clutch DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 975 of 1285

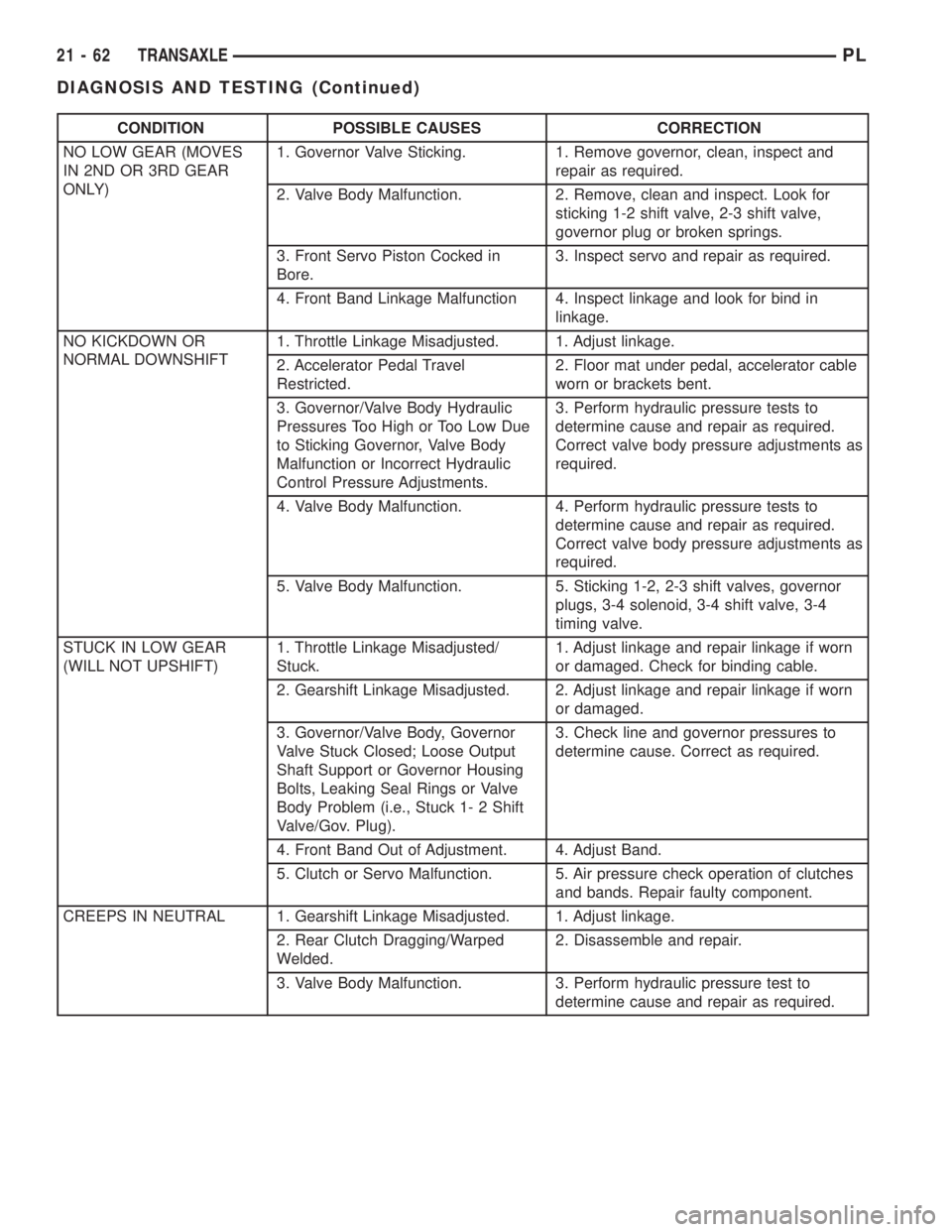

CONDITION POSSIBLE CAUSES CORRECTION

NO LOW GEAR (MOVES

IN 2ND OR 3RD GEAR

ONLY)1. Governor Valve Sticking. 1. Remove governor, clean, inspect and

repair as required.

2. Valve Body Malfunction. 2. Remove, clean and inspect. Look for

sticking 1-2 shift valve, 2-3 shift valve,

governor plug or broken springs.

3. Front Servo Piston Cocked in

Bore.3. Inspect servo and repair as required.

4. Front Band Linkage Malfunction 4. Inspect linkage and look for bind in

linkage.

NO KICKDOWN OR

NORMAL DOWNSHIFT1. Throttle Linkage Misadjusted. 1. Adjust linkage.

2. Accelerator Pedal Travel

Restricted.2. Floor mat under pedal, accelerator cable

worn or brackets bent.

3. Governor/Valve Body Hydraulic

Pressures Too High or Too Low Due

to Sticking Governor, Valve Body

Malfunction or Incorrect Hydraulic

Control Pressure Adjustments.3. Perform hydraulic pressure tests to

determine cause and repair as required.

Correct valve body pressure adjustments as

required.

4. Valve Body Malfunction. 4. Perform hydraulic pressure tests to

determine cause and repair as required.

Correct valve body pressure adjustments as

required.

5. Valve Body Malfunction. 5. Sticking 1-2, 2-3 shift valves, governor

plugs, 3-4 solenoid, 3-4 shift valve, 3-4

timing valve.

STUCK IN LOW GEAR

(WILL NOT UPSHIFT)1. Throttle Linkage Misadjusted/

Stuck.1. Adjust linkage and repair linkage if worn

or damaged. Check for binding cable.

2. Gearshift Linkage Misadjusted. 2. Adjust linkage and repair linkage if worn

or damaged.

3. Governor/Valve Body, Governor

Valve Stuck Closed; Loose Output

Shaft Support or Governor Housing

Bolts, Leaking Seal Rings or Valve

Body Problem (i.e., Stuck 1- 2 Shift

Valve/Gov. Plug).3. Check line and governor pressures to

determine cause. Correct as required.

4. Front Band Out of Adjustment. 4. Adjust Band.

5. Clutch or Servo Malfunction. 5. Air pressure check operation of clutches

and bands. Repair faulty component.

CREEPS IN NEUTRAL 1. Gearshift Linkage Misadjusted. 1. Adjust linkage.

2. Rear Clutch Dragging/Warped

Welded.2. Disassemble and repair.

3. Valve Body Malfunction. 3. Perform hydraulic pressure test to

determine cause and repair as required.

21 - 62 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 976 of 1285

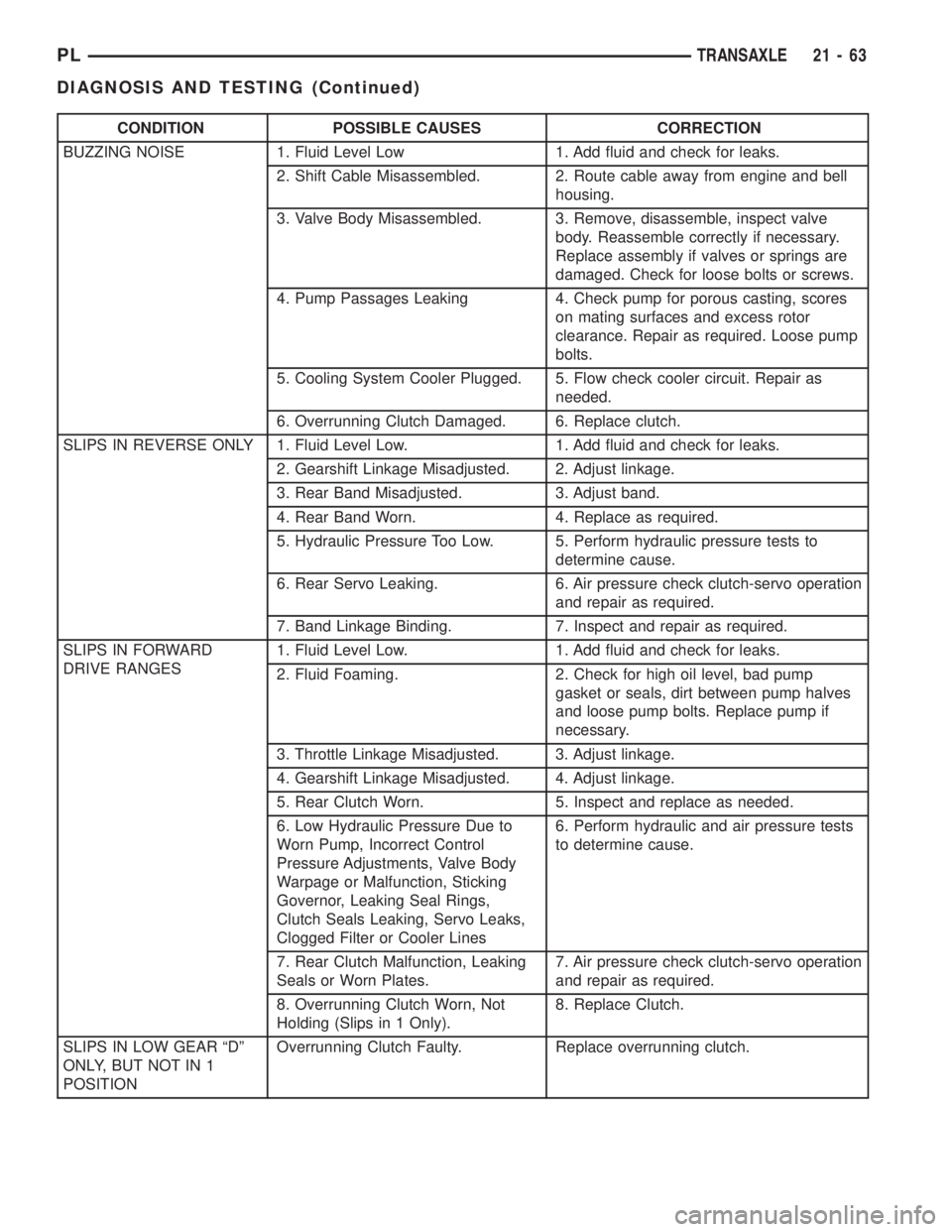

CONDITION POSSIBLE CAUSES CORRECTION

BUZZING NOISE 1. Fluid Level Low 1. Add fluid and check for leaks.

2. Shift Cable Misassembled. 2. Route cable away from engine and bell

housing.

3. Valve Body Misassembled. 3. Remove, disassemble, inspect valve

body. Reassemble correctly if necessary.

Replace assembly if valves or springs are

damaged. Check for loose bolts or screws.

4. Pump Passages Leaking 4. Check pump for porous casting, scores

on mating surfaces and excess rotor

clearance. Repair as required. Loose pump

bolts.

5. Cooling System Cooler Plugged. 5. Flow check cooler circuit. Repair as

needed.

6. Overrunning Clutch Damaged. 6. Replace clutch.

SLIPS IN REVERSE ONLY 1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Gearshift Linkage Misadjusted. 2. Adjust linkage.

3. Rear Band Misadjusted. 3. Adjust band.

4. Rear Band Worn. 4. Replace as required.

5. Hydraulic Pressure Too Low. 5. Perform hydraulic pressure tests to

determine cause.

6. Rear Servo Leaking. 6. Air pressure check clutch-servo operation

and repair as required.

7. Band Linkage Binding. 7. Inspect and repair as required.

SLIPS IN FORWARD

DRIVE RANGES1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Fluid Foaming. 2. Check for high oil level, bad pump

gasket or seals, dirt between pump halves

and loose pump bolts. Replace pump if

necessary.

3. Throttle Linkage Misadjusted. 3. Adjust linkage.

4. Gearshift Linkage Misadjusted. 4. Adjust linkage.

5. Rear Clutch Worn. 5. Inspect and replace as needed.

6. Low Hydraulic Pressure Due to

Worn Pump, Incorrect Control

Pressure Adjustments, Valve Body

Warpage or Malfunction, Sticking

Governor, Leaking Seal Rings,

Clutch Seals Leaking, Servo Leaks,

Clogged Filter or Cooler Lines6. Perform hydraulic and air pressure tests

to determine cause.

7. Rear Clutch Malfunction, Leaking

Seals or Worn Plates.7. Air pressure check clutch-servo operation

and repair as required.

8. Overrunning Clutch Worn, Not

Holding (Slips in 1 Only).8. Replace Clutch.

SLIPS IN LOW GEAR ªDº

ONLY, BUT NOT IN 1

POSITIONOverrunning Clutch Faulty. Replace overrunning clutch.

PLTRANSAXLE 21 - 63

DIAGNOSIS AND TESTING (Continued)

Page 977 of 1285

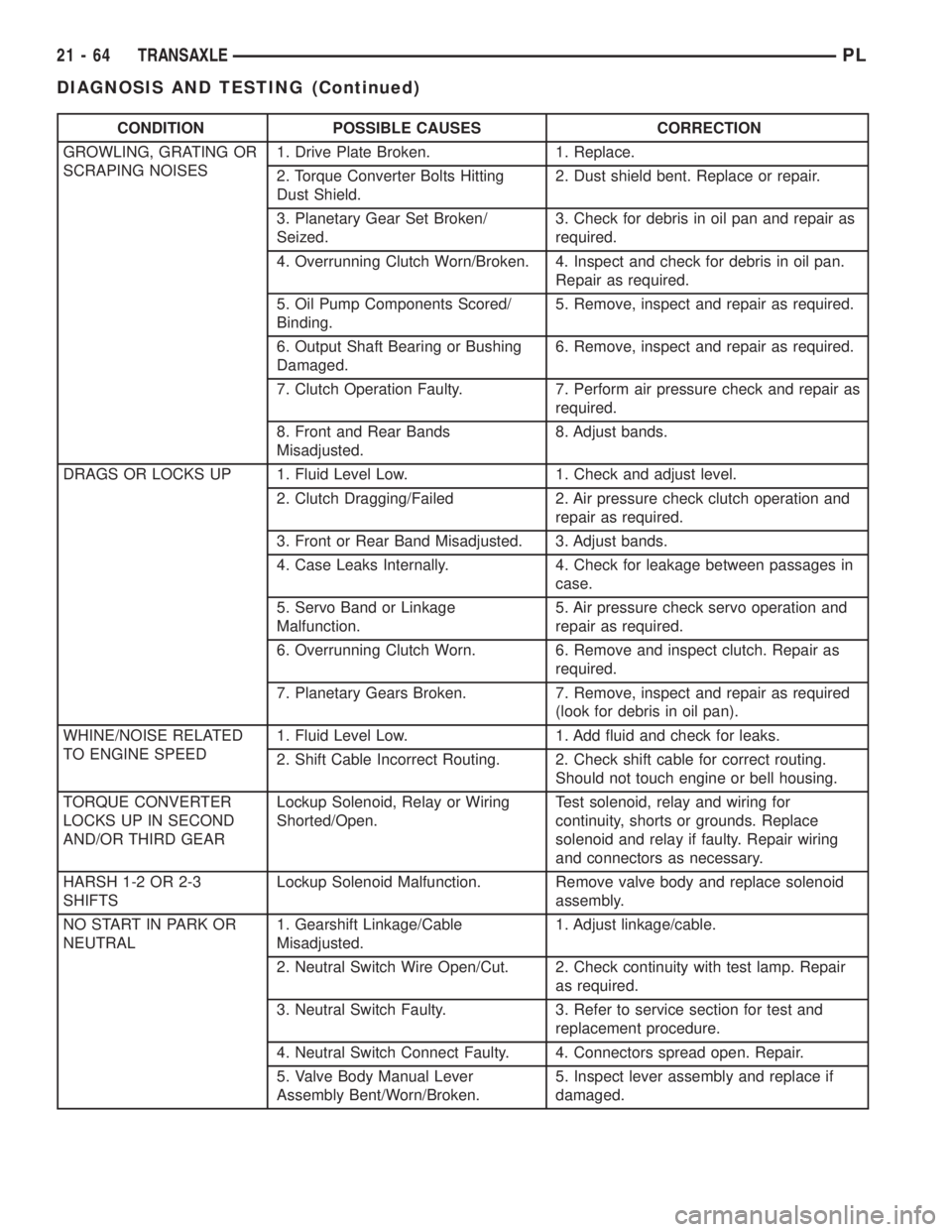

CONDITION POSSIBLE CAUSES CORRECTION

GROWLING, GRATING OR

SCRAPING NOISES1. Drive Plate Broken. 1. Replace.

2. Torque Converter Bolts Hitting

Dust Shield.2. Dust shield bent. Replace or repair.

3. Planetary Gear Set Broken/

Seized.3. Check for debris in oil pan and repair as

required.

4. Overrunning Clutch Worn/Broken. 4. Inspect and check for debris in oil pan.

Repair as required.

5. Oil Pump Components Scored/

Binding.5. Remove, inspect and repair as required.

6. Output Shaft Bearing or Bushing

Damaged.6. Remove, inspect and repair as required.

7. Clutch Operation Faulty. 7. Perform air pressure check and repair as

required.

8. Front and Rear Bands

Misadjusted.8. Adjust bands.

DRAGS OR LOCKS UP 1. Fluid Level Low. 1. Check and adjust level.

2. Clutch Dragging/Failed 2. Air pressure check clutch operation and

repair as required.

3. Front or Rear Band Misadjusted. 3. Adjust bands.

4. Case Leaks Internally. 4. Check for leakage between passages in

case.

5. Servo Band or Linkage

Malfunction.5. Air pressure check servo operation and

repair as required.

6. Overrunning Clutch Worn. 6. Remove and inspect clutch. Repair as

required.

7. Planetary Gears Broken. 7. Remove, inspect and repair as required

(look for debris in oil pan).

WHINE/NOISE RELATED

TO ENGINE SPEED1. Fluid Level Low. 1. Add fluid and check for leaks.

2. Shift Cable Incorrect Routing. 2. Check shift cable for correct routing.

Should not touch engine or bell housing.

TORQUE CONVERTER

LOCKS UP IN SECOND

AND/OR THIRD GEARLockup Solenoid, Relay or Wiring

Shorted/Open.Test solenoid, relay and wiring for

continuity, shorts or grounds. Replace

solenoid and relay if faulty. Repair wiring

and connectors as necessary.

HARSH 1-2 OR 2-3

SHIFTSLockup Solenoid Malfunction. Remove valve body and replace solenoid

assembly.

NO START IN PARK OR

NEUTRAL1. Gearshift Linkage/Cable

Misadjusted.1. Adjust linkage/cable.

2. Neutral Switch Wire Open/Cut. 2. Check continuity with test lamp. Repair

as required.

3. Neutral Switch Faulty. 3. Refer to service section for test and

replacement procedure.

4. Neutral Switch Connect Faulty. 4. Connectors spread open. Repair.

5. Valve Body Manual Lever

Assembly Bent/Worn/Broken.5. Inspect lever assembly and replace if

damaged.

21 - 64 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 978 of 1285

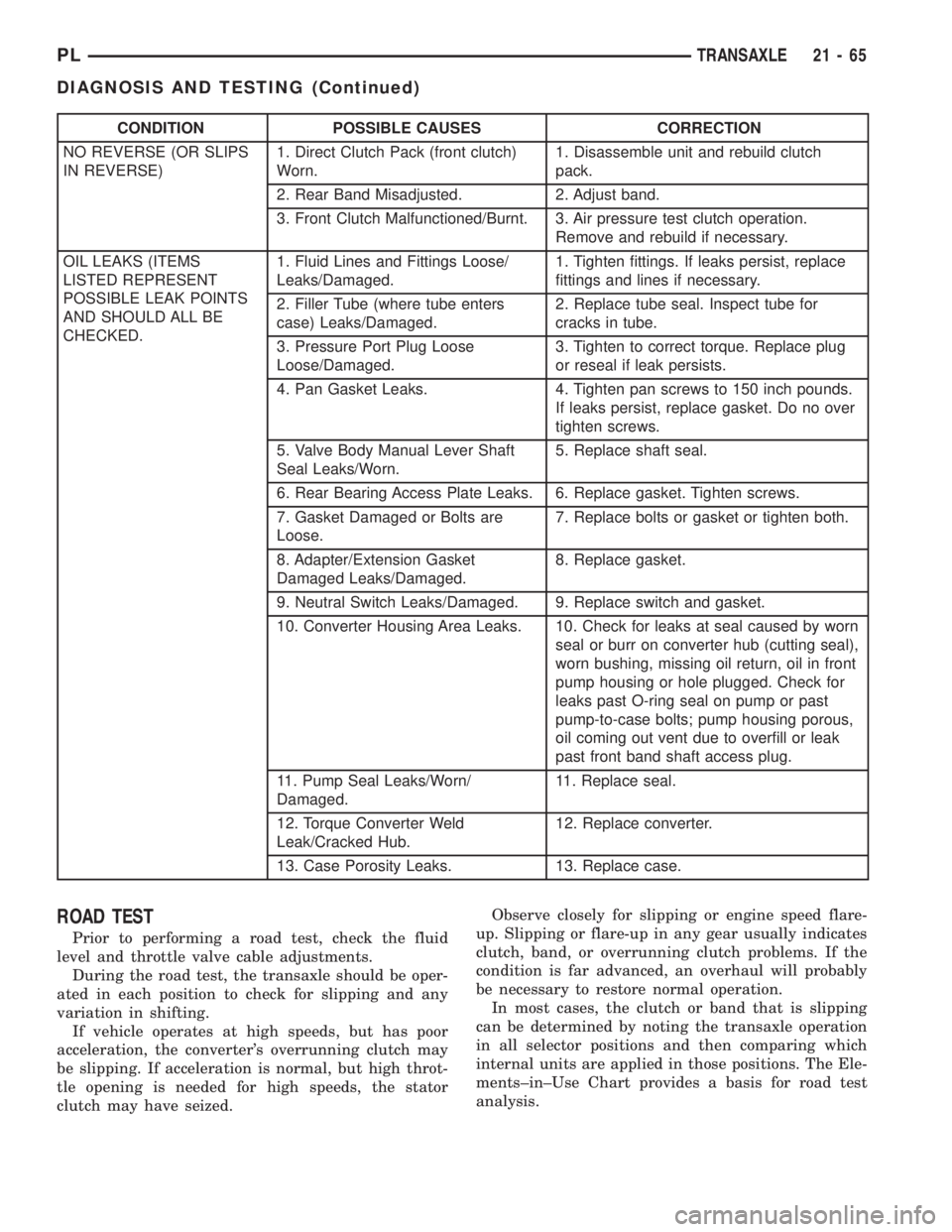

CONDITION POSSIBLE CAUSES CORRECTION

NO REVERSE (OR SLIPS

IN REVERSE)1. Direct Clutch Pack (front clutch)

Worn.1. Disassemble unit and rebuild clutch

pack.

2. Rear Band Misadjusted. 2. Adjust band.

3. Front Clutch Malfunctioned/Burnt. 3. Air pressure test clutch operation.

Remove and rebuild if necessary.

OIL LEAKS (ITEMS

LISTED REPRESENT

POSSIBLE LEAK POINTS

AND SHOULD ALL BE

CHECKED.1. Fluid Lines and Fittings Loose/

Leaks/Damaged.1. Tighten fittings. If leaks persist, replace

fittings and lines if necessary.

2. Filler Tube (where tube enters

case) Leaks/Damaged.2. Replace tube seal. Inspect tube for

cracks in tube.

3. Pressure Port Plug Loose

Loose/Damaged.3. Tighten to correct torque. Replace plug

or reseal if leak persists.

4. Pan Gasket Leaks. 4. Tighten pan screws to 150 inch pounds.

If leaks persist, replace gasket. Do no over

tighten screws.

5. Valve Body Manual Lever Shaft

Seal Leaks/Worn.5. Replace shaft seal.

6. Rear Bearing Access Plate Leaks. 6. Replace gasket. Tighten screws.

7. Gasket Damaged or Bolts are

Loose.7. Replace bolts or gasket or tighten both.

8. Adapter/Extension Gasket

Damaged Leaks/Damaged.8. Replace gasket.

9. Neutral Switch Leaks/Damaged. 9. Replace switch and gasket.

10. Converter Housing Area Leaks. 10. Check for leaks at seal caused by worn

seal or burr on converter hub (cutting seal),

worn bushing, missing oil return, oil in front

pump housing or hole plugged. Check for

leaks past O-ring seal on pump or past

pump-to-case bolts; pump housing porous,

oil coming out vent due to overfill or leak

past front band shaft access plug.

11. Pump Seal Leaks/Worn/

Damaged.11. Replace seal.

12. Torque Converter Weld

Leak/Cracked Hub.12. Replace converter.

13. Case Porosity Leaks. 13. Replace case.

ROAD TEST

Prior to performing a road test, check the fluid

level and throttle valve cable adjustments.

During the road test, the transaxle should be oper-

ated in each position to check for slipping and any

variation in shifting.

If vehicle operates at high speeds, but has poor

acceleration, the converter's overrunning clutch may

be slipping. If acceleration is normal, but high throt-

tle opening is needed for high speeds, the stator

clutch may have seized.Observe closely for slipping or engine speed flare-

up. Slipping or flare-up in any gear usually indicates

clutch, band, or overrunning clutch problems. If the

condition is far advanced, an overhaul will probably

be necessary to restore normal operation.

In most cases, the clutch or band that is slipping

can be determined by noting the transaxle operation

in all selector positions and then comparing which

internal units are applied in those positions. The Ele-

ments±in±Use Chart provides a basis for road test

analysis.

PLTRANSAXLE 21 - 65

DIAGNOSIS AND TESTING (Continued)

Page 979 of 1285

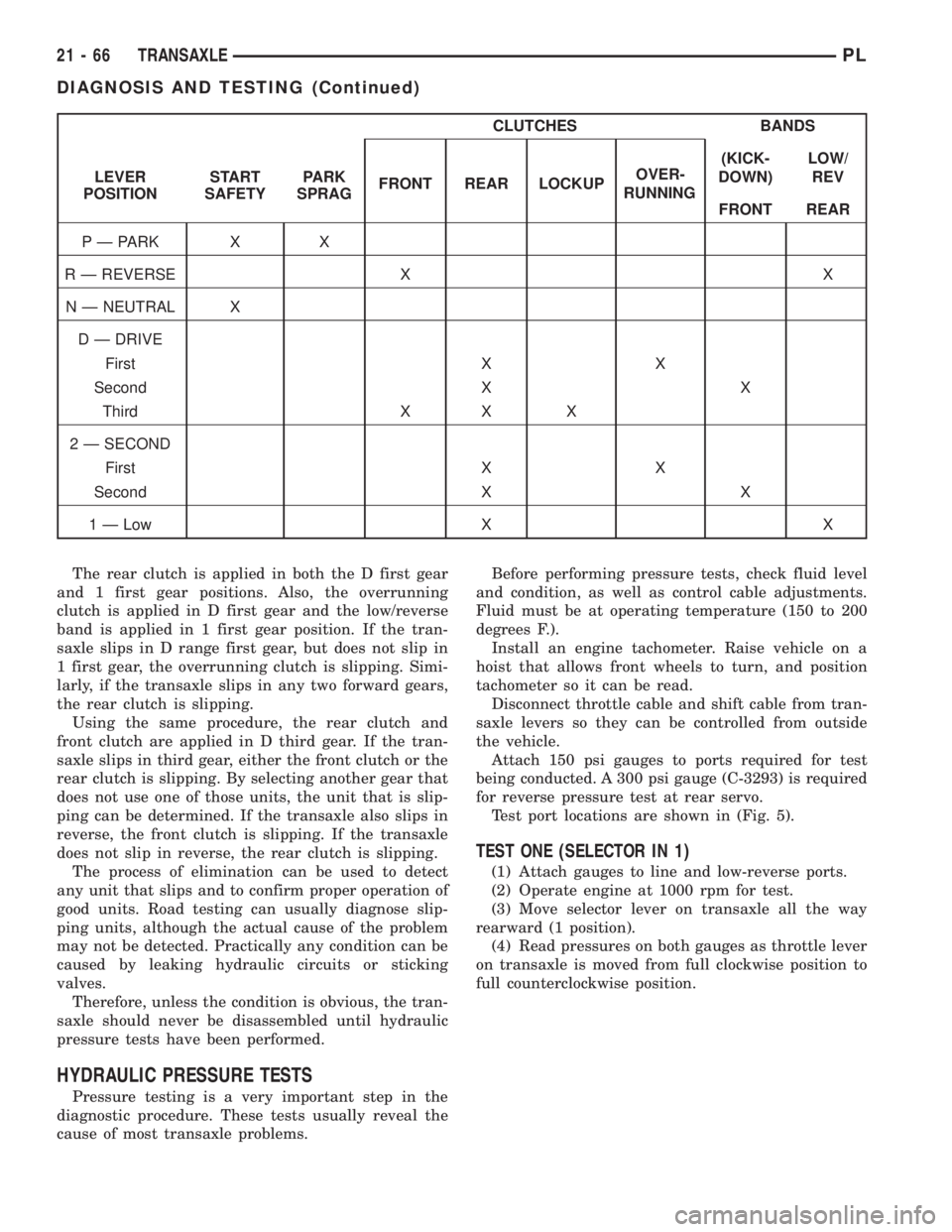

CLUTCHES BANDS

LEVER START PARK

FRONT REAR LOCKUPOVER-

RUNNING(KICK-

DOWN)LOW/

REV

POSITION SAFETY SPRAG

FRONT REAR

P Ð PARK X X

R Ð REVERSE X X

N Ð NEUTRAL X

D Ð DRIVE

First X X

Second X X

Third X X X

2 Ð SECOND

First X X

Second X X

1 Ð Low X X

The rear clutch is applied in both the D first gear

and 1 first gear positions. Also, the overrunning

clutch is applied in D first gear and the low/reverse

band is applied in 1 first gear position. If the tran-

saxle slips in D range first gear, but does not slip in

1 first gear, the overrunning clutch is slipping. Simi-

larly, if the transaxle slips in any two forward gears,

the rear clutch is slipping.

Using the same procedure, the rear clutch and

front clutch are applied in D third gear. If the tran-

saxle slips in third gear, either the front clutch or the

rear clutch is slipping. By selecting another gear that

does not use one of those units, the unit that is slip-

ping can be determined. If the transaxle also slips in

reverse, the front clutch is slipping. If the transaxle

does not slip in reverse, the rear clutch is slipping.

The process of elimination can be used to detect

any unit that slips and to confirm proper operation of

good units. Road testing can usually diagnose slip-

ping units, although the actual cause of the problem

may not be detected. Practically any condition can be

caused by leaking hydraulic circuits or sticking

valves.

Therefore, unless the condition is obvious, the tran-

saxle should never be disassembled until hydraulic

pressure tests have been performed.

HYDRAULIC PRESSURE TESTS

Pressure testing is a very important step in the

diagnostic procedure. These tests usually reveal the

cause of most transaxle problems.Before performing pressure tests, check fluid level

and condition, as well as control cable adjustments.

Fluid must be at operating temperature (150 to 200

degrees F.).

Install an engine tachometer. Raise vehicle on a

hoist that allows front wheels to turn, and position

tachometer so it can be read.

Disconnect throttle cable and shift cable from tran-

saxle levers so they can be controlled from outside

the vehicle.

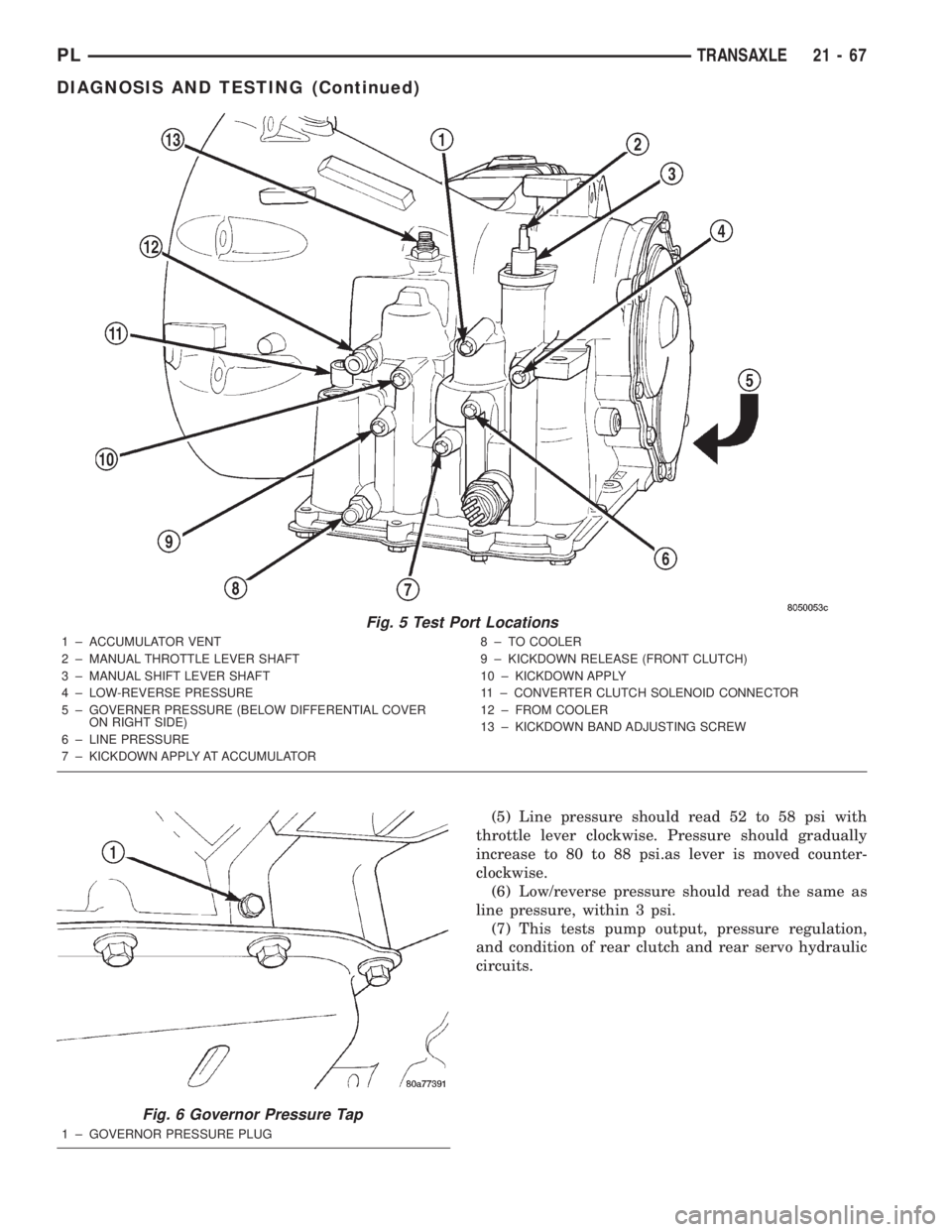

Attach 150 psi gauges to ports required for test

being conducted. A 300 psi gauge (C-3293) is required

for reverse pressure test at rear servo.

Test port locations are shown in (Fig. 5).

TEST ONE (SELECTOR IN 1)

(1) Attach gauges to line and low-reverse ports.

(2) Operate engine at 1000 rpm for test.

(3) Move selector lever on transaxle all the way

rearward (1 position).

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise position to

full counterclockwise position.

21 - 66 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 980 of 1285

(5) Line pressure should read 52 to 58 psi with

throttle lever clockwise. Pressure should gradually

increase to 80 to 88 psi.as lever is moved counter-

clockwise.

(6) Low/reverse pressure should read the same as

line pressure, within 3 psi.

(7) This tests pump output, pressure regulation,

and condition of rear clutch and rear servo hydraulic

circuits.

Fig. 5 Test Port Locations

1 ± ACCUMULATOR VENT

2 ± MANUAL THROTTLE LEVER SHAFT

3 ± MANUAL SHIFT LEVER SHAFT

4 ± LOW-REVERSE PRESSURE

5 ± GOVERNER PRESSURE (BELOW DIFFERENTIAL COVER

ON RIGHT SIDE)

6 ± LINE PRESSURE

7 ± KICKDOWN APPLY AT ACCUMULATOR8 ± TO COOLER

9 ± KICKDOWN RELEASE (FRONT CLUTCH)

10 ± KICKDOWN APPLY

11 ± CONVERTER CLUTCH SOLENOID CONNECTOR

12 ± FROM COOLER

13 ± KICKDOWN BAND ADJUSTING SCREW

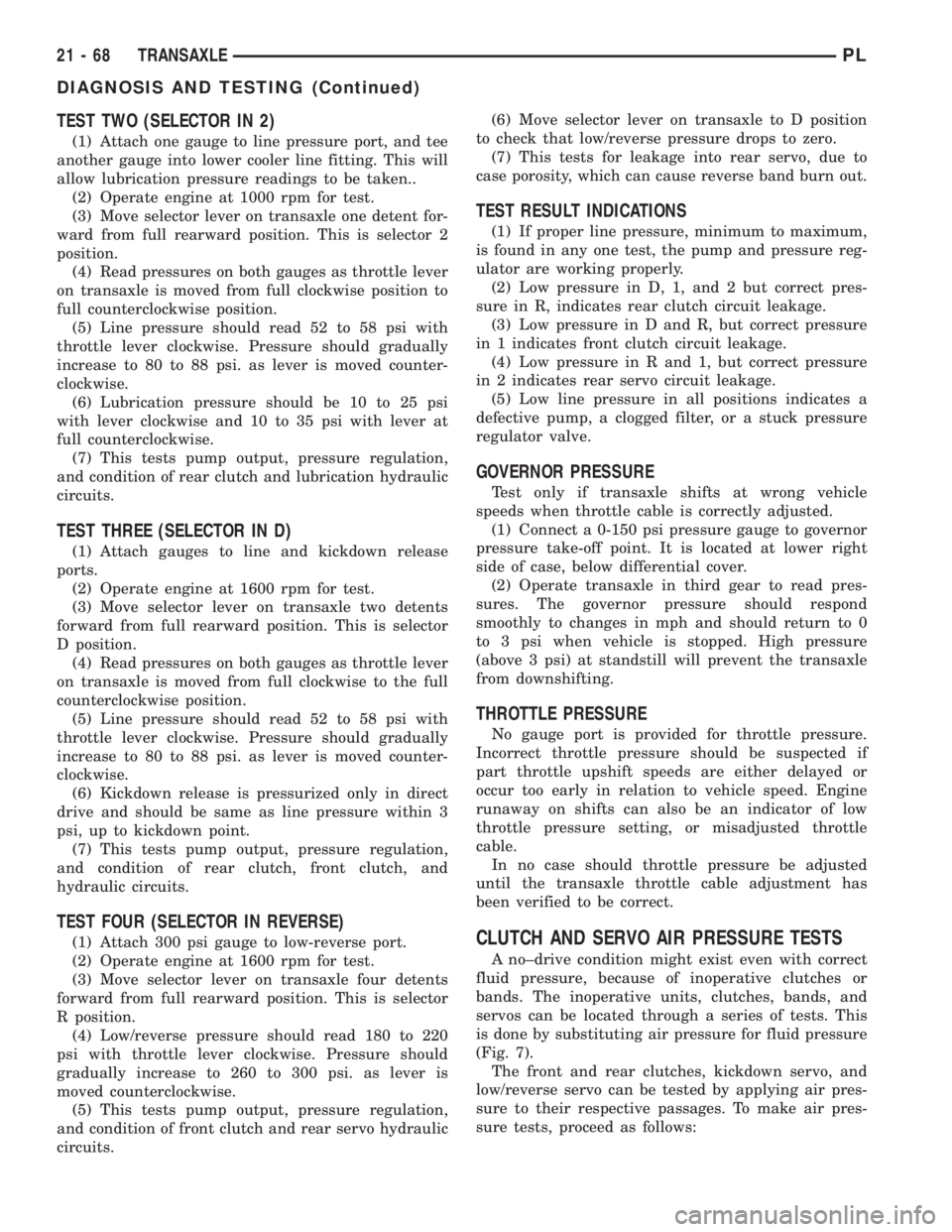

Fig. 6 Governor Pressure Tap

1 ± GOVERNOR PRESSURE PLUG

PLTRANSAXLE 21 - 67

DIAGNOSIS AND TESTING (Continued)

Page 981 of 1285

TEST TWO (SELECTOR IN 2)

(1) Attach one gauge to line pressure port, and tee

another gauge into lower cooler line fitting. This will

allow lubrication pressure readings to be taken..

(2) Operate engine at 1000 rpm for test.

(3) Move selector lever on transaxle one detent for-

ward from full rearward position. This is selector 2

position.

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise position to

full counterclockwise position.

(5) Line pressure should read 52 to 58 psi with

throttle lever clockwise. Pressure should gradually

increase to 80 to 88 psi. as lever is moved counter-

clockwise.

(6) Lubrication pressure should be 10 to 25 psi

with lever clockwise and 10 to 35 psi with lever at

full counterclockwise.

(7) This tests pump output, pressure regulation,

and condition of rear clutch and lubrication hydraulic

circuits.

TEST THREE (SELECTOR IN D)

(1) Attach gauges to line and kickdown release

ports.

(2) Operate engine at 1600 rpm for test.

(3) Move selector lever on transaxle two detents

forward from full rearward position. This is selector

D position.

(4) Read pressures on both gauges as throttle lever

on transaxle is moved from full clockwise to the full

counterclockwise position.

(5) Line pressure should read 52 to 58 psi with

throttle lever clockwise. Pressure should gradually

increase to 80 to 88 psi. as lever is moved counter-

clockwise.

(6) Kickdown release is pressurized only in direct

drive and should be same as line pressure within 3

psi, up to kickdown point.

(7) This tests pump output, pressure regulation,

and condition of rear clutch, front clutch, and

hydraulic circuits.

TEST FOUR (SELECTOR IN REVERSE)

(1) Attach 300 psi gauge to low-reverse port.

(2) Operate engine at 1600 rpm for test.

(3) Move selector lever on transaxle four detents

forward from full rearward position. This is selector

R position.

(4) Low/reverse pressure should read 180 to 220

psi with throttle lever clockwise. Pressure should

gradually increase to 260 to 300 psi. as lever is

moved counterclockwise.

(5) This tests pump output, pressure regulation,

and condition of front clutch and rear servo hydraulic

circuits.(6) Move selector lever on transaxle to D position

to check that low/reverse pressure drops to zero.

(7) This tests for leakage into rear servo, due to

case porosity, which can cause reverse band burn out.

TEST RESULT INDICATIONS

(1) If proper line pressure, minimum to maximum,

is found in any one test, the pump and pressure reg-

ulator are working properly.

(2) Low pressure in D, 1, and 2 but correct pres-

sure in R, indicates rear clutch circuit leakage.

(3) Low pressure in D and R, but correct pressure

in 1 indicates front clutch circuit leakage.

(4) Low pressure in R and 1, but correct pressure

in 2 indicates rear servo circuit leakage.

(5) Low line pressure in all positions indicates a

defective pump, a clogged filter, or a stuck pressure

regulator valve.

GOVERNOR PRESSURE

Test only if transaxle shifts at wrong vehicle

speeds when throttle cable is correctly adjusted.

(1) Connect a 0-150 psi pressure gauge to governor

pressure take-off point. It is located at lower right

side of case, below differential cover.

(2) Operate transaxle in third gear to read pres-

sures. The governor pressure should respond

smoothly to changes in mph and should return to 0

to 3 psi when vehicle is stopped. High pressure

(above 3 psi) at standstill will prevent the transaxle

from downshifting.

THROTTLE PRESSURE

No gauge port is provided for throttle pressure.

Incorrect throttle pressure should be suspected if

part throttle upshift speeds are either delayed or

occur too early in relation to vehicle speed. Engine

runaway on shifts can also be an indicator of low

throttle pressure setting, or misadjusted throttle

cable.

In no case should throttle pressure be adjusted

until the transaxle throttle cable adjustment has

been verified to be correct.

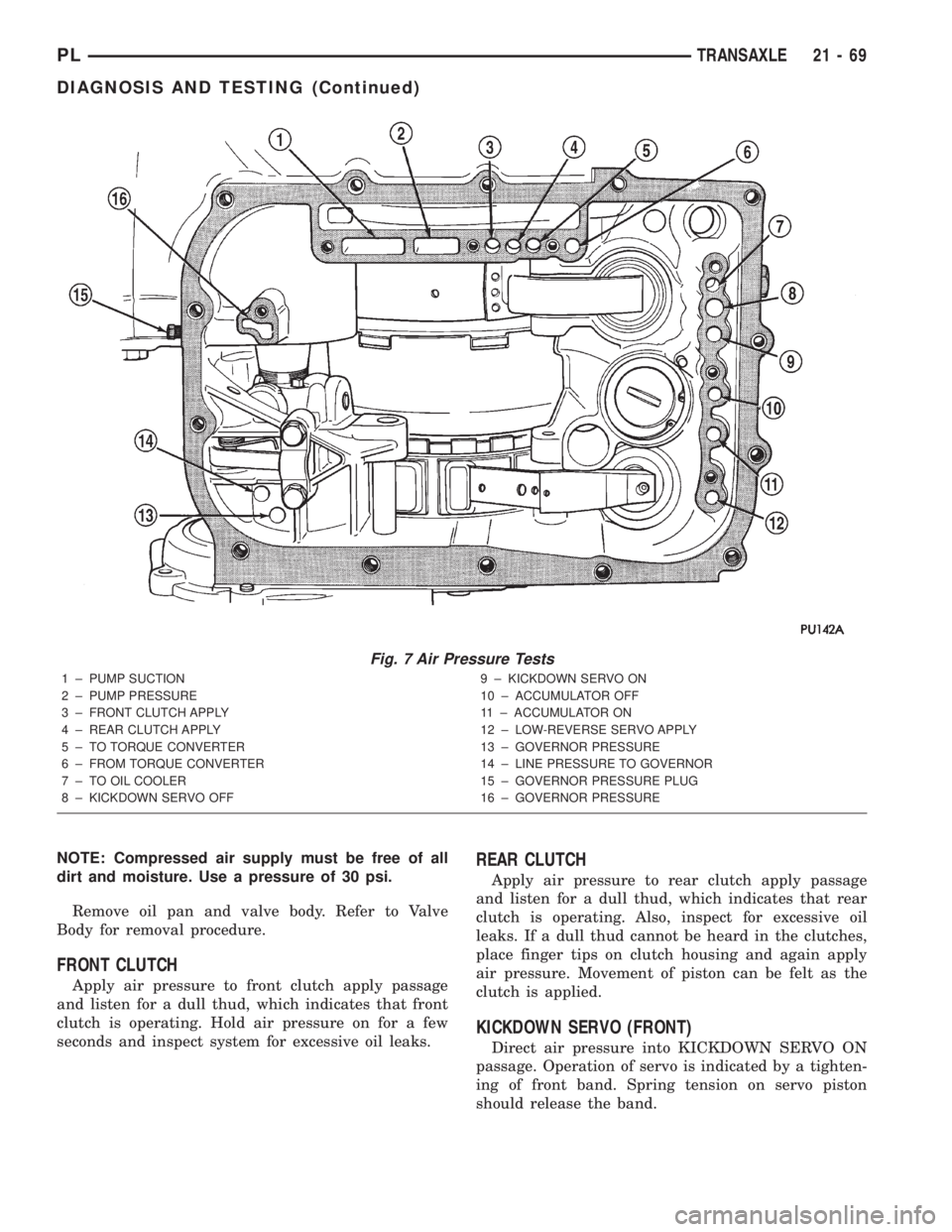

CLUTCH AND SERVO AIR PRESSURE TESTS

A no±drive condition might exist even with correct

fluid pressure, because of inoperative clutches or

bands. The inoperative units, clutches, bands, and

servos can be located through a series of tests. This

is done by substituting air pressure for fluid pressure

(Fig. 7).

The front and rear clutches, kickdown servo, and

low/reverse servo can be tested by applying air pres-

sure to their respective passages. To make air pres-

sure tests, proceed as follows:

21 - 68 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 982 of 1285

NOTE: Compressed air supply must be free of all

dirt and moisture. Use a pressure of 30 psi.

Remove oil pan and valve body. Refer to Valve

Body for removal procedure.

FRONT CLUTCH

Apply air pressure to front clutch apply passage

and listen for a dull thud, which indicates that front

clutch is operating. Hold air pressure on for a few

seconds and inspect system for excessive oil leaks.

REAR CLUTCH

Apply air pressure to rear clutch apply passage

and listen for a dull thud, which indicates that rear

clutch is operating. Also, inspect for excessive oil

leaks. If a dull thud cannot be heard in the clutches,

place finger tips on clutch housing and again apply

air pressure. Movement of piston can be felt as the

clutch is applied.

KICKDOWN SERVO (FRONT)

Direct air pressure into KICKDOWN SERVO ON

passage. Operation of servo is indicated by a tighten-

ing of front band. Spring tension on servo piston

should release the band.

Fig. 7 Air Pressure Tests

1 ± PUMP SUCTION

2 ± PUMP PRESSURE

3 ± FRONT CLUTCH APPLY

4 ± REAR CLUTCH APPLY

5 ± TO TORQUE CONVERTER

6 ± FROM TORQUE CONVERTER

7 ± TO OIL COOLER

8 ± KICKDOWN SERVO OFF9 ± KICKDOWN SERVO ON

10 ± ACCUMULATOR OFF

11 ± ACCUMULATOR ON

12 ± LOW-REVERSE SERVO APPLY

13 ± GOVERNOR PRESSURE

14 ± LINE PRESSURE TO GOVERNOR

15 ± GOVERNOR PRESSURE PLUG

16 ± GOVERNOR PRESSURE

PLTRANSAXLE 21 - 69

DIAGNOSIS AND TESTING (Continued)

Page 983 of 1285

LOW AND REVERSE SERVO (REAR)

Direct air pressure into LOW/REVERSE SERVO

APPLY passage. Operation of servo is indicated by a

tightening of rear band. Spring tension on servo pis-

ton should release the band.

If clutches and servos operate properly, no upshift

indicates that a malfunction exists in the valve body.

FLUID LEAKAGE-TRANSAXLE TORQUE

CONVERTER HOUSING AREA

(1) Check for source of leakage.

(2) Since fluid leakage near the torque converter

area may be from an engine oil leak, the area should

be checked closely. Factory fill fluid is dyed red and,

therefore, can be distinguished from engine oil.

(3) Prior to removing the transaxle, perform the

following checks:

(4) When leakage is determined to originate from

the transaxle, check fluid level prior to removal of

the transaxle and torque converter.

(5) High oil level can result in oil leakage out the

vent in the dipstick. If the fluid level is high, adjust

to proper level.

(6) After performing this operation, inspect for

leakage. If a leak persists, perform the following

operation on the vehicle. This will determine if the

torque converter or transaxle is leaking.

TORQUE CONVERTER LEAKAGE

Possible sources of torque converter leakage are:

²Torque converter weld leaks at the outside diam-

eter (peripheral) weld

²Torque converter hub weld

²Torque converter impeller shell cracked adjacent

to hub

²At drive lug welds

NOTE: Hub weld is inside and not visible. Do not

attempt to repair. Replace torque converter.

BRAKE TRANSMISSION SHIFT INTERLOCK

The following chart describes the normal operation

of the Brake Transmission Shift Interlock (BTSI) sys-

tem. If the ªexpected responseº differs from the vehi-

cle's response, then system repair and/or adjustment

is necessary. Refer to Brake Transmission Interlock

Removal and Installation or Adjustment in this

Group.

SERVICE PROCEDURES

TRANSAXLE FLUID AND FILTER SERVICE

NOTE: Refer to Group 0, Lubrication and Mainte-

nance, or the vehicle owner's manual, for the rec-

ommended maintenance (fluid/filter change)

intervals for this transaxle.

NOTE: Only fluids of the type labeled MoparT

ATF+4 (Automatic Transmission Fluid) Type 9602

should be used. A filter change should be made at

the time of the transmission oil change. The magnet

(on the inside of the oil pan) should also be cleaned

with a clean, dry cloth.

NOTE: If the transaxle is disassembled for any rea-

son, the fluid and filter should be changed.

FLUID/FILTER SERVICE (RECOMMENDED)

(1) Raise vehicle on a hoist (See Lubrication,

Group 0). Place a drain container with a large open-

ing, under transaxle oil pan.

(2) Loosen pan bolts and tap the pan at one corner

to break it loose allowing fluid to drain, then remove

the oil pan.

(3) Install a new filter and o-ring on bottom of the

valve body and tighten retaining screws to 5 N´m (40

in. lbs.).

ACTION EXPECTED RESPONSE

1. Turn key to the ªOFFº

position.1. Shifter CAN be shifted

out of park.

2. Turn key to the

9ON/RUNº position.2. Shifter CANNOT be

shifted out of park.

3. Turn key to the

ªON/RUNº position and

depress the brake pedal.3. Shifter CAN be shifted

out of park.

4. Leave shifter in any

gear and try to return key

to the ªLOCKº or9ACCº

position.4. Key cannot be

returned to the ªLOCKº or

ªACCº position.

5. Return shifter to

ªPARKº and try to remove

the key.5. Key can be removed

(after returning to ªLOCKº

position).

6. With the key removed,

try to shift out of ªPARKº.6. Shifter cannot be

shifted out of ªPARKº.

NOTE: Any failure to meet these expected

responses requires system adjustment or repair.

21 - 70 TRANSAXLEPL

DIAGNOSIS AND TESTING (Continued)

Page 997 of 1285

PARK/NEUTRAL STARTING AND BACK-UP

LAMP SWITCH

TEST

The park/neutral starting switch is the center ter-

minal of the three terminal switch. It provides

ground for the starter solenoid circuit through the

selector lever in PARK and NEUTRAL positions only.

(1) To test switch, remove wiring connector from

switch and test for continuity between center pin of

switch and transaxle case. Continuity should exist

only when transaxle is in PARK or NEUTRAL.

(2) Check gearshift cable adjustment before replac-

ing a switch that tests bad.

REMOVAL

(1) Unscrew switch from transaxle case allowing

fluid to drain into a container. Move selector lever to

PARK, then to NEUTRAL position, and inspect to see

the switch operating lever fingers are centered in

switch opening.

INSTALLATION

(1) Screw the switch with a new seal into tran-

saxle case and tighten to 33 N´m (24 ft. lbs.). Retest

switch with the test lamp.

(2) Add fluid to transaxle to bring up to proper

level.

(3) The back-up lamp switch circuit is through the

two outside terminals of the three terminal switch.

(4) To test switch, remove wiring connector from

switch and test for continuity between the two out-

side pins.

(5) Continuity should exist only with transaxle in

REVERSE position.

(6) No continuity should exist from either pin to

the case.

TRANSAXLE AND TORQUE CONVERTER

REMOVAL

(1) Raise hood.

(2) Disconnect both battery cables, remove battery

hold down clamp and bolt, and remove battery.

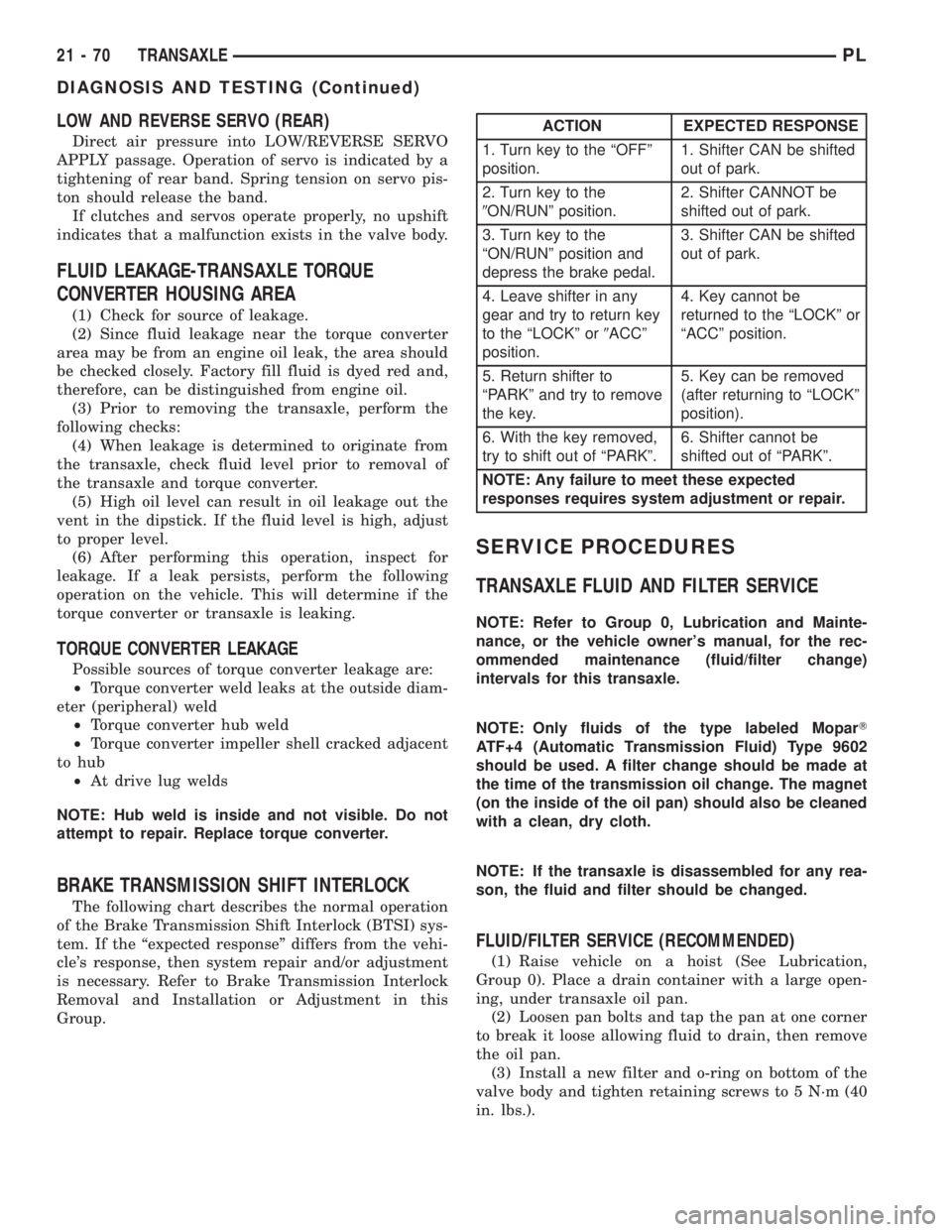

(3) Remove air cleaner/throttle body assy. (Fig. 45)

as follows:

(a) Disconnect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(b) Disconnect the Throttle Position Sensor

(TPS) and Idle Air Control (IAC) connectors.

(c) Remove mounting bolt and nut (Fig. 45) and

partially remove air cleaner assembly.

(d) Disconnect accelerator, transaxle kickdown,

and speed control (if equipped) cables after the

assy. is removed from position. Remove air cleaner

assembly from vehicle.(4) Remove battery tray from bracket.

(5) Disconnect torque converter clutch solenoid and

neutral safety/back-up lamp switch connectors.

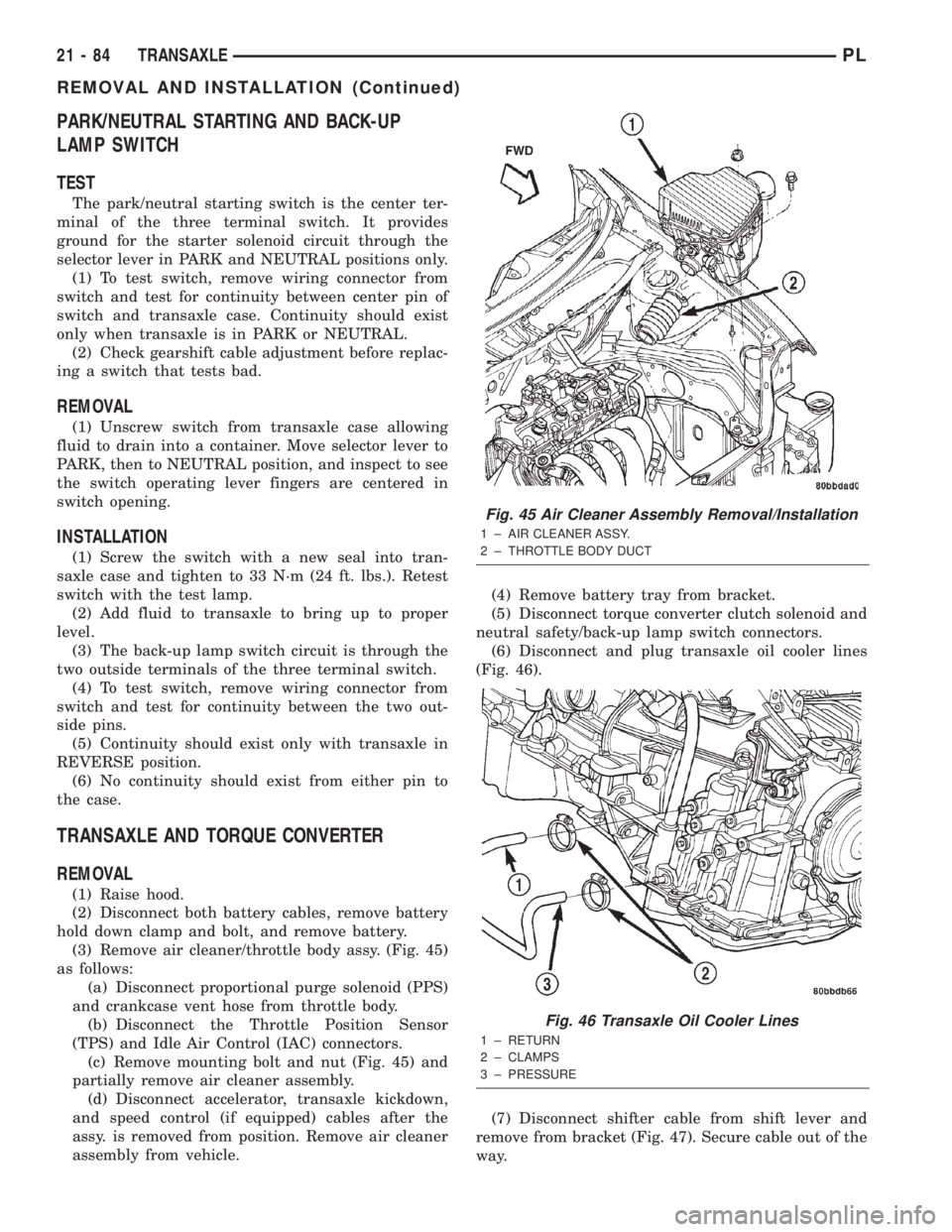

(6) Disconnect and plug transaxle oil cooler lines

(Fig. 46).

(7) Disconnect shifter cable from shift lever and

remove from bracket (Fig. 47). Secure cable out of the

way.

Fig. 45 Air Cleaner Assembly Removal/Installation

1 ± AIR CLEANER ASSY.

2 ± THROTTLE BODY DUCT

Fig. 46 Transaxle Oil Cooler Lines

1 ± RETURN

2 ± CLAMPS

3 ± PRESSURE

21 - 84 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)