instrument panel DODGE NEON 2000 Service Repair Manual

[x] Cancel search | Manufacturer: DODGE, Model Year: 2000, Model line: NEON, Model: DODGE NEON 2000Pages: 1285, PDF Size: 29.42 MB

Page 911 of 1285

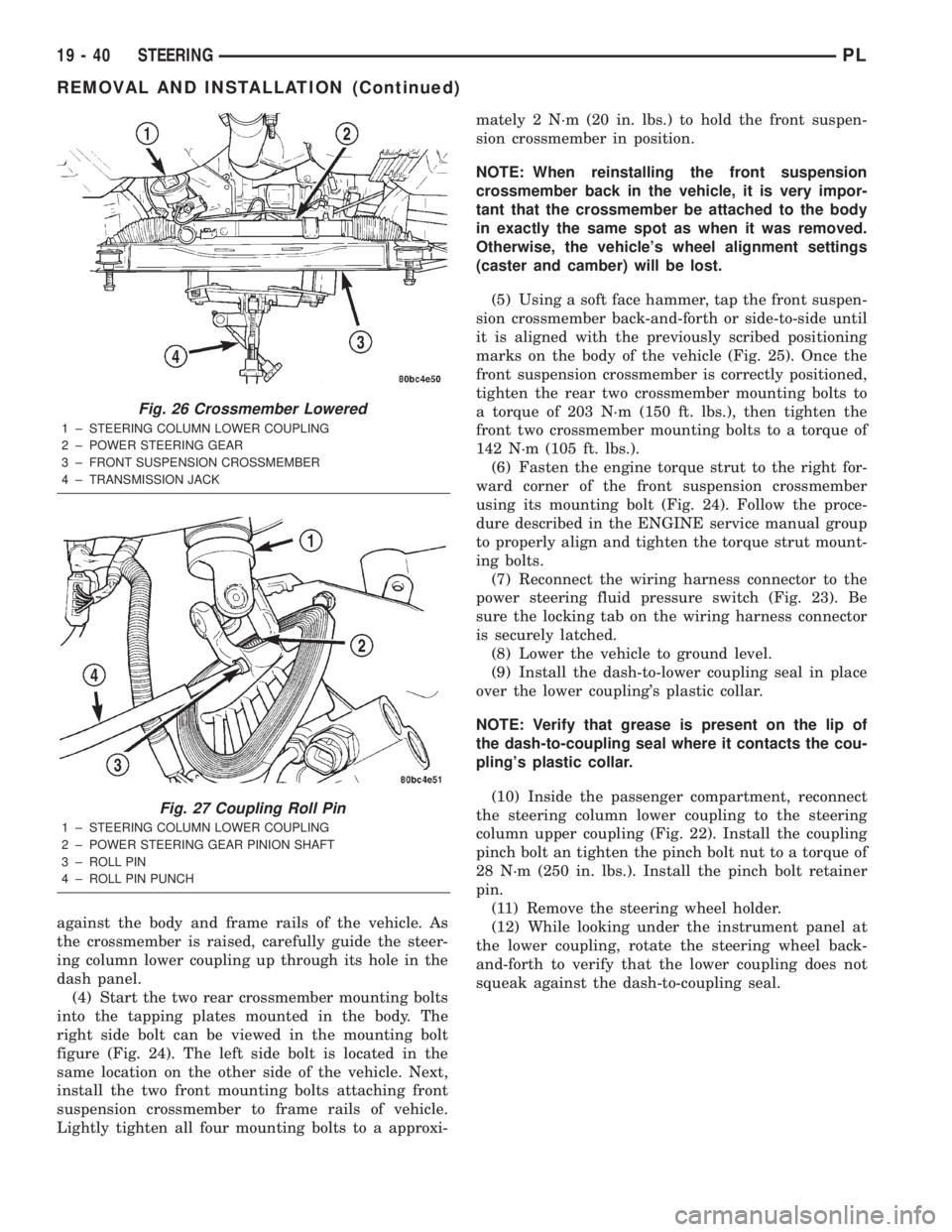

against the body and frame rails of the vehicle. As

the crossmember is raised, carefully guide the steer-

ing column lower coupling up through its hole in the

dash panel.

(4) Start the two rear crossmember mounting bolts

into the tapping plates mounted in the body. The

right side bolt can be viewed in the mounting bolt

figure (Fig. 24). The left side bolt is located in the

same location on the other side of the vehicle. Next,

install the two front mounting bolts attaching front

suspension crossmember to frame rails of vehicle.

Lightly tighten all four mounting bolts to a approxi-mately 2 N´m (20 in. lbs.) to hold the front suspen-

sion crossmember in position.

NOTE: When reinstalling the front suspension

crossmember back in the vehicle, it is very impor-

tant that the crossmember be attached to the body

in exactly the same spot as when it was removed.

Otherwise, the vehicle's wheel alignment settings

(caster and camber) will be lost.

(5) Using a soft face hammer, tap the front suspen-

sion crossmember back-and-forth or side-to-side until

it is aligned with the previously scribed positioning

marks on the body of the vehicle (Fig. 25). Once the

front suspension crossmember is correctly positioned,

tighten the rear two crossmember mounting bolts to

a torque of 203 N´m (150 ft. lbs.), then tighten the

front two crossmember mounting bolts to a torque of

142 N´m (105 ft. lbs.).

(6) Fasten the engine torque strut to the right for-

ward corner of the front suspension crossmember

using its mounting bolt (Fig. 24). Follow the proce-

dure described in the ENGINE service manual group

to properly align and tighten the torque strut mount-

ing bolts.

(7) Reconnect the wiring harness connector to the

power steering fluid pressure switch (Fig. 23). Be

sure the locking tab on the wiring harness connector

is securely latched.

(8) Lower the vehicle to ground level.

(9) Install the dash-to-lower coupling seal in place

over the lower coupling's plastic collar.

NOTE: Verify that grease is present on the lip of

the dash-to-coupling seal where it contacts the cou-

pling's plastic collar.

(10) Inside the passenger compartment, reconnect

the steering column lower coupling to the steering

column upper coupling (Fig. 22). Install the coupling

pinch bolt an tighten the pinch bolt nut to a torque of

28 N´m (250 in. lbs.). Install the pinch bolt retainer

pin.

(11) Remove the steering wheel holder.

(12) While looking under the instrument panel at

the lower coupling, rotate the steering wheel back-

and-forth to verify that the lower coupling does not

squeak against the dash-to-coupling seal.

Fig. 26 Crossmember Lowered

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR

3 ± FRONT SUSPENSION CROSSMEMBER

4 ± TRANSMISSION JACK

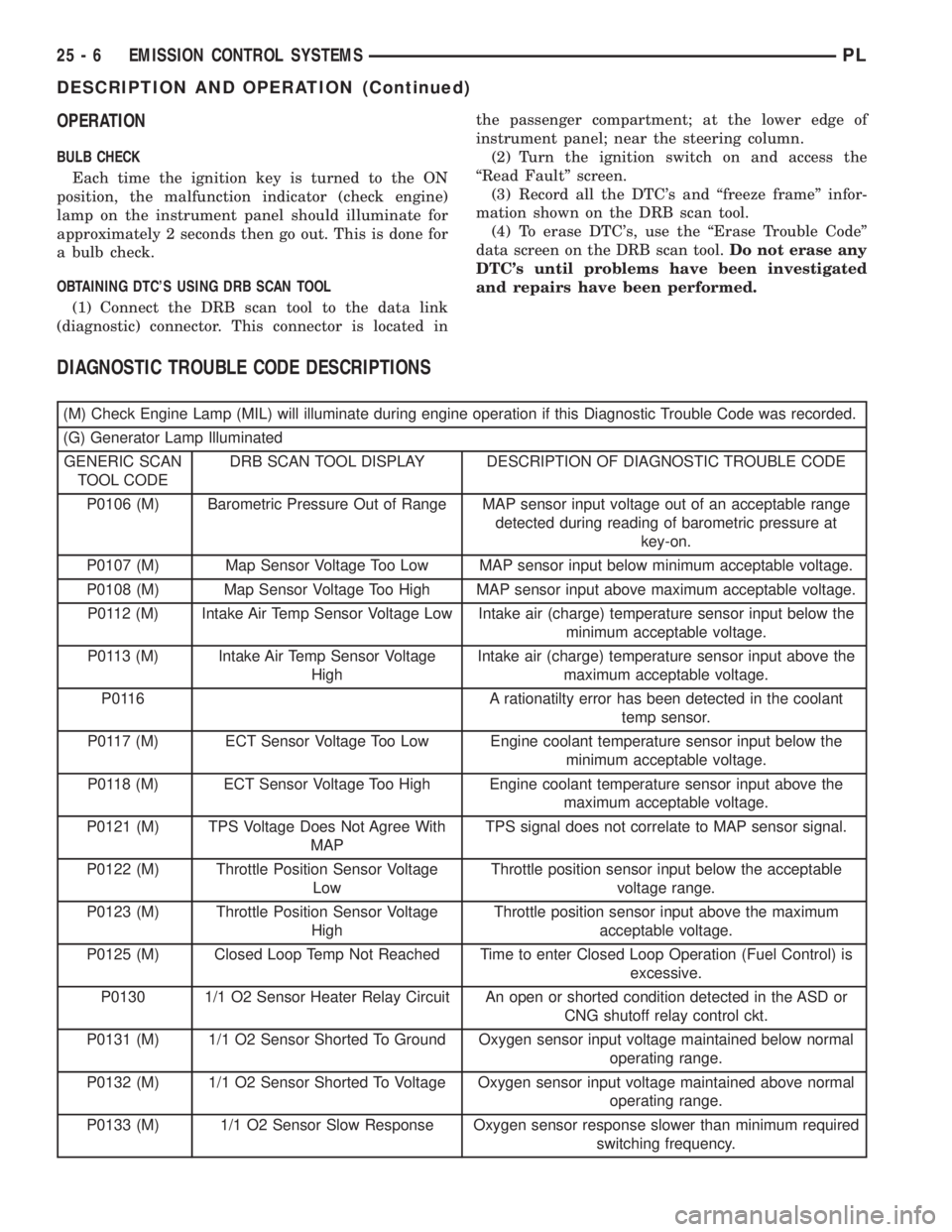

Fig. 27 Coupling Roll Pin

1 ± STEERING COLUMN LOWER COUPLING

2 ± POWER STEERING GEAR PINION SHAFT

3 ± ROLL PIN

4 ± ROLL PIN PUNCH

19 - 40 STEERINGPL

REMOVAL AND INSTALLATION (Continued)

Page 1093 of 1285

OPERATION

BULB CHECK

Each time the ignition key is turned to the ON

position, the malfunction indicator (check engine)

lamp on the instrument panel should illuminate for

approximately 2 seconds then go out. This is done for

a bulb check.

OBTAINING DTC'S USING DRB SCAN TOOL

(1) Connect the DRB scan tool to the data link

(diagnostic) connector. This connector is located inthe passenger compartment; at the lower edge of

instrument panel; near the steering column.

(2) Turn the ignition switch on and access the

ªRead Faultº screen.

(3) Record all the DTC's and ªfreeze frameº infor-

mation shown on the DRB scan tool.

(4) To erase DTC's, use the ªErase Trouble Codeº

data screen on the DRB scan tool.Do not erase any

DTC's until problems have been investigated

and repairs have been performed.

DIAGNOSTIC TROUBLE CODE DESCRIPTIONS

(M) Check Engine Lamp (MIL) will illuminate during engine operation if this Diagnostic Trouble Code was recorded.

(G) Generator Lamp Illuminated

GENERIC SCAN

TOOL CODEDRB SCAN TOOL DISPLAY DESCRIPTION OF DIAGNOSTIC TROUBLE CODE

P0106 (M) Barometric Pressure Out of Range MAP sensor input voltage out of an acceptable range

detected during reading of barometric pressure at

key-on.

P0107 (M) Map Sensor Voltage Too Low MAP sensor input below minimum acceptable voltage.

P0108 (M) Map Sensor Voltage Too High MAP sensor input above maximum acceptable voltage.

P0112 (M) Intake Air Temp Sensor Voltage Low Intake air (charge) temperature sensor input below the

minimum acceptable voltage.

P0113 (M) Intake Air Temp Sensor Voltage

HighIntake air (charge) temperature sensor input above the

maximum acceptable voltage.

P0116 A rationatilty error has been detected in the coolant

temp sensor.

P0117 (M) ECT Sensor Voltage Too Low Engine coolant temperature sensor input below the

minimum acceptable voltage.

P0118 (M) ECT Sensor Voltage Too High Engine coolant temperature sensor input above the

maximum acceptable voltage.

P0121 (M) TPS Voltage Does Not Agree With

MAPTPS signal does not correlate to MAP sensor signal.

P0122 (M) Throttle Position Sensor Voltage

LowThrottle position sensor input below the acceptable

voltage range.

P0123 (M) Throttle Position Sensor Voltage

HighThrottle position sensor input above the maximum

acceptable voltage.

P0125 (M) Closed Loop Temp Not Reached Time to enter Closed Loop Operation (Fuel Control) is

excessive.

P0130 1/1 O2 Sensor Heater Relay Circuit An open or shorted condition detected in the ASD or

CNG shutoff relay control ckt.

P0131 (M) 1/1 O2 Sensor Shorted To Ground Oxygen sensor input voltage maintained below normal

operating range.

P0132 (M) 1/1 O2 Sensor Shorted To Voltage Oxygen sensor input voltage maintained above normal

operating range.

P0133 (M) 1/1 O2 Sensor Slow Response Oxygen sensor response slower than minimum required

switching frequency.

25 - 6 EMISSION CONTROL SYSTEMSPL

DESCRIPTION AND OPERATION (Continued)

Page 1122 of 1285

(4) Place protective covers over instrument panel

and hood.

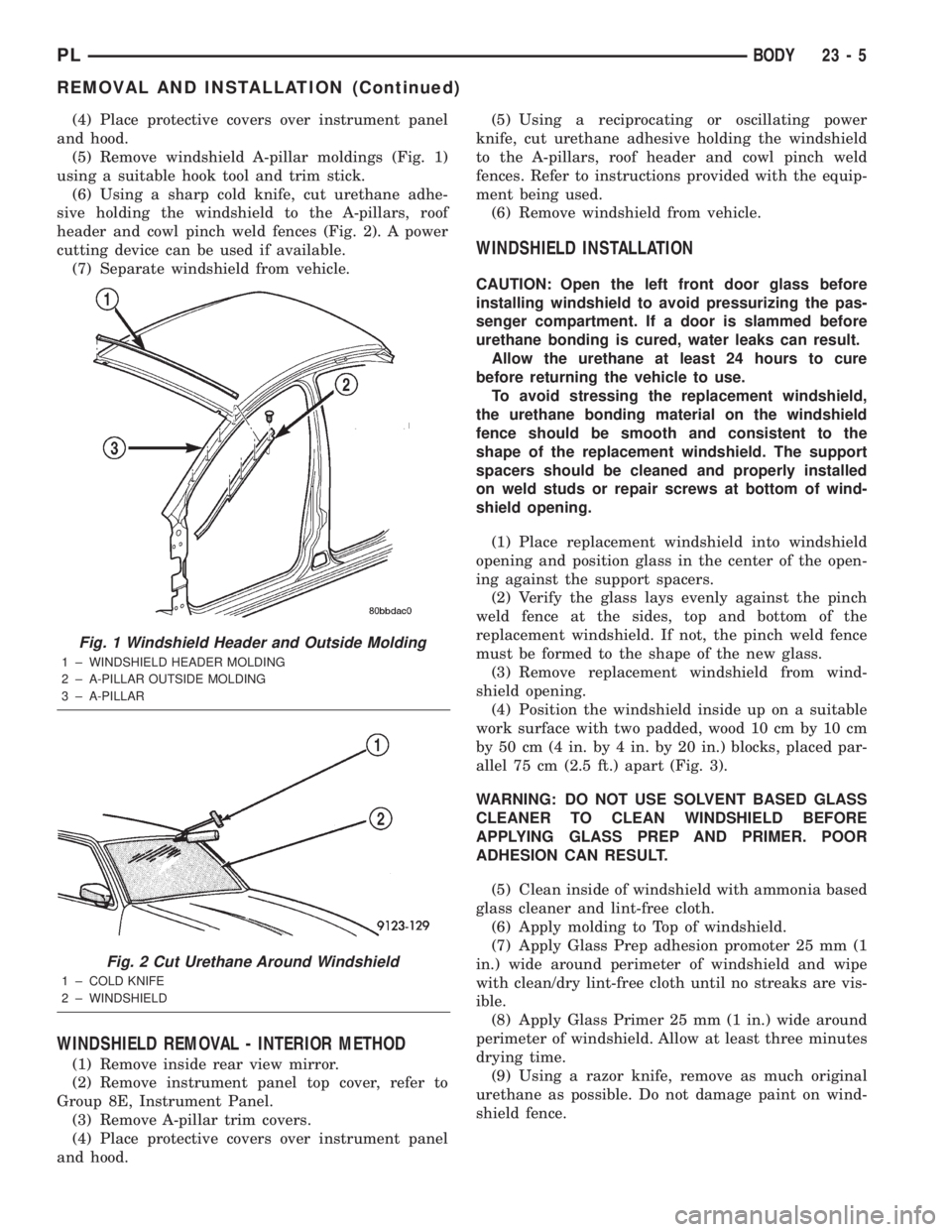

(5) Remove windshield A-pillar moldings (Fig. 1)

using a suitable hook tool and trim stick.

(6) Using a sharp cold knife, cut urethane adhe-

sive holding the windshield to the A-pillars, roof

header and cowl pinch weld fences (Fig. 2). A power

cutting device can be used if available.

(7) Separate windshield from vehicle.

WINDSHIELD REMOVAL - INTERIOR METHOD

(1) Remove inside rear view mirror.

(2) Remove instrument panel top cover, refer to

Group 8E, Instrument Panel.

(3) Remove A-pillar trim covers.

(4) Place protective covers over instrument panel

and hood.(5) Using a reciprocating or oscillating power

knife, cut urethane adhesive holding the windshield

to the A-pillars, roof header and cowl pinch weld

fences. Refer to instructions provided with the equip-

ment being used.

(6) Remove windshield from vehicle.

WINDSHIELD INSTALLATION

CAUTION: Open the left front door glass before

installing windshield to avoid pressurizing the pas-

senger compartment. If a door is slammed before

urethane bonding is cured, water leaks can result.

Allow the urethane at least 24 hours to cure

before returning the vehicle to use.

To avoid stressing the replacement windshield,

the urethane bonding material on the windshield

fence should be smooth and consistent to the

shape of the replacement windshield. The support

spacers should be cleaned and properly installed

on weld studs or repair screws at bottom of wind-

shield opening.

(1) Place replacement windshield into windshield

opening and position glass in the center of the open-

ing against the support spacers.

(2) Verify the glass lays evenly against the pinch

weld fence at the sides, top and bottom of the

replacement windshield. If not, the pinch weld fence

must be formed to the shape of the new glass.

(3) Remove replacement windshield from wind-

shield opening.

(4) Position the windshield inside up on a suitable

work surface with two padded, wood 10 cm by 10 cm

by 50 cm (4 in. by 4 in. by 20 in.) blocks, placed par-

allel 75 cm (2.5 ft.) apart (Fig. 3).

WARNING: DO NOT USE SOLVENT BASED GLASS

CLEANER TO CLEAN WINDSHIELD BEFORE

APPLYING GLASS PREP AND PRIMER. POOR

ADHESION CAN RESULT.

(5) Clean inside of windshield with ammonia based

glass cleaner and lint-free cloth.

(6) Apply molding to Top of windshield.

(7) Apply Glass Prep adhesion promoter 25 mm (1

in.) wide around perimeter of windshield and wipe

with clean/dry lint-free cloth until no streaks are vis-

ible.

(8) Apply Glass Primer 25 mm (1 in.) wide around

perimeter of windshield. Allow at least three minutes

drying time.

(9) Using a razor knife, remove as much original

urethane as possible. Do not damage paint on wind-

shield fence.

Fig. 1 Windshield Header and Outside Molding

1 ± WINDSHIELD HEADER MOLDING

2 ± A-PILLAR OUTSIDE MOLDING

3 ± A-PILLAR

Fig. 2 Cut Urethane Around Windshield

1 ± COLD KNIFE

2 ± WINDSHIELD

PLBODY 23 - 5

REMOVAL AND INSTALLATION (Continued)

Page 1142 of 1285

(3) Remove hood latch striker from vehicle.

INSTALLATION

(1) Position hood latch striker on vehicle.

(2) Install bolts attaching hood latch striker to

hood. Tighten bolts to 13.5 N´m (10 ft. lbs.) torque.

(3) Align hood latch striker to engage smoothly

into hood latch.(4) Verify hood operation and alignment. Adjust as

necessary.

(5) Tighten attaching bolts to 13.5 N´m (10 ft. lbs.)

torque.

HOOD RELEASE CABLE

REMOVAL

(1) Disconnect remote hood release cable from

hood latch.

(2) Remove left front cowl trim panel.

(3) Remove screws attaching hood release handle

to cowl panel (Fig. 19).

(4) Disconnect rubber grommet from dash panel

behind instrument panel.

(5) Pull release cable through hole in dash panel.

(6) Remove cable and handle from vehicle.

INSTALLATION

(1) Assemble cable and handle onto vehicle.

(2) Push release cable through hole in dash panel.

(3) Connect rubber grommet into dash panel.

(4) Install screws attaching hood release handle to

cowl panel.

(5) Install left front cowl trim panel.

(6) Connect remote hood release cable to hood

latch.

(7) Close hood and verify operation.

Fig. 18 Hood Latch

1 ± HOOD LATCH RELEASE CABLE

2 ± HOOD PROP ROD3 ± HOOD SECURITY ALARM

4 ± HOOD LATCH

Fig. 17 Grille

1 ± GRILLE

PLBODY 23 - 25

REMOVAL AND INSTALLATION (Continued)

Page 1173 of 1285

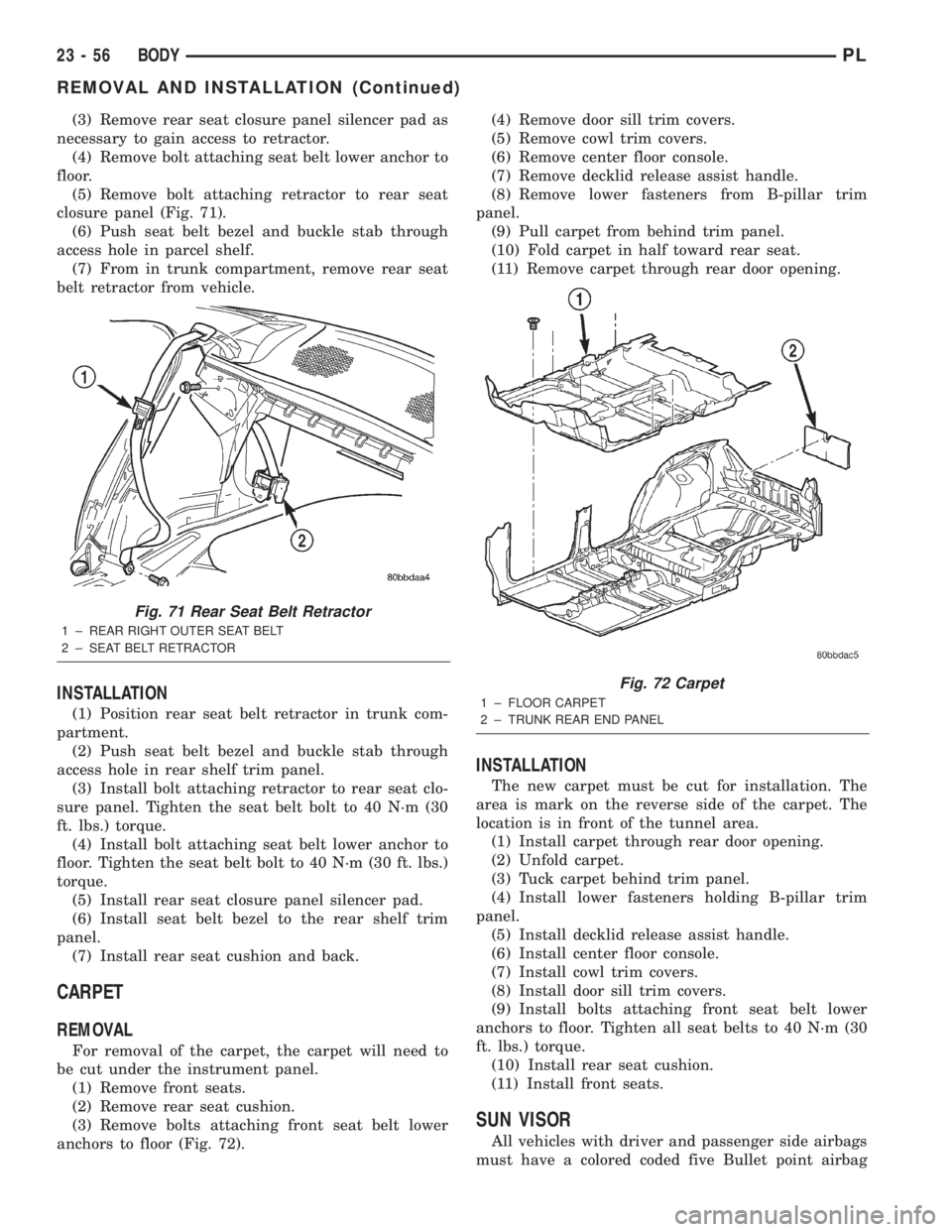

(3) Remove rear seat closure panel silencer pad as

necessary to gain access to retractor.

(4) Remove bolt attaching seat belt lower anchor to

floor.

(5) Remove bolt attaching retractor to rear seat

closure panel (Fig. 71).

(6) Push seat belt bezel and buckle stab through

access hole in parcel shelf.

(7) From in trunk compartment, remove rear seat

belt retractor from vehicle.

INSTALLATION

(1) Position rear seat belt retractor in trunk com-

partment.

(2) Push seat belt bezel and buckle stab through

access hole in rear shelf trim panel.

(3) Install bolt attaching retractor to rear seat clo-

sure panel. Tighten the seat belt bolt to 40 N´m (30

ft. lbs.) torque.

(4) Install bolt attaching seat belt lower anchor to

floor. Tighten the seat belt bolt to 40 N´m (30 ft. lbs.)

torque.

(5) Install rear seat closure panel silencer pad.

(6) Install seat belt bezel to the rear shelf trim

panel.

(7) Install rear seat cushion and back.

CARPET

REMOVAL

For removal of the carpet, the carpet will need to

be cut under the instrument panel.

(1) Remove front seats.

(2) Remove rear seat cushion.

(3) Remove bolts attaching front seat belt lower

anchors to floor (Fig. 72).(4) Remove door sill trim covers.

(5) Remove cowl trim covers.

(6) Remove center floor console.

(7) Remove decklid release assist handle.

(8) Remove lower fasteners from B-pillar trim

panel.

(9) Pull carpet from behind trim panel.

(10) Fold carpet in half toward rear seat.

(11) Remove carpet through rear door opening.

INSTALLATION

The new carpet must be cut for installation. The

area is mark on the reverse side of the carpet. The

location is in front of the tunnel area.

(1) Install carpet through rear door opening.

(2) Unfold carpet.

(3) Tuck carpet behind trim panel.

(4) Install lower fasteners holding B-pillar trim

panel.

(5) Install decklid release assist handle.

(6) Install center floor console.

(7) Install cowl trim covers.

(8) Install door sill trim covers.

(9) Install bolts attaching front seat belt lower

anchors to floor. Tighten all seat belts to 40 N´m (30

ft. lbs.) torque.

(10) Install rear seat cushion.

(11) Install front seats.

SUN VISOR

All vehicles with driver and passenger side airbags

must have a colored coded five Bullet point airbag

Fig. 71 Rear Seat Belt Retractor

1 ± REAR RIGHT OUTER SEAT BELT

2 ± SEAT BELT RETRACTOR

Fig. 72 Carpet

1 ± FLOOR CARPET

2 ± TRUNK REAR END PANEL

23 - 56 BODYPL

REMOVAL AND INSTALLATION (Continued)

Page 1233 of 1285

GENERAL INFORMATION

A/C APPLICATION TABLE

Item Description Notes

Vehicle PL Neon

System expansion valve

Total Refrigerant

CapacityR134a 765 grams / 27 oz / 1.69 lbs

Total Oil Capacity ND-8 PAG oil 180 ml / 6.10 oz

Compressor Nippondenso 10S17

Freeze-up Control Fin sensor-3 wire input to PCM, evaporator mounted, cycles

clutch off below 34É F, cycles back on

above 45É F

Low psi Control opens < 14 psi, resets > 38 psi expansion valve mounted

High psi Control opens > 470 psi, resets < 370 - 330 psi compressor mounted switch

Control head manual type

Mode Door cable

Blend Air Door cable

Fresh/Recirc door vacuum actuator

Blower Motor control head switched resistor block

Cooling Fan variable speed PCM controlled ISO solid state fan relay

Clutch

Control relay PCM

Draw 2.5 amps @ 12V60.5V @ 70É F

Gap 0.014º - 0.0269

DRB IIIT

Reads TPS, RPM, A/C switch test, fin sensor

A/C & fan relays

Actuators fan & clutch relays

HEATER AND AIR CONDITIONING CONTROL

Both the heater-only and heater-A/C systems use a

combination of, electrical, cable, and vacuum con-

trols. These controls provide the vehicle operator

with a number of setting options to help control the

climate and comfort within the vehicle. Refer to the

owner's manual in the vehicle glove box for more

information on the features, use, and suggested oper-

ation of these controls.

The heater-only or heater-A/C control panel is located

to the right of the instrument cluster on the instrument

panel. The control panel contains rotary-type knobs.

There is a blower motor speed switch, mode control

switch, temperature control, and airflow control.

The heater-only or heater-A/C control panel cannot

be repaired. If faulty or damaged, the entire unit

must be replaced. The control knobs and the illumi-

nation lamps are available for service replacement.

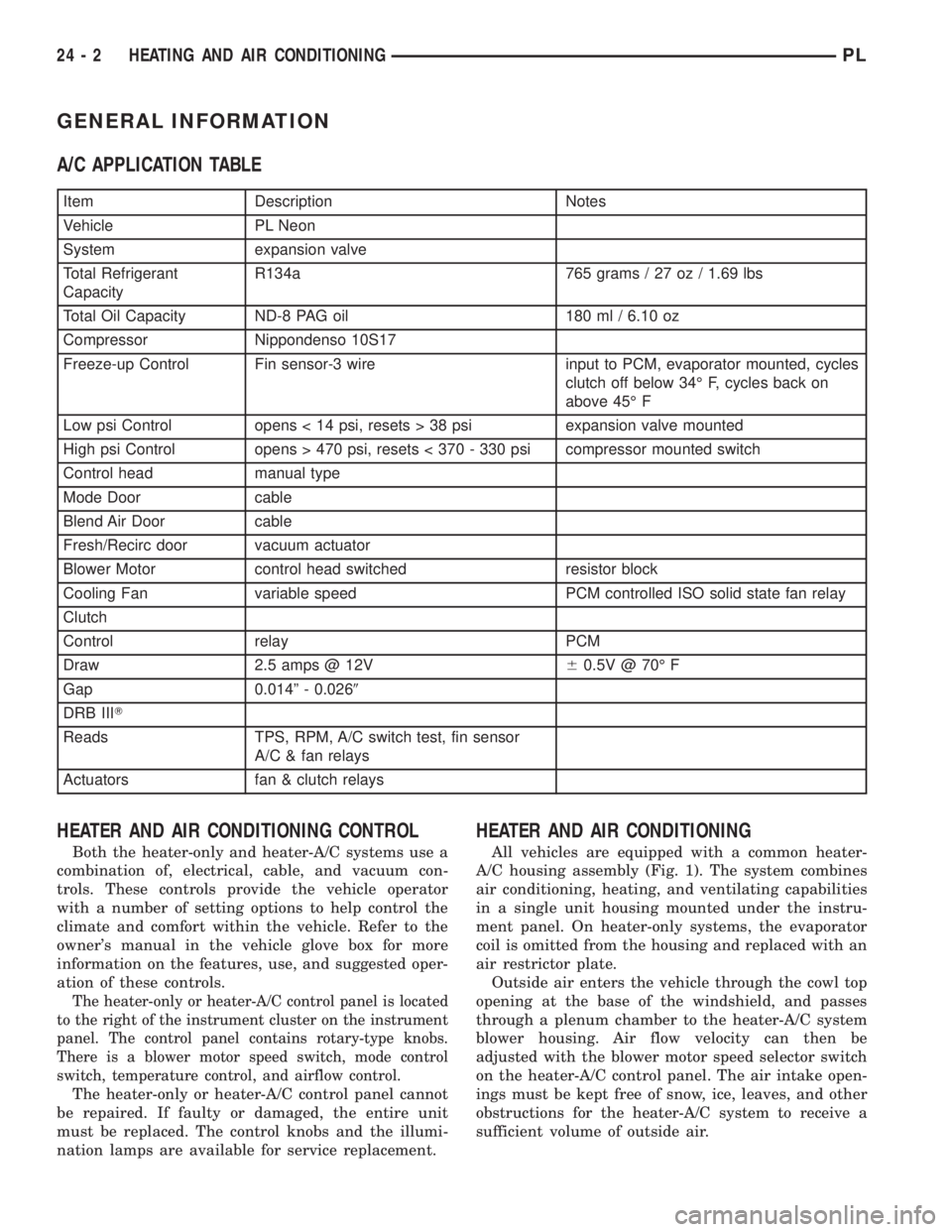

HEATER AND AIR CONDITIONING

All vehicles are equipped with a common heater-

A/C housing assembly (Fig. 1). The system combines

air conditioning, heating, and ventilating capabilities

in a single unit housing mounted under the instru-

ment panel. On heater-only systems, the evaporator

coil is omitted from the housing and replaced with an

air restrictor plate.

Outside air enters the vehicle through the cowl top

opening at the base of the windshield, and passes

through a plenum chamber to the heater-A/C system

blower housing. Air flow velocity can then be

adjusted with the blower motor speed selector switch

on the heater-A/C control panel. The air intake open-

ings must be kept free of snow, ice, leaves, and other

obstructions for the heater-A/C system to receive a

sufficient volume of outside air.

24 - 2 HEATING AND AIR CONDITIONINGPL

Page 1234 of 1285

It is also important to keep the air intake openings

clear of debris because leaf particles and other debris

that is small enough to pass through the cowl ple-

num screen can accumulate within the heater-A/C

housing. The closed, warm, damp and dark environ-

ment created within the heater-A/C housing is ideal

for the growth of certain molds, mildews and other

fungi. Any accumulation of decaying plant matter

provides an additional food source for fungal spores,

which enter the housing with the fresh air. Excess

debris, as well as objectionable odors created by

decaying plant matter and growing fungi can be dis-

charged into the passenger compartment during

heater-A/C system operation.

The heater and optional air conditioner are blend-

air type systems. In a blend-air system, a blend-air

door controls the amount of unconditioned air (or

cooled air from the evaporator on models with air

conditioning) that is allowed to flow through, or

around, the heater core. A temperature control knob

on the heater-A/C control panel determines the dis-

charge air temperature by moving a cable, which

operates the blend-air door. This allows an almost

immediate manual control of the output air tempera-

ture of the system.

The mode control knob on the heater-only or heat-

er-A/C control panel is used to direct the conditioned

air to the selected system outlets. The mode control

switch uses a cable to control the mode door, while

the recirculation air door is operated by a vacuum

actuator motor.On air conditioned vehicles, the outside air intake

can be shut off by selecting the recirculation mode

(Recirc) with the mode control knob. This will oper-

ate a vacuum actuated recirculating air door that

closes off the outside fresh air intake and recirculates

the air that is already inside the vehicle.

The optional air conditioner for all models is

designed for the use of non-CFC, R-134a refrigerant.

The air conditioning system has an evaporator to cool

and dehumidify the incoming air prior to blending it

with the heated air. This air conditioning system

uses an evaporator probe to maintain minimum

evaporator temperature and prevent evaporator

freezing, and cycles the compressor clutch.

INTRODUCTION

Both the heater and the heater/air conditioning

systems share many of the same functioning compo-

nents. This group will deal with both systems

together when component function is common, and

separately when they are not.

For proper operation of the instrument panel con-

trols, refer to the Owner's Manual provided with the

vehicle.

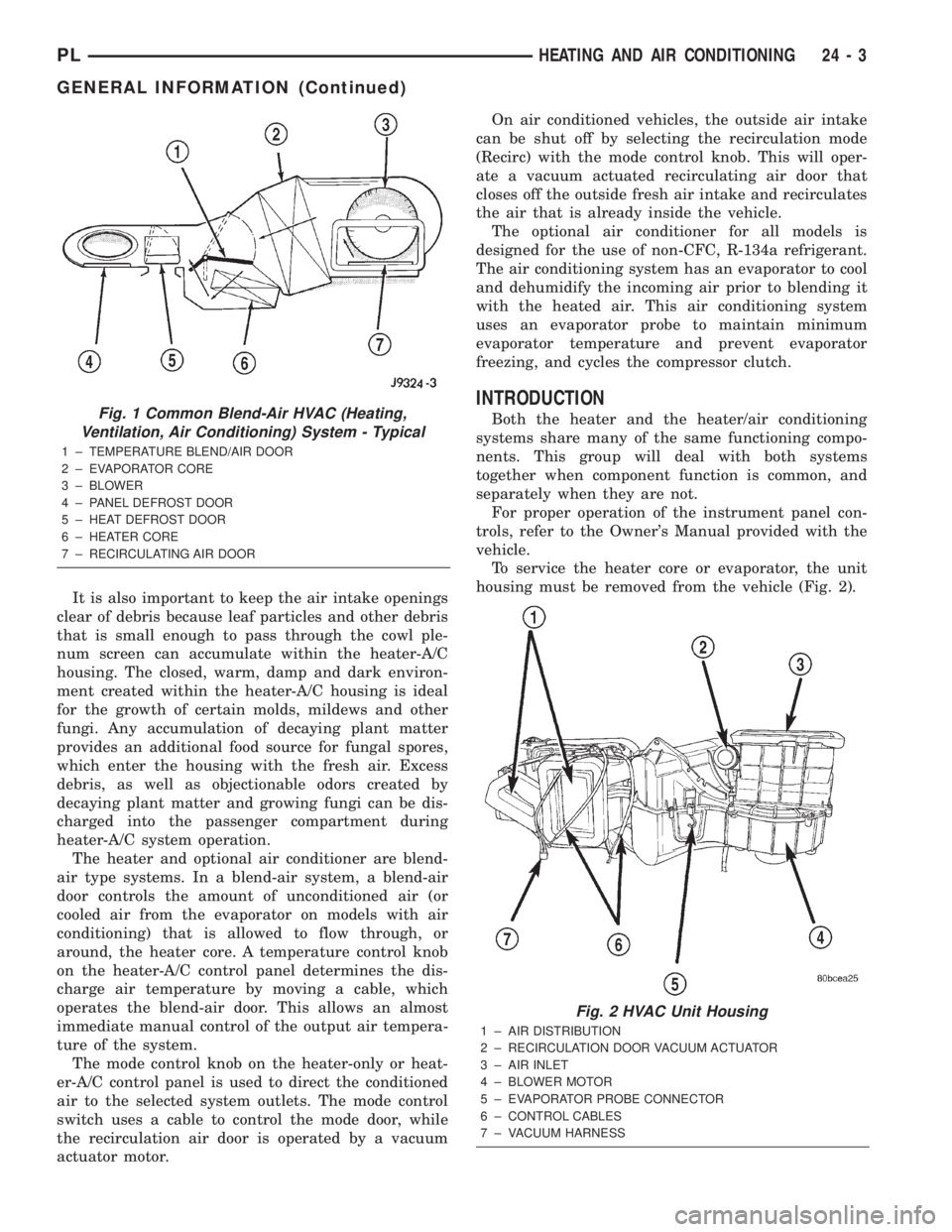

To service the heater core or evaporator, the unit

housing must be removed from the vehicle (Fig. 2).Fig. 1 Common Blend-Air HVAC (Heating,

Ventilation, Air Conditioning) System - Typical

1 ± TEMPERATURE BLEND/AIR DOOR

2 ± EVAPORATOR CORE

3 ± BLOWER

4 ± PANEL DEFROST DOOR

5 ± HEAT DEFROST DOOR

6 ± HEATER CORE

7 ± RECIRCULATING AIR DOOR

Fig. 2 HVAC Unit Housing

1 ± AIR DISTRIBUTION

2 ± RECIRCULATION DOOR VACUUM ACTUATOR

3 ± AIR INLET

4 ± BLOWER MOTOR

5 ± EVAPORATOR PROBE CONNECTOR

6 ± CONTROL CABLES

7 ± VACUUM HARNESS

PLHEATING AND AIR CONDITIONING 24 - 3

GENERAL INFORMATION (Continued)

Page 1238 of 1285

SIDE WINDOW DEMISTERS

The demisters direct air from the unit housing

through the outlets located on the top corners of the

instrument panel. The demisters operate when the

mode selector is anywhere between floor and defrost

settings. Some air may be noticeable from the demis-

ter outlets when the mode selector is in the bilevel to

floor positions.

SYSTEM AIRFLOW

The system pulls outside (ambient) air through the

cowl opening at the base of the windshield. Then it

goes into the plenum chamber above the unit hous-

ing. On air conditioned vehicles, the air passes

through the evaporator. Air flow can be directed

either through or around the heater core. This is

done by adjusting the blend-air door with the TEMP

control on the instrument panel. The air flow can

then be directed from the panel, floor and defrost

outlets in various combinations using the mode selec-

tor. There are 17 different mode selections possible.

Air flow velocity can be adjusted with the blower

speed selector switch on the instrument panel.

On A/C equipped vehicles the ambient air intake

can be controlled by opening and closing the recircu-

lating air door. When placed in RECIRC, air that is

inside vehicle is removed continuously and recircu-

lated through unit housing. Ambient air cannot be

controlled on vehicles without A/C. The system uses

outside air at all times.

The air conditioning compressor can be engaged by

turning the fan switch counterclockwise from the off

position. It can also be engaged by placing the mode

control in the mix to defrost positions. This will

remove heat and humidity from the air before it is

directed through or around the heater core.

SYSTEM OIL LEVEL

It is important to have the correct amount of oil in

the A/C system to ensure proper lubrication of the

compressor. Too little oil will result in damage to the

compressor. Too much oil will reduce the cooling

capacity of the system and consequently result in

higher discharge air temperatures.

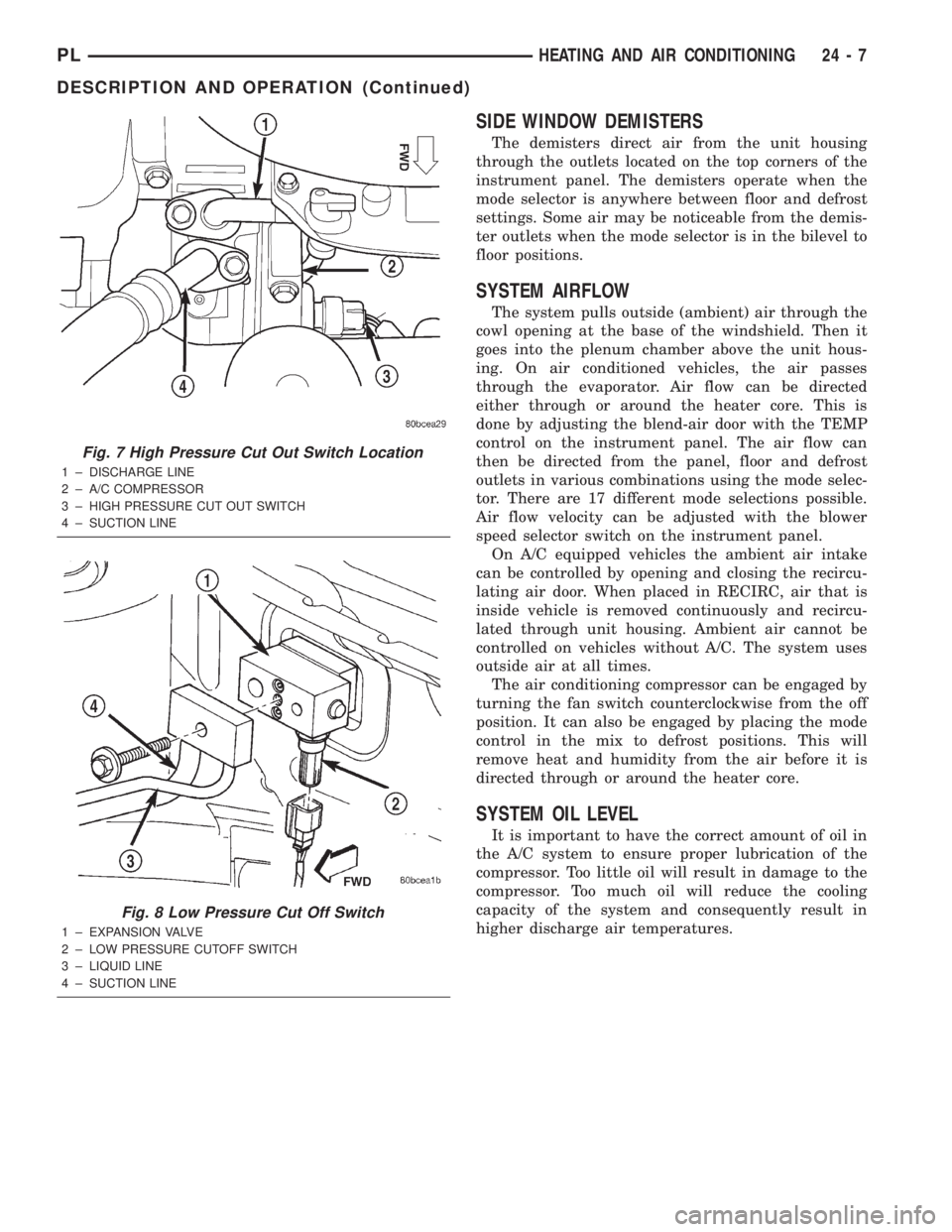

Fig. 7 High Pressure Cut Out Switch Location

1 ± DISCHARGE LINE

2 ± A/C COMPRESSOR

3 ± HIGH PRESSURE CUT OUT SWITCH

4 ± SUCTION LINE

Fig. 8 Low Pressure Cut Off Switch

1 ± EXPANSION VALVE

2 ± LOW PRESSURE CUTOFF SWITCH

3 ± LIQUID LINE

4 ± SUCTION LINE

PLHEATING AND AIR CONDITIONING 24 - 7

DESCRIPTION AND OPERATION (Continued)

Page 1240 of 1285

Normally, vacuum is supplied to the actuator by

placing the Circulation control knob in the Recircula-

tion position. The Mode and the circulation control

are mechanically interlocked so the circulation con-

trol cannot be placed in the RECIRC position if the

mode control is at or between the mix and defrost

positions. Vacuum is supplied to the actuator only

when circulation control is at the RECIRC position.

If the circulation control is between the outside air

position and RECIRC position the system will be in

outside air. If the circulation control is in the

RECIRC position and the mode control is moved from

the floor to the defrost positions, the circulation con-

trol will move from the RECIRC position, to the out-

side air position beginning at the mix position. This

is to prevent window fogging.

DIAGNOSIS AND TESTING

A/C PERFORMANCE TEST

The air conditioning system is designed to remove

heat and humidity from the air entering the passen-

ger compartment. The evaporator, located in the

heater A/C unit, is cooled to temperatures near the

freezing point. As warm damp air passes over the

fins in the evaporator, moisture in the air condenses

to water, dehumidifying the air. Condensation on the

evaporator fins reduces the evaporators ability to

absorb heat. During periods of high heat and humid-

ity, an air conditioning system will be less effective.

With the instrument control set to RECIRC, only air

from the passenger compartment passes through theevaporator. As the passenger compartment air dehu-

midifies, A/C performance levels rise.

PERFORMANCE TEST PROCEDURE

Review Safety Precautions and Warnings in this

group before proceeding with this procedure. Air tem-

perature in test room and on vehicle must be 21É C

(70ÉF) minimum for this test.

NOTE: When connecting the service equipment

coupling to the line fitting, verify that the valve of

the coupling is fully closed. This will reduce the

amount of effort required to make the connection.

(1) Connect a tachometer and manifold gauge set.

(2) Set control to A/C, RECIRC, and PANEL, tem-

perature lever on full cool and blower on high.

(3) Start engine and hold at 1000 rpm with A/C

clutch engaged.

(4) Engine should be warmed up with doors and

windows closed.

(5) Insert a thermometer in the left center A/C

outlet and operate the engine for five minutes. The

A/C clutch may cycle depending on ambient condi-

tions.

(6) With the A/C clutch engaged, compare the dis-

charge air temperature to the A/C Performance Tem-

peratures chart.

(7) If the discharge air temperature fails to meet

the specifications in the performance temperature

chart. Refer to the Refrigerant Service Procedures for

further diagnosis.

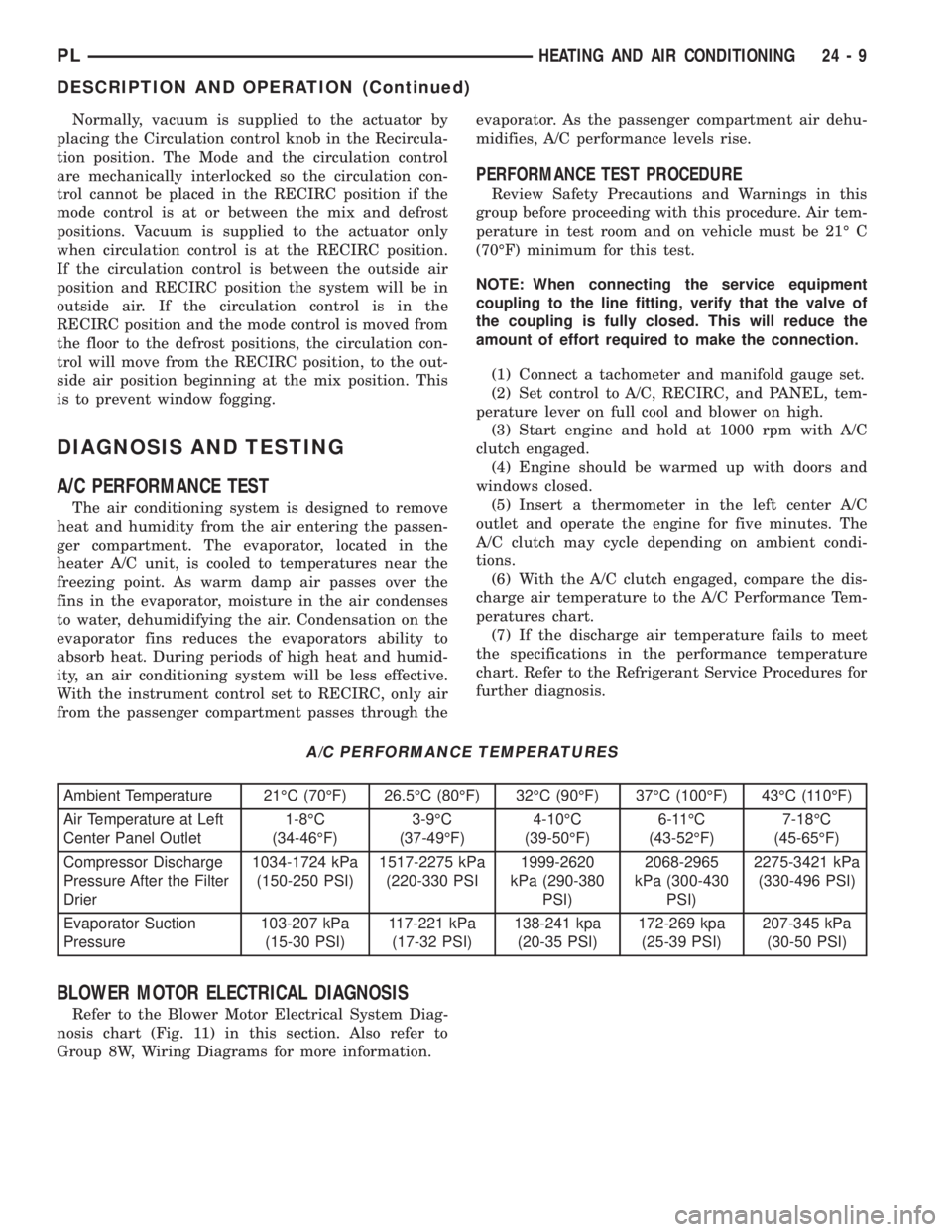

A/C PERFORMANCE TEMPERATURES

Ambient Temperature 21ÉC (70ÉF) 26.5ÉC (80ÉF) 32ÉC (90ÉF) 37ÉC (100ÉF) 43ÉC (110ÉF)

Air Temperature at Left

Center Panel Outlet1-8ÉC

(34-46ÉF)3-9ÉC

(37-49ÉF)4-10ÉC

(39-50ÉF)6-11ÉC

(43-52ÉF)7-18ÉC

(45-65ÉF)

Compressor Discharge

Pressure After the Filter

Drier1034-1724 kPa

(150-250 PSI)1517-2275 kPa

(220-330 PSI1999-2620

kPa (290-380

PSI)2068-2965

kPa (300-430

PSI)2275-3421 kPa

(330-496 PSI)

Evaporator Suction

Pressure103-207 kPa

(15-30 PSI)117-221 kPa

(17-32 PSI)138-241 kpa

(20-35 PSI)172-269 kpa

(25-39 PSI)207-345 kPa

(30-50 PSI)

BLOWER MOTOR ELECTRICAL DIAGNOSIS

Refer to the Blower Motor Electrical System Diag-

nosis chart (Fig. 11) in this section. Also refer to

Group 8W, Wiring Diagrams for more information.

PLHEATING AND AIR CONDITIONING 24 - 9

DESCRIPTION AND OPERATION (Continued)

Page 1245 of 1285

POSSIBLE LOCATIONS OR CAUSE OF

OBSTRUCTED COOLANT FLOW

(1) Pinched or kinked heater hoses.

(2) Improper heater hose routing.

(3) Plugged heater hoses or supply and return

ports at cooling system connections, refer to Group 7,

Cooling System.

(4) Plugged heater core.

(5) Air locked heater core.

(6) If coolant flow is verified and outlet tempera-

ture is insufficient, a mechanical problem may exist.

POSSIBLE LOCATION OR CAUSE OF INSUFFICIENT

HEAT

(1) Obstructed cowl air intake.

(2) Obstructed heater system outlets.

(3) Blend-air door not functioning properly.

TEMPERATURE CONTROL

If temperature cannot be adjusted with the TEMP

lever on the control panel, the following could require

service:

(1) Blend-air door binding.

(2) Faulty blend-air door cable.

(3) Improper engine coolant temperature.

(4) Faulty Instrument Panel Control.

LOW PRESSURE CUT OFF SWITCH

The work area must not be below 21ÉC (70ÉF) to

test the compressor clutch circuit.

(1) With gear selector in park or neutral and park

brake set, start engine and allow to idle.

(2) Raise hood and disconnect low pressure cut off

switch connector boot.

(3) Using a suitable jumper wire, jump across the

terminals inside wire connector boot.

(4) If the compressor clutch does not engage, the

cycling clutch switch, wiring, relay, or fuse can be

defective. Refer to Group 8W, Wiring Diagrams.

(5) If clutch engages, connect manifold gauge set.

Read low pressure gauge. At pressure above 97 kPa

(14 psi) and above, low pressure out off switch will

complete the clutch circuit. If the low pressure gauge

reads below 140 kPa (20 psi), the system is low on

refrigerant charge or empty due to a leak. Refer to

Service Procedures, System Leak Checking in this

section.

(6) Install connector boot on switch and repeat

Step 3. If the clutch does not engage, replace the low

pressure cut off switch.

SYSTEM CHARGE LEVEL TEST

The procedure below should be used to check

and/or fill the refrigerant charge in the air condition-

ing system.

WARNING: AVOID BREATHING A/C REFRIGERANT

AND LUBRICANT VAPOR OR MIST. EXPOSURE MAY

IRRITATE EYES, NOSE AND THROAT. USE ONLY

APPROVED SERVICE EQUIPMENT MEETING SAE

REQUIREMENTS TO DISCHARGE R-134a SYSTEM.

IF ACCIDENTAL SYSTEM DISCHARGE OCCURS,

VENTILATE WORK AREA BEFORE RESUMING SER-

VICE.

R-134a SERVICE EQUIPMENT OR VEHICLE A/C

SYSTEM SHOULD NOT BE PRESSURE TESTED OR

LEAK TESTED WITH COMPRESSED AIR. MIXTURE

OF AIR and R-134a CAN BE COMBUSTIBLE AT ELE-

VATED PRESSURES. THESE MIXTURES ARE

POTENTIALLY DANGEROUS AND MAY RESULT IN

FIRE OR EXPLOSION CAUSING INJURY OR PROP-

ERTY DAMAGE.

NOTE: The maximum amount of R-134a refrigerant

that the air conditioning system holds is 765 grams

(27 oz. or 1.69 lbs.)

It is recommended to use the gauges or reclaim/re-

cycle equipment.

(1) Use a manifold gauge and check the liquid line

pressure.

(2) Attach a clamp-on thermocouple (P. S. E.

66-324-0014 or 80PK-1A) or equivalent to the liquid

line near the filter/drier.

(3) The vehicle must be in the following modes:

²Automatic transaxle in park or manual tran-

saxle in neutral.

²Engine at idle

²A/C controls set to outside air

²Panel mode

²A/C ON full cool

²Blower motor ON high speed

²Vehicle windows closed

(4) Operate system for a couple of minutes to allow

the system to stabilize.

(5) Observe filter/drier pressure and Liquid line

temperature. Using the Charge Determination Chart

(Fig. 14) determine where the system is currently

operating. If the system is not in the proper range,

reclaim all the refrigerant and recharge per A/C

label.

24 - 14 HEATING AND AIR CONDITIONINGPL

DIAGNOSIS AND TESTING (Continued)