DODGE NEON 2000 Service Repair Manual

NEON 2000

DODGE

DODGE

https://www.carmanualsonline.info/img/12/56910/w960_56910-0.png

DODGE NEON 2000 Service Repair Manual

Page 1001 of 1285

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(11) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(12) Connect vehicle speed sensor connector (Fig.

50).

(13) Install right lateral bending brace and tighten

bolts to 81 N´m (60 ft. lbs.) torque.

(14) Lower vehicle.

(15) Connect transaxle cooler lines and tighten

clamps (Fig. 46).

(16) Connect torque converter clutch solenoid and

neutral safety/back-up lamp switch connectors.

(17) Install transaxle dipstick tube.

(18) Install gear shift cable to bracket and connect

to shift lever (Fig. 47).

(19) Install transaxle kickdown cable to bracket

and lever as shown in (Fig. 48).

(20) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

(21) Install the air cleaner/throttle body assy. as

follows:

(a) Connect the accelerator, transaxle kickdown,

and speed control (if equipped) cables to the air

cleaner/throttle body assy.

(b) Install assy into position and tighten fasten-

ers to 14 N´m (120 in. lbs.) torque.

(c) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(d) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(22) Fill transaxle with a suitable amount of

ATF+4.

(23) Road test vehicle.

(24) Check for leaks, inspect fluid level, and adjust

as necessary.

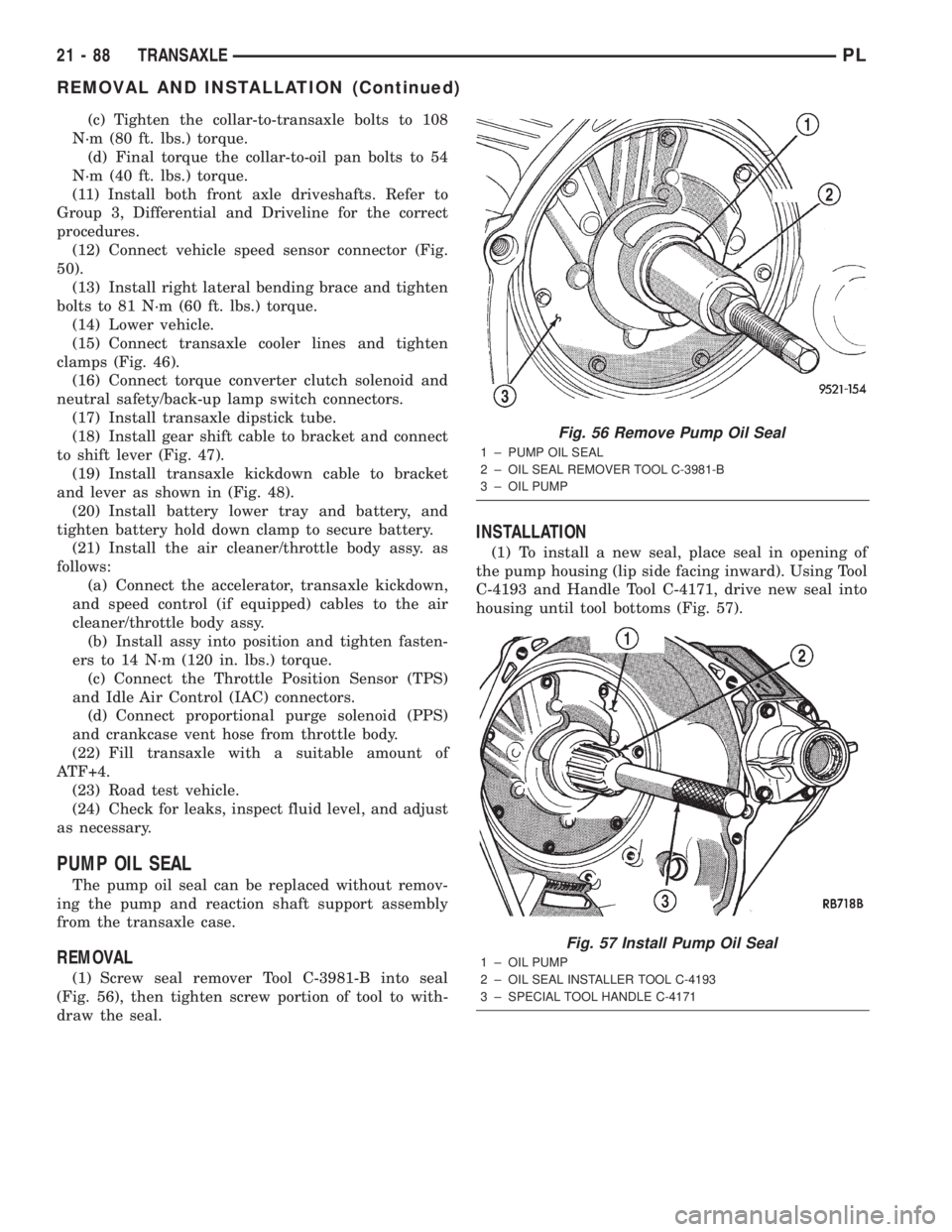

PUMP OIL SEAL

The pump oil seal can be replaced without remov-

ing the pump and reaction shaft support assembly

from the transaxle case.

REMOVAL

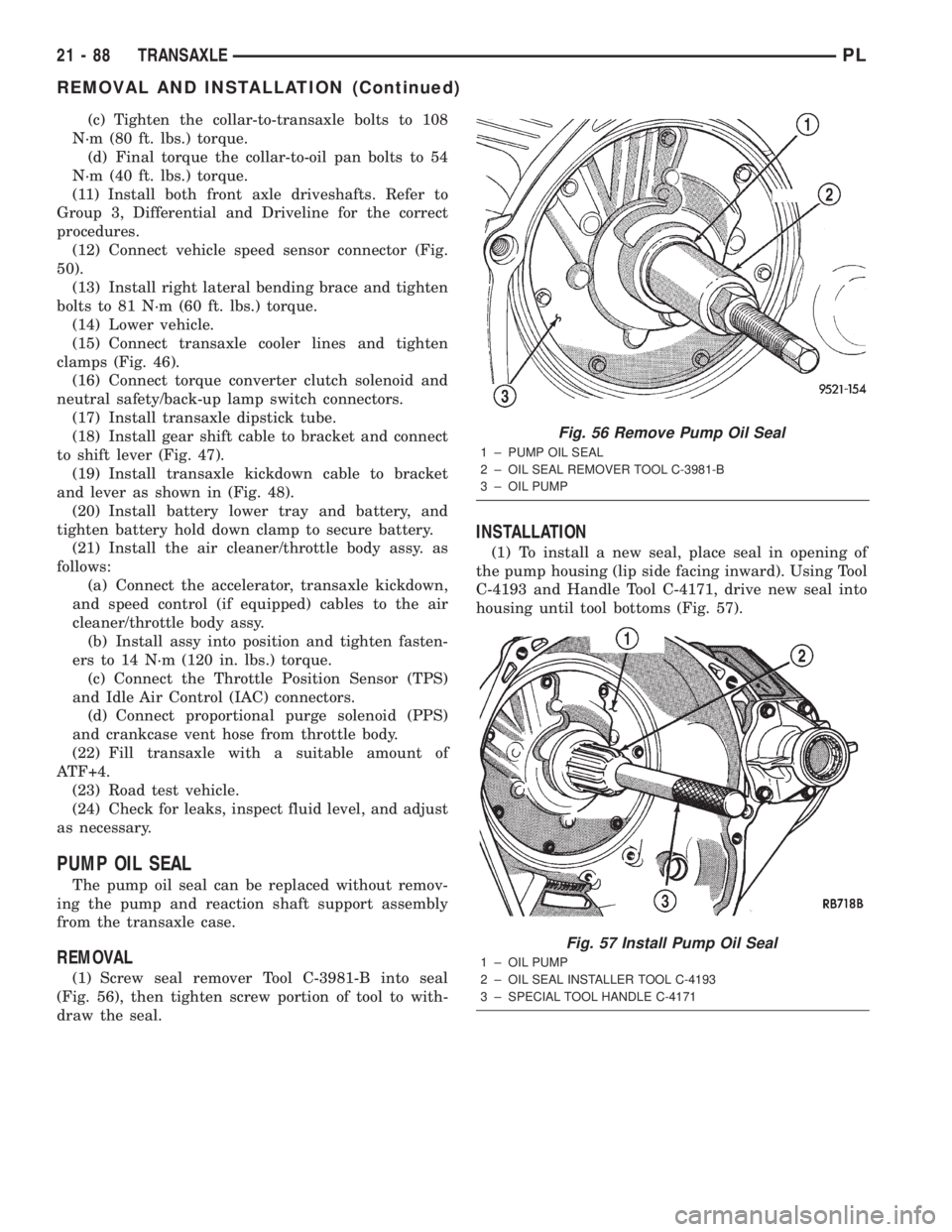

(1) Screw seal remover Tool C-3981-B into seal

(Fig. 56), then tighten screw portion of tool to with-

draw the seal.

INSTALLATION

(1) To install a new seal, place seal in opening of

the pump housing (lip side facing inward). Using Tool

C-4193 and Handle Tool C-4171, drive new seal into

housing until tool bottoms (Fig. 57).

Fig. 56 Remove Pump Oil Seal

1 ± PUMP OIL SEAL

2 ± OIL SEAL REMOVER TOOL C-3981-B

3 ± OIL PUMP

Fig. 57 Install Pump Oil Seal

1 ± OIL PUMP

2 ± OIL SEAL INSTALLER TOOL C-4193

3 ± SPECIAL TOOL HANDLE C-4171

21 - 88 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1005 of 1285

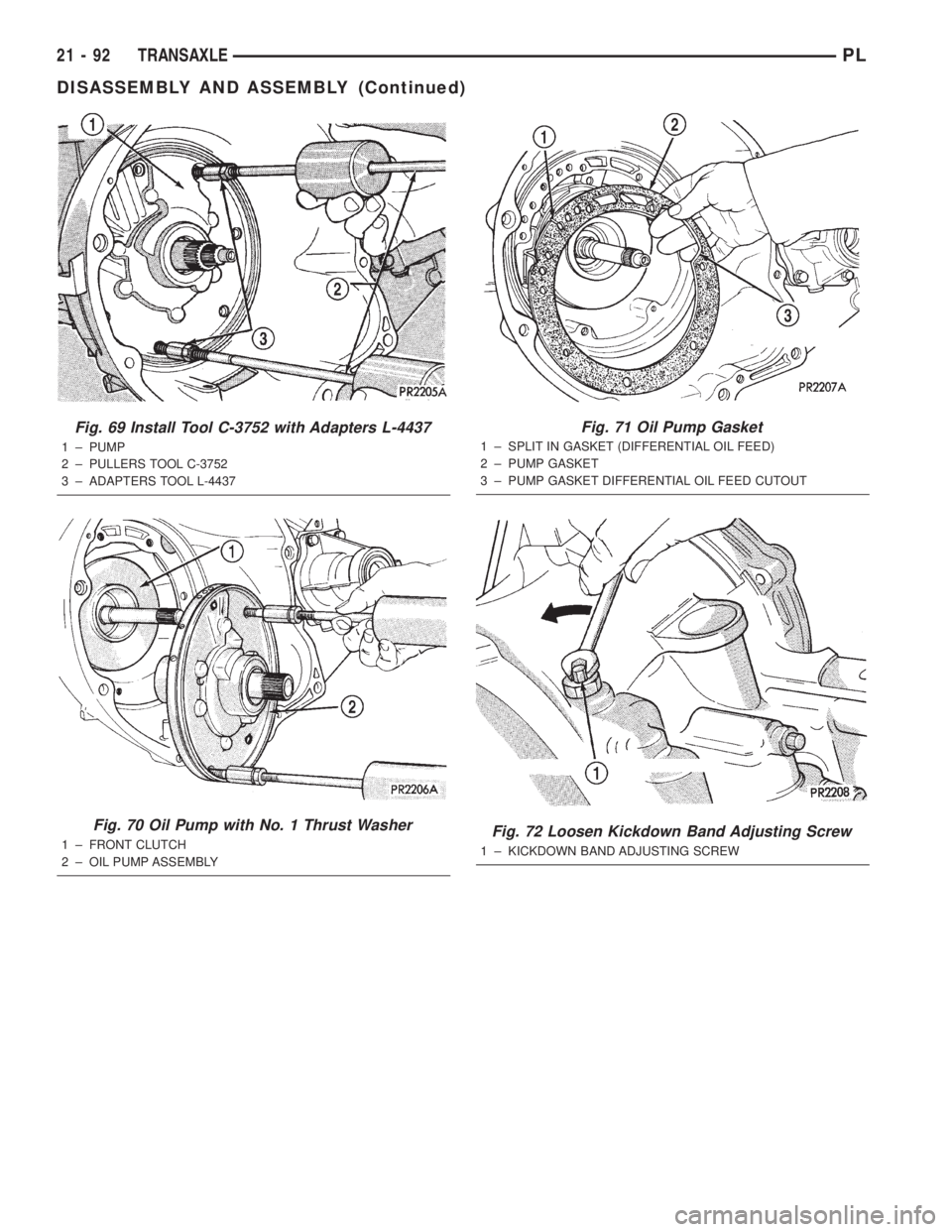

Fig. 69 Install Tool C-3752 with Adapters L-4437

1 ± PUMP

2 ± PULLERS TOOL C-3752

3 ± ADAPTERS TOOL L-4437

Fig. 70 Oil Pump with No. 1 Thrust Washer

1 ± FRONT CLUTCH

2 ± OIL PUMP ASSEMBLY

Fig. 71 Oil Pump Gasket

1 ± SPLIT IN GASKET (DIFFERENTIAL OIL FEED)

2 ± PUMP GASKET

3 ± PUMP GASKET DIFFERENTIAL OIL FEED CUTOUT

Fig. 72 Loosen Kickdown Band Adjusting Screw

1 ± KICKDOWN BAND ADJUSTING SCREW

21 - 92 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1006 of 1285

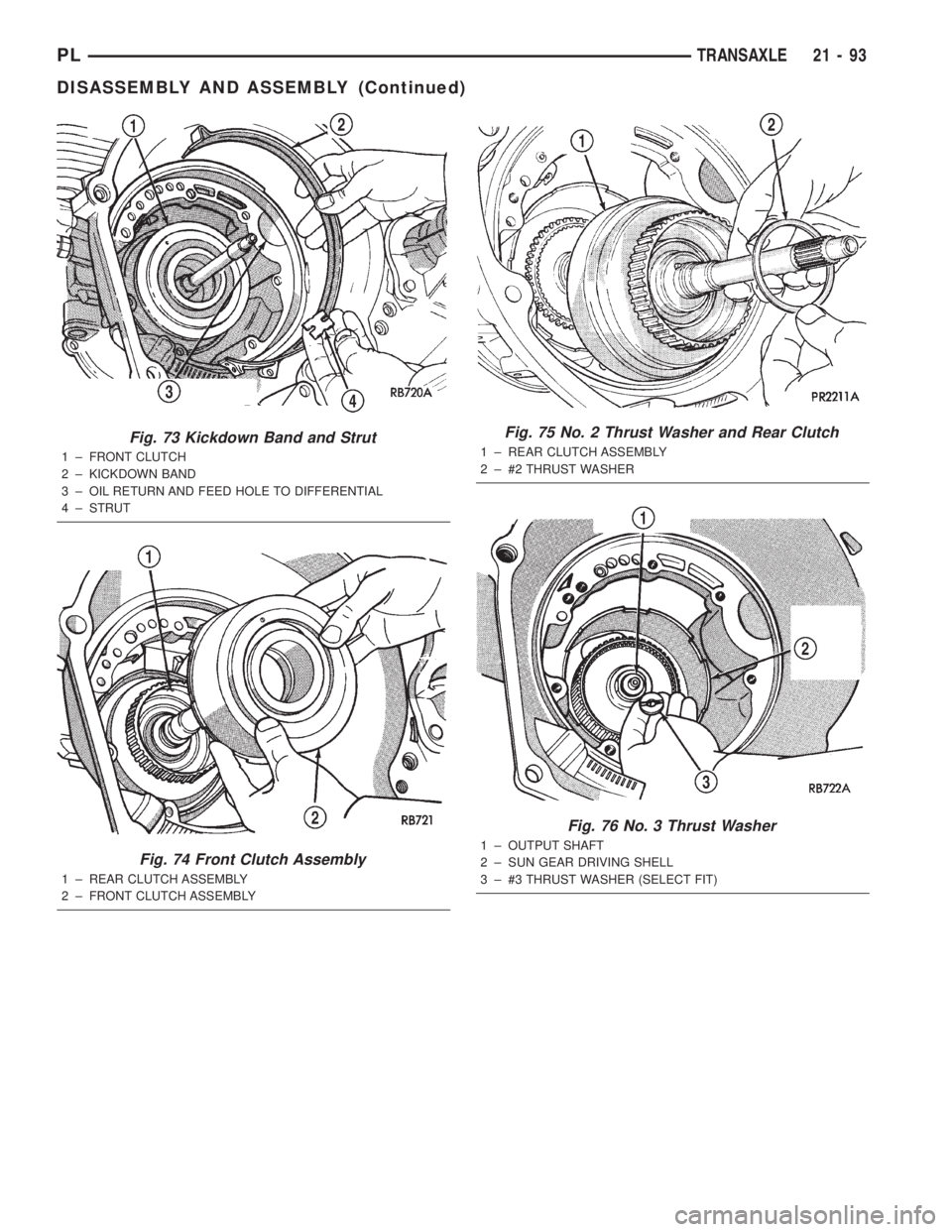

Fig. 73 Kickdown Band and Strut

1 ± FRONT CLUTCH

2 ± KICKDOWN BAND

3 ± OIL RETURN AND FEED HOLE TO DIFFERENTIAL

4 ± STRUT

Fig. 74 Front Clutch Assembly

1 ± REAR CLUTCH ASSEMBLY

2 ± FRONT CLUTCH ASSEMBLY

Fig. 75 No. 2 Thrust Washer and Rear Clutch

1 ± REAR CLUTCH ASSEMBLY

2 ± #2 THRUST WASHER

Fig. 76 No. 3 Thrust Washer

1 ± OUTPUT SHAFT

2 ± SUN GEAR DRIVING SHELL

3 ± #3 THRUST WASHER (SELECT FIT)

PLTRANSAXLE 21 - 93

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1008 of 1285

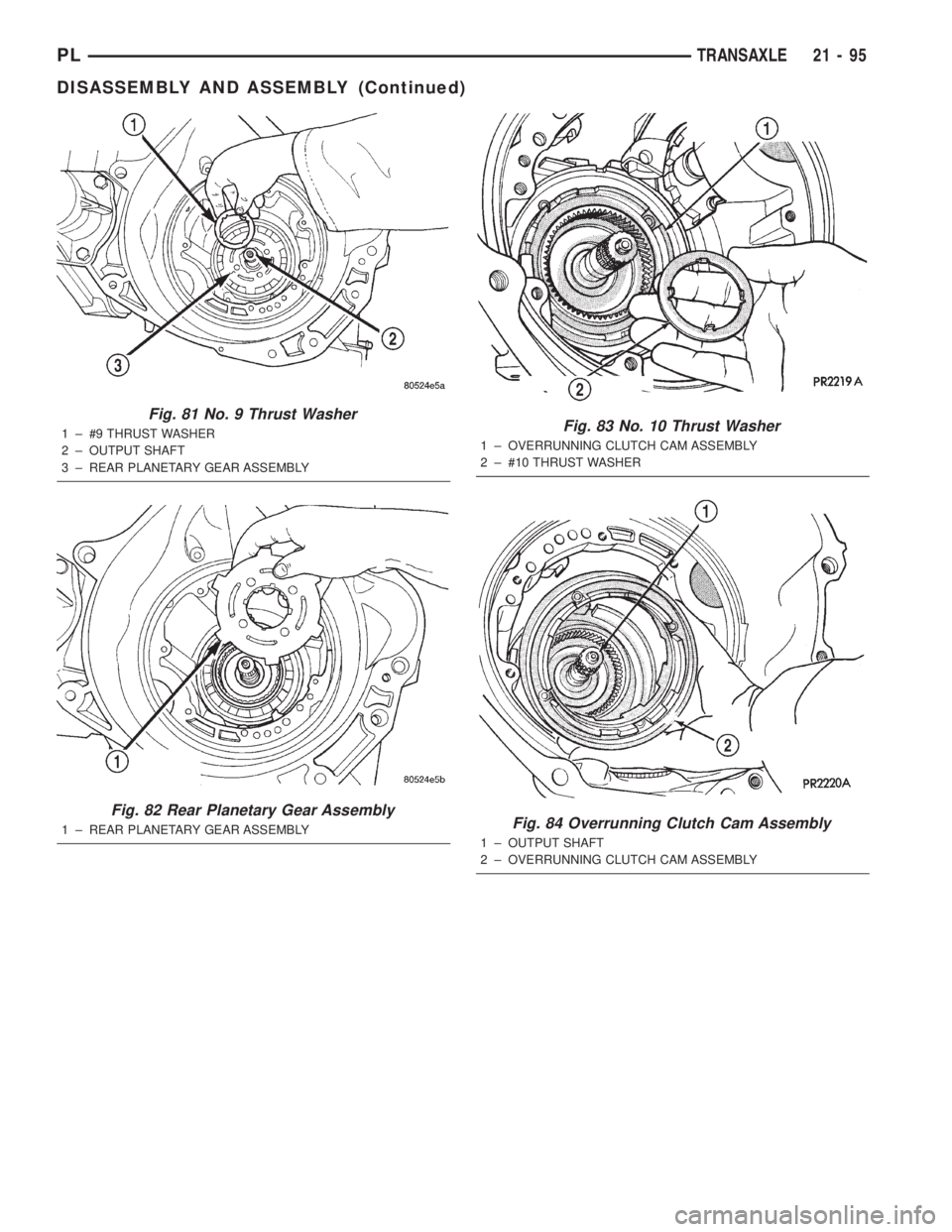

Fig. 81 No. 9 Thrust Washer

1 ± #9 THRUST WASHER

2 ± OUTPUT SHAFT

3 ± REAR PLANETARY GEAR ASSEMBLY

Fig. 82 Rear Planetary Gear Assembly

1 ± REAR PLANETARY GEAR ASSEMBLY

Fig. 83 No. 10 Thrust Washer

1 ± OVERRUNNING CLUTCH CAM ASSEMBLY

2 ± #10 THRUST WASHER

Fig. 84 Overrunning Clutch Cam Assembly

1 ± OUTPUT SHAFT

2 ± OVERRUNNING CLUTCH CAM ASSEMBLY

PLTRANSAXLE 21 - 95

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1009 of 1285

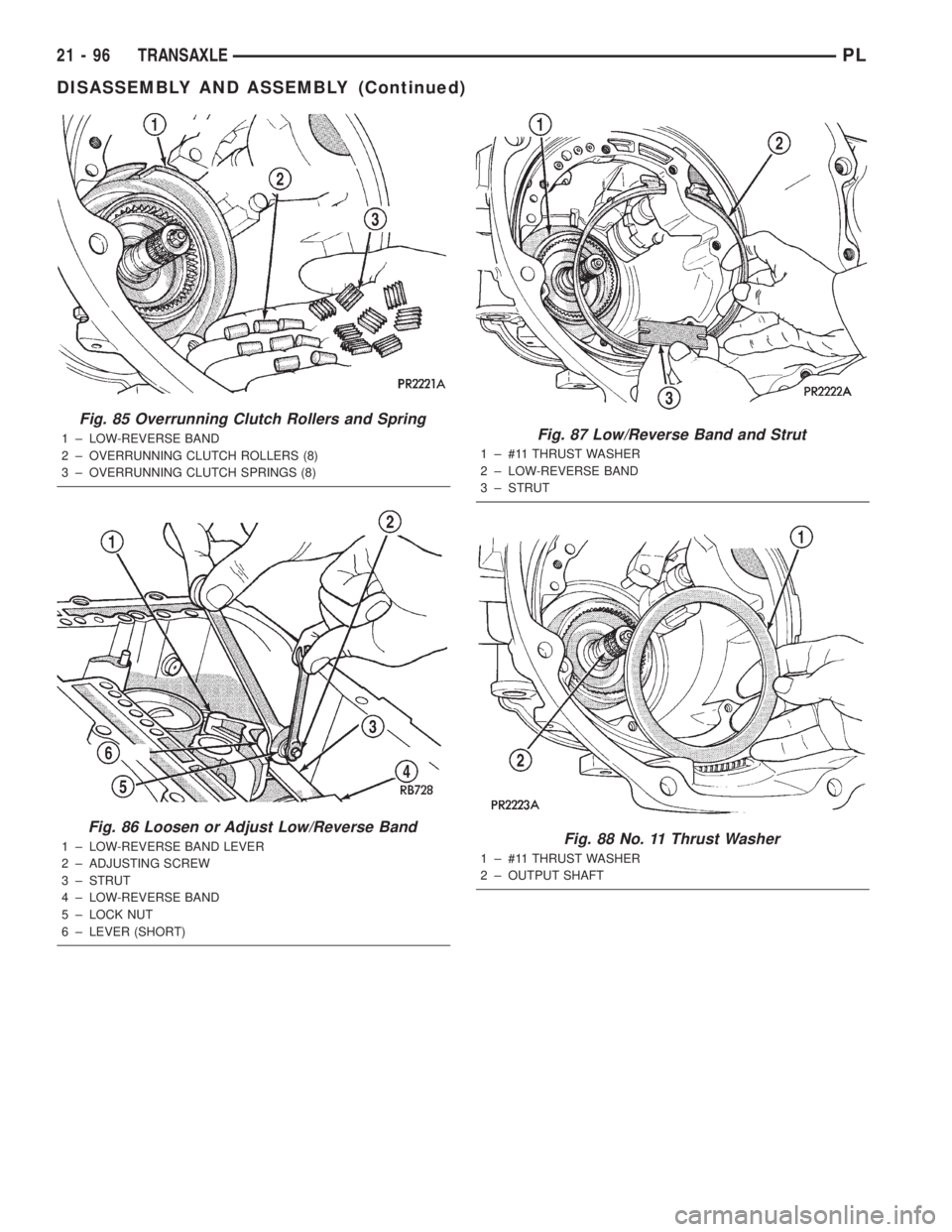

Fig. 85 Overrunning Clutch Rollers and Spring

1 ± LOW-REVERSE BAND

2 ± OVERRUNNING CLUTCH ROLLERS (8)

3 ± OVERRUNNING CLUTCH SPRINGS (8)

Fig. 86 Loosen or Adjust Low/Reverse Band

1 ± LOW-REVERSE BAND LEVER

2 ± ADJUSTING SCREW

3 ± STRUT

4 ± LOW-REVERSE BAND

5 ± LOCK NUT

6 ± LEVER (SHORT)

Fig. 87 Low/Reverse Band and Strut

1 ± #11 THRUST WASHER

2 ± LOW-REVERSE BAND

3 ± STRUT

Fig. 88 No. 11 Thrust Washer

1 ± #11 THRUST WASHER

2 ± OUTPUT SHAFT

21 - 96 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1010 of 1285

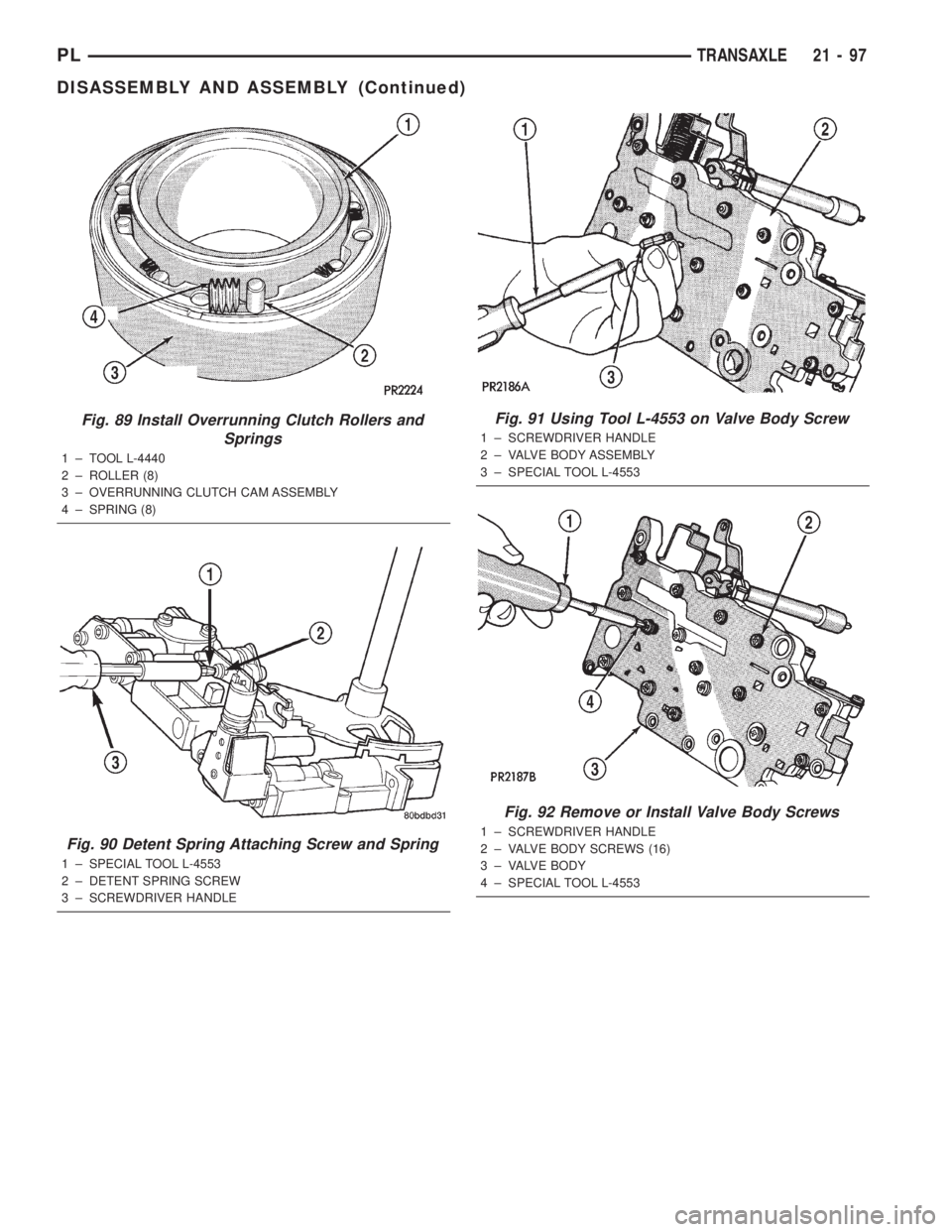

Fig. 89 Install Overrunning Clutch Rollers and

Springs

1 ± TOOL L-4440

2 ± ROLLER (8)

3 ± OVERRUNNING CLUTCH CAM ASSEMBLY

4 ± SPRING (8)

Fig. 90 Detent Spring Attaching Screw and Spring

1 ± SPECIAL TOOL L-4553

2 ± DETENT SPRING SCREW

3 ± SCREWDRIVER HANDLE

Fig. 91 Using Tool L-4553 on Valve Body Screw

1 ± SCREWDRIVER HANDLE

2 ± VALVE BODY ASSEMBLY

3 ± SPECIAL TOOL L-4553

Fig. 92 Remove or Install Valve Body Screws

1 ± SCREWDRIVER HANDLE

2 ± VALVE BODY SCREWS (16)

3 ± VALVE BODY

4 ± SPECIAL TOOL L-4553

PLTRANSAXLE 21 - 97

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1015 of 1285

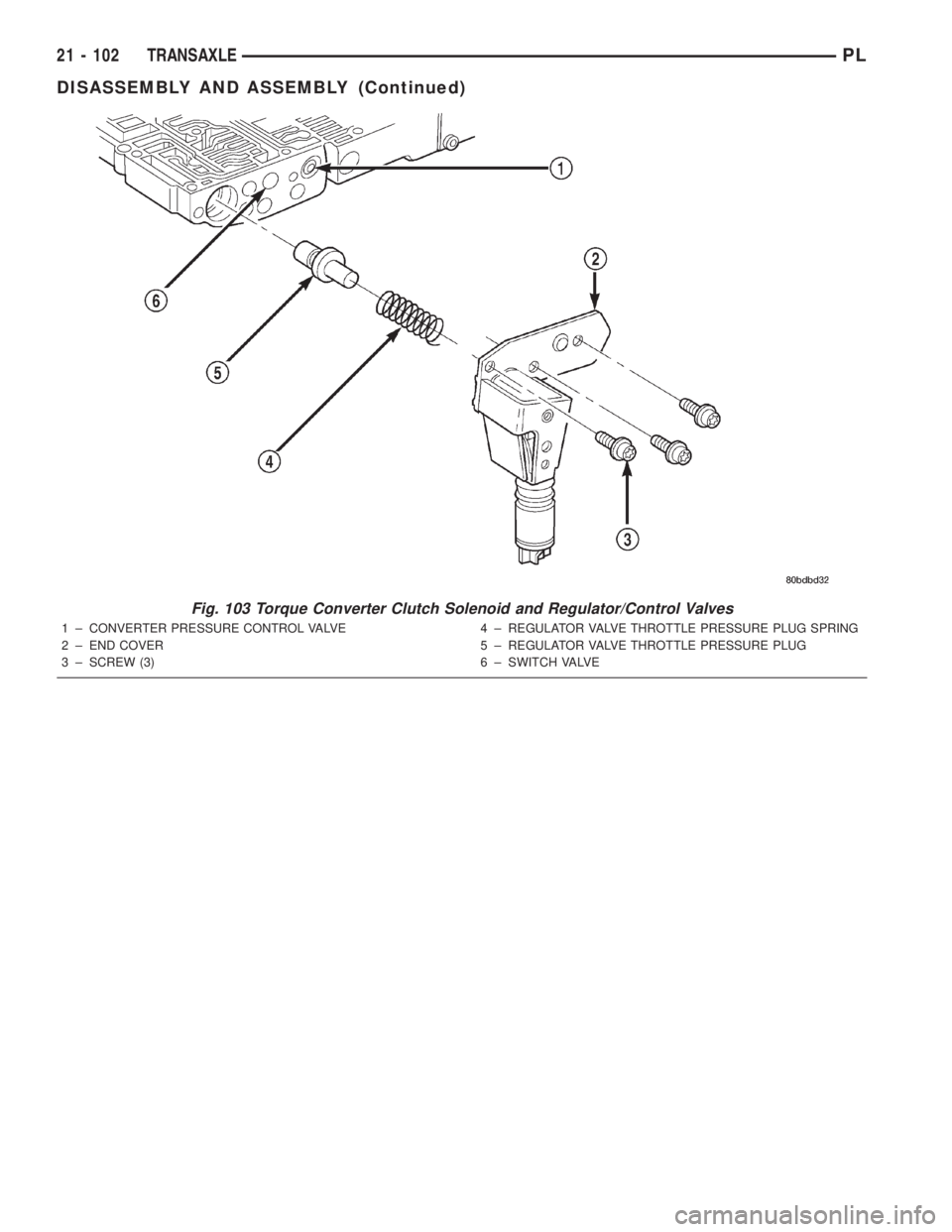

Fig. 103 Torque Converter Clutch Solenoid and Regulator/Control Valves

1 ± CONVERTER PRESSURE CONTROL VALVE

2 ± END COVER

3 ± SCREW (3)4 ± REGULATOR VALVE THROTTLE PRESSURE PLUG SPRING

5 ± REGULATOR VALVE THROTTLE PRESSURE PLUG

6 ± SWITCH VALVE

21 - 102 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1016 of 1285

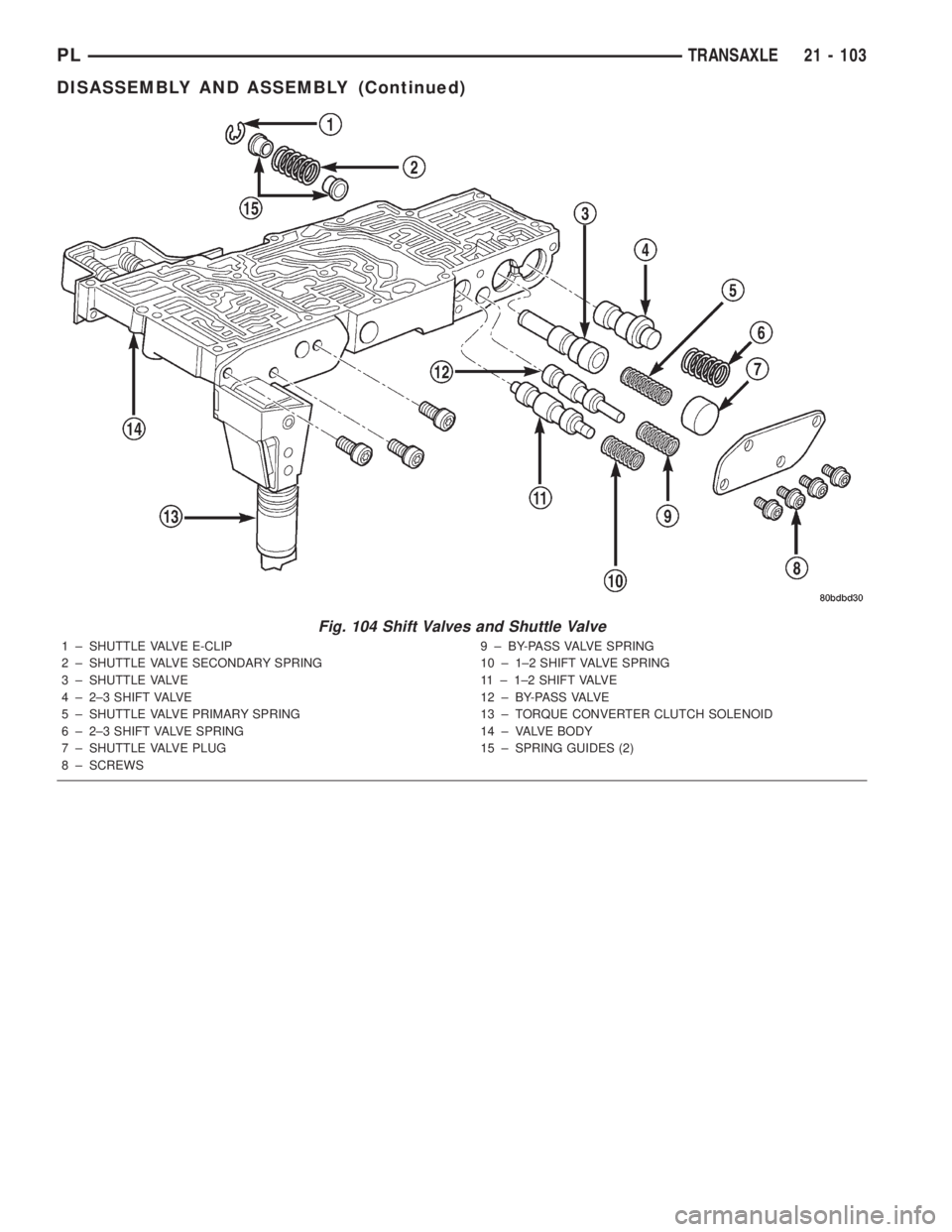

Fig. 104 Shift Valves and Shuttle Valve

1 ± SHUTTLE VALVE E-CLIP

2 ± SHUTTLE VALVE SECONDARY SPRING

3 ± SHUTTLE VALVE

4 ± 2±3 SHIFT VALVE

5 ± SHUTTLE VALVE PRIMARY SPRING

6 ± 2±3 SHIFT VALVE SPRING

7 ± SHUTTLE VALVE PLUG

8 ± SCREWS9 ± BY-PASS VALVE SPRING

10 ± 1±2 SHIFT VALVE SPRING

11 ± 1±2 SHIFT VALVE

1 2 ± B Y- PA S S VA LV E

13 ± TORQUE CONVERTER CLUTCH SOLENOID

14 ± VALVE BODY

15 ± SPRING GUIDES (2)

PLTRANSAXLE 21 - 103

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1018 of 1285

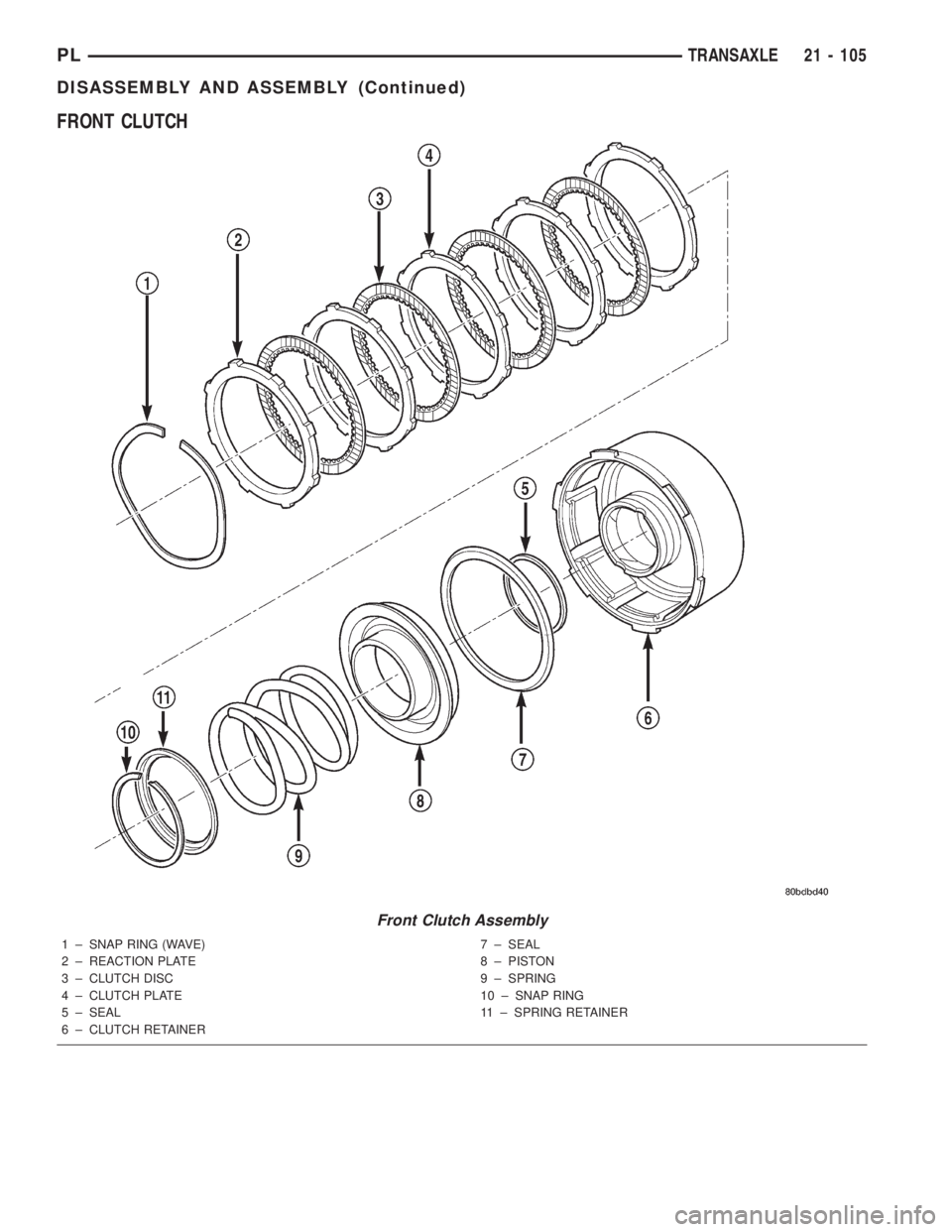

FRONT CLUTCH

Front Clutch Assembly

1 ± SNAP RING (WAVE)

2 ± REACTION PLATE

3 ± CLUTCH DISC

4 ± CLUTCH PLATE

5 ± SEAL

6 ± CLUTCH RETAINER7 ± SEAL

8 ± PISTON

9 ± SPRING

10 ± SNAP RING

11 ± SPRING RETAINER

PLTRANSAXLE 21 - 105

DISASSEMBLY AND ASSEMBLY (Continued)

Page 1019 of 1285

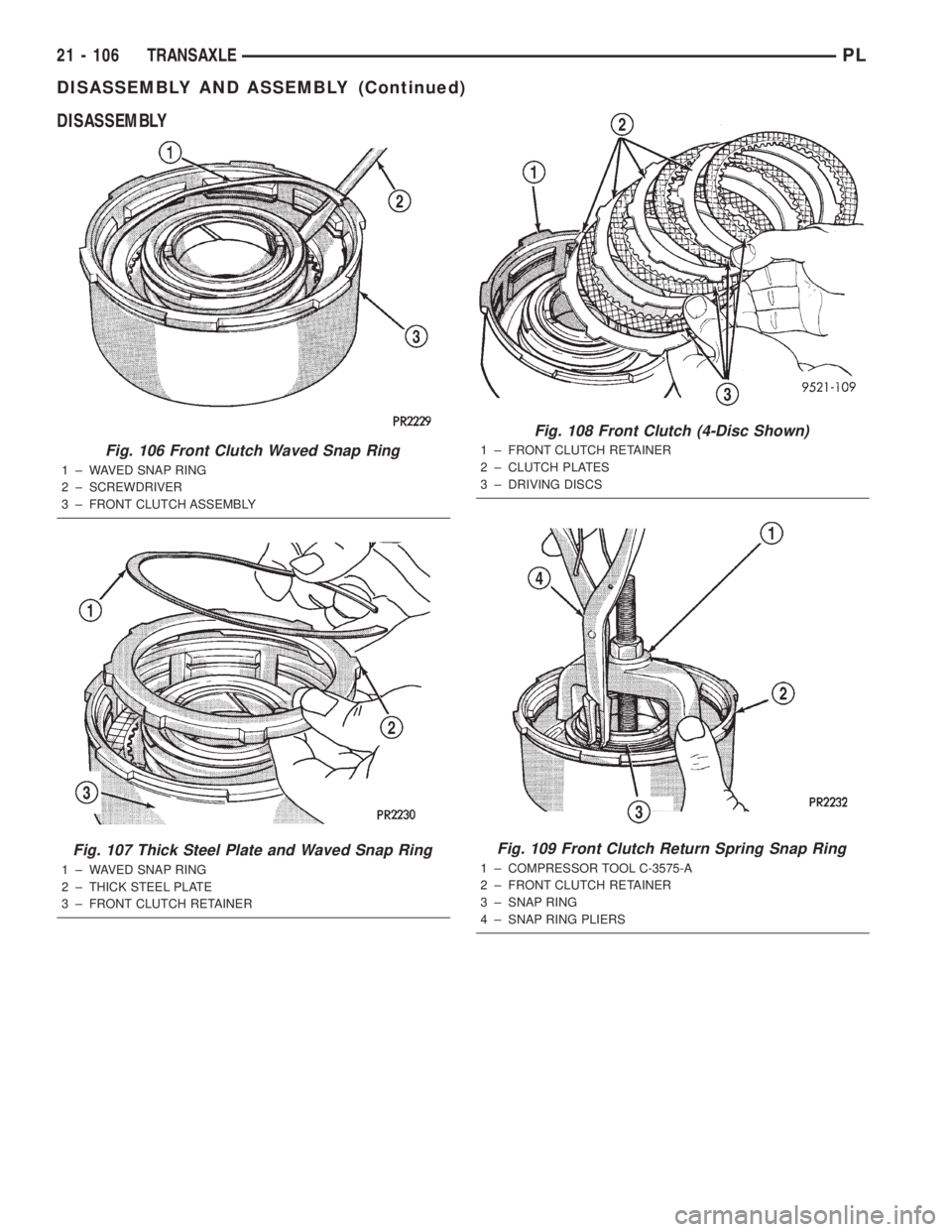

DISASSEMBLY

Fig. 106 Front Clutch Waved Snap Ring

1 ± WAVED SNAP RING

2 ± SCREWDRIVER

3 ± FRONT CLUTCH ASSEMBLY

Fig. 107 Thick Steel Plate and Waved Snap Ring

1 ± WAVED SNAP RING

2 ± THICK STEEL PLATE

3 ± FRONT CLUTCH RETAINER

Fig. 108 Front Clutch (4-Disc Shown)

1 ± FRONT CLUTCH RETAINER

2 ± CLUTCH PLATES

3 ± DRIVING DISCS

Fig. 109 Front Clutch Return Spring Snap Ring

1 ± COMPRESSOR TOOL C-3575-A

2 ± FRONT CLUTCH RETAINER

3 ± SNAP RING

4 ± SNAP RING PLIERS

21 - 106 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)