clutch DODGE NEON 2000 Service Manual Online

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 925 of 1285

INSTALLATION

(1) Install pinion gear to speed sensor (Fig. 30).

(2) Using a NEW o-ring, install the speed sensor

to the transaxle (Fig. 30).

(3) Install the bolt and torque to 7 N´m (60 in.

lbs.).

(4) Connect speed sensor connector (Fig. 30).

(5) Lower vehicle and road test to verify proper

speedometer operation.

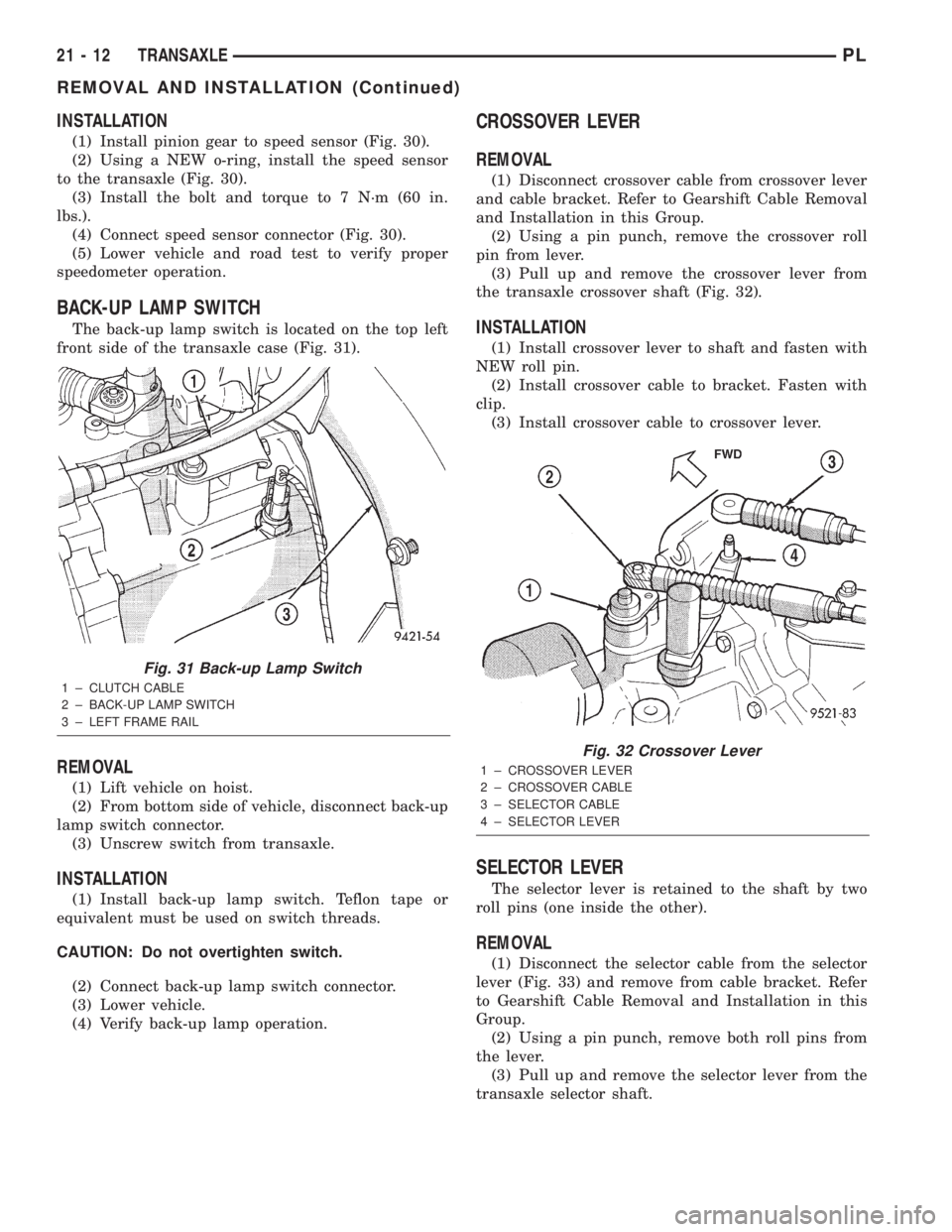

BACK-UP LAMP SWITCH

The back-up lamp switch is located on the top left

front side of the transaxle case (Fig. 31).

REMOVAL

(1) Lift vehicle on hoist.

(2) From bottom side of vehicle, disconnect back-up

lamp switch connector.

(3) Unscrew switch from transaxle.

INSTALLATION

(1) Install back-up lamp switch. Teflon tape or

equivalent must be used on switch threads.

CAUTION: Do not overtighten switch.

(2) Connect back-up lamp switch connector.

(3) Lower vehicle.

(4) Verify back-up lamp operation.

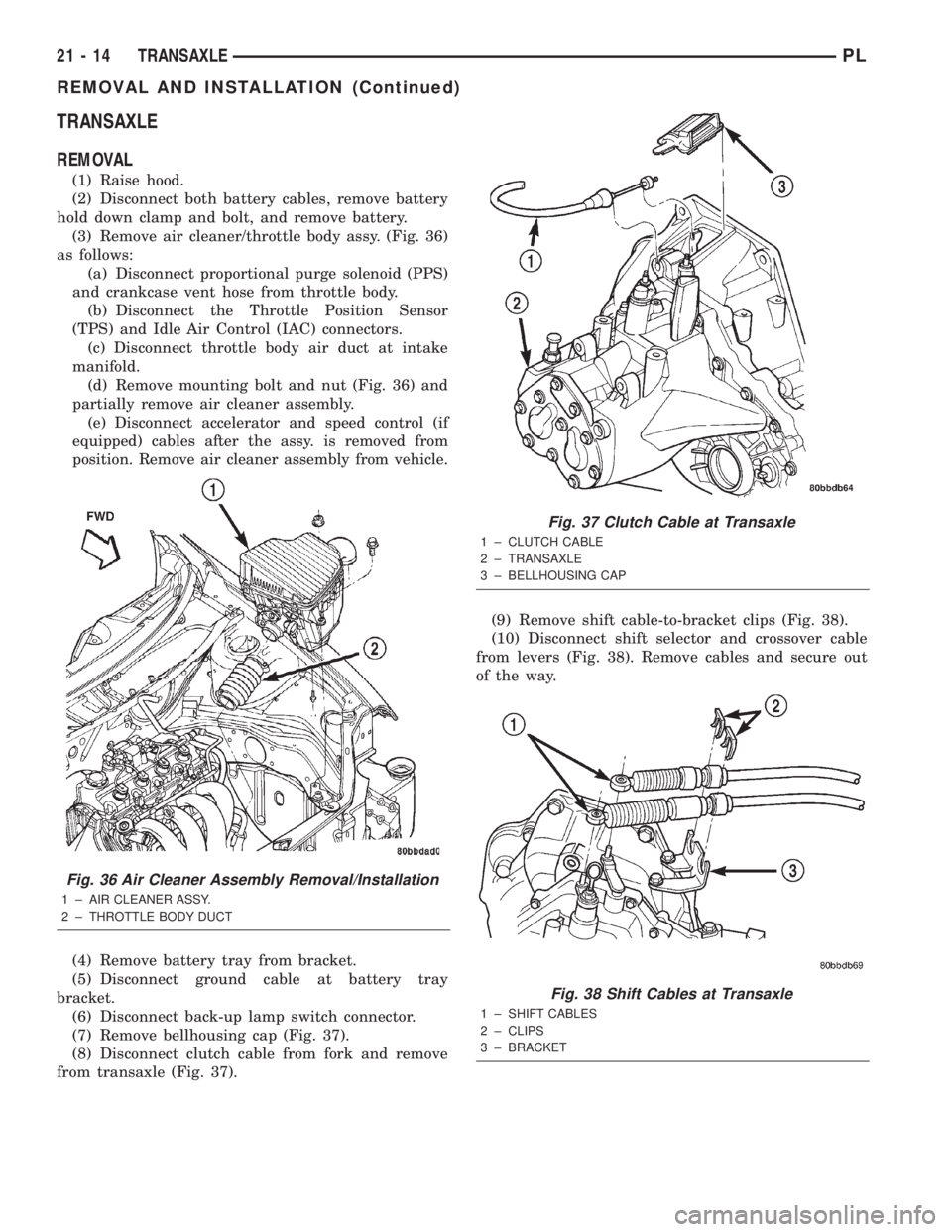

CROSSOVER LEVER

REMOVAL

(1) Disconnect crossover cable from crossover lever

and cable bracket. Refer to Gearshift Cable Removal

and Installation in this Group.

(2) Using a pin punch, remove the crossover roll

pin from lever.

(3) Pull up and remove the crossover lever from

the transaxle crossover shaft (Fig. 32).

INSTALLATION

(1) Install crossover lever to shaft and fasten with

NEW roll pin.

(2) Install crossover cable to bracket. Fasten with

clip.

(3) Install crossover cable to crossover lever.

SELECTOR LEVER

The selector lever is retained to the shaft by two

roll pins (one inside the other).

REMOVAL

(1) Disconnect the selector cable from the selector

lever (Fig. 33) and remove from cable bracket. Refer

to Gearshift Cable Removal and Installation in this

Group.

(2) Using a pin punch, remove both roll pins from

the lever.

(3) Pull up and remove the selector lever from the

transaxle selector shaft.

Fig. 31 Back-up Lamp Switch

1 ± CLUTCH CABLE

2 ± BACK-UP LAMP SWITCH

3 ± LEFT FRAME RAIL

Fig. 32 Crossover Lever

1 ± CROSSOVER LEVER

2 ± CROSSOVER CABLE

3 ± SELECTOR CABLE

4 ± SELECTOR LEVER

21 - 12 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 927 of 1285

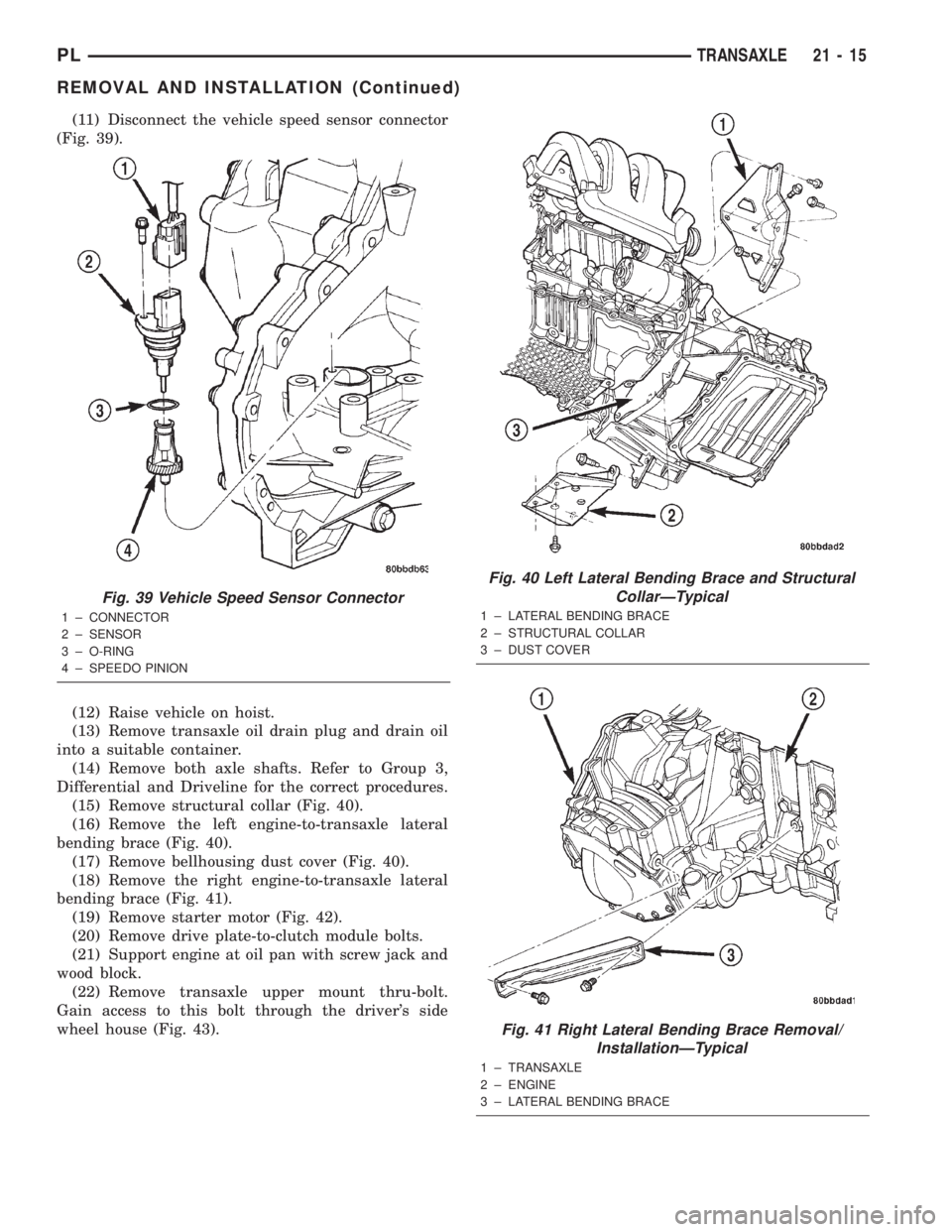

TRANSAXLE

REMOVAL

(1) Raise hood.

(2) Disconnect both battery cables, remove battery

hold down clamp and bolt, and remove battery.

(3) Remove air cleaner/throttle body assy. (Fig. 36)

as follows:

(a) Disconnect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(b) Disconnect the Throttle Position Sensor

(TPS) and Idle Air Control (IAC) connectors.

(c) Disconnect throttle body air duct at intake

manifold.

(d) Remove mounting bolt and nut (Fig. 36) and

partially remove air cleaner assembly.

(e)

Disconnect accelerator and speed control (if

equipped) cables after the assy. is removed from

position. Remove air cleaner assembly from vehicle.

(4) Remove battery tray from bracket.

(5) Disconnect ground cable at battery tray

bracket.

(6) Disconnect back-up lamp switch connector.

(7) Remove bellhousing cap (Fig. 37).

(8) Disconnect clutch cable from fork and remove

from transaxle (Fig. 37).(9) Remove shift cable-to-bracket clips (Fig. 38).

(10) Disconnect shift selector and crossover cable

from levers (Fig. 38). Remove cables and secure out

of the way.

Fig. 36 Air Cleaner Assembly Removal/Installation

1 ± AIR CLEANER ASSY.

2 ± THROTTLE BODY DUCT

Fig. 37 Clutch Cable at Transaxle

1 ± CLUTCH CABLE

2 ± TRANSAXLE

3 ± BELLHOUSING CAP

Fig. 38 Shift Cables at Transaxle

1 ± SHIFT CABLES

2 ± CLIPS

3 ± BRACKET

21 - 14 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 928 of 1285

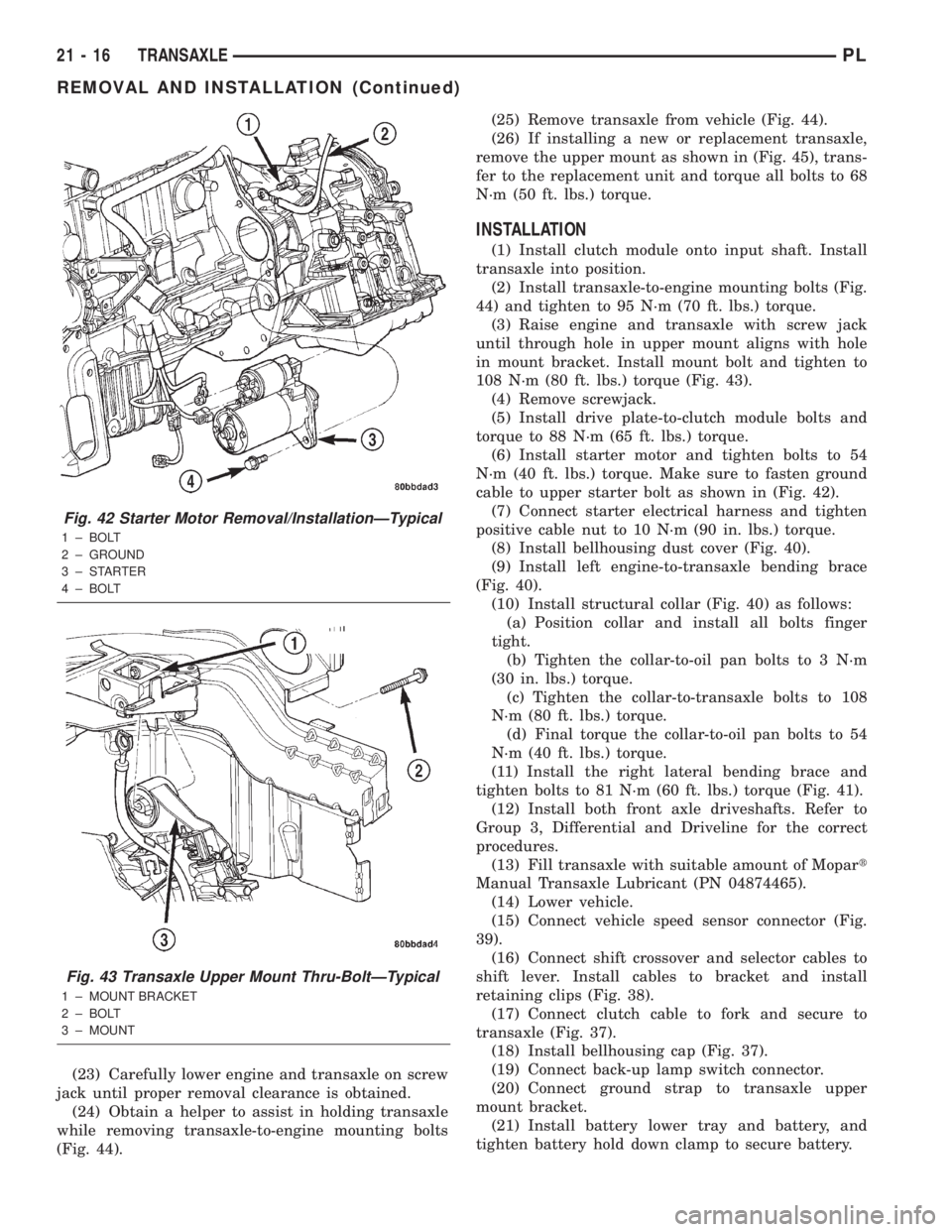

(11) Disconnect the vehicle speed sensor connector

(Fig. 39).

(12) Raise vehicle on hoist.

(13) Remove transaxle oil drain plug and drain oil

into a suitable container.

(14) Remove both axle shafts. Refer to Group 3,

Differential and Driveline for the correct procedures.

(15) Remove structural collar (Fig. 40).

(16) Remove the left engine-to-transaxle lateral

bending brace (Fig. 40).

(17) Remove bellhousing dust cover (Fig. 40).

(18) Remove the right engine-to-transaxle lateral

bending brace (Fig. 41).

(19) Remove starter motor (Fig. 42).

(20) Remove drive plate-to-clutch module bolts.

(21) Support engine at oil pan with screw jack and

wood block.

(22) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 43).

Fig. 39 Vehicle Speed Sensor Connector

1 ± CONNECTOR

2 ± SENSOR

3 ± O-RING

4 ± SPEEDO PINION

Fig. 40 Left Lateral Bending Brace and Structural

CollarÐTypical

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 41 Right Lateral Bending Brace Removal/

InstallationÐTypical

1 ± TRANSAXLE

2 ± ENGINE

3 ± LATERAL BENDING BRACE

PLTRANSAXLE 21 - 15

REMOVAL AND INSTALLATION (Continued)

Page 929 of 1285

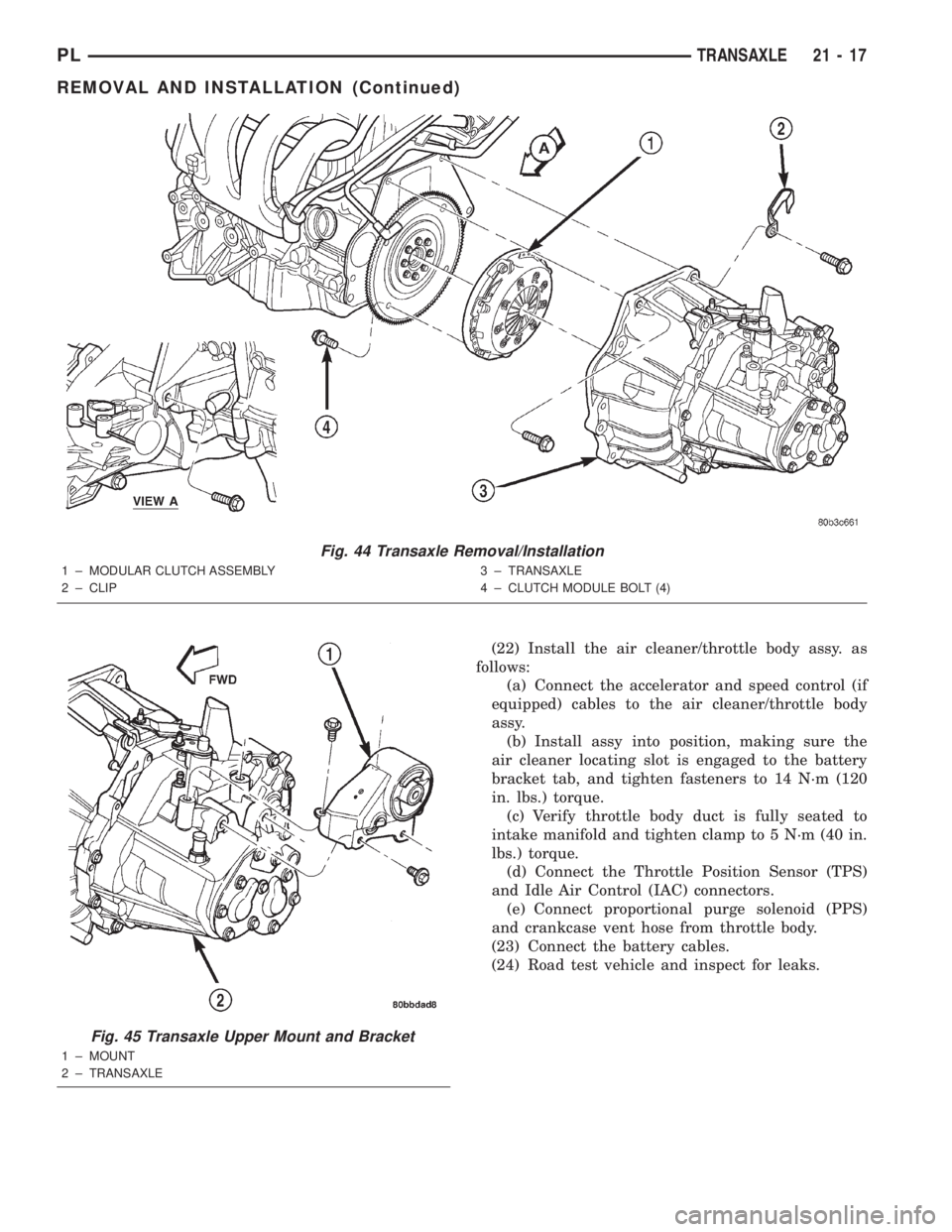

(23) Carefully lower engine and transaxle on screw

jack until proper removal clearance is obtained.

(24) Obtain a helper to assist in holding transaxle

while removing transaxle-to-engine mounting bolts

(Fig. 44).(25) Remove transaxle from vehicle (Fig. 44).

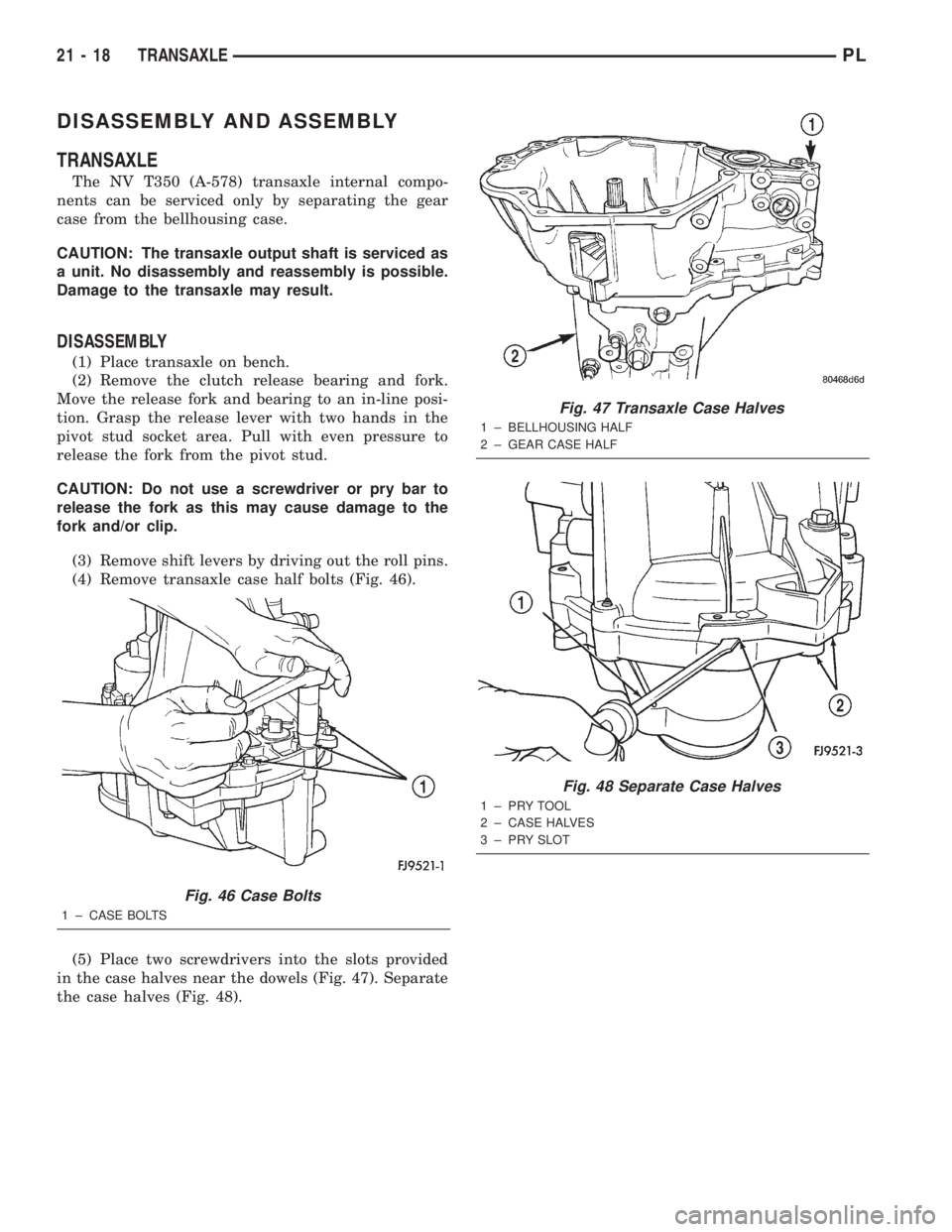

(26) If installing a new or replacement transaxle,

remove the upper mount as shown in (Fig. 45), trans-

fer to the replacement unit and torque all bolts to 68

N´m (50 ft. lbs.) torque.

INSTALLATION

(1) Install clutch module onto input shaft. Install

transaxle into position.

(2) Install transaxle-to-engine mounting bolts (Fig.

44) and tighten to 95 N´m (70 ft. lbs.) torque.

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 43).

(4) Remove screwjack.

(5) Install drive plate-to-clutch module bolts and

torque to 88 N´m (65 ft. lbs.) torque.

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 42).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 40).

(9) Install left engine-to-transaxle bending brace

(Fig. 40).

(10) Install structural collar (Fig. 40) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

(c) Tighten the collar-to-transaxle bolts to 108

N´m (80 ft. lbs.) torque.

(d) Final torque the collar-to-oil pan bolts to 54

N´m (40 ft. lbs.) torque.

(11) Install the right lateral bending brace and

tighten bolts to 81 N´m (60 ft. lbs.) torque (Fig. 41).

(12) Install both front axle driveshafts. Refer to

Group 3, Differential and Driveline for the correct

procedures.

(13) Fill transaxle with suitable amount of Mopart

Manual Transaxle Lubricant (PN 04874465).

(14) Lower vehicle.

(15) Connect vehicle speed sensor connector (Fig.

39).

(16) Connect shift crossover and selector cables to

shift lever. Install cables to bracket and install

retaining clips (Fig. 38).

(17) Connect clutch cable to fork and secure to

transaxle (Fig. 37).

(18) Install bellhousing cap (Fig. 37).

(19) Connect back-up lamp switch connector.

(20) Connect ground strap to transaxle upper

mount bracket.

(21) Install battery lower tray and battery, and

tighten battery hold down clamp to secure battery.

Fig. 42 Starter Motor Removal/InstallationÐTypical

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 43 Transaxle Upper Mount Thru-BoltÐTypical

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

21 - 16 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 930 of 1285

(22) Install the air cleaner/throttle body assy. as

follows:

(a) Connect the accelerator and speed control (if

equipped) cables to the air cleaner/throttle body

assy.

(b) Install assy into position, making sure the

air cleaner locating slot is engaged to the battery

bracket tab, and tighten fasteners to 14 N´m (120

in. lbs.) torque.

(c) Verify throttle body duct is fully seated to

intake manifold and tighten clamp to 5 N´m (40 in.

lbs.) torque.

(d) Connect the Throttle Position Sensor (TPS)

and Idle Air Control (IAC) connectors.

(e) Connect proportional purge solenoid (PPS)

and crankcase vent hose from throttle body.

(23) Connect the battery cables.

(24) Road test vehicle and inspect for leaks.

Fig. 44 Transaxle Removal/Installation

1 ± MODULAR CLUTCH ASSEMBLY

2 ± CLIP3 ± TRANSAXLE

4 ± CLUTCH MODULE BOLT (4)

Fig. 45 Transaxle Upper Mount and Bracket

1 ± MOUNT

2 ± TRANSAXLE

PLTRANSAXLE 21 - 17

REMOVAL AND INSTALLATION (Continued)

Page 931 of 1285

DISASSEMBLY AND ASSEMBLY

TRANSAXLE

The NV T350 (A-578) transaxle internal compo-

nents can be serviced only by separating the gear

case from the bellhousing case.

CAUTION: The transaxle output shaft is serviced as

a unit. No disassembly and reassembly is possible.

Damage to the transaxle may result.

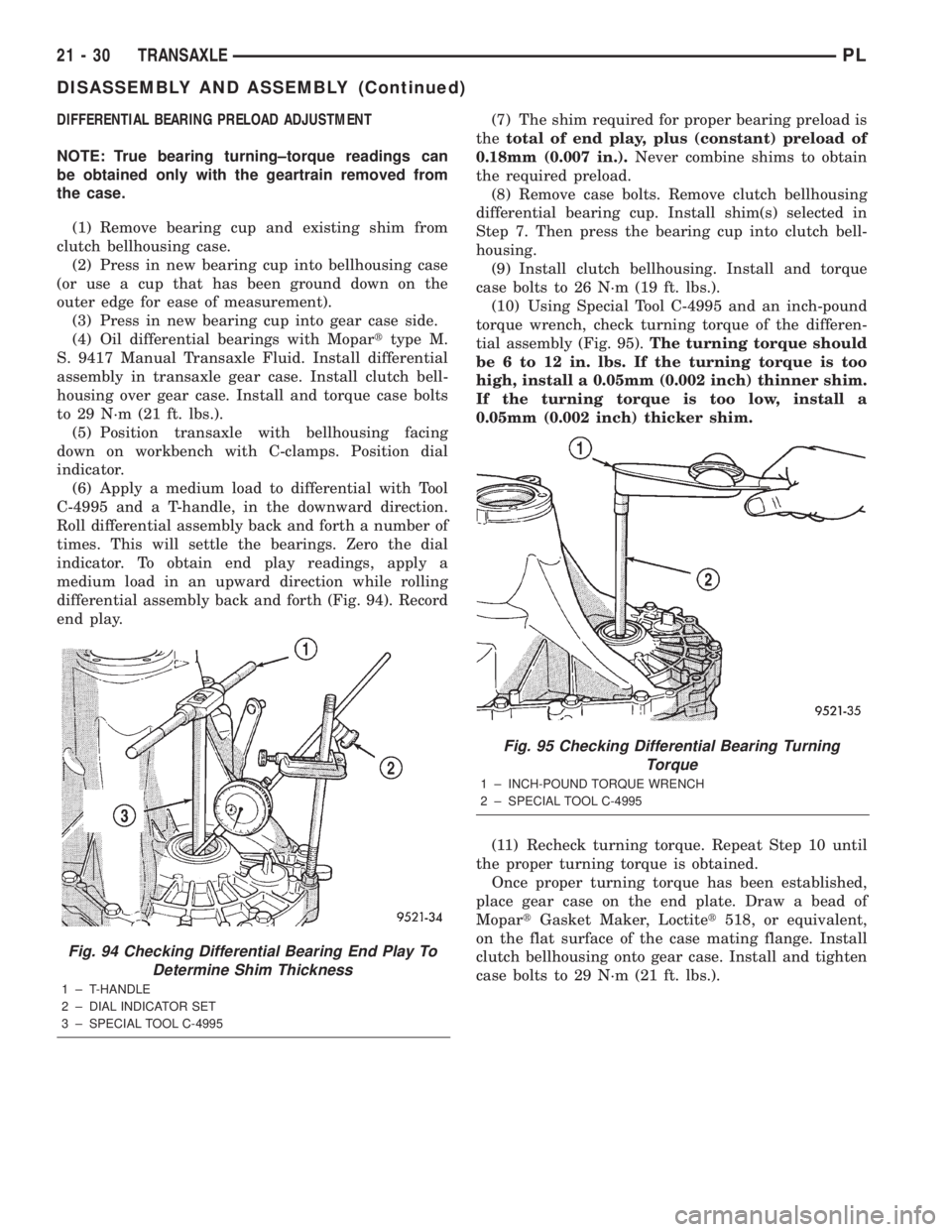

DISASSEMBLY

(1) Place transaxle on bench.

(2) Remove the clutch release bearing and fork.

Move the release fork and bearing to an in-line posi-

tion. Grasp the release lever with two hands in the

pivot stud socket area. Pull with even pressure to

release the fork from the pivot stud.

CAUTION: Do not use a screwdriver or pry bar to

release the fork as this may cause damage to the

fork and/or clip.

(3) Remove shift levers by driving out the roll pins.

(4) Remove transaxle case half bolts (Fig. 46).

(5) Place two screwdrivers into the slots provided

in the case halves near the dowels (Fig. 47). Separate

the case halves (Fig. 48).

Fig. 46 Case Bolts

1 ± CASE BOLTS

Fig. 47 Transaxle Case Halves

1 ± BELLHOUSING HALF

2 ± GEAR CASE HALF

Fig. 48 Separate Case Halves

1±PRYTOOL

2 ± CASE HALVES

3 ± PRY SLOT

21 - 18 TRANSAXLEPL

Page 943 of 1285

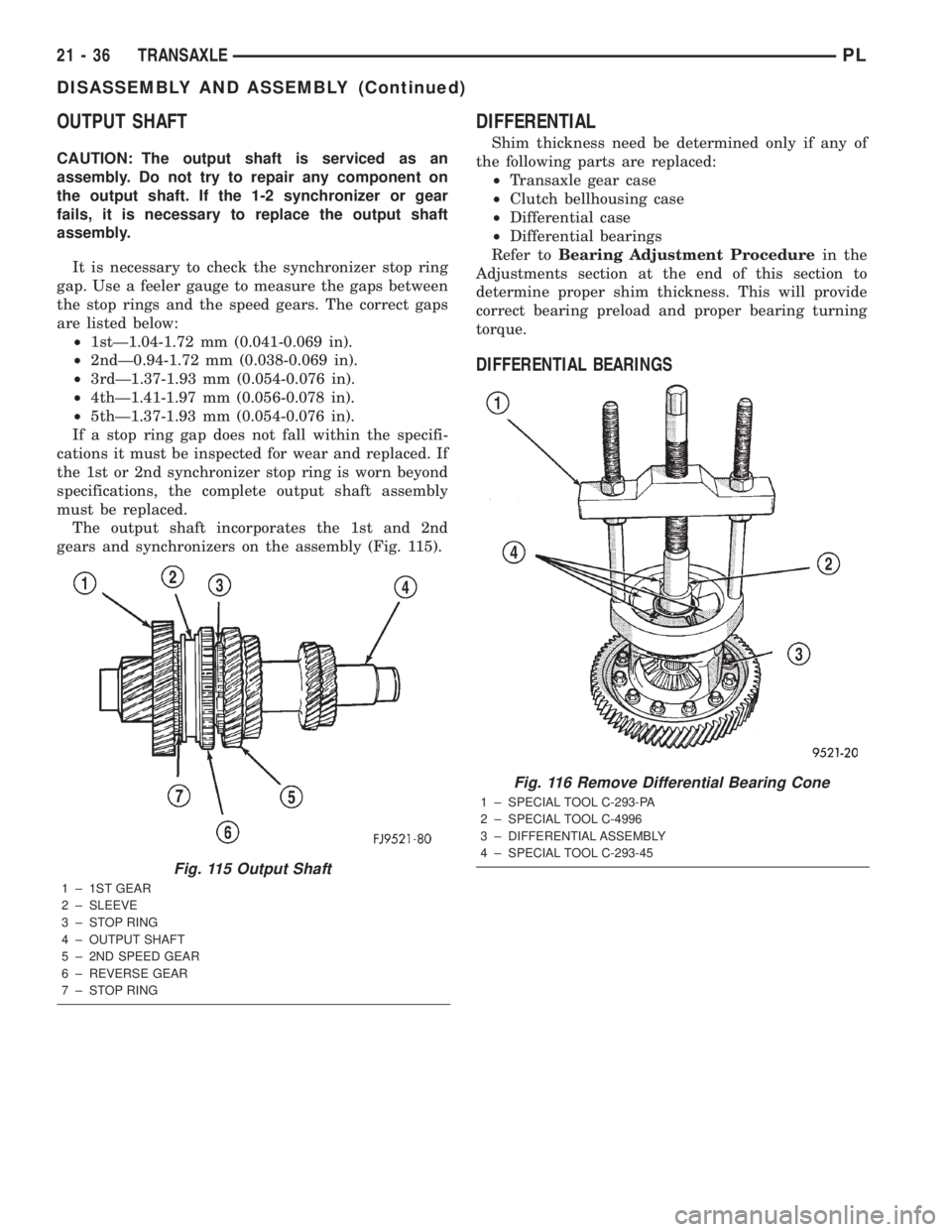

DIFFERENTIAL BEARING PRELOAD ADJUSTMENT

NOTE: True bearing turning±torque readings can

be obtained only with the geartrain removed from

the case.

(1) Remove bearing cup and existing shim from

clutch bellhousing case.

(2) Press in new bearing cup into bellhousing case

(or use a cup that has been ground down on the

outer edge for ease of measurement).

(3) Press in new bearing cup into gear case side.

(4) Oil differential bearings with Moparttype M.

S. 9417 Manual Transaxle Fluid. Install differential

assembly in transaxle gear case. Install clutch bell-

housing over gear case. Install and torque case bolts

to 29 N´m (21 ft. lbs.).

(5) Position transaxle with bellhousing facing

down on workbench with C-clamps. Position dial

indicator.

(6) Apply a medium load to differential with Tool

C-4995 and a T-handle, in the downward direction.

Roll differential assembly back and forth a number of

times. This will settle the bearings. Zero the dial

indicator. To obtain end play readings, apply a

medium load in an upward direction while rolling

differential assembly back and forth (Fig. 94). Record

end play.(7) The shim required for proper bearing preload is

thetotal of end play, plus (constant) preload of

0.18mm (0.007 in.).Never combine shims to obtain

the required preload.

(8) Remove case bolts. Remove clutch bellhousing

differential bearing cup. Install shim(s) selected in

Step 7. Then press the bearing cup into clutch bell-

housing.

(9) Install clutch bellhousing. Install and torque

case bolts to 26 N´m (19 ft. lbs.).

(10) Using Special Tool C-4995 and an inch-pound

torque wrench, check turning torque of the differen-

tial assembly (Fig. 95).The turning torque should

be 6 to 12 in. lbs. If the turning torque is too

high, install a 0.05mm (0.002 inch) thinner shim.

If the turning torque is too low, install a

0.05mm (0.002 inch) thicker shim.

(11) Recheck turning torque. Repeat Step 10 until

the proper turning torque is obtained.

Once proper turning torque has been established,

place gear case on the end plate. Draw a bead of

MopartGasket Maker, Loctitet518, or equivalent,

on the flat surface of the case mating flange. Install

clutch bellhousing onto gear case. Install and tighten

case bolts to 29 N´m (21 ft. lbs.).

Fig. 94 Checking Differential Bearing End Play To

Determine Shim Thickness

1 ± T-HANDLE

2 ± DIAL INDICATOR SET

3 ± SPECIAL TOOL C-4995

Fig. 95 Checking Differential Bearing Turning

Torque

1 ± INCH-POUND TORQUE WRENCH

2 ± SPECIAL TOOL C-4995

21 - 30 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 949 of 1285

OUTPUT SHAFT

CAUTION: The output shaft is serviced as an

assembly. Do not try to repair any component on

the output shaft. If the 1-2 synchronizer or gear

fails, it is necessary to replace the output shaft

assembly.

It is necessary to check the synchronizer stop ring

gap. Use a feeler gauge to measure the gaps between

the stop rings and the speed gears. The correct gaps

are listed below:

²1stÐ1.04-1.72 mm (0.041-0.069 in).

²2ndÐ0.94-1.72 mm (0.038-0.069 in).

²3rdÐ1.37-1.93 mm (0.054-0.076 in).

²4thÐ1.41-1.97 mm (0.056-0.078 in).

²5thÐ1.37-1.93 mm (0.054-0.076 in).

If a stop ring gap does not fall within the specifi-

cations it must be inspected for wear and replaced. If

the 1st or 2nd synchronizer stop ring is worn beyond

specifications, the complete output shaft assembly

must be replaced.

The output shaft incorporates the 1st and 2nd

gears and synchronizers on the assembly (Fig. 115).

DIFFERENTIAL

Shim thickness need be determined only if any of

the following parts are replaced:

²Transaxle gear case

²Clutch bellhousing case

²Differential case

²Differential bearings

Refer toBearing Adjustment Procedurein the

Adjustments section at the end of this section to

determine proper shim thickness. This will provide

correct bearing preload and proper bearing turning

torque.

DIFFERENTIAL BEARINGS

Fig. 115 Output Shaft

1 ± 1ST GEAR

2 ± SLEEVE

3 ± STOP RING

4 ± OUTPUT SHAFT

5 ± 2ND SPEED GEAR

6 ± REVERSE GEAR

7 ± STOP RING

Fig. 116 Remove Differential Bearing Cone

1 ± SPECIAL TOOL C-293-PA

2 ± SPECIAL TOOL C-4996

3 ± DIFFERENTIAL ASSEMBLY

4 ± SPECIAL TOOL C-293-45

21 - 36 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 955 of 1285

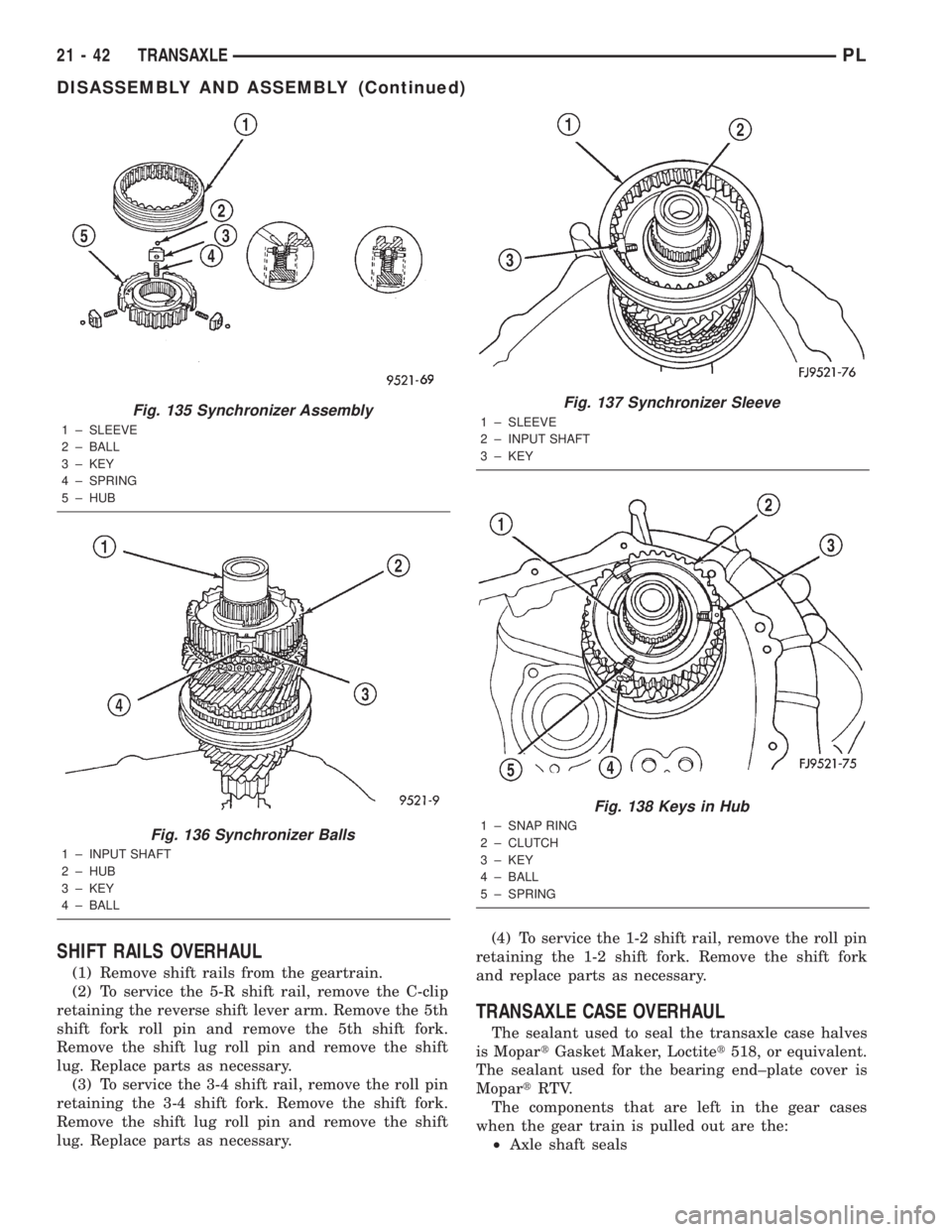

SHIFT RAILS OVERHAUL

(1) Remove shift rails from the geartrain.

(2) To service the 5-R shift rail, remove the C-clip

retaining the reverse shift lever arm. Remove the 5th

shift fork roll pin and remove the 5th shift fork.

Remove the shift lug roll pin and remove the shift

lug. Replace parts as necessary.

(3) To service the 3-4 shift rail, remove the roll pin

retaining the 3-4 shift fork. Remove the shift fork.

Remove the shift lug roll pin and remove the shift

lug. Replace parts as necessary.(4) To service the 1-2 shift rail, remove the roll pin

retaining the 1-2 shift fork. Remove the shift fork

and replace parts as necessary.

TRANSAXLE CASE OVERHAUL

The sealant used to seal the transaxle case halves

is MopartGasket Maker, Loctitet518, or equivalent.

The sealant used for the bearing end±plate cover is

MopartRTV.

The components that are left in the gear cases

when the gear train is pulled out are the:

²Axle shaft seals

Fig. 135 Synchronizer Assembly

1 ± SLEEVE

2 ± BALL

3 ± KEY

4 ± SPRING

5 ± HUB

Fig. 136 Synchronizer Balls

1 ± INPUT SHAFT

2 ± HUB

3 ± KEY

4 ± BALL

Fig. 137 Synchronizer Sleeve

1 ± SLEEVE

2 ± INPUT SHAFT

3 ± KEY

Fig. 138 Keys in Hub

1 ± SNAP RING

2 ± CLUTCH

3 ± KEY

4 ± BALL

5 ± SPRING

21 - 42 TRANSAXLEPL

DISASSEMBLY AND ASSEMBLY (Continued)

Page 958 of 1285

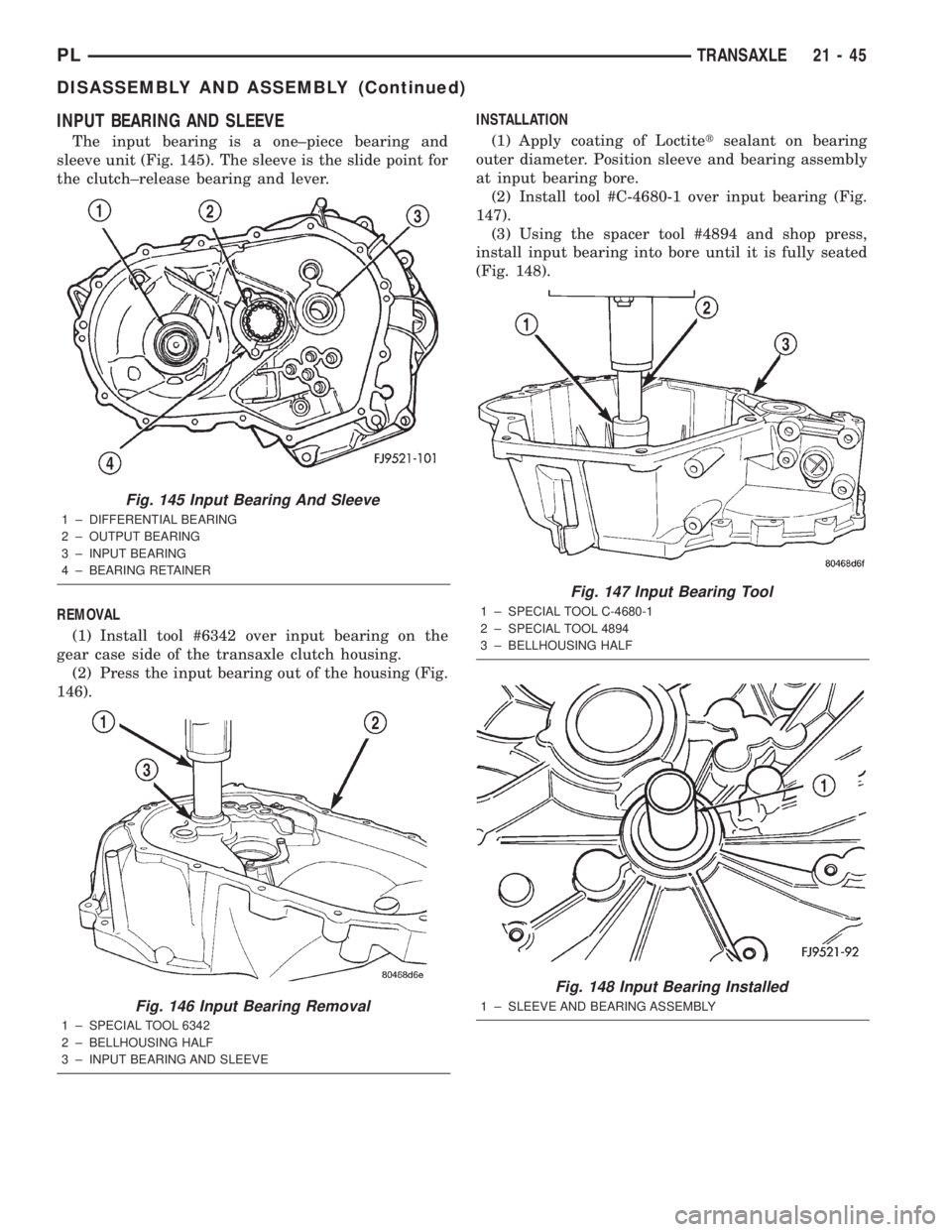

INPUT BEARING AND SLEEVE

The input bearing is a one±piece bearing and

sleeve unit (Fig. 145). The sleeve is the slide point for

the clutch±release bearing and lever.

REMOVAL

(1) Install tool #6342 over input bearing on the

gear case side of the transaxle clutch housing.

(2) Press the input bearing out of the housing (Fig.

146).INSTALLATION

(1) Apply coating of Loctitetsealant on bearing

outer diameter. Position sleeve and bearing assembly

at input bearing bore.

(2) Install tool #C-4680-1 over input bearing (Fig.

147).

(3) Using the spacer tool #4894 and shop press,

install input bearing into bore until it is fully seated

(Fig. 148).

Fig. 145 Input Bearing And Sleeve

1 ± DIFFERENTIAL BEARING

2 ± OUTPUT BEARING

3 ± INPUT BEARING

4 ± BEARING RETAINER

Fig. 146 Input Bearing Removal

1 ± SPECIAL TOOL 6342

2 ± BELLHOUSING HALF

3 ± INPUT BEARING AND SLEEVE

Fig. 147 Input Bearing Tool

1 ± SPECIAL TOOL C-4680-1

2 ± SPECIAL TOOL 4894

3 ± BELLHOUSING HALF

Fig. 148 Input Bearing Installed

1 ± SLEEVE AND BEARING ASSEMBLY

PLTRANSAXLE 21 - 45

DISASSEMBLY AND ASSEMBLY (Continued)