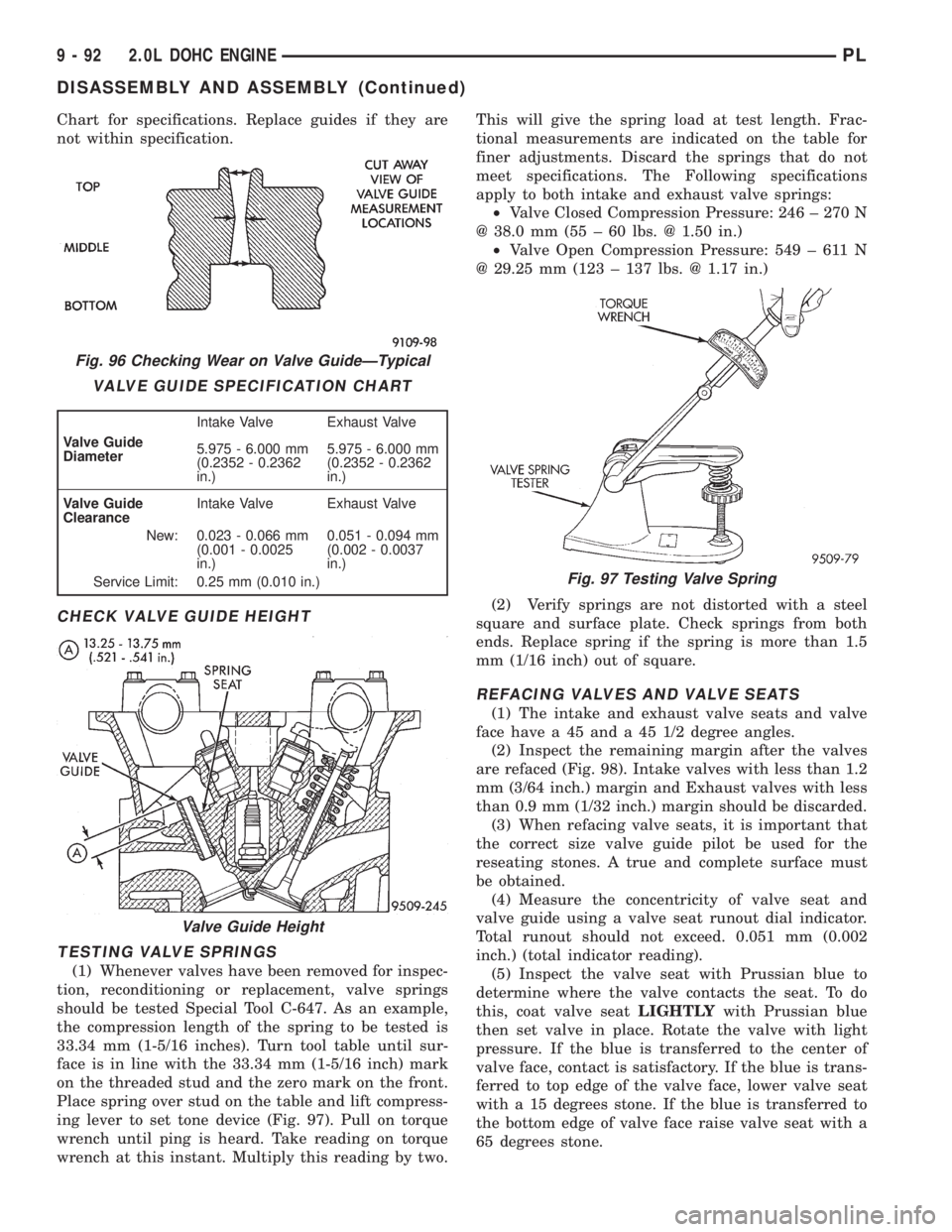

Chart for specifications. Replace guides if they are

not within specification.

CHECK VALVE GUIDE HEIGHT

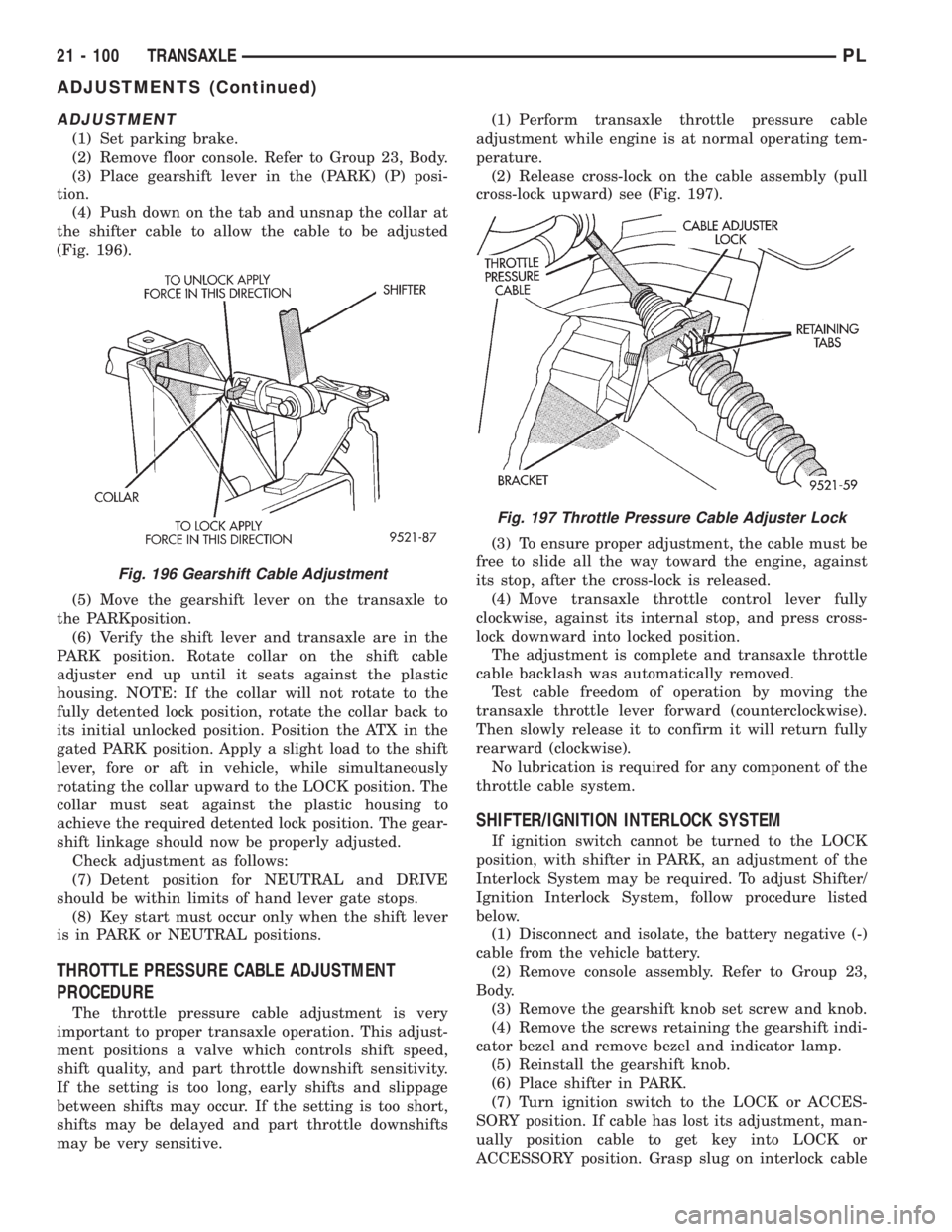

TESTING VALVE SPRINGS

(1) Whenever valves have been removed for inspec-

tion, reconditioning or replacement, valve springs

should be tested Special Tool C-647. As an example,

the compression length of the spring to be tested is

33.34 mm (1-5/16 inches). Turn tool table until sur-

face is in line with the 33.34 mm (1-5/16 inch) mark

on the threaded stud and the zero mark on the front.

Place spring over stud on the table and lift compress-

ing lever to set tone device (Fig. 97). Pull on torque

wrench until ping is heard. Take reading on torque

wrench at this instant. Multiply this reading by two.This will give the spring load at test length. Frac-

tional measurements are indicated on the table for

finer adjustments. Discard the springs that do not

meet specifications. The Following specifications

apply to both intake and exhaust valve springs:

²Valve Closed Compression Pressure: 246 ± 270 N

@ 38.0 mm (55 ± 60 lbs. @ 1.50 in.)

²Valve Open Compression Pressure: 549 ± 611 N

@ 29.25 mm (123 ± 137 lbs. @ 1.17 in.)

(2) Verify springs are not distorted with a steel

square and surface plate. Check springs from both

ends. Replace spring if the spring is more than 1.5

mm (1/16 inch) out of square.

REFACING VALVES AND VALVE SEATS

(1) The intake and exhaust valve seats and valve

face have a 45 and a 45 1/2 degree angles.

(2) Inspect the remaining margin after the valves

are refaced (Fig. 98). Intake valves with less than 1.2

mm (3/64 inch.) margin and Exhaust valves with less

than 0.9 mm (1/32 inch.) margin should be discarded.

(3) When refacing valve seats, it is important that

the correct size valve guide pilot be used for the

reseating stones. A true and complete surface must

be obtained.

(4) Measure the concentricity of valve seat and

valve guide using a valve seat runout dial indicator.

Total runout should not exceed. 0.051 mm (0.002

inch.) (total indicator reading).

(5) Inspect the valve seat with Prussian blue to

determine where the valve contacts the seat. To do

this, coat valve seatLIGHTLYwith Prussian blue

then set valve in place. Rotate the valve with light

pressure. If the blue is transferred to the center of

valve face, contact is satisfactory. If the blue is trans-

ferred to top edge of the valve face, lower valve seat

with a 15 degrees stone. If the blue is transferred to

the bottom edge of valve face raise valve seat with a

65 degrees stone.

Fig. 96 Checking Wear on Valve GuideÐTypical

VALVE GUIDE SPECIFICATION CHART

Valve Guide

DiameterIntake Valve Exhaust Valve

5.975 - 6.000 mm

(0.2352 - 0.2362

in.)5.975 - 6.000 mm

(0.2352 - 0.2362

in.)

Valve Guide

ClearanceIntake Valve Exhaust Valve

New: 0.023 - 0.066 mm

(0.001 - 0.0025

in.)0.051 - 0.094 mm

(0.002 - 0.0037

in.)

Service Limit: 0.25 mm (0.010 in.)

Valve Guide Height

Fig. 97 Testing Valve Spring

9 - 92 2.0L DOHC ENGINEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1043 of 1200

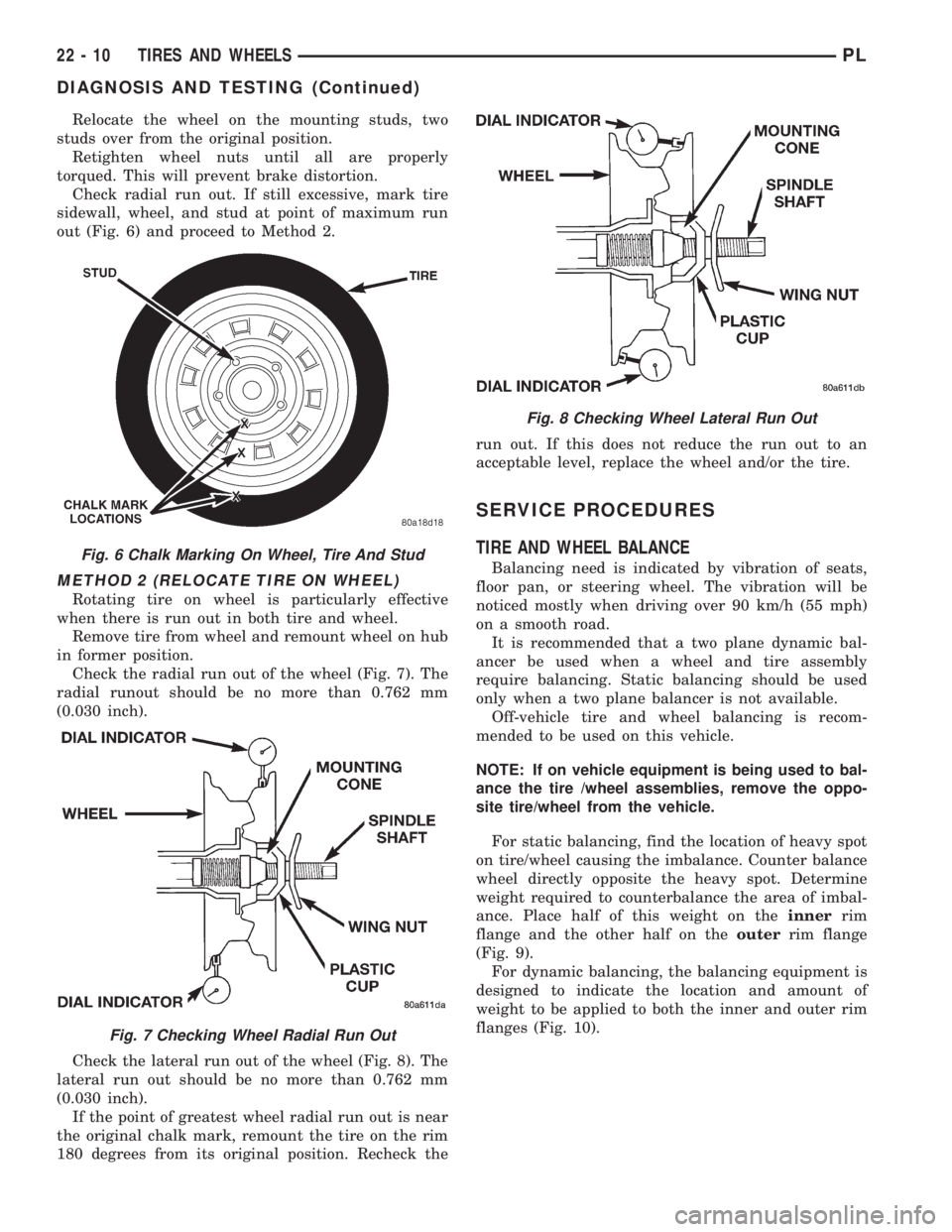

ADJUSTMENT

(1) Set parking brake.

(2) Remove floor console. Refer to Group 23, Body.

(3) Place gearshift lever in the (PARK) (P) posi-

tion.

(4) Push down on the tab and unsnap the collar at

the shifter cable to allow the cable to be adjusted

(Fig. 196).

(5) Move the gearshift lever on the transaxle to

the PARKposition.

(6) Verify the shift lever and transaxle are in the

PARK position. Rotate collar on the shift cable

adjuster end up until it seats against the plastic

housing. NOTE: If the collar will not rotate to the

fully detented lock position, rotate the collar back to

its initial unlocked position. Position the ATX in the

gated PARK position. Apply a slight load to the shift

lever, fore or aft in vehicle, while simultaneously

rotating the collar upward to the LOCK position. The

collar must seat against the plastic housing to

achieve the required detented lock position. The gear-

shift linkage should now be properly adjusted.

Check adjustment as follows:

(7) Detent position for NEUTRAL and DRIVE

should be within limits of hand lever gate stops.

(8) Key start must occur only when the shift lever

is in PARK or NEUTRAL positions.

THROTTLE PRESSURE CABLE ADJUSTMENT

PROCEDURE

The throttle pressure cable adjustment is very

important to proper transaxle operation. This adjust-

ment positions a valve which controls shift speed,

shift quality, and part throttle downshift sensitivity.

If the setting is too long, early shifts and slippage

between shifts may occur. If the setting is too short,

shifts may be delayed and part throttle downshifts

may be very sensitive.(1) Perform transaxle throttle pressure cable

adjustment while engine is at normal operating tem-

perature.

(2) Release cross-lock on the cable assembly (pull

cross-lock upward) see (Fig. 197).

(3) To ensure proper adjustment, the cable must be

free to slide all the way toward the engine, against

its stop, after the cross-lock is released.

(4) Move transaxle throttle control lever fully

clockwise, against its internal stop, and press cross-

lock downward into locked position.

The adjustment is complete and transaxle throttle

cable backlash was automatically removed.

Test cable freedom of operation by moving the

transaxle throttle lever forward (counterclockwise).

Then slowly release it to confirm it will return fully

rearward (clockwise).

No lubrication is required for any component of the

throttle cable system.

SHIFTER/IGNITION INTERLOCK SYSTEM

If ignition switch cannot be turned to the LOCK

position, with shifter in PARK, an adjustment of the

Interlock System may be required. To adjust Shifter/

Ignition Interlock System, follow procedure listed

below.

(1) Disconnect and isolate, the battery negative (-)

cable from the vehicle battery.

(2) Remove console assembly. Refer to Group 23,

Body.

(3) Remove the gearshift knob set screw and knob.

(4) Remove the screws retaining the gearshift indi-

cator bezel and remove bezel and indicator lamp.

(5) Reinstall the gearshift knob.

(6) Place shifter in PARK.

(7) Turn ignition switch to the LOCK or ACCES-

SORY position. If cable has lost its adjustment, man-

ually position cable to get key into LOCK or

ACCESSORY position. Grasp slug on interlock cable

Fig. 196 Gearshift Cable Adjustment

Fig. 197 Throttle Pressure Cable Adjuster Lock

21 - 100 TRANSAXLEPL

ADJUSTMENTS (Continued)

Page 1077 of 1200

Relocate the wheel on the mounting studs, two

studs over from the original position.

Retighten wheel nuts until all are properly

torqued. This will prevent brake distortion.

Check radial run out. If still excessive, mark tire

sidewall, wheel, and stud at point of maximum run

out (Fig. 6) and proceed to Method 2.

METHOD 2 (RELOCATE TIRE ON WHEEL)

Rotating tire on wheel is particularly effective

when there is run out in both tire and wheel.

Remove tire from wheel and remount wheel on hub

in former position.

Check the radial run out of the wheel (Fig. 7). The

radial runout should be no more than 0.762 mm

(0.030 inch).

Check the lateral run out of the wheel (Fig. 8). The

lateral run out should be no more than 0.762 mm

(0.030 inch).

If the point of greatest wheel radial run out is near

the original chalk mark, remount the tire on the rim

180 degrees from its original position. Recheck therun out. If this does not reduce the run out to an

acceptable level, replace the wheel and/or the tire.

SERVICE PROCEDURES

TIRE AND WHEEL BALANCE

Balancing need is indicated by vibration of seats,

floor pan, or steering wheel. The vibration will be

noticed mostly when driving over 90 km/h (55 mph)

on a smooth road.

It is recommended that a two plane dynamic bal-

ancer be used when a wheel and tire assembly

require balancing. Static balancing should be used

only when a two plane balancer is not available.

Off-vehicle tire and wheel balancing is recom-

mended to be used on this vehicle.

NOTE: If on vehicle equipment is being used to bal-

ance the tire /wheel assemblies, remove the oppo-

site tire/wheel from the vehicle.

For static balancing, find the location of heavy spot

on tire/wheel causing the imbalance. Counter balance

wheel directly opposite the heavy spot. Determine

weight required to counterbalance the area of imbal-

ance. Place half of this weight on theinnerrim

flange and the other half on theouterrim flange

(Fig. 9).

For dynamic balancing, the balancing equipment is

designed to indicate the location and amount of

weight to be applied to both the inner and outer rim

flanges (Fig. 10).Fig. 6 Chalk Marking On Wheel, Tire And Stud

Fig. 7 Checking Wheel Radial Run Out

Fig. 8 Checking Wheel Lateral Run Out

22 - 10 TIRES AND WHEELSPL

DIAGNOSIS AND TESTING (Continued)

Page 1082 of 1200

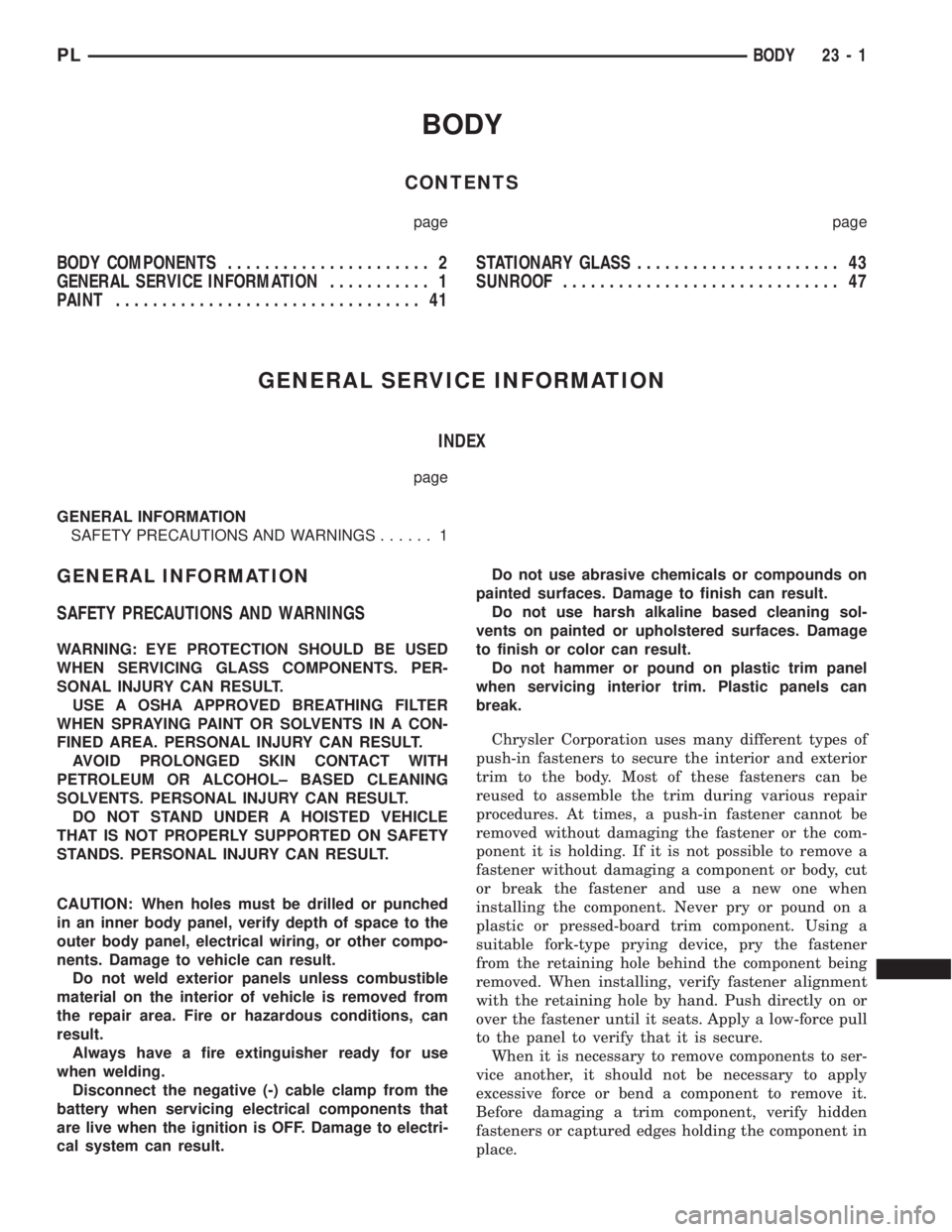

BODY

CONTENTS

page page

BODY COMPONENTS...................... 2

GENERAL SERVICE INFORMATION........... 1

PAINT................................. 41STATIONARY GLASS...................... 43

SUNROOF.............................. 47

GENERAL SERVICE INFORMATION

INDEX

page

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS...... 1

GENERAL INFORMATION

SAFETY PRECAUTIONS AND WARNINGS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

USE A OSHA APPROVED BREATHING FILTER

WHEN SPRAYING PAINT OR SOLVENTS IN A CON-

FINED AREA. PERSONAL INJURY CAN RESULT.

AVOID PROLONGED SKIN CONTACT WITH

PETROLEUM OR ALCOHOL± BASED CLEANING

SOLVENTS. PERSONAL INJURY CAN RESULT.

DO NOT STAND UNDER A HOISTED VEHICLE

THAT IS NOT PROPERLY SUPPORTED ON SAFETY

STANDS. PERSONAL INJURY CAN RESULT.

CAUTION: When holes must be drilled or punched

in an inner body panel, verify depth of space to the

outer body panel, electrical wiring, or other compo-

nents. Damage to vehicle can result.

Do not weld exterior panels unless combustible

material on the interior of vehicle is removed from

the repair area. Fire or hazardous conditions, can

result.

Always have a fire extinguisher ready for use

when welding.

Disconnect the negative (-) cable clamp from the

battery when servicing electrical components that

are live when the ignition is OFF. Damage to electri-

cal system can result.Do not use abrasive chemicals or compounds on

painted surfaces. Damage to finish can result.

Do not use harsh alkaline based cleaning sol-

vents on painted or upholstered surfaces. Damage

to finish or color can result.

Do not hammer or pound on plastic trim panel

when servicing interior trim. Plastic panels can

break.

Chrysler Corporation uses many different types of

push-in fasteners to secure the interior and exterior

trim to the body. Most of these fasteners can be

reused to assemble the trim during various repair

procedures. At times, a push-in fastener cannot be

removed without damaging the fastener or the com-

ponent it is holding. If it is not possible to remove a

fastener without damaging a component or body, cut

or break the fastener and use a new one when

installing the component. Never pry or pound on a

plastic or pressed-board trim component. Using a

suitable fork-type prying device, pry the fastener

from the retaining hole behind the component being

removed. When installing, verify fastener alignment

with the retaining hole by hand. Push directly on or

over the fastener until it seats. Apply a low-force pull

to the panel to verify that it is secure.

When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges holding the component in

place.

PLBODY 23 - 1

Page 1088 of 1200

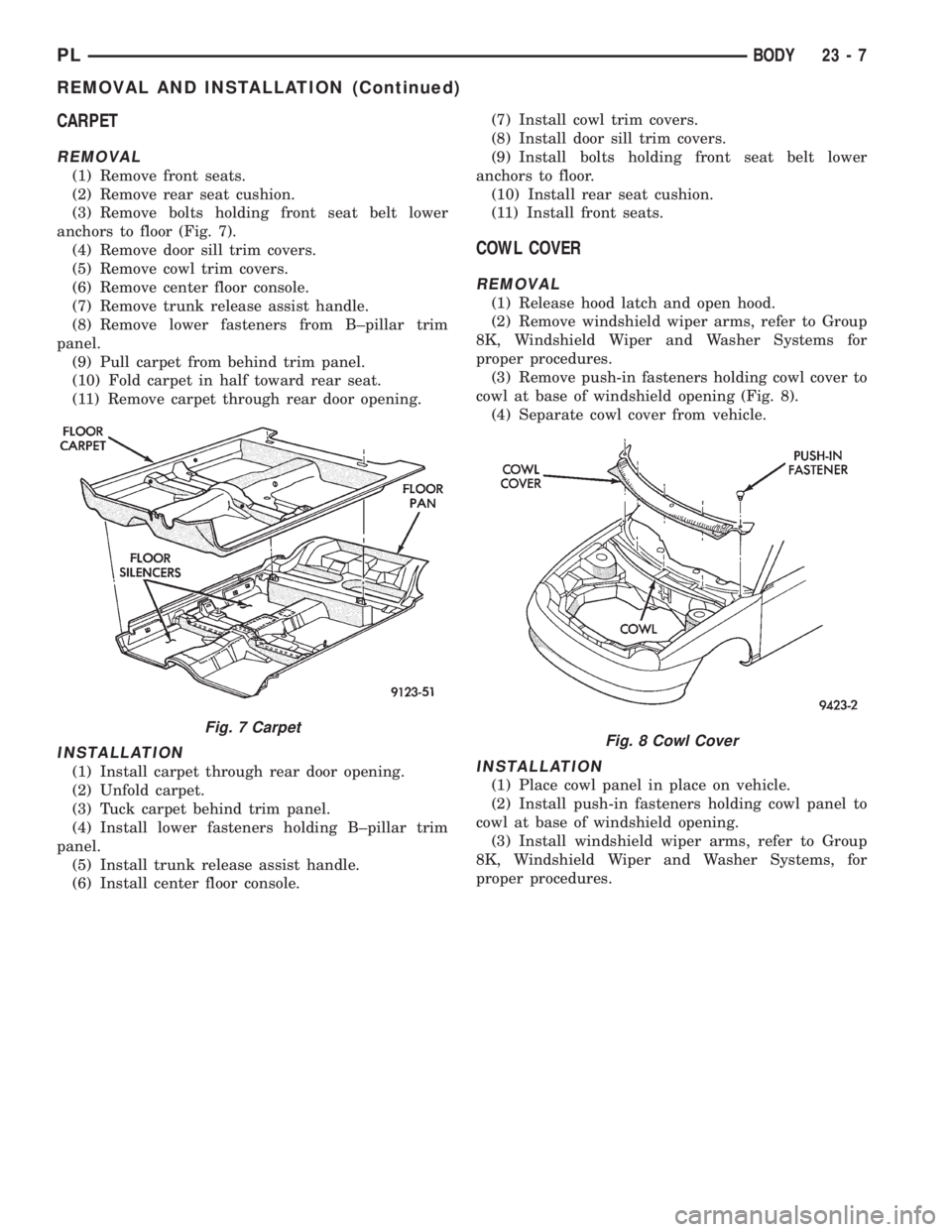

CARPET

REMOVAL

(1) Remove front seats.

(2) Remove rear seat cushion.

(3) Remove bolts holding front seat belt lower

anchors to floor (Fig. 7).

(4) Remove door sill trim covers.

(5) Remove cowl trim covers.

(6) Remove center floor console.

(7) Remove trunk release assist handle.

(8) Remove lower fasteners from B±pillar trim

panel.

(9) Pull carpet from behind trim panel.

(10) Fold carpet in half toward rear seat.

(11) Remove carpet through rear door opening.

INSTALLATION

(1) Install carpet through rear door opening.

(2) Unfold carpet.

(3) Tuck carpet behind trim panel.

(4) Install lower fasteners holding B±pillar trim

panel.

(5) Install trunk release assist handle.

(6) Install center floor console.(7) Install cowl trim covers.

(8) Install door sill trim covers.

(9) Install bolts holding front seat belt lower

anchors to floor.

(10) Install rear seat cushion.

(11) Install front seats.

COWL COVER

REMOVAL

(1) Release hood latch and open hood.

(2) Remove windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems for

proper procedures.

(3) Remove push-in fasteners holding cowl cover to

cowl at base of windshield opening (Fig. 8).

(4) Separate cowl cover from vehicle.

INSTALLATION

(1) Place cowl panel in place on vehicle.

(2) Install push-in fasteners holding cowl panel to

cowl at base of windshield opening.

(3) Install windshield wiper arms, refer to Group

8K, Windshield Wiper and Washer Systems, for

proper procedures.

Fig. 7 CarpetFig. 8 Cowl Cover

PLBODY 23 - 7

REMOVAL AND INSTALLATION (Continued)