battery DODGE NEON 2000 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 303 of 1285

WINDSHIELD WIPER MODULE

REMOVAL

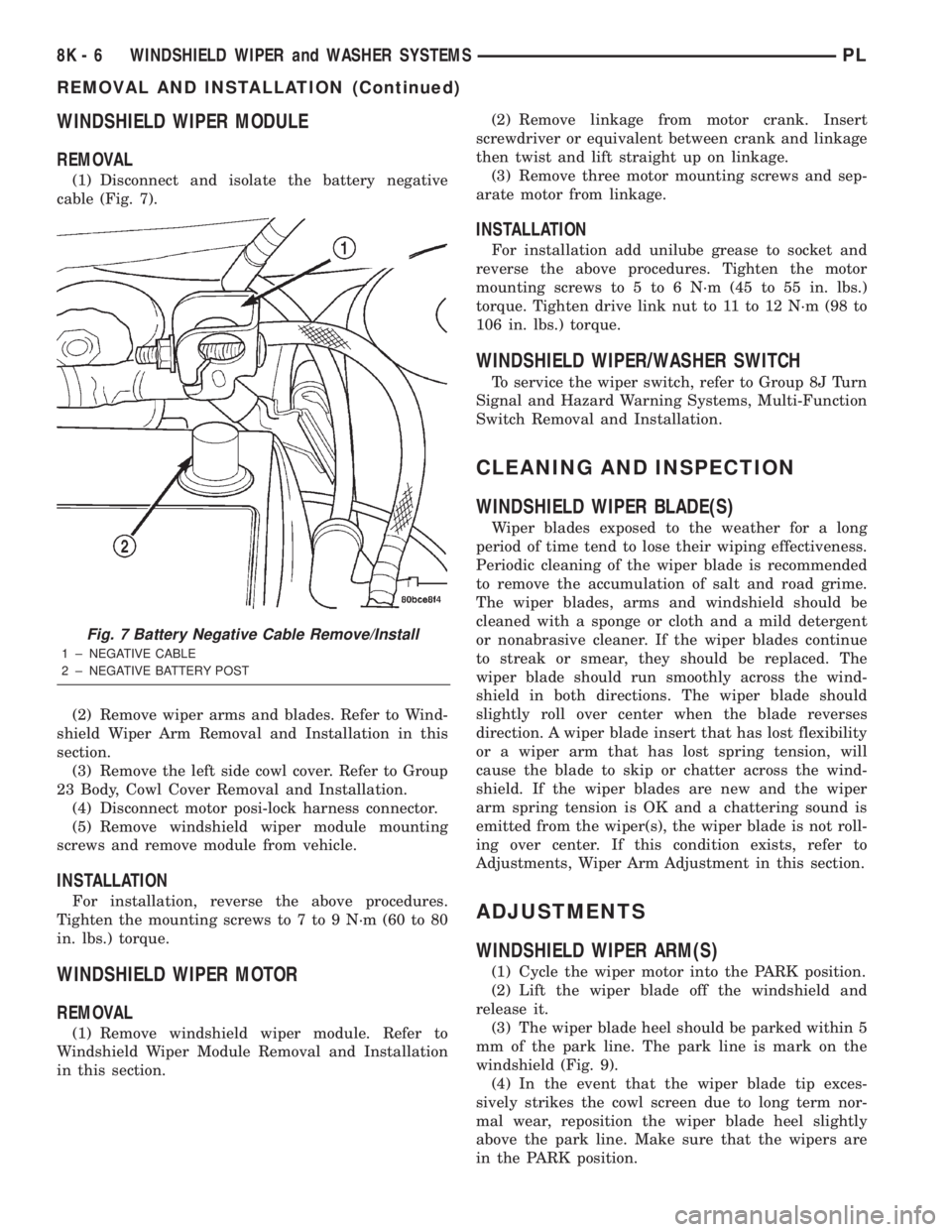

(1) Disconnect and isolate the battery negative

cable (Fig. 7).

(2) Remove wiper arms and blades. Refer to Wind-

shield Wiper Arm Removal and Installation in this

section.

(3) Remove the left side cowl cover. Refer to Group

23 Body, Cowl Cover Removal and Installation.

(4) Disconnect motor posi-lock harness connector.

(5) Remove windshield wiper module mounting

screws and remove module from vehicle.

INSTALLATION

For installation, reverse the above procedures.

Tighten the mounting screws to 7 to 9 N´m (60 to 80

in. lbs.) torque.

WINDSHIELD WIPER MOTOR

REMOVAL

(1) Remove windshield wiper module. Refer to

Windshield Wiper Module Removal and Installation

in this section.(2) Remove linkage from motor crank. Insert

screwdriver or equivalent between crank and linkage

then twist and lift straight up on linkage.

(3) Remove three motor mounting screws and sep-

arate motor from linkage.

INSTALLATION

For installation add unilube grease to socket and

reverse the above procedures. Tighten the motor

mounting screws to 5 to 6 N´m (45 to 55 in. lbs.)

torque. Tighten drive link nut to 11 to 12 N´m (98 to

106 in. lbs.) torque.

WINDSHIELD WIPER/WASHER SWITCH

To service the wiper switch, refer to Group 8J Turn

Signal and Hazard Warning Systems, Multi-Function

Switch Removal and Installation.

CLEANING AND INSPECTION

WINDSHIELD WIPER BLADE(S)

Wiper blades exposed to the weather for a long

period of time tend to lose their wiping effectiveness.

Periodic cleaning of the wiper blade is recommended

to remove the accumulation of salt and road grime.

The wiper blades, arms and windshield should be

cleaned with a sponge or cloth and a mild detergent

or nonabrasive cleaner. If the wiper blades continue

to streak or smear, they should be replaced. The

wiper blade should run smoothly across the wind-

shield in both directions. The wiper blade should

slightly roll over center when the blade reverses

direction. A wiper blade insert that has lost flexibility

or a wiper arm that has lost spring tension, will

cause the blade to skip or chatter across the wind-

shield. If the wiper blades are new and the wiper

arm spring tension is OK and a chattering sound is

emitted from the wiper(s), the wiper blade is not roll-

ing over center. If this condition exists, refer to

Adjustments, Wiper Arm Adjustment in this section.

ADJUSTMENTS

WINDSHIELD WIPER ARM(S)

(1) Cycle the wiper motor into the PARK position.

(2) Lift the wiper blade off the windshield and

release it.

(3) The wiper blade heel should be parked within 5

mm of the park line. The park line is mark on the

windshield (Fig. 9).

(4) In the event that the wiper blade tip exces-

sively strikes the cowl screen due to long term nor-

mal wear, reposition the wiper blade heel slightly

above the park line. Make sure that the wipers are

in the PARK position.

Fig. 7 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

8K - 6 WINDSHIELD WIPER and WASHER SYSTEMSPL

REMOVAL AND INSTALLATION (Continued)

Page 306 of 1285

DIAGNOSIS AND TESTING

WINDSHIELD WASHER SYSTEM

Whenever a windshield washer malfunction occurs,

first verify that the windshield washer wire harnessis properly connected to all connectors before starting

normal diagnosis and repair procedures. Refer to

Windshield Washer System Test table.

WINDSHIELD WASHER SYSTEM TEST

CONDITION POSSIBLE CAUSE CORRECTION

PUMP RUNS NO FLUID

FLOWING.1. NO FLUID IN THE

RESERVOIR.

2. NOZZLE PLUGGED

OR FROZEN.

3. BROKEN, LOOSE OR

PINCHED HOSE.

4. FAULTY PUMP.1. FILL RESERVOIR.

2. THAW AND CHECK FLOW IF BLOCKED

3. CHECK FLOW THROUGH HOSE CONNECTIONS.

4. APPLY BATTERY VOLTAGE TO MOTOR

TERMINALS, REPLACE IF PUMP DOES NOT RUN.

SYSTEM OPERATES

INTERMITTENTLY.1. LOOSE WIRE

CONNECTION.

2. FAULTY SWITCH.1. CHECK WIRE CONNECTIONS.

2. DISCONNECT WIRE HARNESS USE

VOLTMETER TO CHECK SWITCH.

SYSTEM OUTPUT IS

LOW.1. PINCHED HOSE.

2. HOSE BLOCKED.1. CHECK FLOW THROUGH HOSE CONNECTION.

2. DISCONNECT HOSE AT NOZZLE AND Y

CONNECTOR CHECK FOR FLOW. REPLACE ASS

NECESSARY.

REMOVAL AND INSTALLATION

WINDSHIELD WASHER HOSE

REMOVAL

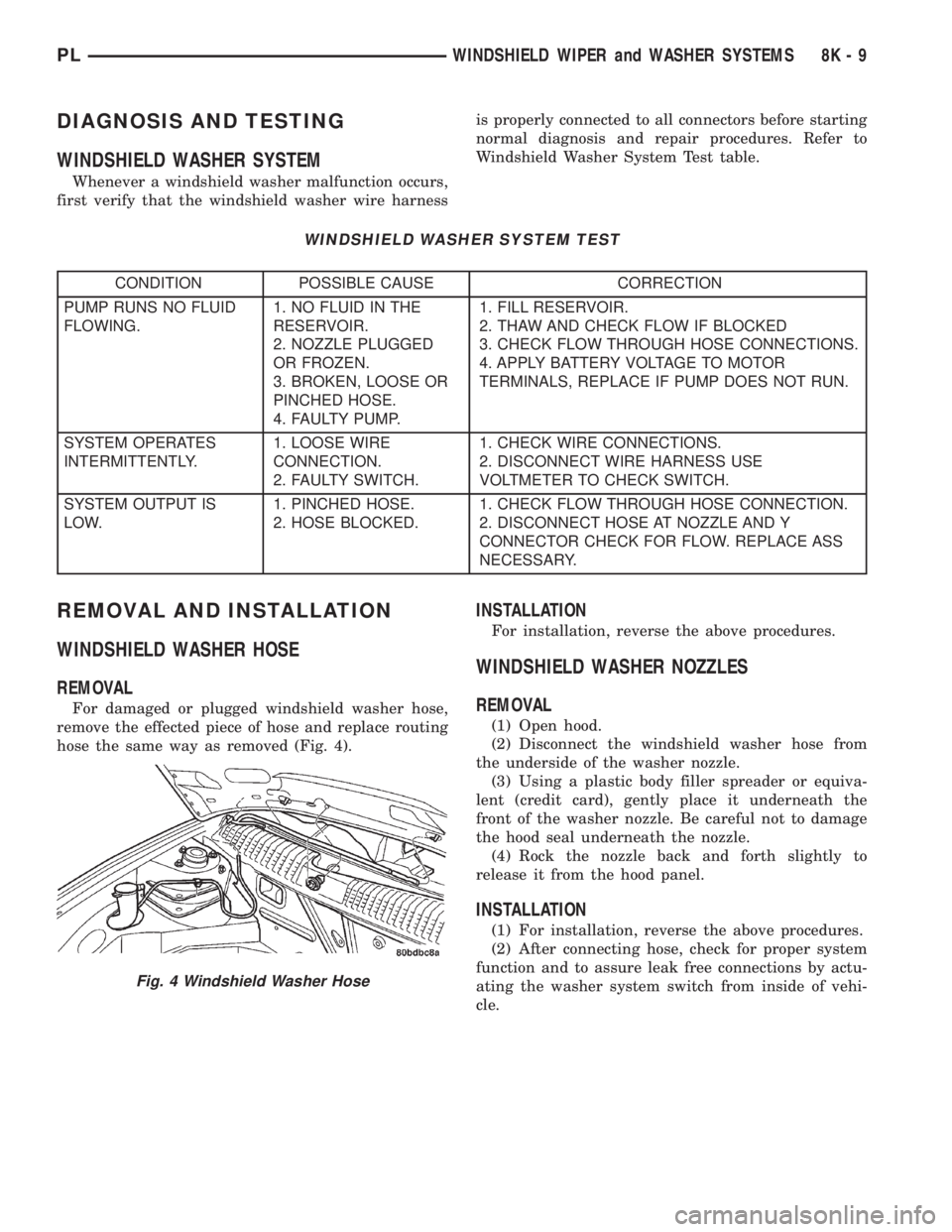

For damaged or plugged windshield washer hose,

remove the effected piece of hose and replace routing

hose the same way as removed (Fig. 4).

INSTALLATION

For installation, reverse the above procedures.

WINDSHIELD WASHER NOZZLES

REMOVAL

(1) Open hood.

(2) Disconnect the windshield washer hose from

the underside of the washer nozzle.

(3) Using a plastic body filler spreader or equiva-

lent (credit card), gently place it underneath the

front of the washer nozzle. Be careful not to damage

the hood seal underneath the nozzle.

(4) Rock the nozzle back and forth slightly to

release it from the hood panel.

INSTALLATION

(1) For installation, reverse the above procedures.

(2) After connecting hose, check for proper system

function and to assure leak free connections by actu-

ating the washer system switch from inside of vehi-

cle.

Fig. 4 Windshield Washer Hose

PLWINDSHIELD WIPER and WASHER SYSTEMS 8K - 9

Page 308 of 1285

LAMPS

TABLE OF CONTENTS

page page

LAMP DIAGNOSIS......................... 1

HEADLAMP ALIGNMENT.................... 4

LAMP BULB SERVICE...................... 7LAMP SERVICE........................... 12

LAMP SYSTEMS.......................... 16

BULB APPLICATION....................... 17

LAMP DIAGNOSIS

TABLE OF CONTENTS

page page

DESCRIPTION AND OPERATION

DIAGNOSTIC PROCEDURES................1

SAFETY PRECAUTIONS....................1

DAYTIME RUNNING LAMP MODULE...........1DIAGNOSIS AND TESTING

HEADLAMP DIAGNOSIS....................1

FOG LAMP..............................3

DESCRIPTION AND OPERATION

DIAGNOSTIC PROCEDURES

When a vehicle experiences problems with the

headlamp system, verify the condition of the battery

connections, fuses, charging system, headlamp bulbs,

wire connectors, relay, high beam switch, dimmer

switch, and headlamp switch. Refer to Group 8W,

Wiring Diagrams for component locations and circuit

information.

SAFETY PRECAUTIONS

WARNING: EYE PROTECTION SHOULD BE USED

WHEN SERVICING GLASS COMPONENTS. PER-

SONAL INJURY CAN RESULT.

CAUTION: Do not touch the glass of halogen bulbs

with fingers or other possibly oily surface, reduced

bulb life will result.

Do not use bulbs with higher candle power than

indicated in the Bulb Application table at the end of

this group. Damage to lamp and/or Daytime Run-

ning Lamp Module can result.

Do not use fuses, circuit breakers or relays hav-

ing greater amperage value than indicated on the

fuse panel or in the Owners Manual.When it is necessary to remove components to ser-

vice another, it should not be necessary to apply

excessive force or bend a component to remove it.

Before damaging a trim component, verify hidden

fasteners or captured edges are not holding the com-

ponent in place.

DAYTIME RUNNING LAMP MODULE

PL vehicles built for use in Canada are equipped

with a Daytime Running Lamp (DRL) system. Turn

signal lamp circuitry always comes from the multi-

function switch, and goes to the cluster connector,

into the cluster, then back out to the front turn sig-

nal switch lamps. The Canadian cluster provides

steady illumination of the front turn signal when the

ignition switch is in the ON position. The DRL func-

tion may be inhibited by activating the turn signals,

the hazard flashers, the headlamp switch, or park

brake.

DIAGNOSIS AND TESTING

HEADLAMP DIAGNOSIS

Always begin any diagnosis by testing all of the

fuses and circuit breakers in the system. Refer to

Group 8W, Wiring Diagrams.

Conventional and halogen headlamps are inter-

changeable. It is recommended that they not be

intermixed on a given vehicle.

PLLAMPS 8L - 1

Page 309 of 1285

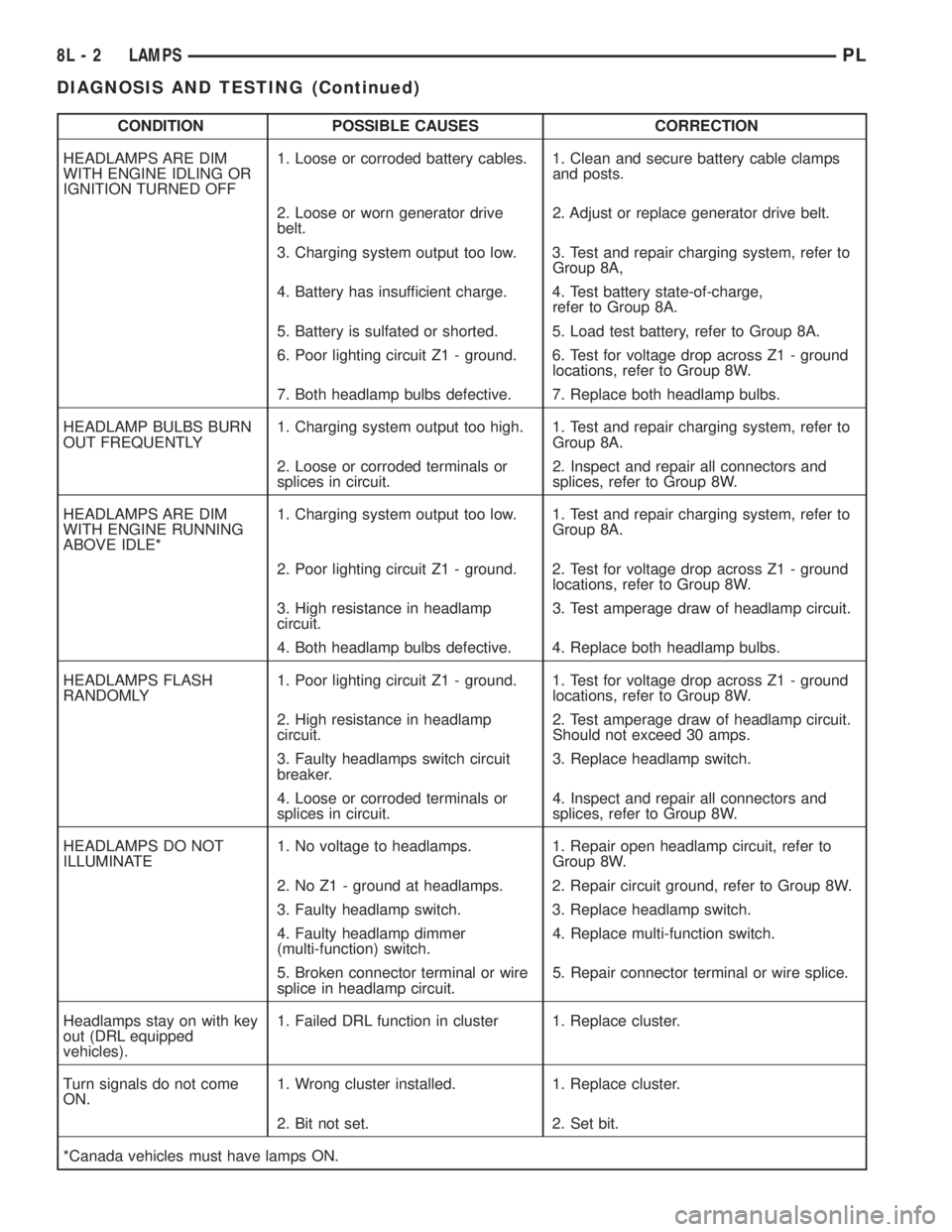

CONDITION POSSIBLE CAUSES CORRECTION

HEADLAMPS ARE DIM

WITH ENGINE IDLING OR

IGNITION TURNED OFF1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

2. Loose or worn generator drive

belt.2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system, refer to

Group 8A,

4. Battery has insufficient charge. 4. Test battery state-of-charge,

refer to Group 8A.

5. Battery is sulfated or shorted. 5. Load test battery, refer to Group 8A.

6. Poor lighting circuit Z1 - ground. 6. Test for voltage drop across Z1 - ground

locations, refer to Group 8W.

7. Both headlamp bulbs defective. 7. Replace both headlamp bulbs.

HEADLAMP BULBS BURN

OUT FREQUENTLY1. Charging system output too high. 1. Test and repair charging system, refer to

Group 8A.

2. Loose or corroded terminals or

splices in circuit.2. Inspect and repair all connectors and

splices, refer to Group 8W.

HEADLAMPS ARE DIM

WITH ENGINE RUNNING

ABOVE IDLE*1. Charging system output too low. 1. Test and repair charging system, refer to

Group 8A.

2. Poor lighting circuit Z1 - ground. 2. Test for voltage drop across Z1 - ground

locations, refer to Group 8W.

3. High resistance in headlamp

circuit.3. Test amperage draw of headlamp circuit.

4. Both headlamp bulbs defective. 4. Replace both headlamp bulbs.

HEADLAMPS FLASH

RANDOMLY1. Poor lighting circuit Z1 - ground. 1. Test for voltage drop across Z1 - ground

locations, refer to Group 8W.

2. High resistance in headlamp

circuit.2. Test amperage draw of headlamp circuit.

Should not exceed 30 amps.

3. Faulty headlamps switch circuit

breaker.3. Replace headlamp switch.

4. Loose or corroded terminals or

splices in circuit.4. Inspect and repair all connectors and

splices, refer to Group 8W.

HEADLAMPS DO NOT

ILLUMINATE1. No voltage to headlamps. 1. Repair open headlamp circuit, refer to

Group 8W.

2. No Z1 - ground at headlamps. 2. Repair circuit ground, refer to Group 8W.

3. Faulty headlamp switch. 3. Replace headlamp switch.

4. Faulty headlamp dimmer

(multi-function) switch.4. Replace multi-function switch.

5. Broken connector terminal or wire

splice in headlamp circuit.5. Repair connector terminal or wire splice.

Headlamps stay on with key

out (DRL equipped

vehicles).1. Failed DRL function in cluster 1. Replace cluster.

Turn signals do not come

ON.1. Wrong cluster installed. 1. Replace cluster.

2. Bit not set. 2. Set bit.

*Canada vehicles must have lamps ON.

8L - 2 LAMPSPL

DIAGNOSIS AND TESTING (Continued)

Page 310 of 1285

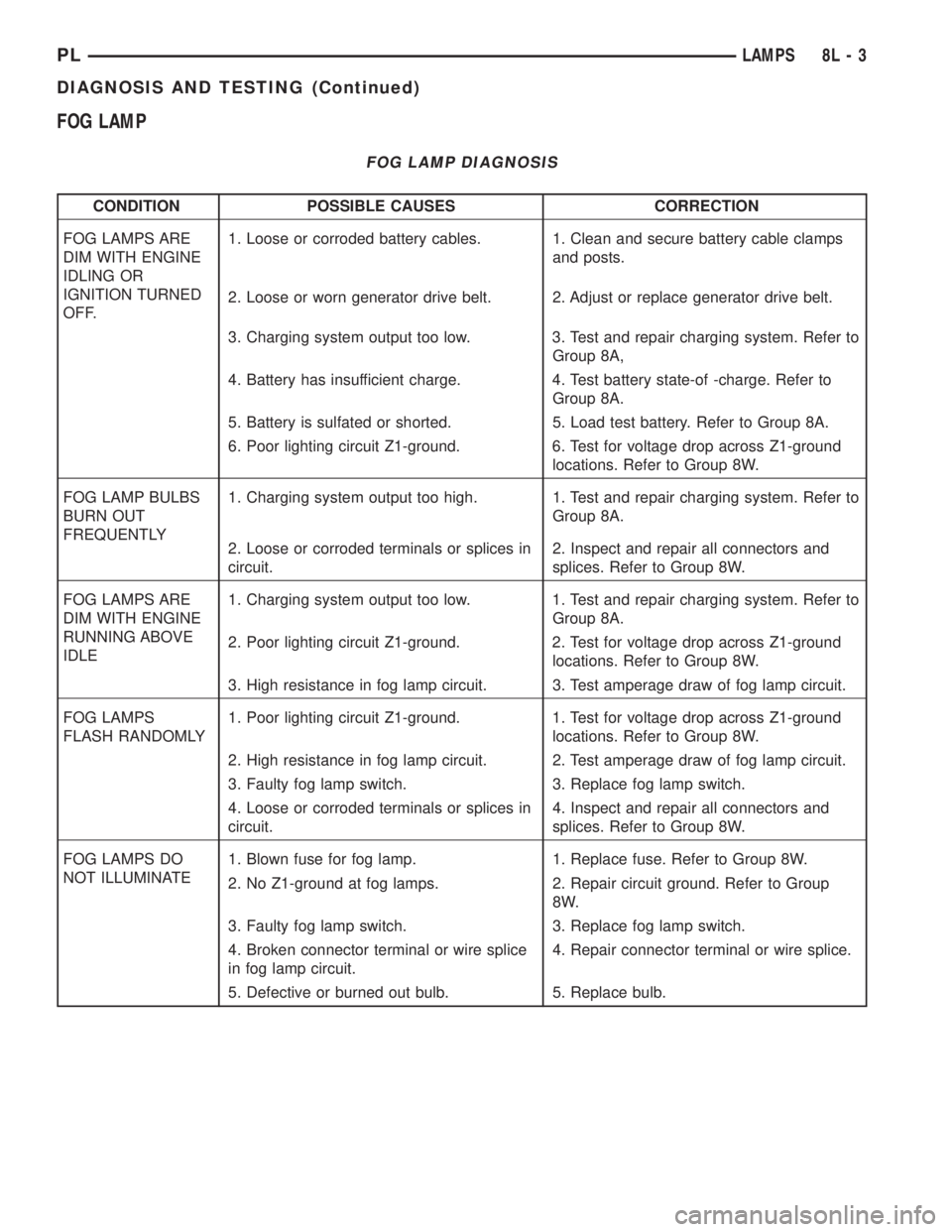

FOG LAMP

FOG LAMP DIAGNOSIS

CONDITION POSSIBLE CAUSES CORRECTION

FOG LAMPS ARE

DIM WITH ENGINE

IDLING OR

IGNITION TURNED

OFF.1. Loose or corroded battery cables. 1. Clean and secure battery cable clamps

and posts.

2. Loose or worn generator drive belt. 2. Adjust or replace generator drive belt.

3. Charging system output too low. 3. Test and repair charging system. Refer to

Group 8A,

4. Battery has insufficient charge. 4. Test battery state-of -charge. Refer to

Group 8A.

5. Battery is sulfated or shorted. 5. Load test battery. Refer to Group 8A.

6. Poor lighting circuit Z1-ground. 6. Test for voltage drop across Z1-ground

locations. Refer to Group 8W.

FOG LAMP BULBS

BURN OUT

FREQUENTLY1. Charging system output too high. 1. Test and repair charging system. Refer to

Group 8A.

2. Loose or corroded terminals or splices in

circuit.2. Inspect and repair all connectors and

splices. Refer to Group 8W.

FOG LAMPS ARE

DIM WITH ENGINE

RUNNING ABOVE

IDLE1. Charging system output too low. 1. Test and repair charging system. Refer to

Group 8A.

2. Poor lighting circuit Z1-ground. 2. Test for voltage drop across Z1-ground

locations. Refer to Group 8W.

3. High resistance in fog lamp circuit. 3. Test amperage draw of fog lamp circuit.

FOG LAMPS

FLASH RANDOMLY1. Poor lighting circuit Z1-ground. 1. Test for voltage drop across Z1-ground

locations. Refer to Group 8W.

2. High resistance in fog lamp circuit. 2. Test amperage draw of fog lamp circuit.

3. Faulty fog lamp switch. 3. Replace fog lamp switch.

4. Loose or corroded terminals or splices in

circuit.4. Inspect and repair all connectors and

splices. Refer to Group 8W.

FOG LAMPS DO

NOT ILLUMINATE1. Blown fuse for fog lamp. 1. Replace fuse. Refer to Group 8W.

2. No Z1-ground at fog lamps. 2. Repair circuit ground. Refer to Group

8W.

3. Faulty fog lamp switch. 3. Replace fog lamp switch.

4. Broken connector terminal or wire splice

in fog lamp circuit.4. Repair connector terminal or wire splice.

5. Defective or burned out bulb. 5. Replace bulb.

PLLAMPS 8L - 3

DIAGNOSIS AND TESTING (Continued)

Page 338 of 1285

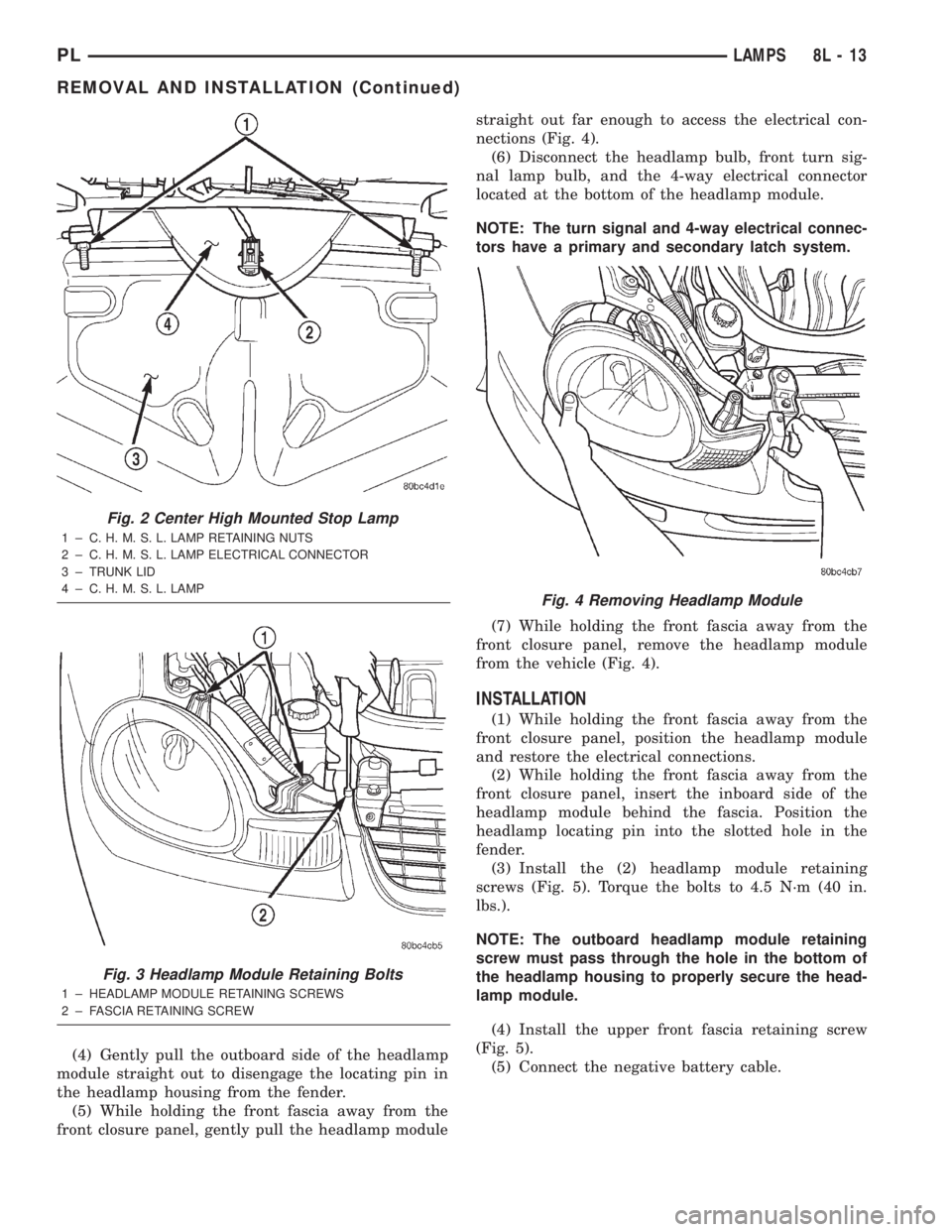

(4) Gently pull the outboard side of the headlamp

module straight out to disengage the locating pin in

the headlamp housing from the fender.

(5) While holding the front fascia away from the

front closure panel, gently pull the headlamp modulestraight out far enough to access the electrical con-

nections (Fig. 4).

(6) Disconnect the headlamp bulb, front turn sig-

nal lamp bulb, and the 4-way electrical connector

located at the bottom of the headlamp module.

NOTE: The turn signal and 4-way electrical connec-

tors have a primary and secondary latch system.

(7) While holding the front fascia away from the

front closure panel, remove the headlamp module

from the vehicle (Fig. 4).

INSTALLATION

(1) While holding the front fascia away from the

front closure panel, position the headlamp module

and restore the electrical connections.

(2) While holding the front fascia away from the

front closure panel, insert the inboard side of the

headlamp module behind the fascia. Position the

headlamp locating pin into the slotted hole in the

fender.

(3) Install the (2) headlamp module retaining

screws (Fig. 5). Torque the bolts to 4.5 N´m (40 in.

lbs.).

NOTE: The outboard headlamp module retaining

screw must pass through the hole in the bottom of

the headlamp housing to properly secure the head-

lamp module.

(4) Install the upper front fascia retaining screw

(Fig. 5).

(5) Connect the negative battery cable.

Fig. 2 Center High Mounted Stop Lamp

1 ± C. H. M. S. L. LAMP RETAINING NUTS

2 ± C. H. M. S. L. LAMP ELECTRICAL CONNECTOR

3 ± TRUNK LID

4 ± C. H. M. S. L. LAMP

Fig. 3 Headlamp Module Retaining Bolts

1 ± HEADLAMP MODULE RETAINING SCREWS

2 ± FASCIA RETAINING SCREW

Fig. 4 Removing Headlamp Module

PLLAMPS 8L - 13

REMOVAL AND INSTALLATION (Continued)

Page 346 of 1285

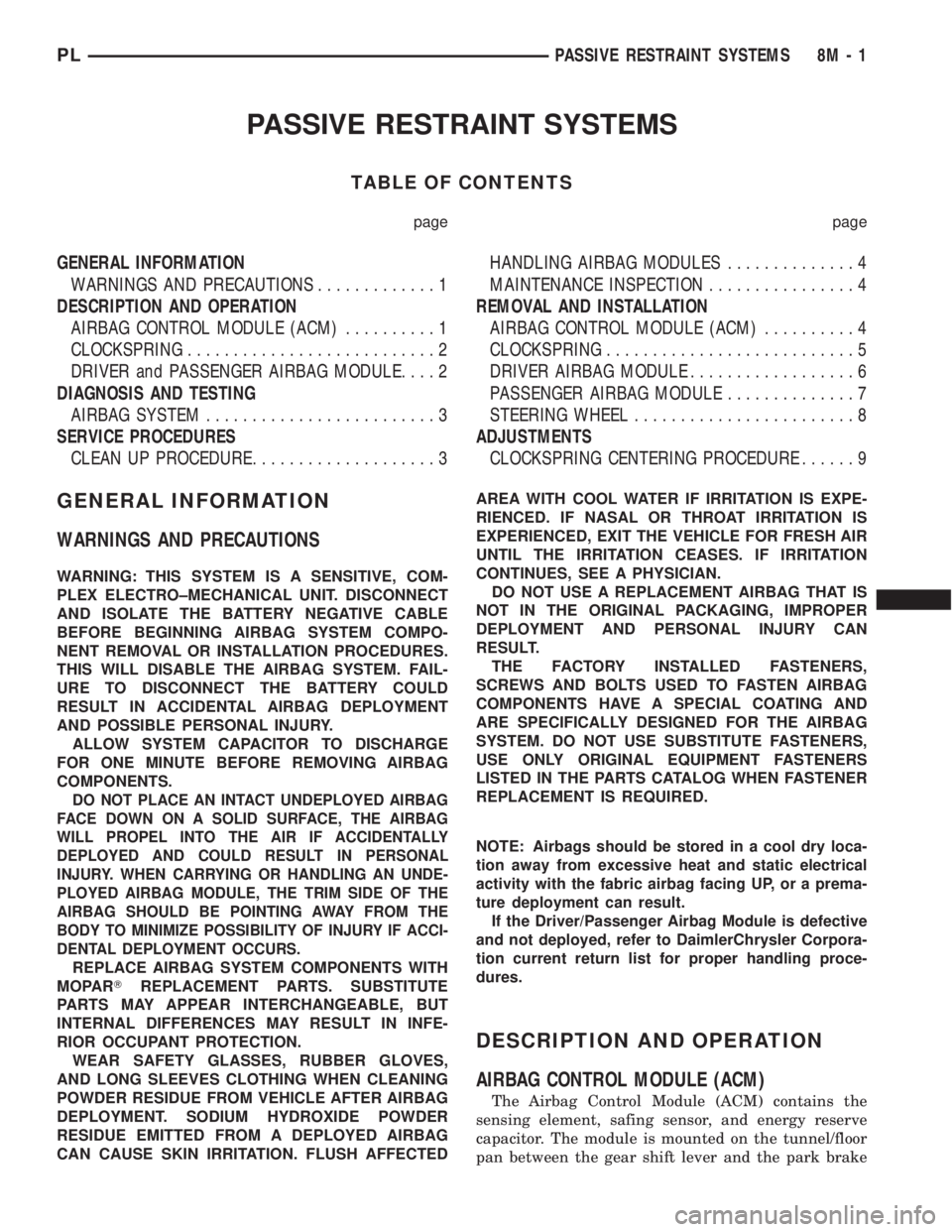

PASSIVE RESTRAINT SYSTEMS

TABLE OF CONTENTS

page page

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS.............1

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE (ACM)..........1

CLOCKSPRING...........................2

DRIVER and PASSENGER AIRBAG MODULE....2

DIAGNOSIS AND TESTING

AIRBAG SYSTEM.........................3

SERVICE PROCEDURES

CLEAN UP PROCEDURE....................3HANDLING AIRBAG MODULES..............4

MAINTENANCE INSPECTION................4

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE (ACM)..........4

CLOCKSPRING...........................5

DRIVER AIRBAG MODULE..................6

PASSENGER AIRBAG MODULE..............7

STEERING WHEEL........................8

ADJUSTMENTS

CLOCKSPRING CENTERING PROCEDURE......9

GENERAL INFORMATION

WARNINGS AND PRECAUTIONS

WARNING: THIS SYSTEM IS A SENSITIVE, COM-

PLEX ELECTRO±MECHANICAL UNIT. DISCONNECT

AND ISOLATE THE BATTERY NEGATIVE CABLE

BEFORE BEGINNING AIRBAG SYSTEM COMPO-

NENT REMOVAL OR INSTALLATION PROCEDURES.

THIS WILL DISABLE THE AIRBAG SYSTEM. FAIL-

URE TO DISCONNECT THE BATTERY COULD

RESULT IN ACCIDENTAL AIRBAG DEPLOYMENT

AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR ONE MINUTE BEFORE REMOVING AIRBAG

COMPONENTS.

DO NOT PLACE AN INTACT UNDEPLOYED AIRBAG

FACE DOWN ON A SOLID SURFACE, THE AIRBAG

WILL PROPEL INTO THE AIR IF ACCIDENTALLY

DEPLOYED AND COULD RESULT IN PERSONAL

INJURY. WHEN CARRYING OR HANDLING AN UNDE-

PLOYED AIRBAG MODULE, THE TRIM SIDE OF THE

AIRBAG SHOULD BE POINTING AWAY FROM THE

BODY TO MINIMIZE POSSIBILITY OF INJURY IF ACCI-

DENTAL DEPLOYMENT OCCURS.

REPLACE AIRBAG SYSTEM COMPONENTS WITH

MOPARTREPLACEMENT PARTS. SUBSTITUTE

PARTS MAY APPEAR INTERCHANGEABLE, BUT

INTERNAL DIFFERENCES MAY RESULT IN INFE-

RIOR OCCUPANT PROTECTION.

WEAR SAFETY GLASSES, RUBBER GLOVES,

AND LONG SLEEVES CLOTHING WHEN CLEANING

POWDER RESIDUE FROM VEHICLE AFTER AIRBAG

DEPLOYMENT. SODIUM HYDROXIDE POWDER

RESIDUE EMITTED FROM A DEPLOYED AIRBAG

CAN CAUSE SKIN IRRITATION. FLUSH AFFECTEDAREA WITH COOL WATER IF IRRITATION IS EXPE-

RIENCED. IF NASAL OR THROAT IRRITATION IS

EXPERIENCED, EXIT THE VEHICLE FOR FRESH AIR

UNTIL THE IRRITATION CEASES. IF IRRITATION

CONTINUES, SEE A PHYSICIAN.

DO NOT USE A REPLACEMENT AIRBAG THAT IS

NOT IN THE ORIGINAL PACKAGING, IMPROPER

DEPLOYMENT AND PERSONAL INJURY CAN

RESULT.

THE FACTORY INSTALLED FASTENERS,

SCREWS AND BOLTS USED TO FASTEN AIRBAG

COMPONENTS HAVE A SPECIAL COATING AND

ARE SPECIFICALLY DESIGNED FOR THE AIRBAG

SYSTEM. DO NOT USE SUBSTITUTE FASTENERS,

USE ONLY ORIGINAL EQUIPMENT FASTENERS

LISTED IN THE PARTS CATALOG WHEN FASTENER

REPLACEMENT IS REQUIRED.

NOTE: Airbags should be stored in a cool dry loca-

tion away from excessive heat and static electrical

activity with the fabric airbag facing UP, or a prema-

ture deployment can result.

If the Driver/Passenger Airbag Module is defective

and not deployed, refer to DaimlerChrysler Corpora-

tion current return list for proper handling proce-

dures.

DESCRIPTION AND OPERATION

AIRBAG CONTROL MODULE (ACM)

The Airbag Control Module (ACM) contains the

sensing element, safing sensor, and energy reserve

capacitor. The module is mounted on the tunnel/floor

pan between the gear shift lever and the park brake

PLPASSIVE RESTRAINT SYSTEMS 8M - 1

Page 348 of 1285

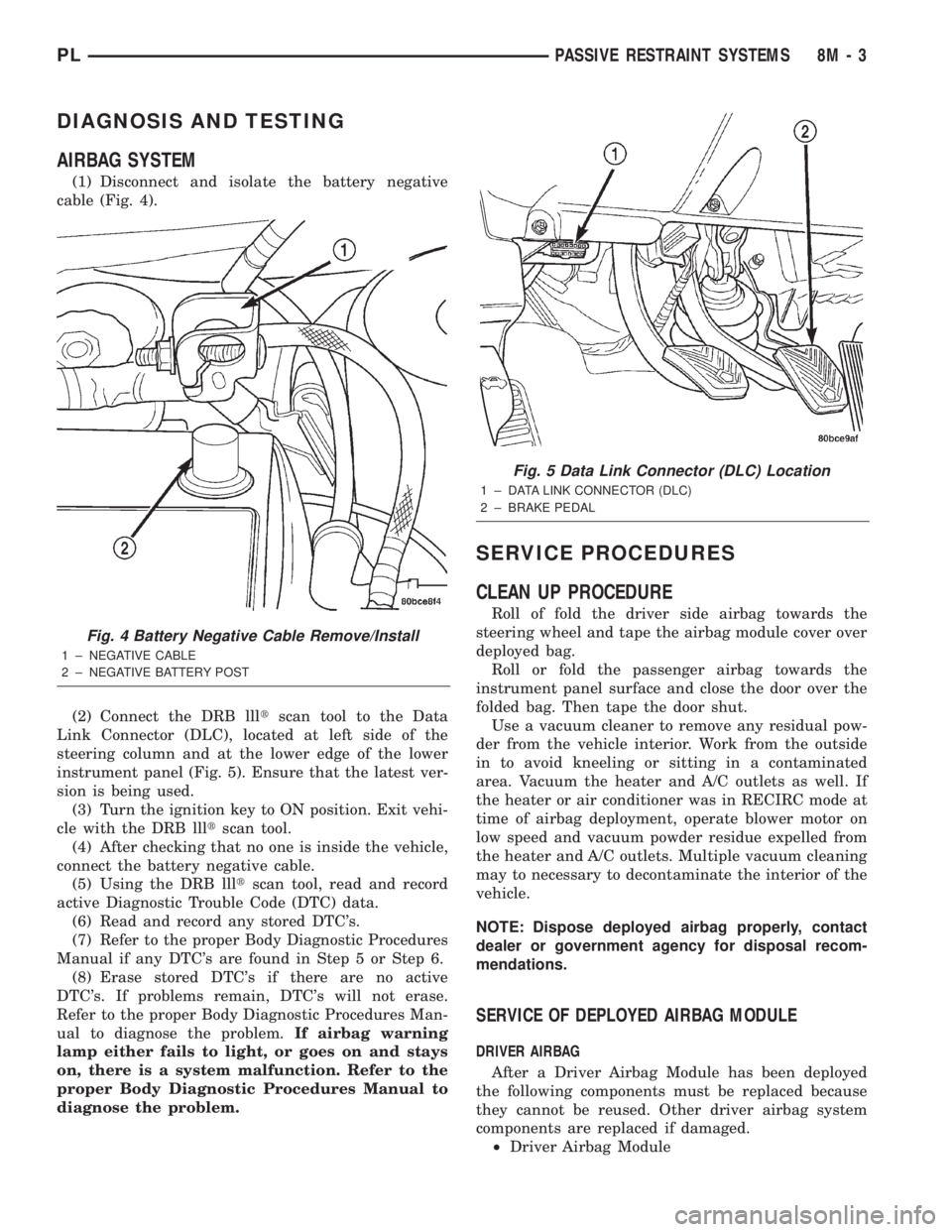

DIAGNOSIS AND TESTING

AIRBAG SYSTEM

(1) Disconnect and isolate the battery negative

cable (Fig. 4).

(2) Connect the DRB llltscan tool to the Data

Link Connector (DLC), located at left side of the

steering column and at the lower edge of the lower

instrument panel (Fig. 5). Ensure that the latest ver-

sion is being used.

(3) Turn the ignition key to ON position. Exit vehi-

cle with the DRB llltscan tool.

(4) After checking that no one is inside the vehicle,

connect the battery negative cable.

(5) Using the DRB llltscan tool, read and record

active Diagnostic Trouble Code (DTC) data.

(6) Read and record any stored DTC's.

(7) Refer to the proper Body Diagnostic Procedures

Manual if any DTC's are found in Step 5 or Step 6.

(8) Erase stored DTC's if there are no active

DTC's. If problems remain, DTC's will not erase.

Refer to the proper Body Diagnostic Procedures Man-

ual to diagnose the problem.If airbag warning

lamp either fails to light, or goes on and stays

on, there is a system malfunction. Refer to the

proper Body Diagnostic Procedures Manual to

diagnose the problem.

SERVICE PROCEDURES

CLEAN UP PROCEDURE

Roll of fold the driver side airbag towards the

steering wheel and tape the airbag module cover over

deployed bag.

Roll or fold the passenger airbag towards the

instrument panel surface and close the door over the

folded bag. Then tape the door shut.

Use a vacuum cleaner to remove any residual pow-

der from the vehicle interior. Work from the outside

in to avoid kneeling or sitting in a contaminated

area. Vacuum the heater and A/C outlets as well. If

the heater or air conditioner was in RECIRC mode at

time of airbag deployment, operate blower motor on

low speed and vacuum powder residue expelled from

the heater and A/C outlets. Multiple vacuum cleaning

may to necessary to decontaminate the interior of the

vehicle.

NOTE: Dispose deployed airbag properly, contact

dealer or government agency for disposal recom-

mendations.

SERVICE OF DEPLOYED AIRBAG MODULE

DRIVER AIRBAG

After a Driver Airbag Module has been deployed

the following components must be replaced because

they cannot be reused. Other driver airbag system

components are replaced if damaged.

²Driver Airbag Module

Fig. 4 Battery Negative Cable Remove/Install

1 ± NEGATIVE CABLE

2 ± NEGATIVE BATTERY POST

Fig. 5 Data Link Connector (DLC) Location

1 ± DATA LINK CONNECTOR (DLC)

2 ± BRAKE PEDAL

PLPASSIVE RESTRAINT SYSTEMS 8M - 3

Page 349 of 1285

²Clockspring assembly

²Steering Column Assembly w/Lower Steering

Column Coupler

PASSENGER AIRBAG

After a Passenger Airbag Module has been

deployed, replace the following components because

they cannot be reused.

²Passenger Airbag Module

Inspect all the attaching hardware and instrument

panel for damage. If damage is evident, components

should be replaced.

HANDLING AIRBAG MODULES

DEPLOYED AIRBAG MODULE

The vehicle interior may contain a very small

amount of sodium hydroxide powder, a by-product of

airbag deployment. Sodium hydroxide powder can

irritate the skin, eyes, nose and throat. Wear safety

glasses, rubber gloves, and long sleeved clothing

when cleaning any of the powder residue from the

vehicle.

If you find that the cleanup is irritating your skin,

run cool water over the affected area. Also, if you

experience nasal or throat irritation, exit the vehicle

for fresh air until the irritation ceases. If irritation

continues, see a physician.

UNDEPLOYED AIRBAG MODULE

The airbag modules must be stored in its original

special container until used for service. At no time

should a source of electricity be permitted near the

inflator on the back of an airbag module. When car-

rying or handling an undeployed airbag module, the

trim side of the airbag should be pointing away from

the body to minimize possibility of injury if acciden-

tal deployment occurs. Do not place undeployed air-

bag face down on a solid surface, the airbag will

propel into the air if accidentally deployment occurs.

MAINTENANCE INSPECTION

(1) Check the airbag warning lamp for proper

operation as follows:

(a) Turn ignition switch to the ON position, the

airbag warning lamp should light. If not, test the

system using a DRB llltscan tool and the proper

Body Diagnostic Procedures Manual.

(b) The airbag warning lamp lights, but fails to

go out after eight seconds. Test the system using a

DRB llltscan tool and the proper Body Diagnostic

Procedures Manual.

(c) After correcting active malfunction erase

stored Diagnostic Trouble Codes (DTC's).

REMOVAL AND INSTALLATION

AIRBAG CONTROL MODULE (ACM)

WARNING: THE ACM CONTAINS THE SENSING

ELEMENT AND A SAFING SENSOR WHICH

ENABLES THE SYSTEM TO DEPLOY THE AIR-

BAGS. TO AVOID ACCIDENTAL DEPLOYMENT,

NEVER CONNECT ACM ELECTRICALLY TO THE

SYSTEM WHILE VEHICLE BATTERY IS CON-

NECTED.

DISCONNECT AND ISOLATE THE BATTERY NEG-

ATIVE (GROUND) CABLE BEFORE BEGINNING ANY

AIRBAG SYSTEM COMPONENT REMOVAL OR

INSTALLATION PROCEDURE. THIS WILL DISABLE

THE AIRBAG SYSTEM. FAILURE TO DISCONNECT

BATTERY COULD RESULT IN ACCIDENTAL AIRBAG

DEPLOYMENT AND POSSIBLE PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 1 MINUTE BEFORE REMOVING ANY AIRBAG

COMPONENTS.

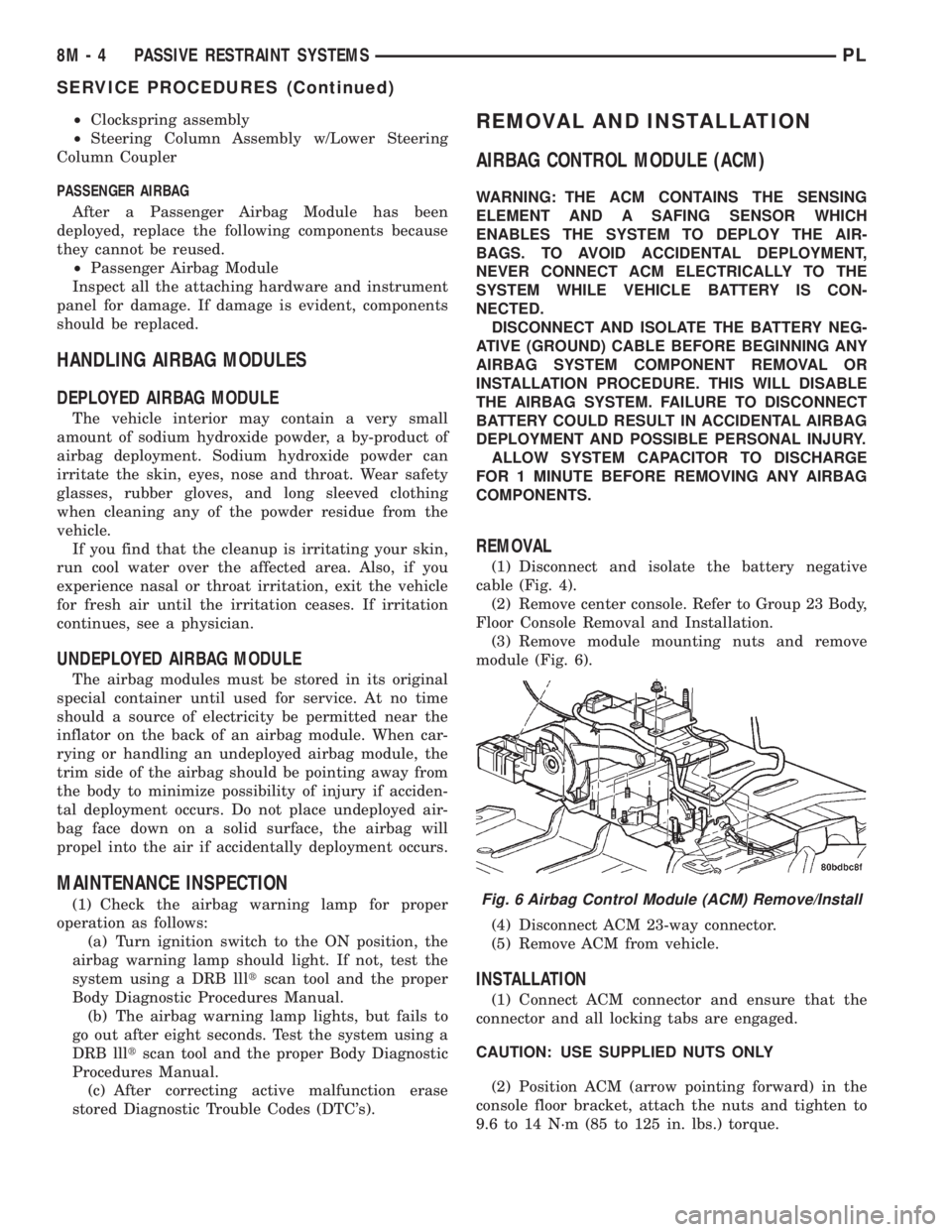

REMOVAL

(1) Disconnect and isolate the battery negative

cable (Fig. 4).

(2) Remove center console. Refer to Group 23 Body,

Floor Console Removal and Installation.

(3) Remove module mounting nuts and remove

module (Fig. 6).

(4) Disconnect ACM 23-way connector.

(5) Remove ACM from vehicle.

INSTALLATION

(1) Connect ACM connector and ensure that the

connector and all locking tabs are engaged.

CAUTION: USE SUPPLIED NUTS ONLY

(2) Position ACM (arrow pointing forward) in the

console floor bracket, attach the nuts and tighten to

9.6 to 14 N´m (85 to 125 in. lbs.) torque.

Fig. 6 Airbag Control Module (ACM) Remove/Install

8M - 4 PASSIVE RESTRAINT SYSTEMSPL

SERVICE PROCEDURES (Continued)

Page 350 of 1285

(3) Install center console assembly. Refer to Group

23 Body, Floor Console Removal and Installation.

(4) Do not connect battery negative cable. Refer to

Diagnosis and Testing for Airbag System Test for the

proper procedures.

CLOCKSPRING

WARNING: DISCONNECT AND ISOLATE THE BAT-

TERY NEGATIVE (GROUND) CABLE BEFORE

BEGINNING ANY AIRBAG SYSTEM COMPONENT

REMOVAL OR INSTALLATION PROCEDURE. THIS

WILL DISABLE THE AIRBAG SYSTEM. FAILURE TO

DISCONNECT BATTERY COULD RESULT IN ACCI-

DENTAL AIRBAG DEPLOYMENT AND POSSIBLE

PERSONAL INJURY.

ALLOW SYSTEM CAPACITOR TO DISCHARGE

FOR 1 MINUTE BEFORE REMOVING ANY AIRBAG

COMPONENTS.

REMOVAL

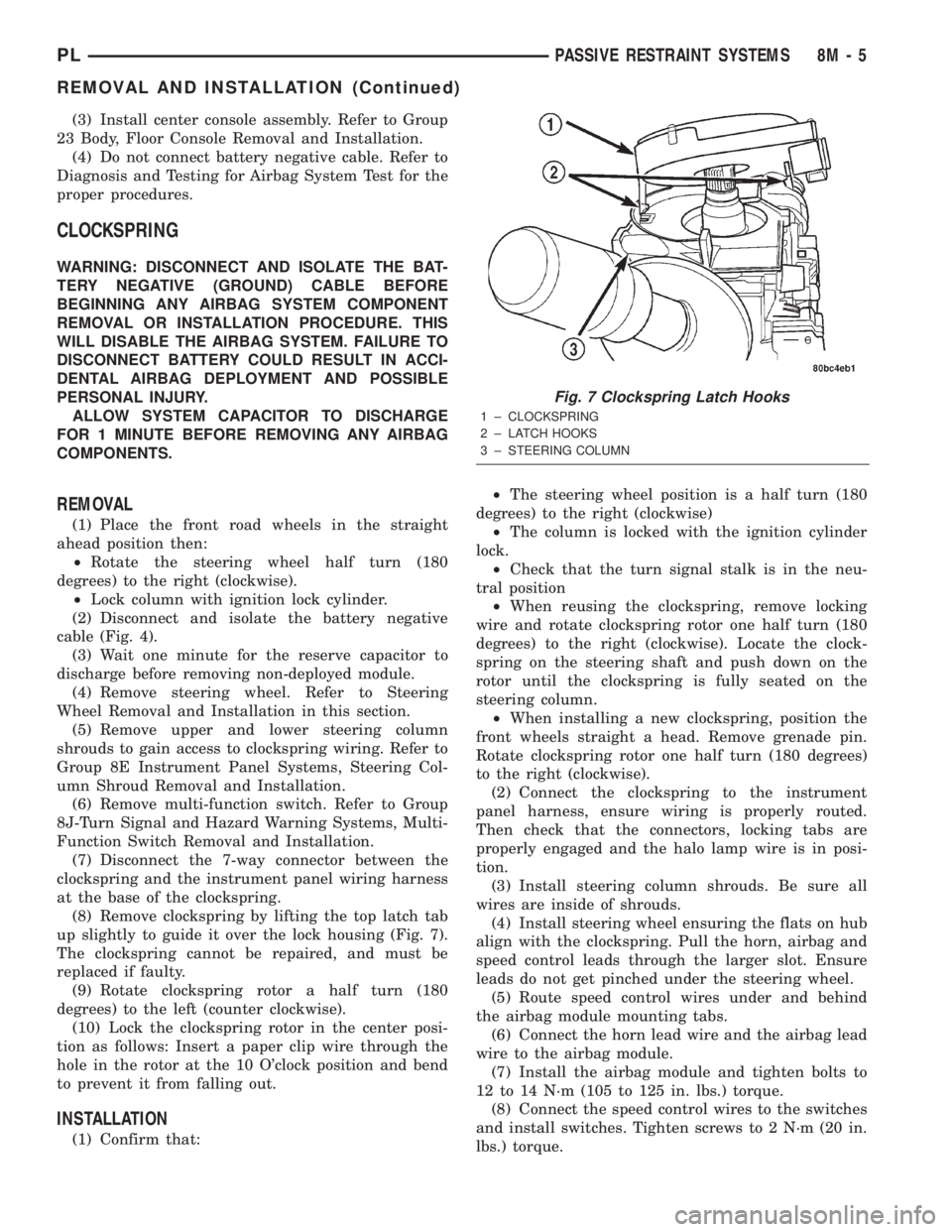

(1) Place the front road wheels in the straight

ahead position then:

²Rotate the steering wheel half turn (180

degrees) to the right (clockwise).

²Lock column with ignition lock cylinder.

(2) Disconnect and isolate the battery negative

cable (Fig. 4).

(3) Wait one minute for the reserve capacitor to

discharge before removing non-deployed module.

(4) Remove steering wheel. Refer to Steering

Wheel Removal and Installation in this section.

(5) Remove upper and lower steering column

shrouds to gain access to clockspring wiring. Refer to

Group 8E Instrument Panel Systems, Steering Col-

umn Shroud Removal and Installation.

(6) Remove multi-function switch. Refer to Group

8J-Turn Signal and Hazard Warning Systems, Multi-

Function Switch Removal and Installation.

(7) Disconnect the 7-way connector between the

clockspring and the instrument panel wiring harness

at the base of the clockspring.

(8) Remove clockspring by lifting the top latch tab

up slightly to guide it over the lock housing (Fig. 7).

The clockspring cannot be repaired, and must be

replaced if faulty.

(9) Rotate clockspring rotor a half turn (180

degrees) to the left (counter clockwise).

(10) Lock the clockspring rotor in the center posi-

tion as follows: Insert a paper clip wire through the

hole in the rotor at the 10 O'clock position and bend

to prevent it from falling out.

INSTALLATION

(1) Confirm that:²The steering wheel position is a half turn (180

degrees) to the right (clockwise)

²The column is locked with the ignition cylinder

lock.

²Check that the turn signal stalk is in the neu-

tral position

²When reusing the clockspring, remove locking

wire and rotate clockspring rotor one half turn (180

degrees) to the right (clockwise). Locate the clock-

spring on the steering shaft and push down on the

rotor until the clockspring is fully seated on the

steering column.

²When installing a new clockspring, position the

front wheels straight a head. Remove grenade pin.

Rotate clockspring rotor one half turn (180 degrees)

to the right (clockwise).

(2) Connect the clockspring to the instrument

panel harness, ensure wiring is properly routed.

Then check that the connectors, locking tabs are

properly engaged and the halo lamp wire is in posi-

tion.

(3) Install steering column shrouds. Be sure all

wires are inside of shrouds.

(4) Install steering wheel ensuring the flats on hub

align with the clockspring. Pull the horn, airbag and

speed control leads through the larger slot. Ensure

leads do not get pinched under the steering wheel.

(5) Route speed control wires under and behind

the airbag module mounting tabs.

(6) Connect the horn lead wire and the airbag lead

wire to the airbag module.

(7) Install the airbag module and tighten bolts to

12 to 14 N´m (105 to 125 in. lbs.) torque.

(8) Connect the speed control wires to the switches

and install switches. Tighten screws to 2 N´m (20 in.

lbs.) torque.

Fig. 7 Clockspring Latch Hooks

1 ± CLOCKSPRING

2 ± LATCH HOOKS

3 ± STEERING COLUMN

PLPASSIVE RESTRAINT SYSTEMS 8M - 5

REMOVAL AND INSTALLATION (Continued)