battery DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 470 of 1285

8W-20 CHARGING SYSTEM

Component Page

Automatic Shut Down Relay............8W-20-2

Battery............................8W-20-2

Engine Starter Motor.................8W-20-2

Fuse 21 (PDC)......................8W-20-2

Fusible Link........................8W-20-2

G104..............................8W-20-2Component Page

G105..............................8W-20-2

Generator..........................8W-20-2

Inlet Air Temperature Sensor...........8W-20-2

Power Distribution Center.............8W-20-2

Powertrain Control Module............8W-20-2

PL8W - 20 CHARGING SYSTEM 8W - 20 - 1

Page 471 of 1285

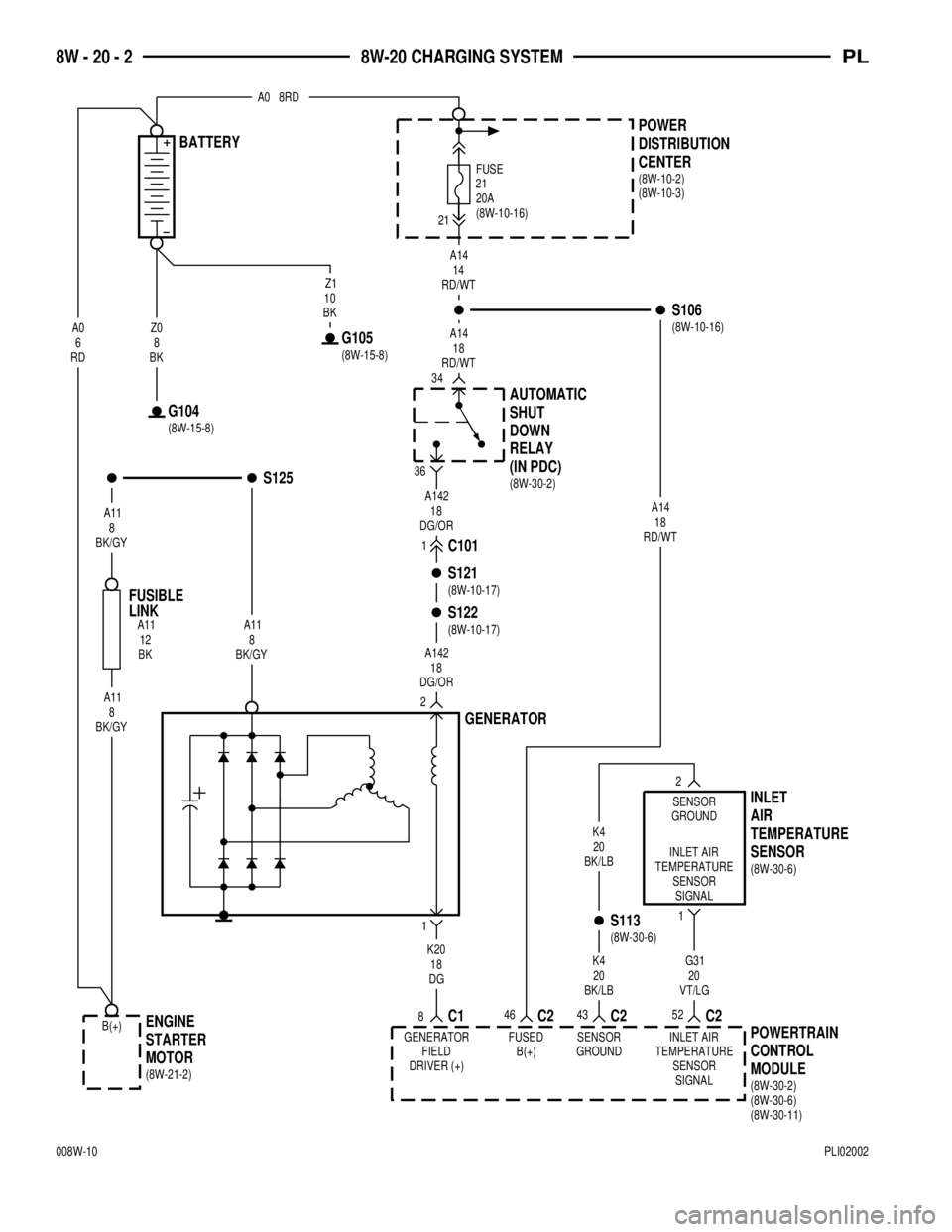

GENERATOR

ENGINE

STARTER

MOTOR

C18

GENERATOR

FIELD

DRIVER (+)POWERTRAIN

CONTROL

MODULE

K20

18

DG

21FUSE20A

21

34

36

POWER

DISTRIBUTION

CENTER BATTERY

A0

6

RD

A0 8RD

Z0

8

BK

Z1

10

BK

G105

A142

18

DG/OR

1C101

A142

18

DG/OR

S122

2

1

RELAY DOWN

SHUT

AUTOMATIC

A14

18

RD/WT

S106

A14

14

RD/WT

(IN PDC)

B(+)

S121

GROUNDSENSOR INLET AIR

TEMPERATURE

SENSOR

SIGNAL GROUNDSENSOR

SIGNAL SENSOR TEMPERATUREINLET AIR

VT/LG20 G31BK/LB20 K4

BK/LB20 K4

1 2

C243C252

S113

RD/WT18 A14

46C2

B(+) FUSED

SENSOR

TEMPERATURE

AIR

INLET

A11

12

BK

BK/GY8 A11

FUSIBLE

LINK

S125

BK/GY8 A11

BK/GY8 A11

G104

(8W-30-2)

(8W-30-6)

(8W-30-11) (8W-10-16)(8W-10-2)

(8W-10-3)

(8W-15-8)

(8W-10-17)

(8W-21-2)(8W-30-2)(8W-10-16)

(8W-10-17)

(8W-30-6)(8W-30-6) (8W-15-8)

8W - 20 - 2 8W-20 CHARGING SYSTEMPL

008W-10PLI02002

Page 472 of 1285

8W-21 STARTING SYSTEM

Component Page

Battery............................8W-21-2

Engine Starter Motor.................8W-21-2

Engine Starter Motor Relay............8W-21-2

Fuse 9 (PDC).......................8W-21-2

Fusible Link A11....................8W-21-2Component Page

Generator..........................8W-21-2

Ignition Switch......................8W-21-2

Power Distribution Center.............8W-21-2

Powertrain Control Module............8W-21-2

PL8W - 21 STARTING SYSTEM 8W - 21 - 1

Page 473 of 1285

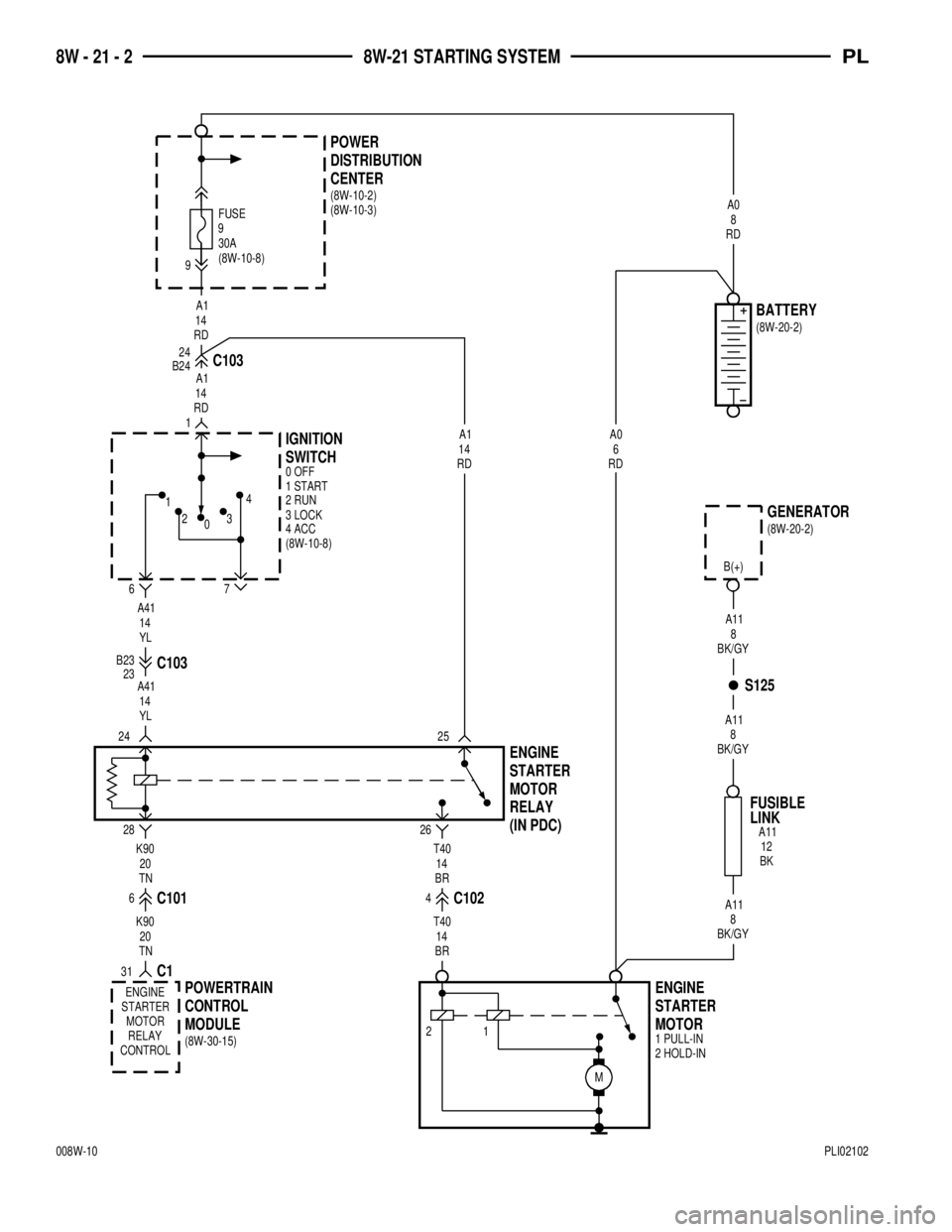

28 26

2524

T40

14

BR

ENGINE

STARTER

MOTOR

RELAY

(IN PDC)

6

SWITCH IGNITION

MOTOR STARTER

ENGINE

BR14 T40

30A

FUSE

9

9

A0

6

RD

CENTER DISTRIBUTION

POWER

1 2

A0

8

RD

BATTERY

S125

BK/GY8 A11

GENERATOR

4C102

M

3 LOCK 0 OFF

2 RUN 1 START

2 HOLD-IN 1 PULL-IN A41

14

YL

A41

14

YL23C103B23

C131

POWERTRAIN

CONTROL

MODULE

K90

20

TN

K90

20

TN

6C101

A1

14

RD

B24C10324

A1

14

RD

A1

14

RD

B(+)

STARTER

RELAY

CONTROL

4

1

2

03

7

1

4 ACC

MOTOR ENGINE

A11

12

BK

BK/GY8 A11

FUSIBLE

LINK

BK/GY8 A11

(8W-10-8)(8W-10-2)

(8W-10-3)

(8W-20-2)

(8W-20-2)

(8W-10-8)

(8W-30-15)

8W - 21 - 2 8W-21 STARTING SYSTEMPL

008W-10PLI02102

Page 509 of 1285

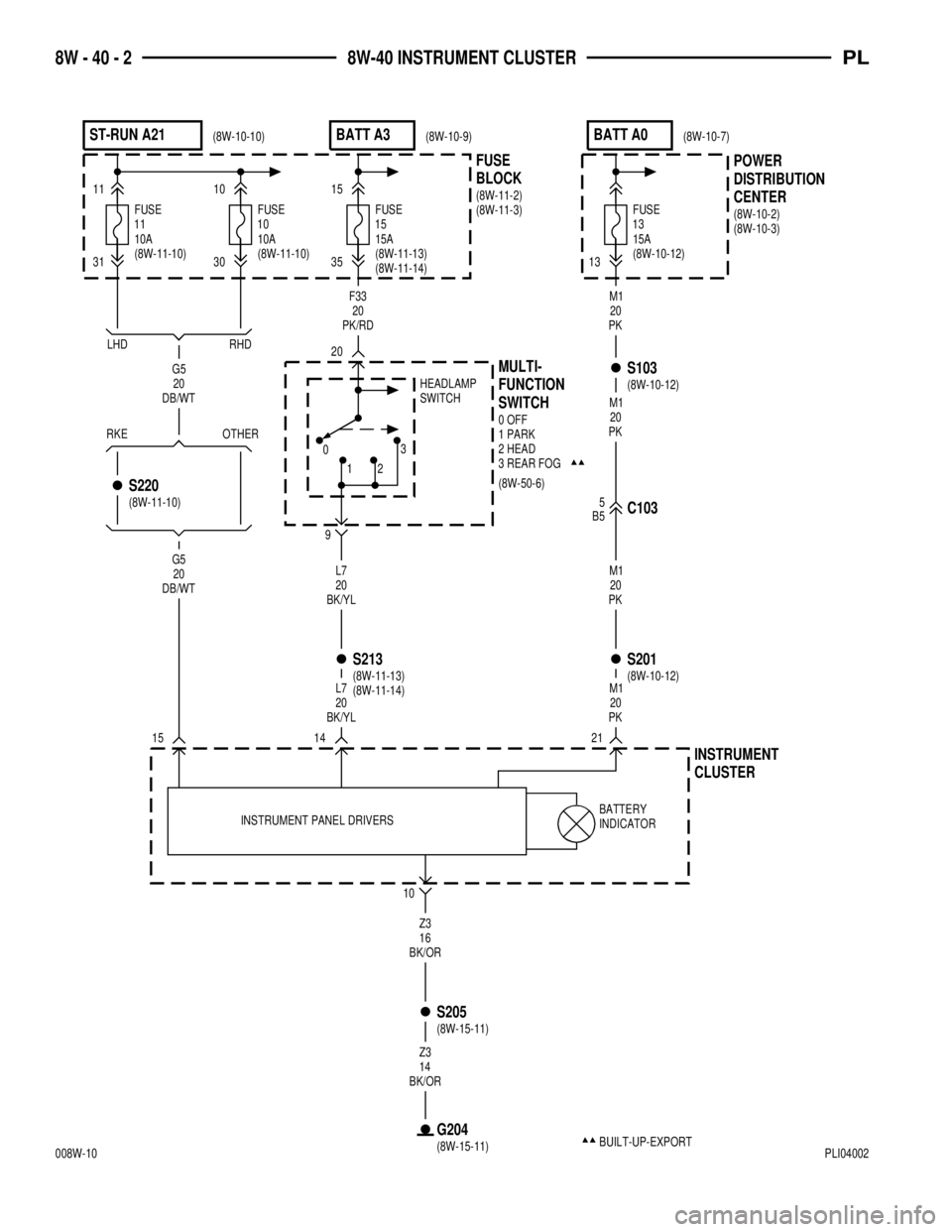

ST-RUN A21

10 11

FUSE

BLOCK

10A

FUSE

1110FUSE10A

31 30

RHD LHD35

15A

FUSE

15 15

BATT A3BATT A0

13FUSE15A

13

POWER

DISTRIBUTION

CENTER

10 15

INSTRUMENT

CLUSTER

14 21

RKE OTHER

S103

S201 S213 S220

G204

5C103B5

INSTRUMENT PANEL DRIVERSBATTERY

INDICATOR G5

20

DB/WT

G5

20

DB/WT

F33

20

PK/RD

L7

20

BK/YL

L7

20

BK/YLM1

20

PK

M1

20

PK

M1

20

PK

M1

20

PK

S205

Z3

16

BK/OR

Z3

14

BK/OR

MULTI-

FUNCTION

SWITCH

2 HEAD 1 PARK

0 OFF

20

9

HEADLAMP

SWITCH

BUILT-UP-EXPORT

3

2 1 03 REAR FOG

(8W-10-10)

(8W-11-2)

(8W-11-3)

(8W-11-10) (8W-11-10) (8W-11-13)

(8W-11-14)(8W-10-9) (8W-10-7)

(8W-10-12)(8W-10-2)

(8W-10-3)

(8W-10-12)

(8W-10-12) (8W-11-13)

(8W-11-14) (8W-11-10)

(8W-15-11) (8W-15-11)(8W-50-6)

8W - 40 - 2 8W-40 INSTRUMENT CLUSTERPL

008W-10PLI04002

Page 660 of 1285

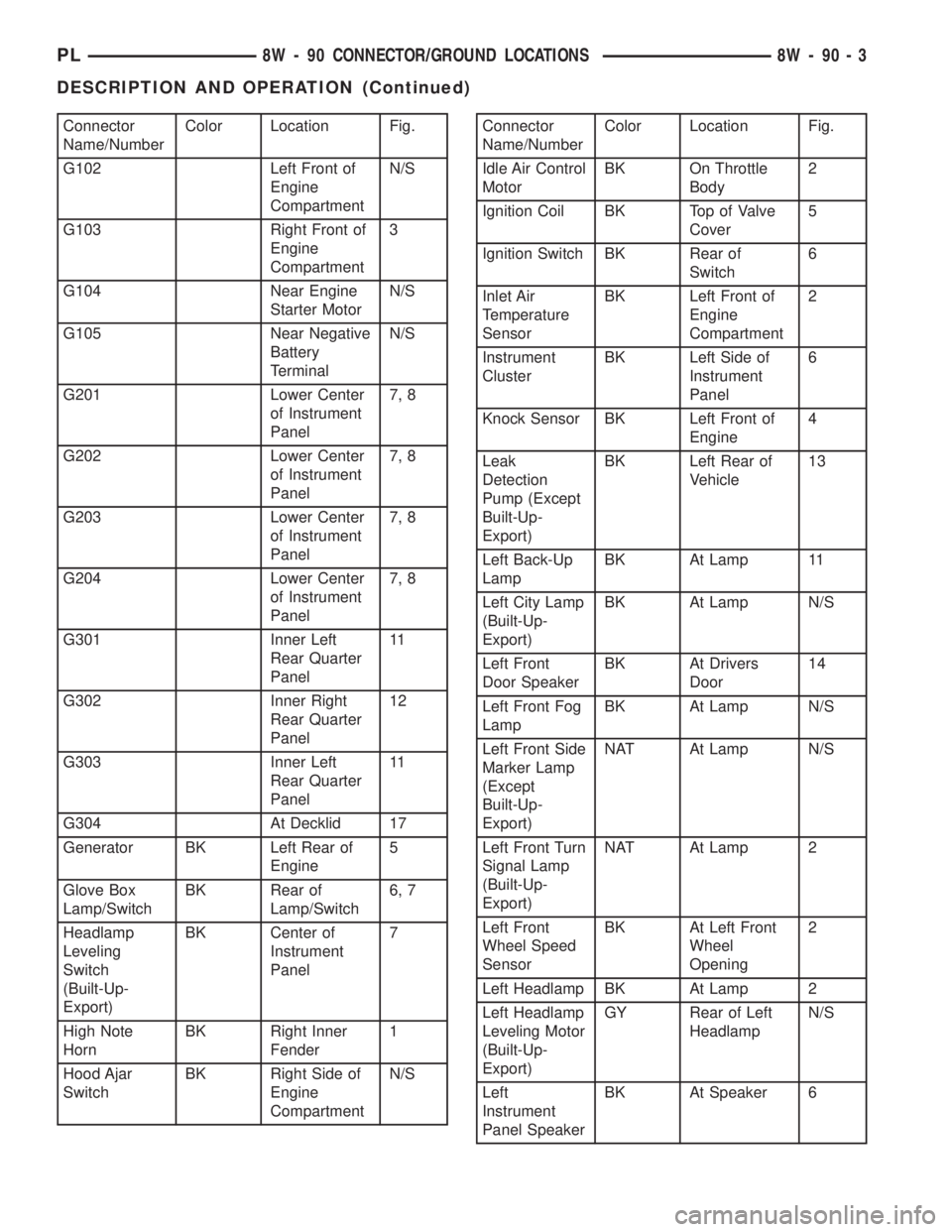

Connector

Name/NumberColor Location Fig.

G102 Left Front of

Engine

CompartmentN/S

G103 Right Front of

Engine

Compartment3

G104 Near Engine

Starter MotorN/S

G105 Near Negative

Battery

TerminalN/S

G201 Lower Center

of Instrument

Panel7, 8

G202 Lower Center

of Instrument

Panel7, 8

G203 Lower Center

of Instrument

Panel7, 8

G204 Lower Center

of Instrument

Panel7, 8

G301 Inner Left

Rear Quarter

Panel11

G302 Inner Right

Rear Quarter

Panel12

G303 Inner Left

Rear Quarter

Panel11

G304 At Decklid 17

Generator BK Left Rear of

Engine5

Glove Box

Lamp/SwitchBK Rear of

Lamp/Switch6, 7

Headlamp

Leveling

Switch

(Built-Up-

Export)BK Center of

Instrument

Panel7

High Note

HornBK Right Inner

Fender1

Hood Ajar

SwitchBK Right Side of

Engine

CompartmentN/SConnector

Name/NumberColor Location Fig.

Idle Air Control

MotorBK On Throttle

Body2

Ignition Coil BK Top of Valve

Cover5

Ignition Switch BK Rear of

Switch6

Inlet Air

Temperature

SensorBK Left Front of

Engine

Compartment2

Instrument

ClusterBK Left Side of

Instrument

Panel6

Knock Sensor BK Left Front of

Engine4

Leak

Detection

Pump (Except

Built-Up-

Export)BK Left Rear of

Vehicle13

Left Back-Up

LampBK At Lamp 11

Left City Lamp

(Built-Up-

Export)BK At Lamp N/S

Left Front

Door SpeakerBK At Drivers

Door14

Left Front Fog

LampBK At Lamp N/S

Left Front Side

Marker Lamp

(Except

Built-Up-

Export)NAT At Lamp N/S

Left Front Turn

Signal Lamp

(Built-Up-

Export)NAT At Lamp 2

Left Front

Wheel Speed

SensorBK At Left Front

Wheel

Opening2

Left Headlamp BK At Lamp 2

Left Headlamp

Leveling Motor

(Built-Up-

Export)GY Rear of Left

HeadlampN/S

Left

Instrument

Panel SpeakerBK At Speaker 6

PL8W - 90 CONNECTOR/GROUND LOCATIONS 8W - 90 - 3

DESCRIPTION AND OPERATION (Continued)

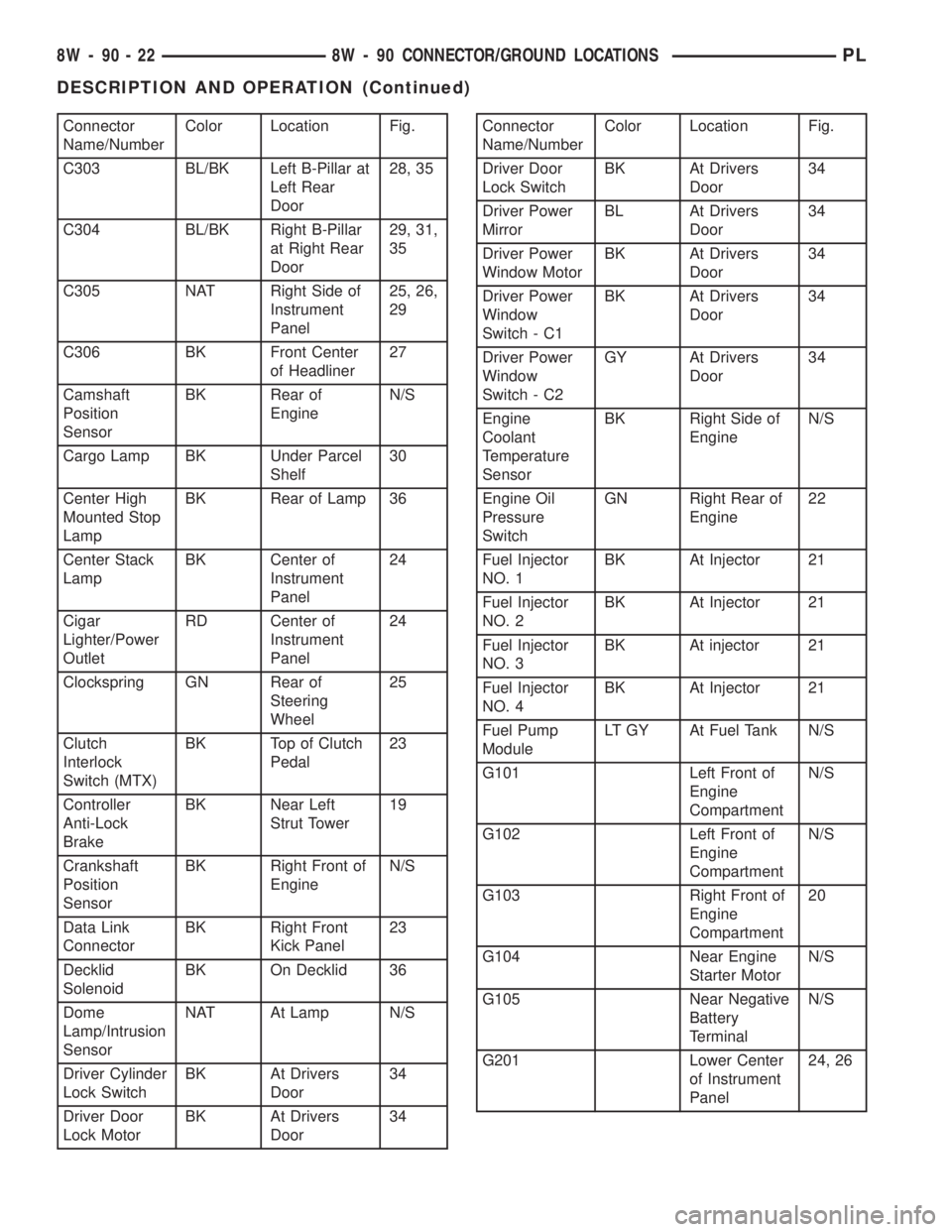

Page 679 of 1285

Connector

Name/NumberColor Location Fig.

C303 BL/BK Left B-Pillar at

Left Rear

Door28, 35

C304 BL/BK Right B-Pillar

at Right Rear

Door29, 31,

35

C305 NAT Right Side of

Instrument

Panel25, 26,

29

C306 BK Front Center

of Headliner27

Camshaft

Position

SensorBK Rear of

EngineN/S

Cargo Lamp BK Under Parcel

Shelf30

Center High

Mounted Stop

LampBK Rear of Lamp 36

Center Stack

LampBK Center of

Instrument

Panel24

Cigar

Lighter/Power

OutletRD Center of

Instrument

Panel24

Clockspring GN Rear of

Steering

Wheel25

Clutch

Interlock

Switch (MTX)BK Top of Clutch

Pedal23

Controller

Anti-Lock

BrakeBK Near Left

Strut Tower19

Crankshaft

Position

SensorBK Right Front of

EngineN/S

Data Link

ConnectorBK Right Front

Kick Panel23

Decklid

SolenoidBK On Decklid 36

Dome

Lamp/Intrusion

SensorNAT At Lamp N/S

Driver Cylinder

Lock SwitchBK At Drivers

Door34

Driver Door

Lock MotorBK At Drivers

Door34Connector

Name/NumberColor Location Fig.

Driver Door

Lock SwitchBK At Drivers

Door34

Driver Power

MirrorBL At Drivers

Door34

Driver Power

Window MotorBK At Drivers

Door34

Driver Power

Window

Switch - C1BK At Drivers

Door34

Driver Power

Window

Switch - C2GY At Drivers

Door34

Engine

Coolant

Temperature

SensorBK Right Side of

EngineN/S

Engine Oil

Pressure

SwitchGN Right Rear of

Engine22

Fuel Injector

NO. 1BK At Injector 21

Fuel Injector

NO. 2BK At Injector 21

Fuel Injector

NO. 3BK At injector 21

Fuel Injector

NO. 4BK At Injector 21

Fuel Pump

ModuleLT GY At Fuel Tank N/S

G101 Left Front of

Engine

CompartmentN/S

G102 Left Front of

Engine

CompartmentN/S

G103 Right Front of

Engine

Compartment20

G104 Near Engine

Starter MotorN/S

G105 Near Negative

Battery

TerminalN/S

G201 Lower Center

of Instrument

Panel24, 26

8W - 90 - 22 8W - 90 CONNECTOR/GROUND LOCATIONSPL

DESCRIPTION AND OPERATION (Continued)

Page 728 of 1285

²When checking #2 main bearing shim #1 & #3

main bearing.

²When checking #3 main bearing shim #2 & #4

main bearing.

²When checking #4 main bearing shim #3 main

bearing.

NOTE: REMOVE ALL SHIMS BEFORE REASSEM-

BLING ENGINE

ALTERNATIVE METHOD

The weight of the crankshaft can be supported by a

jack under the counterweight adjacent to the bearing

being checked.

PLASTIGAGE PROCEDURE

(1) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(2) Place a piece of Plastigage across the entire

width of the bearing shell in the cap approximately

6.35 mm (1/4 in.) off center and away from the oil

holes (Fig. 5). (In addition, suspected areas can be

checked by placing the Plastigage in the suspected

area). Torque the bearing cap bolts of the bearing

being checked to the proper specifications.

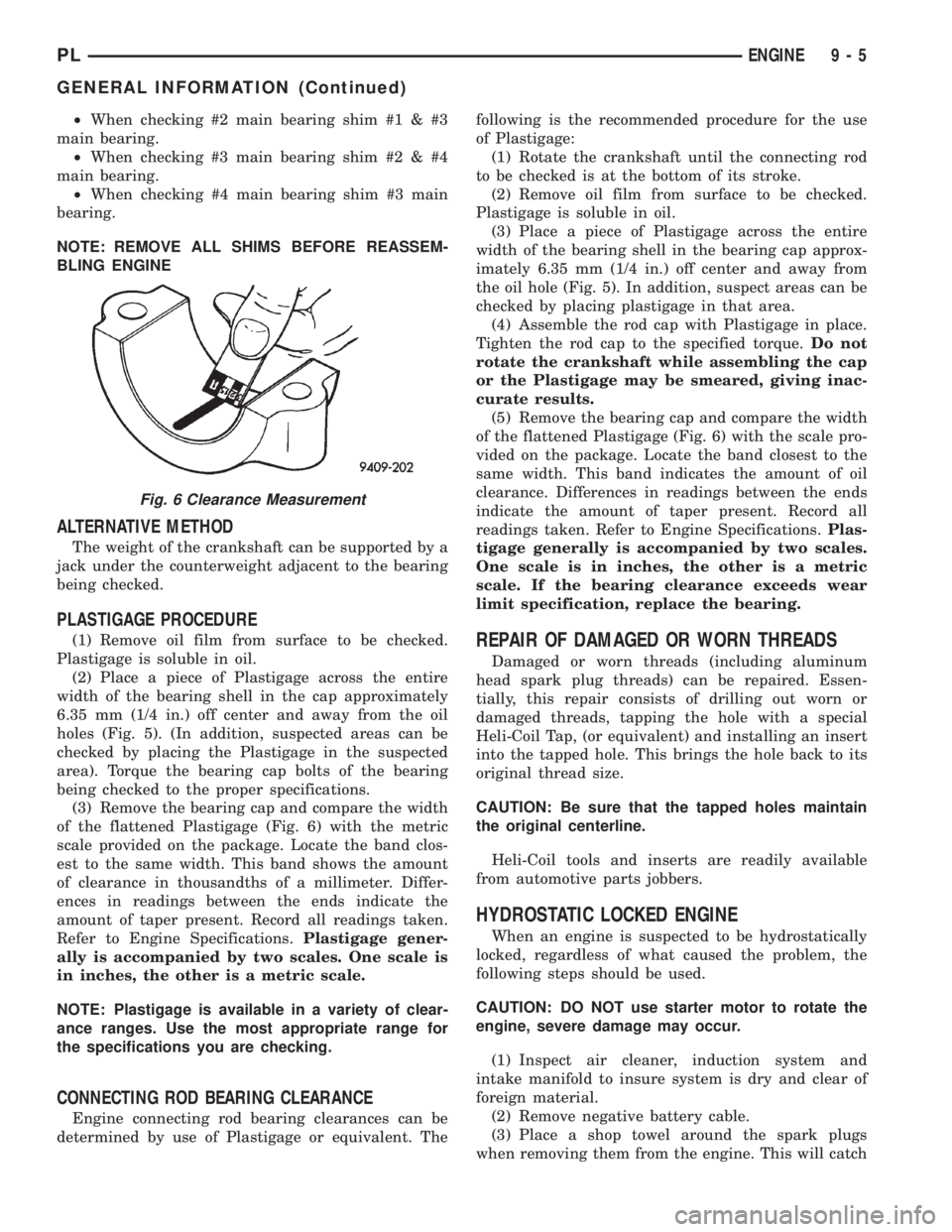

(3) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 6) with the metric

scale provided on the package. Locate the band clos-

est to the same width. This band shows the amount

of clearance in thousandths of a millimeter. Differ-

ences in readings between the ends indicate the

amount of taper present. Record all readings taken.

Refer to Engine Specifications.Plastigage gener-

ally is accompanied by two scales. One scale is

in inches, the other is a metric scale.

NOTE: Plastigage is available in a variety of clear-

ance ranges. Use the most appropriate range for

the specifications you are checking.

CONNECTING ROD BEARING CLEARANCE

Engine connecting rod bearing clearances can be

determined by use of Plastigage or equivalent. Thefollowing is the recommended procedure for the use

of Plastigage:

(1) Rotate the crankshaft until the connecting rod

to be checked is at the bottom of its stroke.

(2) Remove oil film from surface to be checked.

Plastigage is soluble in oil.

(3) Place a piece of Plastigage across the entire

width of the bearing shell in the bearing cap approx-

imately 6.35 mm (1/4 in.) off center and away from

the oil hole (Fig. 5). In addition, suspect areas can be

checked by placing plastigage in that area.

(4) Assemble the rod cap with Plastigage in place.

Tighten the rod cap to the specified torque.Do not

rotate the crankshaft while assembling the cap

or the Plastigage may be smeared, giving inac-

curate results.

(5) Remove the bearing cap and compare the width

of the flattened Plastigage (Fig. 6) with the scale pro-

vided on the package. Locate the band closest to the

same width. This band indicates the amount of oil

clearance. Differences in readings between the ends

indicate the amount of taper present. Record all

readings taken. Refer to Engine Specifications.Plas-

tigage generally is accompanied by two scales.

One scale is in inches, the other is a metric

scale. If the bearing clearance exceeds wear

limit specification, replace the bearing.

REPAIR OF DAMAGED OR WORN THREADS

Damaged or worn threads (including aluminum

head spark plug threads) can be repaired. Essen-

tially, this repair consists of drilling out worn or

damaged threads, tapping the hole with a special

Heli-Coil Tap, (or equivalent) and installing an insert

into the tapped hole. This brings the hole back to its

original thread size.

CAUTION: Be sure that the tapped holes maintain

the original centerline.

Heli-Coil tools and inserts are readily available

from automotive parts jobbers.

HYDROSTATIC LOCKED ENGINE

When an engine is suspected to be hydrostatically

locked, regardless of what caused the problem, the

following steps should be used.

CAUTION: DO NOT use starter motor to rotate the

engine, severe damage may occur.

(1) Inspect air cleaner, induction system and

intake manifold to insure system is dry and clear of

foreign material.

(2) Remove negative battery cable.

(3) Place a shop towel around the spark plugs

when removing them from the engine. This will catch

Fig. 6 Clearance Measurement

PLENGINE 9 - 5

GENERAL INFORMATION (Continued)

Page 729 of 1285

any fluid that may possibly be in the cylinder under

pressure.

(4) With all spark plugs removed, rotate engine

crankshaft using a breaker bar and socket.

(5) Identify the fluid in the cylinder(s) (i.e., cool-

ant, fuel, oil or other).

(6) Make sure all fluid has been removed from the

cylinders. Inspect engine for damage (i.e., connecting

rods, pistons, valves, etc.).

(7) Repair engine or components as necessary to

prevent this problem from re-occurring.

CAUTION: Squirt approximately one teaspoon of oil

into the cylinders, rotate engine to lubricate the cyl-

inder walls to prevent damage on restart.

(8) Install new spark plugs.

(9) Drain engine oil and remove oil filter.

(10) Fill engine with specified amount of approved

oil and install new oil filter.

(11) Connect negative battery cable.

(12) Start engine and check for any leaks.

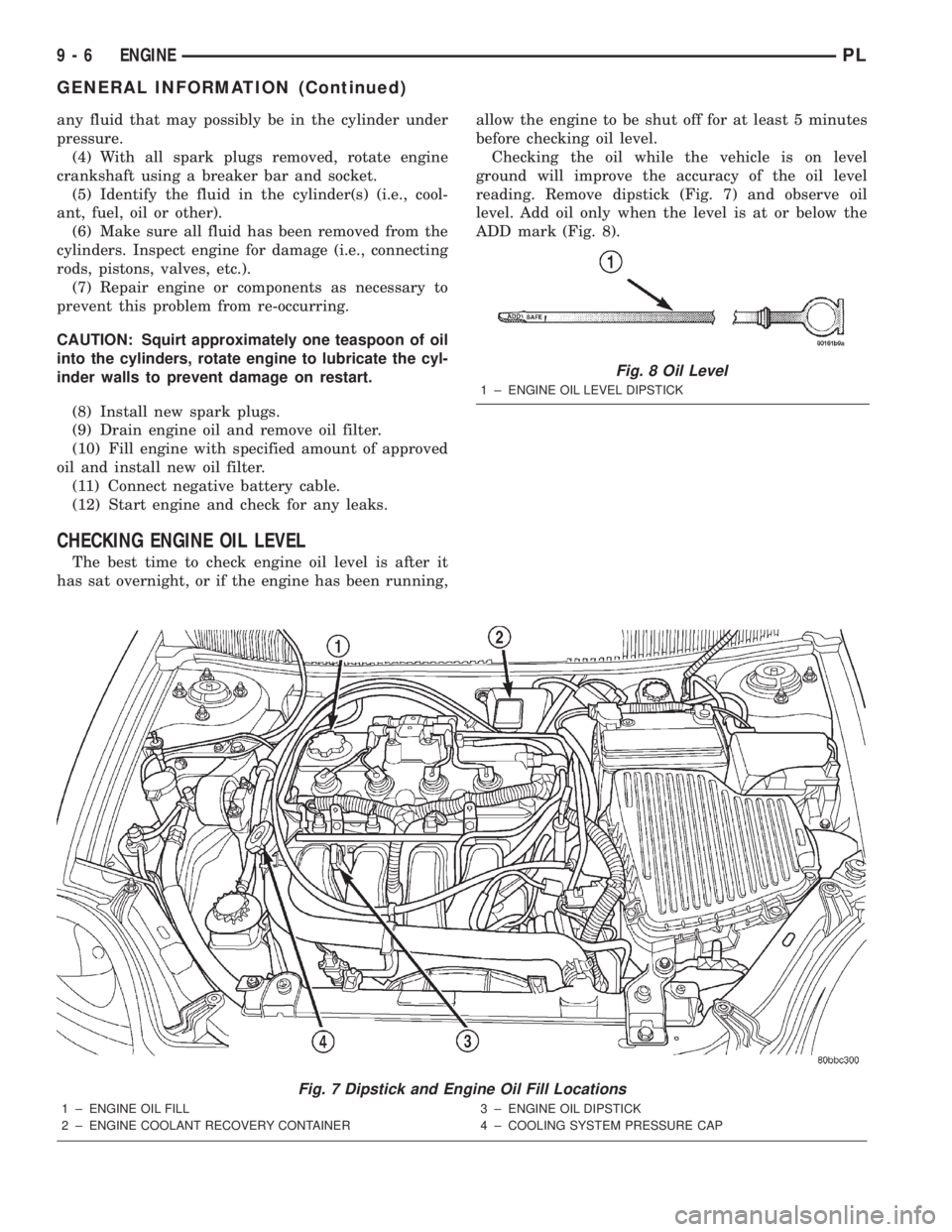

CHECKING ENGINE OIL LEVEL

The best time to check engine oil level is after it

has sat overnight, or if the engine has been running,allow the engine to be shut off for at least 5 minutes

before checking oil level.

Checking the oil while the vehicle is on level

ground will improve the accuracy of the oil level

reading. Remove dipstick (Fig. 7) and observe oil

level. Add oil only when the level is at or below the

ADD mark (Fig. 8).

Fig. 7 Dipstick and Engine Oil Fill Locations

1 ± ENGINE OIL FILL

2 ± ENGINE COOLANT RECOVERY CONTAINER3 ± ENGINE OIL DIPSTICK

4 ± COOLING SYSTEM PRESSURE CAP

Fig. 8 Oil Level

1 ± ENGINE OIL LEVEL DIPSTICK

9 - 6 ENGINEPL

GENERAL INFORMATION (Continued)

Page 731 of 1285

ENGINE DIAGNOSIS

TABLE OF CONTENTS

page page

DIAGNOSIS AND TESTING

GENERAL INFORMATION...................8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS......8

CYLINDER COMPRESSION PRESSURE TEST . . . 8

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.........................9LASH ADJUSTER (TAPPET) NOISE

DIAGNOSIS............................9

ENGINE OIL LEAK INSPECTION..............9

ENGINE DIAGNOSISÐPERFORMANCE........11

ENGINE DIAGNOSISÐMECHANICAL.........12

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689 kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

9 - 8 ENGINEPL