engine oil DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 998 of 1285

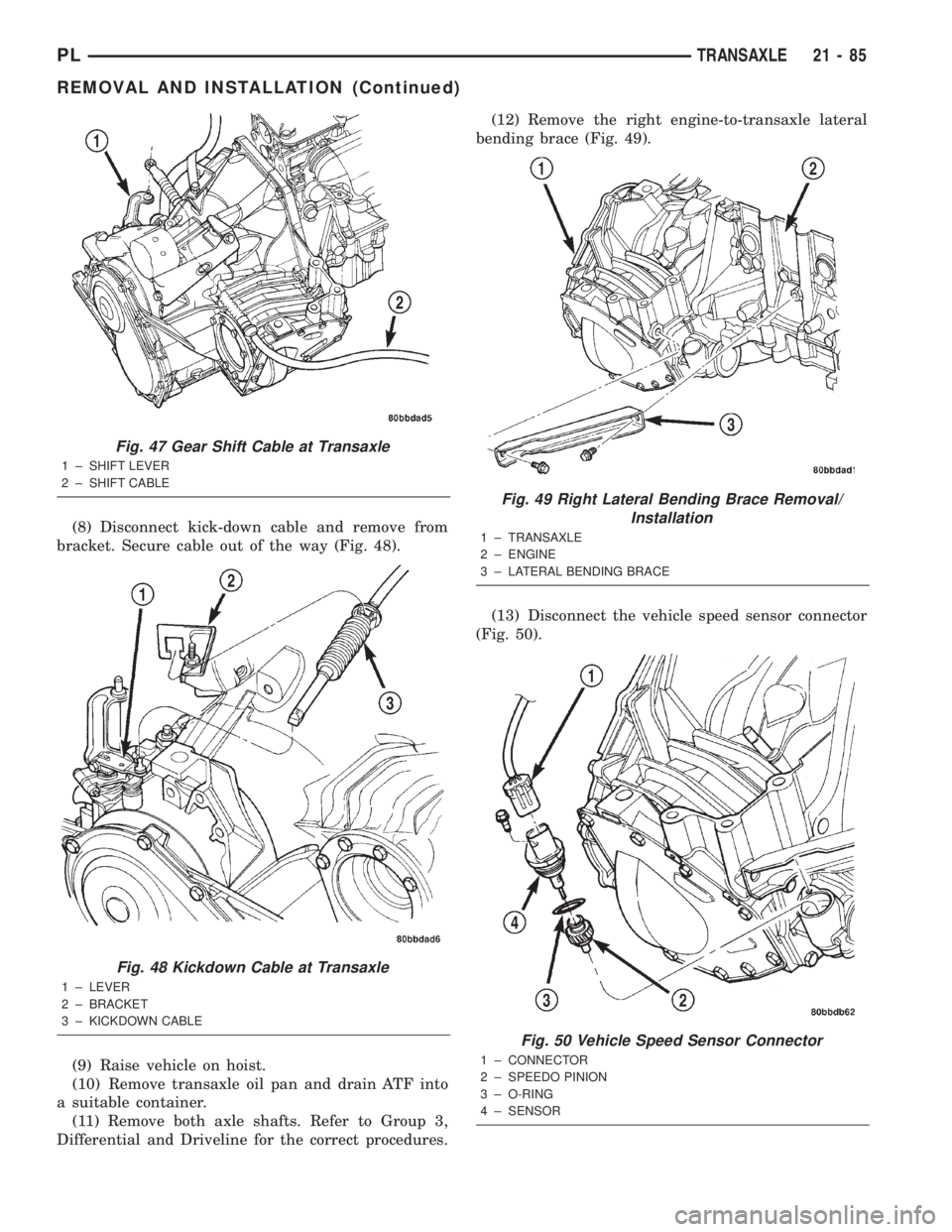

(8) Disconnect kick-down cable and remove from

bracket. Secure cable out of the way (Fig. 48).

(9) Raise vehicle on hoist.

(10) Remove transaxle oil pan and drain ATF into

a suitable container.

(11) Remove both axle shafts. Refer to Group 3,

Differential and Driveline for the correct procedures.(12) Remove the right engine-to-transaxle lateral

bending brace (Fig. 49).

(13) Disconnect the vehicle speed sensor connector

(Fig. 50).

Fig. 47 Gear Shift Cable at Transaxle

1 ± SHIFT LEVER

2 ± SHIFT CABLE

Fig. 48 Kickdown Cable at Transaxle

1 ± LEVER

2 ± BRACKET

3 ± KICKDOWN CABLE

Fig. 49 Right Lateral Bending Brace Removal/

Installation

1 ± TRANSAXLE

2 ± ENGINE

3 ± LATERAL BENDING BRACE

Fig. 50 Vehicle Speed Sensor Connector

1 ± CONNECTOR

2 ± SPEEDO PINION

3 ± O-RING

4 ± SENSOR

PLTRANSAXLE 21 - 85

REMOVAL AND INSTALLATION (Continued)

Page 999 of 1285

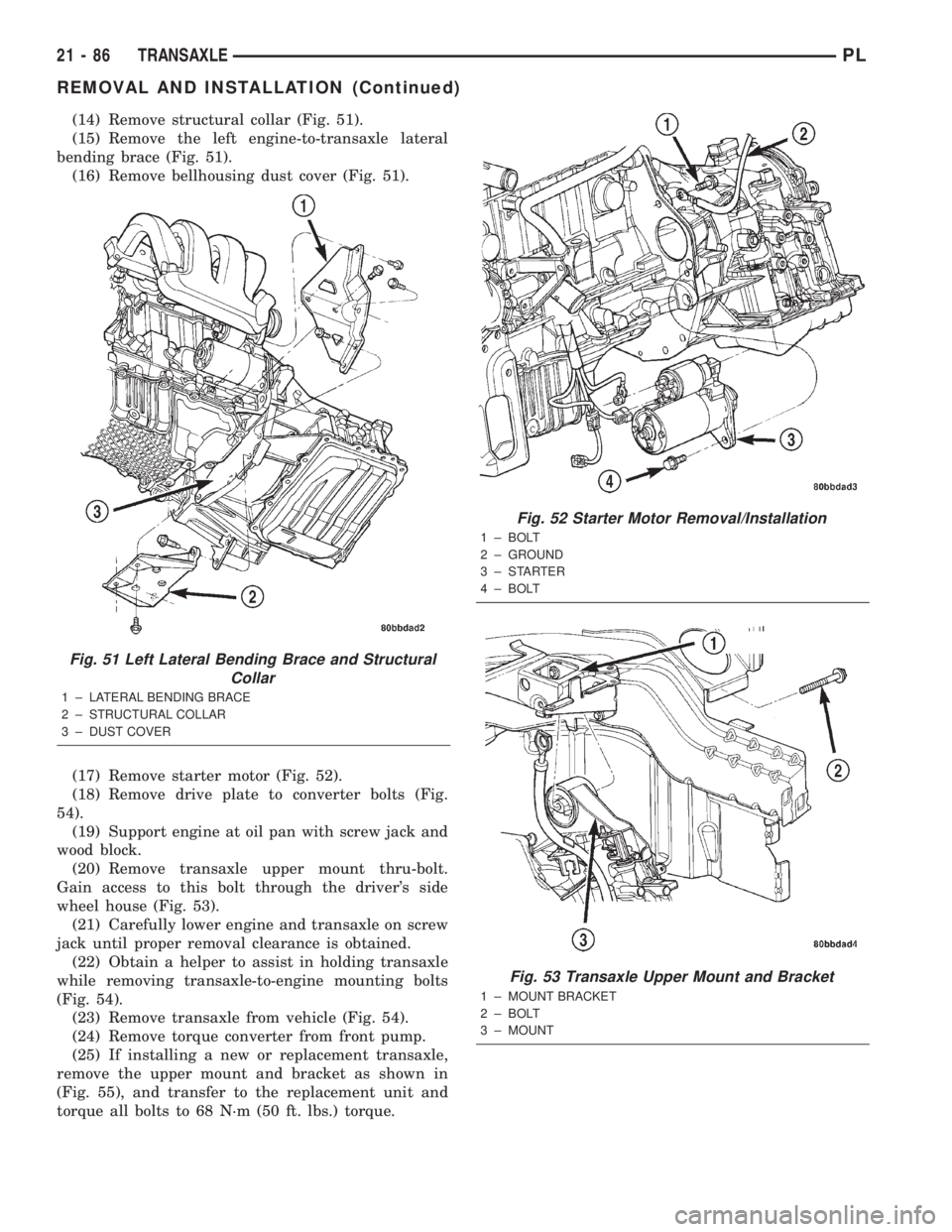

(14) Remove structural collar (Fig. 51).

(15) Remove the left engine-to-transaxle lateral

bending brace (Fig. 51).

(16) Remove bellhousing dust cover (Fig. 51).

(17) Remove starter motor (Fig. 52).

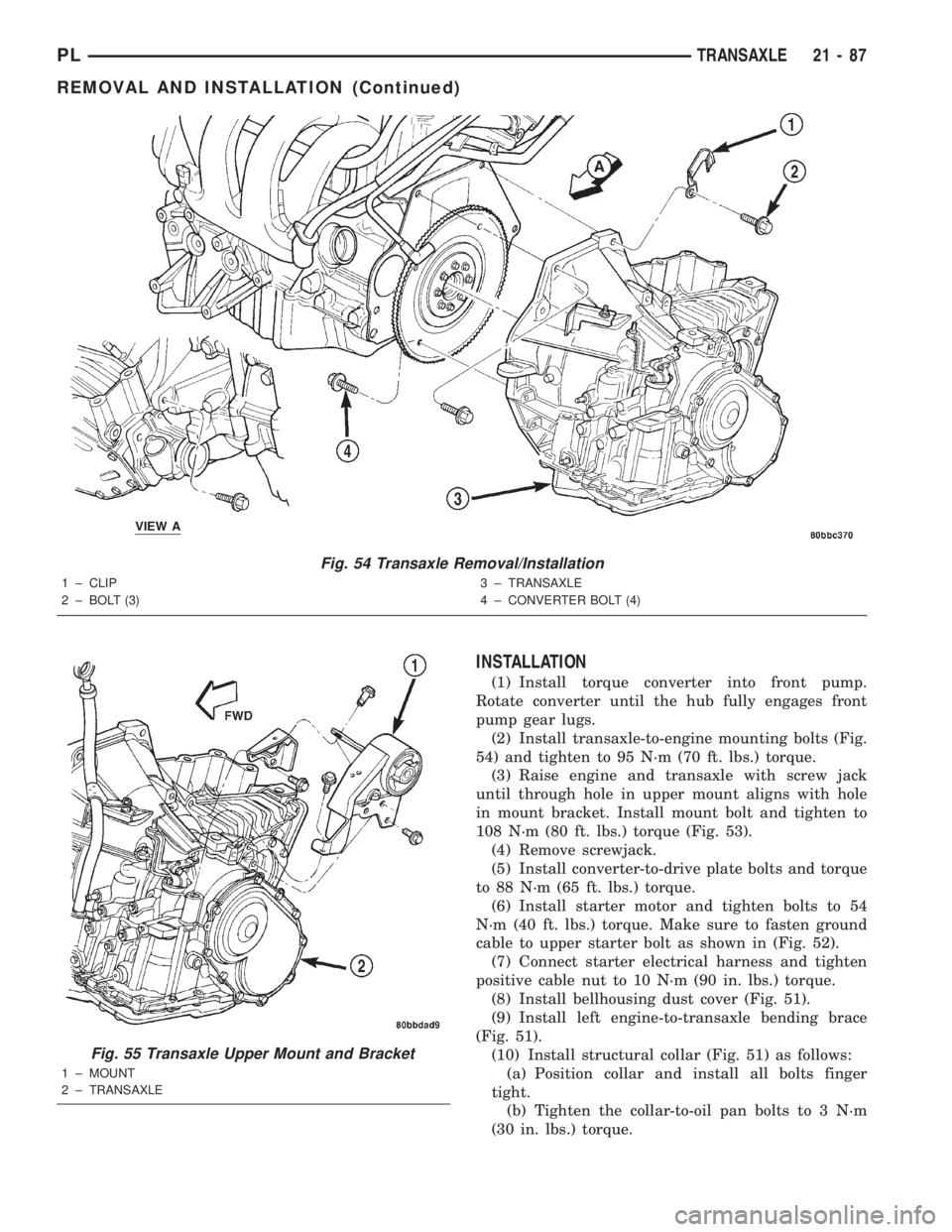

(18) Remove drive plate to converter bolts (Fig.

54).

(19) Support engine at oil pan with screw jack and

wood block.

(20) Remove transaxle upper mount thru-bolt.

Gain access to this bolt through the driver's side

wheel house (Fig. 53).

(21) Carefully lower engine and transaxle on screw

jack until proper removal clearance is obtained.

(22) Obtain a helper to assist in holding transaxle

while removing transaxle-to-engine mounting bolts

(Fig. 54).

(23) Remove transaxle from vehicle (Fig. 54).

(24) Remove torque converter from front pump.

(25) If installing a new or replacement transaxle,

remove the upper mount and bracket as shown in

(Fig. 55), and transfer to the replacement unit and

torque all bolts to 68 N´m (50 ft. lbs.) torque.

Fig. 51 Left Lateral Bending Brace and Structural

Collar

1 ± LATERAL BENDING BRACE

2 ± STRUCTURAL COLLAR

3 ± DUST COVER

Fig. 52 Starter Motor Removal/Installation

1 ± BOLT

2 ± GROUND

3±STARTER

4 ± BOLT

Fig. 53 Transaxle Upper Mount and Bracket

1 ± MOUNT BRACKET

2 ± BOLT

3 ± MOUNT

21 - 86 TRANSAXLEPL

REMOVAL AND INSTALLATION (Continued)

Page 1000 of 1285

INSTALLATION

(1) Install torque converter into front pump.

Rotate converter until the hub fully engages front

pump gear lugs.

(2) Install transaxle-to-engine mounting bolts (Fig.

54) and tighten to 95 N´m (70 ft. lbs.) torque.

(3) Raise engine and transaxle with screw jack

until through hole in upper mount aligns with hole

in mount bracket. Install mount bolt and tighten to

108 N´m (80 ft. lbs.) torque (Fig. 53).

(4) Remove screwjack.

(5) Install converter-to-drive plate bolts and torque

to 88 N´m (65 ft. lbs.) torque.

(6) Install starter motor and tighten bolts to 54

N´m (40 ft. lbs.) torque. Make sure to fasten ground

cable to upper starter bolt as shown in (Fig. 52).

(7) Connect starter electrical harness and tighten

positive cable nut to 10 N´m (90 in. lbs.) torque.

(8) Install bellhousing dust cover (Fig. 51).

(9) Install left engine-to-transaxle bending brace

(Fig. 51).

(10) Install structural collar (Fig. 51) as follows:

(a) Position collar and install all bolts finger

tight.

(b) Tighten the collar-to-oil pan bolts to 3 N´m

(30 in. lbs.) torque.

Fig. 54 Transaxle Removal/Installation

1 ± CLIP

2 ± BOLT (3)3 ± TRANSAXLE

4 ± CONVERTER BOLT (4)

Fig. 55 Transaxle Upper Mount and Bracket

1 ± MOUNT

2 ± TRANSAXLE

PLTRANSAXLE 21 - 87

REMOVAL AND INSTALLATION (Continued)

Page 1048 of 1285

CLEANING AND INSPECTION

VALVE BODY

Allow all parts to soak a few minutes in a suitable

clean solvent. Wash thoroughly and blow dry with

compressed air. Be sure all passages are clean and

free from obstructions.

Inspect manual and throttle valve operating levers

and shafts for being bent, worn or loose. If a lever is

loose on its shaft, it should be replaced. Do not

attempt to straighten bent levers.

Inspect all mating surfaces for burrs, nicks and

scratches. Minor blemishes may be removed with cro-

cus cloth, using only a very light pressure. Using a

straightedge, inspect all mating surfaces for warpage

or distortion. Slight distortion may be corrected,

using a surface plate. Be sure all metering holes in

steel plate are open. Using a penlight, inspect bores

in valve body for scores, scratches, pits, and irregu-

larities.

Inspect all valve springs for distortion and col-

lapsed coils. Inspect all valves and plugs for burrs,

nicks, and scores. Small nicks and scores may be

removed with crocus cloth, providing extreme care is

taken not to round off sharp edges. The sharpness of

these edges is vitally important. It prevents foreign

matter from lodging between valve and valve body.

This reduces the possibility of sticking. Inspect all

valves and plugs for freedom of operation in valve

body bores.

When bores, valves, and plugs are clean and dry,

the valves and plugs should fall freely in the bores.

The valve body bores do not change their dimensions

with use. Therefore, a valve body that was function-

ing properly when vehicle was new, will operate cor-

rectly if it is properly and thoroughly cleaned. There

is no need to replace a valve body unless it is dam-

aged in handling.

ADJUSTMENTS

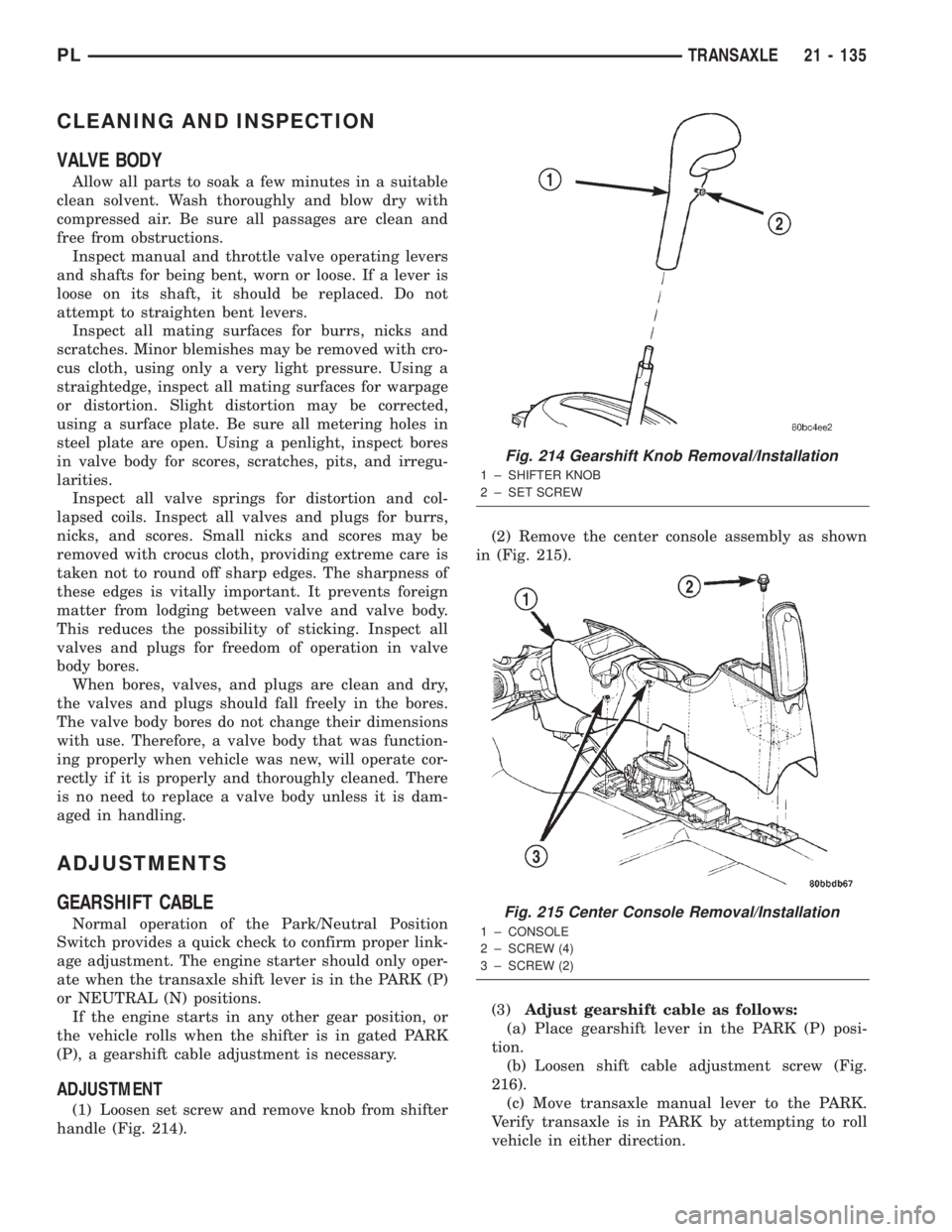

GEARSHIFT CABLE

Normal operation of the Park/Neutral Position

Switch provides a quick check to confirm proper link-

age adjustment. The engine starter should only oper-

ate when the transaxle shift lever is in the PARK (P)

or NEUTRAL (N) positions.

If the engine starts in any other gear position, or

the vehicle rolls when the shifter is in gated PARK

(P), a gearshift cable adjustment is necessary.

ADJUSTMENT

(1) Loosen set screw and remove knob from shifter

handle (Fig. 214).(2) Remove the center console assembly as shown

in (Fig. 215).

(3)Adjust gearshift cable as follows:

(a) Place gearshift lever in the PARK (P) posi-

tion.

(b) Loosen shift cable adjustment screw (Fig.

216).

(c) Move transaxle manual lever to the PARK.

Verify transaxle is in PARK by attempting to roll

vehicle in either direction.

Fig. 214 Gearshift Knob Removal/Installation

1 ± SHIFTER KNOB

2 ± SET SCREW

Fig. 215 Center Console Removal/Installation

1 ± CONSOLE

2 ± SCREW (4)

3 ± SCREW (2)

PLTRANSAXLE 21 - 135

Page 1096 of 1285

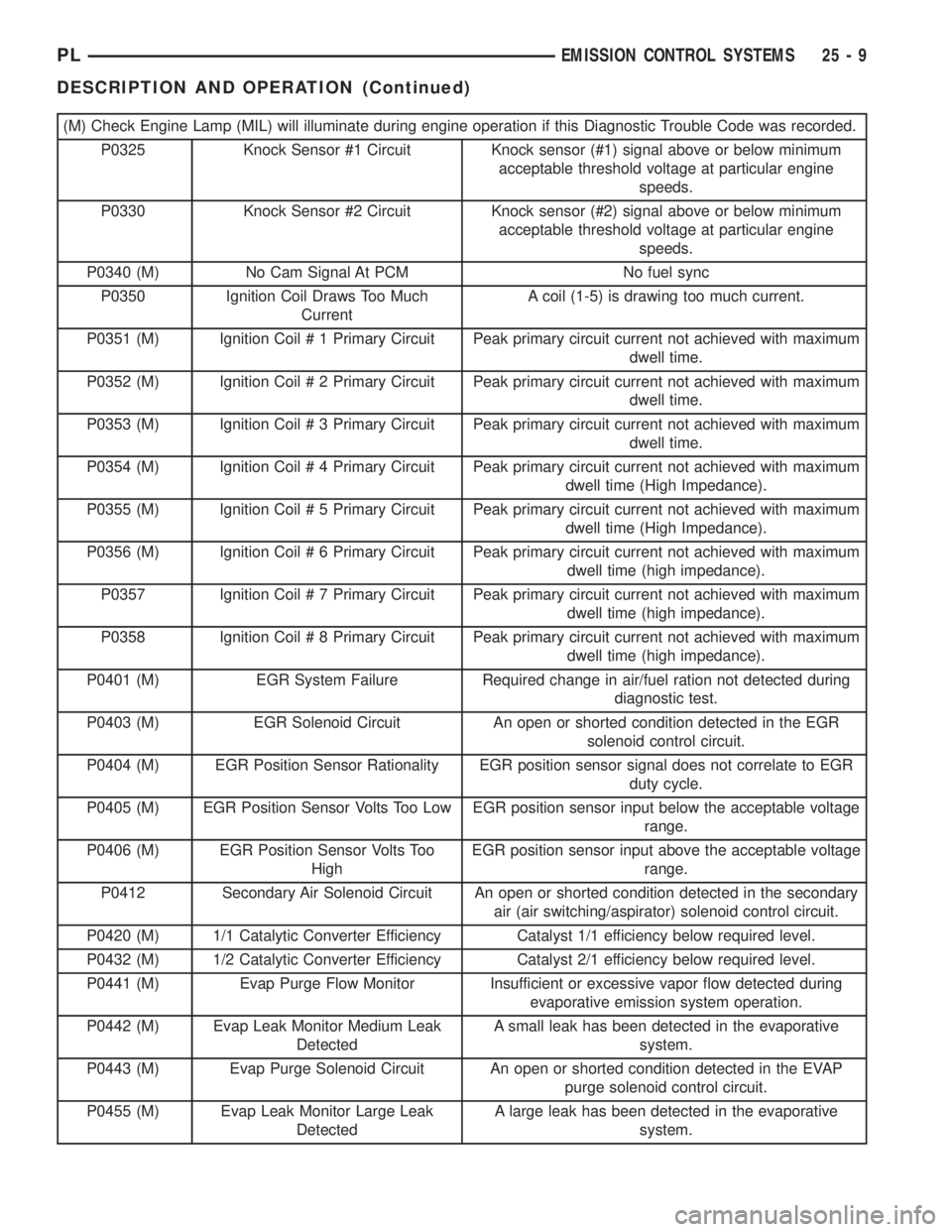

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0325 Knock Sensor #1 Circuit Knock sensor (#1) signal above or below minimum

acceptable threshold voltage at particular engine

speeds.

P0330 Knock Sensor #2 Circuit Knock sensor (#2) signal above or below minimum

acceptable threshold voltage at particular engine

speeds.

P0340 (M) No Cam Signal At PCM No fuel sync

P0350 Ignition Coil Draws Too Much

CurrentA coil (1-5) is drawing too much current.

P0351 (M) Ignition Coil # 1 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0352 (M) Ignition Coil # 2 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0353 (M) Ignition Coil # 3 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time.

P0354 (M) Ignition Coil # 4 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0355 (M) Ignition Coil # 5 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (High Impedance).

P0356 (M) Ignition Coil # 6 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0357 Ignition Coil # 7 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0358 Ignition Coil # 8 Primary Circuit Peak primary circuit current not achieved with maximum

dwell time (high impedance).

P0401 (M) EGR System Failure Required change in air/fuel ration not detected during

diagnostic test.

P0403 (M) EGR Solenoid Circuit An open or shorted condition detected in the EGR

solenoid control circuit.

P0404 (M) EGR Position Sensor Rationality EGR position sensor signal does not correlate to EGR

duty cycle.

P0405 (M) EGR Position Sensor Volts Too Low EGR position sensor input below the acceptable voltage

range.

P0406 (M) EGR Position Sensor Volts Too

HighEGR position sensor input above the acceptable voltage

range.

P0412 Secondary Air Solenoid Circuit An open or shorted condition detected in the secondary

air (air switching/aspirator) solenoid control circuit.

P0420 (M) 1/1 Catalytic Converter Efficiency Catalyst 1/1 efficiency below required level.

P0432 (M) 1/2 Catalytic Converter Efficiency Catalyst 2/1 efficiency below required level.

P0441 (M) Evap Purge Flow Monitor Insufficient or excessive vapor flow detected during

evaporative emission system operation.

P0442 (M) Evap Leak Monitor Medium Leak

DetectedA small leak has been detected in the evaporative

system.

P0443 (M) Evap Purge Solenoid Circuit An open or shorted condition detected in the EVAP

purge solenoid control circuit.

P0455 (M) Evap Leak Monitor Large Leak

DetectedA large leak has been detected in the evaporative

system.

PLEMISSION CONTROL SYSTEMS 25 - 9

DESCRIPTION AND OPERATION (Continued)

Page 1097 of 1285

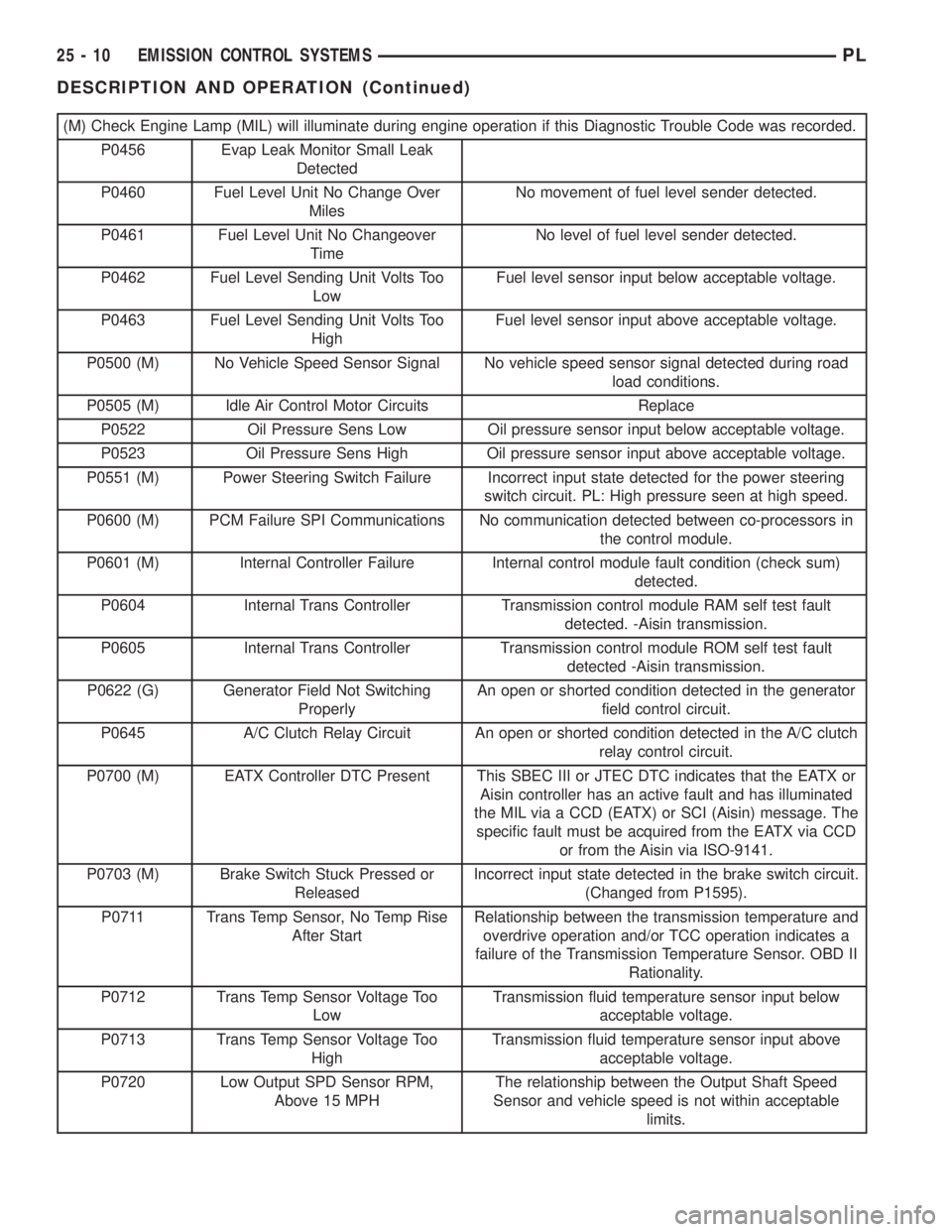

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

P0456 Evap Leak Monitor Small Leak

Detected

P0460 Fuel Level Unit No Change Over

MilesNo movement of fuel level sender detected.

P0461 Fuel Level Unit No Changeover

TimeNo level of fuel level sender detected.

P0462 Fuel Level Sending Unit Volts Too

LowFuel level sensor input below acceptable voltage.

P0463 Fuel Level Sending Unit Volts Too

HighFuel level sensor input above acceptable voltage.

P0500 (M) No Vehicle Speed Sensor Signal No vehicle speed sensor signal detected during road

load conditions.

P0505 (M) Idle Air Control Motor Circuits Replace

P0522 Oil Pressure Sens Low Oil pressure sensor input below acceptable voltage.

P0523 Oil Pressure Sens High Oil pressure sensor input above acceptable voltage.

P0551 (M) Power Steering Switch Failure Incorrect input state detected for the power steering

switch circuit. PL: High pressure seen at high speed.

P0600 (M) PCM Failure SPI Communications No communication detected between co-processors in

the control module.

P0601 (M) Internal Controller Failure Internal control module fault condition (check sum)

detected.

P0604 Internal Trans Controller Transmission control module RAM self test fault

detected. -Aisin transmission.

P0605 Internal Trans Controller Transmission control module ROM self test fault

detected -Aisin transmission.

P0622 (G) Generator Field Not Switching

ProperlyAn open or shorted condition detected in the generator

field control circuit.

P0645 A/C Clutch Relay Circuit An open or shorted condition detected in the A/C clutch

relay control circuit.

P0700 (M) EATX Controller DTC Present This SBEC III or JTEC DTC indicates that the EATX or

Aisin controller has an active fault and has illuminated

the MIL via a CCD (EATX) or SCI (Aisin) message. The

specific fault must be acquired from the EATX via CCD

or from the Aisin via ISO-9141.

P0703 (M) Brake Switch Stuck Pressed or

ReleasedIncorrect input state detected in the brake switch circuit.

(Changed from P1595).

P0711 Trans Temp Sensor, No Temp Rise

After StartRelationship between the transmission temperature and

overdrive operation and/or TCC operation indicates a

failure of the Transmission Temperature Sensor. OBD II

Rationality.

P0712 Trans Temp Sensor Voltage Too

LowTransmission fluid temperature sensor input below

acceptable voltage.

P0713 Trans Temp Sensor Voltage Too

HighTransmission fluid temperature sensor input above

acceptable voltage.

P0720 Low Output SPD Sensor RPM,

Above 15 MPHThe relationship between the Output Shaft Speed

Sensor and vehicle speed is not within acceptable

limits.

25 - 10 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1102 of 1285

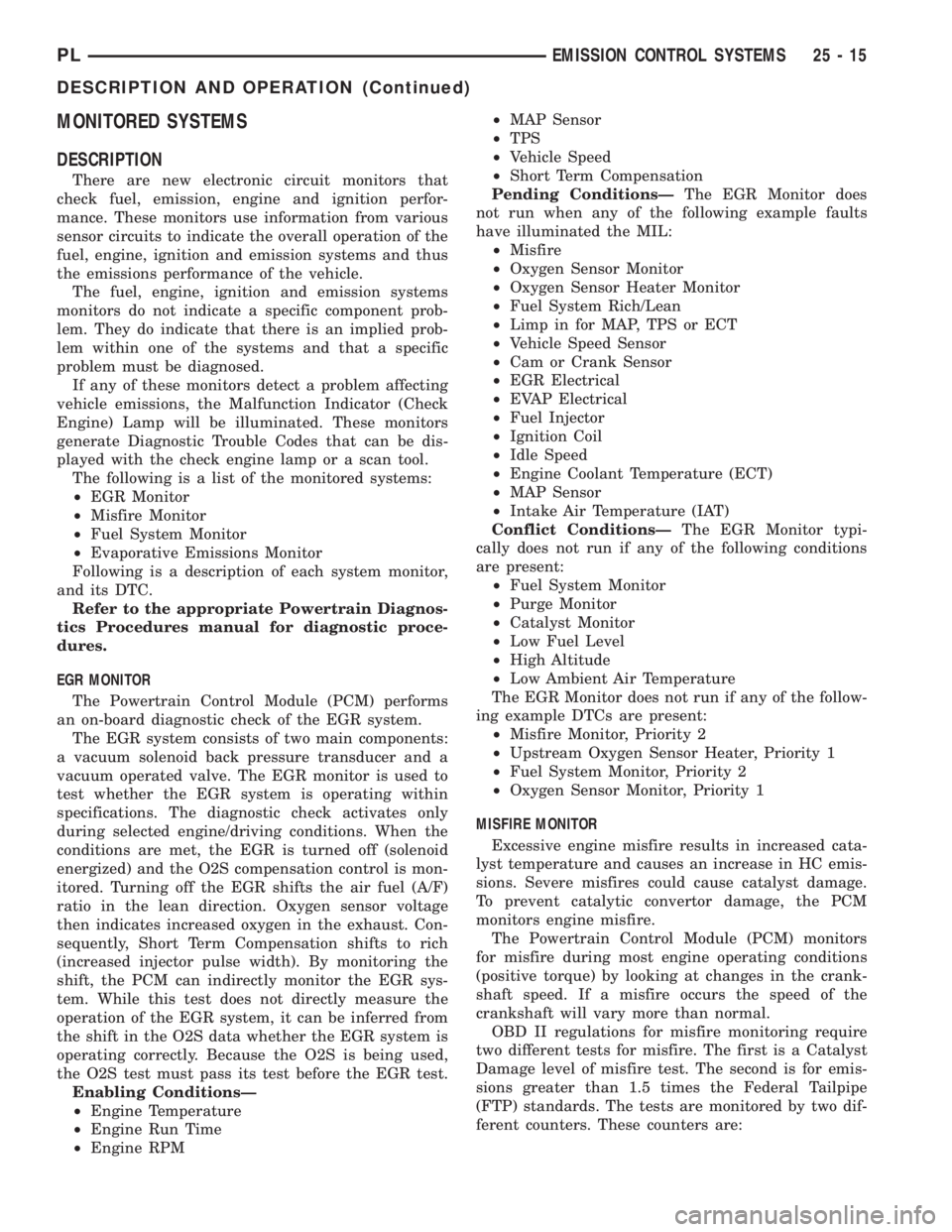

MONITORED SYSTEMS

DESCRIPTION

There are new electronic circuit monitors that

check fuel, emission, engine and ignition perfor-

mance. These monitors use information from various

sensor circuits to indicate the overall operation of the

fuel, engine, ignition and emission systems and thus

the emissions performance of the vehicle.

The fuel, engine, ignition and emission systems

monitors do not indicate a specific component prob-

lem. They do indicate that there is an implied prob-

lem within one of the systems and that a specific

problem must be diagnosed.

If any of these monitors detect a problem affecting

vehicle emissions, the Malfunction Indicator (Check

Engine) Lamp will be illuminated. These monitors

generate Diagnostic Trouble Codes that can be dis-

played with the check engine lamp or a scan tool.

The following is a list of the monitored systems:

²EGR Monitor

²Misfire Monitor

²Fuel System Monitor

²Evaporative Emissions Monitor

Following is a description of each system monitor,

and its DTC.

Refer to the appropriate Powertrain Diagnos-

tics Procedures manual for diagnostic proce-

dures.

EGR MONITOR

The Powertrain Control Module (PCM) performs

an on-board diagnostic check of the EGR system.

The EGR system consists of two main components:

a vacuum solenoid back pressure transducer and a

vacuum operated valve. The EGR monitor is used to

test whether the EGR system is operating within

specifications. The diagnostic check activates only

during selected engine/driving conditions. When the

conditions are met, the EGR is turned off (solenoid

energized) and the O2S compensation control is mon-

itored. Turning off the EGR shifts the air fuel (A/F)

ratio in the lean direction. Oxygen sensor voltage

then indicates increased oxygen in the exhaust. Con-

sequently, Short Term Compensation shifts to rich

(increased injector pulse width). By monitoring the

shift, the PCM can indirectly monitor the EGR sys-

tem. While this test does not directly measure the

operation of the EGR system, it can be inferred from

the shift in the O2S data whether the EGR system is

operating correctly. Because the O2S is being used,

the O2S test must pass its test before the EGR test.

Enabling ConditionsÐ

²Engine Temperature

²Engine Run Time

²Engine RPM²MAP Sensor

²TPS

²Vehicle Speed

²Short Term Compensation

Pending ConditionsÐThe EGR Monitor does

not run when any of the following example faults

have illuminated the MIL:

²Misfire

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Fuel System Rich/Lean

²Limp in for MAP, TPS or ECT

²Vehicle Speed Sensor

²Cam or Crank Sensor

²EGR Electrical

²EVAP Electrical

²Fuel Injector

²Ignition Coil

²Idle Speed

²Engine Coolant Temperature (ECT)

²MAP Sensor

²Intake Air Temperature (IAT)

Conflict ConditionsÐThe EGR Monitor typi-

cally does not run if any of the following conditions

are present:

²Fuel System Monitor

²Purge Monitor

²Catalyst Monitor

²Low Fuel Level

²High Altitude

²Low Ambient Air Temperature

The EGR Monitor does not run if any of the follow-

ing example DTCs are present:

²Misfire Monitor, Priority 2

²Upstream Oxygen Sensor Heater, Priority 1

²Fuel System Monitor, Priority 2

²Oxygen Sensor Monitor, Priority 1

MISFIRE MONITOR

Excessive engine misfire results in increased cata-

lyst temperature and causes an increase in HC emis-

sions. Severe misfires could cause catalyst damage.

To prevent catalytic convertor damage, the PCM

monitors engine misfire.

The Powertrain Control Module (PCM) monitors

for misfire during most engine operating conditions

(positive torque) by looking at changes in the crank-

shaft speed. If a misfire occurs the speed of the

crankshaft will vary more than normal.

OBD II regulations for misfire monitoring require

two different tests for misfire. The first is a Catalyst

Damage level of misfire test. The second is for emis-

sions greater than 1.5 times the Federal Tailpipe

(FTP) standards. The tests are monitored by two dif-

ferent counters. These counters are:

PLEMISSION CONTROL SYSTEMS 25 - 15

DESCRIPTION AND OPERATION (Continued)

Page 1104 of 1285

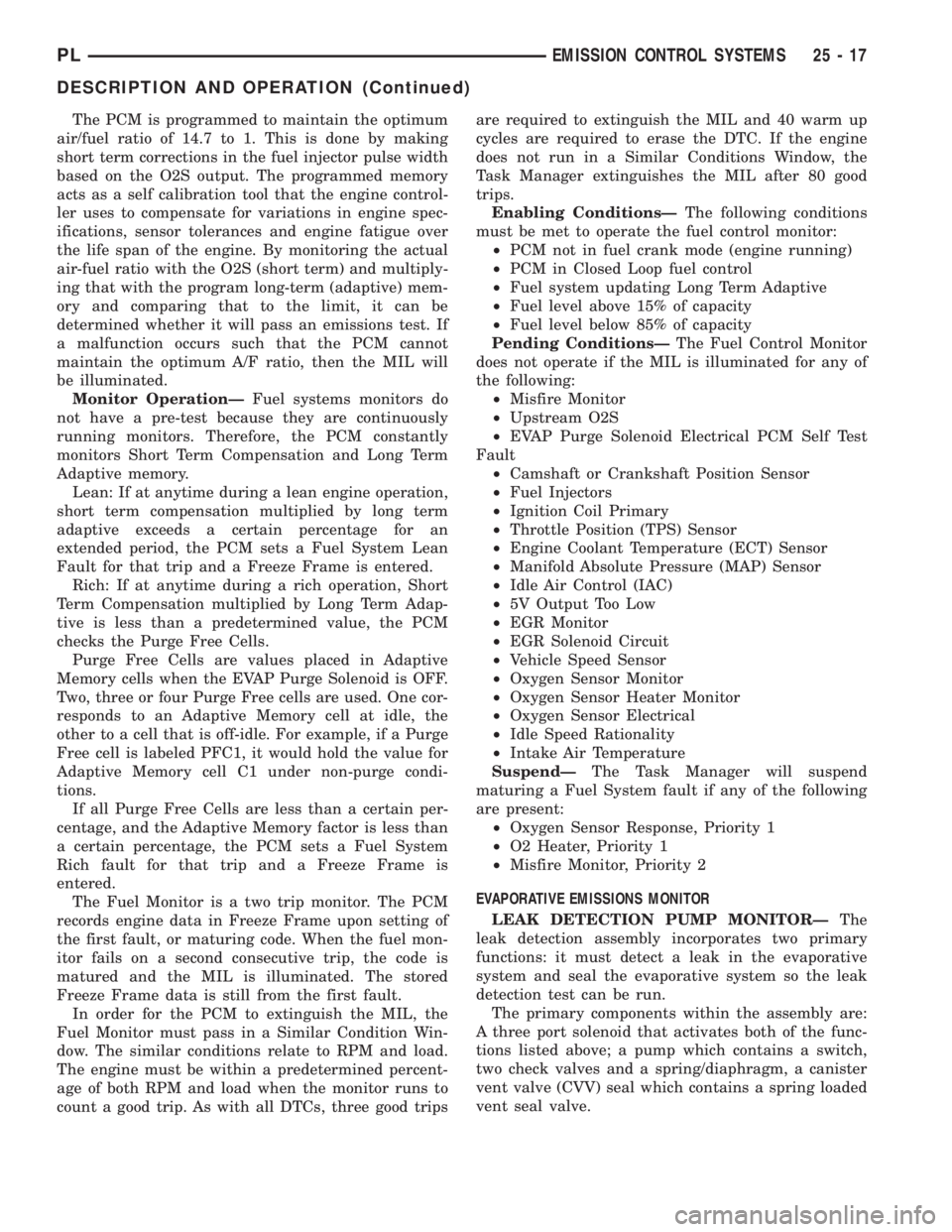

The PCM is programmed to maintain the optimum

air/fuel ratio of 14.7 to 1. This is done by making

short term corrections in the fuel injector pulse width

based on the O2S output. The programmed memory

acts as a self calibration tool that the engine control-

ler uses to compensate for variations in engine spec-

ifications, sensor tolerances and engine fatigue over

the life span of the engine. By monitoring the actual

air-fuel ratio with the O2S (short term) and multiply-

ing that with the program long-term (adaptive) mem-

ory and comparing that to the limit, it can be

determined whether it will pass an emissions test. If

a malfunction occurs such that the PCM cannot

maintain the optimum A/F ratio, then the MIL will

be illuminated.

Monitor OperationÐFuel systems monitors do

not have a pre-test because they are continuously

running monitors. Therefore, the PCM constantly

monitors Short Term Compensation and Long Term

Adaptive memory.

Lean: If at anytime during a lean engine operation,

short term compensation multiplied by long term

adaptive exceeds a certain percentage for an

extended period, the PCM sets a Fuel System Lean

Fault for that trip and a Freeze Frame is entered.

Rich: If at anytime during a rich operation, Short

Term Compensation multiplied by Long Term Adap-

tive is less than a predetermined value, the PCM

checks the Purge Free Cells.

Purge Free Cells are values placed in Adaptive

Memory cells when the EVAP Purge Solenoid is OFF.

Two, three or four Purge Free cells are used. One cor-

responds to an Adaptive Memory cell at idle, the

other to a cell that is off-idle. For example, if a Purge

Free cell is labeled PFC1, it would hold the value for

Adaptive Memory cell C1 under non-purge condi-

tions.

If all Purge Free Cells are less than a certain per-

centage, and the Adaptive Memory factor is less than

a certain percentage, the PCM sets a Fuel System

Rich fault for that trip and a Freeze Frame is

entered.

The Fuel Monitor is a two trip monitor. The PCM

records engine data in Freeze Frame upon setting of

the first fault, or maturing code. When the fuel mon-

itor fails on a second consecutive trip, the code is

matured and the MIL is illuminated. The stored

Freeze Frame data is still from the first fault.

In order for the PCM to extinguish the MIL, the

Fuel Monitor must pass in a Similar Condition Win-

dow. The similar conditions relate to RPM and load.

The engine must be within a predetermined percent-

age of both RPM and load when the monitor runs to

count a good trip. As with all DTCs, three good tripsare required to extinguish the MIL and 40 warm up

cycles are required to erase the DTC. If the engine

does not run in a Similar Conditions Window, the

Task Manager extinguishes the MIL after 80 good

trips.

Enabling ConditionsÐThe following conditions

must be met to operate the fuel control monitor:

²PCM not in fuel crank mode (engine running)

²PCM in Closed Loop fuel control

²Fuel system updating Long Term Adaptive

²Fuel level above 15% of capacity

²Fuel level below 85% of capacity

Pending ConditionsÐThe Fuel Control Monitor

does not operate if the MIL is illuminated for any of

the following:

²Misfire Monitor

²Upstream O2S

²EVAP Purge Solenoid Electrical PCM Self Test

Fault

²Camshaft or Crankshaft Position Sensor

²Fuel Injectors

²Ignition Coil Primary

²Throttle Position (TPS) Sensor

²Engine Coolant Temperature (ECT) Sensor

²Manifold Absolute Pressure (MAP) Sensor

²Idle Air Control (IAC)

²5V Output Too Low

²EGR Monitor

²EGR Solenoid Circuit

²Vehicle Speed Sensor

²Oxygen Sensor Monitor

²Oxygen Sensor Heater Monitor

²Oxygen Sensor Electrical

²Idle Speed Rationality

²Intake Air Temperature

SuspendÐThe Task Manager will suspend

maturing a Fuel System fault if any of the following

are present:

²Oxygen Sensor Response, Priority 1

²O2 Heater, Priority 1

²Misfire Monitor, Priority 2

EVAPORATIVE EMISSIONS MONITOR

LEAK DETECTION PUMP MONITORÐThe

leak detection assembly incorporates two primary

functions: it must detect a leak in the evaporative

system and seal the evaporative system so the leak

detection test can be run.

The primary components within the assembly are:

A three port solenoid that activates both of the func-

tions listed above; a pump which contains a switch,

two check valves and a spring/diaphragm, a canister

vent valve (CVV) seal which contains a spring loaded

vent seal valve.

PLEMISSION CONTROL SYSTEMS 25 - 17

DESCRIPTION AND OPERATION (Continued)

Page 1107 of 1285

NOTE: Comprehensive component monitors are

continuous. Therefore, enabling conditions do not

apply.

Input RationalityÐWhile input signals to the

PCM are constantly being monitored for electrical

opens and shorts, they are also tested for rationality.

This means that the input signal is compared against

other inputs and information to see if it makes sense

under the current conditions.

PCM sensor inputs that are checked for rationality

include:

²Manifold Absolute Pressure (MAP) Sensor

²Oxygen Sensor (O2S)

²Engine Coolant Temperature (ECT) Sensor

²Camshaft Position (CMP) Sensor

²Vehicle Speed Sensor

²Crankshaft Position (CKP) Sensor

²Intake Air Temperature (IAT) Sensor

²Throttle Position (TPS) Sensor

²Ambient/Battery Temperature Sensors

²Power Steering Switch

²Oxygen Sensor Heater

²Engine Controller

²Brake Switch

²Leak Detection Pump Switch

²P/N Switch

²Trans Controls

Output FunctionalityÐPCM outputs are tested

for functionality in addition to testing for opens and

shorts. When the PCM provides a voltage to an out-

put component, it can verify that the command was

carried out by monitoring specific input signals for

expected changes. For example, when the PCM com-

mands the Idle Air Control (IAC) Motor to a specific

position under certain operating conditions, it expects

to see a specific (target) idle speed (RPM). If it does

not, it stores a DTC.

PCM outputs monitored for functionality include:

²Fuel Injectors

²Ignition Coils

²Torque Converter Clutch Solenoid

²Idle Air Control

²Purge Solenoid

²EGR Solenoid

²LDP Solenoid

²Radiator Fan Control

²Trans Controls

OXYGEN SENSOR (O2S) MONITOR

DESCRIPTIONÐEffective control of exhaust

emissions is achieved by an oxygen feedback system.

The most important element of the feedback system

is the O2S. The O2S is located in the exhaust path.

Once it reaches operating temperature 300É to 350ÉC

(572É to 662ÉF), the sensor generates a voltage that

is inversely proportional to the amount of oxygen inthe exhaust. When there is a large amount of oxygen

in the exhaust caused by a lean condition, the sensor

produces a low voltage, below 450 mV. When the oxy-

gen content is lower, caused by a rich condition, the

sensor produces a higher voltage, above 450mV.

The information obtained by the sensor is used to

calculate the fuel injector pulse width. This main-

tains a 14.7 to 1 air fuel (A/F) ratio. At this mixture

ratio, the catalyst works best to remove hydrocarbons

(HC), carbon monoxide (CO) and nitrous oxide (NOx)

from the exhaust.

The O2S is also the main sensing element for the

EGR, Catalyst and Fuel Monitors.

The O2S may fail in any or all of the following

manners:

²Slow response rate (Big Slope)

²Reduced output voltage (Half Cycle)

²Heater Performance

Slow Response Rate (Big Slope)ÐResponse

rate is the time required for the sensor to switch

from lean to rich signal output once it is exposed to a

richer than optimum A/F mixture or vice versa. As

the PCM adjusts the air/fuel ratio, the sensor must

be able to rapidly detect the change. As the sensor

ages, it could take longer to detect the changes in the

oxygen content of the exhaust gas. The rate of

change that an oxygen sensor experiences is called

'Big Slope'. The PCM checks the oxygen sensor volt-

age in increments of a few milliseconds.

Reduced Output Voltage (Half Cycle)ÐThe

output voltage of the O2S ranges from 0 to 1 volt. A

good sensor can easily generate any output voltage in

this range as it is exposed to different concentrations

of oxygen. To detect a shift in the A/F mixture (lean

or rich), the output voltage has to change beyond a

threshold value. A malfunctioning sensor could have

difficulty changing beyond the threshold value. Each

time the voltage signal surpasses the threshold, a

counter is incremented by one. This is called the Half

Cycle Counter.

Heater PerformanceÐThe heater is tested by a

separate monitor. Refer to the Oxygen Sensor Heater

Monitor.

OPERATIONÐAs the Oxygen Sensor signal

switches, the PCM monitors the half cycle and big

slope signals from the oxygen sensor. If during the

test neither counter reaches a predetermined value, a

malfunction is entered and a Freeze Frame is stored.

Only one counter reaching its predetermined value is

needed for the monitor to pass.

The Oxygen Sensor Monitor is a two trip monitor

that is tested only once per trip. When the Oxygen

Sensor fails the test in two consecutive trips, the

MIL is illuminated and a DTC is set. The MIL is

extinguished when the Oxygen Sensor monitor

passes in three consecutive trips. The DTC is erased

25 - 20 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1108 of 1285

from memory after 40 consecutive warm-up cycles

without test failure.

Enabling ConditionsÐThe following conditions

must typically be met for the PCM to run the oxygen

sensor monitor:

²Battery voltage

²Engine temperature

²Engine run time

²Engine run time at a predetermined speed

²Engine run time at a predetermined speed and

throttle opening

²Transmission in gear (automatic only)

²Fuel system in Closed Loop

²Long Term Adaptive (within parameters)

²Power Steering Switch in low PSI (no load)

²Engine at idle

²Fuel level above 15%

²Ambient air temperature

²Barometric pressure

²Engine RPM within acceptable range of desired

idle

²Closed throttle speed

Pending ConditionsÐThe Task Manager typi-

cally does not run the Oxygen Sensor Monitor if over-

lapping monitors are running or the MIL is

illuminated for any of the following:

²Misfire Monitor

²Front Oxygen Sensor and Heater Monitor

²MAP Sensor

²Vehicle Speed Sensor

²Engine Coolant Temperature Sensor

²Throttle Position Sensor

²Engine Controller Self Test Faults

²Cam or Crank Sensor

²Injector and Coil

²Idle Air Control Motor

²EVAP Electrical

²EGR Solenoid Electrical

²Intake Air Temperature

²5 Volt Feed

ConflictÐThe Task Manager does not run the

Oxygen Sensor Monitor if any of the following condi-

tions are present:

²A/C ON (A/C clutch cycling temporarily sus-

pends monitor)

²Purge flow in progress

SuspendÐThe Task Manager suspends maturing

a fault for the Oxygen Sensor Monitor if an of the fol-

lowing are present:

²Oxygen Sensor Heater Monitor, Priority 1

²Misfire Monitor, Priority 2

OXYGEN SENSOR HEATER MONITOR

DESCRIPTIONÐIf there is an oxygen sensor

(O2S) DTC as well as a O2S heater DTC, the O2S

fault MUST be repaired first. After the O2S fault isrepaired, verify that the heater circuit is operating

correctly.

The voltage readings taken from the O2S are very

temperature sensitive. The readings are not accurate

below 300ÉC. Heating of the O2S is done to allow the

engine controller to shift to closed loop control as

soon as possible. The heating element used to heat

the O2S must be tested to ensure that it is heating

the sensor properly.

The heater element itself is not tested. The sensor

output is used to test the heater by isolating the

effect of the heater element on the O2S output volt-

age from the other effects. The resistance is normally

between 100 ohms and 4.5 megaohms. When oxygen

sensor temperature increases, the resistance in the

internal circuit decreases. The PCM sends a 5 volts

biased signal through the oxygen sensors to ground

this monitoring circuit. As the temperature increases,

resistance decreases and the PCM detects a lower

voltage at the reference signal. Inversely, as the tem-

perature decreases, the resistance increases and the

PCM detects a higher voltage at the reference signal.

an The O2S circuit is monitored for a drop in voltage.

OPERATIONÐThe Oxygen Sensor Heater Moni-

tor begins after the ignition has been turned OFF

and the O2 sensors have cooled. The PCM sends a 5

volt bias to the oxygen sensor every 1.6 seconds. The

PCM keeps it biased for 35 ms each time. As the sen-

sor cools down, the resistance increases and the PCM

reads the increase in voltage. Once voltage has

increased to a predetermined amount, higher than

when the test started, the oxygen sensor is cool

enough to test heater operation.

When the oxygen sensor is cool enough, the PCM

energizes the ASD relay. Voltage to the O2 sensor

begins to increase the temperature. As the sensor

temperature increases, the internal resistance

decreases. The PCM continues biasing the 5 volt sig-

nal to the sensor. Each time the signal is biased, the

PCM reads a voltage decrease. When the PCM

detects a voltage decrease of a predetermined value

for several biased pulses, the test passes.

The heater elements are tested each time the

engine is turned OFF if all the enabling conditions

are met. If the monitor fails, the PCM stores a

maturing fault and a Freeze Frame is entered. If two

consecutive tests fail, a DTC is stored. Because the

ignition is OFF, the MIL is illuminated at the begin-

ning of the next key cycle.

Enabling ConditionsÐThe following conditions

must be met for the PCM to run the oxygen sensor

heater test:

²Engine run time of at least 5.1 minutes

²Key OFF power down

²Battery voltage of at least 10 volts

²Sufficient Oxygen Sensor cool down

PLEMISSION CONTROL SYSTEMS 25 - 21

DESCRIPTION AND OPERATION (Continued)