battery DODGE NEON 2000 Service Manual PDF

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 260 of 1285

INSTRUMENT PANEL AND SYSTEMS

TABLE OF CONTENTS

page page

DIAGNOSIS AND TESTING

HEADLAMP LEVELING SWITCH..............1

INSTRUMENT PANEL AND COMPONENTS.....1

REMOVAL AND INSTALLATION

HEADLAMP LEVELING SWITCH..............2INSTRUMENT PANEL ± R. H. D..............3

SPECIFICATIONS

TORQUE SPECIFICATIONS..................9

DIAGNOSIS AND TESTING

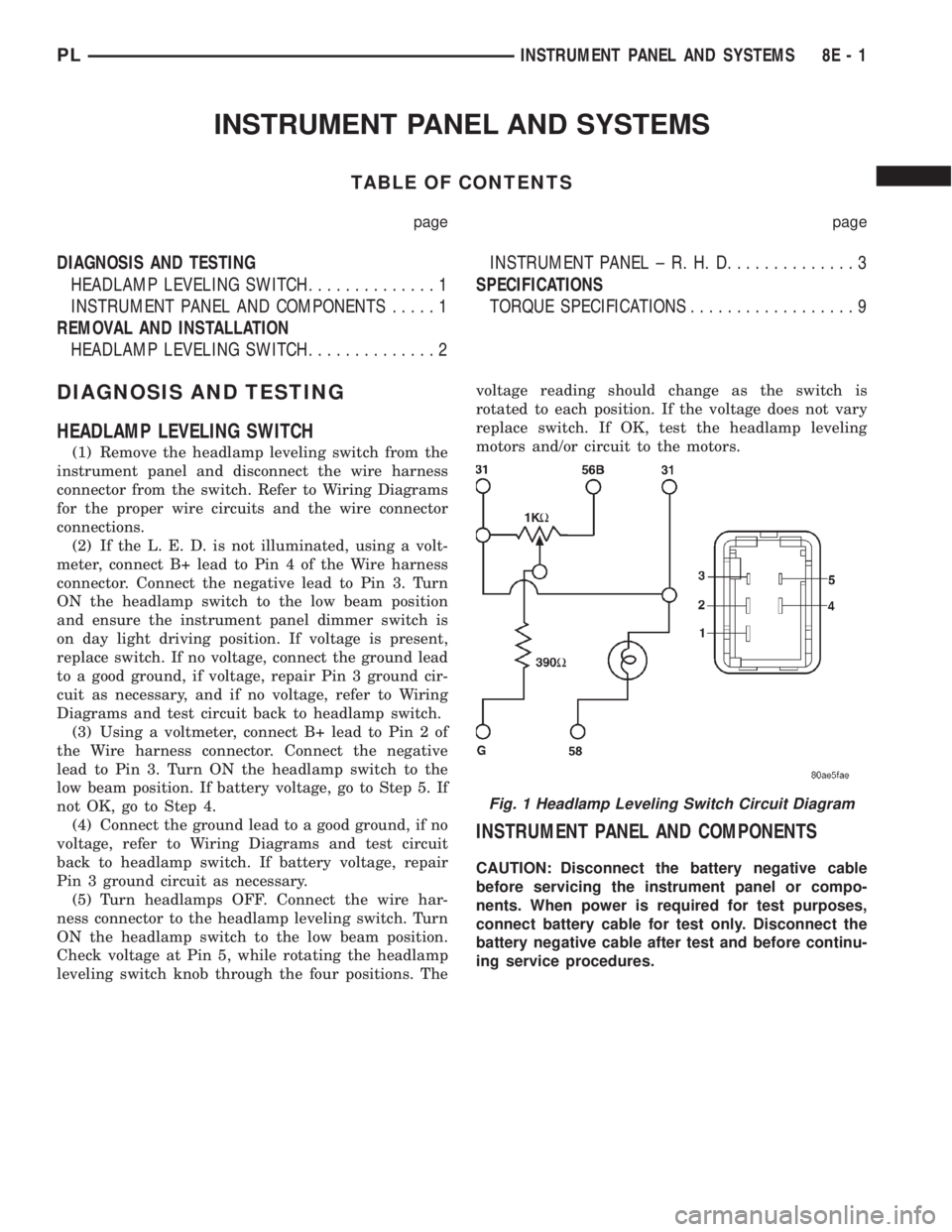

HEADLAMP LEVELING SWITCH

(1) Remove the headlamp leveling switch from the

instrument panel and disconnect the wire harness

connector from the switch. Refer to Wiring Diagrams

for the proper wire circuits and the wire connector

connections.

(2) If the L. E. D. is not illuminated, using a volt-

meter, connect B+ lead to Pin 4 of the Wire harness

connector. Connect the negative lead to Pin 3. Turn

ON the headlamp switch to the low beam position

and ensure the instrument panel dimmer switch is

on day light driving position. If voltage is present,

replace switch. If no voltage, connect the ground lead

to a good ground, if voltage, repair Pin 3 ground cir-

cuit as necessary, and if no voltage, refer to Wiring

Diagrams and test circuit back to headlamp switch.

(3) Using a voltmeter, connect B+ lead to Pin 2 of

the Wire harness connector. Connect the negative

lead to Pin 3. Turn ON the headlamp switch to the

low beam position. If battery voltage, go to Step 5. If

not OK, go to Step 4.

(4) Connect the ground lead to a good ground, if no

voltage, refer to Wiring Diagrams and test circuit

back to headlamp switch. If battery voltage, repair

Pin 3 ground circuit as necessary.

(5) Turn headlamps OFF. Connect the wire har-

ness connector to the headlamp leveling switch. Turn

ON the headlamp switch to the low beam position.

Check voltage at Pin 5, while rotating the headlamp

leveling switch knob through the four positions. Thevoltage reading should change as the switch is

rotated to each position. If the voltage does not vary

replace switch. If OK, test the headlamp leveling

motors and/or circuit to the motors.

INSTRUMENT PANEL AND COMPONENTS

CAUTION: Disconnect the battery negative cable

before servicing the instrument panel or compo-

nents. When power is required for test purposes,

connect battery cable for test only. Disconnect the

battery negative cable after test and before continu-

ing service procedures.

Fig. 1 Headlamp Leveling Switch Circuit Diagram

PLINSTRUMENT PANEL AND SYSTEMS 8E - 1

Page 263 of 1285

(1) Disconnect the negative battery cable.

(2) Remove the floor console. Refer to Group 23,

Body for the procedure.

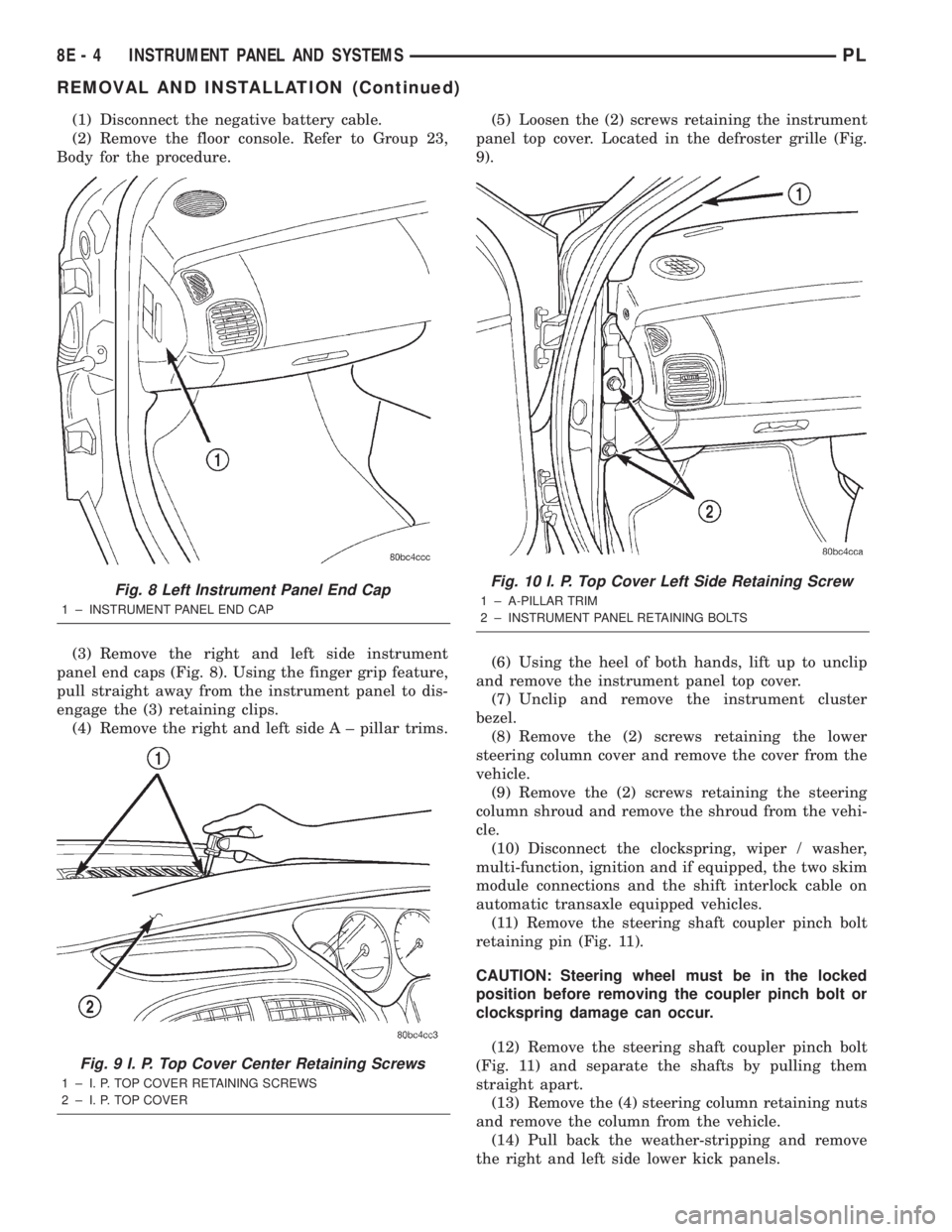

(3) Remove the right and left side instrument

panel end caps (Fig. 8). Using the finger grip feature,

pull straight away from the instrument panel to dis-

engage the (3) retaining clips.

(4) Remove the right and left side A ± pillar trims.(5) Loosen the (2) screws retaining the instrument

panel top cover. Located in the defroster grille (Fig.

9).

(6) Using the heel of both hands, lift up to unclip

and remove the instrument panel top cover.

(7) Unclip and remove the instrument cluster

bezel.

(8) Remove the (2) screws retaining the lower

steering column cover and remove the cover from the

vehicle.

(9) Remove the (2) screws retaining the steering

column shroud and remove the shroud from the vehi-

cle.

(10) Disconnect the clockspring, wiper / washer,

multi-function, ignition and if equipped, the two skim

module connections and the shift interlock cable on

automatic transaxle equipped vehicles.

(11) Remove the steering shaft coupler pinch bolt

retaining pin (Fig. 11).

CAUTION: Steering wheel must be in the locked

position before removing the coupler pinch bolt or

clockspring damage can occur.

(12) Remove the steering shaft coupler pinch bolt

(Fig. 11) and separate the shafts by pulling them

straight apart.

(13) Remove the (4) steering column retaining nuts

and remove the column from the vehicle.

(14) Pull back the weather-stripping and remove

the right and left side lower kick panels.

Fig. 8 Left Instrument Panel End Cap

1 ± INSTRUMENT PANEL END CAP

Fig. 9 I. P. Top Cover Center Retaining Screws

1 ± I. P. TOP COVER RETAINING SCREWS

2 ± I. P. TOP COVER

Fig. 10 I. P. Top Cover Left Side Retaining Screw

1 ± A-PILLAR TRIM

2 ± INSTRUMENT PANEL RETAINING BOLTS

8E - 4 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 267 of 1285

(17) Install the A/C outlet registers in the center

instrument bezel.

(18) Install the right and left side lower kick pan-

els. Reposition the weather-strip in its original posi-

tion.

(19) Install the steering column. Torque the retain-

ing nuts to 17 N´m (150 in. lbs.).

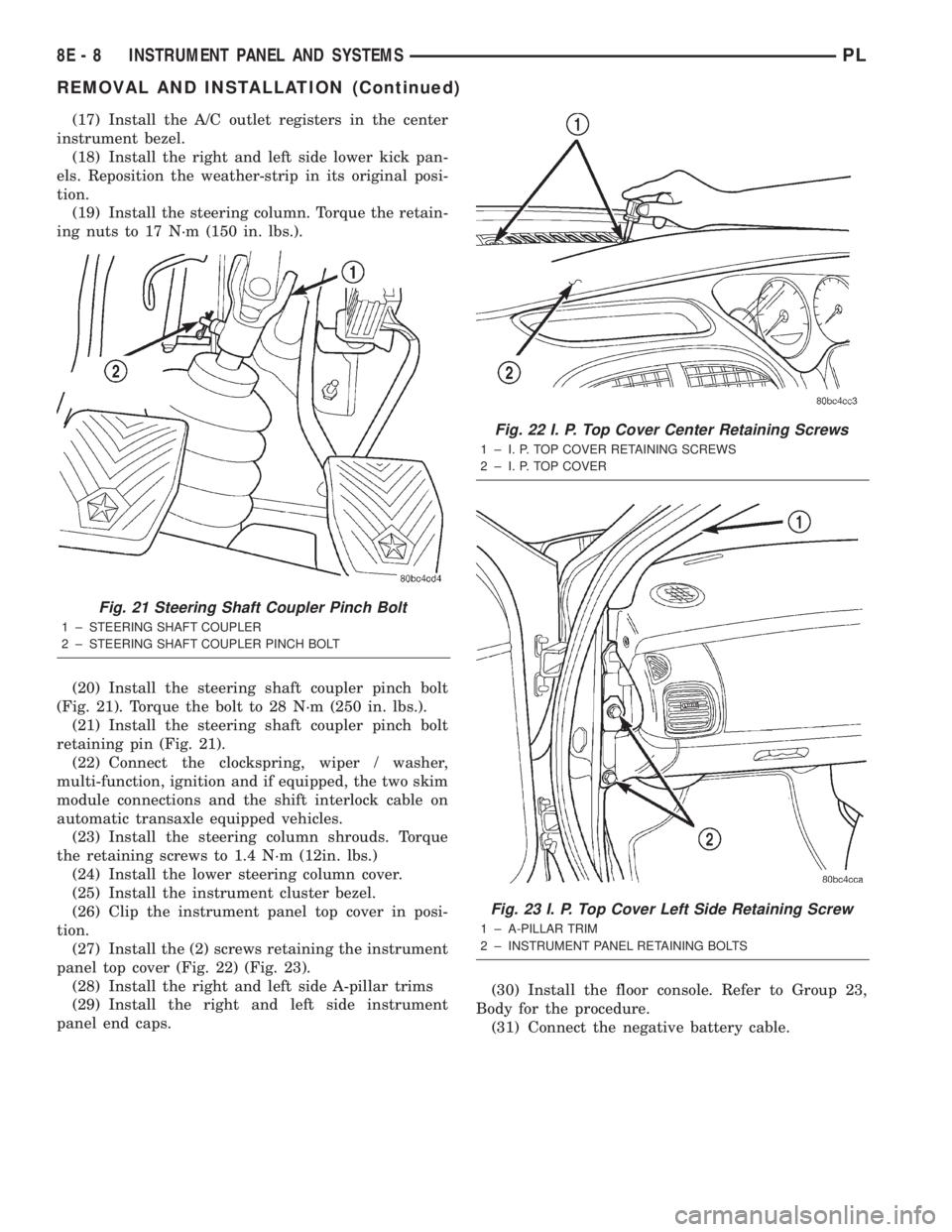

(20) Install the steering shaft coupler pinch bolt

(Fig. 21). Torque the bolt to 28 N´m (250 in. lbs.).

(21) Install the steering shaft coupler pinch bolt

retaining pin (Fig. 21).

(22) Connect the clockspring, wiper / washer,

multi-function, ignition and if equipped, the two skim

module connections and the shift interlock cable on

automatic transaxle equipped vehicles.

(23) Install the steering column shrouds. Torque

the retaining screws to 1.4 N´m (12in. lbs.)

(24) Install the lower steering column cover.

(25) Install the instrument cluster bezel.

(26) Clip the instrument panel top cover in posi-

tion.

(27) Install the (2) screws retaining the instrument

panel top cover (Fig. 22) (Fig. 23).

(28) Install the right and left side A-pillar trims

(29) Install the right and left side instrument

panel end caps.(30) Install the floor console. Refer to Group 23,

Body for the procedure.

(31) Connect the negative battery cable.

Fig. 21 Steering Shaft Coupler Pinch Bolt

1 ± STEERING SHAFT COUPLER

2 ± STEERING SHAFT COUPLER PINCH BOLT

Fig. 22 I. P. Top Cover Center Retaining Screws

1 ± I. P. TOP COVER RETAINING SCREWS

2 ± I. P. TOP COVER

Fig. 23 I. P. Top Cover Left Side Retaining Screw

1 ± A-PILLAR TRIM

2 ± INSTRUMENT PANEL RETAINING BOLTS

8E - 8 INSTRUMENT PANEL AND SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 270 of 1285

AUDIO SYSTEM

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION...............1

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES......1

TESTING................................1

BENCH TEST FOR ANTENNA MALFUNCTION...7REMOVAL AND INSTALLATION

CD CHANGER............................7

FRONT DOOR SPEAKER....................8

INSTRUMENT PANEL SPEAKER(S)...........8

MAST and ANTENNA ASSEMBLY.............8

RADIO..................................9

REAR SHELF SPEAKER(S).................10

GENERAL INFORMATION

INTRODUCTION

Operating instructions for the factory installed

audio systems can be found in the Owner's Manual

provided with the vehicle.

The vehicles are equipped with an Interior (Igni-

tion Off Draw) fuse in the Power Distribution Center

located in the engine compartment. After the Interior

(IOD) fuse or battery has been disconnected the clock

will require resetting. The radio station presets have

a nonvolatile memory and will retain the preset sta-

tions after a battery disconnect.

The available radio options are:

²AM/FM Stereo Cassette w/Clock

²AM/FM/CD

²AM/FM Cassette w/CD Changer Controls and

Display

²CD/4 Disc Changer - In-Dash (used w/Radio CD

Changer Controls)

DESCRIPTION AND OPERATION

INTERFERENCE ELIMINATION

The radio utilizes a ground wire plugged on to a

blade terminal and is bolted to the radio chassis.

Both connector and terminal should be securely

attached. The engine has two separate ground straps

to suppress ignition noise which may interfere with

radio reception.

²Left engine mount clip on strap

²Engine to shock tower reinforcement

Inductive type spark plug cables in the high ten-

sion circuit of the ignition system complete the inter-

ference suppression. Faulty or deteriorated spark

plug wires should be replaced.

DIAGNOSIS AND TESTING

AUDIO DIAGNOSTIC TEST PROCEDURES

CAUTION: The CD player will only operate between

approximate temperatures of -23ÉC and +65ÉC (-10ÉF

and +145ÉF).

Whenever a radio malfunction occurs;

(1) First check FUSES:

(a) Power Distribution Center (PDC), Interior

lamp fuse, M1 - Radio Memory Feed

(b) Fuse Block:

(I) Fuse 12, Illumination in the fuse block

(II) Fuse 16, Ignition feed in the fuse block

NOTE: The vehicles are shipped with the INTERIOR

LAMP fuse disconnected.

(2) Verify, the radio wire harness are properly con-

nected before starting normal diagnosis and repair

procedures. Refer to Audio Diagnostic Charts and/or

Group 8W, Wiring Diagrams, Radio Section.

TESTING

The antenna has a short cable which connects into

the instrument panel harness. The connection is

made on the right side of the instrument panel.

Antenna performance may be tested by substitut-

ing a known good antenna. It is also possible to

check short or open circuits with an ohmmeter or

continuity light once the antenna cable is discon-

nected from the radio as follows:

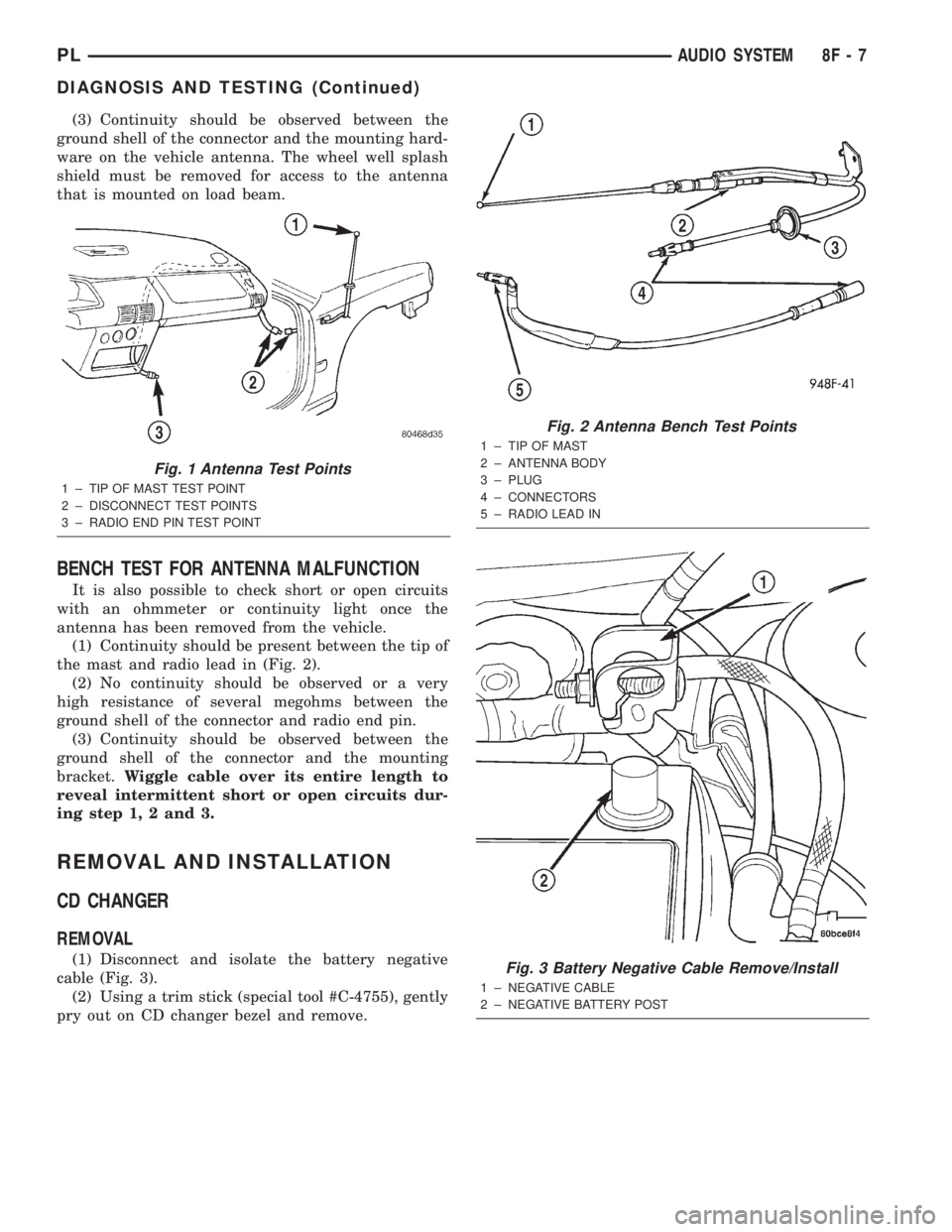

(1) Continuity should be present between the

antenna mast and radio end pin of antenna cable

plug (Fig. 1).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

PLAUDIO SYSTEM 8F - 1

Page 276 of 1285

(3) Continuity should be observed between the

ground shell of the connector and the mounting hard-

ware on the vehicle antenna. The wheel well splash

shield must be removed for access to the antenna

that is mounted on load beam.

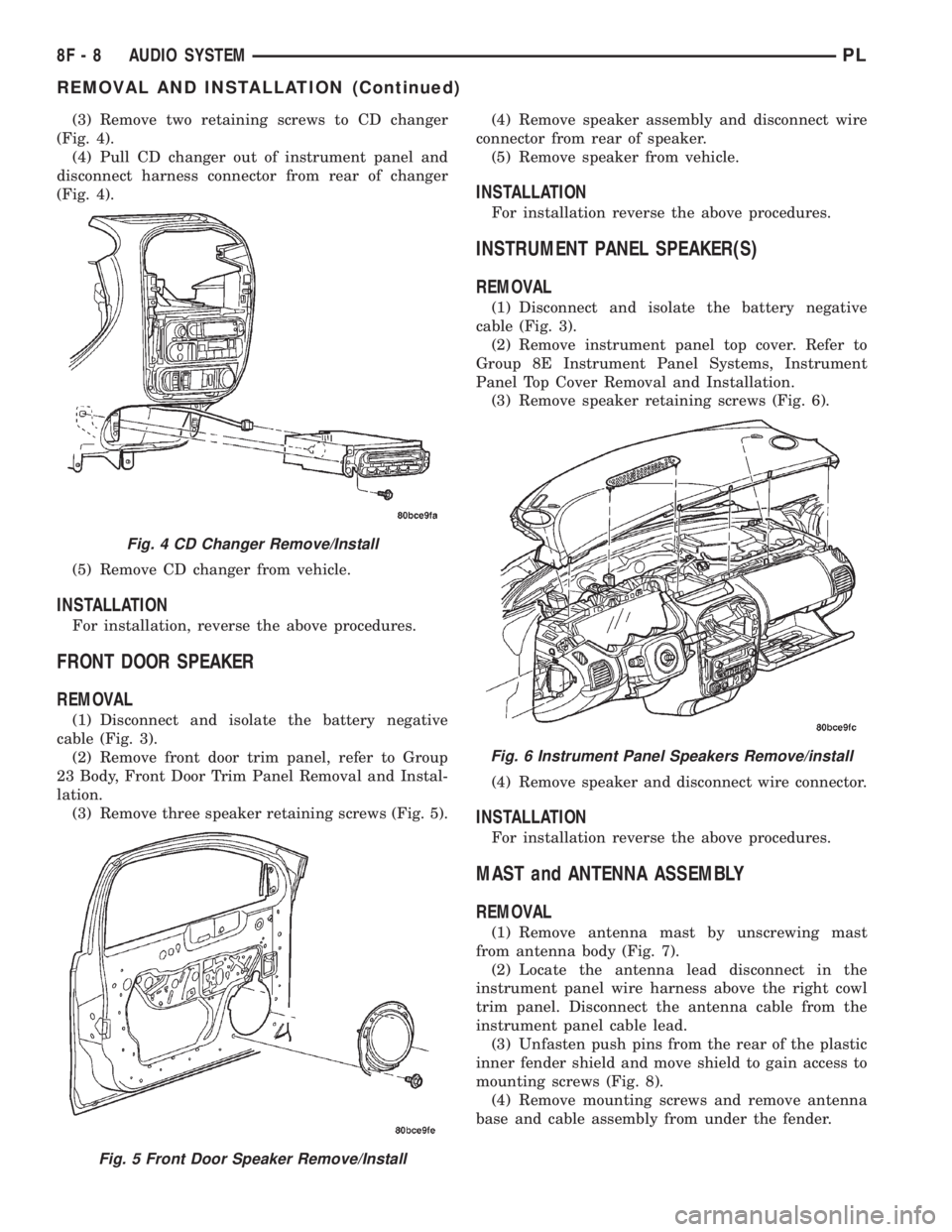

BENCH TEST FOR ANTENNA MALFUNCTION

It is also possible to check short or open circuits

with an ohmmeter or continuity light once the

antenna has been removed from the vehicle.

(1) Continuity should be present between the tip of

the mast and radio lead in (Fig. 2).

(2) No continuity should be observed or a very

high resistance of several megohms between the

ground shell of the connector and radio end pin.

(3) Continuity should be observed between the

ground shell of the connector and the mounting

bracket.Wiggle cable over its entire length to

reveal intermittent short or open circuits dur-

ing step 1, 2 and 3.

REMOVAL AND INSTALLATION

CD CHANGER

REMOVAL

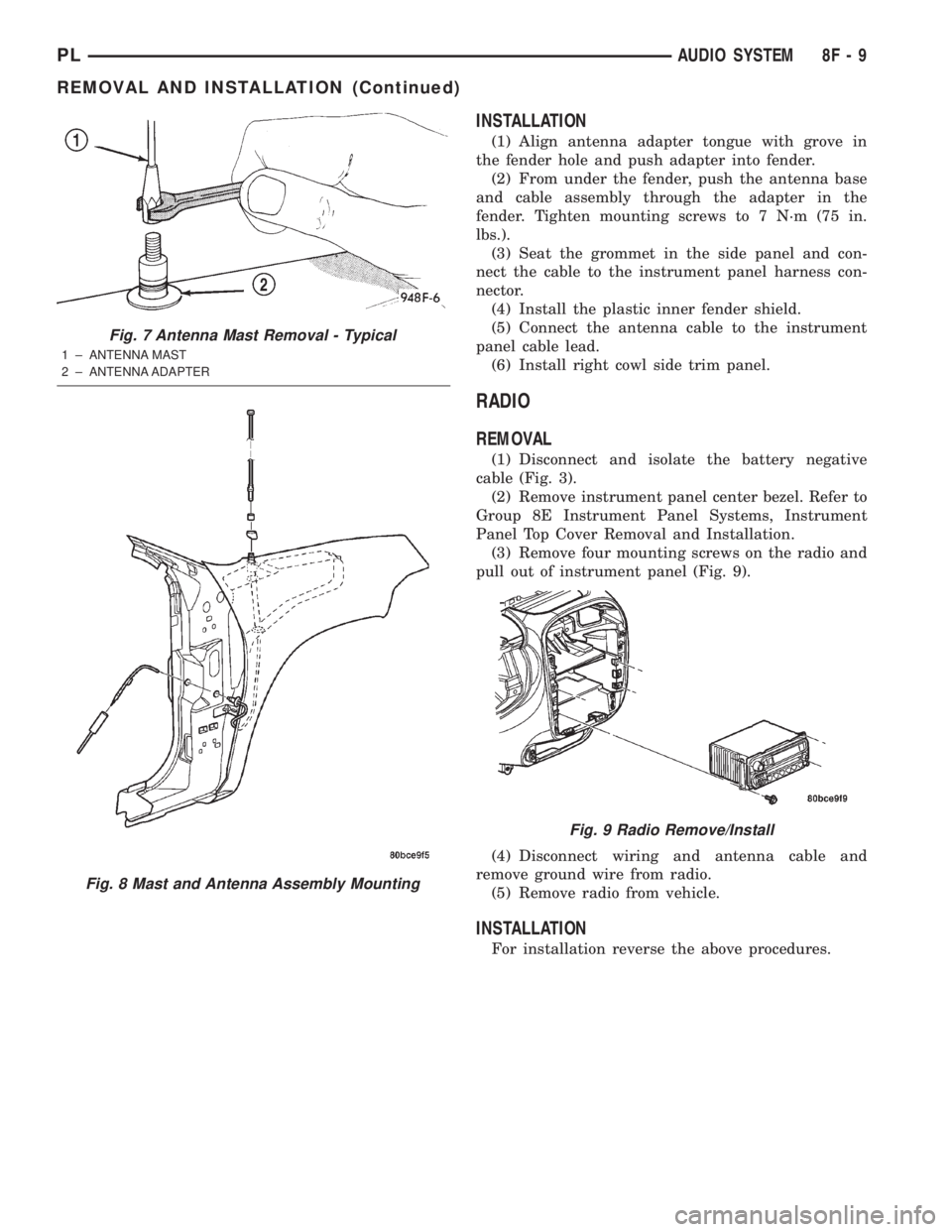

(1) Disconnect and isolate the battery negative

cable (Fig. 3).

(2) Using a trim stick (special tool #C-4755), gently

pry out on CD changer bezel and remove.

Fig. 1 Antenna Test Points

1 ± TIP OF MAST TEST POINT

2 ± DISCONNECT TEST POINTS

3 ± RADIO END PIN TEST POINT

Fig. 2 Antenna Bench Test Points

1 ± TIP OF MAST

2 ± ANTENNA BODY

3 ± PLUG

4 ± CONNECTORS

5 ± RADIO LEAD IN

Fig. 3 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

PLAUDIO SYSTEM 8F - 7

DIAGNOSIS AND TESTING (Continued)

Page 277 of 1285

(3) Remove two retaining screws to CD changer

(Fig. 4).

(4) Pull CD changer out of instrument panel and

disconnect harness connector from rear of changer

(Fig. 4).

(5) Remove CD changer from vehicle.

INSTALLATION

For installation, reverse the above procedures.

FRONT DOOR SPEAKER

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 3).

(2) Remove front door trim panel, refer to Group

23 Body, Front Door Trim Panel Removal and Instal-

lation.

(3) Remove three speaker retaining screws (Fig. 5).(4) Remove speaker assembly and disconnect wire

connector from rear of speaker.

(5) Remove speaker from vehicle.

INSTALLATION

For installation reverse the above procedures.

INSTRUMENT PANEL SPEAKER(S)

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 3).

(2) Remove instrument panel top cover. Refer to

Group 8E Instrument Panel Systems, Instrument

Panel Top Cover Removal and Installation.

(3) Remove speaker retaining screws (Fig. 6).

(4) Remove speaker and disconnect wire connector.

INSTALLATION

For installation reverse the above procedures.

MAST and ANTENNA ASSEMBLY

REMOVAL

(1) Remove antenna mast by unscrewing mast

from antenna body (Fig. 7).

(2) Locate the antenna lead disconnect in the

instrument panel wire harness above the right cowl

trim panel. Disconnect the antenna cable from the

instrument panel cable lead.

(3) Unfasten push pins from the rear of the plastic

inner fender shield and move shield to gain access to

mounting screws (Fig. 8).

(4) Remove mounting screws and remove antenna

base and cable assembly from under the fender.

Fig. 4 CD Changer Remove/Install

Fig. 5 Front Door Speaker Remove/Install

Fig. 6 Instrument Panel Speakers Remove/install

8F - 8 AUDIO SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 278 of 1285

INSTALLATION

(1) Align antenna adapter tongue with grove in

the fender hole and push adapter into fender.

(2) From under the fender, push the antenna base

and cable assembly through the adapter in the

fender. Tighten mounting screws to 7 N´m (75 in.

lbs.).

(3) Seat the grommet in the side panel and con-

nect the cable to the instrument panel harness con-

nector.

(4) Install the plastic inner fender shield.

(5) Connect the antenna cable to the instrument

panel cable lead.

(6) Install right cowl side trim panel.

RADIO

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 3).

(2) Remove instrument panel center bezel. Refer to

Group 8E Instrument Panel Systems, Instrument

Panel Top Cover Removal and Installation.

(3) Remove four mounting screws on the radio and

pull out of instrument panel (Fig. 9).

(4) Disconnect wiring and antenna cable and

remove ground wire from radio.

(5) Remove radio from vehicle.

INSTALLATION

For installation reverse the above procedures.

Fig. 7 Antenna Mast Removal - Typical

1 ± ANTENNA MAST

2 ± ANTENNA ADAPTER

Fig. 8 Mast and Antenna Assembly Mounting

Fig. 9 Radio Remove/Install

PLAUDIO SYSTEM 8F - 9

REMOVAL AND INSTALLATION (Continued)

Page 279 of 1285

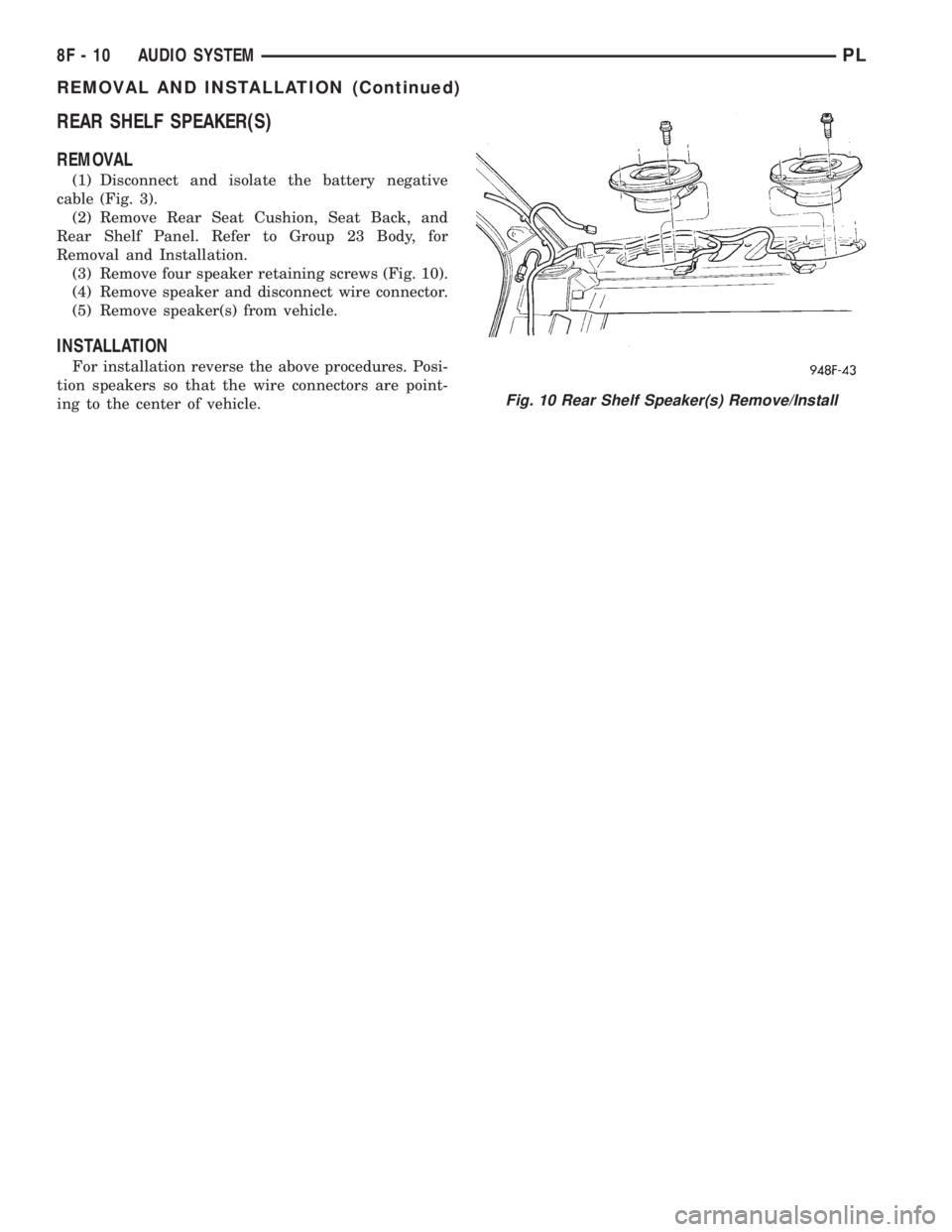

REAR SHELF SPEAKER(S)

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 3).

(2) Remove Rear Seat Cushion, Seat Back, and

Rear Shelf Panel. Refer to Group 23 Body, for

Removal and Installation.

(3) Remove four speaker retaining screws (Fig. 10).

(4) Remove speaker and disconnect wire connector.

(5) Remove speaker(s) from vehicle.

INSTALLATION

For installation reverse the above procedures. Posi-

tion speakers so that the wire connectors are point-

ing to the center of vehicle.

Fig. 10 Rear Shelf Speaker(s) Remove/Install

8F - 10 AUDIO SYSTEMPL

REMOVAL AND INSTALLATION (Continued)

Page 280 of 1285

HORNS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

INTRODUCTION..........................1

DIAGNOSIS AND TESTING

HORN..................................2

HORN RELAY............................2

HORN SWITCH...........................2HORN SYSTEM TEST......................2

REMOVAL AND INSTALLATION

HORN..................................4

HORN RELAY............................4

HORN SWITCH...........................5

DESCRIPTION AND OPERATION

INTRODUCTION

WARNING: ON VEHICLES EQUIPPED WITH AIR-

BAG, SEE GROUP 8M, PASSIVE RESTRAINT SYS-

TEMS FOR STEERING WHEEL REMOVAL.

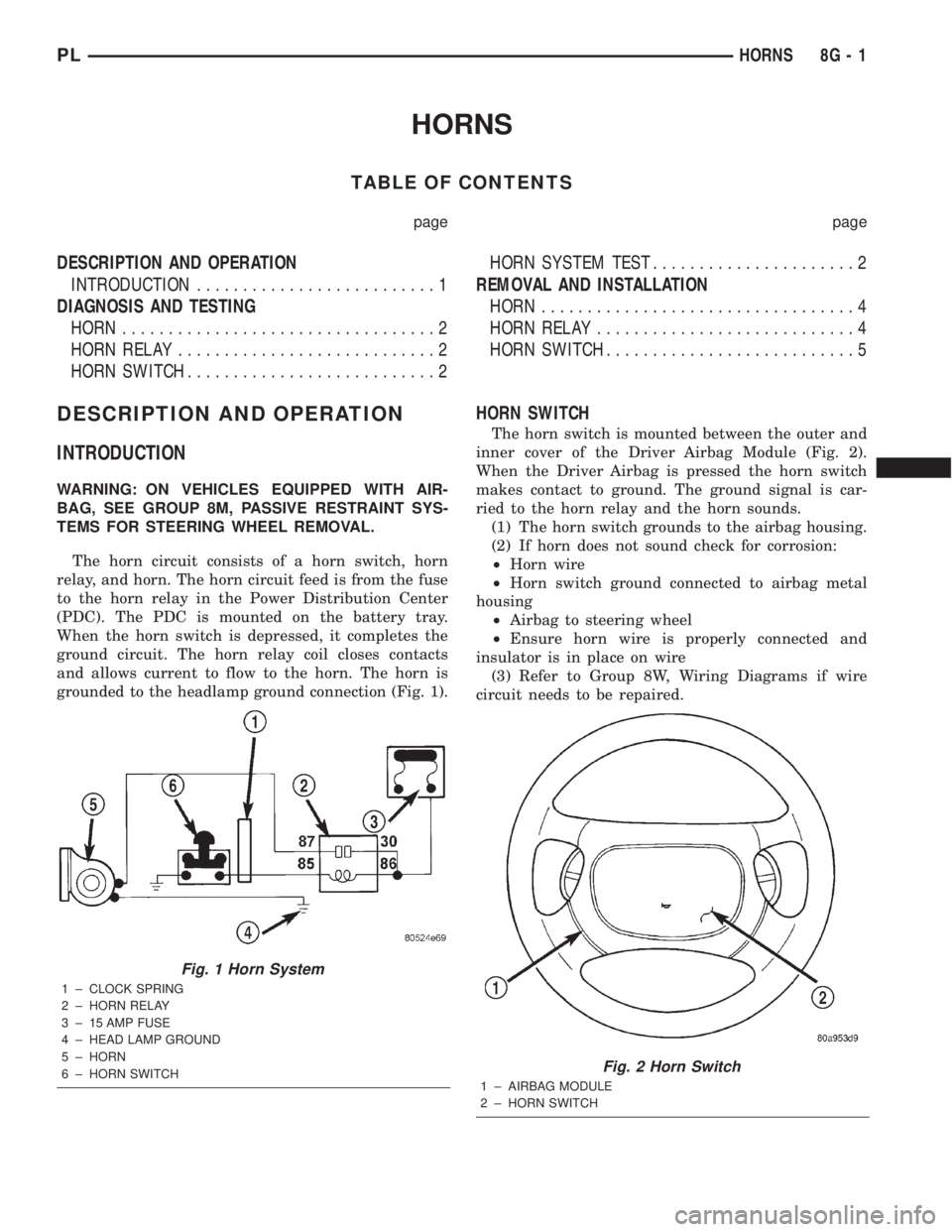

The horn circuit consists of a horn switch, horn

relay, and horn. The horn circuit feed is from the fuse

to the horn relay in the Power Distribution Center

(PDC). The PDC is mounted on the battery tray.

When the horn switch is depressed, it completes the

ground circuit. The horn relay coil closes contacts

and allows current to flow to the horn. The horn is

grounded to the headlamp ground connection (Fig. 1).

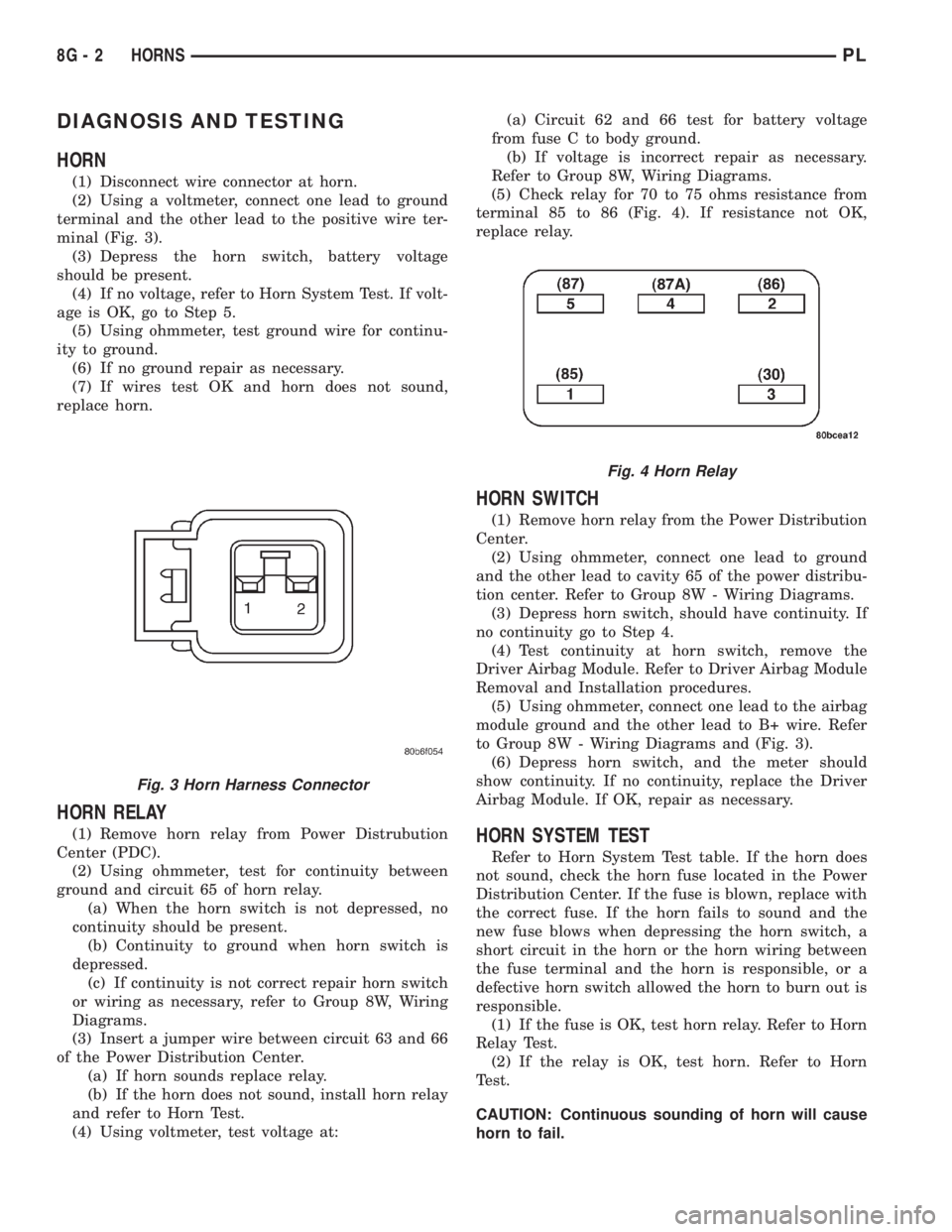

HORN SWITCH

The horn switch is mounted between the outer and

inner cover of the Driver Airbag Module (Fig. 2).

When the Driver Airbag is pressed the horn switch

makes contact to ground. The ground signal is car-

ried to the horn relay and the horn sounds.

(1) The horn switch grounds to the airbag housing.

(2) If horn does not sound check for corrosion:

²Horn wire

²Horn switch ground connected to airbag metal

housing

²Airbag to steering wheel

²Ensure horn wire is properly connected and

insulator is in place on wire

(3) Refer to Group 8W, Wiring Diagrams if wire

circuit needs to be repaired.

Fig. 1 Horn System

1 ± CLOCK SPRING

2 ± HORN RELAY

3 ± 15 AMP FUSE

4 ± HEAD LAMP GROUND

5 ± HORN

6 ± HORN SWITCH

Fig. 2 Horn Switch

1 ± AIRBAG MODULE

2 ± HORN SWITCH

PLHORNS 8G - 1

Page 281 of 1285

DIAGNOSIS AND TESTING

HORN

(1) Disconnect wire connector at horn.

(2) Using a voltmeter, connect one lead to ground

terminal and the other lead to the positive wire ter-

minal (Fig. 3).

(3) Depress the horn switch, battery voltage

should be present.

(4) If no voltage, refer to Horn System Test. If volt-

age is OK, go to Step 5.

(5) Using ohmmeter, test ground wire for continu-

ity to ground.

(6) If no ground repair as necessary.

(7) If wires test OK and horn does not sound,

replace horn.

HORN RELAY

(1) Remove horn relay from Power Distrubution

Center (PDC).

(2) Using ohmmeter, test for continuity between

ground and circuit 65 of horn relay.

(a) When the horn switch is not depressed, no

continuity should be present.

(b) Continuity to ground when horn switch is

depressed.

(c) If continuity is not correct repair horn switch

or wiring as necessary, refer to Group 8W, Wiring

Diagrams.

(3) Insert a jumper wire between circuit 63 and 66

of the Power Distribution Center.

(a) If horn sounds replace relay.

(b) If the horn does not sound, install horn relay

and refer to Horn Test.

(4) Using voltmeter, test voltage at:(a) Circuit 62 and 66 test for battery voltage

from fuse C to body ground.

(b) If voltage is incorrect repair as necessary.

Refer to Group 8W, Wiring Diagrams.

(5) Check relay for 70 to 75 ohms resistance from

terminal 85 to 86 (Fig. 4). If resistance not OK,

replace relay.

HORN SWITCH

(1) Remove horn relay from the Power Distribution

Center.

(2) Using ohmmeter, connect one lead to ground

and the other lead to cavity 65 of the power distribu-

tion center. Refer to Group 8W - Wiring Diagrams.

(3) Depress horn switch, should have continuity. If

no continuity go to Step 4.

(4) Test continuity at horn switch, remove the

Driver Airbag Module. Refer to Driver Airbag Module

Removal and Installation procedures.

(5) Using ohmmeter, connect one lead to the airbag

module ground and the other lead to B+ wire. Refer

to Group 8W - Wiring Diagrams and (Fig. 3).

(6) Depress horn switch, and the meter should

show continuity. If no continuity, replace the Driver

Airbag Module. If OK, repair as necessary.

HORN SYSTEM TEST

Refer to Horn System Test table. If the horn does

not sound, check the horn fuse located in the Power

Distribution Center. If the fuse is blown, replace with

the correct fuse. If the horn fails to sound and the

new fuse blows when depressing the horn switch, a

short circuit in the horn or the horn wiring between

the fuse terminal and the horn is responsible, or a

defective horn switch allowed the horn to burn out is

responsible.

(1) If the fuse is OK, test horn relay. Refer to Horn

Relay Test.

(2) If the relay is OK, test horn. Refer to Horn

Test.

CAUTION: Continuous sounding of horn will cause

horn to fail.

Fig. 3 Horn Harness Connector

Fig. 4 Horn Relay

8G - 2 HORNSPL