warning DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 731 of 1285

ENGINE DIAGNOSIS

TABLE OF CONTENTS

page page

DIAGNOSIS AND TESTING

GENERAL INFORMATION...................8

INTAKE MANIFOLD LEAKAGE DIAGNOSIS......8

CYLINDER COMPRESSION PRESSURE TEST . . . 8

CYLINDER COMBUSTION PRESSURE

LEAKAGE TEST.........................9LASH ADJUSTER (TAPPET) NOISE

DIAGNOSIS............................9

ENGINE OIL LEAK INSPECTION..............9

ENGINE DIAGNOSISÐPERFORMANCE........11

ENGINE DIAGNOSISÐMECHANICAL.........12

DIAGNOSIS AND TESTING

GENERAL INFORMATION

Engine diagnosis is helpful in determining the

causes of malfunctions not detected and remedied by

routine maintenance.

These malfunctions may be classified as either

mechanical (e.g., a strange noise), or performance

(e.g., engine idles rough and stalls).

Refer to the Service DiagnosisÐMechanical Chart

and the Service DiagnosisÐPerformance Chart, for

possible causes and corrections of malfunctions. Refer

to Group 14, Fuel System, for the fuel system diag-

nosis.

Additional tests and diagnostic procedures may be

necessary for specific engine malfunctions that can-

not be isolated with the Service Diagnosis charts.

Information concerning additional tests and diagno-

sis is provided within the following:

²Cylinder Compression Pressure Test

²Cylinder Combustion Pressure Leakage Test

²Engine Cylinder Head Gasket Failure Diagnosis

²Intake Manifold Leakage Diagnosis

INTAKE MANIFOLD LEAKAGE DIAGNOSIS

An intake manifold air leak is characterized by

lower than normal manifold vacuum. Also, one or

more cylinders may not be functioning.

WARNING: USE EXTREME CAUTION WHEN THE

ENGINE IS OPERATING. DO NOT STAND IN A

DIRECT LINE WITH THE FAN. DO NOT PUT YOUR

HANDS NEAR THE PULLEYS, BELTS OR THE FAN.

DO NOT WEAR LOOSE CLOTHING.

(1) Start the engine.

(2) Spray a small stream of water (Spray Bottle) at

the suspected leak area.

(3) If engine RPM'S change, the area of the sus-

pected leak has been found.

(4) Repair as required.

CYLINDER COMPRESSION PRESSURE TEST

The results of a cylinder compression pressure test

can be utilized to diagnose several engine malfunc-

tions.

Ensure the battery is completely charged and the

engine starter motor is in good operating condition.

Otherwise the indicated compression pressures may

not be valid for diagnosis purposes.

(1) Check engine oil level and add oil if necessary.

(2) Drive the vehicle until engine reaches normal

operating temperature. Select a route free from traf-

fic and other forms of congestion, observe all traffic

laws, and accelerate through the gears several times

briskly.

(3) Remove all spark plugs from engine. As spark

plugs are being removed, check electrodes for abnor-

mal firing indicators fouled, hot, oily, etc. Record cyl-

inder number of spark plug for future reference.

(4) Disconnect coil wire from distributor and

secure to good ground to prevent a spark from start-

ing a fire (Conventional Ignition System). For Direct

Ignition System DIS disconnect the coil connector.

(5) Be sure throttle blade is fully open during the

compression check.

(6) Insert compression gage adaptor into the #1

spark plug hole in cylinder head. Crank engine until

maximum pressure is reached on gage. Record this

pressure as #1 cylinder pressure.

(7) Repeat the previous step for all remaining cyl-

inders.

(8) Compression should not be less than (689 kPa)

100 psi and not vary more than 25 percent from cyl-

inder to cylinder.

(9) If one or more cylinders have abnormally low

compression pressures, repeat the compression test.

(10) If the same cylinder or cylinders repeat an

abnormally low reading on the second compression

test, it could indicate the existence of a problem in

the cylinder in question.The recommended com-

pression pressures are to be used only as a

guide to diagnosing engine problems. An engine

9 - 8 ENGINEPL

Page 732 of 1285

should not be disassembled to determine the

cause of low compression unless some malfunc-

tion is present.

(11) Clean or replace spark plugs as necessary and

adjust gap as specified in Group 8, Electrical.

Tighten to specifications.

(12) Test resistance of spark plug cables. Refer to

Group 8, Electrical Ignition System Secondary Cir-

cuit Inspection.

(13) Test coil output voltage, primary and second-

ary resistance. Replace parts as necessary. Refer to

Group 8, Electrical Ignition System.

(14) Check fuel pump pressure at idle and differ-

ent RPM ranges. Refer to Group 14, Fuel System for

Specifications.

(15) The air filter elements should be replaced as

specified in Group 0, Lubrication and Maintenance.

(16) Inspect crankcase ventilation system as out

lined in Group 0, Lubrication and Maintenance. For

emission controls see Group 25, Emission Controls

for service procedures.

(17) Inspect and adjust accessory belt drives refer-

ring to Group 7, Cooling System, Accessory Drive

Belts for proper adjustments.

(18) Road test vehicle as a final test.

CYLINDER COMBUSTION PRESSURE LEAKAGE

TEST

The combustion pressure leakage test provides an

accurate means for determining engine condition.

Combustion pressure leakage testing will detect:

²Exhaust and intake valve leaks (improper seat-

ing).

²Leaks between adjacent cylinders or into water

jacket.

²Any causes for combustion/compression pressure

loss.

WARNING: DO NOT REMOVE THE RADIATOR CAP

WITH THE SYSTEM HOT AND UNDER PRESSURE

BECAUSE SERIOUS BURNS FROM COOLANT CAN

OCCUR.

Check the coolant level and fill as required. DO

NOT install the radiator cap.

Start and operate the engine until it attains nor-

mal operating temperature, then turn the engine

OFF.

Clean spark plug recesses with compressed air.

Remove the spark plugs.

Remove the oil filler cap.

Remove the air cleaner.

Calibrate the tester according to the manufactur-

er's instructions. The shop air source for testing

should maintain 483 kPa (70 psi) minimum, 1,379kPa (200 psi) maximum, with 552 kPa (80 psi) rec-

ommended.

Perform the test procedures on each cylinder

according to the tester manufacturer's instructions.

While testing, listen for pressurized air escaping

through the throttle body, tailpipe and oil filler cap

opening. Check for bubbles in the radiator coolant.

All gauge pressure indications should be equal,

with no more than 25% leakage per cylinder.

FOR EXAMPLE:At 552 kPa (80 psi) input pres-

sure, a minimum of 414 kPa (60 psi) should be main-

tained in the cylinder.

LASH ADJUSTER (TAPPET) NOISE DIAGNOSIS

A tappet-like noise may be produced from several

items. Check the following items.

(1) Engine oil level too high or too low. This may

cause aerated oil to enter the adjusters and cause

them to be spongy.

(2) Insufficient running time after rebuilding cylin-

der head. Low speed running up to 1 hour may be

required.

(3) During this time, turn engine off and let set for

a few minutes before restarting. Repeat this several

times after engine has reached normal operating

temperature.

(4) Low oil pressure.

(5) The oil restrictor pressed into the vertical oil

passage to the cylinder head is plugged with debris.

(6) Air ingested into oil due to broken or cracked

oil pump pick up.

(7) Worn valve guides.

(8) Rocker arm ears contacting valve spring

retainer.

(9) Rocker arm loose, adjuster stuck or at maxi-

mum extension and still leaves lash in the system.

(10) Faulty lash adjuster.

a. Check lash adjusters for sponginess while

installed in cylinder head. Depress part of rocker

arm over adjuster. Normal adjusters should feel very

firm. Spongy adjusters can be bottomed out easily.

b. Remove suspected rocker arms (sohc) or lash

adjuster (dohc) and replace.

ENGINE OIL LEAK INSPECTION

Begin with a thorough visual inspection of the

engine, particularly at the area of the suspected leak.

If an oil leak source is not readily identifiable, the

following steps should be followed:

(1) Do not clean or degrease the engine at this

time because some solvents may cause rubber to

swell, temporarily stopping the leak.

(2) Add an oil soluble dye (use as recommended by

manufacturer). Start the engine and let idle for

approximately 15 minutes. Check the oil dipstick to

PLENGINE 9 - 9

DIAGNOSIS AND TESTING (Continued)

Page 749 of 1285

(4) Discharge air conditioning system, if equipped.

Refer to Group 24, Heating and Air Conditioning for

procedure.

(5) Disconnect the following: air intake duct at

intake manifold, throttle cables, electrical connectors

from throttle body and air cleaner housing.

(6) Remove air cleaner housing assembly.

(7) Remove upper radiator hose and fan module.

Refer to Group 7, Cooling System for procedure.

(8) Remove lower radiator hose.

(9) Disconnect automatic transmission cooler lines

and plug, if equipped.

(10) Disconnect shift linkage, electrical connectors,

and clutch cable, if equipped with manual transaxle.

(11) Disconnect engine wiring harness.

(12) Disconnect positive cable from Power Distri-

bution Center (PDC) and ground wire from vehicle

body.

(13) Disconnect ground wire from the vehicle body-

to-engine at the right side strut tower.

(14) Disconnect heater hoses.

(15) Disconnect vacuum hose from brake booster.

(16) Disconnect coolant reserve/recovery hose.

(17) Remove accessory drive belts. Refer to Group

7, Cooling System for procedure.

(18) Remove power steering pump and reservoir

and set them aside.

(19) Hoist vehicle and remove right inner splash

shield.

(20) Drain engine oil.

(21) Remove front wheels.

(22) Remove axle shafts. Refer to Group 3, Differ-

ential and Driveline for procedure.

(23) Disconnect exhaust system from manifold.

(24) Disconnect the downstream oxygen sensor

connector.

(25) Remove lower engine torque strut.

(26) Remove structural collar. Refer to procedure

in this section.

(27) Lower vehicle and remove A/C compressor.

(28) Raise vehicle enough to allow engine dolly

and cradle, Special Tools 6135 and 6710 to be

installed under vehicle.

(29) Loosen engine support posts to allow move-

ment for positioning onto engine locating holes and

flange on the engine bedplate. Lower vehicle and

position cradle until the engine is resting on support

posts (Fig. 26). Tighten mounts to cradle frame. This

will keep support posts from moving when removing

or installing engine and transmission.

(30) Install safety straps around the engine to cra-

dle (Fig. 26). Tighten straps and lock them into posi-

tion.

WARNING: Safety straps MUST be used.(31) Raise vehicle enough to see if straps are tight

enough to hold cradle assembly to engine.

(32) Lower vehicle so weight of the engine and

transmission ONLY is on the cradle assembly.

(33) Remove the upper engine torque strut.

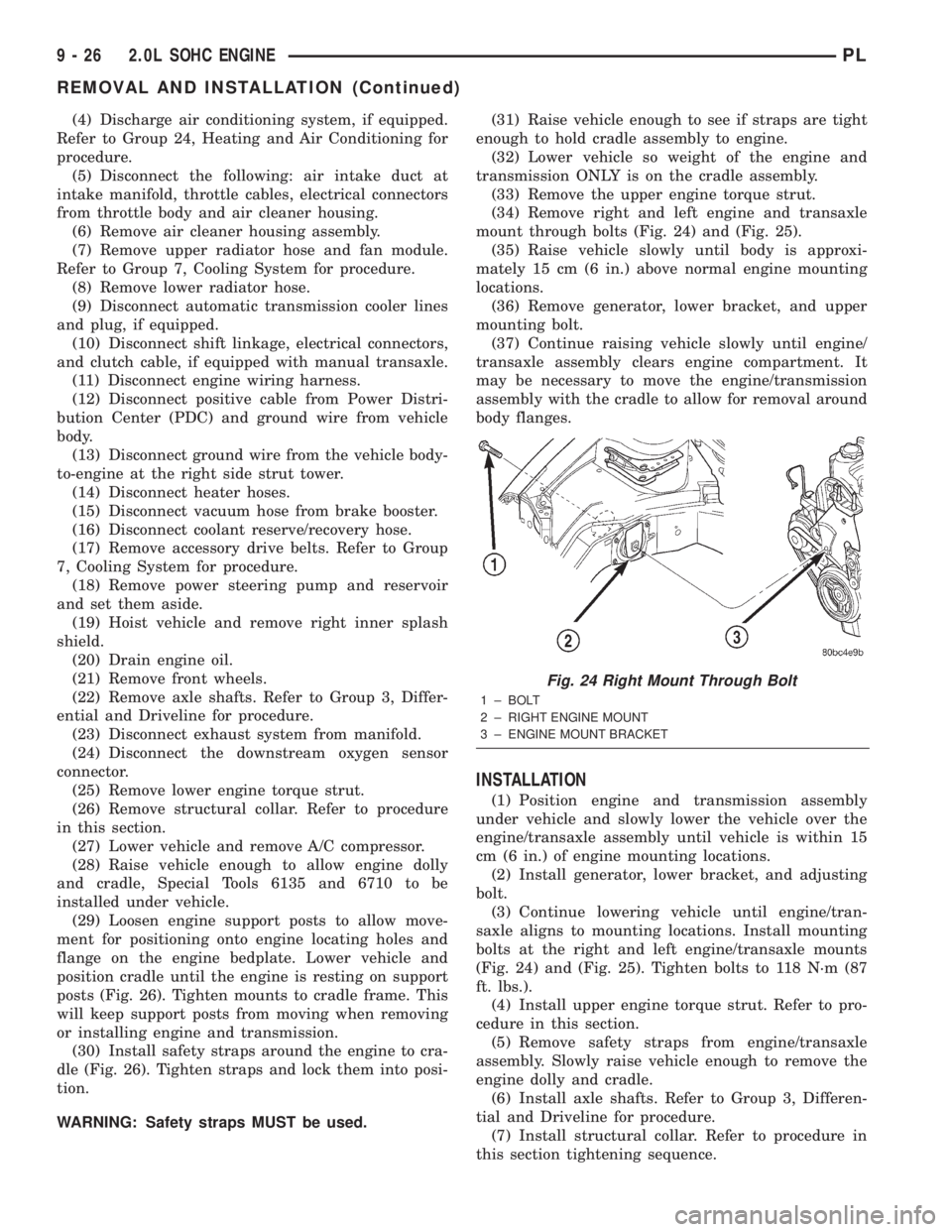

(34) Remove right and left engine and transaxle

mount through bolts (Fig. 24) and (Fig. 25).

(35) Raise vehicle slowly until body is approxi-

mately 15 cm (6 in.) above normal engine mounting

locations.

(36) Remove generator, lower bracket, and upper

mounting bolt.

(37) Continue raising vehicle slowly until engine/

transaxle assembly clears engine compartment. It

may be necessary to move the engine/transmission

assembly with the cradle to allow for removal around

body flanges.

INSTALLATION

(1) Position engine and transmission assembly

under vehicle and slowly lower the vehicle over the

engine/transaxle assembly until vehicle is within 15

cm (6 in.) of engine mounting locations.

(2) Install generator, lower bracket, and adjusting

bolt.

(3) Continue lowering vehicle until engine/tran-

saxle aligns to mounting locations. Install mounting

bolts at the right and left engine/transaxle mounts

(Fig. 24) and (Fig. 25). Tighten bolts to 118 N´m (87

ft. lbs.).

(4) Install upper engine torque strut. Refer to pro-

cedure in this section.

(5) Remove safety straps from engine/transaxle

assembly. Slowly raise vehicle enough to remove the

engine dolly and cradle.

(6) Install axle shafts. Refer to Group 3, Differen-

tial and Driveline for procedure.

(7) Install structural collar. Refer to procedure in

this section tightening sequence.

Fig. 24 Right Mount Through Bolt

1 ± BOLT

2 ± RIGHT ENGINE MOUNT

3 ± ENGINE MOUNT BRACKET

9 - 26 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 751 of 1285

(27) Start engine and run until operating temper-

ature is reached.

(28) Ensure engine is properly positioned. Refer to

Torque Struts in this section for adjustment proce-

dure.

(29) Adjust transmission linkage, if necessary.

INTAKE MANIFOLD

REMOVAL

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Disconnect negative cable from battery.

(2) Remove the inlet air duct from intake manifold

to throttle body.

(3) Perform fuel system pressure release procedure

before attempting any repairs.Refer to Group 14,

Fuel System for procedures.

WARNING: WRAP SHOP TOWELS AROUND FUEL

HOSE TO CATCH ANY GASOLINE SPILLAGE

(4) Disconnect fuel supply line quick connect at the

fuel tube assembly. Refer to Group 14, Fuel System

for procedures.

(5) Remove fuel rail assembly attaching screws

and remove fuel rail assembly from engine. Cover

injector holes with suitable covering.

CAUTION: Do not set fuel injectors on their tips,

damage may occur to the injectors

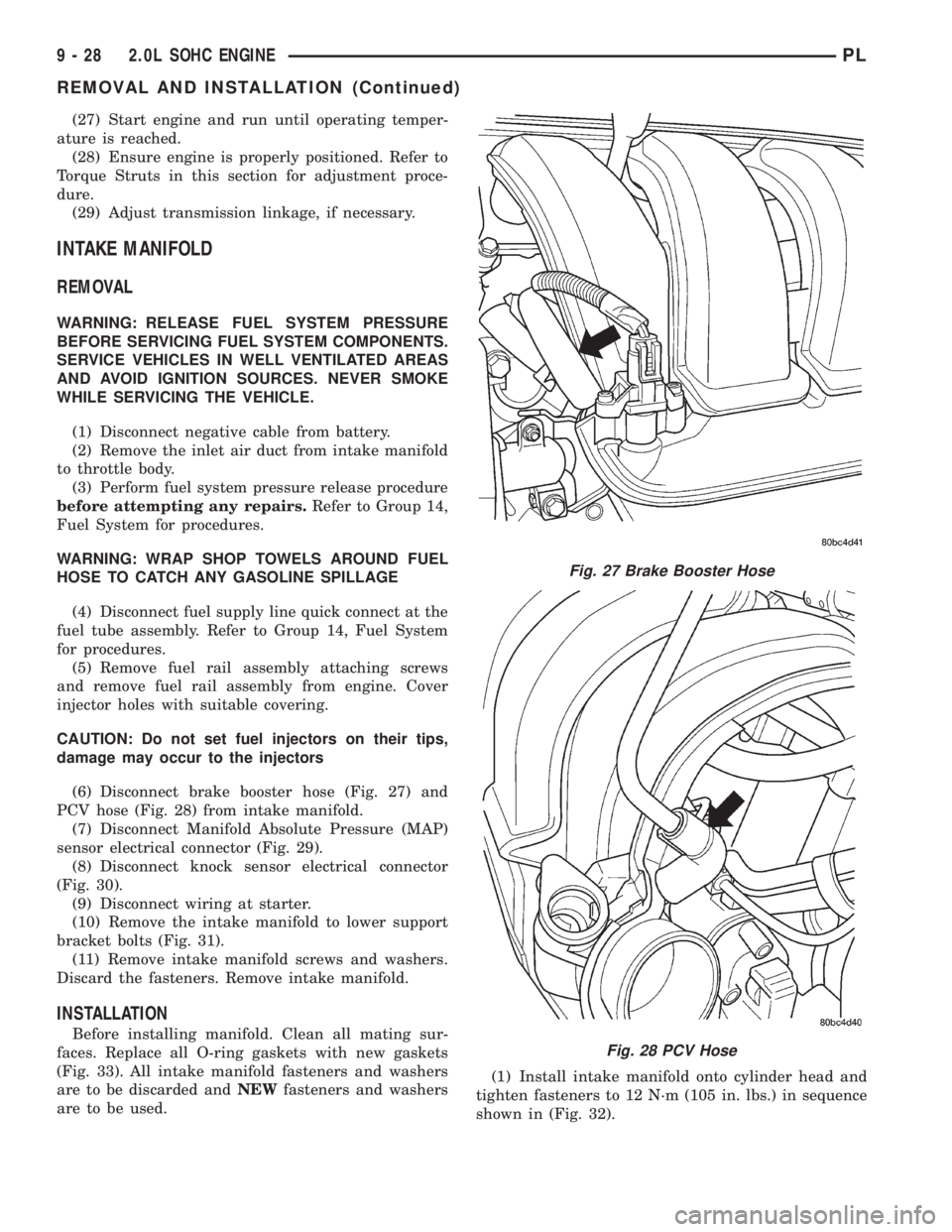

(6) Disconnect brake booster hose (Fig. 27) and

PCV hose (Fig. 28) from intake manifold.

(7) Disconnect Manifold Absolute Pressure (MAP)

sensor electrical connector (Fig. 29).

(8) Disconnect knock sensor electrical connector

(Fig. 30).

(9) Disconnect wiring at starter.

(10) Remove the intake manifold to lower support

bracket bolts (Fig. 31).

(11) Remove intake manifold screws and washers.

Discard the fasteners. Remove intake manifold.

INSTALLATION

Before installing manifold. Clean all mating sur-

faces. Replace all O-ring gaskets with new gaskets

(Fig. 33). All intake manifold fasteners and washers

are to be discarded andNEWfasteners and washers

are to be used.(1) Install intake manifold onto cylinder head and

tighten fasteners to 12 N´m (105 in. lbs.) in sequence

shown in (Fig. 32).

Fig. 27 Brake Booster Hose

Fig. 28 PCV Hose

9 - 28 2.0L SOHC ENGINEPL

REMOVAL AND INSTALLATION (Continued)

Page 801 of 1285

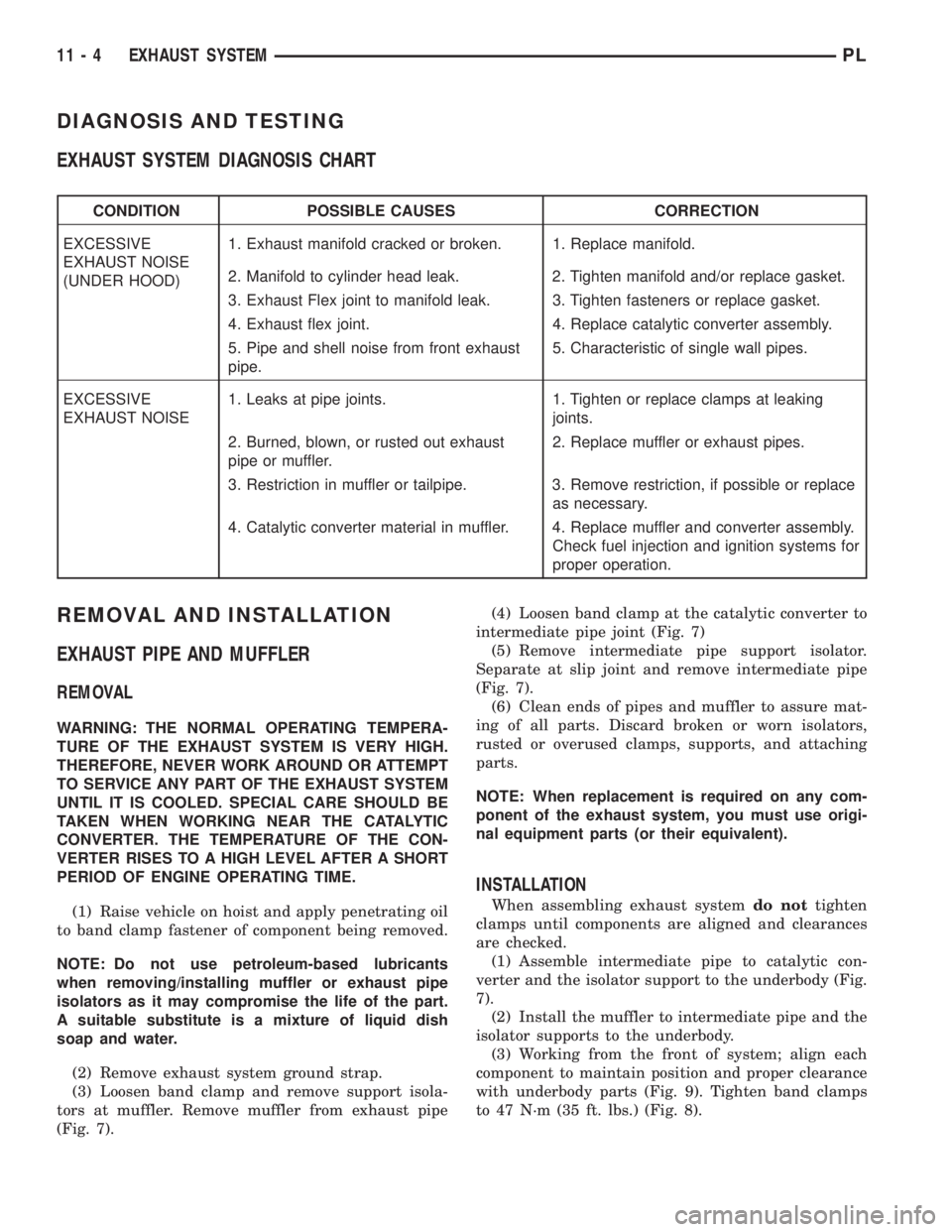

DIAGNOSIS AND TESTING

EXHAUST SYSTEM DIAGNOSIS CHART

CONDITION POSSIBLE CAUSES CORRECTION

EXCESSIVE

EXHAUST NOISE

(UNDER HOOD)1. Exhaust manifold cracked or broken. 1. Replace manifold.

2. Manifold to cylinder head leak. 2. Tighten manifold and/or replace gasket.

3. Exhaust Flex joint to manifold leak. 3. Tighten fasteners or replace gasket.

4. Exhaust flex joint. 4. Replace catalytic converter assembly.

5. Pipe and shell noise from front exhaust

pipe.5. Characteristic of single wall pipes.

EXCESSIVE

EXHAUST NOISE1. Leaks at pipe joints. 1. Tighten or replace clamps at leaking

joints.

2. Burned, blown, or rusted out exhaust

pipe or muffler.2. Replace muffler or exhaust pipes.

3. Restriction in muffler or tailpipe. 3. Remove restriction, if possible or replace

as necessary.

4. Catalytic converter material in muffler. 4. Replace muffler and converter assembly.

Check fuel injection and ignition systems for

proper operation.

REMOVAL AND INSTALLATION

EXHAUST PIPE AND MUFFLER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER WORK AROUND OR ATTEMPT

TO SERVICE ANY PART OF THE EXHAUST SYSTEM

UNTIL IT IS COOLED. SPECIAL CARE SHOULD BE

TAKEN WHEN WORKING NEAR THE CATALYTIC

CONVERTER. THE TEMPERATURE OF THE CON-

VERTER RISES TO A HIGH LEVEL AFTER A SHORT

PERIOD OF ENGINE OPERATING TIME.

(1) Raise vehicle on hoist and apply penetrating oil

to band clamp fastener of component being removed.

NOTE: Do not use petroleum-based lubricants

when removing/installing muffler or exhaust pipe

isolators as it may compromise the life of the part.

A suitable substitute is a mixture of liquid dish

soap and water.

(2) Remove exhaust system ground strap.

(3) Loosen band clamp and remove support isola-

tors at muffler. Remove muffler from exhaust pipe

(Fig. 7).(4) Loosen band clamp at the catalytic converter to

intermediate pipe joint (Fig. 7)

(5) Remove intermediate pipe support isolator.

Separate at slip joint and remove intermediate pipe

(Fig. 7).

(6) Clean ends of pipes and muffler to assure mat-

ing of all parts. Discard broken or worn isolators,

rusted or overused clamps, supports, and attaching

parts.

NOTE: When replacement is required on any com-

ponent of the exhaust system, you must use origi-

nal equipment parts (or their equivalent).

INSTALLATION

When assembling exhaust systemdo nottighten

clamps until components are aligned and clearances

are checked.

(1) Assemble intermediate pipe to catalytic con-

verter and the isolator support to the underbody (Fig.

7).

(2) Install the muffler to intermediate pipe and the

isolator supports to the underbody.

(3) Working from the front of system; align each

component to maintain position and proper clearance

with underbody parts (Fig. 9). Tighten band clamps

to 47 N´m (35 ft. lbs.) (Fig. 8).

11 - 4 EXHAUST SYSTEMPL

Page 804 of 1285

CATALYTIC CONVERTER

REMOVAL

WARNING: THE NORMAL OPERATING TEMPERA-

TURE OF THE EXHAUST SYSTEM IS VERY HIGH.

THEREFORE, NEVER ATTEMPT TO SERVICE ANY

PART OF THE EXHAUST SYSTEM UNTIL IT IS

COOLED. SPECIAL CARE SHOULD BE TAKEN

WHEN WORKING NEAR THE CATALYTIC CON-

VERTER. THE TEMPERATURE OF THE CONVERTER

RISES TO A HIGH LEVEL AFTER A SHORT PERIOD

OF ENGINE OPERATION TIME.

NOTE: Vehicles equipped with the ULEV emission

package are equipped with an additional catalytic

converter that is integral to the exhaust manifold.

Refer to Exhaust Manifold in Group 9, Engine for

procedure.

(1) Remove muffler and exhaust pipe. Refer to pro-

cedure in this section.

(2) Disconnect downstream oxygen sensor electri-

cal connector.

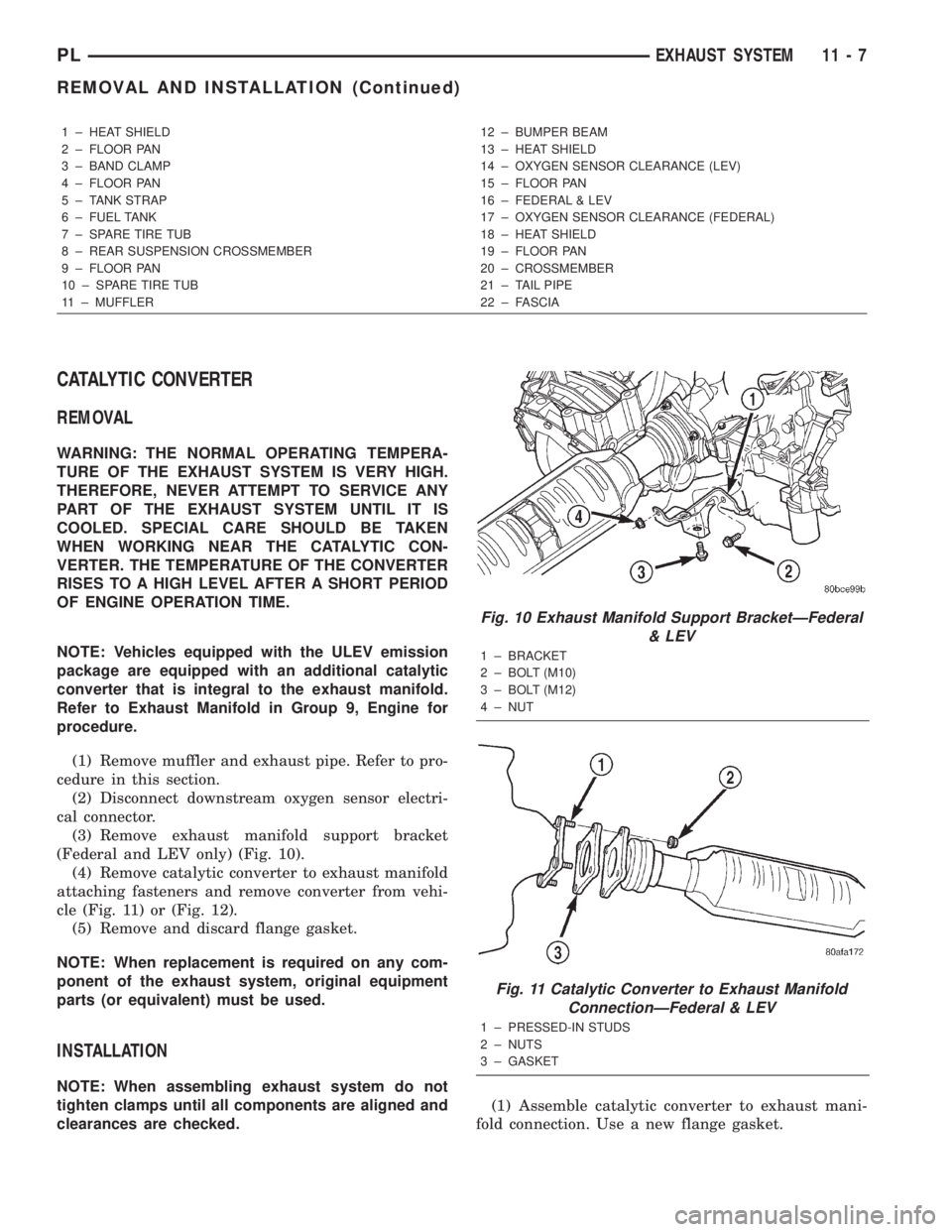

(3) Remove exhaust manifold support bracket

(Federal and LEV only) (Fig. 10).

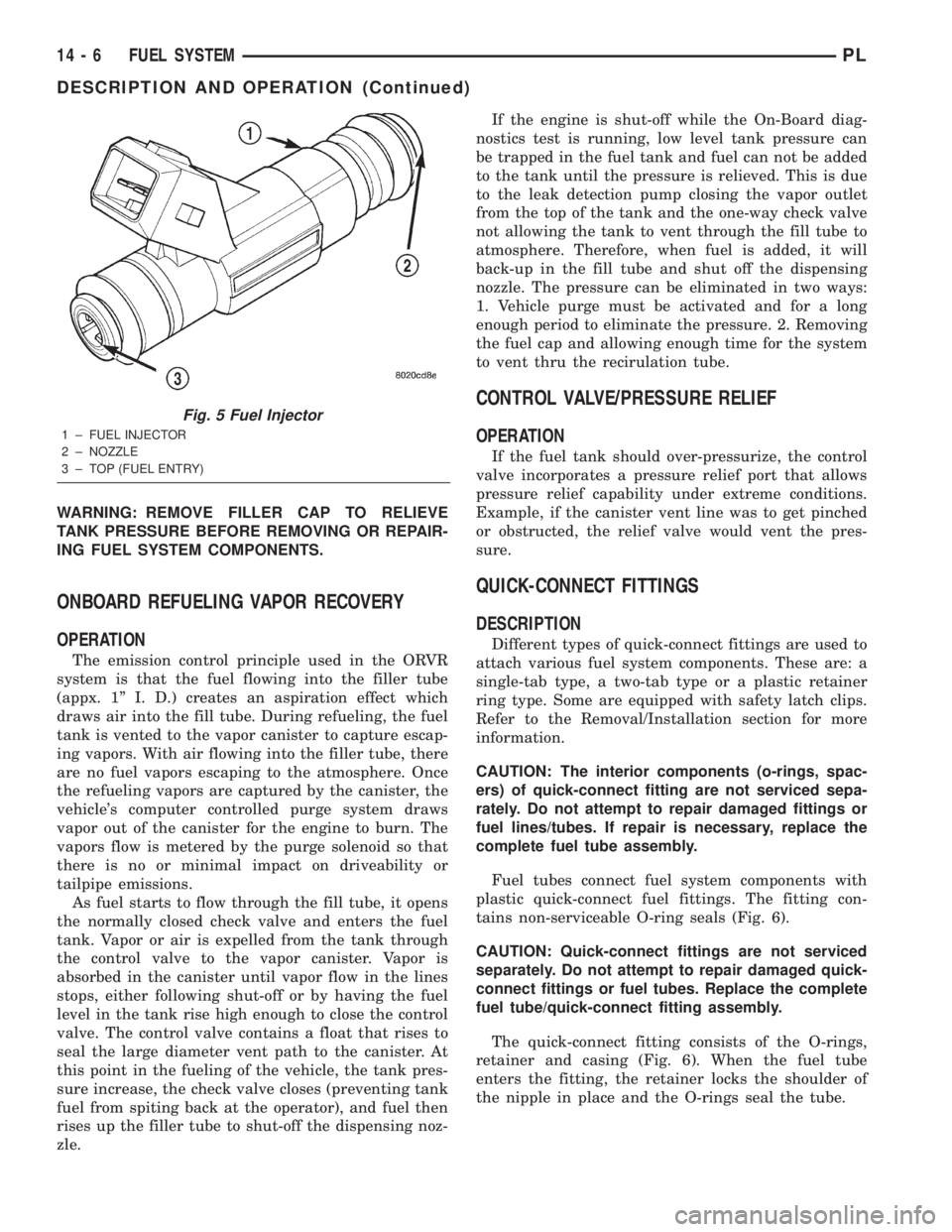

(4) Remove catalytic converter to exhaust manifold

attaching fasteners and remove converter from vehi-

cle (Fig. 11) or (Fig. 12).

(5) Remove and discard flange gasket.

NOTE: When replacement is required on any com-

ponent of the exhaust system, original equipment

parts (or equivalent) must be used.

INSTALLATION

NOTE: When assembling exhaust system do not

tighten clamps until all components are aligned and

clearances are checked.(1) Assemble catalytic converter to exhaust mani-

fold connection. Use a new flange gasket.

1 ± HEAT SHIELD

2 ± FLOOR PAN

3 ± BAND CLAMP

4 ± FLOOR PAN

5 ± TANK STRAP

6 ± FUEL TANK

7 ± SPARE TIRE TUB

8 ± REAR SUSPENSION CROSSMEMBER

9 ± FLOOR PAN

10 ± SPARE TIRE TUB

11 ± MUFFLER12 ± BUMPER BEAM

13 ± HEAT SHIELD

14 ± OXYGEN SENSOR CLEARANCE (LEV)

15 ± FLOOR PAN

16 ± FEDERAL & LEV

17 ± OXYGEN SENSOR CLEARANCE (FEDERAL)

18 ± HEAT SHIELD

19 ± FLOOR PAN

20 ± CROSSMEMBER

21 ± TAIL PIPE

22 ± FASCIA

Fig. 10 Exhaust Manifold Support BracketÐFederal

& LEV

1 ± BRACKET

2 ± BOLT (M10)

3 ± BOLT (M12)

4 ± NUT

Fig. 11 Catalytic Converter to Exhaust Manifold

ConnectionÐFederal & LEV

1 ± PRESSED-IN STUDS

2 ± NUTS

3 ± GASKET

PLEXHAUST SYSTEM 11 - 7

REMOVAL AND INSTALLATION (Continued)

Page 827 of 1285

WARNING: REMOVE FILLER CAP TO RELIEVE

TANK PRESSURE BEFORE REMOVING OR REPAIR-

ING FUEL SYSTEM COMPONENTS.

ONBOARD REFUELING VAPOR RECOVERY

OPERATION

The emission control principle used in the ORVR

system is that the fuel flowing into the filler tube

(appx. 1º I. D.) creates an aspiration effect which

draws air into the fill tube. During refueling, the fuel

tank is vented to the vapor canister to capture escap-

ing vapors. With air flowing into the filler tube, there

are no fuel vapors escaping to the atmosphere. Once

the refueling vapors are captured by the canister, the

vehicle's computer controlled purge system draws

vapor out of the canister for the engine to burn. The

vapors flow is metered by the purge solenoid so that

there is no or minimal impact on driveability or

tailpipe emissions.

As fuel starts to flow through the fill tube, it opens

the normally closed check valve and enters the fuel

tank. Vapor or air is expelled from the tank through

the control valve to the vapor canister. Vapor is

absorbed in the canister until vapor flow in the lines

stops, either following shut-off or by having the fuel

level in the tank rise high enough to close the control

valve. The control valve contains a float that rises to

seal the large diameter vent path to the canister. At

this point in the fueling of the vehicle, the tank pres-

sure increase, the check valve closes (preventing tank

fuel from spiting back at the operator), and fuel then

rises up the filler tube to shut-off the dispensing noz-

zle.If the engine is shut-off while the On-Board diag-

nostics test is running, low level tank pressure can

be trapped in the fuel tank and fuel can not be added

to the tank until the pressure is relieved. This is due

to the leak detection pump closing the vapor outlet

from the top of the tank and the one-way check valve

not allowing the tank to vent through the fill tube to

atmosphere. Therefore, when fuel is added, it will

back-up in the fill tube and shut off the dispensing

nozzle. The pressure can be eliminated in two ways:

1. Vehicle purge must be activated and for a long

enough period to eliminate the pressure. 2. Removing

the fuel cap and allowing enough time for the system

to vent thru the recirulation tube.

CONTROL VALVE/PRESSURE RELIEF

OPERATION

If the fuel tank should over-pressurize, the control

valve incorporates a pressure relief port that allows

pressure relief capability under extreme conditions.

Example, if the canister vent line was to get pinched

or obstructed, the relief valve would vent the pres-

sure.

QUICK-CONNECT FITTINGS

DESCRIPTION

Different types of quick-connect fittings are used to

attach various fuel system components. These are: a

single-tab type, a two-tab type or a plastic retainer

ring type. Some are equipped with safety latch clips.

Refer to the Removal/Installation section for more

information.

CAUTION: The interior components (o-rings, spac-

ers) of quick-connect fitting are not serviced sepa-

rately. Do not attempt to repair damaged fittings or

fuel lines/tubes. If repair is necessary, replace the

complete fuel tube assembly.

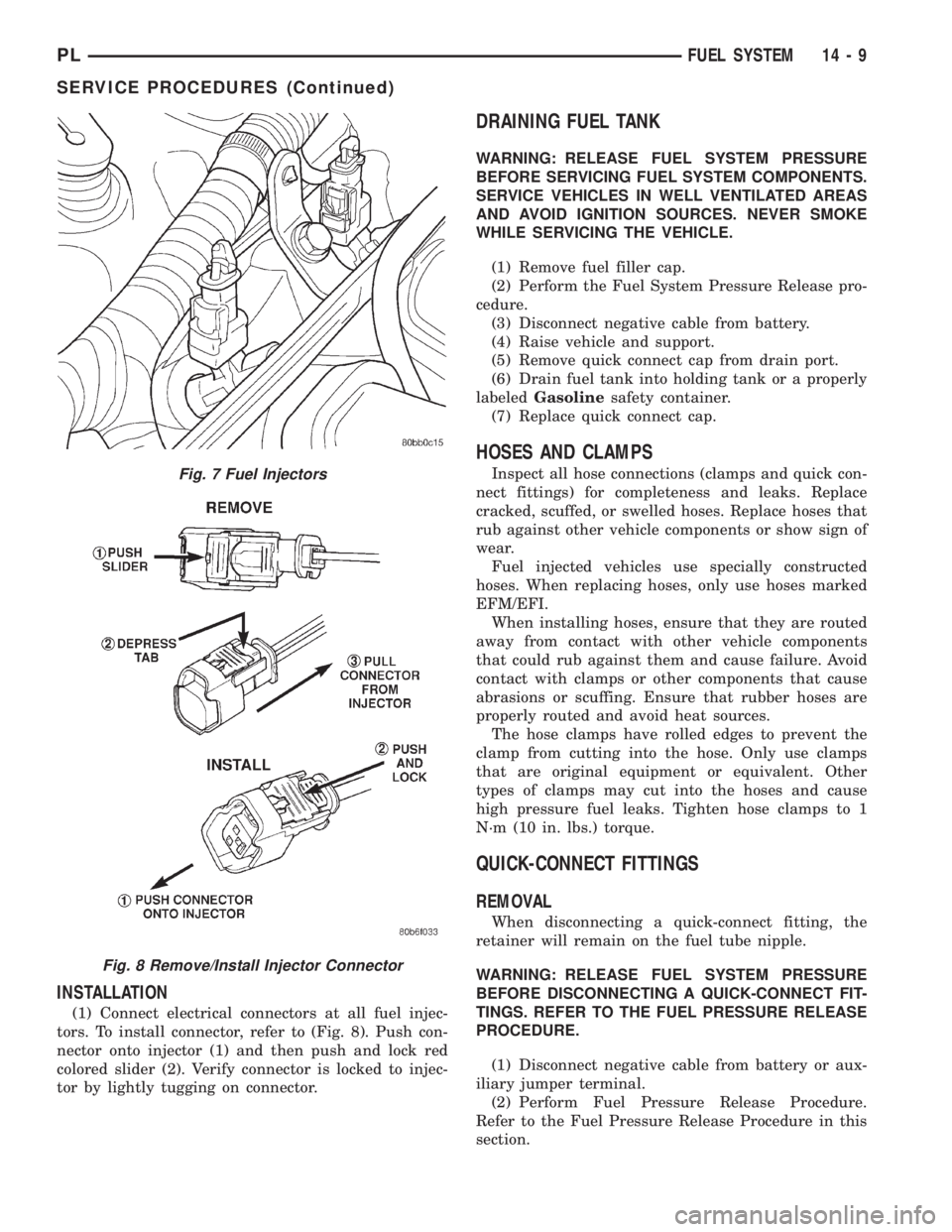

Fuel tubes connect fuel system components with

plastic quick-connect fuel fittings. The fitting con-

tains non-serviceable O-ring seals (Fig. 6).

CAUTION: Quick-connect fittings are not serviced

separately. Do not attempt to repair damaged quick-

connect fittings or fuel tubes. Replace the complete

fuel tube/quick-connect fitting assembly.

The quick-connect fitting consists of the O-rings,

retainer and casing (Fig. 6). When the fuel tube

enters the fitting, the retainer locks the shoulder of

the nipple in place and the O-rings seal the tube.

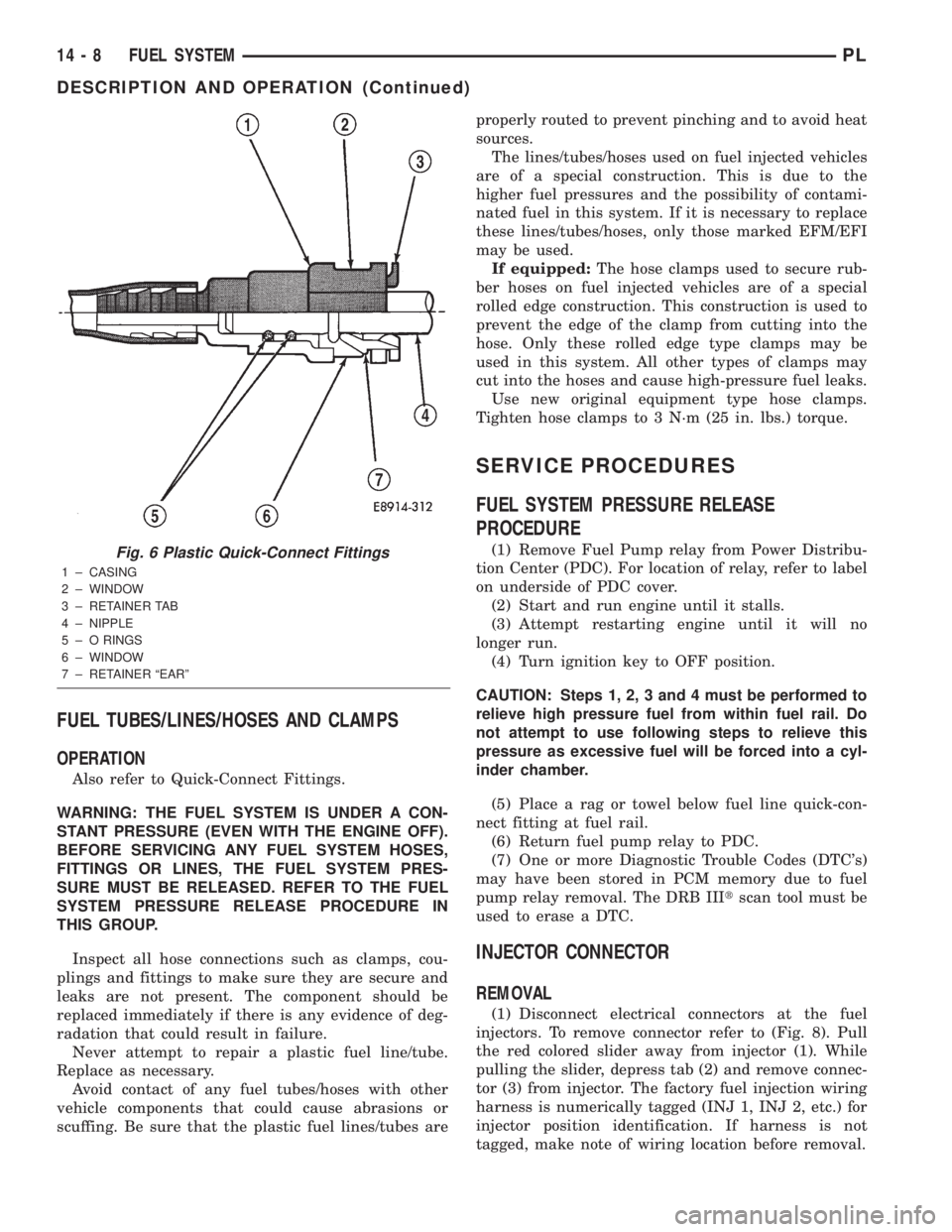

Fig. 5 Fuel Injector

1 ± FUEL INJECTOR

2 ± NOZZLE

3 ± TOP (FUEL ENTRY)

14 - 6 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 829 of 1285

FUEL TUBES/LINES/HOSES AND CLAMPS

OPERATION

Also refer to Quick-Connect Fittings.

WARNING: THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES,

FITTINGS OR LINES, THE FUEL SYSTEM PRES-

SURE MUST BE RELEASED. REFER TO THE FUEL

SYSTEM PRESSURE RELEASE PROCEDURE IN

THIS GROUP.

Inspect all hose connections such as clamps, cou-

plings and fittings to make sure they are secure and

leaks are not present. The component should be

replaced immediately if there is any evidence of deg-

radation that could result in failure.

Never attempt to repair a plastic fuel line/tube.

Replace as necessary.

Avoid contact of any fuel tubes/hoses with other

vehicle components that could cause abrasions or

scuffing. Be sure that the plastic fuel lines/tubes areproperly routed to prevent pinching and to avoid heat

sources.

The lines/tubes/hoses used on fuel injected vehicles

are of a special construction. This is due to the

higher fuel pressures and the possibility of contami-

nated fuel in this system. If it is necessary to replace

these lines/tubes/hoses, only those marked EFM/EFI

may be used.

If equipped:The hose clamps used to secure rub-

ber hoses on fuel injected vehicles are of a special

rolled edge construction. This construction is used to

prevent the edge of the clamp from cutting into the

hose. Only these rolled edge type clamps may be

used in this system. All other types of clamps may

cut into the hoses and cause high-pressure fuel leaks.

Use new original equipment type hose clamps.

Tighten hose clamps to 3 N´m (25 in. lbs.) torque.

SERVICE PROCEDURES

FUEL SYSTEM PRESSURE RELEASE

PROCEDURE

(1) Remove Fuel Pump relay from Power Distribu-

tion Center (PDC). For location of relay, refer to label

on underside of PDC cover.

(2) Start and run engine until it stalls.

(3) Attempt restarting engine until it will no

longer run.

(4) Turn ignition key to OFF position.

CAUTION: Steps 1, 2, 3 and 4 must be performed to

relieve high pressure fuel from within fuel rail. Do

not attempt to use following steps to relieve this

pressure as excessive fuel will be forced into a cyl-

inder chamber.

(5) Place a rag or towel below fuel line quick-con-

nect fitting at fuel rail.

(6) Return fuel pump relay to PDC.

(7) One or more Diagnostic Trouble Codes (DTC's)

may have been stored in PCM memory due to fuel

pump relay removal. The DRB IIItscan tool must be

used to erase a DTC.

INJECTOR CONNECTOR

REMOVAL

(1) Disconnect electrical connectors at the fuel

injectors. To remove connector refer to (Fig. 8). Pull

the red colored slider away from injector (1). While

pulling the slider, depress tab (2) and remove connec-

tor (3) from injector. The factory fuel injection wiring

harness is numerically tagged (INJ 1, INJ 2, etc.) for

injector position identification. If harness is not

tagged, make note of wiring location before removal.

Fig. 6 Plastic Quick-Connect Fittings

1 ± CASING

2 ± WINDOW

3 ± RETAINER TAB

4 ± NIPPLE

5 ± O RINGS

6 ± WINDOW

7 ± RETAINER ªEARº

14 - 8 FUEL SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 830 of 1285

INSTALLATION

(1) Connect electrical connectors at all fuel injec-

tors. To install connector, refer to (Fig. 8). Push con-

nector onto injector (1) and then push and lock red

colored slider (2). Verify connector is locked to injec-

tor by lightly tugging on connector.

DRAINING FUEL TANK

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE SERVICING FUEL SYSTEM COMPONENTS.

SERVICE VEHICLES IN WELL VENTILATED AREAS

AND AVOID IGNITION SOURCES. NEVER SMOKE

WHILE SERVICING THE VEHICLE.

(1) Remove fuel filler cap.

(2) Perform the Fuel System Pressure Release pro-

cedure.

(3) Disconnect negative cable from battery.

(4) Raise vehicle and support.

(5) Remove quick connect cap from drain port.

(6) Drain fuel tank into holding tank or a properly

labeledGasolinesafety container.

(7) Replace quick connect cap.

HOSES AND CLAMPS

Inspect all hose connections (clamps and quick con-

nect fittings) for completeness and leaks. Replace

cracked, scuffed, or swelled hoses. Replace hoses that

rub against other vehicle components or show sign of

wear.

Fuel injected vehicles use specially constructed

hoses. When replacing hoses, only use hoses marked

EFM/EFI.

When installing hoses, ensure that they are routed

away from contact with other vehicle components

that could rub against them and cause failure. Avoid

contact with clamps or other components that cause

abrasions or scuffing. Ensure that rubber hoses are

properly routed and avoid heat sources.

The hose clamps have rolled edges to prevent the

clamp from cutting into the hose. Only use clamps

that are original equipment or equivalent. Other

types of clamps may cut into the hoses and cause

high pressure fuel leaks. Tighten hose clamps to 1

N´m (10 in. lbs.) torque.

QUICK-CONNECT FITTINGS

REMOVAL

When disconnecting a quick-connect fitting, the

retainer will remain on the fuel tube nipple.

WARNING: RELEASE FUEL SYSTEM PRESSURE

BEFORE DISCONNECTING A QUICK-CONNECT FIT-

TINGS. REFER TO THE FUEL PRESSURE RELEASE

PROCEDURE.

(1) Disconnect negative cable from battery or aux-

iliary jumper terminal.

(2) Perform Fuel Pressure Release Procedure.

Refer to the Fuel Pressure Release Procedure in this

section.

Fig. 7 Fuel Injectors

Fig. 8 Remove/Install Injector Connector

PLFUEL SYSTEM 14 - 9

SERVICE PROCEDURES (Continued)

Page 831 of 1285

(3) Squeeze retainer tabs together and pull fuel

tube/quick-connect fitting assembly off of fuel tube

nipple. The retainer will remain on fuel tube.

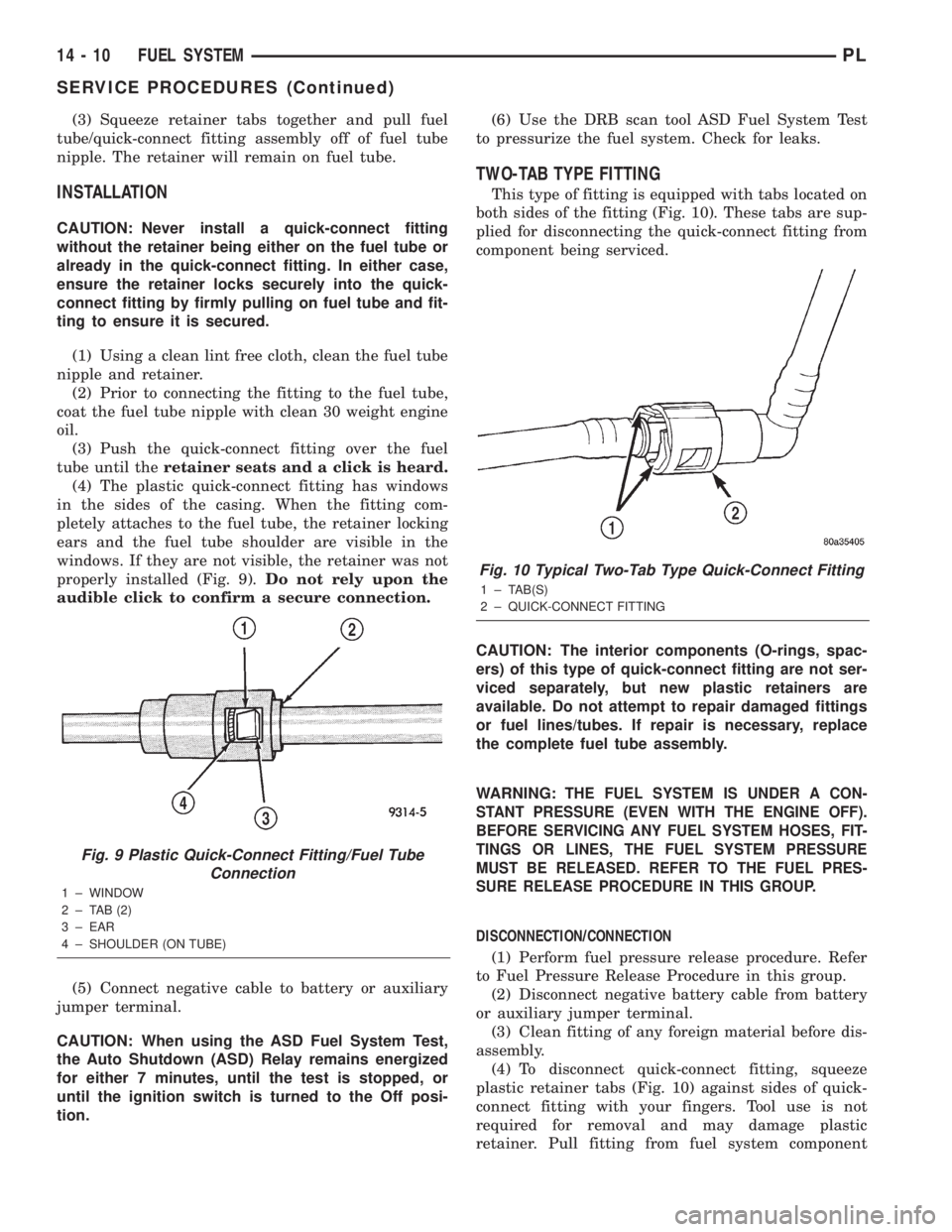

INSTALLATION

CAUTION: Never install a quick-connect fitting

without the retainer being either on the fuel tube or

already in the quick-connect fitting. In either case,

ensure the retainer locks securely into the quick-

connect fitting by firmly pulling on fuel tube and fit-

ting to ensure it is secured.

(1) Using a clean lint free cloth, clean the fuel tube

nipple and retainer.

(2) Prior to connecting the fitting to the fuel tube,

coat the fuel tube nipple with clean 30 weight engine

oil.

(3) Push the quick-connect fitting over the fuel

tube until theretainer seats and a click is heard.

(4) The plastic quick-connect fitting has windows

in the sides of the casing. When the fitting com-

pletely attaches to the fuel tube, the retainer locking

ears and the fuel tube shoulder are visible in the

windows. If they are not visible, the retainer was not

properly installed (Fig. 9).Do not rely upon the

audible click to confirm a secure connection.

(5) Connect negative cable to battery or auxiliary

jumper terminal.

CAUTION: When using the ASD Fuel System Test,

the Auto Shutdown (ASD) Relay remains energized

for either 7 minutes, until the test is stopped, or

until the ignition switch is turned to the Off posi-

tion.(6) Use the DRB scan tool ASD Fuel System Test

to pressurize the fuel system. Check for leaks.

TWO-TAB TYPE FITTING

This type of fitting is equipped with tabs located on

both sides of the fitting (Fig. 10). These tabs are sup-

plied for disconnecting the quick-connect fitting from

component being serviced.

CAUTION: The interior components (O-rings, spac-

ers) of this type of quick-connect fitting are not ser-

viced separately, but new plastic retainers are

available. Do not attempt to repair damaged fittings

or fuel lines/tubes. If repair is necessary, replace

the complete fuel tube assembly.

WARNING:

THE FUEL SYSTEM IS UNDER A CON-

STANT PRESSURE (EVEN WITH THE ENGINE OFF).

BEFORE SERVICING ANY FUEL SYSTEM HOSES, FIT-

TINGS OR LINES, THE FUEL SYSTEM PRESSURE

MUST BE RELEASED. REFER TO THE FUEL PRES-

SURE RELEASE PROCEDURE IN THIS GROUP.

DISCONNECTION/CONNECTION

(1) Perform fuel pressure release procedure. Refer

to Fuel Pressure Release Procedure in this group.

(2) Disconnect negative battery cable from battery

or auxiliary jumper terminal.

(3) Clean fitting of any foreign material before dis-

assembly.

(4) To disconnect quick-connect fitting, squeeze

plastic retainer tabs (Fig. 10) against sides of quick-

connect fitting with your fingers. Tool use is not

required for removal and may damage plastic

retainer. Pull fitting from fuel system component

Fig. 9 Plastic Quick-Connect Fitting/Fuel Tube

Connection

1 ± WINDOW

2 ± TAB (2)

3 ± EAR

4 ± SHOULDER (ON TUBE)

Fig. 10 Typical Two-Tab Type Quick-Connect Fitting

1 ± TAB(S)

2 ± QUICK-CONNECT FITTING

14 - 10 FUEL SYSTEMPL

SERVICE PROCEDURES (Continued)