relay DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 147 of 1285

CONTROLLER ANTILOCK BRAKE INPUTS

²wheel speed sensors (four)

²stop lamp switch

²ignition switch

²system relay voltage

²ground

²traction control lamp

²diagnostic communication (PCI)

CONTROLLER ANTILOCK BRAKE OUTPUTS

²amber ABS warning lamp actuation (through

MIC)

²red BRAKE warning lamp actuation (through

MIC)

²traction control lamp actuation (through MIC)

²diagnostic communication. (PCI)

HYDRAULIC CONTROL UNIT (HCU)

The hydraulic control unit (HCU) is mounted to

the CAB as part of the ICU (Fig. 2). The HCU con-

trols the flow of brake fluid to the brakes using a

series of valves and accumulators. A pump/motor is

mounted on the HCU to supply build pressure to the

brakes during an ABS stop.

VALVES AND SOLENOIDS

The valve block contains four inlet valves and four

outlet solenoid valves. The inlet valves are spring-

loaded in the open position and the outlet valves are

spring-loaded in the closed position during normal

braking. The fluid is allowed to flow from the master

cylinder to the wheel brakes.

During an ABS stop, these valves cycle to maintain

the proper slip ratio for each wheel. The inlet valve

closes preventing further pressure increase and the

outlet valve opens to provide a path from the wheel

brake to the HCU accumulators and pump/motor.

This releases (decays) pressure from the wheel brake,

thus releasing the wheel from excessive slippage.

Once the wheel is no longer slipping, the outlet valve

is closed and the inlet valve is opened to reapply

(build) pressure.

There are four other valves in the HCU. These four

remaining valves are used for traction control. Two

traction control (TC) valves, mounted in the HCU

valve block, are normally in the open position and

close only when the traction control is applied. There

are also two shuttle valves which control pressure

return to the master cylinder under ABS and traction

control conditions.

These TC valves are used to isolate the rear (non-

driving) wheels of the vehicle from the hydraulic

pressure that the HCU pump/motor is sending to the

front (driving) wheels when traction control is being

applied. The rear brakes need to be isolated from the

master cylinder when traction control is beingapplied so the rear wheels do not drag. For more

information on the TC and shuttle valves, see TRAC-

TION CONTROL SYSTEM in this section.

BRAKE FLUID ACCUMULATORS

There are two fluid accumulators in the HCU: one

for the primary hydraulic circuit, and one for the sec-

ondary hydraulic circuit. Each hydraulic circuit uses

a 3 cc accumulator.

The fluid accumulators temporarily store brake

fluid that is removed from the wheel brakes during

an ABS cycle. This stored fluid is used by the pump/

motor to provide build pressure for the brake hydrau-

lic system. When the antilock stop is complete, the

accumulators are drained by the pump/motor.

There are two noise dampening chambers in the

HCU on this vehicle equipped with traction control.

PUMP/MOTOR

There are two pump assemblies in the HCU: one

for the primary hydraulic circuit, and one for the sec-

ondary hydraulic circuit. Both pumps are driven by a

common electric motor (Fig. 2). This DC-type motor

is integral to the HCU and is controlled by the CAB.

The pump/motor provides the extra amount of

brake fluid needed during antilock braking. Brake

fluid is released to the accumulators when the outlet

valve is opened during an antilock stop. The pump

mechanism consists of two opposing pistons operated

by an eccentric camshaft. In operation, these pistons

are used to purge fluid from the accumulators back

into the master cylinder circuits. When the antilock

stop is complete, the pump/motor drains the accumu-

lators.

The pump motor is also used to build pressure

when the system goes into traction control mode. For

more information, refer to TRACTION CONTROL

SYSTEM in this section.

The CAB may turn on the pump/motor when an

antilock stop is detected. The pump/motor continues

to run during the antilock stop and is turned off after

the stop is complete. Under some conditions, the

pump/motor runs to drain the accumulators during

the next drive-off.

The pump/motor is not a serviceable item; if it

requires replacement, the HCU must be replaced.

ABS FUSES

The ABS fuse and the ABS pump/motor fuse are

located in the power distribution center (PDC). Refer

to the sticker on the inside of the PDC cover for the

location of these fuses. The PDC is located on the

driver's side of the engine compartment between the

back of the battery and the brake master cylinder.

The CAB fuse can be found in the fuse junction

block under the instrument panel.

5 - 68 BRAKESPL

DESCRIPTION AND OPERATION (Continued)

Page 154 of 1285

ABS ELECTRONIC DIAGNOSIS

The following information is presented to give the

technician a general background on the diagnostic

capabilities of the ABS system. Complete electronic

diagnosis of the ABS system used on this vehicle is

covered in the Chassis Diagnostic Procedures manual.

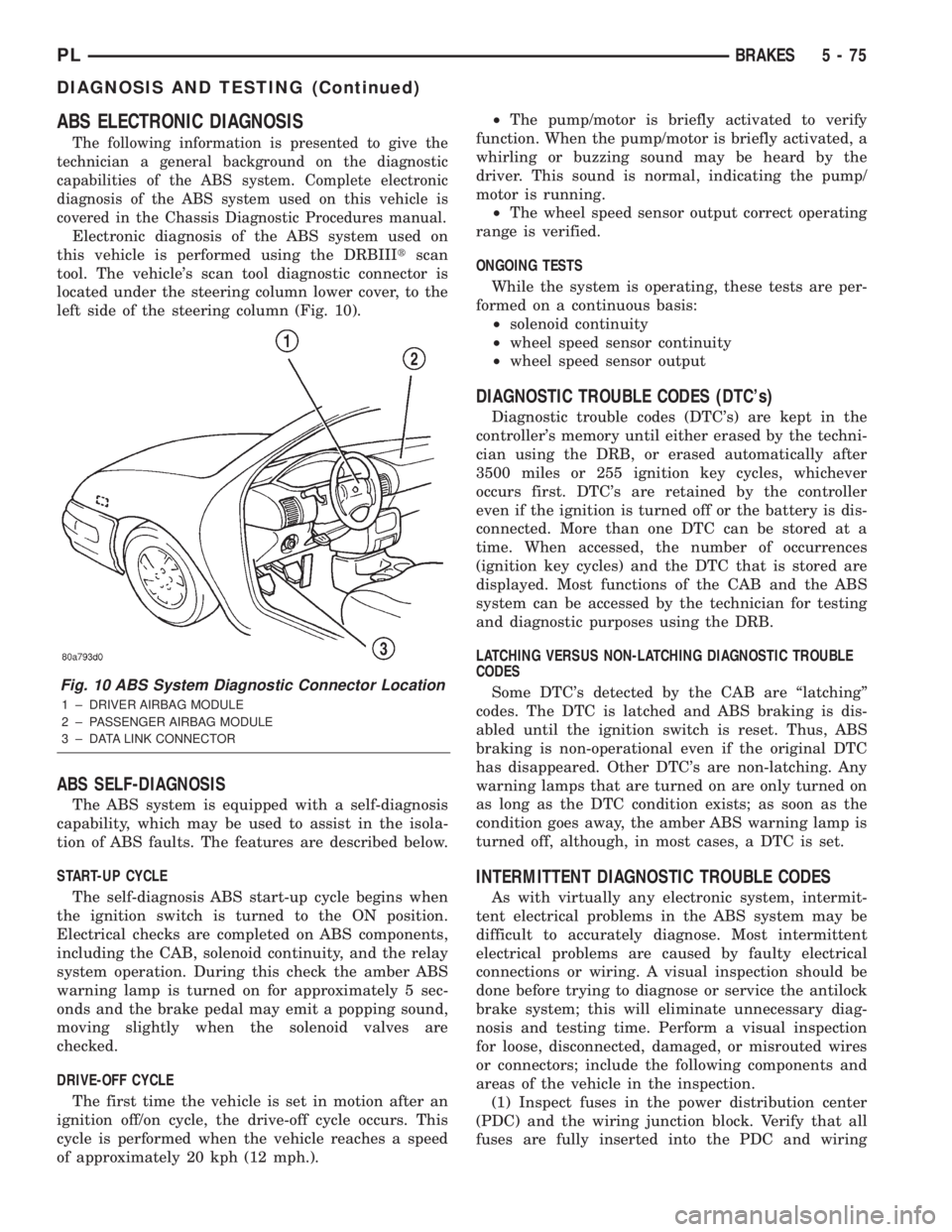

Electronic diagnosis of the ABS system used on

this vehicle is performed using the DRBIIItscan

tool. The vehicle's scan tool diagnostic connector is

located under the steering column lower cover, to the

left side of the steering column (Fig. 10).

ABS SELF-DIAGNOSIS

The ABS system is equipped with a self-diagnosis

capability, which may be used to assist in the isola-

tion of ABS faults. The features are described below.

START-UP CYCLE

The self-diagnosis ABS start-up cycle begins when

the ignition switch is turned to the ON position.

Electrical checks are completed on ABS components,

including the CAB, solenoid continuity, and the relay

system operation. During this check the amber ABS

warning lamp is turned on for approximately 5 sec-

onds and the brake pedal may emit a popping sound,

moving slightly when the solenoid valves are

checked.

DRIVE-OFF CYCLE

The first time the vehicle is set in motion after an

ignition off/on cycle, the drive-off cycle occurs. This

cycle is performed when the vehicle reaches a speed

of approximately 20 kph (12 mph.).²The pump/motor is briefly activated to verify

function. When the pump/motor is briefly activated, a

whirling or buzzing sound may be heard by the

driver. This sound is normal, indicating the pump/

motor is running.

²The wheel speed sensor output correct operating

range is verified.

ONGOING TESTS

While the system is operating, these tests are per-

formed on a continuous basis:

²solenoid continuity

²wheel speed sensor continuity

²wheel speed sensor output

DIAGNOSTIC TROUBLE CODES (DTC's)

Diagnostic trouble codes (DTC's) are kept in the

controller's memory until either erased by the techni-

cian using the DRB, or erased automatically after

3500 miles or 255 ignition key cycles, whichever

occurs first. DTC's are retained by the controller

even if the ignition is turned off or the battery is dis-

connected. More than one DTC can be stored at a

time. When accessed, the number of occurrences

(ignition key cycles) and the DTC that is stored are

displayed. Most functions of the CAB and the ABS

system can be accessed by the technician for testing

and diagnostic purposes using the DRB.

LATCHING VERSUS NON-LATCHING DIAGNOSTIC TROUBLE

CODES

Some DTC's detected by the CAB are ªlatchingº

codes. The DTC is latched and ABS braking is dis-

abled until the ignition switch is reset. Thus, ABS

braking is non-operational even if the original DTC

has disappeared. Other DTC's are non-latching. Any

warning lamps that are turned on are only turned on

as long as the DTC condition exists; as soon as the

condition goes away, the amber ABS warning lamp is

turned off, although, in most cases, a DTC is set.

INTERMITTENT DIAGNOSTIC TROUBLE CODES

As with virtually any electronic system, intermit-

tent electrical problems in the ABS system may be

difficult to accurately diagnose. Most intermittent

electrical problems are caused by faulty electrical

connections or wiring. A visual inspection should be

done before trying to diagnose or service the antilock

brake system; this will eliminate unnecessary diag-

nosis and testing time. Perform a visual inspection

for loose, disconnected, damaged, or misrouted wires

or connectors; include the following components and

areas of the vehicle in the inspection.

(1) Inspect fuses in the power distribution center

(PDC) and the wiring junction block. Verify that all

fuses are fully inserted into the PDC and wiring

Fig. 10 ABS System Diagnostic Connector Location

1 ± DRIVER AIRBAG MODULE

2 ± PASSENGER AIRBAG MODULE

3 ± DATA LINK CONNECTOR

PLBRAKES 5 - 75

DIAGNOSIS AND TESTING (Continued)

Page 155 of 1285

junction block. A label on the underside of the PDC

cover identifies the locations of the ABS fuses.

(2) Inspect the 25-way electrical connector at the

CAB for damaged, spread, or backed-out wiring ter-

minals. Verify that the 25-way connector is fully

inserted in the socket of the CAB. Be sure that wires

are not stretched tight or pulled out of the connector.

(3) Verify that all the wheel speed sensor connec-

tions are secure.

(4) Look for poor mating of connector halves or ter-

minals not fully seated in the connector body.

(5)

Check for improperly formed or damaged termi-

nals. All connector terminals in a suspect circuit should

be carefully reformed to increase contact tension.

(6) Look for poor terminal-to-wire connections.

This requires removing the terminal from the connec-

tor body to inspect it.

(7) Verify pin presence in the connector assembly

(8) Check for proper ground connections. Check all

ground connections for signs of corrosion, loose fas-

teners, or other potential defects. Refer to the wiring

diagrams for ground locations.

(9) Look for problems with the main power sources

of the vehicle. Inspect the battery, generator, ignition

circuits and other related relays and fuses.

If a visual check does not find the cause of the

problem, operate the car in an attempt to duplicate

the condition and record any trouble codes.

Most failures of the ABS disable the ABS function

for the entire ignition cycle even if the fault clears

before key-off. There are some failure conditions,

however, that allow ABS operation to resume during

the ignition cycle in which the trouble occurred even

if the trouble conditions are no longer present.

The following trouble conditions may result in

intermittent illumination of the amber ABS warning

lamp.

²Low system voltage. If Low System Voltage is

detected by the CAB, the CAB will turn on the ABS

Warning Lamp until normal system voltage is

achieved. Once normal voltage is seen at the CAB,

normal operation resumes.

²High system voltage. If high system voltage is

detected by the CAB, the CAB will turn on the

Amber ABS Warning Lamp until normal system volt-

age is achieved. Once normal voltage is again

detected by the CAB, normal ABS operation resumes.

Additional possible causes that may result in the

illumination of the amber ABS warning lamp are as

follows:

²Any condition that interrupts electrical current

to the CAB may cause the amber ABS warning lamp

to turn on intermittently.

²If PCI communication between the body control-

ler and the CAB is interrupted, the body controller

can turn on the amber ABS warning lamp.

TONE WHEEL

Tone wheels can cause erratic wheel speed sensor

signals. Inspect tone wheels for the following possible

causes:

²missing, chipped, or broken teeth

²contact with the wheel speed sensor

²wheel speed sensor to tone wheel alignment

²wheel speed sensor to tone wheel clearance

²excessive tone wheel runout

²tone wheel loose on its mounting surface

If a front tone wheel is found to need replacement,

the drive shaft must be replaced. No attempt should

be made to replace just the tone wheel. Refer to the

DIFFERENTIAL AND DRIVELINE group in this

service manual for removal and installation.

If a rear tone wheel is found to need replacement,

the rear hub and bearing must be replaced. No

attempt should be made to replace just the tone

wheel. Refer to the SUSPENSION group in this ser-

vice manual for removal and installation.

If wheel speed sensor to tone wheel contact is evi-

dent, determine the cause and correct it before

replacing the wheel speed sensor or tone wheel.

Check the gap between the speed sensor head and

the tone wheel to ensure it is within specifications.

Refer to SPECIFICATIONS in this section of the ser-

vice manual for the minimum and maximum wheel

speed sensor to tone wheel clearance.

Excessive wheel speed sensor runout can cause

erratic wheel speed sensor signals. Refer to SPECI-

FICATIONS in this section of the service manual for

the maximum allowed tone wheel runout. If tone

wheel runout is excessive, determine if it is caused

by a defect in the driveshaft assembly or hub and

bearing. Replace as necessary.

Tone wheels are pressed onto their mounting sur-

faces and should not rotate independently from the

mounting surface. Replacement of the front drive-

shaft or rear hub and bearing is necessary.

BRAKE FLUID CONTAMINATION

Indications of fluid contamination are swollen or

deteriorated rubber parts. Swelling indicates the

presence of petroleum in the brake fluid.

To test for contamination, put a small amount of

drained brake fluid in clear glass jar. If the fluid sep-

arates into layers, there is mineral oil or other fluid

contamination of the brake fluid.

If the brake fluid is contaminated, drain and thor-

oughly flush the brake system. Replace all the rubber

parts or components containing rubber coming into

contact with the brake fluid including: the master

cylinder; proportioning valves; caliper seals; wheel

cylinder seals; ABS hydraulic control unit; and all

hydraulic fluid hoses.

5 - 76 BRAKESPL

DIAGNOSIS AND TESTING (Continued)

Page 183 of 1285

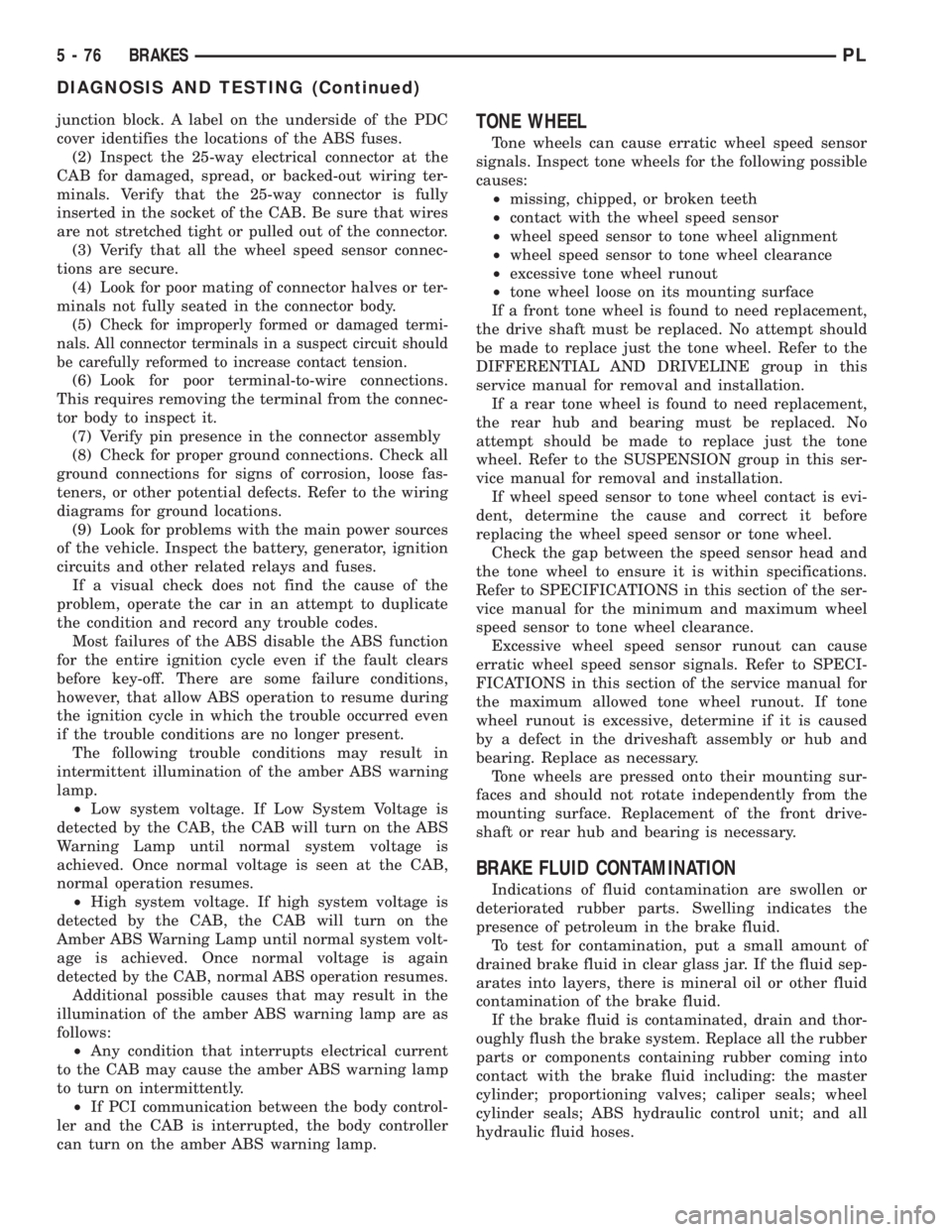

Radiator cooling fan control operation is accomplished

two ways. The fan always runs when the air condition-

ing compressor clutch is engaged. In addition to this

control, the fan is turned on by the temperature of the

coolant which is sensed by the coolant temperature sen-

sor which sends the message to the Powertrain Control

Module (PCM). The PCM turns on the fan through a

fan relay by grounding the relay's coil. The fan relay is

located in the Power Distribution Center (PDC) (Fig. 4).

Refer to the label beneath the PDC cover for location of

fan relay.

The PCM will actuate the fan relay whenever the A/C

clutch is engaged regardless of coolant temperature and

vehicle speed. If the A/C clutch is not engaged, the PCM

will actuate the fan relay when the coolant temperature

reaches approximately (97É C) 207É F and turns off the

fan relay when the coolant temperature drops to

approximately (94ÉC) 201É F. The fan relay is also

turned off when the vehicle speed is above approxi-

mately 100 Km/h (62 MPH). Refer to Group 8W, Wiring

Diagrams for circuity provided.

If the cooling fan is inoperative or a Diagnostic

Trouble Code (DTC) related to fan control has been

set, refer to the appropriate Powertrain Diagnostic

Manual for complete diagnostic procedures.

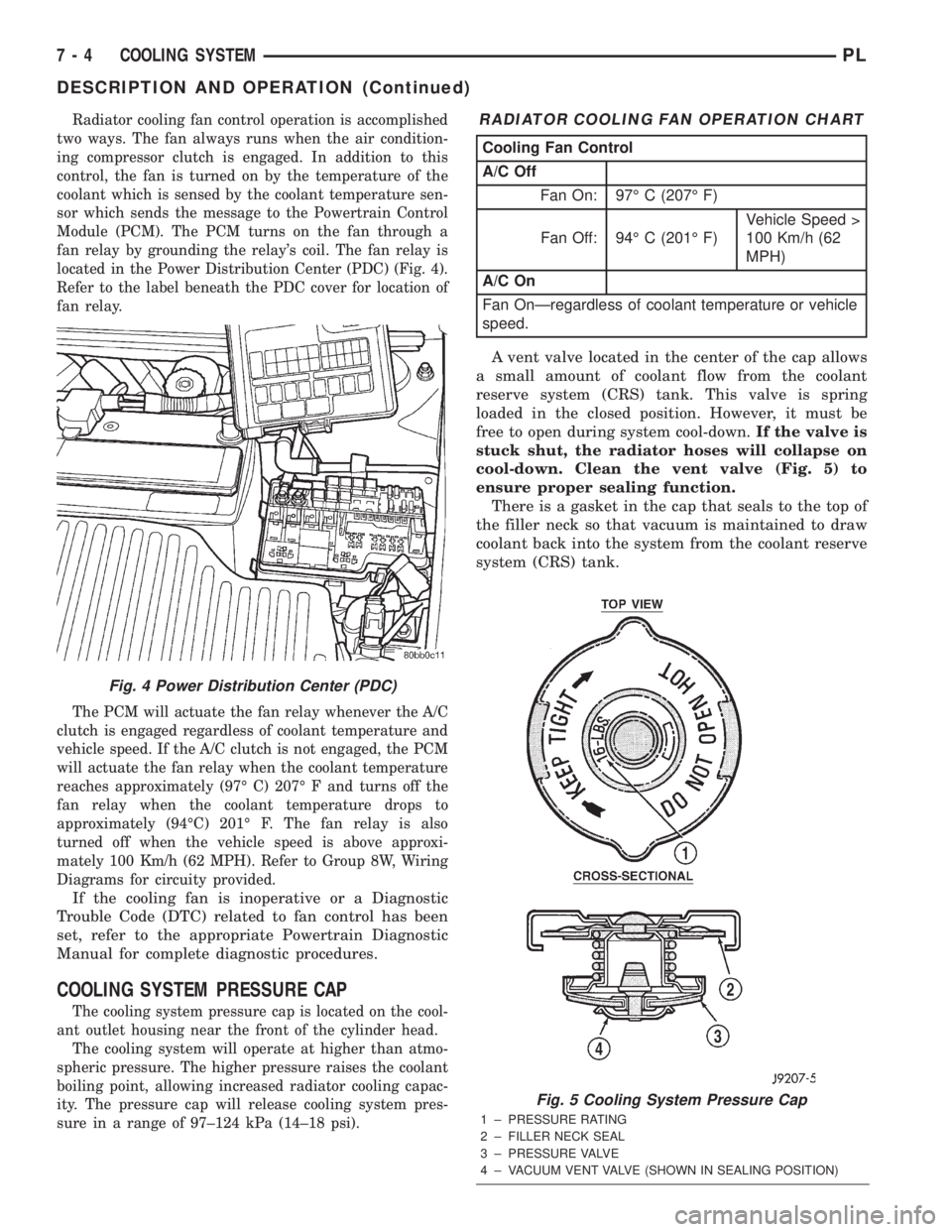

COOLING SYSTEM PRESSURE CAP

The cooling system pressure cap is located on the cool-

ant outlet housing near the front of the cylinder head.

The cooling system will operate at higher than atmo-

spheric pressure. The higher pressure raises the coolant

boiling point, allowing increased radiator cooling capac-

ity. The pressure cap will release cooling system pres-

sure in a range of 97±124 kPa (14±18 psi).

A vent valve located in the center of the cap allows

a small amount of coolant flow from the coolant

reserve system (CRS) tank. This valve is spring

loaded in the closed position. However, it must be

free to open during system cool-down.If the valve is

stuck shut, the radiator hoses will collapse on

cool-down. Clean the vent valve (Fig. 5) to

ensure proper sealing function.

There is a gasket in the cap that seals to the top of

the filler neck so that vacuum is maintained to draw

coolant back into the system from the coolant reserve

system (CRS) tank.

Fig. 4 Power Distribution Center (PDC)

RADIATOR COOLING FAN OPERATION CHART

Cooling Fan Control

A/C Off

Fan On: 97É C (207É F)

Fan Off: 94É C (201É F)Vehicle Speed >

100 Km/h (62

MPH)

A/C On

Fan OnÐregardless of coolant temperature or vehicle

speed.

Fig. 5 Cooling System Pressure Cap

1 ± PRESSURE RATING

2 ± FILLER NECK SEAL

3 ± PRESSURE VALVE

4 ± VACUUM VENT VALVE (SHOWN IN SEALING POSITION)

7 - 4 COOLING SYSTEMPL

DESCRIPTION AND OPERATION (Continued)

Page 189 of 1285

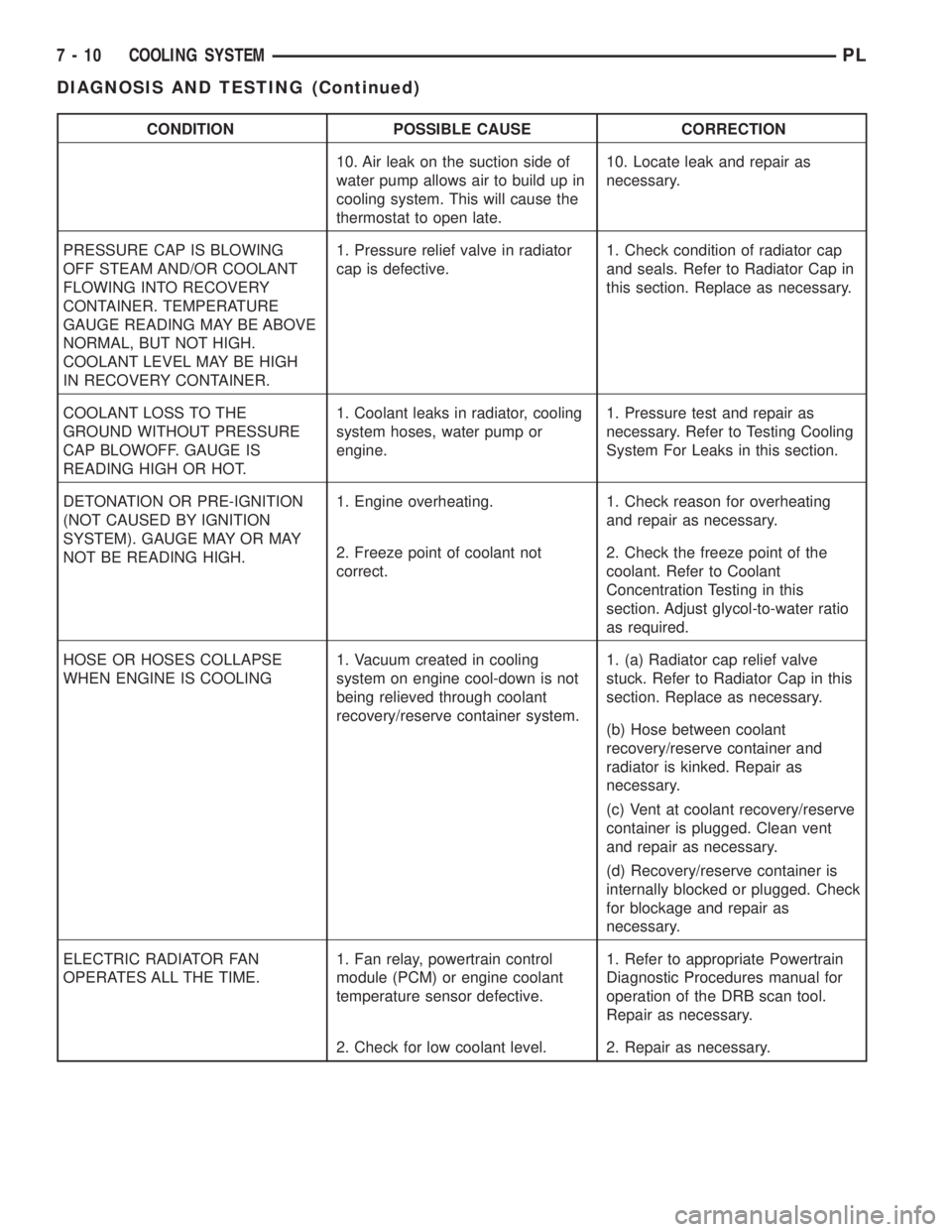

CONDITION POSSIBLE CAUSE CORRECTION

10. Air leak on the suction side of

water pump allows air to build up in

cooling system. This will cause the

thermostat to open late.10. Locate leak and repair as

necessary.

PRESSURE CAP IS BLOWING

OFF STEAM AND/OR COOLANT

FLOWING INTO RECOVERY

CONTAINER. TEMPERATURE

GAUGE READING MAY BE ABOVE

NORMAL, BUT NOT HIGH.

COOLANT LEVEL MAY BE HIGH

IN RECOVERY CONTAINER.1. Pressure relief valve in radiator

cap is defective.1. Check condition of radiator cap

and seals. Refer to Radiator Cap in

this section. Replace as necessary.

COOLANT LOSS TO THE

GROUND WITHOUT PRESSURE

CAP BLOWOFF. GAUGE IS

READING HIGH OR HOT.1. Coolant leaks in radiator, cooling

system hoses, water pump or

engine.1. Pressure test and repair as

necessary. Refer to Testing Cooling

System For Leaks in this section.

DETONATION OR PRE-IGNITION

(NOT CAUSED BY IGNITION

SYSTEM). GAUGE MAY OR MAY

NOT BE READING HIGH.1. Engine overheating. 1. Check reason for overheating

and repair as necessary.

2. Freeze point of coolant not

correct.2. Check the freeze point of the

coolant. Refer to Coolant

Concentration Testing in this

section. Adjust glycol-to-water ratio

as required.

HOSE OR HOSES COLLAPSE

WHEN ENGINE IS COOLING1. Vacuum created in cooling

system on engine cool-down is not

being relieved through coolant

recovery/reserve container system.1. (a) Radiator cap relief valve

stuck. Refer to Radiator Cap in this

section. Replace as necessary.

(b) Hose between coolant

recovery/reserve container and

radiator is kinked. Repair as

necessary.

(c) Vent at coolant recovery/reserve

container is plugged. Clean vent

and repair as necessary.

(d) Recovery/reserve container is

internally blocked or plugged. Check

for blockage and repair as

necessary.

ELECTRIC RADIATOR FAN

OPERATES ALL THE TIME.1. Fan relay, powertrain control

module (PCM) or engine coolant

temperature sensor defective.1. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

2. Check for low coolant level. 2. Repair as necessary.

7 - 10 COOLING SYSTEMPL

DIAGNOSIS AND TESTING (Continued)

Page 190 of 1285

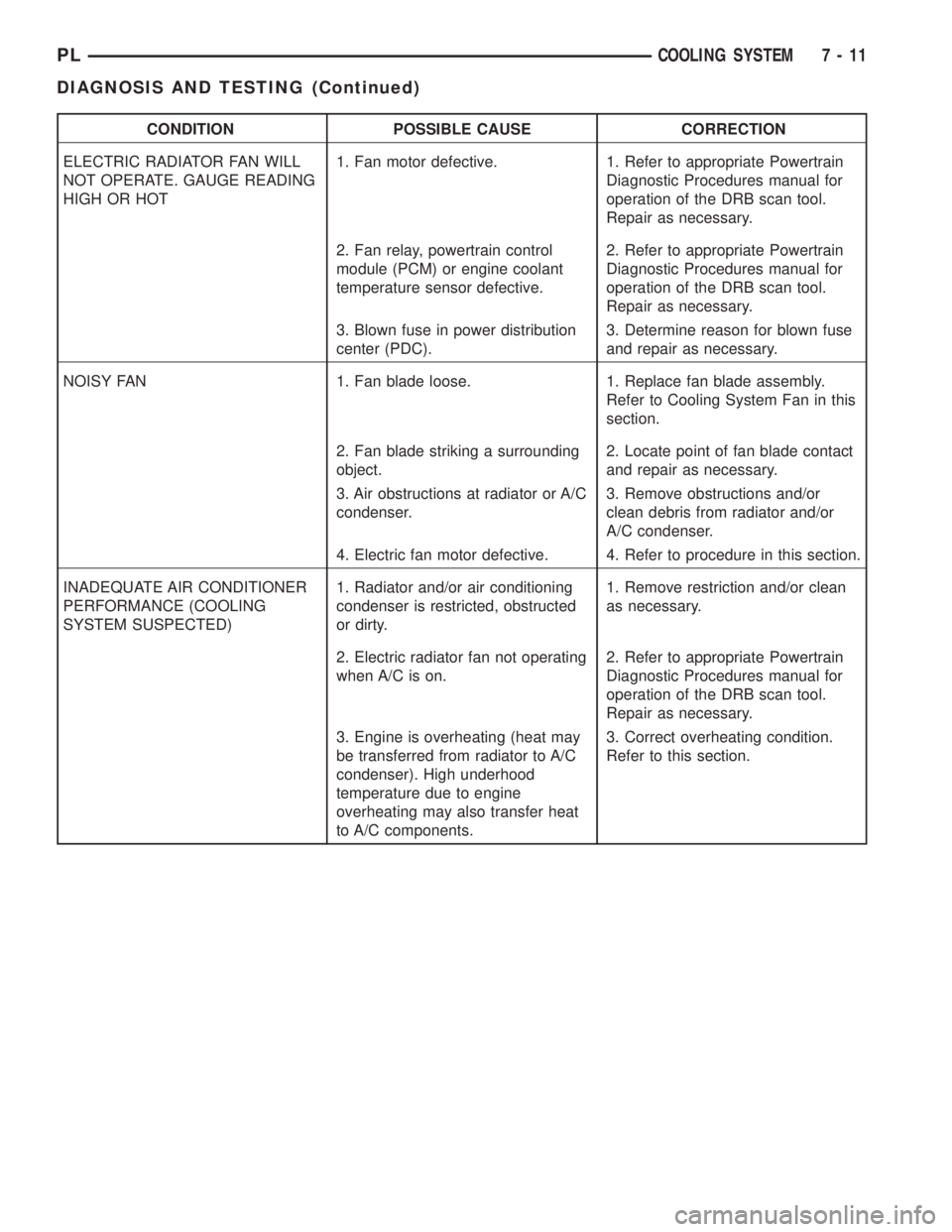

CONDITION POSSIBLE CAUSE CORRECTION

ELECTRIC RADIATOR FAN WILL

NOT OPERATE. GAUGE READING

HIGH OR HOT1. Fan motor defective. 1. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

2. Fan relay, powertrain control

module (PCM) or engine coolant

temperature sensor defective.2. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

3. Blown fuse in power distribution

center (PDC).3. Determine reason for blown fuse

and repair as necessary.

NOISY FAN 1. Fan blade loose. 1. Replace fan blade assembly.

Refer to Cooling System Fan in this

section.

2. Fan blade striking a surrounding

object.2. Locate point of fan blade contact

and repair as necessary.

3. Air obstructions at radiator or A/C

condenser.3. Remove obstructions and/or

clean debris from radiator and/or

A/C condenser.

4. Electric fan motor defective. 4. Refer to procedure in this section.

INADEQUATE AIR CONDITIONER

PERFORMANCE (COOLING

SYSTEM SUSPECTED)1. Radiator and/or air conditioning

condenser is restricted, obstructed

or dirty.1. Remove restriction and/or clean

as necessary.

2. Electric radiator fan not operating

when A/C is on.2. Refer to appropriate Powertrain

Diagnostic Procedures manual for

operation of the DRB scan tool.

Repair as necessary.

3. Engine is overheating (heat may

be transferred from radiator to A/C

condenser). High underhood

temperature due to engine

overheating may also transfer heat

to A/C components.3. Correct overheating condition.

Refer to this section.

PLCOOLING SYSTEM 7 - 11

DIAGNOSIS AND TESTING (Continued)

Page 222 of 1285

STARTING SYSTEMS

TABLE OF CONTENTS

page page

GENERAL INFORMATION

INTRODUCTION..........................1

SUPPLY CIRCUIT AND CONTROL CIRCUIT.....1

DESCRIPTION AND OPERATION

STARTER MOTOR.........................1

DIAGNOSIS AND TESTING

CONTROL CIRCUIT........................2

FEED CIRCUIT RESISTANCE................3

FEED CIRCUIT...........................5STARTING SYSTEM.......................6

REMOVAL AND INSTALLATION

SAFETY SWITCHES.......................8

STARTER MOTOR.........................8

STARTER RELAY.........................8

SPECIFICATIONS

STARTER MOTOR.........................9

TORQUE................................9

GENERAL INFORMATION

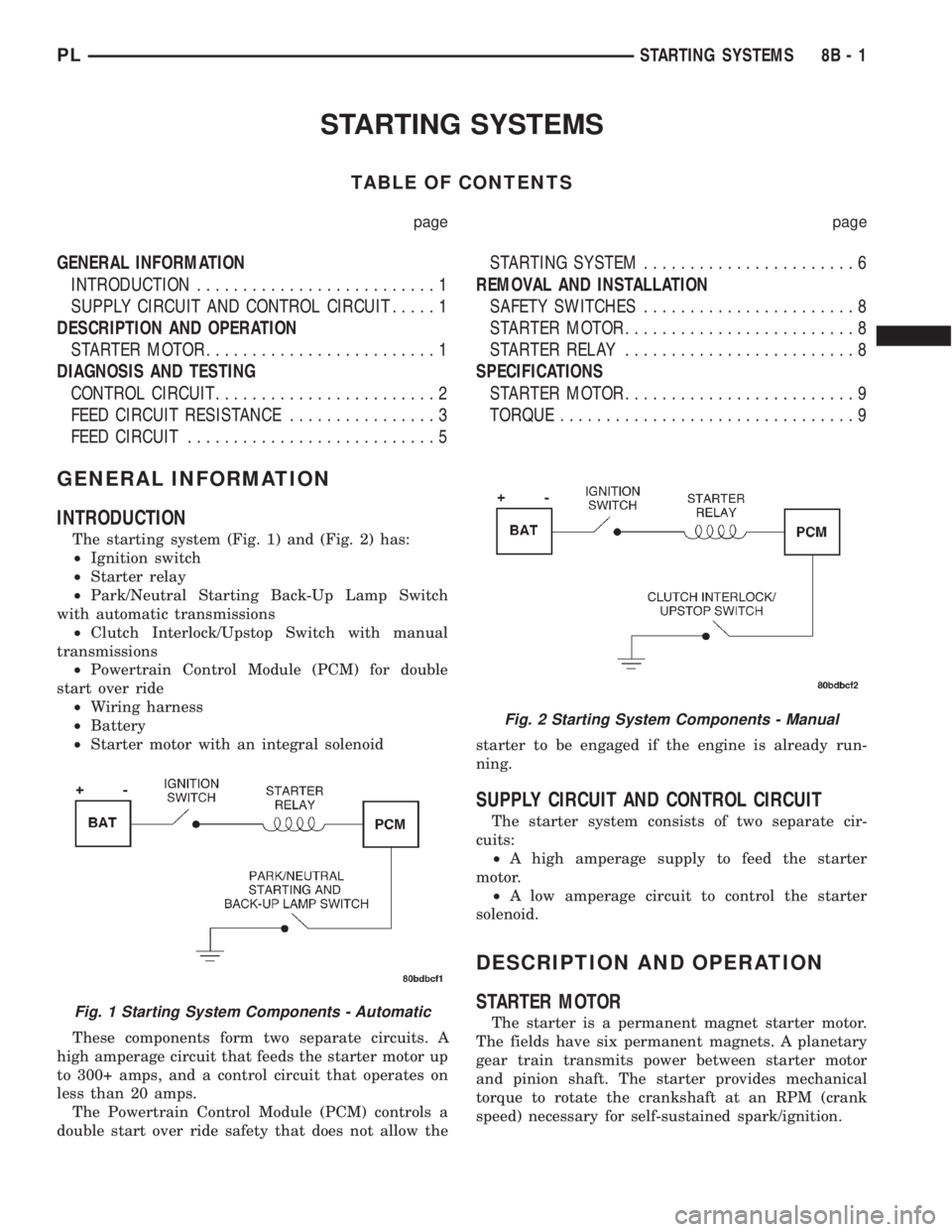

INTRODUCTION

The starting system (Fig. 1) and (Fig. 2) has:

²Ignition switch

²Starter relay

²Park/Neutral Starting Back-Up Lamp Switch

with automatic transmissions

²Clutch Interlock/Upstop Switch with manual

transmissions

²Powertrain Control Module (PCM) for double

start over ride

²Wiring harness

²Battery

²Starter motor with an integral solenoid

These components form two separate circuits. A

high amperage circuit that feeds the starter motor up

to 300+ amps, and a control circuit that operates on

less than 20 amps.

The Powertrain Control Module (PCM) controls a

double start over ride safety that does not allow thestarter to be engaged if the engine is already run-

ning.

SUPPLY CIRCUIT AND CONTROL CIRCUIT

The starter system consists of two separate cir-

cuits:

²A high amperage supply to feed the starter

motor.

²A low amperage circuit to control the starter

solenoid.

DESCRIPTION AND OPERATION

STARTER MOTOR

The starter is a permanent magnet starter motor.

The fields have six permanent magnets. A planetary

gear train transmits power between starter motor

and pinion shaft. The starter provides mechanical

torque to rotate the crankshaft at an RPM (crank

speed) necessary for self-sustained spark/ignition.Fig. 1 Starting System Components - Automatic

Fig. 2 Starting System Components - Manual

PLSTARTING SYSTEMS 8B - 1

Page 223 of 1285

DIAGNOSIS AND TESTING

CONTROL CIRCUIT

The starter control circuit has:

²Starter solenoid

²Starter relay

²Park/Neutral Starting and Back-Up Lamp

Switch with automatic transmissions

²Clutch Interlock/Upstop Switch with manual

transmissions

²Ignition switch

²Battery

²All related wiring and connections

²Double Start Override algorithm located in the

PCM

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

²To disable ignition and fuel systems, disconnect

the Automatic Shutdown Relay (ASD). The ASD relay

is located in the in the Power Distribution Center

(PDC). Refer to the PDC cover for the proper relay

location.

STARTER SOLENOID

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED

(1) Verify battery condition. Battery must be in

good condition with a full charge before performing

any starter tests. Refer to Battery Tests.

(2) Perform Starter Solenoid test BEFORE per-

forming the starter relay test.

(3) Raise the vehicle.

(4) Perform a visual inspection of the starter/

starter solenoid for corrosion, loose connections or

faulty wiring.

(5) Lower the vehicle.

(6) Locate and remove the starter relay from the

Power Distribution Center (PDC). Refer to the PDC

label for relay identification and location.

(7) Connect a starter switch or a jumper wire

between the remote battery positive post and termi-

nal 87 of the starter relay connector.

(a) If engine cranks, starter motor and starter

solenoid is good. Go to the Starter Relay Test.(b) If engine does not crank or solenoid chatters,

check wiring and connectors from starter relay to

starter solenoid for loose or corroded connections.

Check for corroded connections at starter termi-

nals.

(c) Repeat test. If engine still fails to crank prop-

erly, trouble is within starter or starter mounted

solenoid, and replace starter.

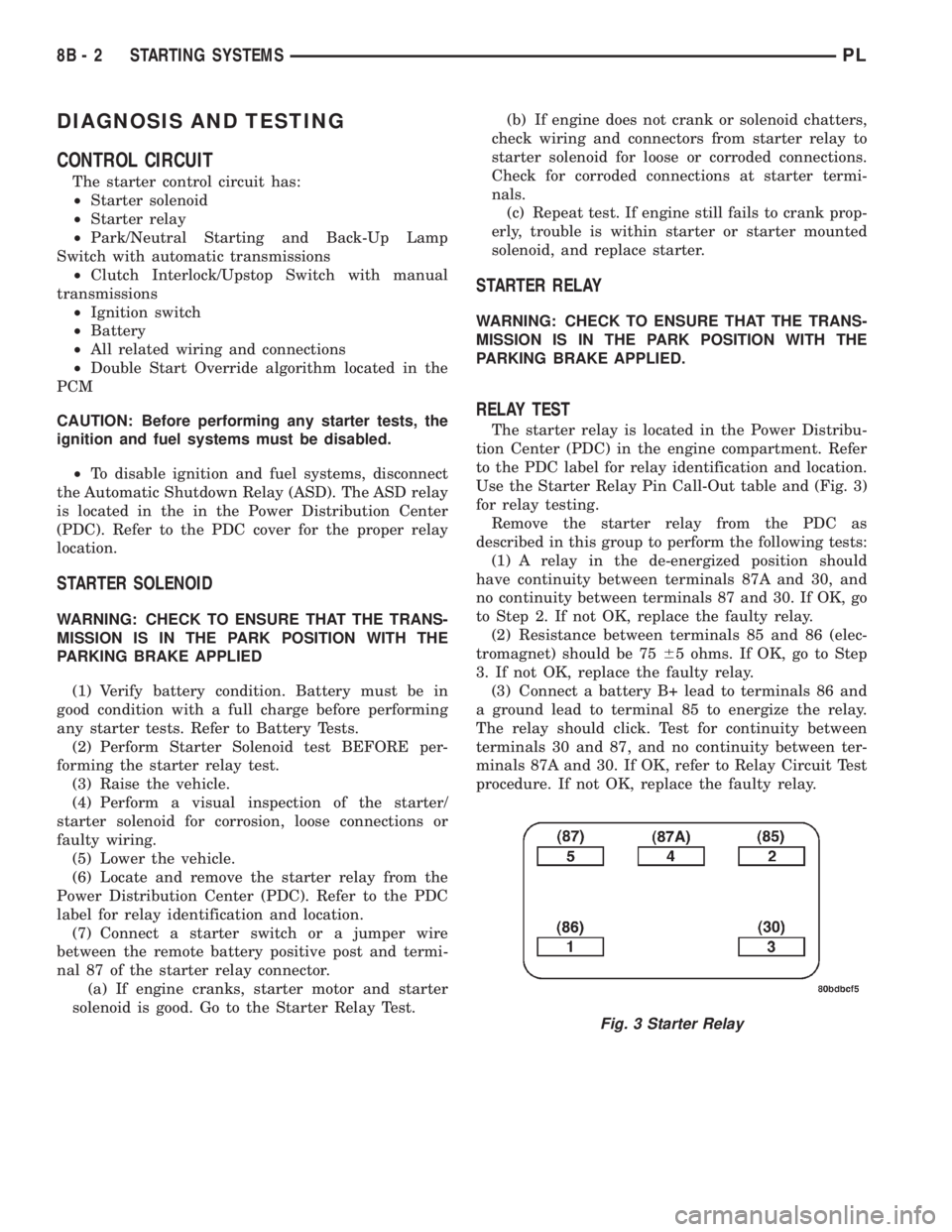

STARTER RELAY

WARNING: CHECK TO ENSURE THAT THE TRANS-

MISSION IS IN THE PARK POSITION WITH THE

PARKING BRAKE APPLIED.

RELAY TEST

The starter relay is located in the Power Distribu-

tion Center (PDC) in the engine compartment. Refer

to the PDC label for relay identification and location.

Use the Starter Relay Pin Call-Out table and (Fig. 3)

for relay testing.

Remove the starter relay from the PDC as

described in this group to perform the following tests:

(1) A relay in the de-energized position should

have continuity between terminals 87A and 30, and

no continuity between terminals 87 and 30. If OK, go

to Step 2. If not OK, replace the faulty relay.

(2) Resistance between terminals 85 and 86 (elec-

tromagnet) should be 7565 ohms. If OK, go to Step

3. If not OK, replace the faulty relay.

(3) Connect a battery B+ lead to terminals 86 and

a ground lead to terminal 85 to energize the relay.

The relay should click. Test for continuity between

terminals 30 and 87, and no continuity between ter-

minals 87A and 30. If OK, refer to Relay Circuit Test

procedure. If not OK, replace the faulty relay.

Fig. 3 Starter Relay

8B - 2 STARTING SYSTEMSPL

Page 224 of 1285

STARTER RELAY PIN CALL-OUT

PIN CIRCUIT COLOR DESCRIPTION

1 (86) A041 YL IGNITION SWITCH OUTPUT (START)

2 (85) K090 TN PCM

3 (30) A001 RD FUSED B+

4 (87A) NOT USED

5 (87) T040 BR STARTER SOLENOID

RELAY CIRCUIT TEST

(1) The relay common feed terminal cavity (30) is

connected to battery voltage and should be hot at all

times. If OK, go to Step 2. If not OK, repair the open

circuit to the PDC fuse as required.

(2) The relay normally closed terminal (87A) is

connected to terminal 30 in the de-energized position,

but is not used for this application. Go to Step 3.

(3) The relay normally open terminal (87) is con-

nected to the common feed terminal (30) in the ener-

gized position. This terminal supplies battery voltage

to the starter solenoid field coils. There should be

continuity between the cavity for relay terminal 87

and the starter solenoid terminal at all times. If OK,

go to Step 4. If not OK, repair the open circuit to the

starter solenoid as required.

(4) The coil battery terminal (86) is connected to

the electromagnet in the relay. It is energized when

the ignition switch is held in the START position. On

vehicles with a manual transmission, the clutch

pedal must be fully depressed for this test. Check for

battery voltage at the cavity for relay terminal 86

with the ignition switch in the START position, and

no voltage when the ignition switch is released to the

ON position. If OK, go to Step 5. If not OK with an

automatic transmission, check for an open or short

circuit to the ignition switch and repair, if required.

If the circuit to the ignition switch is OK, see the

Ignition Switch Test procedure in this group. If not

OK with a manual transmission, check the circuit

between the relay and the clutch interlock/upstop

switch for an open or a short circuit. If the circuit is

OK, refer to the Clutch Interlock/Upstop Switch

Diagnosis and Testing in Group 6-Clutch.

(5) The coil ground terminal (85) is connected to

the electromagnet in the relay. It is grounded

through the PCM only when the gearshift selector

lever is in the Park or Neutral positions. On vehicles

with a manual transmission, it is grounded through

the PCM when the clutch pedal is depressed. Check

for continuity to ground at the cavity for relay termi-

nal 85. If not OK, check for an open or short circuit

to the park/neutral starting and back-up lamp

switch, or the clutch interlock/upstop switch. Repair,

as necessary. If the circuit is OK, refer to the Park/Neutral Starting and Back-Up Lamp Switch Removal

and Installation in Group 21-Transaxle. Testing is

located within the Removal and Installation proce-

dures.

SAFETY SWITCHES

For diagnosis of:

²Clutch Interlock/Upstop Switch, refer to Diagno-

sis and Testing in Group 6-Clutch.

²Park/Neutral Starting and Back-Up Lamp

Switch, refer to Removal and Installation in Group

21-Transaxle. Testing is located within the Removal

and Installation procedures.

IGNITION SWITCH

After testing starter solenoid and relay, test igni-

tion switch and wiring. Check all wiring for opens or

shorts, and all connectors for being loose or corroded.

Refer to Group 8D-Ignition Systems, or Group

8W-Wiring Diagrams.

BATTERY

Refer to Group 8A-Battery for Diagnosis and Test-

ing of the battery.

ALL RELATED WIRING AND CONNECTORS

Refer to Group 8W-Wiring Diagrams.

FEED CIRCUIT RESISTANCE

Before proceeding with this operation, review Diag-

nostic Preparation and Starter Feed Circuit Tests.

The following operation will require a voltmeter,

accurate to 1/10 of a volt.

CAUTION: Ignition system also must be disabled to

prevent engine start while performing the following

tests.

(1) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown (ASD) Relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(2) With all wiring harnesses and components

properly connected, perform the following:

PLSTARTING SYSTEMS 8B - 3

DIAGNOSIS AND TESTING (Continued)

Page 226 of 1285

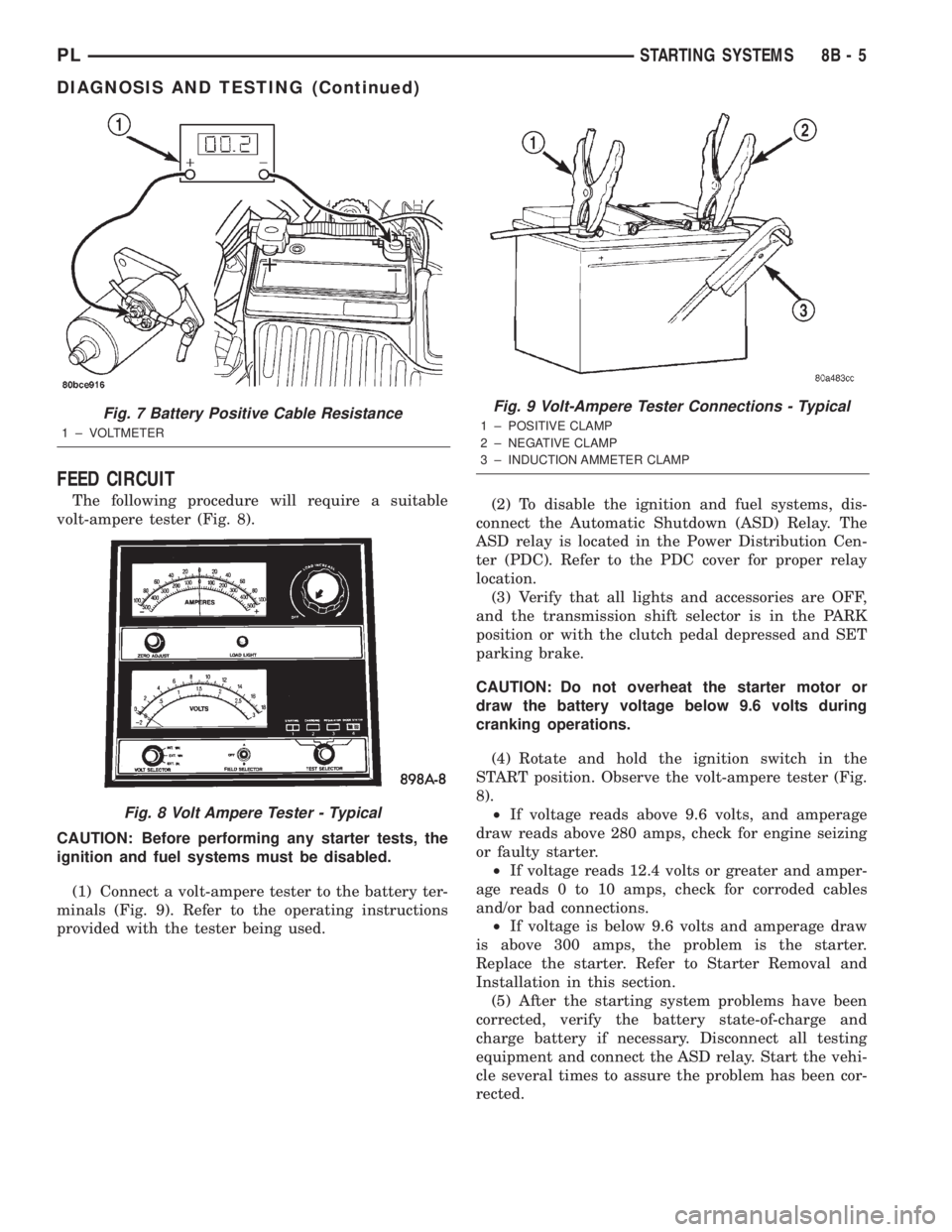

FEED CIRCUIT

The following procedure will require a suitable

volt-ampere tester (Fig. 8).

CAUTION: Before performing any starter tests, the

ignition and fuel systems must be disabled.

(1) Connect a volt-ampere tester to the battery ter-

minals (Fig. 9). Refer to the operating instructions

provided with the tester being used.(2) To disable the ignition and fuel systems, dis-

connect the Automatic Shutdown (ASD) Relay. The

ASD relay is located in the Power Distribution Cen-

ter (PDC). Refer to the PDC cover for proper relay

location.

(3) Verify that all lights and accessories are OFF,

and the transmission shift selector is in the PARK

position or with the clutch pedal depressed and SET

parking brake.

CAUTION: Do not overheat the starter motor or

draw the battery voltage below 9.6 volts during

cranking operations.

(4) Rotate and hold the ignition switch in the

START position. Observe the volt-ampere tester (Fig.

8).

²If voltage reads above 9.6 volts, and amperage

draw reads above 280 amps, check for engine seizing

or faulty starter.

²If voltage reads 12.4 volts or greater and amper-

age reads 0 to 10 amps, check for corroded cables

and/or bad connections.

²If voltage is below 9.6 volts and amperage draw

is above 300 amps, the problem is the starter.

Replace the starter. Refer to Starter Removal and

Installation in this section.

(5) After the starting system problems have been

corrected, verify the battery state-of-charge and

charge battery if necessary. Disconnect all testing

equipment and connect the ASD relay. Start the vehi-

cle several times to assure the problem has been cor-

rected.

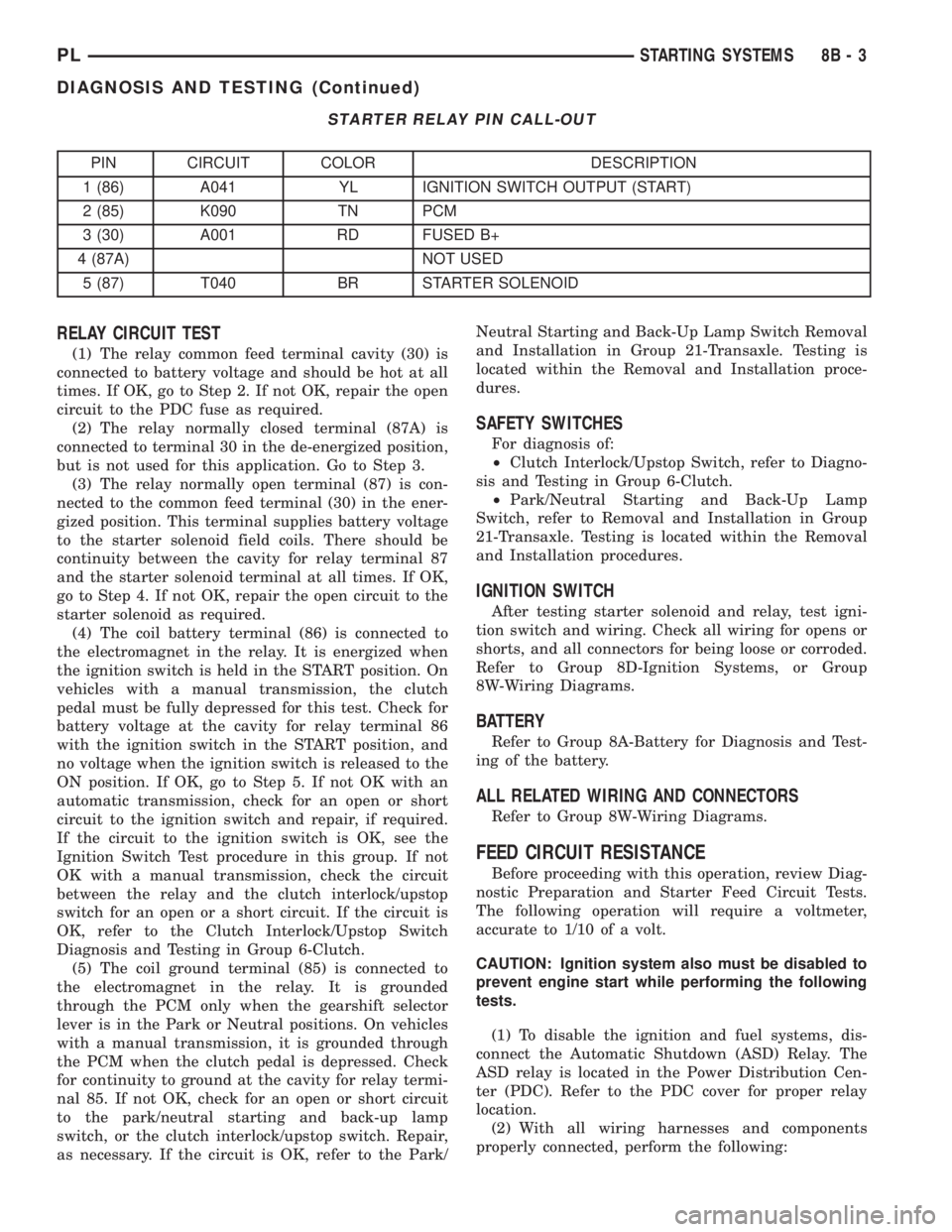

Fig. 7 Battery Positive Cable Resistance

1 ± VOLTMETER

Fig. 8 Volt Ampere Tester - Typical

Fig. 9 Volt-Ampere Tester Connections - Typical

1 ± POSITIVE CLAMP

2 ± NEGATIVE CLAMP

3 ± INDUCTION AMMETER CLAMP

PLSTARTING SYSTEMS 8B - 5

DIAGNOSIS AND TESTING (Continued)