battery DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 367 of 1285

REMOTE KEYLESS ENTRY (RKE)

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................4

REMOTE KEYLESS ENTRY SYSTEM..........5

REMOTE KEYLESS ENTRY TRANSMITTER.....5

HORN CHIRP TOGGLE.....................5

DIAGNOSIS AND TESTING

REMOTE KEYLESS ENTRY MODULE..........5

DECKLID RELEASE SOLENOID...............5

SERVICE PROCEDURES

HORN CHIRP TOGGLE.....................5SWITCHING OPERATING MODES/

CONFIGURING A NEW MODULE............6

TRANSMITTER PROGRAMMING..............6

REMOVAL AND INSTALLATION

DECK LID RELEASE SOLENOID..............6

REMOTE KEYLESS ENTRY MODULE..........6

SPECIFICATIONS

TRANSMITTER BATTERY...................7

TRANSMITTER RANGE.....................7

DESCRIPTION AND OPERATION

INTRODUCTION

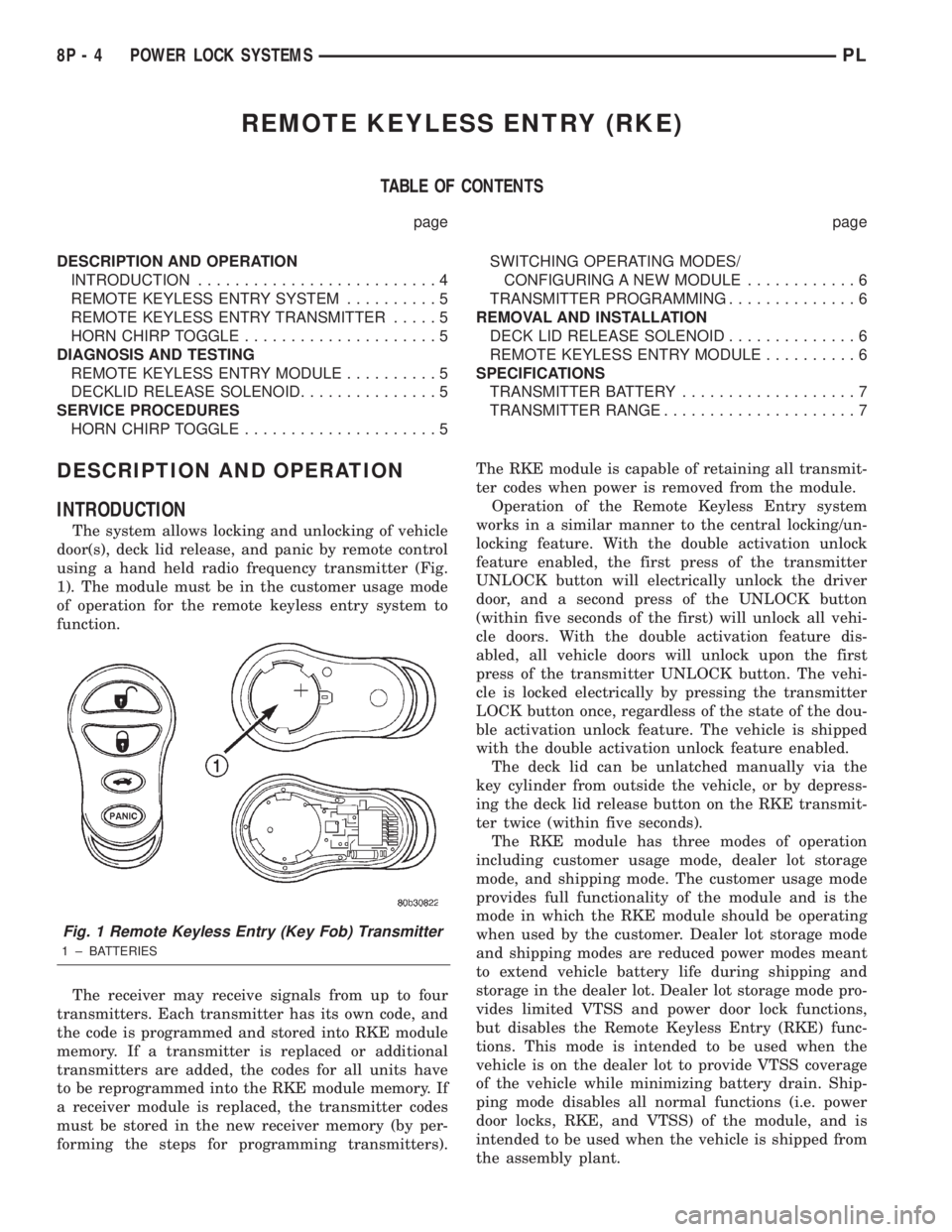

The system allows locking and unlocking of vehicle

door(s), deck lid release, and panic by remote control

using a hand held radio frequency transmitter (Fig.

1). The module must be in the customer usage mode

of operation for the remote keyless entry system to

function.

The receiver may receive signals from up to four

transmitters. Each transmitter has its own code, and

the code is programmed and stored into RKE module

memory. If a transmitter is replaced or additional

transmitters are added, the codes for all units have

to be reprogrammed into the RKE module memory. If

a receiver module is replaced, the transmitter codes

must be stored in the new receiver memory (by per-

forming the steps for programming transmitters).The RKE module is capable of retaining all transmit-

ter codes when power is removed from the module.

Operation of the Remote Keyless Entry system

works in a similar manner to the central locking/un-

locking feature. With the double activation unlock

feature enabled, the first press of the transmitter

UNLOCK button will electrically unlock the driver

door, and a second press of the UNLOCK button

(within five seconds of the first) will unlock all vehi-

cle doors. With the double activation feature dis-

abled, all vehicle doors will unlock upon the first

press of the transmitter UNLOCK button. The vehi-

cle is locked electrically by pressing the transmitter

LOCK button once, regardless of the state of the dou-

ble activation unlock feature. The vehicle is shipped

with the double activation unlock feature enabled.

The deck lid can be unlatched manually via the

key cylinder from outside the vehicle, or by depress-

ing the deck lid release button on the RKE transmit-

ter twice (within five seconds).

The RKE module has three modes of operation

including customer usage mode, dealer lot storage

mode, and shipping mode. The customer usage mode

provides full functionality of the module and is the

mode in which the RKE module should be operating

when used by the customer. Dealer lot storage mode

and shipping modes are reduced power modes meant

to extend vehicle battery life during shipping and

storage in the dealer lot. Dealer lot storage mode pro-

vides limited VTSS and power door lock functions,

but disables the Remote Keyless Entry (RKE) func-

tions. This mode is intended to be used when the

vehicle is on the dealer lot to provide VTSS coverage

of the vehicle while minimizing battery drain. Ship-

ping mode disables all normal functions (i.e. power

door locks, RKE, and VTSS) of the module, and is

intended to be used when the vehicle is shipped from

the assembly plant.

Fig. 1 Remote Keyless Entry (Key Fob) Transmitter

1 ± BATTERIES

8P - 4 POWER LOCK SYSTEMSPL

Page 369 of 1285

(1) With the ignition switch in RUN position, press

and hold the transmitter Unlock button (Fig. 1) for a

minimum of 4 seconds to a maximum of 10 seconds.

(2) Within the 4-10 second range, depress the

transmitter Lock button (Fig. 1). A chime will be

heard to indicate a successful toggle, at which time

the buttons may be released.

SWITCHING OPERATING MODES/

CONFIGURING A NEW MODULE

Refer to Group 8Q-Vehicle Theft/Security Systems,

Switching Operating Modes/Configuring A New Mod-

ule under Service Procedures.

TRANSMITTER PROGRAMMING

The Remote Keyless Entry transmitters can be

programmed with the use of the DRB IIItscan tool

or by the customer.

DRB lllTPROGRAMMING

When using the DRB IIItscan tool, select:

(1) ªTheft Alarmº

(2) ªVTSSº

(3) ªMiscellaneousº

and then the desired function.

CUSTOMER PROGRAMMING

For a customer to be able to program RKE trans-

mitters themselves, at least one RKE transmitter

must be programmed already. This procedure is to

add additional transmitters. If all transmitters are

lost, the DRB IIItscan tool must be used to program

the new transmitters.

(1) With the ignition switch in RUN position, press

and hold the transmitter Unlock button (Fig. 1) for a

minimum of 4 seconds to a maximum of 10 seconds.

(2) Within the 4-10 second range, depress the

transmitter Lock button (Fig. 1). A chime will be

heard to indicate successful toggle, at which time the

buttons may be released.

(3) Turn the ignition switch off to exist transmitter

programming mode.

REMOVAL AND INSTALLATION

DECK LID RELEASE SOLENOID

REMOVAL

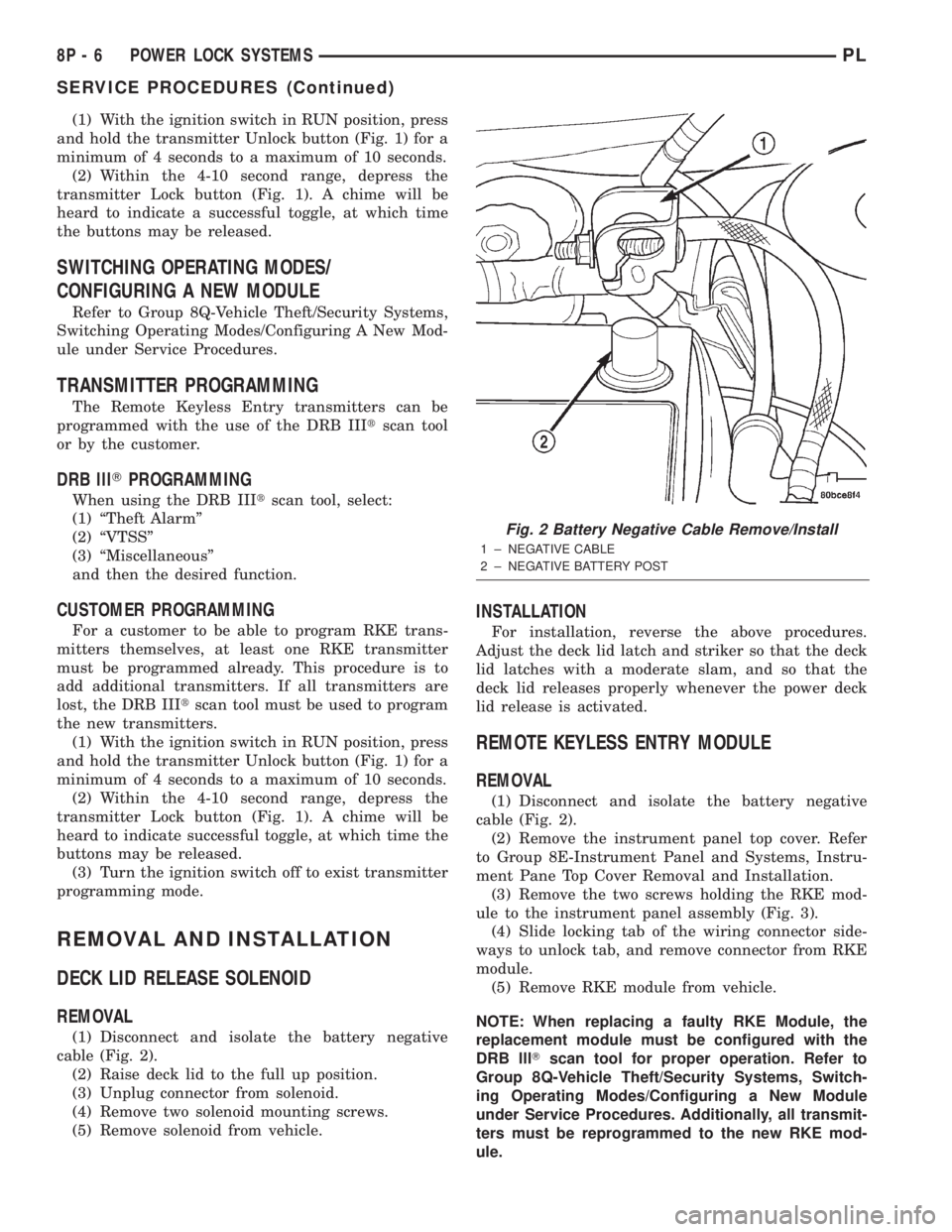

(1) Disconnect and isolate the battery negative

cable (Fig. 2).

(2) Raise deck lid to the full up position.

(3) Unplug connector from solenoid.

(4) Remove two solenoid mounting screws.

(5) Remove solenoid from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Adjust the deck lid latch and striker so that the deck

lid latches with a moderate slam, and so that the

deck lid releases properly whenever the power deck

lid release is activated.

REMOTE KEYLESS ENTRY MODULE

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 2).

(2) Remove the instrument panel top cover. Refer

to Group 8E-Instrument Panel and Systems, Instru-

ment Pane Top Cover Removal and Installation.

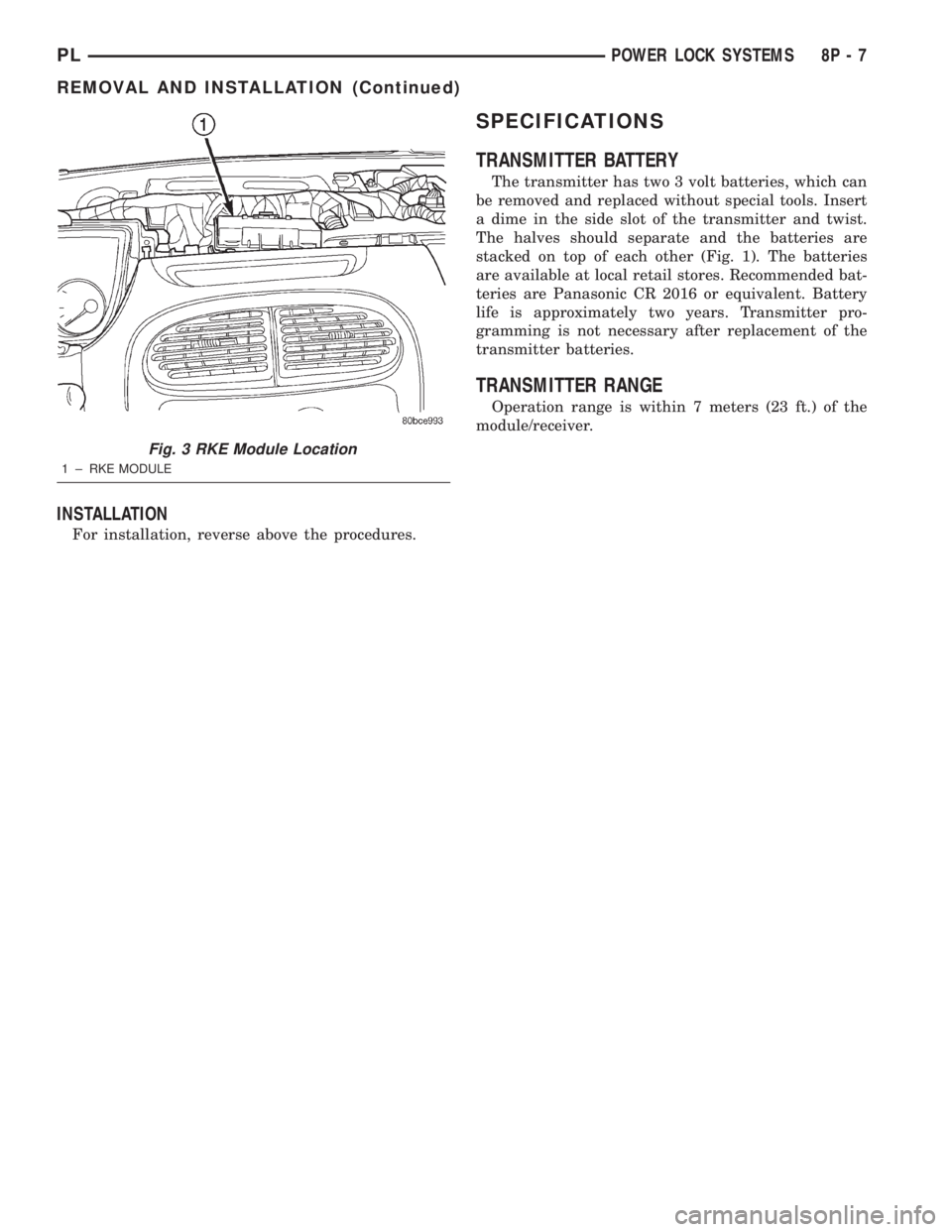

(3) Remove the two screws holding the RKE mod-

ule to the instrument panel assembly (Fig. 3).

(4) Slide locking tab of the wiring connector side-

ways to unlock tab, and remove connector from RKE

module.

(5) Remove RKE module from vehicle.

NOTE: When replacing a faulty RKE Module, the

replacement module must be configured with the

DRB lllTscan tool for proper operation. Refer to

Group 8Q-Vehicle Theft/Security Systems, Switch-

ing Operating Modes/Configuring a New Module

under Service Procedures. Additionally, all transmit-

ters must be reprogrammed to the new RKE mod-

ule.

Fig. 2 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

8P - 6 POWER LOCK SYSTEMSPL

SERVICE PROCEDURES (Continued)

Page 370 of 1285

INSTALLATION

For installation, reverse above the procedures.

SPECIFICATIONS

TRANSMITTER BATTERY

The transmitter has two 3 volt batteries, which can

be removed and replaced without special tools. Insert

a dime in the side slot of the transmitter and twist.

The halves should separate and the batteries are

stacked on top of each other (Fig. 1). The batteries

are available at local retail stores. Recommended bat-

teries are Panasonic CR 2016 or equivalent. Battery

life is approximately two years. Transmitter pro-

gramming is not necessary after replacement of the

transmitter batteries.

TRANSMITTER RANGE

Operation range is within 7 meters (23 ft.) of the

module/receiver.

Fig. 3 RKE Module Location

1 ± RKE MODULE

PLPOWER LOCK SYSTEMS 8P - 7

REMOVAL AND INSTALLATION (Continued)

Page 372 of 1285

VEHICLE THEFT/SECURITY SYSTEM

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

VEHICLE THEFT/SECURITY SYSTEM (VTSS)...1

SENTRY KEY IMMOBILIZER SYSTEM (SKIS)...2

SENTRY KEY IMMOBILIZER MODULE

(SKIM)................................2

SENTRY KEY IMMOBILIZER SYSTEM

TRANSPONDER.........................3

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP.......................4

TRIGGERING THE VTSS....................4

DIAGNOSIS AND TESTING

SENTRY KEY IMMOBILIZER SYSTEM.........4

VEHICLE THEFT/SECURITY SYSTEM (VTSS)...5SERVICE PROCEDURES

SENTRY KEY IMMOBILIZER SYSTEM

INITIALIZATION.........................5

SENTRY KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING...........5

SWITCHING OPERATING MODES/

CONFIGURING A NEW MODULE............6

REMOVAL AND INSTALLATION

DOOR CYLINDER LOCK SWITCH.............7

HOOD AJAR SWITCH......................7

SENTRY KEY IMMOBILIZER MODULE

(SKIM)................................7

VEHICLE THEFT/SECURITY SYSTEM DECK

LID SECURITY (KNOCK OUT) SWITCH.......8

DESCRIPTION AND OPERATION

INTRODUCTION

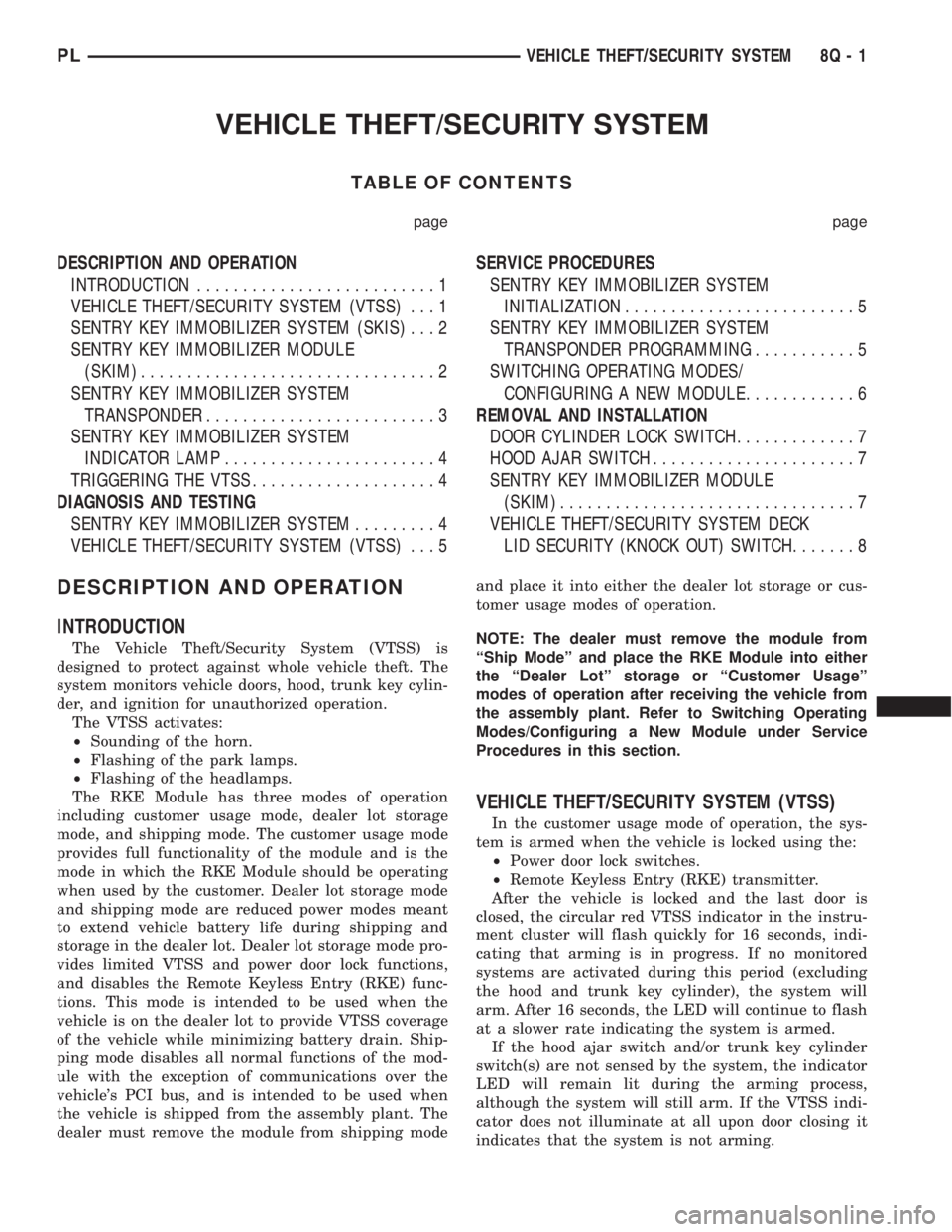

The Vehicle Theft/Security System (VTSS) is

designed to protect against whole vehicle theft. The

system monitors vehicle doors, hood, trunk key cylin-

der, and ignition for unauthorized operation.

The VTSS activates:

²Sounding of the horn.

²Flashing of the park lamps.

²Flashing of the headlamps.

The RKE Module has three modes of operation

including customer usage mode, dealer lot storage

mode, and shipping mode. The customer usage mode

provides full functionality of the module and is the

mode in which the RKE Module should be operating

when used by the customer. Dealer lot storage mode

and shipping mode are reduced power modes meant

to extend vehicle battery life during shipping and

storage in the dealer lot. Dealer lot storage mode pro-

vides limited VTSS and power door lock functions,

and disables the Remote Keyless Entry (RKE) func-

tions. This mode is intended to be used when the

vehicle is on the dealer lot to provide VTSS coverage

of the vehicle while minimizing battery drain. Ship-

ping mode disables all normal functions of the mod-

ule with the exception of communications over the

vehicle's PCI bus, and is intended to be used when

the vehicle is shipped from the assembly plant. The

dealer must remove the module from shipping modeand place it into either the dealer lot storage or cus-

tomer usage modes of operation.

NOTE: The dealer must remove the module from

ªShip Modeº and place the RKE Module into either

the ªDealer Lotº storage or ªCustomer Usageº

modes of operation after receiving the vehicle from

the assembly plant. Refer to Switching Operating

Modes/Configuring a New Module under Service

Procedures in this section.

VEHICLE THEFT/SECURITY SYSTEM (VTSS)

In the customer usage mode of operation, the sys-

tem is armed when the vehicle is locked using the:

²Power door lock switches.

²Remote Keyless Entry (RKE) transmitter.

After the vehicle is locked and the last door is

closed, the circular red VTSS indicator in the instru-

ment cluster will flash quickly for 16 seconds, indi-

cating that arming is in progress. If no monitored

systems are activated during this period (excluding

the hood and trunk key cylinder), the system will

arm. After 16 seconds, the LED will continue to flash

at a slower rate indicating the system is armed.

If the hood ajar switch and/or trunk key cylinder

switch(s) are not sensed by the system, the indicator

LED will remain lit during the arming process,

although the system will still arm. If the VTSS indi-

cator does not illuminate at all upon door closing it

indicates that the system is not arming.

PLVEHICLE THEFT/SECURITY SYSTEM 8Q - 1

Page 375 of 1285

memory to determine whether a valid key is in the

ignition lock cylinder.

The Sentry Key transponder cannot be repaired

and, if faulty or damaged, it must be replaced.

SENTRY KEY IMMOBILIZER SYSTEM

INDICATOR LAMP

The Sentry Key Immobilizer System (SKIS) uses

the Vehicle Theft Security System (VTSS) indicator

LED to give an indication when the SKIS is faulty or

when the vehicle has been immobilized due to the

use of an invalid ignition key. The LED is controlled

by the instrument cluster circuitry based upon mes-

sages received from the Sentry Key Immobilizer

Module (SKIM) through the Body Control Module

(BCM) on the Programmable Communication Inter-

face (PCI) bus.

The SKIM sends messages to the instrument clus-

ter, via the BCM, to turn the LED on for about three

seconds when the ignition switch is turned to the ON

position as a bulb test. After completion of the bulb

test, the SKIM sends PCI bus messages to keep the

LED off for a duration of about one second. Then the

SKIM sends messages to the instrument cluster cir-

cuitry to turn the LED on or off based upon the

results of the SKIS self-tests. If the VTSS indicator

LED comes on and stays on after the bulb test, it

indicates that the SKIM has detected a system mal-

function and/or that the SKIS has become inopera-

tive. If the SKIM detects an invalid key when the

ignition switch is turned to the ON position, it sends

messages to the instrument cluster to flash the VTSS

indicator LED.

The SKIM can also send messages to the instru-

ment cluster to flash the LED and to generate a sin-

gle audible chime tone. These functions serve as an

indication to the customer that the SKIS has been

placed in its ªCustomer Learnº programming mode.

See Sentry Key Immobilizer System Transponder

Programming in this group for more information on

the ªCustomer Learnº programming mode.

The VTSS indicator LED uses a replaceable Light

Emitting Diode (LED) on the instrument cluster elec-

tronic circuit board. Refer to Group 8E - Instrument

Panel Systems for Cluster Lamp Removal and Instal-

lation. If the VTSS indicator LED comes on and

stays on after the bulb test function, diagnosis of the

SKIS should be performed with a DRB IIItscan tool

and the proper Body Diagnostic Procedures Manual.

TRIGGERING THE VTSS

After the VTSS is armed, any of the following will

trigger the system:

²Opening any door.

²Opening the hood.

²Removing the trunk lock cylinder.²Turning the ignition to the RUN/START position

with an invalid Sentry Key.

NOTE: The ignition switch can be turned to the

accessory position without triggering the alarm sys-

tem.

DIAGNOSIS AND TESTING

SENTRY KEY IMMOBILIZER SYSTEM

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

NOTE: The following tests may not prove conclu-

sive in the diagnosis of this system. The most reli-

able, efficient, and accurate means to diagnose the

Sentry Key Immobilizer System (SKIS) involves the

use of a DRB lllTscan tool and the proper Body

Diagnostic Procedures Manual.

The Sentry Key Immobilizer System (SKIS) and

the Programmable Communication Interface (PCI)

bus network should be diagnosed using a DRB lllt

scan tool. The DRB IIItwill allow confirmation that

the PCI bus is functional, that the Sentry Key Immo-

bilizer Module (SKIM) is placing the proper messages

on the PCI bus, and that the Powertrain Control

Module (PCM) and the instrument cluster are receiv-

ing the PCI bus messages. Refer to the proper Body

Diagnostic Procedures Manual. Refer to Group

8W-Wiring Diagrams for complete circuit descriptions

and diagrams.

(1) Check the fuses in the fuse block. If OK, go to

Step 2. If not OK, repair the shorted circuit or com-

ponent as required and replace the faulty fuse.

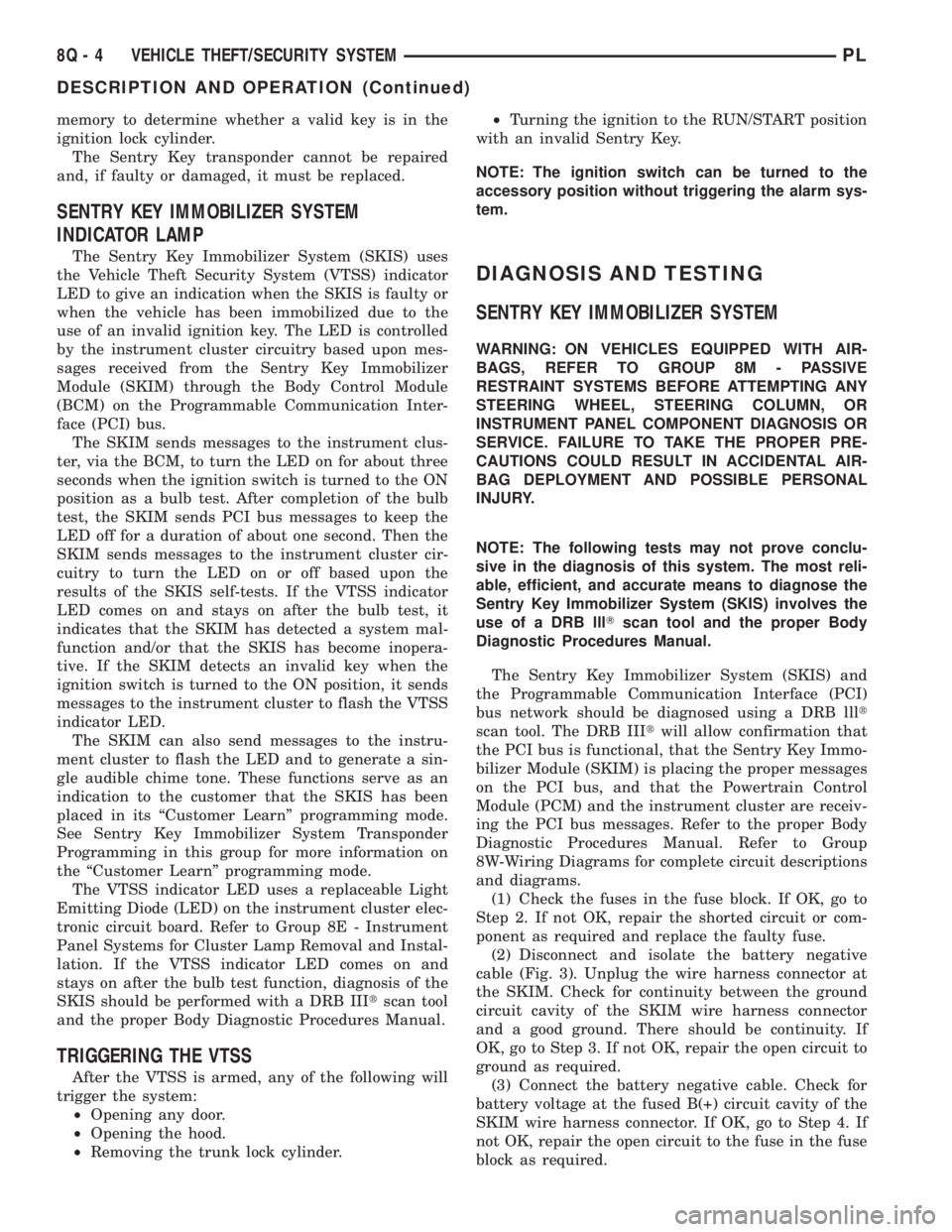

(2) Disconnect and isolate the battery negative

cable (Fig. 3). Unplug the wire harness connector at

the SKIM. Check for continuity between the ground

circuit cavity of the SKIM wire harness connector

and a good ground. There should be continuity. If

OK, go to Step 3. If not OK, repair the open circuit to

ground as required.

(3) Connect the battery negative cable. Check for

battery voltage at the fused B(+) circuit cavity of the

SKIM wire harness connector. If OK, go to Step 4. If

not OK, repair the open circuit to the fuse in the fuse

block as required.

8Q - 4 VEHICLE THEFT/SECURITY SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 376 of 1285

(4) Turn the ignition switch to the ON position.

Check for battery voltage at the fused ignition switch

output (run/start) circuit cavity of the SKIM wire

harness connector. If OK, use a DRB IIItscan tool

and the proper Body Diagnostic Procedures Manual

to complete the diagnosis of the SKIS. If not OK,

repair the open circuit to the fuse in the fuse block as

required.

VEHICLE THEFT/SECURITY SYSTEM (VTSS)

To diagnose the Vehicle Theft/Security System

(VTSS), use a DRB IIItscan tool and the proper

Body Diagnostic Procedures Manual.

SERVICE PROCEDURES

SENTRY KEY IMMOBILIZER SYSTEM

INITIALIZATION

The Sentry Key Immobilizer System (SKIS) initial-

ization should be performed following a Sentry Key

Immobilizer Module (SKIM) replacement.

It can be summarized by the following:

(1) Obtain the vehicles unique PIN number

assigned to it's original SKIM from the vehicle

owner, the vehicle's invoice or from Daimler-

Chrysler's Customer Center.

(2) With the DRB IIItscan tool, select ªTheft

Alarm,º ªSKIM,º Miscellaneous.º Select ªSKIM Mod-ule Replacedº function and the DRB llltwill prompt

you through the following steps.

(3) Enter secured access mode using the unique

four digit PIN number.

(4) Program the vehicle's VIN number into the

SKIM's memory.

(5) Program the country code into the SKIM's

memory (U. S.).

(6) Transfer the vehicle's unique Secret Key data

from the PCM. This process will require the SKIM to

be insecured access mode. The PIN number must

be entered into the DRB IIItbefore the SKIM will

entersecured access mode. Oncesecured access

modeis active, the SKIM will remain in that mode

for 60 seconds.

(7) Program all customer keys into the SKIM's

memory. This required that the SKIM be insecured

access modeThe SKIM will immediately exit

secured access modeafter each key is pro-

grammed.

NOTE: SECURED ACCESS MODE is not required to

query the programmed status of the key.

NOTE: If a PCM is replaced, the unique ªSecret

Keyº data must be transferred from the SKIM to the

PCM. This procedure requires the SKIM to be

placed in SECURED ACCESS MODE using the four

digit PIN code.

SENTRY KEY IMMOBILIZER SYSTEM

TRANSPONDER PROGRAMMING

Three programmed Sentry Key transponders are

included with the Sentry Key Immobilizer System

(SKIS) when it is shipped from the factory. The Sen-

try Key Immobilizer Module (SKIM) can be pro-

grammed to recognize up to five additional

transponders, for a total of eight Sentry Keys. The

following ªCustomer Learnº programming procedure

for the programming of additional transponders

requires access to at least two of the valid Sentry

Keys. If two valid Sentry Keys are not available, Sen-

try Key programming will require the use of a DRB

IIItscan tool.

CUSTOMER LEARN PROGRAMMING

(1) Obtain the additional Sentry Key transponder

blank(s) that are to be programmed for the vehicle.

Cut the additional Sentry Key transponder blanks to

match the ignition lock cylinder mechanical key

codes.

(2) Insert one of the two valid Sentry Key tran-

sponders into the ignition switch and turn the igni-

tion switch to the ON position.

Fig. 3 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

PLVEHICLE THEFT/SECURITY SYSTEM 8Q - 5

DIAGNOSIS AND TESTING (Continued)

Page 378 of 1285

REMOVAL AND INSTALLATION

DOOR CYLINDER LOCK SWITCH

REMOVAL

(1) Refer to Group 23, Body for door trim and

water shield Removal and Installation.

(2) Remove illuminated entry switch wiring clip

and disconnect connector.

(3) Remove door cylinder lock switch from door

handle.

INSTALLATION

For installation reverse the above procedures.

HOOD AJAR SWITCH

REMOVAL

(1) Open hood.

(2) Disconnect and isolate the battery negative

remote cable (Fig. 3).

(3) Using a trim stick (special tool #C-4755) or

equivalent, gently pry switch up and out of mounting

bracket.

(4) Disconnect wire harness connector from hood

ajar switch.

(5) Remove switch from vehicle.

INSTALLATION

For installation reverse above procedures.

SENTRY KEY IMMOBILIZER MODULE (SKIM)

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAGS, REFER TO GROUP 8M - PASSIVE

RESTRAINT SYSTEMS BEFORE ATTEMPTING ANY

STEERING WHEEL, STEERING COLUMN, OR

INSTRUMENT PANEL COMPONENT DIAGNOSIS OR

SERVICE. FAILURE TO TAKE THE PROPER PRE-

CAUTIONS COULD RESULT IN ACCIDENTAL AIR-

BAG DEPLOYMENT AND POSSIBLE PERSONAL

INJURY.

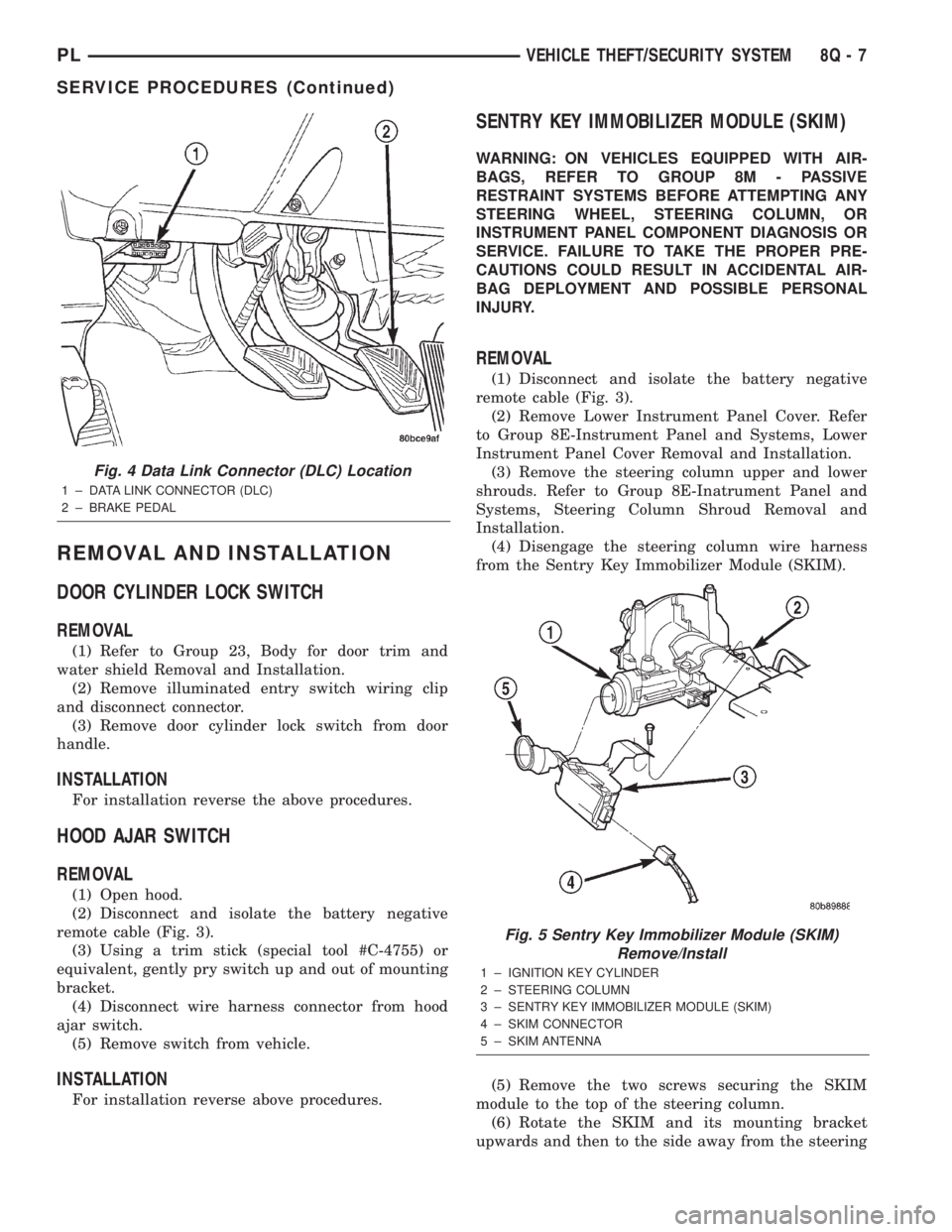

REMOVAL

(1) Disconnect and isolate the battery negative

remote cable (Fig. 3).

(2) Remove Lower Instrument Panel Cover. Refer

to Group 8E-Instrument Panel and Systems, Lower

Instrument Panel Cover Removal and Installation.

(3) Remove the steering column upper and lower

shrouds. Refer to Group 8E-Inatrument Panel and

Systems, Steering Column Shroud Removal and

Installation.

(4) Disengage the steering column wire harness

from the Sentry Key Immobilizer Module (SKIM).

(5) Remove the two screws securing the SKIM

module to the top of the steering column.

(6) Rotate the SKIM and its mounting bracket

upwards and then to the side away from the steering

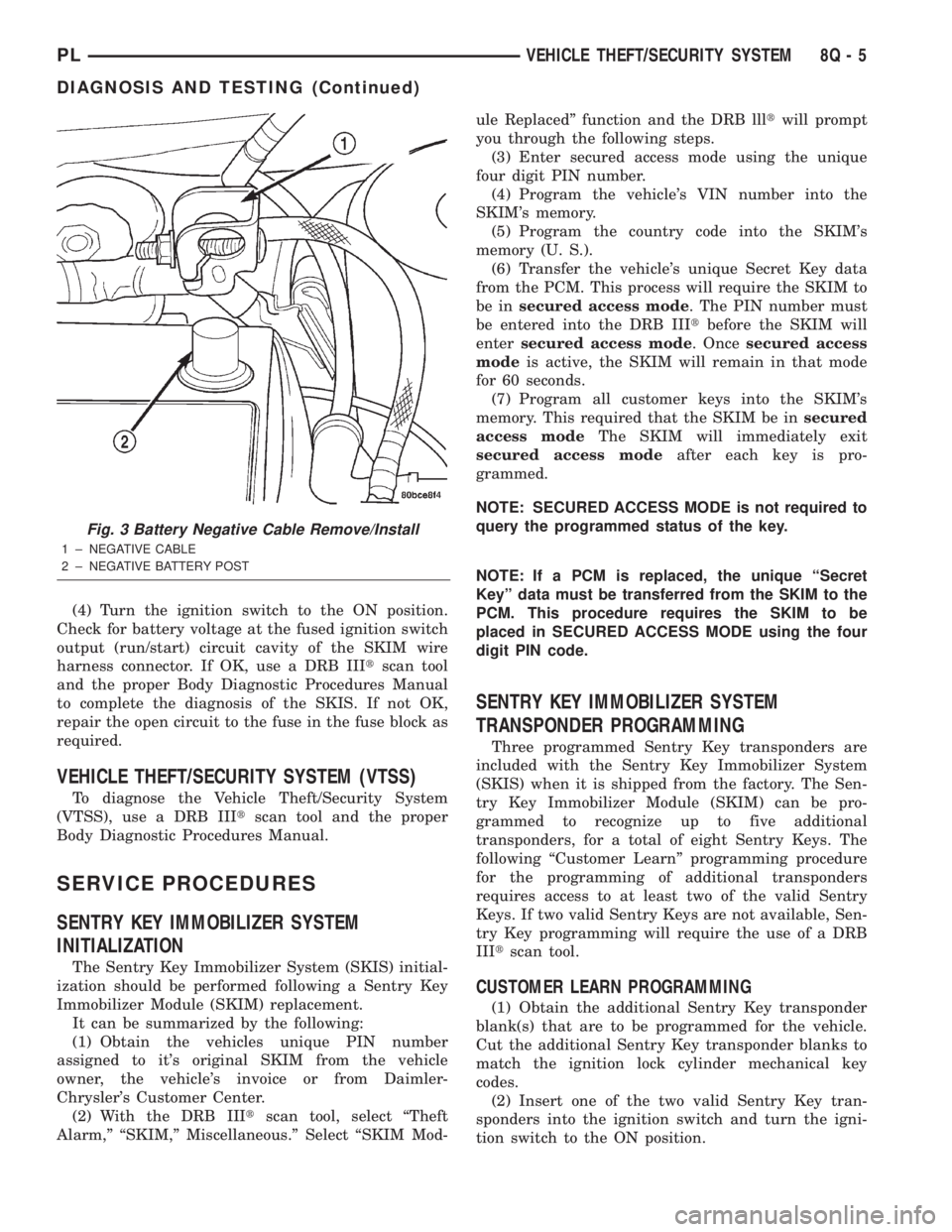

Fig. 4 Data Link Connector (DLC) Location

1 ± DATA LINK CONNECTOR (DLC)

2 ± BRAKE PEDAL

Fig. 5 Sentry Key Immobilizer Module (SKIM)

Remove/Install

1 ± IGNITION KEY CYLINDER

2 ± STEERING COLUMN

3 ± SENTRY KEY IMMOBILIZER MODULE (SKIM)

4 ± SKIM CONNECTOR

5 ± SKIM ANTENNA

PLVEHICLE THEFT/SECURITY SYSTEM 8Q - 7

SERVICE PROCEDURES (Continued)

Page 380 of 1285

POWER WINDOWS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

WIRING TEST............................1

WINDOW SWITCH........................1WINDOW MOTOR.........................1

REMOVAL AND INSTALLATION

WINDOW SWITCH........................2

WINDOW MOTOR.........................2

DESCRIPTION AND OPERATION

INTRODUCTION

The window lift motors are of the permanent mag-

net type. A battery positive and negative connection

to either of the two motor terminals will cause the

motor to rotate in one direction. Reversing current

through these same two connections will cause the

motor to rotate in the opposite direction.

Each individual motor is grounded through the

master switch.

DIAGNOSIS AND TESTING

WIRING TEST

The following wiring test determines whether or

not voltage is continuous through the body harness

to the power window switches.

Remove switch for testing. Connect a voltmeter

positive lead to Pin 4 and negative lead to Pin 3 of

the switch harness connector. Turn ignition switch to

the ON position. Voltmeter should read battery volt-

age. If OK, go to Window Switch Diagnosis and Test-

ing. If not OK, check the 30 amp circuit breaker in

the fuse block or for a broken wire. Refer to Group

8W-Wiring Diagrams, for Connector Pin-Outs and

circuit descriptions.

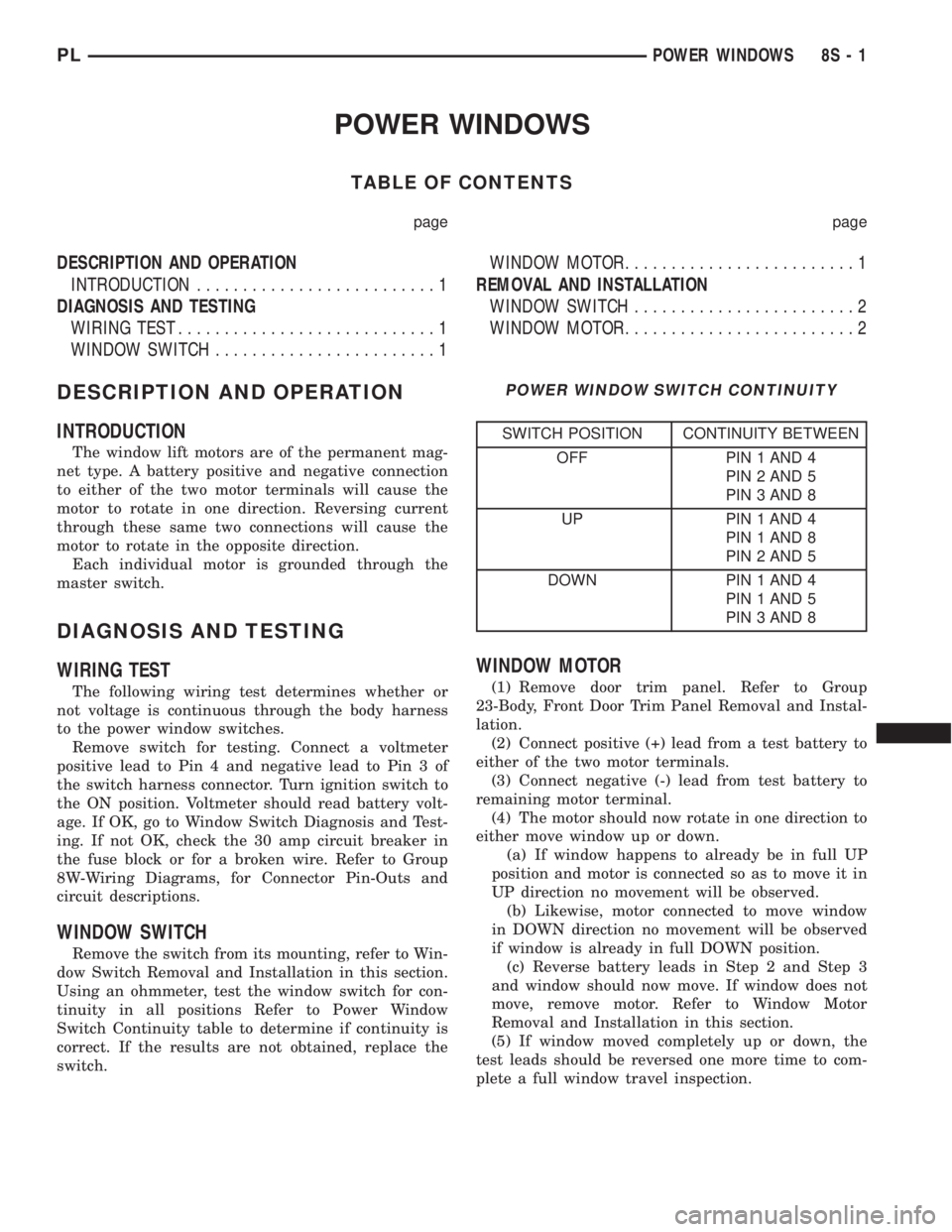

WINDOW SWITCH

Remove the switch from its mounting, refer to Win-

dow Switch Removal and Installation in this section.

Using an ohmmeter, test the window switch for con-

tinuity in all positions Refer to Power Window

Switch Continuity table to determine if continuity is

correct. If the results are not obtained, replace the

switch.

WINDOW MOTOR

(1) Remove door trim panel. Refer to Group

23-Body, Front Door Trim Panel Removal and Instal-

lation.

(2) Connect positive (+) lead from a test battery to

either of the two motor terminals.

(3) Connect negative (-) lead from test battery to

remaining motor terminal.

(4) The motor should now rotate in one direction to

either move window up or down.

(a) If window happens to already be in full UP

position and motor is connected so as to move it in

UP direction no movement will be observed.

(b) Likewise, motor connected to move window

in DOWN direction no movement will be observed

if window is already in full DOWN position.

(c) Reverse battery leads in Step 2 and Step 3

and window should now move. If window does not

move, remove motor. Refer to Window Motor

Removal and Installation in this section.

(5) If window moved completely up or down, the

test leads should be reversed one more time to com-

plete a full window travel inspection.

POWER WINDOW SWITCH CONTINUITY

SWITCH POSITION CONTINUITY BETWEEN

OFF PIN 1 AND 4

PIN 2 AND 5

PIN 3 AND 8

UP PIN 1 AND 4

PIN 1 AND 8

PIN 2 AND 5

DOWN PIN 1 AND 4

PIN 1 AND 5

PIN 3 AND 8

PLPOWER WINDOWS 8S - 1

Page 381 of 1285

(6) If window does not move, check to make sure

that it is free to move.

(7) It is necessary that the window be free to slide

up and down in the glass channels. If the window is

not free to move up and down, the window lift motor

will not be able to move the glass.

(8) To determine if the glass is free, disconnect the

regulator from the glass lift plate and slide the win-

dow up and down by hand.

REMOVAL AND INSTALLATION

WINDOW SWITCH

REMOVAL

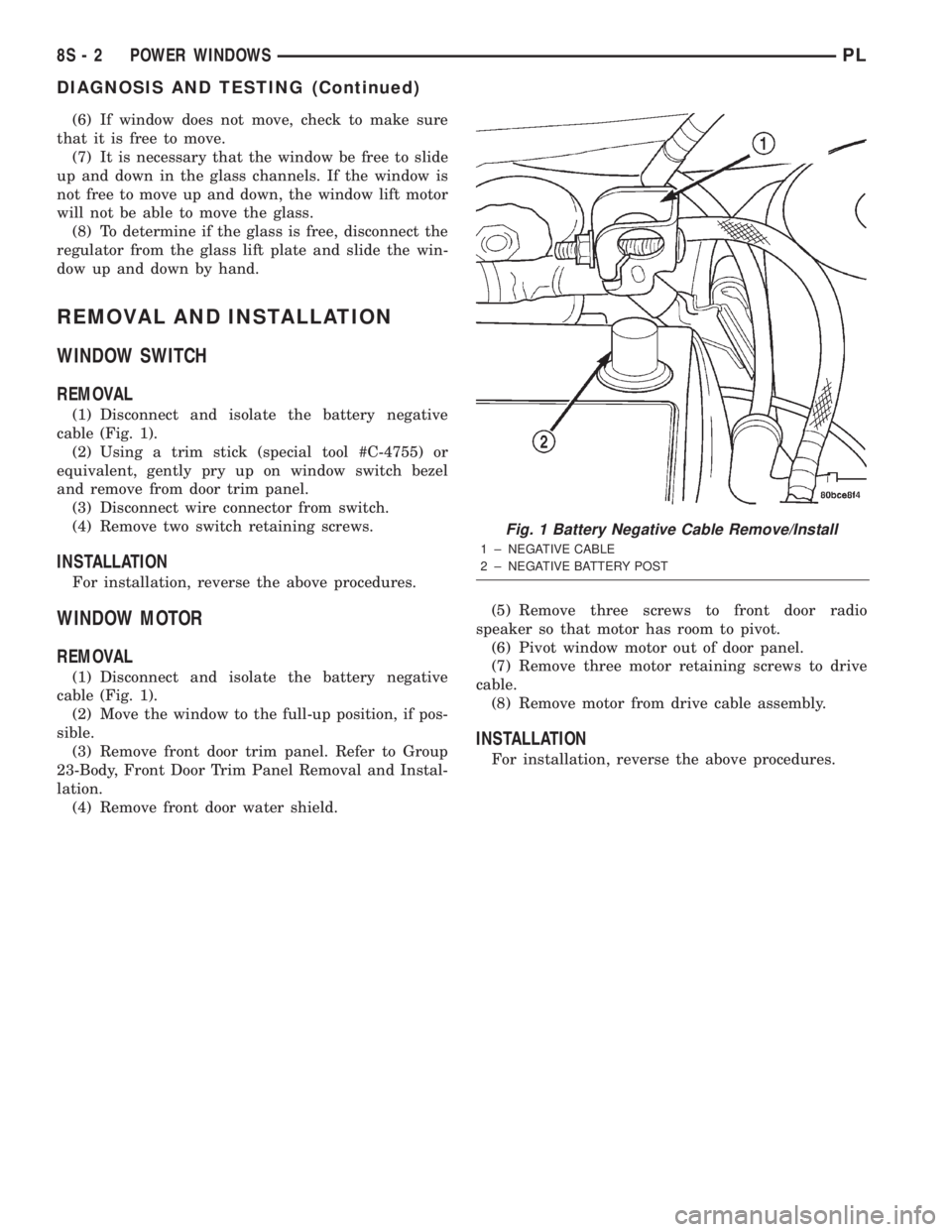

(1) Disconnect and isolate the battery negative

cable (Fig. 1).

(2) Using a trim stick (special tool #C-4755) or

equivalent, gently pry up on window switch bezel

and remove from door trim panel.

(3) Disconnect wire connector from switch.

(4) Remove two switch retaining screws.

INSTALLATION

For installation, reverse the above procedures.

WINDOW MOTOR

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 1).

(2) Move the window to the full-up position, if pos-

sible.

(3) Remove front door trim panel. Refer to Group

23-Body, Front Door Trim Panel Removal and Instal-

lation.

(4) Remove front door water shield.(5) Remove three screws to front door radio

speaker so that motor has room to pivot.

(6) Pivot window motor out of door panel.

(7) Remove three motor retaining screws to drive

cable.

(8) Remove motor from drive cable assembly.

INSTALLATION

For installation, reverse the above procedures.

Fig. 1 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

8S - 2 POWER WINDOWSPL

DIAGNOSIS AND TESTING (Continued)

Page 383 of 1285

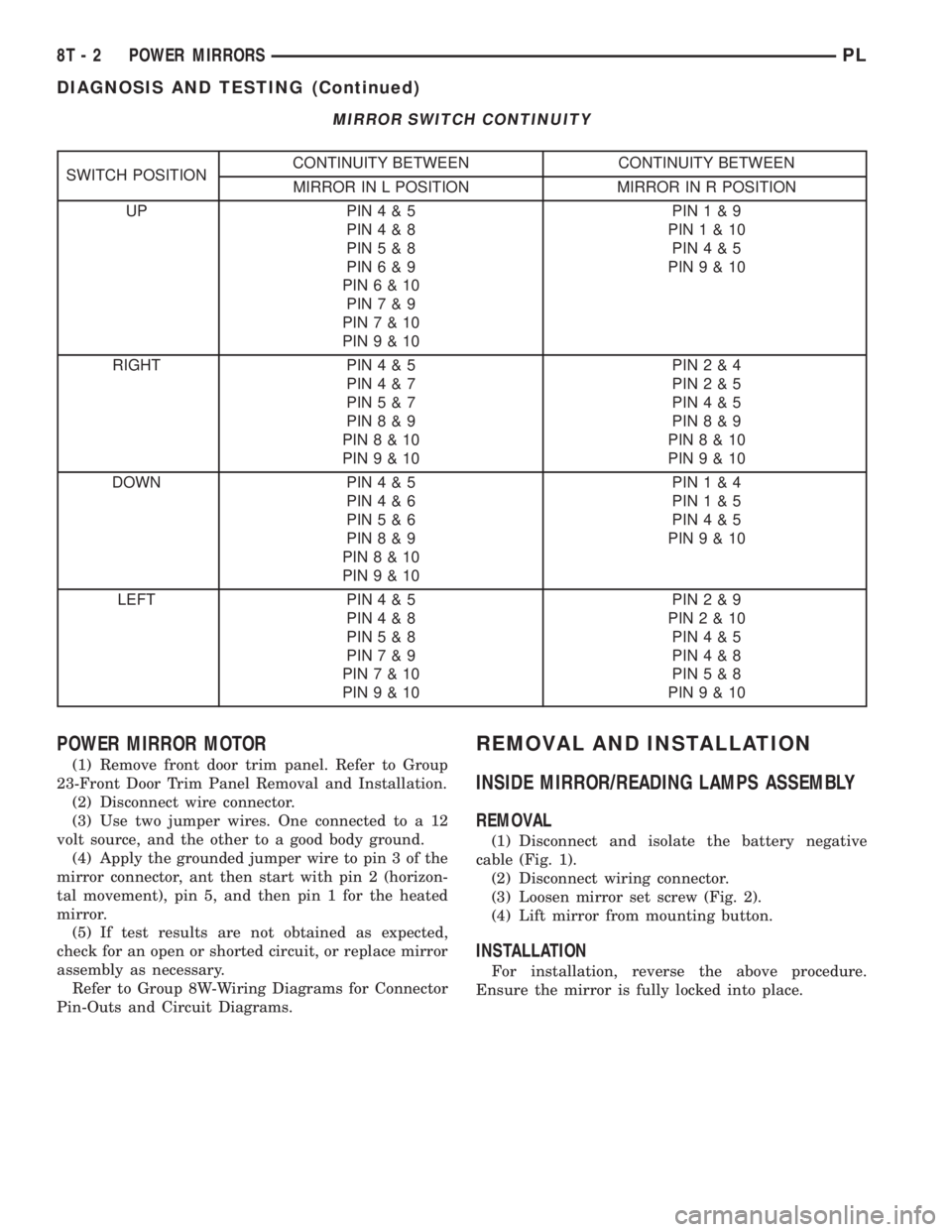

MIRROR SWITCH CONTINUITY

SWITCH POSITIONCONTINUITY BETWEEN CONTINUITY BETWEEN

MIRROR IN L POSITION MIRROR IN R POSITION

UP PIN4&5

PIN4&8

PIN5&8

PIN6&9

PIN6&10

PIN7&9

PIN7&10

PIN9&10PIN1&9

PIN1&10

PIN4&5

PIN9&10

RIGHT PIN4&5

PIN4&7

PIN5&7

PIN8&9

PIN8&10

PIN9&10PIN2&4

PIN2&5

PIN4&5

PIN8&9

PIN8&10

PIN9&10

DOWN PIN4&5

PIN4&6

PIN5&6

PIN8&9

PIN8&10

PIN9&10PIN1&4

PIN1&5

PIN4&5

PIN9&10

LEFT PIN4&5

PIN4&8

PIN5&8

PIN7&9

PIN7&10

PIN9&10PIN2&9

PIN2&10

PIN4&5

PIN4&8

PIN5&8

PIN9&10

POWER MIRROR MOTOR

(1) Remove front door trim panel. Refer to Group

23-Front Door Trim Panel Removal and Installation.

(2) Disconnect wire connector.

(3) Use two jumper wires. One connected to a 12

volt source, and the other to a good body ground.

(4) Apply the grounded jumper wire to pin 3 of the

mirror connector, ant then start with pin 2 (horizon-

tal movement), pin 5, and then pin 1 for the heated

mirror.

(5) If test results are not obtained as expected,

check for an open or shorted circuit, or replace mirror

assembly as necessary.

Refer to Group 8W-Wiring Diagrams for Connector

Pin-Outs and Circuit Diagrams.

REMOVAL AND INSTALLATION

INSIDE MIRROR/READING LAMPS ASSEMBLY

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 1).

(2) Disconnect wiring connector.

(3) Loosen mirror set screw (Fig. 2).

(4) Lift mirror from mounting button.

INSTALLATION

For installation, reverse the above procedure.

Ensure the mirror is fully locked into place.

8T - 2 POWER MIRRORSPL

DIAGNOSIS AND TESTING (Continued)